Abstract

Anthropogenic microfibres are a prevalent, persistent and globally distributed form of marine debris. Evidence of microfibre ingestion has been demonstrated in a range of organisms, including Mytilus spp. (mussels), but the extent of any impacts on these organisms are poorly understood. This study investigates, for the first time, the effect of exposing juvenile mussels to polyester and cotton microfibres at environmentally relevant concentrations (both current and predicted future scenarios) over a chronic timescale (94 days). Sublethal biomarkers included growth rate, respiration rate and clearance rate. Mussels were exposed to polyester (median length 149 µm) and cotton (median length 132 µm) microfibres in three treatments: polyester (~ 8 fibres L−1), polyester (~ 80 fibres L−1) and cotton (~ 80 fibres L−1). Mussels exposed to 80 polyester or cotton microfibres L−1 exhibited a decrease in growth rate of 35.6% (polyester) and 18.7% (cotton), with mussels exposed to ~ 80 polyester microfibres L−1 having a significantly lower growth rate than the control population (P < 0.05). This study demonstrates that polyester microfibres have the potential to adversely impact upon mussel growth rates in realistic future scenarios, which may have compounding effects throughout the marine ecosystem and implications for commercial viability.

Graphical Abstract

Similar content being viewed by others

Synopsis

Anthropogenic microfibres are a common type of marine debris. Juvenile mussels chronically exposed to environmentally-relevant concentrations of plastic microfibres exhibited significantly reduced growth rates.

Introduction

Microplastics are a persistent and pervasive contaminant that have been identified in freshwater, terrestrial and marine ecosystems worldwide [1,2,3,4,5]. Studies suggest that as much as 4.8 to 12.7 million metric tons of plastic enters the world’s oceans every year [6] and this is expected to rise as plastic manufacturing rates are forecast to increase [7]. Microplastics are found in the environment in a myriad of different shapes, commonly categorized as fragments, fibres, films, or beads. Fibres are one of the most common morphologies of microplastic identified in environmental studies [8,9,10,11,12,13], accounting for up to 91% of the total identified microplastics in some studies [14]. These small anthropogenic fibres, termed microfibres, are typically composed of polyester, polypropylene or nylon, however numerous studies also report the presence of naturally derived and semi-synthetic cellulosic microfibres (e.g. cotton, rayon) in environmental samples [15,16,17,18]. Despite their prevalence in environmental samples, semi-synthetic microfibres have received relatively little attention compared to their traditional plastic counterparts [18]. Microfibres are predominantly generated from the fragmentation of textiles, stemming from the day-to-day use and washing of clothes, and from the weathering and abrasion of marine infrastructure such as netting and rope [19,20,21,22,23,24,25]. For an informative review on the sources, sinks and exposure pathways of microfibres, see Suaria et al. [18].

Bivalve shellfish, including mussels, oysters and clams, are highly cultivated marine species critical for global marine food security [26, 27]. Bivalve shellfish have been demonstrated to readily consume microplastics (e.g. [28,29,30,31,32], and in a recent review, shellfish were shown to typically have far higher body burdens of microplastics (microplastics gram−1 wet weight) than pelagic and demersal fish [33]. The environmental concentration of microplastics with a size range that is bioavailable to mussels is typically in the range of 0.01—10 microplastics L−1 [34]. However, such values are likely underestimated owing to the complexities of sampling and identifying < 100 µm microplastics [12, 13]. Indeed, recently studies have shown waterborne microplastic concentrations of 88 items L−1 [35]. There are concerns microplastics might pose a risk to these ecologically and economically important organisms, for example, by reducing growth rates or survival, or increasing risk of disease, thereby posing a risk to shellfish commercial viability. As a result of microplastic exposure, marine mussels (e.g. Mytilus edulis, Mytilus galloprovincialis) can display inflammatory responses [36], increased antioxidant enzyme levels [37,38,39], increased hemocyte mortality [40] and a reduction in the number of byssal threads produced and attachment strength [41]. However, most studies investigating the effect of microplastic ingestion by marine organisms use plastic concentrations many orders of magnitude larger than those currently seen in the environment [42, 43], Lenz, Enders and Nielsen [34] note this discrepancy may result in inaccurate predictions and perceptions of the effect of microplastics upon the marine ecosystem. Furthermore, the majority of toxicity studies have not investigated the effects of microplastic fibres, which are the most common morphology of plastic identified in environmental samples [13, 44, 45]. Other research gaps or critiques we have identified include: studies are typically performed over relatively short periods of time, precluding the monitoring of chronic health effects; a lack of non-plastic controls; and, a focus upon the adult life stage, with little data emerging on the risks to juvenile or larval stages, which are generally much less resilient to environmental pollutants [46]. Two studies which did consider effects on juvenile life stages of bivalve shellfish are Capolupo et al. [47], who investigated the effect of the ingestion of 3 µm polystyrene microplastics on Mytilus galloprovincialis larvae, observing RNA transcriptional changes as a result of microplastic ingestion at 50,000 and 500,000 microplastics L−1 (upregulation of shell biogenesis and immunomodulation genes and inhibition of genes coding for lysosomal enzymes); and Thomas et al. [48], who observed increased mortality and a decrease in lysosomal membrane stability and condition index (a measure of the physiological state of the animal) in juvenile oysters exposed to 106 polystyrene beads L−1 (6 µm diameter) over 80 days. In both these studies, however, microplastic concentrations were far greater than what is currently reported in the environment [34].

This study seeks to address these research gaps by undertaking a chronic exposure study in which juvenile mussels are exposed to current environmentally relevant and feasible future-scenario concentrations of microfibres over a three-month period. Microfibres comprised both polyester and cotton to enable a direct comparison of the toxicity of microplastic fibres and a cellulose-based semi-synthetic microfibre control. We seek to test the hypothesis that sublethal health markers, such as growth rate, respiration rate and clearance rate, are affected in mussels by the presence of anthropogenic microfibres. This study provides evidence of the risk that microfibres pose to the growth of Mytilus spp., a keystone genus important for global food security [49].

Experimental methods

Contamination control

Care was taken at all stages to prevent the contamination and cross-contamination of microfibre exposure treatments. Wherever possible, glass apparatus and consumables were used to prevent the introduction of microfibres. When this was not possible, sterile, clean plastic consumables were used. All apparatus and consumables were rinsed thoroughly with Milli-Q prior to use. Samples and equipment were covered with aluminium foil wherever possible to minimize exposure to airborne contamination. Microfibre manufacture, mussel preparation, and microscopy were performed within the Plymouth Marine Laboratory ultraclean microplastics facility, which minimizes microplastic contamination via a HEPA filtered positive pressure airflow system (which removes 99.95% of airborne particles with a diameter of 0.3 µm), in addition to controlled personnel entry, cotton lab coats (of a different colour to the cotton microfibres used in the study) and tack mats to remove footwear contamination.

The model organism

Juvenile Mytilus spp. (~ 1 cm anterior–posterior length; n = 200) were gathered on 15th June 2020 from Trebarwith Beach, Cornwall (50.643794 N, -4.763651 W). Mussels were harvested from intertidal rocks and placed into buckets filled with seawater from the same location; buckets were placed into cool boxes surrounded by ice packs and transported to a 15 °C controlled temperature laboratory. Subsequently, mussels were housed in two 5 L beakers filled with filtered seawater (100 mussels in each beaker). Filtered seawater (FSW) was prepared using natural seawater sampled from station L4 (www.westernchannelobservatory.org) in the western English Channel, diluted with ultrapure water to Salinity = 35, filtered through two 5 µm filter cartridges (RS Pro House S cartridge) and UV sterilized (EHEIM reeflexUV 350). Mussels were fed by pipetting 1 mL concentrated microalgae feed (35 µg/mL), comprising Isochrysis, Pavlova, Tetraselmis, Thalassiosira weissflogii, and Thalassiosira pseudonana, into each beaker ad libitum (Instant Algae Shellfish Diet 1800, Reed Mariculture). Mussels were visually inspected every 24 h for one week, removing any deceased organisms; seawater was changed and mussels were fed every 48 h.

Manufacture of microfibres

Small sections of 100% cotton or 100% polyester fabric (verified using a PerkinElmer Spotlight 400 FT-IR microscope) were cut from new textiles, and microfibres were manufactured from these garments through manual cryogrinding. The textiles chosen were brightly coloured (yellow cotton; red polyester) to allow for easy identification of fibres and to distinguish from any contamination. Textile sections were frozen using liquid nitrogen, and ground using a mortar and pestle to produce individual fibres. Resultant fibres were then rinsed several times with Milli-Q water and size-fractionated by vacuum filtration over two filters (10 and 500 µm nylon mesh discs) to retain microfibres approximately 10–500 µm in length. The two microfibre stocks were stored in Milli-Q water in the dark at ~ 2 °C to limit microbial growth. Fifty fibres from each stock were measured using an Olympus SZX16 microscope (Magnification: 8.06x) with CellSens software (Olympus): polyester microfibres had a median length of 148.95 µm (mean 293.5 µm, SE ± 47) and a median diameter of 10.21 µm (mean 12.03 µm ± 0.72 SE); cotton microfibres had a median length of 132.33 µm (mean 171.5 µm, SE ± 22.0) and a median diameter of 19.23 µm (mean 20.47 µm ± 0.69 SE).

Experimental set up

All experimental work was conducted within a controlled temperature laboratory (15 °C, 16:8 h light/dark cycle). Header tanks (80 L clear polypropylene crates with lids; n = 4) were filled with 40 L FSW (salinity 35 ± 1), with the addition of microalgae (Shellfish Diet 1800) to a final concentration of 0.74 µg L−1 (concentration based upon pilot experiments, see Supplementary information). Water temperature and salinity were monitored throughout the experiment, and salinity adjusted by adding Milli-Q water where required. One header tank was used for each treatment, with the addition of either cotton or polyester microfibres to achieve nominal concentrations of either 8 or 80 microfibres L−1, with 8 microfibres L−1 being representative of microplastic concentrations observed in the natural environment [9, 34, 50,51,52], and 80 microfibres L−1 representing a feasible future-scenario environmental concentration given continued growth in global plastic production rates, and representative of current microplastic concentrations in heavily polluted water bodies close to anthropogenic input such as estuaries [35, 53]. Actual concentrations were verified throughout the exposure period by filtering 1 L subsamples through a GFF filter (Whatman) and enumerating microfibres under an Olympus SZX16 microscope. Recirculation pumps in each tank ensured microfibre homogeneity, and a peristaltic pump (Watson Marlow 323S) was used to dispense treatments to mussel aquaria (1 L glass beakers with lids, n = 5 per treatment) at a flow rate of 76 mL/h. This ensured that aquarium volume was maintained at 1 L volume which was replaced approximately twice within a 24-h period, thereby removing waste materials and providing a continuous supply of food and microfibres to the mussels. Pump filters were removed to prevent microfibre retention within pumps. Header tanks were swapped with clean tanks weekly, and old tanks cleaned thoroughly with a surface active cleaning agent (Decon 90) and MilliQ water; header tanks were placed randomly (Excel random number generator) each week to remove any positional effect. The 20 mussel aquaria were housed in large spill trays so that displaced water could be continuously removed. To ensure mussels remained within the water column, for each replicate five juvenile mussels were secured onto a wooden spatula (spaced 5–10 mm apart), using non-toxic, aquarium-safe silicone, and then spatulas fully submerged into individual aquaria (see Supplementary Fig. SI1). Each replicate aquaria therefore housed five mussels, for a total of 25 mussels per treatment. Aquaria housing the mussels were cleaned weekly, with the mussels carefully removed and the 20 aquaria emptied and cleaned, before being rinsed and refilled with 1 L of the corresponding treatment solution from the header tank, ensuring consistent microfibre exposure concentrations throughout the study. The experiment was performed over a 94-day period. An experimental flowchart and labelled picture of the experimental set-up can be found in the Supplementary data (SI2 and SI3, respectively).

Evidence of microfibre ingestion

To verify that the mussels had consumed the experimental fibres, at the end of the exposure period mussels were digested to isolate experimental microfibres. Mussels were euthanized via freezing, then soft tissues excised and rinsed in Milli-Q water to remove any microfibres present within the cavity around the soft tissues. Soft tissues were placed into pre-weighed individual glass vials and dried in a dehydrator overnight, then weighed again (Oxford A2205D) to ascertain mussel dry weight (mg). Tissues were digested using 10 mL 10% KOH with addition of 0.01% Tween20 surfactant for 48 h at 50 °C, in a rotational incubation chamber (Stuart Scientific SI50; 125 rpm). Both polyester and cotton are resistant to KOH digestion in the conditions utilized in this experiment [54]. Digested samples were filtered onto polycarbonate filter discs (10 µm pore size, 47 mm diameter) in a laminar flow hood, and rinsed with copious amounts of Milli-Q. Filters were covered and dried in a dehydrator, then visually inspected under an Olympus SZX16 microscope to quantify experimental microfibres; experimental microfibres were first identified by their physical characteristics (i.e. distinctive shape, size and colour), then a subset were verified using a PerkinElmer Spotlight 400 FT-IR microscope and comparing to the spectra from the pre-exposure microfibres.

Measurement of biological endpoints

Three variables were measured throughout the experiment: mussel shell length, clearance rate, and respiration rate. Clearance and respiration rate measurements were taken on alternate weeks to reduce handling stress. Where mussel mortality occurred, the data for the affected mussel was removed from the whole time series, to remove any bias from pre-mortality effects on mussel growth, clearance rate or respiration.

As mussels were kept alive throughout the experimental period, soft tissue weight could not be used to assess mussel growth. Instead, mussel anterior–posterior shell length was measured for the assessment of mussel growth on days 0, 11, 21, 32, 44, 59, 72, 86 and 93. Mussels on spatulas were removed from aquaria and gently placed onto the stage of an Olympus SZX16 stereomicroscope where images of the mussels were captured using a DP74 camera and CellSens software (Olympus, v2.1), and promptly returned to their aquaria. Images were analysed using Image J version 1.52a [55]; shell lengths (µm) for individual mussels were measured in triplicate for each timepoint.

Mussel clearance rates (L h−1) were measured on days 30, 44, 58, 72, 86 and 93 to track shifts in feeding activity. A stock of 10 L FSW containing 1 mL of Shellfish Diet 1800 was prepared, and 500 mL aliquots dispensed into 1 L beakers (n = 20). Spatulas housing the mussels were removed from aquaria and carefully placed into these beakers for 2 h, before being placed back in their aquaria. 10 mL samples from each beaker were transferred into labelled 15 mL Falcon tubes at T = 0, T = 1 h and T = 2 h. At each timepoint, the water in the beaker was gently mixed before the solution was removed to ensure sample homogeneity. Samples were filtered onto clean GF/F filters (0.1 µm pore size); filters were placed into 15 mL Falcon tubes with 10 mL 90% acetone solution and left overnight in a -20 °C freezer, to extract chlorophyll. Chlorophyll a concentrations were measured in triplicate using a fluorometer (Turner Designs Trilogy, model #7200–000). The fluorometer was calibrated using a serial dilution of chlorophyll stock solution of known concentration (1057.9 µg L−1) to create a standard curve; the linear regression equation of this line of best fit (R2 > 0.99) was used to convert sample fluorescence (RFU) to chlorophyll-a concentration (µg L−1) in the clearance rate samples. Subsequently, clearance rates were calculated using Chlorophyll a values following the method set out in Widdows and Staff [56] and the equation in Coughlan [57] (see Supplementary information).

Oxygen consumption rates of mussels in each replicate were measured on days 22, 37, 51, 65, 79 and 93 and were used to calculate respiration rates (µmol L−1 O2). Glass respiration vials (40 mL) were fitted with an oxygen sensitive spot (503,090, World Precision Instruments) and filled to the brim with aerated FSW. Spatulas housing the mussels were removed from each beaker and carefully placed into the respiration vial; the vial was then sealed with a rubber bung, and the mussels left to acclimate for 5 min. Oxygen concentrations in the vials were ascertained via a fibre optic oxygen meter (Oxy mini, World Precision Instruments) and oxygen saturation (%) and phase shift was recorded every 15 min for an hour (T = 0, 15, 30, 45, and 60 min after measurement start time). This timeframe ensured that oxygen concentrations never decreased by more than 50% during the monitoring period. Mussels were then promptly returned to their aquaria. Data were calibrated using both a 0% oxygen solution (Hanna Instruments HI7040) and a 100% oxygen saturated seawater solution. The average phase shift results of these two standards were used to create a calibration curve, through which the recorded phase shift values were converted to a temperature and salinity corrected %O2 saturation value. Finally, the %O2 saturation data was converted into µmol L−1 O2 as per Talbot et al. [58].

Statistical analysis

Statistics were conducted using R statistical analysis software (version 3.6.0). Data were tested for normality (Shapiro–Wilk) and homogeneity of variance (Levene’s test). Where data passed assumptions of normality, parametric ANOVA tests with Tukey’s post-hoc testing were used. In data where results violated a-priori assumptions of normality, non-parametric Kruskal–Wallis tests were performed, followed by Dunn’s post-hoc pairwise testing to observe whether individual experimental groups differ significantly. Statistical significance is assigned where P < 0.05 (95% confidence interval).

Results

Microfibre concentrations

Microfibre concentrations were monitored throughout the exposure period (Table 1), with average waterborne concentrations of: 7.88 fibres L−1 ± 0.74 SE (nominal: 8 polyester fibres L−1); 78.8 fibres L−1 ± 5.8 SE (nominal: 80 polyester fibres L−1); and 81.7 fibres L−1 ± 7.5 SE (nominal: 80 cotton fibres L−1). Conditions will be referred to herein by their nominal concentrations (8 or 80 fibres L−1) for clarity.

Digestion of mussels and identification of microfibres

Digestion and microscopic analysis of mussels revealed experimental microfibres within the soft tissues, which were verified via FT-IR spectral analysis (Table 1, Supplementary Figs. SI4 and SI5). In the polyester treatments, an average of 8.65 ± 1.6 SE and 18.78 ± 3.4 SE fibres were identified within mussels exposed to 8 L−1 microfibres and 80 L−1 microfibres, respectively. In the cotton treatment, an average of 34.36 fibres ± 3.9 SE were identified (Table 1). In all treatments, we observed an average of 4.25 ± 0.87 SE non-experimental fibres per individual, likely owing to airborne contamination in the controlled temperature laboratory; this background contamination was removed from the results.

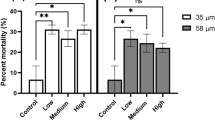

Mortality

The average survival rate across treatments was 72.5%, with the majority of individuals lost in the first few weeks of the exposure (79% of the total mortality was recorded in the first month). Treatment had no significant effect on mortality (Kruskal–Wallis, P = 0.77). Where > 50% mussel mortality was observed within an aquarium (i.e. the loss of 3 out of 5 individuals), this replicate was removed from further analysis; this occurred in one control aquaria, two 80 L−1 cotton exposure aquaria, and one 80 L−1 polyester exposure condition, leaving a minimum of n = 3 replicates for each condition.

Effects of microfibers on mussel growth

Mussel growth was observed in all treatments (see Supplementary Table SI6 for raw data). The largest increase in mean shell length over the three-month period was in the control group (938.5 µm ± 230.0 SE). Mean growth was comparatively lower in all treatment groups (Fig. 1A): 906.3 µm ± 89.0 SE (8 polyester L−1), 644.1 µm ± 88.0 SE (80 polyester L−1) and 778.4 µm ± 130.0 SE (80 cotton L−1). A significant reduction in growth was observed in the 80 polyester microfibres L−1 treatment group from Day 32 onwards (Kruskal–Wallis, P < 0.05), and on Day 59 only in the 80 cotton microfibres L−1 treatment (Kruskal–Wallis, P < 0.05).

A Plot displaying mean increase in mussel shell length over time (µm) for each experimental condition. Coloured shading shows SE around the mean at each timepoint. * denotes results which are significantly lower than the control at each timepoint, P < 0.05 (Kruskal–Wallis with Dunn’s, post-hoc test). B Box and whisker plot showing median mussel growth rate (µm day−1 mussel−1) for each experimental exposure condition. Box displays interquartile range, whiskers display full range. Letters denote statistical significance between treatments, P < 0.05 (Kruskal–Wallis test with Dunn’s post-hoc test). For a colour version of this figure, the reader is directed to the online version

Mean growth rate (Fig. 1B) in the control was 9.75 µm day−1 mussel−1. Mussels exposed to 80 polyester microfibres L−1 had significantly reduced growth rates (6.28 µm day−1 mussel−1; 35.6% decrease; Kruskal–Wallis, P = 0.004) as compared with the control (9.75 µm day−1 mussel−1). The mean growth rates of the 8 polyester L−1 exposure group (9.45 µm day−1 mussel−1; 3.1% decrease; Kruskal–Wallis, P = 0.40) and the 80 cotton L−1 exposure group (7.93 µm day−1 mussel−1; 18.7% decrease; Kruskal–Wallis, P = 0.09) appeared lower than the control, but this decrease was not statistically significant. In comparing polyester and cotton (at 80 microfibres L−1), no significant difference in growth rate was observed (Kruskal–Wallis, P = 0.12).

Effect of microfibres on mussel clearance rate

Mussel clearance rate decreased over the experimental period for all experimental treatments (Fig. 2A, Supplementary Table SI7), although this decrease was not uniform between conditions. Statistical difference in clearance rates differed by timepoint; for example, in the 8 polyester L−1 exposure mussels had a significantly lower clearance rate than the control group at day 44 (Kruskal–Wallis, P = 0.004), however at day 58, mussels in both the 8 polyester L−1 and 80 polyester L−1 exposure conditions exhibited significantly higher clearance rates than the control group (Kruskal–Wallis, P = 0.030 and 0.011, respectively). The 80 cotton L−1 condition had a statistically higher clearance rate compared to the control (Kruskal–Wallis, P = 0.024) on day 30. After day 58, no significant difference in clearance rate between experimental groups was observed. Clearance rate in each experimental exposure condition varied more and had a greater range than the control group; control clearance rate varied by a maximum of 67.1% from the first timepoint (day 30), whereas the three experimental groups varied by a maximum of 85.4%, 77.6%, and 88.9% (8 polyester L−1, 80 polyester L−1 and 80 cotton L−1 respectively). The 80 polyester L−1 and 80 cotton L−1 clearance rate results did not differ significantly at any timepoint (P > 0.05, all timepoints).

A Average clearance rate per mussel (L h−1 mussel−1) for each experimental exposure condition. x-axis denotes days after experiment start. B Average respiration rate per mussel (µmol O2 L−1 h.−1) for each experimental exposure condition. x-axis denotes days after experiment start. * denotes statistical significance when compared to the control group at each timepoint, P < 0.05 (Kruskal–Wallis test with Dunn’s post-hoc test)

Effect of microfibres on mussel respiration rate

Mussel respiration rate decreased over the experimental period for all conditions (Fig. 2B, Supplementary Table SI8). In the control group, respiration rates stabilized more quickly than in all three microfibre exposure conditions. Compared to the control group, respiration rate was significantly higher in the 8 L−1 polyester exposure group in the first three experimental timepoints (Kruskal–Wallis: d 22, P = 0.044; d37, P = 0.014; d51, P = 0.013). Throughout the experiment there was no significant difference in respiration rate between the control group and the 80 L−1 cotton or polyester microfibre exposure groups. As with the clearance rate results, there was no significant difference between the 80 L−1 polyester or cotton microfibre exposures throughout the experiment (P > 0.05 at every timepoint).

Discussion

This is the first chronic exposure experiment assessing the effect of anthropogenic microfibres on bivalves. Juvenile mussel growth rates were significantly reduced when exposed to 80 polyester microfibres L−1, with significant differences in growth evident after 32 days of exposure. Microfibre treatments had no significant impact on mortality, respiration rates or clearance rates.

Microfibre ingestion

The uptake of cotton and polyester microfibres by juvenile mussels was confirmed by isolating experimental microfibres from the soft tissues. When exposed to a higher concentration of polyester microfibres, a higher number of polyester microfibres were identified in mussel tissues, in agreeance with findings elsewhere [59]. Almost twice as many cotton microfibres were found in soft tissues as compared with polyester microfibres (when provided at equal concentration); this may be due to the mussels having a greater capacity to deal with cellulosic fibres such as cotton, as Mytilus spp. are known to possess a high level of cellulase activity [60, 61], or may possibly reflect subtle differences in fibre morphology (cotton microfibres had a greater diameter than polyester microfibres) or variance in the egestion time of the different microfibres. The two microfibres were different in colour, however there is no evidence that mussels can selectively ingest particles based on their colour. While we can conclude microfibres were ingested by the mussels, owing to the small size of the juvenile mussels utilized here, we were unable to excise and digest specific tissues, and cannot confirm which organs they might affect or for how long the microfibres may be retained. Previous studies using adult specimens have identified microplastics within the digestive gland, gills, digestive tract, mantle and circulatory system [32, 38, 62,63,64].

Biological endpoints

Exposure to anthropogenic microfibres were demonstrated to reduce growth rates of juvenile mussels. Significant reductions in growth were observed in mussels following 32 days exposure to 80 polyester microfibres L−1. This reflects probable future scenarios for microplastics in coastal waters as global plastic production rates rise, and is representative of microplastic concentrations already observed in heavily polluted marine and estuarine sites, which have seen microplastic concentrations of 88–247 particles L−1 [35, 53, 65]. Our results highlight the importance of conducting chronic exposure studies when considering microplastic toxicity. While the impact of microplastics on lower levels of biological hierarchy (i.e. molecular endpoints) can become evident over short timescales [66], the impact of environmentally relevant concentrations of microplastics on apical endpoints (e.g. growth, reproduction, survival) that have the greatest relevance to populations and communities, require far longer observation periods. Other aquatic organisms have also exhibited lower growth rates when exposed to microplastics, including fish [67], zooplankton [68], crustaceans [69], and corals [70].

We postulate that observed reductions in mussel growth in response to microfibres stem from either an energetic shortfall, or a shift in the energetic budget. An energetic shortfall, resulting from reduced feeding or assimilation rates, would play an instrumental role in curtailing growth. Such effects could stem from a ‘false satiation’ effect, as indigestible anthropogenic particles replace volumetric mass of digestible matter, [71,72,73], or shifts in feeding behaviors to avoid consuming microplastics. For example, the copepod Calanus helgolandicus has been observed to shift to foraging smaller microalgae to avoid consuming larger microplastics, which resulted in reduced energetic uptake and consequently the production of smaller eggs with reduced hatching success [74]. Previous studies have shown adult mussels can increase pseudofaeces production to reduce uptake of 75–1075 µm nylon microfibres when 34–495 microfibres are offered to actively feeding organisms [75]. However, we observed no significant decrease in the clearance rates of mussels exposed to 8–80 microfibres L−1, and must therefore surmise these mussels suffered no energetic shortfall. However, reduced growth rate could also stem from energy being diverted away from growth into processing ingested microfibres in the gastrointestinal tract [76, 77], or repairing damage caused by these microfibres. A number of toxicity studies provide evidence that microplastics can cause adverse sub-lethal health effects at the molecular and cellular level of biological hierarchy in adult Mytilus edulis and Mytilus galloprovincialis. For example: exposure to < 100 µm polyethylene and polystyrene powders for 7 days can alter granulocyte/hyalinocyte ratios indicative of an increased immune response [38, 78]; exposure to > 0–80 μm high-density polyethylene grains for up to 96 h can result in decreased lysosomal membrane stability and increased granulocytoma formation indicative of cellular damage [36]; exposure to a mixture of < 400 µm polyethylene and polypropylene powder for 10 days increased superoxide dismutase (SOD) activity in the digestive glands and gills, indicative of oxidative damage, and haemocytic DNA damage [37]. A heightened immune response, DNA, cellular and tissue repair, and upregulation of antioxidative pathways will all require energetic expenditure, thereby shifting energy away from growth and reproduction [79]. Indeed, dynamic energy budget modelling of Adult Pacific oysters (Crassostrea gigas) exposed to 2 and 6 µm polystyrene microspheres reveals homeostatic changes in stress and immune responses resulting in energy flow disruption, redirecting energy away from reproduction towards organism maintenance and growth [76]. Whilst not considered in the present study, a combined investigation of energy budgets and subcellular toxicity of microfibres in a similar chronic exposure experiment may clarify the mode of effect of microfibres on mussels over chronic timescales.

We found no evidence of microfibres impacting upon mussel feeding or respiration rates. Similarly, exposure to 1 and 10 µm polystyrene beads for 8 days had no significant effect on Pacific oyster (Crassostrea gigas) larvae feeding or growth at ≤ 100 microplastics mL–1 [80]. Furthermore, European flat oysters (Ostrea edulis) exposed to HDPE and PLA at concentrations of 0.8 and 80 μg L−1 for 2 months showed no alteration in respiration, clearance rates or growth rate compared to control organisms [81]. Conversely, mussels exposed to 3000–30,000 polyester microfibres L−1 (length 459 µm) for 72 h exhibited significant reductions in their filtration rates [32],however, these concentrations are around 340 × higher than used in this experiment and are not reflective of environmental concentrations. In this study, clearance and respiration rates decreased over the first 6 weeks of exposure, and then remained stable for the remainder of the experiment. Previous studies have indicated that mussel acclimation to laboratory conditions takes around 14–21 days [82,83,84]. However, the clearance and respiration rate measurements observed here suggest that juvenile mussels may take even longer to acclimate.

Comparing polyester and cotton microfibres

While plastic microfibres such as polyester are widely investigated in the literature, this study is among the first to consider the effect of anthropogenic cellulosic fibres such as cotton. Growth rates of mussels exposed to 80 cotton or polyester microfibres L−1 were not significantly different, however when compared to the control condition, only polyester microfibres caused a consistent significant decrease in growth rate. Given the comparable morphologies of the cotton and polyester microfibres in this study, the difference in their effect on mussel growth rate may be due to their chemical characteristics, which were not investigated in this study. Future research should therefore consider the mechanisms by which different anthropogenic polymers (whether natural, semi-synthetic or fully synthetic, with and without additives and dyes) may affect organisms. Though the perceived decrease in growth rate of 19% in mussels exposed to 80 cotton microfibres L−1 was not significantly lower than the control group in this study, given the large numbers of semi-synthetic microfibres used in textiles and found in marine samples [18], we recommend investigations into the effects of manmade cellulosic microfibres on marine biota are made a research priority. Greater use of positive controls in microplastic studies, such as the use of cotton microfibres, are recommended to help explain the mechanisms by which anthropogenic particulates cause toxicity in marine organisms.

Environmental relevance

Mussels provide a range of ecosystem services, including biofiltration, food provision and carbon sequestration [85]. A reduction in growth rate will result in smaller mussels with comparatively lower clearance rates, reducing their capacity to function as effective biofilters and remove carbon through consumption and egestion of phytoplankton. While mussels with reduced growth rates may reach the same size as the control population over a longer period of time, this may pose a risk to bioenergetics within marine food webs, as in natural populations, smaller mussels will be less energetically valuable to predators (e.g. gastropods, echinoderms, seabirds and mammals). While in commercial populations, a reduction in growth rate will increase the time taken for mussels to reach harvestable size, with smaller mussels having lower commercial value. Molluscs (mostly bivalves) were the second-most farmed group of aquatic animals after finfish in 2018 [26], with 17.7 million tonnes produced by global aquaculture; as such, negative impacts on the growth of bivalve shellfish has the potential to impact upon their commercial viability.

Data presented here explores the effect of microfibres on mussel health in a controlled environment. However, in the marine environment, mussels are exposed to multiple stressors, from pollutants to climate change (e.g. warmer temperatures, acidification). Effects observed here may therefore be compounded through multi-stress impacts on mussels which may leave populations less resilient and lead to decreased population health [86, 87]. As bivalve populations take longer to grow they may be more prone to disease, or susceptible to morbidity or mortality following extreme events (e.g. heat stress, oxygen depletion) [88,89,90]. Global bivalve populations are already declining, with many bivalve species listed as endangered and several classified as extinct [45]; it is possible that increasing concentrations of microplastics and microfibres may exacerbate this rate of decline, though further research is required to confirm this hypothesis.

Conclusion

The growth rate of juvenile mussels was significantly decreased when exposed to 80 polyester microfibres L−1. This reduction in growth rate may increase the time taken for bivalves to grow to a harvestable size, increasing the time and investment required for the growing of bivalves for human consumption, potentially increasing costs and presenting a risk to commercial viability. Further, the mean growth rate of mussels exposed to 80 cotton microfibres L−1 was reduced by 19%; though this was not a significant reduction, it nevertheless highlights the importance of investigating the effects of other anthropogenic particles on biota. The effects detailed here could have broadscale effects on marine ecosystems; as bivalves are a prey item for many species, sublethal health effects such as reduced growth rates will cause additional stress in an ecosystem already suffering from multiple stressors through the effects of climate change, overfishing, and anthropogenic pollution.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Andrady AL. Microplastics in the marine environment. Mar Pollut Bull. 2011;62(8):1596–605. https://doi.org/10.1016/J.MARPOLBUL.2011.05.030.

Horton AA, et al. Microplastics in freshwater and terrestrial environments: Evaluating the current understanding to identify the knowledge gaps and future research priorities. Sci Total Environ. 2017;586:127–41. https://doi.org/10.1016/j.scitotenv.2017.01.190.

Karbalaei S, et al. Occurrence, sources, human health impacts and mitigation of microplastic pollution. Environ Sci Pollut Res. 2018;25(36):36046–63. https://doi.org/10.1007/s11356-018-3508-7.

Li J, Liu H, Paul Chen J. Microplastics in freshwater systems: A review on occurrence, environmental effects, and methods for microplastics detection. Water Res. 2018;137:362–74. https://doi.org/10.1016/j.watres.2017.12.056.

Thompson RC, et al. Lost at Sea: Where Is All the Plastic? Science. 2004;304(5672):838 LP – 838. https://doi.org/10.1126/science.1094559.

Jambeck JR, et al. Plastic waste inputs from land into the ocean. Science. 2015. https://doi.org/10.1126/science.1260352.

PlasticsEurope. Plastics − the Facts 2020’, Plastics Europe: Association of Plastics Manufacturers. 2020. p. 1–64. Available at: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020.

Browne MA, et al. Accumulation of microplastic on shorelines woldwide: Sources and sinks. Environ Sci Technol. 2011;45(21):9175–9. https://doi.org/10.1021/es201811s.

Desforges JPW, et al. Widespread distribution of microplastics in subsurface seawater in the NE Pacific Ocean. Mar Pollut Bull. 2014;79(1–2):94–9. https://doi.org/10.1016/j.marpolbul.2013.12.035.

Ivar Do Sul JA, Costa MF. The present and future of microplastic pollution in the marine environment. Environ Pollut. 2014. https://doi.org/10.1016/j.envpol.2013.10.036.

Kooi M, Koelmans AA. Simplifying Microplastic via Continuous Probability Distributions for Size, Shape, and Density. Environ Sci Technol Lett. 2019;6(9):551–7. https://doi.org/10.1021/acs.estlett.9b00379.

Lindeque PK, et al. Are we underestimating microplastic abundance in the marine environment? A comparison of microplastic capture with nets of different mesh-size. Environ Pollut. 2020;265:114721. https://doi.org/10.1016/j.envpol.2020.114721.

Rebelein A, et al. Microplastic fibers — Underestimated threat to aquatic organisms? Sci Total Environ. 2021. https://doi.org/10.1016/j.scitotenv.2021.146045.

Barrows APW, Cathey SE, Petersen CW. Marine environment microfiber contamination: Global patterns and the diversity of microparticle origins. Environ Pollut. 2018;237:275–84. https://doi.org/10.1016/J.ENVPOL.2018.02.062.

Bessa F, et al. Occurrence of microplastics in commercial fish from a natural estuarine environment. Mar Pollut Bull. 2018;128:575–84. https://doi.org/10.1016/j.marpolbul.2018.01.044.

Yu X, et al. Occurrence and distribution of microplastics at selected coastal sites along the southeastern United States. Sci Total Environ. 2018;613–614:298–305. https://doi.org/10.1016/j.scitotenv.2017.09.100.

Avio CG, et al. Distribution and characterization of microplastic particles and textile microfibers in Adriatic food webs: General insights for biomonitoring strategies. Environ Pollut. 2020;258:113766. https://doi.org/10.1016/j.envpol.2019.113766.

Suaria G, et al. Microfibers in oceanic surface waters: A global characterization. Sci Adv. 2020;6(23):eaay8493. https://doi.org/10.1126/sciadv.aay8493.

Carr SA. Sources and dispersive modes of micro-fibers in the environment. Integr Environ Assess Manag. 2017. https://doi.org/10.1002/ieam.1916.

Hernandez E, Nowack B, Mitrano DM. Polyester Textiles as a Source of Microplastics from Households: A Mechanistic Study to Understand Microfiber Release During Washing. Environ Sci Technol. 2017;51(12):7036–46. https://doi.org/10.1021/acs.est.7b01750.

Napper IE, Thompson RC. Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar Pollut Bull. 2016;112(1–2):39–45. https://doi.org/10.1016/j.marpolbul.2016.09.025.

Zambrano MC, et al. Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar Pollut Bull. 2019;142:394–407. https://doi.org/10.1016/j.marpolbul.2019.02.062.

Mishra S, et al. Synthetic microfibers: Source, transport and their remediation. J Water Process Eng. 2020;38:101612. https://doi.org/10.1016/j.jwpe.2020.101612.

Xu C, et al. Are we underestimating the sources of microplastic pollution in terrestrial environment? J Hazard Mater. 2020. https://doi.org/10.1016/j.jhazmat.2020.123228.

Xue B, et al. Underestimated Microplastic Pollution Derived from Fishery Activities and “Hidden” in Deep Sediment. Environ Sci Technol. 2020;54(4):2210–7. https://doi.org/10.1021/acs.est.9b04850.

FAO. The State of World Fisheries and Aquaculture 2020, The State of World Fisheries and Aquaculture 2020. 2020. https://doi.org/10.4060/ca9229en.

Azra MN, et al. The Contributions of Shellfish Aquaculture to Global Food Security: Assessing Its Characteristics From a Future Food Perspective. Front Marine Sci. 2021;8:654897. https://doi.org/10.3389/fmars.2021.654897.

Van Cauwenberghe L, et al. Microplastics are taken up by mussels (Mytilus edulis) and lugworms (Arenicola marina) living in natural habitats. Environ Pollut. 2015;199:10–7. https://doi.org/10.1016/J.ENVPOL.2015.01.008.

Digka N, et al. Microplastics in mussels and fish from the Northern Ionian Sea. Mar Pollut Bull. 2018;135:30–40. https://doi.org/10.1016/J.MARPOLBUL.2018.06.063.

Li J, et al. Microplastics in mussels along the coastal waters of China. Environ Pollut. 2016;214:177–84. https://doi.org/10.1016/J.ENVPOL.2016.04.012.

Li J, et al. Using mussel as a global bioindicator of coastal microplastic pollution. Environ Pollut. 2019;244:522–33. https://doi.org/10.1016/J.ENVPOL.2018.10.032.

Woods MN, et al. Microplastic fiber uptake, ingestion, and egestion rates in the blue mussel (Mytilus edulis). Mar Pollut Bull. 2018;137:638–45. https://doi.org/10.1016/J.MARPOLBUL.2018.10.061.

Walkinshaw C, et al. Microplastics and seafood: lower trophic organisms at highest risk of contamination. Ecotoxicol Environ Saf. 2020;190:110066. https://doi.org/10.1016/j.ecoenv.2019.110066.

Lenz R, Enders K, Nielsen TG. Microplastic exposure studies should be environmentally realistic. Proc Natl Acad Sci. 2016. https://doi.org/10.1073/pnas.1606615113.

Gray AD, et al. Microplastic in two South Carolina Estuaries: Occurrence, distribution, and composition. Mar Pollut Bull. 2018;128:223–33. https://doi.org/10.1016/j.marpolbul.2018.01.030.

Von Moos N, Burkhardt-Holm P, Köhler A. Uptake and effects of microplastics on cells and tissue of the blue mussel Mytilus edulis L. after an experimental exposure. Environ Sci Technol. 2012. https://doi.org/10.1021/es302332w.

Revel M, et al. ‘Tissue-Specific Biomarker Responses in the Blue Mussel Mytilus spp. Exposed to a Mixture of Microplastics at Environmentally Relevant Concentrations. Front Environ Sci. 2019;7:33. https://doi.org/10.3389/fenvs.2019.00033.

Cole M, et al. Microplastics, microfibres and nanoplastics cause variable sub-lethal responses in mussels (Mytilus spp.). Mar Pollut Bull. 2020;160:111552. https://doi.org/10.1016/j.marpolbul.2020.111552.

Li Z, et al. Is microplastic an oxidative stressor? Evidence from a meta-analysis on bivalves. J Hazard Mater. 2022;423:127211. https://doi.org/10.1016/j.jhazmat.2021.127211.

Paul-Pont I, et al. Exposure of marine mussels Mytilus spp. to polystyrene microplastics: Toxicity and influence on fluoranthene bioaccumulation. Environ Pollut. 2016;216:724–37. https://doi.org/10.1016/j.envpol.2016.06.039.

Green DS, et al. Exposure to microplastics reduces attachment strength and alters the haemolymph proteome of blue mussels (Mytilus edulis). Environ Pollut. 2019;246:423–34. https://doi.org/10.1016/J.ENVPOL.2018.12.017.

Lim XZ. Microplastics are everywhere - but are they harmful? Nature. 2021. https://doi.org/10.1038/d41586-021-01143-3.

Phuong NN, et al. Is there any consistency between the microplastics found in the field and those used in laboratory experiments? Environ Pollut. 2016;211:111–23. https://doi.org/10.1016/j.envpol.2015.12.035.

Christoforou E, et al. Effects of long-term exposure to microfibers on ecosystem services provided by coastal mussels. Environ Pollut. 2020;266:115184. https://doi.org/10.1016/j.envpol.2020.115184.

Zhang F, et al. Direct and indirect effects of microplastics on bivalves, with a focus on edible species: A mini-review. Crit Rev Environ Sci Technol. 2020;50(20):2109–43. https://doi.org/10.1080/10643389.2019.1700752.

Stevens A, Gobler C. Interactive effects of acidification, hypoxia, and thermal stress on growth, respiration, and survival of four North Atlantic bivalves. Mar Ecol Prog Ser. 2018;604:143–61 Available at: https://www.int-res.com/abstracts/meps/v604/p143-161/.

Capolupo M, et al. Uptake and transcriptional effects of polystyrene microplastics in larval stages of the Mediterranean mussel Mytilus galloprovincialis. Environ Pollut. 2018;241:1038–47. https://doi.org/10.1016/j.envpol.2018.06.035.

Thomas M, et al. The world is your oyster: low-dose, long-term microplastic exposure of juvenile oysters. Heliyon. 2020;6(1):e03103. https://doi.org/10.1016/J.HELIYON.2019.E03103.

Larsson J, et al. Regional genetic differentiation in the blue mussel from the Baltic Sea area. Estuar Coast Shelf Sci. 2017;195:98–109. https://doi.org/10.1016/j.ecss.2016.06.016.

Barrows APW, et al. Grab vs. neuston tow net: a microplastic sampling performance comparison and possible advances in the field. Anal Methods. 2017;9(9):1446–53. https://doi.org/10.1039/C6AY02387H.

Cai M, et al. Lost but can’t be neglected: Huge quantities of small microplastics hide in the South China Sea. Sci Total Environ. 2018;633:1206–16. https://doi.org/10.1016/j.scitotenv.2018.03.197.

Karlsson TM, et al. Screening for microplastics in sediment, water, marine invertebrates and fish: Method development and microplastic accumulation. Mar Pollut Bull. 2017;122(1):403–8. https://doi.org/10.1016/j.marpolbul.2017.06.081.

Naidoo T, Glassom D, Smit AJ. Plastic pollution in five urban estuaries of KwaZulu-Natal, South Africa. Mar Pollut Bull. 2015;101(1):473–80. https://doi.org/10.1016/j.marpolbul.2015.09.044.

Treilles R, et al. Impacts of organic matter digestion protocols on synthetic, artificial and natural raw fibers. Sci Total Environ. 2020;748:141230. https://doi.org/10.1016/J.SCITOTENV.2020.141230.

Schneider CA, Rasband WS, Eliceiri KW. NIH Image to ImageJ : 25 years of image analysis HISTORICAL commentary NIH Image to ImageJ : 25 years of image analysis. Nat Methods. 2012;9(7):671–5. https://doi.org/10.1038/nmeth.2089.

Widdows J, Staff F. Biological Effects of contaminants: measurement of scope for growth in mussels. In: ICES Techniques in Marine Environmental Sciences. 2006.

Coughlan J. The estimation of filtering rate from the clearance of suspensions. Mar Biol. 1969;2(4):356–8. https://doi.org/10.1007/BF00355716.

Talbot SE, et al. Adapting the dynamic energy budget (DEB) approach to include non-continuous growth (moulting) and provide better predictions of biological performance in crustaceans. ICES J Mar Sci. 2019;76(1):192–205. https://doi.org/10.1093/icesjms/fsy164.

Scott N, et al. Particle characteristics of microplastics contaminating the mussel Mytilus edulis and their surrounding environments. Mar Pollut Bull. 2019;146:125–33. https://doi.org/10.1016/j.marpolbul.2019.05.041.

Fernández-Reiriz M, Labarta U, Navarro J, et al. Enzymatic digestive activity in Mytilus chilensis (Hupé 1854) in response to food regimes and past feeding history. J Comp Physiol B. 2001;171:449–456. https://doi.org/10.1007/s003600100194.

Labarta U, Fernández-Reiriz M, Navarro J, et al. Enzymatic digestive activity in epifaunal (Mytilus chilensis) and infaunal (Mulinia edulis) bivalves in response to changes in food regimes in a natural environment. Mar Biol. 2002;140:669–76. https://doi.org/10.1007/s00227-001-0742-0.

Browne MA, et al. Ingested microscopic plastic translocates to the circulatory system of the mussel, Mytilus edulis (L.). Environ Sci Technol. 2008. https://doi.org/10.1021/es800249a.

Kolandhasamy P, et al. Adherence of microplastics to soft tissue of mussels: A novel way to uptake microplastics beyond ingestion. Sci Total Environ. 2018;610–611:635–40. https://doi.org/10.1016/J.SCITOTENV.2017.08.053.

Wang S, et al. Ingestion of nano/micro plastic particles by the mussel Mytilus coruscus is size dependent. Chemosphere. 2021;263:127957. https://doi.org/10.1016/j.chemosphere.2020.127957.

Song YK, et al. Occurrence and Distribution of Microplastics in the Sea Surface Microlayer in Jinhae Bay, South Korea. Arch Environ Contam Toxicol. 2015;69(3):279–87. https://doi.org/10.1007/s00244-015-0209-9.

Galloway TS, Cole M, Lewis C. Interactions of microplastic debris throughout the marine ecosystem. Nat Ecol Evol. 2017. https://doi.org/10.1038/s41559-017-0116.

Naidoo T, Glassom D. Decreased growth and survival in small juvenile fish, after chronic exposure to environmentally relevant concentrations of microplastic. Mar Pollut Bull. 2019;145:254–9. https://doi.org/10.1016/j.marpolbul.2019.02.037.

Ziajahromi S, et al. Impact of Microplastic Beads and Fibers on Waterflea (Ceriodaphnia dubia) Survival, Growth, and Reproduction: Implications of Single and Mixture Exposures. Environ Sci Technol. 2017;51(22):13397–406. https://doi.org/10.1021/acs.est.7b03574.

Welden NAC, Cowie PR. ‘Long-term microplastic retention causes reduced body condition in the langoustine, Nephrops norvegicus. Environ Pollut. 2016;218:895–900. https://doi.org/10.1016/j.envpol.2016.08.020.

Chapron L, et al. Macro- and microplastics affect cold-water corals growth, feeding and behaviour. Sci Rep. 2018;8(1):15299. https://doi.org/10.1038/s41598-018-33683-6.

Science Advice for Policy by European Academies (SAPEA). A Scientific Perspective on Microplastics in Nature and Society | SAPEA, Evidence Review Report. 2019. https://doi.org/10.26356/microplastics.

Koelmans AA, et al. Solving the Nonalignment of Methods and Approaches Used in Microplastic Research to Consistently Characterize Risk. Environ Sci Technol. 2020;54(19):12307–15. https://doi.org/10.1021/acs.est.0c02982.

De Ruijter VN, et al. Quality Criteria for Microplastic Effect Studies in the Context of Risk Assessment: A Critical Review. Environ Sci Technol. 2020;54(19):11692–705. https://doi.org/10.1021/acs.est.0c03057.

Cole M, et al. The impact of polystyrene microplastics on feeding, function and fecundity in the marine copepod Calanus helgolandicus. Environ Sci Technol. 2015. https://doi.org/10.1021/es504525u.

Ward JE, et al. Selective Ingestion and Egestion of Plastic Particles by the Blue Mussel (Mytilus edulis) and Eastern Oyster (Crassostrea virginica): Implications for Using Bivalves as Bioindicators of Microplastic Pollution. Environ Sci Technol. 2019;53(15):8776–84. https://doi.org/10.1021/acs.est.9b02073.

Sussarellu R, et al. Oyster reproduction is affected by exposure to polystyrene microplastics. Proc Natl Acad Sci. 2016. https://doi.org/10.1073/pnas.1519019113.

Wright SL, et al. Microplastic ingestion decreases energy reserves in marine worms. Curr Biol. 2013;23(23):R1031–3. https://doi.org/10.1016/j.cub.2013.10.068.

Avio CG, et al. Pollutants bioavailability and toxicological risk from microplastics to marine mussels. Environ Pollut. 2015;198:211–22. https://doi.org/10.1016/J.ENVPOL.2014.12.021.

Trestrail C, Nugegoda D, Shimeta J. Invertebrate responses to microplasticingestion: Reviewing the role of the antioxidant system. Sci Total Environ. 2020;734:138559. https://doi.org/10.1016/j.scitotenv.2020.138559.

Cole M, Galloway TS. Ingestion of Nanoplastics and Microplastics by Pacific Oyster Larvae. Environ Sci Technol. 2015. https://doi.org/10.1021/acs.est.5b04099.

Green DS. Effects of microplastics on European flat oysters, Ostrea edulis and their associated benthic communities. Environ Pollut. 2016;216:95–103. https://doi.org/10.1016/j.envpol.2016.05.043.

Widdows J. Effect of temperature and food on the heart beat, ventilation rate and oxygen uptake of Mytilus edulis. Mar Biol. 1973;20(4):269–76. https://doi.org/10.1007/BF00354270.

Widdows J. Physiological adaptation ofMytilus edulis to cyclic temperatures. J Comp Physiol. 1976;105(2):115–28. https://doi.org/10.1007/BF00691115.

Moyen NE, Somero GN, Denny MW. Mussel acclimatization to high, variable temperatures is lost slowly upon transfer to benign conditions. J Exp Biol. 2020;223:jeb222893. https://doi.org/10.1242/jeb.222893.

van der Schatte Olivier A, et al. A global review of the ecosystem services provided by bivalve aquaculture. Rev Aquac. 2020;12(1):3–25. https://doi.org/10.1111/raq.12301.

Horton AA, Barnes DKA. Microplastic pollution in a rapidly changing world: Implications for remote and vulnerable marine ecosystems. Sci Total Environ. 2020;738:140349. https://doi.org/10.1016/j.scitotenv.2020.140349.

Negri A, et al. Transcriptional Response of the Mussel Mytilus galloprovincialis (Lam.) following Exposure to Heat Stress and Copper. PLoS ONE. 2013;8(6):e66802. https://doi.org/10.1371/journal.pone.0066802.

Anestis A, et al. Behavioral, metabolic, and molecular stress responses of marine bivalve Mytilus galloprovincialis during long-term acclimation at increasing ambient temperature. Am J Physiol Regul Integr Comp Physiol. 2007;293(2):R911-21. https://doi.org/10.1152/ajpregu.00124.2007.

LeBlanc N, et al. The effect of high air and water temperature on juvenile Mytilus edulis in Prince Edward Island, Canada. Aquaculture. 2005;243(1–4):185–94. https://doi.org/10.1016/j.aquaculture.2004.09.035.

Seuront L, et al. Decreased thermal tolerance under recurrent heat stress conditions explains summer mass mortality of the blue mussel Mytilus edulis. Sci Rep. 2019;9(1):1–4. https://doi.org/10.1038/s41598-019-53580-w.

Acknowledgements

The authors would like to thank Ana Queirós (PML) for providing training in respiration measurements and Zara Botterell (PML) for their assistance in field sampling.

Funding

CW was funded by the Natural Environment Research Council through the EnvEast Doctoral Training Partnership (grant number NE/L002582/1). MC and PL were funded by the March Marine Initiative.

Author information

Authors and Affiliations

Contributions

CW wrote the main manuscript text, conceptualized, developed, and performed the methodology, conducted the formal analysis, curated the data, produced visualizations. MC edited the main manuscript text, provided supervision and conceptualized the project. PKL, TT, RT provided supervision and edited the manuscript. All authors contributed to reviewing and editing the manuscript and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Walkinshaw, C., Tolhurst, T.J., Lindeque, P.K. et al. Impact of polyester and cotton microfibers on growth and sublethal biomarkers in juvenile mussels. Micropl.&Nanopl. 3, 5 (2023). https://doi.org/10.1186/s43591-023-00052-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43591-023-00052-8