Abstract

Background

Antimicrobial resistance is a threat to global public health and requires the development of new antibiotic alternatives to treat bacterial infection. Infection with Escherichia coli (E. coli) is the most common cause of diarrhea in pigs, especially in weaning piglets. The objective of this study was to characterize chemical properties of water-soluble extract (WSE) obtained from yeast cell wall, and study its antibacterial activity and antimicrobial mechanisms against E. coli.

Results

WSE was extracted from yeast cell wall by hot water, followed by anhydrous ethanol precipitation and deproteinization by Sevag method to obtain water-soluble polysaccharides (WSP, accounting for 76.53 ± 5.91% by weight of WSE). WSP was purified by DEAE-52 cellulose column and Sephadex G-100 column to obtain three fractions of polysaccharides, WSNP, WSAP-1 and WSAP-2. Physicochemical properties of them were then characterized. The average molecular weights of WSNP, WSAP-1 and WSAP-2 were 105,130, 94,581 and 91,247 Da, respectively. WSNP was composed of glucosamine (GlcN), glucose (Glc), mannose (Man) and glucuronic acid (GlcA) in a molar ratio of 8.6:55.2:34.4:1.8, WSAP-1 was consisted of GlcN, Glc and Man in a molar ratio of 10.9:42.2:46.9, and WSAP-2 was consisted of GlcN, galactose (Gal), Glc and Man in a molar ratio of 9.0:1.0:55.1:34.9. Spectral analysis indicated that all three polysaccharides had pyran polysaccharides, triple-helix structure, α- and β-glycosidic bond. The minimum inhibitory concentrations of WSE and WSP on E.coli were 25 mg/mL and 100 mg/mL, respectively. WSE can not only disrupt the integrity of the cell wall and membrane of E.coli, but also increase the permeability of the outer membrane.

Conclusions

Our research elucidated chemical composition and structure of WSNP, WSAP-1 and WSAP-2. WSE exerted its bactericidal activity by damaging the bacterial cell wall and membrane and increasing outer membrane permeability. Yeast cell wall products have been recommended as a potential alternative to antibiotics. This work provides more information, regarding chemical properties and anti-E. coli mechanism of WSE, and facilitates the application of yeast cell wall products as a promising antibiotic alternative in animal feed.

Similar content being viewed by others

1 Background

Escherichia coli (E. coli) is a major conditional pathogen causing serious diarrhea either in animals or humans worldwide [1, 2]. The incidence of E. coli diarrhea in weaning piglets is as high as 80% and mortality rates are over 10% [3], which caused huge economic losses to the swine industry. It is estimated that E. coli infections caused 650 million morbidities and approximately 800,000 deaths in children (under 5 years of age) worldwide each year [4]. The unique outer membrane barrier and drug resistance, especially multi-drug resistance, have put the treatment of E. coli disease in jeopardy [5].

There is currently no licensed effective vaccine for the prevention of diarrhea caused by E. coli and reliance is still placed on medication for prevention and treatment. The long-term misuse and/or abuse, of antibiotics, to prevent microbial infections, especially via the addition of subclinical doses of antibiotics to feed as antibacterial growth promoters, has led to widespread and rapid bacterial resistance [6]. To solve the problem of drug resistance, the EU, China and other countries have banned the use of antibiotics as feed additives [7, 8]. However, the prohibition of feed antibiotics has caused new problems: intestinal bacterial infections have increased, animal industry production levels have declined, and the cost of animal production has increased significantly. Therefore, the development of new and safe alternatives to antibiotics is urgently required. Currently, common antibiotic substitutes include prebiotics [9, 10], probiotics [11], plant extracts [12] and enzyme preparations [12].

Products of yeast cell wall origin have been considered as a potential alternative to antibiotics due to their immunomodulatory [13] and antibacterial activities [14]. Several reports have suggested that WSE can improve the intestinal microenvironment, stimulate innate and acquired immunity, adsorb mycotoxins, promote wound healing and prevent cancer, in addition to possessing antioxidant, blood sugar lowering and blood fat lowering effects [15,16,17,18]. Yeast cell wall can be used to replace chlortetracycline, colistin sulfate and other antibiotics in animal production to control necrotic enteritis in chickens [19,20,21], reduce bacterial infections in aquatic animals [22,23,24], reduce the diarrhea rate of young animals such as piglets and calves [25, 26], and promote animal growth and development [27, 28]. It has been reported that yeast cell wall polysaccharides (mainly contains glucan and mannan) are the main active components in yeast cell walls [29,30,31]. Furthermore, studies have found that modification of polysaccharides can improve their biological activities and solubility in water, and researchers have used physical and biological methods to reduce the molecular weights of β-glucan and mannan, as well as chemical methods to change their primary structures [32,33,34,35]. However, whether polysaccharides have antibacterial activity, whether they are the main antibacterial components of WSE and the antibacterial mechanism of the active components have not been well elucidated.

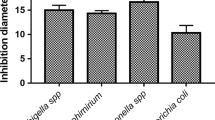

According to our previous studies, the antibacterial ability of water-soluble extract from yeast cell walls against common pathogens was studied via inhibition zone testing; however, the potential antibacterial compounds and physicochemical properties of WSE remain unclear. Therefore, this study aimed to investigate compositional properties, antibacterial activity and mode of action of WSE.

2 Methods

2.1 Chemicals and reagents

Yeast (from Saccharomyces cerevisiae) cell wall powder used in this study, derived from brewer's yeast FX-2 (deposit number is CCTCC NO: M2016418), was provided by Angel Yeast Co., Ltd (Yichang, China). After the yeast broth was fermented and cultured, the yeast cells were collected and the yeast itself was autolytically broken (yeast endogenous enzyme action), followed by enzymatic hydrolysis of alkaline protease, mannanase, β-glucanase and cellulase in that order, and finally the raw yeast cell wall powder was obtained. The finished product obtained was a spray dried powder after enzymatic digestion. DEAE-52 cellulose and Sephadex G-100 were bought from Wuhan Feiyi Technology Co., Ltd. (Wuhan, China). The D-glucose, D-mannose, dextran standards (1152, 5000, 11,600, 23,800, 48,600, 80,900, 148,000, 273,000, 409,800, 667,800 and 3,693,000 Da) and the propidium iodide (PI) were purchased from Sigma Chemical Co. (St. Louis, MO, USA). Monosaccharide standards (mannose (Man), rhamnose (Rha), galactose (Gal), glucose (Glc), arabinose (Ara), xylopyranose (Xyl), fucose (Fuc), guluronic acid (GulA), fructose (Fru), ribose (Rib), amminogalactose (GalN), N-acetyl-D glucosamine (GlcNAc), glucosamine (GlcN), glucuronic acid (GlcA), galacturonic acid (GalA) and mannuronic acid (ManA)) were obtained from Yuanye Biotechnology Co., Ltd. (Shanghai, China). Congo red, trifluoroacetic acid (TFA), dialysis bag (500 Da) and 0.45-μm filters were purchased from Beijing Solarbio Science and Technology Co., Ltd. (Beijing, China). Mueller–Hinton (MH) broth and eosin methylene blue (EMB) medium were purchased from Haibo Biotechnology Co., Ltd (Qingdao, China). Colistin sulfate standards were purchased from China Institute of Veterinary Drugs Control (Beijing, China). The alkaline phosphatase (ALP) assay kit was purchased from Nanjing Jiancheng Bioengineering Institute (Nanjing, China). N-phenyl-1-naphthylamine (NPN) and O-nitrophenyl-β-D-galactoside (ONPG) were purchased from Shanghai Yien Chemical Technology Co., Ltd (Shanghai, China). Other chemicals and reagents were of analytical grade or equivalent.

2.2 Bacteria

E. coli ATCC 25922 was purchased from American Type Culture Collection (Manassas, USA). E. coli 39 (the serotype was O101:K99), isolated from pig with diarrhea, was obtained from the National Reference Laboratory of Veterinary Drug Residues (HZAU) (Wuhan, China). The MIC of ampicillin against E. coli 39 is > 128 μg/mL, cefalothin is > 128 μg/mL, streptomycin is 2 μg/mL, doxycycline is 2 μg/mL, florfenicol is 8 μg/mL, and sulfisoxazole is 16 μg/mL.

2.3 Extraction of WSE

WSE was extracted using the hot water extraction method. Yeast cell wall powder was suspended with deionized water in a 1:10 (g/mL) ratio and then magnetically stirred for 1 h at 50 ℃. The suspension was centrifuged at 6000 rpm for 20 min. The supernatant was collected and concentrated with a rotary evaporator at 50 ℃. The concentrated supernatant was then freeze-dried.

2.4 Extraction of WSP

WSP was obtained by anhydrous ethanol precipitate and deproteinization by the Sevag method. So, the supernatant obtained from 2.3 was precipitated overnight with a four fold volume of anhydrous ethanol at 4 °C, and then centrifuged at 4500 rpm for 10 min. The sediment was dissolved in ultrapure water and deproteinized with Sevag reagent (chloroform/n-butyl alcohol, 4:1) [36]. After the mixture was shaken for 30 min, centrifuged at 10,000 rpm for 5 min, the upper water layer was collected. Use Sevag reagent to remove protein repeatedly 4 times, and confirm that no obvious protein layer appears. Add 4 times the volume of absolute ethanol to the upper water layer and allow it to store at 4 ℃ overnight. Afterward, collect the precipitate and freeze-dry it to obtain crude WSP.

2.5 Separation and purification of WSP

Crude WSPs were purified sequentially by DEAE-52 cellulose and Sephadex G-100 chromatography according to the method of Shi with some modifications [37]. WSP was dissolved with ultrapure water at 20 mg/mL and applied to a DEAE-52 cellulose column (2.6 × 30 cm) with a volume of 5 mL. WSP was eluted with four column volumes (200 mL) of ultrapure water and 0.1, 0.3, 0.5 M NaCl solutions at a flow rate of 1.0 mL/min, and the elution fraction was collected for 10 mL/tube. The sample (100 μL) from odd-numbered tubes was detected for the total sugar contents by phenol-concentrated sulfuric acid method. The elution curve was drawn, and combined with the collection liquid of the same eluting peak to concentrate, dialysis (MWCO 500 Da) and freeze-dry. Then, the eluted fraction obtained from ultrapure water named as WSNP (water-soluble neutral polysaccharide) and 0.1 M NaCl named as WSAP (water-soluble acidic polysaccharide) was further purified in a Sephadex G-100 gel column (1.6 × 75 cm) due to its higher yield. The two fractions were eluted with ultrapure water at a flow rate of 1.0 mL/min, respectively, and the elution fraction (5 mL/tube) was collected and the total sugar content was determined. So, we obtained that WSNP contains one component and WSAP contains two components. The major polysaccharides fraction was freeze-dried and named as WSNP, WSAP-1 and WSAP-2.

2.6 Chemical composition of WSE and WSP

Total sugar contents of the WSE and WSP were determined via the phenol sulfuric acid assay using glucose as a standard [38]. Meanwhile, protein contents of the WSE and WSP were determined via the spectrophotometric assay using bovine serum albumin as the standard [39]. Contents of β-glucan and mannan in the WSE and WSP were determined using high-performance liquid chromatography (HPLC). WSE/WSP (400 mg) was hydrolyzed with 6 mL of 37% hydrochloric acid [40, 41] at 30 ℃ for 45 min with vortexing every 15 min. Next, 100 mL of deionized water was added into the suspension and incubated at 121 ℃ for 60 min. After cooling, the pH of the suspension was adjusted to 7.0 using a 50% sodium hydroxide solution and the sample was diluted to 200 mL using deionized water. The aqueous phase was filtered through a 0.45-µm filter for HPLC analysis. The HPLC system consisted of a Chromaster system, a sugar column (6.5 mm × 300 mm waters sugar pak-1, Techcomp, China), and a refractive index detector (Hitachi, Japan). The mobile phase was 5 mmol/L sulfuric acid solution at a flow rate of 0.6 mL/min, the sample volume was 20 µL, and the column temperature was maintained at 65 ℃ during the experiment.

2.7 Determination of water solubility index

The water solubility index was determined by the method of Anderson et al. [42]. The sample was accurately weighed to 2.500 g, added to 20 mL of distilled water, shaken and dispersed, held at 22 ℃ for 30 min, hand shaken for 30 s at 5 min intervals and centrifuged at 3 000 r/min for 15 min. The supernatant was poured into an aluminum box of constant mass and evaporated to a constant mass in an oven at 105 ℃.

2.8 Structural identification of WSP

2.8.1 Monosaccharide composition

WSNP, WSAP-1 and WSAP-2 (10 mg) underwent hydrolysis in 3 M TFA at 120 ℃ for 3 h, followed by drying with nitrogen gas. After drying, a volume of 5 mL ultrapure water was added and vortexed to mix, then 100 μL was withdrawn from it, and 900 μL of ultrapure water was added, and centrifuged at 12,000 rpm for 5 min. The supernatants were identified and quantified with ion chromatograph (IC) (Thermofisher Scientific, China) using a DionexCarbopacTMPA20 (150 mm × 3 mm) and an electrochemical detector (Hitachi, Japan). The mobile phase was A: H2O, B: 15 mmol/L NaOH, C: 15 mmol/L NaOH and 100 mmol/L NaOAC solutions at a flow rate of 0.3 mL/min, the sample volume was 5 µL, and the column temperature was maintained at 30 ℃ during the experiment. The standard solutions of 16 monosaccharide standards (Man, Rha, Gal, Glc, Ara, Xyl, Fuc, GulA, Fru, Rib, GalN, GlcNAc, GlcN, GlcA, GalA, ManA) were configured with 0.01, 0.1, 0.5, 1, 5, 10, 20 mg/L and processed with the same procedure, respectively.

2.8.2 Molecular weight

The molecular weights of WSNP, WSAP-1 and WSAP-2 were determined by high-performance gel permeation chromatography (HPGPC) using a Chromaster system [43], a BRT105-104-102 series gel column (8 × 300 mm) and a refractive index detector (Hitachi, Japan). The samples were prepared with ultrapure water at 5 mg/mL. The mobile phase was 50 mmol/L NaCl solution at a flow rate of 0.6 mL/min, the sample volume was 20 µL, and the column temperature was maintained at 40 ℃ during the experiment. The molecular weights of the samples were estimated based on the calibration curve obtained from dextran standards with different weight average molecular weights (1152, 5000, 11,600, 23,800, 48,600, 80,900, 148,000, 273,000, 409,800, 667,800, and 3,693,000 Da).

2.8.3 Fourier transform infrared spectra (FT-IR)

Dry potassium bromide was added to 1 mg of WSNP, WSAP-1 and WSAP-2. The pellets were prepared, and their infrared spectra were measured from 400 to 4000 cm−1 using a Fourier transform infrared spectrometer (Thermofisher Scientific, China) [44].

2.8.4 Congo red test

WSNP, WSAP-1 and WSAP-2 (4 mg) were dissolved in 2 mL ultrapure water, then mixed with 2 mL Congo red (80 mmol/L) and different volumes of 1 mol/L NaOH solution to obtain the final concentration of NaOH 0, 0.1, 0.2, 0.3, 0.4, 0.5 mol/L, respectively. The max wavelength was recorded in the range of 400–600 nm by an Ultraviolet spectrophotometer (Lab-Spectrum, China) [45].

2.9 Antibacterial susceptibility test

The minimum inhibitory concentrations (MICs) of WSE and WSP against E. coli were determined by the microbroth dilution method recommended by Clinical and Laboratory Standardization Institute [46]. WSE/WSP was dissolved in deionized water to prepare stock solutions of 1.6 g/mL. Two fold serial drug dilutions were prepared in MH broth to achieve final concentrations ranging from 1.56 to 400 mg/mL. Colistin sulfate, a narrow-spectrum antibiotic used mainly against Gram-negative bacteria and that can interact with lipopolysaccharide to destroy the bacterial outer membrane (OM), was used as a positive control drug [47]. The stock solutions of colistin sulfate were 1280 µg/mL; two fold serial drug dilutions were prepared in MH broth to achieve final concentrations ranging from 0.06 to 16 µg/mL. Each tube contained approximately 5 × 105 CFU/mL E. coli. The MIC was defined as the lowest drug concentration that inhibited bacterial growth for 16–20 h at 37 ℃.

2.10 Antibacterial mechanisms of WSE against E. coli

2.10.1 Time kill assay

WSE (5.0 mL) and E. coli 39 (1.0 mL) in the logarithmic phase (approximately 108–109 CFU/mL) were added to 100 mL MH broth, yielding final concentrations of WSE equivalent to 0.25, 0.5, 1, 2 and 4 MICs. Equal amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. The mixtures were incubated at 37 ℃ at a speed of 220 rpm. Samples were taken at 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22 and 24 h to count the number of surviving bacteria on MH agar plates.

2.10.2 Cell wall integrity assay

ALP is a phosphodiesterase mostly located between the cell wall and the cell membrane [48]. If the bacterial cell wall is disrupted, ALP will be released into the culture medium, and thus ALP activity in the culture medium can reflect the integrity of the bacterial cell wall [49, 50]. WSE (5.0 mL) and E. coli (1.0 mL) in the log phase (approximately 108–109 CFU/mL) were added to 100 mL MH broth to yield final concentrations of WSE equivalent to 0.25, 0.5, 1, 2 and 4 MICs (6.25, 12.5, 25, 50, 100 mg/mL). Equivalent amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. The mixtures were incubated at 37 ℃ at a speed of 220 rpm. Samples were taken following incubations of 2, 4, 6, 8 and 12 h and then centrifuged at 5,000 rpm for 10 min. The supernatant was then collected for ALP activity detection using the ALP assay kit (Nanjing Jiancheng Bioengineering Institute, China).

2.10.3 Cell membrane integrity assay

Damage to the integrity of the cell membrane enables PI, a fluorescent probe, to enter the cell and combine with the DNA and RNA therein [51]. The cultures of E. coli (1.0 mL) in the log phase (approximately 108–109 CFU/mL) were incubated with various concentrations of WSE (0.25, 0.5, 1, 2, or 4 MIC = 6.25, 12.5, 25, 50, 100 mg/mL) at 37 ℃ for 6 h. Equivalent amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. After centrifugation at 13,000 rpm for 10 min, the cells were washed twice with PBS, and then the final cell suspension was adjusted to obtain an OD600 of 0.5. The cell suspension solution (500 μL) was incubated with 1 μL PI (10 mmol/L) at 37 ℃ in the dark for 30 min. The fluorescence intensity was detected by a Flow Cytometer (CytoFLEX LX, USA).

2.10.4 Outer membrane permeability assay

The OM permeability of E. coli treated with WSE was determined via the NPN assay according to previous methods [52]. The cultures of E. coli (1.0 mL) in the log phase (approximately 108–109 CFU/mL) were incubated with various concentrations of WSE (0.25, 0.5, 1, 2 and 4 MICs = 6.25, 12.5, 25, 50, 100 mg/mL) at 37 ℃ for 6 h. Equivalent amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. Following centrifugation at 13,000 rpm for 10 min, the cells were washed twice with PBS and the final cell suspension was adjusted to obtain an OD600 of 0.5. 495 μL of E. coli culture was mixed with 5 μL of NPN (1 mmol/L). The fluorescence intensity was measured with an RF-5301 (PC) S fluorescence spectrophotometer (Shimadzu Corporation, Japan), using an excitation wavelength of 350 nm and an emission wavelength of 420 nm.

2.10.5 Inner membrane permeability assay

The IM permeability of E. coli treated with WSE was determined via the ONPG assay, which was modified for application [53]. The cultures of E. coli (1.0 mL) in the log phase (approximately 108–109 CFU/mL) were incubated with various concentrations of WSE (0.25, 0.5, 1, 2, and 4 MICs = 6.25, 12.5, 25, 50, 100 mg/mL) in MH broth supplemented with 2% lactose at 37 ℃ for 6 h. Equivalent amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. After incubation, the cells were centrifuged at 13,000 rpm for 10 min to separate the supernatant and precipitate. The precipitate was washed twice with PBS and the final cell suspension was adjusted to obtain an OD600 of 0.5. 450 μL of either supernatant or cell suspension was then incubated with 50 μL of ONPG (30 mM) at 37 ℃ for 3 h. The A420 was measured by UV spectrophotometer (Agilent, USA).

2.10.6 Morphological analysis

WSE (1.0 mL) and E. coli (1.0 mL) in the log phase (approximately 108–109 CFU/mL) were added to 2 mL MH broth in order to create final concentrations of WSE solution equivalent to 0.25, 0.5 and 1 MIC (6.25, 12.5, 25 mg/mL). Equivalent amounts of sterile water and colistin sulfate (1 µg/mL) were used as negative and positive controls, respectively. The mixtures were then cultured under shaking at 220 rpm at 37 ℃ for 8 h. Bacterial cells were harvested via centrifugation at 5000 rpm at 4 ℃ for 10 min. Cells were then washed three times with PBS (pH 7.4) before morphological analysis.

2.10.6.1 Scanning electron microscope (SEM)

The washed cells (approximately 106 CFU/mL) were immobilized overnight with 2.5% glutaraldehyde at 4 ℃. After immobilization, the cells were harvested by centrifugation at 5000 rpm for 10 min and then washed with PBS (pH 7.4) three times. Next, the cells were dehydrated using a series of gradually increasing concentrations of ethanol solution (30, 50, 70, 85 and 95%) for 15 min. After dehydration, the cells were washed twice in 100% ethanol for 20 min before being naturally dried for two days, plated with gold and observed under SEM (HITACHI SU-8010, Japan).

2.10.6.2 Transmission electron microscopy (TEM)

Washed bacterial cells (approximately 106 CFU/mL) were immobilized overnight with 2.5% glutaraldehyde at 4 ℃. The immobilized bacteria were then washed three times with 0.1 M phosphate buffer, immobilized with 1% osmic acid (pH 7.4) for 2 h and washed three times with 0.1 M phosphate buffer. Bacterial cells were then collected by centrifugation and then stained with 1% uranyl acetate for 2 h, dehydrated with graded acetone, immersed and embedded. Sample sections for conventional TEM were created using a microtome (Germany Leica ultra-thin microtome EM UC7) and then stained with lead citrate and uranium acetate. Samples were then observed and recorded using a TEM (Tecnal G2 20 TWIN, American FEI company, acceleration voltage: 200 kv).

2.11 Statistical analysis

All statistical analyses were performed using GraphPad Prism software (GraphPad Software Inc., La Jolla, CA, USA) with all data represented as the mean ± standard deviation (SD) from at least three independent experiments.

3 Results

3.1 Extraction and chemical components analysis of WSE and WSP

The yield of WSE is 44.40 ± 0.60% (w/w, given as a percentage of the dry matter). The content of WSP in WSE is 76.53 ± 5.91%, indicating that polysaccharides are the main components in WSE. Therefore, the compositional characteristics of WSP were characterized to help clarify the active antimicrobial components in WSE in subsequent research.

After WSP was purified by DEAE-52 cellulose column, two independent peaks of WSP were obtained (Fig. 1A) as follows: WSNP (neutral polysaccharides, eluted with ultrapure water) and WSAP (acid polysaccharides, eluted with 0.1 mol/L NaCl). Sephadex G-100 chromatographic column was used to separate neutral and acid polysaccharides with different molecular weight ranges. In Fig. 1C, WSAP had two independent elution peaks, representing two molecular weight ranges, namely the elution components: WSAP-1 and WSAP-2. However, Fig. 1B shows a rather wide molecular weight distribution, indicating that sub-fraction is present in WSNP.

In Table 1, the total sugar, protein, β-glucan and mannan contents of WSE, WSP, WSNP, WSAP-1 and WSAP-2 were described. The protein content of WSE was 23.18 ± 0.27% and WSPs (WSP, WSNP, WSAP-1 and WSAP-2) were both at 2–3%. A comparison of the protein content shows that the WSPs still contained a small amount of protein after the removal of the free protein, which indicates that WSPs may contain protein bound to the polysaccharides. Additionally, the β-glucan and mannan contents were 7.37 ± 0.12% and 34.50 ± 0.91% in WSE, and 6.83 ± 0.21% and 30.60 ± 1.93% in WSP, respectively, as determined by HPLC.

3.2 Characterization of WSP

3.2.1 Monosaccharide composition

WSNP consisted of GlcN, Glc, Man and GlcA in a molar ratio of 8.6:55.2:34.4:1.8 (Fig. 2B and Table 1), WSAP-1 consisted of GlcN, Glc and Man in a molar ratio of 10.9:42.2:46.9 (Fig. 2C and Table 1), WSAP-2 consisted of GlcN, Gal, Glc and Man in a molar ratio of 9.0:1.0:55.1:34.9 (Fig. 2D and Table 1), indicating that WSNP, WSAP-1 and WSAP-2 are mainly composed of Glc and Man, and the contents of Glc and Man in WSNP and WSAP-2 are similar (Table 1).

Ion chromatograms and molecular weight distribution of WSNP, WSAP-1 and WSAP-2. A Ion chromatogram of mixed monosaccharide standards; B Ion chromatogram of WSNP; C Ion chromatogram of WSAP-1; D Ion chromatogram of WSAP-2; E Molecular weight chart of WSNP; F: Molecular weight chart of WSAP-1; G Molecular weight chart of WSAP-2

3.2.2 Molecular weight

In Fig. 2E and Table 2, the HPGPC elution curve of WSNP displayed a peak, and the average molecular weight (Mw) of WSNP was 105,130 Da, the number-average Mw (Mn) was 65,053 Da and the peak Mw (Mp) was 82,832 Da. In addition, the Mw of WSAP-1 was 94,581 Da, the Mn was 59,232 Da, and the Mp was 75,008 Da (Fig. 2F and Table 2); the Mw of WSAP-1 was 91,247 Da, the Mn was 57,487 Da, and the Mp was 72,524 Da (Fig. 2G and Table 2).

3.2.3 FT-IR

Vibrations in FT-IR analysis indicate the presence of carbohydrates in WSNP, WSAP-1 and WSAP-2 [54]. As shown in Fig. 3A–C, WSNP, WSAP-1 and WSAP-2 presented similar FT-IR spectra, WSNP had a strong and broad signal at 3262 cm−1, 2935 cm−1, 1636 cm−1, 1410 cm−1, 1022 cm−1, 915 cm−1, 810 cm−1 and 579 cm−1; WSAP-1 had a signal at 3290 cm−1, 2933 cm−1, 1651 cm−1, 1386 cm−1, 1021 cm−1, 911 cm−1, 811 cm−1 and 588 cm−1; WSAP-2 had a signal at 3281 cm−1, 2933 cm−1, 1645 cm−1, 1362 cm−1, 1019 cm−1, 915 cm−1, 808 cm−1. Among them, 3262 cm−1, 3290 cm−1 and 3281 cm−1 had broad absorption peaks, which are the stretching vibrations of the polysaccharides –OH; the absorption peaks at 2935 cm−1 and 2933 cm−1 were the C–H stretching vibrations of polysaccharides; the absorption peaks at 1636 cm−1, 1651 cm−1 and 1645 cm−1 were the bending vibrations of O–H; the absorption peaks at 1386 cm−1 and 1362 cm−1 were the C–H variable-angle vibrations of polysaccharides; the absorption peaks at 1126 cm−1, 1128 cm−1 and 1127 cm−1 were the C–O–C stretching vibrations on the pyran ring; the absorption peaks at 1022 cm−1, 1021 cm−1 and 1019 cm−1 were the C–O–H stretching vibrations on the pyran ring; the absorption peaks at 915 cm−1 and 911 cm−1 indicated the presence of β-glycosidic bonds; the absorption peaks at 810 cm−1, 811 cm−1 and 808 cm−1 indicated the existence of α-glycosidic bonds and the absorption peaks at 579 cm−1, 588 cm−1 and 599 cm−1 were the symmetrical stretching of the pyranose backbone vibration. So, WSNP, WSAP-1 and WSAP-2 are pyranoses, and the monosaccharides were connected by α-glycosidic bonds and β-glycosidic bonds.

3.2.4 Congo red test

Figure 3D shows the variation of λmax for the complexes of Congo Red with WSNP, WSAP-1 and WSAP-2 over the concentration range of 0–0.5 mol/L NaOH. The λmax of WSNP-, WSAP-1- and WSAP-2-Congo red complex was higher than that of Congo red at 0.1 mol/L NaOH, and then gradually decreased as the NaOH concentration increased, which is different from Conge red. Therefore, it could be concluded that WSNP, WSAP-1 and WSAP-2 all exhibited a triple-helix structure.

3.3 MICs of WSE and WSP against E. coli

The results showed that the MICs of WSE and WSPs against E. coli ranged from 25 to 100 mg/mL, WSE was 25 mg/mL, and WSPs all against E. coli were 100 mg/mL (not a high viscosity solutions). The MICs of colistin sulfate against E. coli were 1 µg/mL (Table 2).

3.4 Antibacterial mechanisms of WSE against E. coli

3.4.1 Time to kill assay of E. coli

In Fig. 4, the growth curve of the E. coli in the control group demonstrates that the bacteria entered the logarithmic phase at 2 h and then the stationary phase after 8 h. The growth curves of E. coli treated with 0.25 or 0.5 MICs (6.25 or 12.5 mg/mL) WSE were consistent with that of control group, demonstrating no inhibitory effect on bacterial growth. Importantly, 1 MIC WSE (25 mg/mL) demonstrated significant antibacterial activity from 0 to 8 h, while the bacteria grew slowly after 8 h. In contrast, both 2 and 4 MICs (50 and 100 mg/mL, not a high viscosity solution) WSE, as well as colistin sulfate, restrained growth of the bacteria from 0 to 24 h. These results indicate that the inhibitory activity of WSE against E. coli is concentration-dependent.

3.4.2 Effect of WSE on the cell wall integrity of E. coli

In Fig. 5, both high-dose WSE (1, 2 and 4 MICs = 25, 50 and 100 mg/mL) and 1.0 µg/mL colistin sulfate significantly enhanced ALP levels in the E. coli culture medium when compared to the control group; notably, differences in ALP activity between the high-dose WSE group and the control group were significant from 2 to 12 h, with the most obvious enhancement seen at 4 h. ALP activity began to decrease after 4 h, which may be due to degradation of the ALP itself or absorption of the ALP by bacteria. The above results indicate that WSE inhibits bacteria by destroying the bacterial cell wall.

Effects of WSE and colistin sulfate on the cell wall integrity of E. coli 39. 1/4 MIC: 6.25 mg/mL; 1/2 MIC: 12.5 mg/mL; 1 MIC: 25 mg/mL; 2 MIC: 50 mg/mL; 4 MIC: 100 mg/mL. Different letters represent significant differences based on one-way ANOVA (p < 0.05). n = 3. All values are represented as mean ± SD of three independent experiment

3.4.3 Effect of WSE on the cell membrane integrity of E. coli

The percentages of PI permeable cells observed in our studies were: 27.07% for control treatment (Fig. 6A), 31.93% for 0.25 MIC (6.25 mg/mL) WSE (Fig. 6B), 52.26% for 0.5 MIC (12.5 mg/mL) WSE (Fig. 6C), 62.20% for 1 MIC WSE (25 mg/mL) (Fig. 6D), 87.46% for 2 MIC WSE (50 mg/mL) (Fig. 6E), 90.21% for 4 MIC (100 mg/mL) WSE (Fig. 6F) and 64.55% following treatment with 1 µg/mL colistin sulfate (Fig. 6G). Comparing the percentages of PI permeable cells following control treatment or treatment with 0.25–4 MICs (6.25–100 mg/mL) WSE, it was found that higher concentrations of WSE led to higher percentages of PI permeable cells, proving that E. coli membrane destruction by WSE is concentration-dependent. There was no significant difference between the percentage of PI permeable cells following treatment with either 2 or 4 MICs (50 or 100 mg/mL) WSE (Fig. 6H).

Effects of WSE and colistin sulfate on the cell membrane integrity of E. coli 39. Control (A), 1/4 MIC (B), 1/2 MIC (C), 1 MIC (D), 2 MIC (E), 4 MIC (F) WSE and 1 µg/mL colistin sulfate (G). 1/4 MIC: 6.25 mg/mL; 1/2 MIC: 12.5 mg/mL; 1 MIC: 25 mg/mL; 2 MIC: 50 mg/mL; 4 MIC: 100 mg/mL. Proportion of PI permeable cells under drug action (H). Bars with different lowercase letters indicate significant difference (p < 0.05). n = 3. All values are represented as mean ± SD of three independent experiment

3.4.4 Outer membrane permeabilization assays

When E. coli was treated with 0.25–4 MICs (6.25–100 mg/mL) of WSE, higher concentrations of WSE led to stronger effects on OM permeability (Fig. 7A). There was no significant difference in NPN fluorescence between the 0.25 MIC (6.25 mg/mL) WSE and control treatment groups, while the 4 MIC (100 mg/mL) WSE group displayed the greatest OM permeability. 1 µg/mL colistin sulfate increased OM permeability, while the result was not significantly different from that of 1 MIC (25 mg/mL) WSE. Colistin sulfate acted on the OM to destroy the cell membrane, consistent with Hancock's conclusion that colistin sulfate exerts its antibacterial effect by combining with lipopolysaccharide (LPS) on the OM [55].

Effects of WSE and colistin sulfate on the outer membrane permeabilization and the inner membrane permeabilization of E. coli 39. A The outer membrane permeabilization; B the inner membrane permeabilization (β-galactosidase activity in supernatant); C the inner membrane permeabilization (β-galactosidase activity in cell precipitation). 1/4 MIC: 6.25 mg/mL; 1/2 MIC: 12.5 mg/mL; 1 MIC: 25 mg/mL; 2 MIC: 50 mg/mL; 4 MIC: 100 mg/mL. Bars with different lowercase letters indicate significant difference (p < 0.05). n = 3. All values are represented as mean ± SD of three independent experiment

3.4.5 Inner membrane permeabilization assays

In Fig. 7C, compared to the control treatment, 0.25–4 MICs (6.25–100 mg/mL) WSE and 1 µg/mL colistin sulfate had no significant effect on β-galactosidase activity in the cell precipitation of E. coli 39. In this experiment, there was no significant difference in absorbance in the bacterial precipitates treated with different concentrations of WSP. It was hypothesized that the greater disruption of the inner membrane by WSE may have caused more β-galactosidase to be released into the medium, resulting in a decrease in β-galactosidase activity in the precipitates. Based on this hypothesis, we then examined the OD values in the bacterial culture supernatant. As hypothesized, the β-galactosidase activity in the supernatant of the E. coli was significantly different when comparing WSE treatment groups to the control group, and the comparison results of 1 µg/mL colistin sulfate treatment group were similar (Fig. 7B). β-galactosidase activity outside of the bacteria increased, indicating that both the OM and IM of E. coli were destroyed. Hence, the results indicate that WSE and colistin sulfate can destroy the cell membrane integrity of E. coli.

3.4.6 Scanning electron microscopy

Following exposure to 0.25–1 MICs of WSE, scanning electron microscopy (SEM) (Fig. 8) demonstrated that adhesions and aggregations occurred when E coli treated with 0.25 MIC (6.25 mg/ml) and 0.5 MIC (12.5 mg/ml) of WSE, while treated with 1 MIC (25 mg/ml) of WSE (Fig. 8D), the morphological structure of E. coli was blurred, with almost none single and normal bacterial morphology within view of the observation. After treatment with 1 μg/mL colistin sulfate, E. coli became dried out, adherent, blurred in morphological structure and completely dead (Fig. 8E).

Scanning electron microscopy and transmission electron microscopy of E. coli 39 was treated with Control (A, A1, A2), 1/4 MIC (B, B1, B2), 1/2 MIC (C, C1, C2), 1 MIC (D, D1, D2) WSE and 1 µg/mL colistin sulfate (E, E1, E2). 1/4 MIC: 6.25 mg/mL; 1/2 MIC: 12.5 mg/mL; 1 MIC: 25 mg/mL. The red arrows in the figure indicated that the morphology and internal structure of E. coli have changed

3.4.7 Transmission electron microscopy

The TEM images (Fig. 8) showed that control-treated bacteria displayed a smooth and compact surface with regularly distributed cytoplasm and normal periplasmic space (Fig. 8A1, 2). Compared to the control treatment, the cytoplasm of E. coli treated with either 0.25–1 MICs (6.25–25 mg/mL) WSE (Fig. 8B1, 2, C1, 2, D1, 2) or colistin sulfate (Fig. 8E1, 2) demonstrated material leakage and cytoplasmic matrix coagulation. Furthermore, the surfaces of E. coli treated with 0.5 MIC (12.5 mg/mL) WSE (Fig. 8C2), 1 MIC (25 mg/mL) WSE (Fig. 8D2) and colistin sulfate (Fig. 8E2) were disrupted and covered by an additional tooth-like layer.

4 Discussion

As a potential alternative to antibiotics, polysaccharides are widely studied, whereas the extraction and purification operations have an impact on the composition and structure, directly affecting polysaccharides activity [56, 57]. Although the acid–base method has been used to purify yeast cell wall polysaccharides in most studies, with the advantage of obtaining high purity β-glucan and mannan, it may disrupt the structure of the polysaccharides and make the polysaccharides chain length unstable. The present work is drawn on the purification methods of plant polysaccharides [58, 59], including aqueous-alcoholic precipitation and a Sevag method for protein removal, which were mild and did not destroy the polysaccharides structure. The characterization showed that WSNP, WSAP-1 and WSAP-2 were all pyranose sugars, linked to each other by α- and β-glycosidic bonds, and all featured a triple-helix structure. Notably, WSNP showed a wide range of molecular weights, inferring that it may contain subcomponents. Further experiments are therefore required to determine the additional subcomponents contained in WSNP. Smith et al. found that mannans in yeast cell walls provide collateral susceptibility to antibiotics (phenotypic resistance) by regulating bacterial cellular respiration [60], suggesting that mannans promote animal health without contributing to the growing problem of antibiotic resistance. In this study, both WSE and WSP contained high levels of mannans, making them promising for use as an alternative to antibiotics and for controlling antibiotic resistance.

The huge economic cost of colibacillosis to animal husbandry and the growing problem of antibiotic resistance has forced us to develop new potential antibiotic alternatives. In this study, both WSE and WSPs showed antibacterial activities. Compared to other water-soluble polysaccharides, such as pumpkin polysaccharides [61] and dandelion polysaccharides [62], both of which had a minimum antibacterial concentration of 100 mg/mL against Bacillus subtilis, Staphylococcus aureus and E. coli, the water-soluble polysaccharides in this work showed better antibacterial activity. Previous research in vivo reported that dietary WSE at 0.2–0.4% addition markedly improved the intestinal health of turbot [63]. Considering the wide availability and low price of yeast cell walls, WSE has obvious advantages in the field of antibiotic alternatives for piglet diarrhea.

Comparing the antibacterial results of the five samples (WSE, WSP, WSNP, WSAP-1 and WSAP-2), WSE (MIC = 25 mg/mL) has the best antibacterial activity, indicating that there were other non-polysaccharides active substance in WSE. As previously described, there are killer yeasts that produce toxins having protein nature [64, 65], which is acknowledged as a promising premise for antimicrobial activity [66]. Of course, the reason for the excellent antibacterial activity of WSE does not exclude that the small molecular weight of the monosaccharides or disaccharides in the water-soluble extract exerts antibacterial activity. It will be interesting to identify the non-polysaccharide antimicrobial components of WSE in the future.

The integrity of the cell wall and membrane, as well as the permeability of the inner and outer membrane of bacteria, are essential for maintaining the intrinsic morphology of the bacterium and ensuring proper growth. WSE exerted its antibacterial activity by disrupting the integrity of the E. coli cell wall and membrane, while increasing outer membrane permeability. It has been reported that polysaccharides from Cordyceps cicadae and Chaetomium globosum CGMCC 6882 were capable of acting on the cell wall of E. coli to exert antibacterial activity [50, 67]. In this study, colistin sulfate (positive control) acted on the outer membrane of E. coli, which is the same conclusion as the antibacterial mechanism of colistin sulfate by disrupting the lipopolysaccharide of the outer cell membrane [55]. Zhou et al. used the same method to study the effects of green tea polysaccharide on the cell membrane of E. coli, and the results showed that the proportion of PI permeable cells treated with 0 or 0.6 mg/mL green tea polysaccharides were 8.79% and 15.10%, respectively [51]. This result was similar to our results regarding WSE treatments in those higher drug concentrations led to higher proportions of PI permeable cells. Liu et al. found that depolymerized fucoidans can not only combine with bacterial membrane proteins but also change their structures [26]. However, the antibacterial targets of WSE and the signaling pathways by which they disrupt cell walls and membranes are currently unknown.

SEM results showed that WSE can adsorb and aggregate E. coli. The reason behind SEM analysis was that WSE has adhesive properties, enabling it to adhere to and wrap up bacteria. Cai et al. found that the levan-type exopolysaccharide from Bacillus amylolyticus JN4 was able to closely adhere to enterotoxigenic E. coli [68]. Polysaccharides are similar to the receptor structures on host cells and, thus, can block the binding and adhesion of bacteria to the receptor on the cell, exerting strong antibacterial activities [69]. An additional potential mechanism is that polysaccharides alter bacterial surface charges and enhance the flocculation effect [70]. The TEM results demonstrated that the bacterial cell wall and membrane were broken, which was consistent with the experimental results on the cell wall and cell membrane integrity. In addition, there was a shedding of the bacterial cell wall and outer cell membrane, the same morphological changes were observed in the study of chitosan on E. coli 36 and colistin sulfate on polymyxin B-resistant Pseudomonas aeruginosa 60 [71]. It was also observed in the TEM results that the material inside the bacteria coagulated when the bacterial cell wall and cell membrane were intact. The possible reasons for this are that WSE inhibits the activity of enzymes associated with the growth and reproduction of E. coli, hinders the action of enzymes or alters protein and nucleic acid molecules, so the effect of WSE on bacterial material metabolism needs to be experimentally investigated further.

5 Conclusion

The yeast cell wall was extracted and purified to obtain WSE (water-soluble extract), WSP, WSNP, WSAP-1 and WSAP-2. WSE and WSP both contained β-glucan and mannoprotein, and the mannoprotein content was higher than the β-glucan content. The molecular weight, monosaccharide composition, infrared spectroscopy and Congo red analysis of WSNP, WSAP-1 and WSAP-2 were almost consistent with each other. The comparison of the MIC of WSE, WSP, WSNP, WSAP-1 and WSAP-2 against E. coli showed that WSE had the best antibacterial activity. WSE exerted its antibacterial activity by disrupting the integrity of the cell wall and cell membrane of E. coli. WSE can not only disrupt the integrity of the cell wall and membrane, but also increase the permeability of the outer membrane, resulting in structural lesions and release of cellular components, which can lead to bacterial death.

In conclusion, this research investigated the extraction, isolation, purification, chemical properties of the active components of yeast cell wall, and elucidated inhibition mechanisms of WSE, laying the foundation for antimicrobial mechanistic studies of yeast cell wall products and facilitating their application in animal production.

Availability of data and materials

All relevant data and materials are contained within the article.

Abbreviations

- ALP:

-

Alkaline phosphatase

- E. c oli :

-

Escherichia coli

- FT-IR:

-

Fourier transform infrared spectroscopy

- HPGPC:

-

High-performance gel permeation chromatography

- HPLC:

-

High-performance liquid chromatography

- IC:

-

Ion chromatography

- MIC:

-

Minimal inhibitory concentration

- NPN:

-

N-Phenyl-1-naphthylamine

- ONPG:

-

2-Nitrophenyl β-D-galactopyranoside

- PI:

-

Propidium iodide

- SEM:

-

Scanning electron microscope

- TEM:

-

Transmission electron microscope

- WSE:

-

Water-soluble extract

- WSAP-1:

-

Water-soluble acidic polysaccharide 1

- WSAP-2:

-

Water-soluble acidic polysaccharide 2

- WSNP:

-

Water-soluble neutral polysaccharide

- WSP:

-

Water-soluble polysaccharide

- WSI:

-

Water solubility index

References

Ashbaugh HR, Early JM, Johnson ME, Simons MP, Graf PCF, Riddle MS, Swierczewski BE (2021) A prospective observational study describing severity of acquired diarrhea among U.S. military and Western travelers participating in the Global Travelers’ Diarrhea Study. Travel Med Infect Dis 43:102139

Bublitz DC, Wright PC, Bodager JR, Rasambainarivo FT, Bliska JB, Gillespie TR (2014) Epidemiology of pathogenic enterobacteria in humans, livestock, and peridomestic rodents in rural Madagascar. PLoS ONE 9(7):e101456

Bourgeois AL, Wierzba TF, Walker RI (2016) Status of vaccine research and development for enterotoxigenic Escherichia coli. Vaccine 34(26):2880–2886

Khalil IA, Troeger C, Blacker BF, Rao PC, Brown A, Atherly DE, Brewer TG, Engmann CM, Houpt ER, Kang G, Kotloff KL, Levine MM, Luby SP, MacLennan CA, Pan WK, Pavlinac PB, Platts-Mills JA, Qadri F, Riddle MS, Ryan ET, Shoultz DA, Steele AD, Walson JL, Sanders JW, Mokdad AH, Murray C, Hay SI, Reiner RJ (2018) Morbidity and mortality due to shigella and enterotoxigenic Escherichia coli diarrhoea: the Global Burden of Disease Study 1990–2016. Lancet Infect Dis 18(11):1229–1240

Rueter C, Bielaszewska M (2020) Secretion and delivery of intestinal pathogenic Escherichia coli virulence factors via outer membrane vesicles. Front Cell Infect Microbiol 10:91

Wang M, Zu X, Zhao Z, Fu F, Bai X, Gong X, Zhao P, Gao W, Xue Y (2020) Cephalosporin resistance in Escherichia coli isolated from children with septicemia in mainland China from 2007 to 2017: a systematic review and meta-analysis. Microb Drug Resist 26(10):1250–1259

Santovito E, Greco D, Logrieco AF, Avantaggiato G (2018) Eubiotics for food security at farm level: yeast cell wall products and their antimicrobial potential against pathogenic bacteria. Foodborne Pathog Dis 15(9):531–537

Casewell M (2003) The European ban on growth-promoting antibiotics and emerging consequences for human and animal health. J Antimicrob Chemother 52(2):159–161

Sadeghi AA, Mohammadi A, Shawrang P, Aminafshar M (2013) Immune responses to dietary inclusion of prebiotic-based mannan-oligosaccharide and β -glucan in broiler chicks challenged with Salmonella enteritidis. Turk J Vet Anim Sci 37(2):206–213

Gao J, Azad MAK, Han H, Wan D, Li T (2020) Impact of prebiotics on enteric diseases and oxidative stress. Curr Pharm Des 26(22):2630–2641

Mingmongkolchai S, Psanbangred W (2018) Bacillus probiotics: an alternative to antibiotics for livestock production. J Appl Microbiol 124(6):1334–1346

Yang C, Chowdhury MA, Huo Y, Gong J (2015) Phytogenic compounds as alternatives to in-feed antibiotics: potentials and challenges in application. Pathogens 4(1):137–156

Morales-Lopez R, Brufau J (2013) Immune-modulatory effects of dietary Saccharomyces cerevisiae cell wall in broiler chickens inoculated with Escherichia coli lipopolysaccharide. Brit Poult Sci 54(2):247–251

Ganner A, Stoiber C, Uhlik JT, Dohnal I, Schatzmayr G (2013) Quantitative evaluation of E. coli F4 and Salmonella Typhimurium binding capacity of yeast derivatives. AMB Express 3(1):1–7

Korolenko TA, Bgatova NP, Ovsyukova MV, Shintyapina A, Vetvicka V. Hypolipidemic effects of β-glucans, mannans, and fucoidans: mechanism of action and their prospects for clinical application. Molecules. 2020;25(8):1819. https://doi.org/10.3390/molecules25081819.

Avila-Campos MJ, Oba PM, Santos KM, Vendramini THA, Carciofi AC, Junior AR, Brunetto MA (2018) Effects of dietary yeast cell wall on faecal bacteria and fermentation products in adult cats. J Anim Physiol Anim Nutr (Berl) 102(4):1091–1101

Vetvicka V, Jana V (2020) Anti-infectious and anti-tumor activities of β-glucans. Anticancer Res 40(6):3139–3145

Santos JPF, Aquino AA, Glória MBA, Avila-Campos MJ, Oba PM, Santos KM, Vendramini THA, Carciofi AC, Junior AR, Brunetto MA (2018) Effects of dietary yeast cell wall on faecal bacteria and fermentation products in adult cats. J Anim Physiol Anim Nutr (Berl) 102(4):1091–1101

Liu N, Wang J, Liu Z, Wang Y, Wang J (2018) Effect of supplemental yeast cell walls on growth performance, gut mucosal glutathione pathway, proteolytic enzymes and transporters in growing broiler chickens. J Anim Sci 96(4):1330–1337

Liu N, Wang JQ, Jia SC, Chen YK, Wang JP (2018) Effect of yeast cell wall on the growth performance and gut health of broilers challenged with aflatoxin B1 and necrotic enteritis. Poult Sci 97(2):477–484

Pascual A, Pauletto M, Giantin M, Radaelli G, Ballarin C, Birolo M, Zomeño C, Dacasto M, Bortoletti M, Vascellari M, Xiccato G, Trocino A (2020) Effect of dietary supplementation with yeast cell wall extracts on performance and gut response in broiler chickens. J Anim Sci Biotechnol 11(1):40

Gainza O, Romero J (2020) Effect of mannan oligosaccharides on the microbiota and productivity parameters of Litopenaeus vannamei shrimp under intensive cultivation in Ecuador. Sci Rep-Uk 10(1):2719

Liu L, Dang Y (2020) Antimicrobial activity of mannose binding lectin in grass carp (Ctenopharyngodon idella) in vivo and in vitro. Fish Shellfish Immunol 98:25–33

Lu Z, Feng L, Jiang W, Wu P, Liu Y, Kuang S, Tang L, Zhou X (2020) Mannan oligosaccharides improved growth performance and antioxidant capacity in the intestine of on-growing grass carp (Ctenopharyngodon idella). Aquacult Rep 17:100313

Kim SW, Holanda DM, Gao X, Park I, Yiannikouris A (2019) Efficacy of a yeast cell wall extract to mitigate the effect of naturally Co-occurring mycotoxins contaminating feed ingredients fed to young pigs: impact on gut health, microbiome, and growth. Toxins 11(11):633

Liu G, Yu L, Martínez Y, Ren W, Ni H, Abdullah Al-Dhabi N, Duraipandiyan V, Yin Y (2017) Dietary saccharomyces cerevisiae cell wall extract supplementation alleviates oxidative stress and modulates serum amino acids profiles in weaned piglets. Oxid Med Cell Longev 2017:1–7

Burdick Sanchez NC, Carroll JA, Corley JR, Broadway PR, Callaway TR (2019) Changes in the hematological variables in pigs supplemented with yeast cell wall in response to a salmonella challenge in weaned pigs. Front Vet Sci 6:246

Aung M, Ohtsuka H, Izumi K (2019) Effect of yeast cell wall supplementation on production performances and blood biochemical indices of dairy cows in different lactation periods. Vet World 12(6):796–801

Galinari É, Sabry DA, Sassaki GL, Macedo GR, Passos FML, Mantovani HC, Rocha HAO (2017) Chemical structure, antiproliferative and antioxidant activities of a cell wall α-d-mannan from yeast Kluyveromyces marxianus. Carbohydr Polym 157:1298–1305

Kath F, Kulicke W (1999) Mild enzymatic isolation of mannan and glucan from yeast Saccharomyces cerevisiae. Angew Makromol Chem 268:59–68

Young M, Davies MJ, Bailey D, Gradwell MJ, Smestad-Paulsen B, Wold JK, Barnes RM, Hounsell EF (1998) Characterization of oligosaccharides from an antigenic mannan of Saccharomyces cerevisiae. Glycoconjugate J 15(8):815–822

Ishimoto Y, Ishibashi K, Yamanaka D, Adachi Y, Kanzaki K, Iwakura Y, Ohno N (2018) Production of low-molecular weight soluble yeast β-glucan by an acid degradation method. Int J Biol Macromol 107:2269–2278

Long NT, Anh NTN, Giang BL, Son HN, Luan LQ (2019) Radiation degradation of β-Glucan with a potential for reduction of lipids and glucose in the blood of mice. Polym-Basel 11(6):955

Zheng Z, Huang Q, Ling C (2019) Water-soluble yeast β-glucan fractions with different molecular weights: extraction and separation by acidolysis assisted-size exclusion chromatography and their association with proliferative activity. Int J Biol Macromol 123:269–279

Williams DL, McNamee RB, Jones EL, Pretus HA, Ensley HE, Browder IW, Di Luzio NR (1991) A method for the solubilization of a (1→3)-β-d-glucan isolated from Saccharomyces cerevisiae. Carbohyd Res 219:203–213

Staub AM (1965) Removal of proteins-Sevag method. Methods Carbohydr Chem 5:5–6

Shi X, Zhao Y, Jiao Y, Shi T, Yang X (2013) ROS-dependent mitochondria molecular mechanisms underlying antitumor activity of Pleurotus abalonus acidic polysaccharides in human breast cancer MCF-7 cells. PLoS ONE 8(5):e64266

Dubolis M, Gilles K, Hamilton J, Rebers P, Smith F (1956) Colorimetric method for determination of sugars. Anal Chem 28(3):350–356

Bensadoun A, Weinstein D (1976) Assay of proteins in the presence of interfering materials. Anal Biochem 70(1):241–250

Dallies N, François J, Paquet V (1998) A new method for quantitative determination of polysaccharides in the yeast cell wall. Application to the cell wall defective mutants of Saccharomyces cerevisiae. Yeast (Chichester Engl) 14(14):1297–1306

Li J, Karboune S (2019) Characterization of the composition and the techno-functional properties of mannoproteins from Saccharomyces cerevisiae yeast cell walls. Food Chem 297:124867

Podpora B, Świderski F, Sadowska A, Rakowska R, Wasiak-Zys G (2016) Spent brewer’s yeast extracts as a new component of functional food. Czech J Food Sci 34(6):554–563

Gao X, Qi J, Ho C, Li B, Mu J, Zhang Y, Hu H, Mo W, Chen Z, Xie Y (2020) Structural characterization and immunomodulatory activity of a water-soluble polysaccharide from Ganoderma leucocontextum fruiting bodies. Carbohydr Polym 249:116874

Zhang M, Wang G, Lai F, Wu H (2016) Structural characterization and immunomodulatory activity of a novel polysaccharide from Lepidium meyenii. J Agric Food Chem 64(9):1921–1931

Yi Y, Zhang M, Liao S, Zhang R, Deng Y, Wei Z, Yang B (2012) Effects of alkali dissociation on the molecular conformation and immunomodulatory activity of longan pulp polysaccharide (LPI). Carbohydr Polym 87(2):1311–1317

Clinical and Laboratory Standards Institute [CLSI] (2021). Performance Standards for Antimicrobial Susceptibility Testing, 31st Ed. http://www.emeraldinsight.com Accessed 26 Mar 2021

Bialvaei AZ, Samadi KH (2015) Colistin, mechanisms and prevalence of resistance. Curr Med Res Opin 31(4):707–721

Malamy M, Horecker BL (1961) The localization of alkaline phosphatase in E. coli K12. Biochem Biophys Res Commun 5:104–108

Lv X, Du J, Jie Y, Zhang B, Bai F, Zhao H, Li J (2017) Purification and antibacterial mechanism of fish-borne bacteriocin and its application in shrimp (Penaeus vannamei) for inhibiting Vibrio parahaemolyticus. World J Microbiol Biotechnol 33(8):156

Zhang Y, Wu Y, Zheng W, Han X, Jiang Y, Hu P, Tang Z, Shi L (2017) The antibacterial activity and antibacterial mechanism of a polysaccharide from Cordyceps cicadae. J Funct Foods 38:273–279

Zhou Y, Yao Q, Zhang T, Chen X, Wu Z, Zhang N, Shao Y, Cheng Y (2020) Antibacterial activity and mechanism of green tea polysaccharide conjugates against Escherichia coli. Ind Crop Prod 152:112464

Liu H, Du Y, Wang X, Sun L (2004) Chitosan kills bacteria through cell membrane damage. Int J Food Microbiol 95(2):147–155

Xing K, Chen XG, Kong M, Liu CS, Cha DS, Park HJ (2009) Effect of oleoyl-chitosan nanoparticles as a novel antibacterial dispersion system on viability, membrane permeability and cell morphology of Escherichia coli and Staphylococcus aureus. Carbohydr Polym 76(1):17–22

Andriy S, Miroslav N (2014) Structural analysis of glucans. Ann Transl Med 2(2):17

Hancock RE (1997) Antibacterial peptides and the outer membranes of gram-negative bacilli. J Med Microbiol 46(1):1

Jin W, Zhang W, Liu G, Yao J, Shan T, Sun C, Zhang Q (2017) The structure-activity relationship between polysaccharides from Sargassum thunbergii and anti-tumor activity. Int J Biol Macromol 105:686–692

Ke S, Yu Y, Xu Q, Zhang B, Wang S, Jin W, Wei B, Wang H (2021) Composition-activity relationships of polysaccharides from Saccharina japonica in regulating gut microbiota in short-term high-fat diet-fed mice. J Agric Food Chem 69(37):11121–11130

Beigi M, Jahanbin K (2019) A water-soluble polysaccharide from the roots of Eremurus spectabilis M. B. subsp. spectabilis: extraction, purification and structural features. Int J Biol Macromol 128:648–654

Chen S, Li J, Zhang J (2019) Extraction of yellow pear residue polysaccharides and effects on immune function and antioxidant activity of immunosuppressed mice. Int J Biol Macromol 126:1273–1281

Smith H, Grant S, Parker J, Murphy R (2020) Yeast cell wall mannan rich fraction modulates bacterial cellular respiration potentiating antibiotic efficacy. Sci Rep-UK 10(1):21880

Qian Z (2014) Cellulase-assisted extraction of polysaccharides from Cucurbita moschata and their antibacterial activity. Carbohydr Polym 101:432–434

Wang H (2014) Cellulase-assisted extraction and antibacterial activity of polysaccharides from the dandelion Taraxacum officinale. Carbohydr Polym 103:140–142

Wang T, Yang J, Lin G, Li M, Zhu R, Yiannikouris A, Wang R, Zhang Y, Mai K (2021) Evaluation of the mitigation efficacy of a yeast cell wall extract toward deoxynivalenol contaminated diet fed to turbot (Scophthalmus maximus). Ecotox Environ Safe 216:112221

Schmitt MJ, Breinig F (2006) Yeast viral killer toxins: lethality and self-protection. Nat Rev Microbiol 4(3):212–221

Gier S, Schmitt MJ, Breinig F (2020) Analysis of yeast killer toxin K1 precursor processing via site-directed mutagenesis: implications for toxicity and immunity. Msphere 5(1):e00979-e1019

Giovati L, Ciociola T, De Simone T, Conti S, Magliani W (2021) Wickerhamomyces yeast killer toxins’ medical applications. Toxins 13(9):655

Wang Z, Xue R, Cui J, Wang J, Fan W, Zhang H, Zhan X (2019) Antibacterial activity of a polysaccharide produced from Chaetomium globosum CGMCC 6882. Int J Biol Macromol 125:376–382

Cai G, Liu Y, Li X, Lu J (2019) New levan-type exopolysaccharide from Bacillus amyloliquefaciens as an antiadhesive agent against enterotoxigenic Escherichia coli. J Agric Food Chem 67(28):8029–8034

Wittschier N, Lengsfeld C, Vorthems S, Stratmann U, Ernst JF, Verspohl EJ, Hensel A (2007) Large molecules as anti-adhesive compounds against pathogens. J Pharm Pharmacol 59(6):777–786

He J, Bao Y, Li J, Qiu Z, Liu Y, Zhang X (2019) Nanocomplexes of carboxymethyl chitosan/amorphous calcium phosphate reduce oral bacteria adherence and biofilm formation on human enamel surface. J Dent 80:15–22

Hussein M, Schneider-Futschik EK, Paulin OKA, Allobawi R, Crawford S, Zhou QT, Hanif A, Baker M, Zhu Y, Li J, Velkov T (2020) Effective strategy targeting polymyxin-resistant gram-negative pathogens: polymyxin B in combination with the selective serotonin reuptake inhibitor sertraline. Acs Infect Dis 6(6):1436–1450

Acknowledgements

The analysis of the chemical composition of SWE was commissioned by the Shanghai Fuda Analytical Testing Group. The authors are grateful to Bichao Xu, Pei Zhang and Anna Du from The Core Facility and The Technical Support, Wuhan Institute of Virology, for their technical support in transmission electron microscopy and scanning electron microscope.

Funding

This work was supported by Angel Yeast Co., Ltd. and the National Key Research and Development Project of China (2018YFE0101600).

Author information

Authors and Affiliations

Contributions

YL, BD, FG and JH contributed equally to this work. YL performed the experiment, data analyses and wrote the manuscript. BD reviewed and edited the manuscript. FG and JH contributed to the conceptualization, project administration and financial support. MZ, YP, XW, XH, ZX, HH, GC and ZL helped perform the analysis with constructive discussions. Yulian Wang guided the experiment and revised the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Y., Dou, B., Gong, F. et al. Chemical characteristics and anti-Escherichia coli mechanism of water-soluble extracts from yeast cell walls. Beni-Suef Univ J Basic Appl Sci 12, 82 (2023). https://doi.org/10.1186/s43088-023-00418-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43088-023-00418-0