Abstract

The consumption of imported dairy products is high especially in developing countries including Nigeria where little or no milk is produced locally which makes the products expensive, out of reach to common consumers and also inconvenient for lactose intolerance and vegans. Soymilk, as plant-based milk was substituted for cow’s milk in parts and in whole for the production of yoghurt and the effect of substitution was evaluated on the minerals, vitamins, microbial, and sensory properties of the products using the established methods. Significant differences (p < 0.05) exits among the yoghurt samples in the micronutrient contents. The soymilk substitution produced yoghurts with trace/macro mineral contents’ range of 0.14–28.50 mg/100 g and vitamin contents (ranged 0.02–0.43 mg/100 g) that were of comparable range of values with the yoghurt made with 100% cow’s milk (0.21–29.60 mg/100 g minerals and 0.05–0.58 mg/100 g vitamins). Generally, no significant difference (p < 0.05) was observed in most of the sensory attributes evaluated (range 8.00–8.01) in the entire samples (except in the 100% soymilk yoghurt). The microbial analysis proved the safety of the entire products for consumption. These showed the positive effect of substituting soymilk for cow’s milk at all the levels used, thus, the lactose intolerance and vegans can find alternative to dairy yoghurt in the 100% soymilk substitution and enjoy the functional health benefits of yoghurt. Also, the total dependence on importation of dairy milk and cost of production of composited milk yoghurt could be reduced to improve the nation’s economy and make the product economically accessible to common man.

Graphical abstract

Similar content being viewed by others

Introduction

Yoghurt is a dairy product obtained by lactic acid fermentation as an action of starter culture contained lactic acid bacteria (e.g. Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus thermophiles) which serves as sources of probiotics. This makes yoghurt a functional food having positive effects on immune, cardiovascular or metabolic health (El-Abbadi et al. 2014; Gijsbers et al. 2016; Facioni et al. 2020). A good strain of starter culture not only affects the flavour and aroma, it can also speed up the process and thus reduces the production costs of yoghurt (Abou-Dawood et al. 2013). The bacteria used to make yogurt are known as yogurt cultures and the fermentation of sugars in the milk by these bacteria produces lactic acid which acts on milk protein to give yogurt its texture and characteristic pleasant sour taste (US Food and Drug Administration 2016).

Cow’s milk is the most commonly used dairy in yogurt production and the global consumption of dairy products is high especially in developing countries including Nigeria. Nigeria as a major consumer of dairy products produces little or no type of dairy milk locally. As reported by Adekoya (2016) and Ekumankama (2020), about 98% of all the milk and dairy products consumed in Nigeria are imported (especially the cow’s milk powder) and consequently, the cost of production of cow’s milk yoghurt is high. However, the substitution of cheaper and plant-based milk may reduce the importation of dairy milk as raw material for the production of yogurt (Jimoh 2020). Also, dairy yoghurt is not suitable for lactose intolerant people thus, depriving them of additional health benefits that yoghurt provides (Amirah et al. 2020). These necessitate the need to formulate and develop yoghurt from plant-based milk.

Plant-based milk yoghurt is produced from milk of plant origin, typically made from legumes especially Soya beans (Glycine max), nuts, grains, or seeds (Lima et al. 2017; Silva et al. 2020; Jimoh 2020). These yogurts are suitable for lactose intolerance, vegans, and people who may prefer plant-based milk to cow’s milk yoghurt (Height, 2014; Jimoh, 2020; Amirah et al. 2020; Boukid et al. 2021). The benefits of soya beans must have informed a lot of research been carried out on incorporating Soya beans or any of its products (such as soymilk) into the indigenous diet. Soymilk is an aqueous extract produced from soya beans which are of considerable interest to nutritionists as a possible substitute for cow’s milk (Bolla 2015; Atli 2015; Jimoh 2020; Jayarathna et al. 2021). The various health benefits of the soya bean including the prevention of cardiovascular disease, cancer, as well as osteoporosis in elderly people have been linked to its antioxidants and phytonutrient properties (Schneeman, 2012; Ahmed et al. 2015; Jimoh 2020). Globally, a total of 336.7 million metric tons of soybean were produced in 2017/2018 and the United States had 119.52 million metric tons (USDA 2018). In Africa, a paltry 2.1 million metric tons were produced in 2016 (FAOSTAT, 2018). As such, soybean and its derivatives are at present, incorporated into so many food formulations for both children and adults to enhance the nutritional value of the foods (Bridges 2018).

Production of yogurt from milk of both plant and animal origin is a process of fermentation by the activities of selected microorganisms (Abiola and Oyetayo 2015; Jimoh 2020). The mechanism of food fermentation is essentially the conversion of carbohydrates to alcohols and carbon dioxide or organic acids by yeasts, bacteria or a combination thereof, under anaerobic conditions (Offor et al., 2014; Jimoh, 2020). Over the years, fermentation has become part of the culture and tradition of most indigenous communities in developing countries, especially in Africa (Nwachukwu et al. 2018; Jimoh 2020). Fermented foods such as yoghurt, are defined as those foods which have been subjected to the action of microorganisms or enzymes so that desirable biochemical changes cause significant modifications of health benefits (Adesulu and Awojobi 2014; Jimoh 2020; Łopusiewicz et al. 2020). Nigeria as well as other countries in Africa depends on fermented foods for nutritional and organoleptic satisfaction (Okechukwu et al. 2015; Jimoh 2020).

The insufficiency of cow’s milk in commercial quantity in Nigeria and many other African countries has gingered various efforts by researchers to use plant-based milk-like alternatives for the production of yoghurt in composite formulation with cow’s milk. These include; yoghurt produced from cow’s milk and tigernut milk (Sanful 2009); cow’s milk and fresh corn milk (Makanjuola 2012); cow’s milk, soymilk, and mango pulp (Walia et al. 2013); cow’s milk and peanut milk (Elsamania and Ahmed 2014); cow’s milk and cashew nut milk (Olatidoye et al. 2017); cow’s milk, coconut milk, soymilk, and almond milk (Usman and Bolade 2020); cow’s milk, soymilk, and banana (Jimoh 2020), among others. Also, yoghurt is made from mono or mixtures of 100% plant-based milks such as coconut milk (Amirah et al. 2020); a blend of coconut, almond, and tigernut milk (Omosebiet al. 2022- Unpublished).

Although, dairy yogurt is a popular cultured dairy product that can be made from whole, low-fat or skimmed milk, including reconstituted non-fat dried milk powder (Jimoh 2020). Notwithstanding, in a global context characterised by a food crisis resulting in a significant rise in the prices of basic necessities, the supply of cow’s milk powder for the production of yogurt has become very difficult and unprofitable (Bridges 2018). Faced with these difficulties, it is necessary to explore milk of other sources to reach an acceptable solution. These dictate the importance of looking for plant-based milk that can replace all or parts of cow’s milk for yoghurt production. Moreover, cheaper plant-based milk can be extracted from soybeans and used as a substitute for cow’s milk, and consumption of soymilk and its derivatives has beneficial effects on consumers’ health (Bridges 2018). Soymilk yogurt is a cultured plant-based and cholesterol free product (Sánchez-Calvo et al. 2013). Therefore, it is the aim of this work to substitute parts and all of the cow’s milk with soymilk in the production of yoghurt and determine the effect of the substitution on the nutritional, microbial, and sensory qualities of the products.

Materials and methods

Materials

Cow’s milk powder (Cowbell brand), Soybeans (Glycine max L.), sugar, vanilla flavour (Foster Clark) and milk flavour were purchased from a local market in Ondo town, South West Nigeria, while the commercial freeze-dried yoghurt starter (‘Yogourmet’ brand, LYO-SAN INC., CANADA, J8H 4G4)) was obtained from Sabo market, Yaba, Lagos, Nigeria. Chemicals used for the analysis are of analytical grade.

Methods

Preparation of soymilk

Soybeans (2 kg) were carefully sorted and soaked overnight (12 h) at room temperature (28-30 °C) in 10 l of water, during the soaking period, the water was changed at 2 h intervals (an alarm was set to assist in this regard). After the soaking period, the grains were drained, rinsed with fresh water and boiled for 30 min, cooled under running water and dehulled by manual rubbing in-between the hand palms; the dehulled beans was wet-milled in a fabricated attrition mill (VIKNG Exclusive JONCOD, TYPE YL112M-4, Nigeria). The obtained slurry was diluted with 6 L of water at 80 °C and filtered through 3 layers of cheesecloth for milk extraction. Thereafter, the isolated soymilk was boiled under low heat on a gas cooker for 25 min as a means of concentrating the milk and inactivating trypsin inhibitor to reduce the beany off-flavour and thus, improve the flavour (Achla 2019), then, allowed to cool at room temperature (26-30 °C). The conventional process methods for soymilk extraction especially, to remove beany flavour, basically involve the soaking, grinding, filtering, and cooking steps and various heat treatments before grinding. (Wilkens et al. 2017; Shibata et al. 2018; Niyibituronsa et al. 2018; Niyibituronsa et al. 2019; Silva et al. 2020). The method described by Jimoh (2020) with some modifications was adopted in the extraction of soymilk in the present work (Fig. 1).

Production of yoghurt

The powdered milk was first reconstituted at the ratio of 100 g to 1 l of water after which five samples of yoghurt were made from soy and cow’s milk blends. The various ratios were developed using the Mixture Response Surface Methodology which produced 9 different ratios (runs) out of which 4 different replicated runs were not used. The remaining 5 runs were coded and used for the experiment as follows: SY– 100% soymilk: 0% cow’s milk; SYI– 75% soymilk: 25% cow’s milk; SYII– 50% soymilk: 50% cow’s milk; SYIII– 25% soymilk: 75% cow’s milk; and CY– 0% soymilk: 100% cow’s milk. Four litres each of the mixtures of milk blends was pasteurised at 85 °C for 15 min, cooled to 40–44 °C and inoculated with 120 mL of the prepared activated commercial freeze-dried “Yogourmet” (LYO-SAN INC., CANADA, J8H 4G4) starter culture (prepared according to the manufacturer specification as presented in Fig. 2) then, incubated at about 35 °C overnight. The formed yoghurt was then blended for a smooth consistency using a SILVER CREST MULTIFONCTION BLENDER ROBOTS, CE TUV, Rheinland Product); sugar, milk flavour, and vanilla essence were added to improve the flavour of the yoghurt products, bottled and refrigerated pending the analyses. The flow chart for the production is presented in Fig. 3 (Usman and Bolade 2020).

Determination of mineral content

The method described by Usman and Bolade (2020) was adopted for the mineral analysis. The ash obtained from the furnace incineration method was subjected to mineral analysis where the concentration of calcium (Ca), magnesium (Mg), iron (Fe), zinc (Zn), and copper (Cu) were determined using atomic absorption spectrophotometer (Model SP9 Pye Unicam, UK); having initially prepared a standard curve for each mineral element under investigation. The analysis of sodium (Na) and potassium (K) concentrations of the samples was carried out using flame photometry method (using JENWAY PF P7 photometre) while the phosphorous (P) content in the samples was determined by the Vandate-molybdate method. The content of each mineral element was expressed as mg/100 g of the sample.

Determination of B-vitamin contents

Determination of vitamin B2 (riboflavin)

About 5 g of the sample was extracted with 100 mL of 50% ethanol and shaken for 1 h, this was filtered into a 100 mL flask; 10 mL of the extract was pipetted into a 50 ml volumetric flask. Ten (10) mL of 5% potassium permanganate and 10 mL of 30% hydrogen peroxide (H2O2) was added and allowed to stand over a hot water bath for 30 min. Two (2) mL of 40% sodium sulphate was added and made up to the 50 ml mark and the absorbance was measured at 510 nm using a spectrophotometre (Konings 2006).

Determination of vitamin B9 (folic acid)

The sample solution 1.0 mL (for folic acid determination), was mixed with 1.0 mL of 4 M l- hydrochloric acid, 1.0 mL of 1% (w/v) sodium nitrite, 1.0 mL of 1% (w/v) sulfamic acid, and 1.0 mL of 1% (w/v) 3-aminophenol which resulted in an orange-yellow complex. The absorption of the complex was measured at 460 nm using a UV-visible spectrophotometer (Konings 2006).

Determination of vitamin E and β-carotene

The determination of vitamin E was done by the method of Pearson (1976) while that of β-carotene was by the method of the Association of Official Analytical Chemists (AOAC , (Association of Official Analytical Chemists) 2005).

The absorbance for Vitamin E was measured at a wavelength of 470 nm and that of β-carotene at 436 nm using a spectrophotometer. A cuvette containing pet-ether (blank) was used to calibrate the spectrophotometer to zero point before the readings.

Determination of microbial quality

Microbial analysis was done using the method described by Ijah et al. (2014); the media used include; Nutrient Agar (Sigma-Aldrich-70,148), McConkey Agar (Sigma-M7408), Mannitol Salt Agar (Sigma–Aldrich - D7809), Eosin Methylene Blue (Sigma-Aldrich - 70,186) Agar and Potato Dextrose Agar (Sigma-Aldrich- 70,139). Each of the agar was prepared according to the manufacturer’s specification and used in culturing for total viable bacterial count (TVBC), Coliforms, Staphylococcus, Escherichia coli, and fungi growth, respectively. The prepared media were sterilized at a temperature of 121 °C for 15 minutes, allowed to cool before being dispensed. One (1 ml) of each yoghurt sample was measured aseptically and introduced into 9 ml of sterile water inside a diluent bottle and homogenised. The resulting mixture was serially diluted up to three-fold dilution (10− 1 to 10− 3). One (1 ml) of the desired diluent (10− 3 for TVBC and fungi; 10− 1 for Coliforms, Staphylococcus, and E. coli) was dispensed into a sterile petri dish after which it was overlaid with the respective cooling medium. The plates were closed and allowed to solidify and then inverted. The bacterial plates were incubated at 37 °C for 24 h while that of fungi were incubated at 25 °C for 72 h. After the incubation period, number of colonies and spore formed for bacterial and fungi, respectively were counted using a digital colony counter (Gallenkamp, England) and the observed counts were multiplied by the dilution factor to get the total count according to the diluent used, the result was expressed in colony-forming unit per ml (CFU/ml).

Sensory evaluation

The sensory evaluation of the yoghurt samples was carried out a few hours after the production and refrigeration and analysed for colour, consistency, aroma, taste, and overall acceptability. Twenty semi-trained panelists drawn from the staff and students of the Department of Food Science and Technology of the Institution where the evaluation was carried out were provided with portable water and instructed to rinse their mouths before and after each evaluation. The panellists comprises ten males and ten females between the ages brackets of 20–32 years, they were selected based on their familiarity with yoghurt products while those who were not familiar with the product were excluded to prevent prejudice in the assessment. Also, lactose intolerants were excluded from the exercise to avoid cases of health inconveniences. A 9-point hedonic rating was used to assess the degree of acceptability of yoghurt containing different levels of soymilk substitutions where 9 = like extremely, 8 = like very much, 7 = like moderately, 6 = like slightly, 5 = neither like nor dislike, 4 = dislike slightly, 3 = dislike moderately, 2 = dislike very much, and 1 = dislike extremely (Jimoh 2020).

Statistical analyses

All the determinations were done in triplicates and a mean value was calculated in each case. Analysis of variance (ANOVA) was performed and separation of the means was by Duncan’s Multiple Range Test, significant difference was accepted at p < 0.05 using SPSS version 21.0.

Results and discussion

Mineral composition of yoghurt samples

The result of the mineral analysis of the yoghurt products is presented in Table 1. Significant differences existed among the samples at p < 0.05. Calcium (Ca) concentration is in the range of 5.85 to 8.89 mg/100 g; highest in SYII and lowest in SYI product while magnesium (Mg) concentration in the range of 4.88–10.74 mg/100 g was highest in product with 100% cow’s milk (CY) and lowest in SY (100% soymilk). Calcium is good for bone and teeth development and strengthening while Mg plays an essential role in Ca metabolism for bone development, and is also involved in the prevention of circulatory diseases (Otolowo et al. 2021). According to Rosique-esteban et al. (2018), fermented dairy products such as yoghurt, maybe a source of magnesium. Hence, SYII and CY yoghurts will be a better source for Ca and Mg, respectively, than the rest samples.

Sodium (Na) concentration in the various yoghurt ranged between 12.00 and 21.90 mg/100 g and that of potassium (K) ranged between 20.90 to 29.60 mg/100 g. Both Na and K were highest (21.90; 29.60 mg/100 g, respectively) in CY followed by SYII (17.60; 28.50 mg/100 g, respectively). The varying ratios of sodium to potassium (Na/K) in the entire products ranged from 0.53 to 0.74 mg/100 g which were found within the standard range of value of less than one (< 1) to maintain a balanced body fluid necessary to avoid a case of high blood pressure/hypertension (Ogunka-Nnoka et al. 2017; Otolowo et al. 2021). Usman and Bolade (2020) also noted that potassium makes a contribution to the normal functioning of the nervous system and muscles.

The phosphorus (P) content of the yoghurt types exhibited a range of 1.04 to 2.45 mg /100 g and was the highest in the CY sample. Phosphorus has been implicated in the majority of the metabolic actions in the body system including kidney functioning, cell growth, and contraction of the heart muscle (Usman and Bolade 2020).

The concentrations of determined trace metal elements generally exhibited a non-significant different range of values (at p < 0.05) among the samples in each case; Fe (0.25–0.37 mg/100 g), Zn (0.14 to 0.26 mg/100 g), and Cu (0.15 to 0.21 mg/100 g). The obtained range of values for iron (Fe) content is lower than the range of values reported by Usman and Bolade (2020), possibly as a result of differences in the added contents. The major function of Fe in human nutrition is related to the synthesis of haemoglobin and myoglobin in the blood (Usman and Bolade 2020). Sample SYI had the lowest concentration (0.14 mg/100 g) for Zn which is in agreement with the report of Usman and Bolade (2020) for quality characteristics of imitation yoghurt. Copper (Cu) is an important essential trace element in the human body system (Pavelková et al. 2018). Sample CY was highest in Cu concentration (0.21 mg/100 g) followed by 0.18 mg/100 g in SY and SYII. About a quarter of the copper RDA for adults (900 μg/day) is expected to be met by consuming 100 g of sample CY (Mustafa and AlSharif, 2018). Additionally, Usman and Bolade (2020) noted that increased concentration of Cu decreases the post acidification of fermented milk.

Generally, the occurrence of the concentration of the determined mineral elements was observed to be lower in composited yoghurts than that of 100% cow’s milk which concurred with the report of Facioni et al. (2020) and Usman and Bolade (2020) who observed that non-dairy milk products are low in minerals and vitamins compared to cow’s milk products. However, in comparison with the standard RDA, the obtained values in the present work were lower in the entire samples (RDA for minerals- www.lenntech.com, 1998–2016). Nevertheless, the presence of these nutrients in the soymilk substituted yoghurts as in the present work will add to the daily intake of the consumer. Thus, the consumption of the yoghurt products might serve as a complementary source for the determined mineral elements which is in accordance with the report of Usman and Bolade (2020).

Vitamin compositions of yoghurt samples

Selected vitamin composition of different yoghurt types from the milk blends is presented in Table 2. The samples are significantly different (p < 0.05) in concentrations of the determined vitamins. Sample CY contains the highest presence of vitamin B2 with 0.58 mg/100 g, and sample SY contained the lowest amount (0.10 mg/100 g); the obtained range of values is low in respect of the RDA.

As noted by Facioni et al. (2020), the amount of vitamin B2 is usually low in fermented milk products, such as yoghurt, as these vitamins are absorbed by some latic acid bacteria. The presence of vitamin B9 was highest in sample SYII (0.02 mg/100 g) and lowest in sample SY (0.34 mg/100 g). Sample SY also contains the lowest amount of vitamin E with 0.02 mg/100 g and sample CY had the highest amount of vitamin E (0.36 mg/100 g). A negligible low range of value (6.32E7–2.27E7 mg/100 g) was obtained for β-carotene in the entire samples; β-carotene is a precursor of vitamin A (fat-soluble). Vitamin E also belongs to a group of fat-soluble compounds formerly known as tocopherols with a well-documented antioxidant activity (Sharif et al. 2017; Zhuang et al. 2022). Accordingly, despite its desirable nutritional value, yogurt is generally considered to be a poor source of fat-soluble vitamins including vitamin E (Raikos et al. 2021).

Microbiological properties of the yoghurt

The microbiological properties of the yoghurt samples are depicted in Table 3. The results show that sample CY had the lowest amount of TVBC with 3.0 × 104 CFU/ml while sample SYI had the highest bacteria load (9.0 × 104 CFU/ml). The population of bacteria in the entire yoghurt samples is generally found within the standard range for GRAS (5.0 × 105 CFU/g) food products (CFS (Center for Food Safety) 2007; Otolowo et al. 2021). The coliforms and other indicator microorganisms were absent. The presence of coliforms in food samples is used as an indicator of contamination (Kirby et al. 2016). In the present work, the occurrence of bacteria counts within the acceptable level and absence of total Coliforms, Staphylococcus, and E. coli in the entire samples could be attributed to good hygienic conditions for the production and packaging of the products. This implies that the products are regarded as safe for consumption which is in consonance with the report of Usman and Bolade (2020).

The yeasts/moulds count of the yoghurt types ranged from 2.0 × 104 to 6.0 × 104 CFU/ml with sample SY and CY having the same and lowest count (2.0 × 104 CFU/ml) while sample SYIII had the highest count (6.0 × 104 CFU/ml) of yeast/molds. If the maximum standard of 1.0 × 102 CFU/ml of yeast/mold, set for yoghurt in some countries like Turkey is followed (Usman and Bolade 2020), the yeast/mold population obtained for yoghurt samples in the present work were above the limit. The higher values of yeast/mould observed in the composited yoghurts could be as a result of poor handling during mixing, thus, a high standard of hygiene should be maintained throughout the processing stages. However, the obtained range of values for yeasts/moulds was still within the general standard safe limit (1.0 × 106 CFU/g) for human consumption (Otolowo et al. 2021).

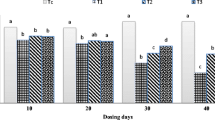

Sensory qualities of the yoghurt samples

The sensory quality rating of different yoghurt types produced from the milk blends is presented in Table 4. Generally, with the 9-point hedonic scale used, there was no significant difference (p < 0.05) in the entire samples for the attributes of colour (7.00–8.00), aroma (7.00–8.01), and taste (7.01–8.00) except in sample SY (100% soymilk), possibly due to lack of familiarity of the panelists to soy yoghurt, notwithstanding, no significant difference was observed in overall acceptability (8.00) of the entire products.

However, there was a significant difference (p < 0.05) observed in the attribute of consistency, this is in agreement with the report of Usman and Bolade (2020). The mean scores for consistency in the present work ranged from 6.01 to 8.00 indicating ‘like slightly’ to ‘like very much on the 9-point hedonic scale used. Sample SYII and CY were rated alike and the highest (8.00) followed by SY and SYIII with values of 7.01 and 7.00, respectively while SYI had the least rating of 6.01; implies that soymilk substitution above 50% in the composited samples resulted in the least preference for consistency. Nevertheless, all the products were found at a good acceptable level of consistency indicating the panelist satisfaction for the composited and 100% soy yoghurt, this is in consonance with the findings of Jayarathna et al. (2021). Most of the sensory attributes considered were rated higher in preference in the entire products (except the 100% cow’s milk sample) than the values reported by Jimoh (2020) possibly, as a result of flavouring agents added to the products in the present work.

Conclusion

The result of this study showed that compositing cow’s milk with soymilk in the production of yoghurt will positively impact the nutritive spectrum of the product (especially the SYII yoghurt, in the contents of Ca, Na, K, Fe, Zn, Cu, and vitamin B9) and the sensory evaluation showed an acceptable preference. Realistically, substitution up to 50% soymilk that is, milk blends of 50% soymilk: 50% cow’s milk (SYII) has the potential of giving an equal measure of nutritive and sensory value as would be obtained from cow’s milk yoghurt. Moreover, the occurrence of sensory attributes of 100% soy yoghurt at a well acceptable level presents it as a good choice for the lactose-intolerant people. Thus, the production of yoghurt from the blends of cow’s milk and soymilk or even 100% soymilk is highly possible. Therefore, the substitution of up to 50% or use of 100% soymilk for yoghurt production could be adopted for better sustainability of the soya bean crop and this may reduce the production cost for the composited yofhurt. However, studies on the storage stability of soymilk yoghurts will be necessary to determine the shelf-life of the products.

Availability of data and materials

The datasets during and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- SY:

-

Soymilk yoghurt (100% soymilk: 0% cow’s milk)

- SYI:

-

Soy/cow’s milk yoghurt I (75% soymilk: 25% cow’s milk)

- SYII:

-

Soy/cow’s milk yoghurt II (50% soymilk: 50% cow’s milk)

- SYIII:

-

Soy/cow’s milk yoghurt III (25% soymilk: 75% cow’s milk)

- CY:

-

Cow’s milk yoghurt (0% soymilk: 100% cow’s milk)

- RDA:

-

Recommended Dietary Allowances

- GRAS:

-

Generally Regarded As Safe

- CFU:

-

Colony Forming Unit

- TVBC:

-

Total Viable Bacteria Count

- Staph:

-

Staphylococcus

- E. coli :

-

Escherichia coli

- Nil:

-

No growth detected

- MRSM:

-

Mixture Response Surface Methodology

- No.:

-

Number

References

Abiola, C., & Oyetayo, V. O. (2015). Effect of liquid and solid fermentation on mineral and amino acid contents of kersting’s groundnut (Macrotyloma geocarpum). Journal of Scientific Research and Reports, 8(7), 1–12.

Abou-Dawood, E. A., Abd Rabo, H. F., Ahmed, S. N., & Hassan, M. A. F. (2013). Manufacture of yoghurt from cow’s milk. Nigeria Journal of Dairy Science, 21, 21–33.

Achla, B. (2019). "the growth of soy-Milk as A dairy alternative". Industry Europe, focus media group ltd. Retrieved 9 January 2020. Available at https://www.wikiwand.com › Soymilk

Adekoya A. (2016). 98% of dairy products in Nigeria are imported. Vangaurd, October 17, 2016. Available on: www.vanguardngr.com/2016/10/98-dairy-productsnigeria-imported-dangote/ Accessed 2017-01-09

Adesulu, A. T., & Awojobi, K. O. (2014). Enhancing sustainable development through indigenous fermented food products in Nigeria. African Journal of Microbiology, 8(12), 1338–1343.

Ahmed, B. O., Idris-Adeniyi, K. M., & Lawal, A. O. (2015). Food security and post-harvest losses in fruit marketing in Lagos metrolis, Nigeria. Discourse Journal of Agriculture and Food Sciences, 3(3), 52–58.

Amirah, A. S., Nor Syazwani, S., Radhiah, S., Anis Shobirin, M. H., Nor-Khaizura, M. A. R., Wan Zunairah, W. I., & Shazini, N. R. (2020). Influence of raisins puree on the physicochemical properties, resistant starch, probiotic viability and sensory attributes of coconut milk yogurt. Food Research, 4(1), 77–84.

AOAC , (Association of Official Analytical Chemists). 2005. Official method of analysis (18th Ed.) Washington D. C.

Atli, A. (2015). Nutrition facts and health effects. Soybeans 101. Available on: www.authoritynutrition.com/foods/soybeans/ Accessed on 2017-05-01

Bolla, K. N. (2015). Soybean consumption and health benefits. International Journal of Scientific & Technology Research, 4(7), 50–53.

Boukid, F., Lamri, M., Dar, B. N., Garron, M., & Castellari, M. (2021). Vegan alternatives to processed cheese and yogurt launched in the European market during 2020: A nutritional challenge. Foods, 10(11), 2782.

Bridges, M. (2018). Moo-ove over, Cow’s Milk: The rise of plant-based dairy alternatives. Practical Gastroenterology, 21, 20-27.

CFS (Center for Food Safety) (2007). Microbiological guidelines for ready- to-eat food: Risk assessment section, food and environmental hygiene department 43/F, Queensway government offices 66 Queensway, Hong Kong, (pp. 1–15).

Ekumankama, O., Ezeoha, A., & Uche, C. (2020). The role of multinational corporations in local dairy value chain development: Case of Friesland Campina WAMCO (FCW) in Nigeria. International Food and Agribusiness Management Review, 23(1), 55–69.

El-Abbadi, N. H., Dao, M. C., & Meydani, S. N. (2014). Yogurt: Role in healthy and active aging. The American Journal of Clinical Nutrition, 99(5 Suppl), 1263S–1270S.

Elsamania, M. O., & Ahmed, I. A. M. (2014). Physicochemical characteristics and organoleptic properties of peanuts milk-based yoghurt fortified with skimmed milk powder. Journal of Research in Applied Sciences, 1(4), 68–72.

Facioni, M. S., Raspini, B., Pivari, F., Dogliotti, E., & Cena, H. (2020). Nutritional management of lactose intolerance: The importance of diet and food labelling. Journal of Translational Medicine, 18(1), 1–9.

FAOSTAT (2018). Food and agriculture data. The food and agriculture Organization of the United Nations (FAO). Available online at: http://www.fao.org/faostat/en/ (Accessed19 Nov 2018).

Gijsbers, L., Ding, E. L., Malik, V. S., de Goede, J., Geleijnse, J. M., & Soedamah-Muthu, S. S. (2016). Consumption of dairy foods and diabetes incidence: A dose-response meta-analysis of observational studies. The American Journal of Clinical Nutrition, 103(4), 1111–1124.

Height A. (2014). How to choose the best non-dairy yogurt, Available on: www.onegreenplanet.org/veganfood/how-to-choose-the-best-non-dairy-yogurt/ Accessed 2017-04-27.

Ijah, U. J. J., Auta, H. S., Aduloju, M. O., & Aranisolam, S. A. (2014). Microbiological, nutritional, and sensory quality of bread produced from wheat and potato flour blends; Vol 2014, article ID 671701, 6 pgs.

Jayarathna, S., Priyashantha, H., Johansson, M., Vidanarachchi, J. K., Jayawardana, B. C., & Liyanage, R. (2021). Probiotic enriched fermented soy-gel as a vegan substitute for dairy yoghurt. Journal of Food Processing & Preservation, 45(1), e15092.

Jimoh, M. O. (2020). Production and analyses of yogurts obtained from cow’s milk and soy milk blended with banana (Musa paradisiacal). International Journal of Food Sciences and Nutrition, 5(2), 20–26 Available at www.foodsciencejournal.com.

Kirby, M. A., Nagel, C. L., Rosa, G., Iyakaremye, L., Zambrano, L. D., & Clasen, T. F. (2016). Faecal contamination of household drinking water in Rwanda: A national cross-sectional study. Science of the Total Environment, 571, 426–434.

Konings, E. J. (2006). Committee on food nutrition: Water-soluble vitamins. Journal of AOAC International, 89(1), 285–289.

Lima, L. D. S. C., Luz, M. L. G. S., Luz, C. A. S., Gadotti, G. I., Maldaner, V., Santos, J. B., & Bernardy, R. (2017). Viabilidade técnica e econômica da implantação de uma agroindústria de extrato vegetal. Science of the Total Environment, 4(2), 48–53. https://doi.org/10.15210/RBES.V4I2.12203.

Łopusiewicz, Ł., Drozłowska, E., Siedlecka, P., Mężyńska, M., & Bartkowiak, A. (2020). Preparation and characterization of novel flaxseed oil cake yogurt-like plant milk fortified with inulin. Journal of Food & Nutrition Research, 59(1), 60-70.

Makanjuola, O. M. (2012). Production and quality evaluation of soy-corn yoghurt. Advance Journal of Food Science and Technology, 4(3), 130–134.

Mustafa, S. K., & AlSharif, M. A. (2018). Copper (cu) an essential redox-active transition metal in living system – A review article. American Journal of Analytical Chemistry, 9, 15–26.

Niyibituronsa, M., Onyango, A. N., Gaidashova, S., Imathiu, S., Boevre, M. D., Leenknecht, D., … Raes, K. (2019). The growth of different probiotic microorganisms in soymilk from different soybean varieties and their effects on anti-oxidant activity and oligosaccharide content. Journal of Food Research, 8(1), 1927–0895 Published by Canadian Center of Science and Education 41. https://biblio.ugent.be/publication/8613059/file/8613062.

Niyibituronsa, M., Onyango, A. N., Gaidashova, S., Imathiu, S., Uwizerwa, M., Phillis, E., Ng’ang’a, O. F., Birungi, J., Ghimire, S. & Harvey, J. (2018). The effect of different processing methods on nutrient and isoflavone content of soymilk obtained from six varieties of soybean grown in Rwanda Food Science & Nutrition First. https://doi.org/10.1002/fsn3.812

Nwachukwu, C. D., Enyoh, E. C., Enyoh, C. E., & Amaobi, C. E. (2018). Effect of fermentation time on the proximate and mineral composition of fermented African oil bean seed ‘Ugba’. Sustain Food Product, 2, 13–20.

Offor, I. F., Ehiri, R. C., & Njoku, C. N. (2014). Proximate nutritional analysis and heavy metal composition of dried Moringa oleifera leaves. Journal of Environmental Science, Toxicology and Food Technology, 8(1), 57–62.

Ogunka-Nnoka, C. U., Amadi, P. U., Ogbonna, P. C., & Ogbegbor, P. O. (2017). Assessment of the protein quality and mineral bioavailability of Dacryodes edulis seed and seed coat mixture. J.Sci. Res Rep, 14, 1–11.

Okechukwu, E. C., Itah, A. Y., & Aguora, S. O. (2015). Effect of varying fermental temperature on proximate composition and mineral content of African oil bean seeds (Pentaclethra macrophylla Benth). Journal of Environmental Science, Toxicology and Food Technology, 6, 21–25.

Olatidoye, O. P., Sobowale, S. S., Ogundipe, O. O., Adebayo-Oyetoro, A. O., & Akinwande, F. F. (2017). Production and quality evaluation of imitation yoghurt from blends of cow milk and cashewnut milk (Anacadium ocidentale). International Journal of Advanced Research and Publications, 1(5), 379–385.

Otolowo, D. T., Araoye, K. T., Maderin, M., & Ogunbusola, E. M. (2021). Evaluation of mineral, microbial, and sensory properties of gluten-free-ready-to-eat snacks produced from blends of water yam (Dioscorea Alata) and Lima bean (PhaseolusLunatus). Journal of Culinary Science & Technology. https://doi.org/10.1080/15428052.2021.1946877.

Pavelková, M., Vysloužil, J., Kubová, K., & Vetchý, D. (2018). Biological role of copper as an essential trace element in the human organism. Biologická role mědi jako základního stopového prvku v lidském organismu. Ceská a Slovenská Farmacie, 67(4), 143–153.

Pearson, D. A. (1976). The chemical analysis of foods, 7th. Edinburgh: Churchill Livingstone.

Raikos, V., Pirie, L. P., Gürel, S., & Hayes, H. E. (2021). Encapsulation of vitamin E in yogurt-based beverage emulsions: Influence of bulk pasteurization and chilled storage on physicochemical stability and starter culture viability. Molecules, 26(6), 1504.

RDA for minerals- www.lenntech.com, 1998-2016. Recommended Dietary Allowance (RDA) and Adequate Intake (AI) for minerals. (www.lenntech.com, 1998–2016), Accessed 31 Mar 2016.

Rosique-Esteban, N., Guasch-Ferré, M., Hernández-Alonso, P., & Salas-Salvadó, J. (2018). Dietary magnesium and cardiovascular disease: A review with emphasis in epidemiological studies. Nutrients, 10(2), 168.

Sánchez-Calvo, J. M., Rodríguez-Iglesias, M. A., Molinillo, J. M., & Macías, F. A. (2013). Soy isoflavones and their relationship with microflora: Beneficial effects on human health in equal producers. Phytochemistry Reviews, 12(4), 979–1000.

Sanful, R. E. (2009). The use of tigernut (Cyperus esculentus), cow milk and their composite substrates for yoghurt production. Pakistan Journal of Nutrition, 8(6), 755758.

Schneeman, B. O. (2012). Gastrointestinal physiology and functions. British Journal of Nutrition, 88(2), 159163.

Sharif, H. R., Goff, H. D., Majeed, H., Liu, F., Nsor-Atindana, J., Haider, J., & Zhong, F. (2017). Physicochemical stability of β-carotene and α-tocopherol enriched nanoemulsions: Influence of carrier oil, emulsifier and antioxidant. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 529, 550–559.

Shibata, M., Hirotsuka, M., Mizutani, Y., Takahashi, H., Kawada, T., Matsumiya, K., & Matsumura, Y. (2018). Thermal treatment of soybean seeds can improve the quality of soymilk by enhancing the extraction efficiency of “kokumi” taste components. Food Science and Technology Research, 24(6), 1111–1119.

Silva, A. R., Silva, M. M., & Ribeiro, B. D. (2020). Health issues and technological aspects of plant-based alternative milk. Food Research International, 131, 108972.

US Food and Drug Administration (2016)."Yogurt: from Part 131 – Milk and Cream. Subpart B – Requirements for Specific Standardized Milk and Cream, Sec. 131.200". Code of Federal Regulations, Title 21

USDA (2018). Food composition databases. United States Department of Agriculture, Agricultural Research Service. Available online at: https://ndb.nal.usda.gov/ndb/. Accessed 19 Nov 2018.

Usman, M. A., & Bolade, M. K. (2020). Quality characteristics of imitation yoghurt produced from the blends of milk from cow, coconut (Cocos nucifera), soybean (glycine max) and almond (terminalia catappa) seeds. Global Scientific Journals, 8(9), 57–78 Available online at: www.Globalscientificjournal.Com.

Walia, A., Mishra, H. N., & Kumar, P. (2013). Effect of fermentation on physico- chemical, textural properties and yoghurt bacteria in mango soy fortified yoghurt. African Journal of Food Science, 7(6), 120–127.

Wilkens, W. F., Mattick, L. R., & Hand, D. B. (2017). Effects of processing method on oxidative off-flavors of soybean milk. Food Technology, 21, 1630–1633.

Zhuang, S., Zheng, W., Na, Y., Chen, N., Gong, F., Huang, B., & Liu, H. (2022). Changes in the content and antioxidative activity of β-carotene and its metabolite vitamin A during gastrointestinal digestion and absorption and optimisation of HPLC-based detection. International Journal of Food Science and Technology, 57(2), 1093–1103.

Acknowledgements

Not Applicable.

Funding

No external funding is involved in this research.

Author information

Authors and Affiliations

Contributions

DTO design the experiment, DTO and TEE performed the experiment/analyses and interpreted the data. DTO was a major contributor in writing the manuscript. KTA and OMO edited the first draft of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Competing interests

The authors declare that they have no competing interests

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Otolowo, D.T., Omosebi, O.M., Araoye, K.T. et al. Effects of the substitution of cow’s milk with soymilk on the micronutrients, microbial, and sensory qualities of yoghurt. Food Prod Process and Nutr 4, 15 (2022). https://doi.org/10.1186/s43014-022-00093-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-022-00093-1