Abstract

Hydrophobicity enhancement of metal-free leather, which is crucial for improving its comprehensive performance, can be achieved by using amphiphilic copolymer retanning agents. However, the relationship between the sequential structure and the hydrophobic modification effect of amphiphilic copolymers remains unclear. Herein, an amphiphilic block copolymer was synthesized using stearyl methacrylate and 2-(dimethylamino)ethyl methacrylate via atom transfer radical polymerization, and the corresponding random copolymer with similar monomer compositions and molecular weights was prepared for comparison. The aggregation behavior of block and random copolymers was investigated. DLS and TEM results indicate that the block copolymer exhibits a larger aggregate size than the corresponding random copolymer. Molecular dynamics simulations suggest that the block copolymer aggregate exhibit a thicker hydrophilic shell and more concentrated distribution of cationic DMA block than the random copolymer aggregate. Subsequently, the block and random copolymers were used for the hydrophobic modification of metal-free tanned collagen fibers (CFs). The block copolymer shows superior binding capacity to CFs than the random one because of its larger size and more concentrated charge distribution. Hence, the block copolymer can form a dense and uniform hydrophobic film on the surface of collagen fibrils and endow CFs with higher hydrophobicity than the random one. This work provides theoretical guidance for modulating the hydrophobicity of CFs by tailoring the sequential structure of amphiphilic copolymers, which is expected to inspire the manufacturing of high-performance metal-free leather.

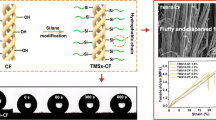

Graphical Abstract

Similar content being viewed by others

1 Introduction

The environmental challenges arising from the use of conventional chrome tanning technology impede the sustainable development of leather manufacturing [1,2,3]. Consequently, the production of metal-free eco-leather as an alternative to chrome tanned leather has received increasing attention [4,5,6,7,8]. Although some metal-free tanning agents are highly reactive in crosslinking with collagen, the performance gap between the metal-free tanned leather and the traditional chrome tanned leather persists. One of the major causes of this gap is the strong water sorption of metal-free tanned leather. This property can be attributed to the fact that a metal-free tanning agent usually has abundant polar groups, and it cannot block as many carboxyl groups on the side chains of collagen as the chrome tanning agent. The elevated water sorption of metal-free tanned leather leads to inadequate fiber dispersion and excessive penetration of base coating agents into leather, resulting in undesirable organoleptic properties, such as stiff feel and lack of fullness, of the finished leather [9]. Previous studies also confirmed that the properties of leather, including thermal stability, softness, and physical strengths, are always closely related to its hydrophobicity [10,11,12]. Therefore, enhancing the hydrophobicity of metal-free tanned leather is crucial for improving its properties.

Anionic amphiphilic copolymers have been prepared as retanning or fatliquoring agents to improve the waterproofness of chrome tanned leather [13, 14]. However, these anionic chemicals cannot be applied in metal-free tanned leather effectively because of the mismatch of surface charges between the chemicals and the leather [15]. Given the charge properties of metal-free tanned leather and the feature of amphiphilic copolymers, cationic amphiphilic copolymer retanning agents were previously synthesized to enhance the hydrophobicity of metal-free tanned leather [16, 17]. Our findings indicated that the modulation of the structural parameters of cationic amphiphilic copolymers, including the monomeric ratio and charge property, can alter the particle size and morphology of their aggregate, thereby regulating the hydrophobicity of the retanned metal-free leather.

The microstructure of copolymer chains, including the sequential structure, monomer composition, and molecular weight, exerts a significant influence on the self-assembled nanostructure of copolymer and plays a vital role in determining the functional properties of copolymer [18, 19]. The sequential structure is defined as the distribution of monomeric units along the copolymer backbone [20]. Among amphiphilic copolymers with diverse sequential structures, random and block copolymers are widely studied. Amphiphilic random and block copolymers exhibit distinct aggregation behavior such as critical micelle concentration [21], particle size of aggregate [22,23,24], and charge nature [25]. As for the cationic amphiphilic copolymer retanning agents, the differences in copolymer aggregation behavior will inevitably influence the hydrophobicity of the retanned metal-free leather based on our previous studies. Thus, exploring the effect of the sequential structure (block versus random copolymer) of copolymers on their hydrophobic effects is necessary.

Herein, the cationic amphiphilic block copolymer was synthesized using hydrophobic monomer stearyl methacrylate (SMA) and hydrophilic monomer 2-(dimethylamino)ethyl methacrylate (DMA) via atom transfer radical polymerization (ATRP). The corresponding random copolymer was also prepared [16]. These block and random copolymers were designed to exhibit identical monomers, similar monomer ratios and comparable molecular weights. The differences in aggregation behavior between block and random copolymers were investigated through transmission electron microscope (TEM), dynamic light scattering (DLS), and molecular dynamics (MD) simulations. Subsequently, the block and random copolymers were utilized for the hydrophobic modification of metal-free tanned collagen fibers (CFs). The relationship among the sequential structure of copolymers, the aggregation behavior of copolymers, and the hydrophobic modification effect of copolymers on CFs was intensively studied. We hope that the results will provide inspiration for improving the hydrophobicity and even the comprehensive performance of metal-free leather.

2 Materials and methods

2.1 Materials

Ethyl 2-bromoisobutyrate (EBiB, purity 98%), 4,4′-Dinonyl-2,2′-dipyridyl (dNbpy, purity 98%), SMA (purity 96%), and 2,2′-Azobis(2,4-dimethyl)valeronitrile (AVBN, purity 98%), were purchased from Aladdin Reagent Co., Ltd. DMA (purity 99.5%) was provided by Feymer Technology Co., Ltd. CuBr, CuBr2, tetrahydrofuran (THF) and other reagents were of analytical purity and purchased from Chengdu Kelong Chemical Reagent Co., Ltd. TWS tanning agent, an amphoteric organic tanning agent containing carboxyl, aldehyde and amino groups, was provided by Tingjiang New Materials Co., Ltd. Metal-free leather tanned with TWS was prepared in our laboratory following previously reported procedures [6, 16]. The CFs were obtained by pulverizing TWS tanned leather into powder with a particle size of 1 mm.

SMA was purified by dissolving in hexane and extracting four times with 5 wt% NaOH. After the organic phase was dried over magnesium sulfate, the solution was passed through a neutral alumina column, and the solvent was removed under reduced pressure. DMA was passed through a column filled with neutral alumina just before use.

2.2 Synthesis of copolymers

Two PSMA-b-PDMA block copolymers, namely, PSMA25-b-PDMA15 and PSMA20-b-PDMA20, were synthesized by ATRP. Two P(SMA-r-DMA) random copolymers prepared in accordance with our previous work [16] were labeled as P(SMA-r-DMA)1:0.6 and P(SMA-r-DMA)1:1. The detailed synthesis procedures are shown in the Supplementary Material (S1.1 and S1.2). The molar ratio of SMA to DMA in PSMA25-b-PDMA15 and P(SMA-r-DMA)1:0.6 was designed to be 1: 0.6, and the molar ratio of SMA to DMA in PSMA20-b-PDMA20 and P(SMA-r-DMA)1:1 was designed to be 1: 1.

2.3 Characterization of copolymers

The weight-average molecular weight (Mw), number-average molecular weight (Mn), and polydispersity index (DPI, the ratio of Mw to Mn) of copolymers were determined by using a gel permeation chromatograph (GPC, LC20AD, Shimadzu, Japan) equipped with a refractive-index detector (RID-20, Shimadzu, Japan). A KF-804L column (Shodex, Japan) was used with THF as the mobile phase flowing at 1.0 mL/min. Polystyrene standards (Mw ranging from 589 to 98,900) were used for calibration. 1H NMR spectra were conducted using a Bruker Avance III 400 MHz NMR spectrometer (Bruker, Germany) with CDCl3 as the solvent. Fourier transformed infrared (FT-IR) spectra were recorded in attenuated total reflection (ATR) mode using a FT-IR spectrometer (INVENIO-R, Bruker, Germany).

Copolymer solutions were prepared as described in the Supplementary Material (S1.3). A drop of copolymer solutions (1.0 g/L) was dripped onto copper net and negatively stained with 3% phosphotungstic acid. Then the samples were observed by using a transmission electron microscope (TEM, 2100Plus, JEOL, Japan) at an accelerating voltage of 200 kV. DLS and zeta potential determinations of copolymer solutions (1.0 g/L) were performed on a particle size and zeta potential analyzer (NanoBrook Omni, Brookhaven, USA) equipped with a 50 mW He–Ne laser (632 nm) at 40 °C. Measurements were conducted in triplicates at a scattering angle of 90°.

2.4 MD simulations of the aggregation behavior of copolymers3

-

(1)

All-atom MD simulations

All-atom MD simulations were conducted using the modeled block copolymer, PSMA25-b-PDMA15, and random copolymer, P(SMA-r-DMA)1:0.6, to study the mechanism by which a single chain of copolymers folds in aqueous phase. The modeling of copolymers and all-atom MD simulations were performed in accordance with our previous studies with some modifications [16, 17]. The simulation details are given in the Supplementary Material (S1.4). System 1 and system 2 are all-atom MD simulation systems for the motion of block and random copolymers in water, respectively.

-

(2)

Coarse-grained (CG) MD simulations

The multi-chain aggregation behavior of block copolymer and random copolymer in aqueous phase was investigated using CG MD simulations. The CG models for PSMA25-b-PDMA15 and P(SMA-r-DMA)1:0.6 were constructed on the basis of the mapping principle in the MARTINI force field [26]. The details of modeling and simulation are given in the Supplementary Material (S1.4). System A and system B are the CG MD simulation systems for the aggregation behavior of block and random copolymers in water, respectively.

2.5 All-atom MD simulations of the interaction between copolymers and collagen

The structures of PSMA25-b-PDMA15 (in system 1) and P(SMA-r-DMA)1:0.6 (in system 2) at the end of simulations were utilized as block and random copolymer models, respectively, to simulate the interaction between copolymers and collagen. A bimolecular collagen model (COL) built previously was used to simulate collagen [10]. The simulations were performed as previously reported [16], and the simulation details are presented in Table S3. The all-atom MD simulations of system 3 and system 4 were performed to investigate the mechanism of interaction between the copolymers and collagen.

2.6 Modification of CFs by copolymers

A total of 0.5 g of CFs was impregnated in a 50 mL copolymer solution (1.0 g/L), and the mixture was stirred at 40 °C and pH 4.0 for 2 h. The copolymer treated CFs were washed 4 times with distilled water and then dried in an oven at 40 °C for 24 h. The CFs modified with PSMA25-b-PDMA15, PSMA20-b-PDMA20, P(SMA-r-DMA)1:0.6 and P(SMA-r-DMA)1:1 were labeled as BP25-15-CFs, BP20-20-CFs, BP1:0.6-CFs and BP1:1-CFs, respectively.

2.7 Characterization of CFs

2.7.1 Structural characterization

The increase in total organic carbon (TOC) of CFs after modification with copolymers was utilized to characterize the binding amount of copolymer on CFs. The inorganic carbon (IC) and total carbon (TC) of CFs were determined using a TOC analyzer (Primacs ATC100-IC-E, Skalar, Netherlands), and TOC was calculated by subtracting IC from TC. In addition, TOC of CFs before and after copolymers modification was marked as TOCbefore and TOCafter. The increase in TOC of CFs was calculated by using Eq. (1).

The FT-IR spectra of the CFs samples were recorded in ATR mode using a FT-IR spectrometer (INVENIO-R, Bruker, Germany). X-ray photoelectron spectroscopic (XPS) characterization was performed to identify the chemical composition of CFs before and after copolymers treatment by using an X-ray photoelectron spectrometer (ESCALAB 250Xi, ThermoFisher, USA).

2.7.2 Morphological observation

The CFs samples were spray-coated with gold and observed using a field-emission scanning electron microscope (FESEM, Nova Nano SEM 450, FEI, USA) with an acceleration voltage of 15 kV.

2.7.3 Hydrophobicity determination

0.2 g of CFs samples was pressed on a glass slide, and the absorption time of CFs to a 5.0 µL water drop was measured using a goniometer system (DSA 30S, Krüss, Germany) under ambient conditions. The difference in the contact angle of water drop was also recorded over time.

The CFs samples were weighed and dried at 105 °C to constant weight (w0). Then the CFs samples were exposed to standard atmosphere (20 °C ± 2 °C, 65% ± 2% RH) and weighed at specific intervals (wt). Moisture sorption was determined as the mass of moisture absorbed per unit mass of absolute dry sample (mg/g) and calculated following Eq. (2). The moisture sorption experiment was continued for 120 min, and the moisture sorption curve was plotted.

3 Results and discussion

3.1 Structural characterization of copolymers

The structural characterization of the random copolymers was presented in our previous work [16]. Herein, the structure of the block copolymers was characterized. The FT-IR, 1H NMR, and GPC analyses shown in Supplementary Material (S2) indicate that the block copolymers were sucessfully synthesized. PSMA25-b-PDMA15 and P(SMA-r-DMA)1:0.6 exhibit similar molar ratio of SMA to DMA (approximately 1: 0.6), and PSMA20-b-PDMA20 and P(SMA-r-DMA)1:1 have similar molar ratio of SMA to DMA (approximately 1: 1.0). The block and random copolymers with similar monomer composition possess comparable Mn (Table S4), which is of great importance for studying the effect of sequential structure on the properties of copolymers.

3.2 Effect of the sequential structure of copolymer on its aggregation behavior

The TEM images shown in Fig. 1a indicate that the block copolymer nano-particles tend to aggregate while the random copolymer nano-particles are well dispersed. Although PSMA25-b-PDMA15 and P(SMA-r-DMA)1:0.6 were designed to exhibit similar monomer composition and molecular weight, the block copolymer has higher number-averaged hydrodynamic diameter (Dh) than the random copolymer (Fig. 1b). The same results can be obtained from Dh of PSMA20-b-PDMA20 and P(SMA-r-DMA)1:1, indicating that random copolymers have a smaller aggregate size and better dispersed state in water than block copolymers. The random copolymer has higher zeta potential than the block copolymer with similar monomer composition at the same pH (Fig. 1c), resulting in stronger intermolecular electrostatic repulsion and better dispersion of random copolymers than the block ones.

Moreover, the morphology of copolymer aggregates can be observed visually by MD simulation (Fig. 2). Fig. 2a shows the morphology of an individual copolymer molecule in water. In the case of the block copolymer PSMA25-b-PDMA15, the hydrophobic SMA block coils and forms a spheroid, while the hydrophilic DMA block remains in its initial state, i.e., long chain. For the random copolymer P(SMA-r-DMA)1:0.6, the hydrophilic DMA segments wrap around the hydrophobic SMA core to form a spheroidal structure. CG MD simulation was further conducted to simulate the aggregation behavior of 40 copolymer molecules in the aqueous phase (Fig. 2b). Given the presence of a long-chain hydrophilic DMA block in each PSMA25-b-PDMA15 molecule, the aggregation of 40 PSMA25-b-PDMA15 molecules results in the formation of a thick hydrophilic shell (red CG particle A and blue CG particle B). The random copolymer P(SMA-r-DMA)1:0.6 exhibits multimolecular aggregation behavior that is distinct from the block copolymer PSMA25-b-PDMA15. Only short DMA side chains aggregate into the hydrophilic shell in P(SMA-r-DMA)1:0.6. Therefore, the block copolymer aggregate possesses a thicker hydrophilic shell compared with the random copolymer aggregate. The block copolymer aggregate exhibits concentrated distribution of cationic DMA block, while the random copolymer aggregate shows dispersed distribution of cationic DMA segment.

a Snapshots of all-atom MD simulations of system 1 and system 2 (Copolymers are presented in Licorice style; SMA segments are colored in blue, DMA segments in orange, and the hydrogen protons are marked by green dot.); (b) Snapshots of CG MD simulations of system A and system B (Water molecules are colored in orange.)

3.3 Effect of the sequential structure of copolymer on its interaction with CFs

MD simulations of the interaction between copolymers and collagen are shown in Fig. 3. Two copolymer molecules in each system combine with COL at the end of all-atom MD simulations. In particular, 5 hydrogen protons (marked as green dots) of the protonated tertiary amine of PSMA25-b-PDMA15 electrostatically bind to the carboxylate ions of glutamic acid (GLU) and aspartic acid (ASP) on COL in system 3. Only 3 hydrogen protons of P(SMA-r-DMA)1:0.6 bind with the carboxylate ions of GLU on COL in system 4. This result indicates that COL is prone to combine with block copolymer rather than the random one through electrostatic interaction. Fig. 3c supports this point by illustrating higher electrostatic energy and Van der Waals energy between COL and PSMA25-b-PDMA15 than those between COL and P(SMA-r-DMA)1:0.6. Higher nonbonded interaction energy (the sum of electrostatic energy and Van der Waals energy) indicates more favorable contacts [27]. The nonbonded interaction energy between COL and PSMA25-b-PDMA15 is significantly higher than that between COL and P(SMA-r-DMA)1:0.6 (Fig. 3c). Therefore, COL achieves more favorable contacts with PSMA25-b-PDMA15 than with P(SMA-r-DMA)1:0.6. The block copolymer exhibits a larger size and more concentrated distribution of cationic DMA block than the random copolymer, resulting in easier contacts and stronger binding of the block copolymer with COL. Moreover, COL forms more H-bonds with PSMA25-b-PDMA15 than with P(SMA-r-DMA)1:0.6 (Fig. 3d).

Snapshots of all-atom MD simulations: (a) system 3 and (b) system 4 at 50 ns (Only the local morphology showing the interaction of COL and copolymers is presented; copolymers are presented in Licorice style, SMA segments are colored in blue, DMA segments are colored in orange and the hydrogen protons are marked by green dot; COL are presented in Cartoon style and colored in cyan; GLU and ASP in COL are presented in Surf and QuickSurf style, respectively); (c) Average energies between copolymer and COL from 35 to 50 ns; (d) Average number of H-bonds between COL and copolymer from 35 to 50 ns

The abovementioned findings of MD simulations indicate that block copolymer shows higher binding capacity on collagen than random copolymer, which was further validated by the experimental results. FT-IR spectroscopy was used to characterize the chemical structure of the CFs before and after copolymer modification. As illustrated in Fig. 4a, the intensities of the absorption bands at 2925 cm−1 and 2853 cm−1 of CFs are higher after copolymer modification because of the introduction of a large number of methylene groups in the copolymer. A new absorption peak at 1732 cm−1 in the FT-IR spectra of the copolymer treated CFs is attributed to the stretching vibration of C = O in the ester groups of the copolymer [28]. These results indicate the successful fixation of the copolymer on CFs. Fig. 4b shows that the increases in TOC of the CFs modified with block copolymers are significantly higher than those of the CFs modified with random copolymers with similar monomeric compositions, suggesting a higher amount of block copolymers bound on CFs. XPS characterization was also performed to investigate the chemical composition of CFs before and after copolymers modification. The carbon contents of CFs are notably increased after copolymer modification (Fig. 4c) because copolymers contain a large number of carbon atoms. Furthermore, BP25-15-CFs obtains more carbon contents than BP1:0.6-CFs, which is consistent with the results showing the increase in TOC of CFs (Fig. 4b). Three components, C − C (284.80 eV), C − O/C − N (286.14 eV), and O − C = O (288.15 eV), are found in the XPS high-resolution C1s spectra of CFs (Figs. 4f, g, h) [29, 30]. The relative intensity of the peak corresponding to C − C of modified CFs is significantly higher than that of initial CFs because of the introduction of copolymers with high amounts of long-chain alkyl groups. The O-C = O peak of CFs after copolymer modification is shifted because the copolymers are electrostatically bonded to the carboxyl groups of CFs by protonated tertiary amines (Figs. 3a, b). The O-C = O peak of BP25-15-CFs shows a larger shift than that of BP1:0.6-CFs, which also implies that the bound amount of block copolymer on CFs is more than that of the random one.

3.4 Effect of the sequential structure of copolymer on the hydrophobicity of modified CFs

The distribution and number-density of water around collagen (Fig. 5a) were extracted from the all-atom MD simulation results of the copolymer–collagen interaction to explore the effect of the sequential structure of copolymer on the hydrophobicity of collagen. More low water-density regions (in light cyan color) are found around the PSMA25-b-PDMA15 modified COL (System 3) in comparison with those around the P(SMA-r-DMA)1:0.6 modified COL (System 4). This phenomenon indicates that PSMA25-b-PDMA15 confers stronger surface hydrophobicity to COL than P(SMA-r-DMA)1:0.6. In addition, the absolute value of the non-bond interaction energy between PSMA25-b-PDMA15 modified COL and water molecules is lower than that between P(SMA-r-DMA)1:0.6 modified COL and water (Fig. 5b). The number of H-bonds formed between COL and water (Fig. 5c) and the number of water molecules bound to COL through H-bonds (Fig. 5d) show the tendency of System 3 < System 4. These results suggest that PSMA25-b-PDMA15 modified COL possesses lower water affinity than P(SMA-r-DMA)1:0.6 modified COL. In summary, MD simulations demonstrate that block copolymer endows collagen with higher hydrophobicity than the corresponding random one.

Furthermore, the hydrophobicity of CFs was characterized by the water drop absorption time and moisture sorption experiment. Based on the dynamic process of the water drop behavior (Fig. 6a), the water drop is completely absorbed into the unmodified CFs within 4 s due to the strong hydrophilicity of CFs. The absorption time of the water drop to copolymer modified CFs is significantly prolonged, indicating that the copolymers can transform the hydrophilic surface of CFs into a hydrophobic surface. This finding can be explained by the fact that copolymers can form a hydrophobic film on the surface of collagen fibrils (Fig. 7). A possible mechanism is that the hydrophilic DMA segments of the amphiphilic copolymer aggregates contact and bind with the hydrophilic fibril surface of CFs first, and then the copolymer aggregates may rearrange and expose the hydrophobic SMA segments to cover the fibrils. However, this conjecture needs further verification. Block copolymers exhibit a larger aggregate size and higher binding capacity with CFs compared with random copolymers, resulting in the formation of a thicker, denser, and more uniform hydrophobic film on the surface of fibrils. Thus, BP-CFs exhibit much higher water drop absorption time and lower equilibrium water adsorption capacity than RP-CFs (Figs. 6b, c), demonstrating that block copolymers confer higher hydrophobicity on CFs than random copolymers. This finding is consistent with the all-atom MD simulation results.

In addition, BP25-15-CFs show higher hydrophobicity (in terms of water drop absorption time and equilibrium water adsorption capacity) than BP20-20-CFs due to the longer hydrophobic block and larger particle size (Fig. 1b) of PSMA25-b-PDMA15 than PSMA20-b-PDMA20. However, the application of block copolymers in leather remains to be investigated because leather possesses a 3D hierarchical structure, and the penetration and fixation of block copolymers with large size in leather matrix may be more complicated than that in CFs.

4 Conclusion

Amphiphilic block copolymers using hydrophobic SMA and hydrophilic DMA were successfully synthesized via ATRP, and the corresponding random copolymers with similar monomer composition and Mn were prepared for comparison. TEM and DLS analyses reveal that the aggregate size of block copolymer was larger than that of random copolymer. MD simulations demonstrate that the block copolymer aggregate has a thicker hydrophilic shell and more concentrated distribution of cationic DMA block than the random copolymer aggregate. Block copolymer exhibits a higher bound amount on CFs than the random one when utilized for CFs modification, which validates the MD simulation result, that is, the binding capacity of block copolymer is superior to that of random copolymer. Moreover, block copolymers impart higher hydrophobicity to CFs than random copolymers by forming a thicker and more uniform hydrophobic film covering fibrils of CFs. This study highlights that the sequential structure of amphiphilic copolymers plays a crucial role in their hydrophobic modification effect on collagen fibers, providing valuable insights for enhancing the hydrophobicity of metal-free leather.

Availability of data and materials

All data from this study are presented in the paper.

Abbreviations

- SMA:

-

Stearyl methacrylate

- DMA:

-

2-(Dimethylamino)ethyl methacrylate

- ATRP:

-

Atom transfer radical polymerization

- PSMA-b-PDMA:

-

The block copolymers synthesized by using SMA and DMA

- P(SMA-r-DMA):

-

The random copolymers synthesized by using SMA and DMA

- CG MD simulation:

-

Coarse-grained molecular dynamics simulation

- CFs:

-

Metal-free tanned collagen fibers

- TOC:

-

Total organic carbon

- IC:

-

Inorganic carbon

- TC:

-

Total carbon

- COL:

-

A bimolecular collagen model

References

Fontaine M, Clement Y, Blanc N, Demesmay C. Hexavalent chromium release from leather over time natural ageing vs accelerated ageing according to a multivariate approach. J Hazard Mater. 2019;368:811–8.

Xu T, Jiang XF, Tang YL, Zeng YH, Zhang WH, Shi B. Oxidation of trivalent chromium induced by unsaturated oils: A pathway for hexavalent chromium formation in soil. J Hazard Mater. 2021;405:124699.

Hedberg YS. Chromium and leather: a review on the chemistry of relevance for allergic contact dermatitis to chromium. J Leather Sci Eng. 2020;2:20.

Zhu HL, Liu H, Tang KY, Liu J, Zheng XJ, Pei Y, Zhong J. Optimization of dialdehyde soluble soybean polysaccharide: preparation by response surface methodology for cleaner leather tanning. RSC Adv. 2022;12:7506–15.

Liang S, Wang XC, Hao DY, Yang J, Dang XG. Facile synthesis of a new eco-friendly epoxy-modified oligomeric chitosan-based chrome-free tanning agent towards sustainable processing of functional leather. Process Saf Environ Prot. 2023;172:753–63.

Li J, Yan L, Shi B, Li B, Zhang J. A novel approach to clean tanning technology. J Chem Eng. 2013;7:1203–12.

Wei C, Wang XC, Wang WN, Sun SW, Liu XH. Bifunctional amphoteric polymer-based ecological integrated retanning/fatliquoring agents for leather manufacturing: Simplifying processes and reducing pollution. J Clean Prod. 2022;369:133229.

Liu XH, Wang WN, Wang XC, Sun SW, Wei C. A “Taiji-Bagua” inspired multi-functional amphoteric polymer for ecological chromium-free organic tanned leather production: Integration of retanning and fatliquoring. J Clean Prod. 2021;319:128658.

Ngwabebhoh FA, Sáha T, Stejskal J, Trchová M, Kopecký D, Pfleger J. Conducting polypyrrole-coated leathers Prog Org Coat. 2023;179:107495.

Sun QY, Zeng YH, Yu Y, Wang YN, Shi B. An exploration of enhancing thermal stability of leather by hydrophilicity regulation: effect of hydrophilicity of phenolic syntan. J Leather Sci Eng. 2022;4:22.

He X, Huang YW, Xiao HZ, Xu XZ, Wang YJ, Huang X, Shi B. Tanning agent free leather making enabled by the dispersity of collagen fibers combined with superhydrophobic coating. Green Chem. 2021;23:3581–7.

Xu SF, Xiao HZ, Shi B. The improvement of dispersity, thermal stability and mechanical properties of collagen fibers by silane modification: an exploration for developing new leather making technology. J Leather Sci Eng. 2022;4:26.

Du JX, Huang C, Peng BY. Influence of hydrophobic side chain structure on the performance of amphiphilic acrylate copolymers in leather-making. J Soc Leather Technol Chem. 2016;100:67–72.

Du JX, Shi L, Peng BY. Amphiphilic acrylate copolymer fatliquor for ecological leather: Influence of molecular weight on performances. J Appl Polym Sci. 2016;133:43440.

Wang YN, Hu LY. Essential role of isoelectric point of skin/leather in leather processing. J Leather Sci Eng. 2022;4(1):25.

Yi YD, Sun QY, Li QJ, Shi B, Wang YN. Cationic amphiphilic acrylic copolymer retanning agent for metal-free eco-leather production. Prog Org Coat. 2024;187:108109.

Yi YD, Li QJ, Sun QY, Wang YN, Shi B. Aggregation behavior of cationic amphiphilic polymers and their application in metal-free leather retanning. Polymer. 2024;295:126738.

Fortney A, Tsai CH, Banerjee M, Yaron D, Kowalewski T, Noonan KJT. Impact of precise control over microstructure in thiophene–selenophene copolymers. Macromolecules. 2018;51(23):9494–501.

Li XH, Liang SN, Wang WJ, Li BG, Luo YW, Zhu SP. Model-based production of polymer chainshaving precisely designed end-to-end gradient copolymer composition and chain topology distributions in controlled radical polymerization, a review. Macromol React Eng. 2015;9(5):409–17.

Matyjaszewski K. Advanced materials by atom transfer radical polymerization. Adv Mater. 2018;30(23):1706441.

Guo HL, Guo QQ, Lan TY, Luo YJ, Pan XH, Yao YF, Li YF, Feng Y, Liu YJ, Tao L, Shen XC. Amphiphilic block versus random copolymer nanoparticles with reactive oxygen species responsiveness as berberine vehicles. J Biomater Sci Polym Ed. 2021;32(13):1657–77.

Shao Y, Jia YG, Shi CY, Luo JT, Zhu XX. Block and random copolymers bearing cholic acid and oligo(ethylene glycol) pendant groups: aggregation, thermosensitivity, and drug loading. Biomacromol. 2014;15(5):1837–44.

Guo QQ, Zhang TQ, An JX, Wu ZM, Zhao Y, Dai XM, Zhang XG, Li CX. Block versus random amphiphilic glycopolymer nanopaticles as glucose-responsive vehicles. Biomacromol. 2015;16(10):3345–56.

Ma ZY, Jia YG, Zhu XX. Glycopolymers bearing galactose and betulin: synthesis, encapsulation, and lectin recognition. Biomacromol. 2017;18(11):3812–8.

Ahmed M, Narain R. The effect of polymer architecture, composition, and molecular weight on the properties of glycopolymer-based non-viral gene delivery systems. Biomaterials. 2011;32(22):5279–90.

Marrink SJ, Risselada HJ, Yefimov S, Tieleman DP, de Vries AH. The MARTINI force field: Coarse grained model forbiomolecular simulations. J Phys Chem. 2007;111(27):7812–24.

Li NK, Xie YX, Yingling YG. Insights into structure and aggregation behavior of elastin-like polypeptide coacervates: all-atom molecular dynamics simulations. J Phys Chem. 2021;125(30):8627–35.

Proietti N, Di Tullio V, Carsote C, Badea E. 13C solid-state NMR complemented by ATR-FTIR and micro-DSC to study modern collagen-based material and historical leather. Magn Reson Chem. 2020;58(9):840–59.

Du D, Wang K, Wen Y, Li Y, Li YY. Photodynamic graphene quantum dot: Reduction condition regulated photoactivity and size dependent efficacy. ACS Appl Mater Interfaces. 2016;8(5):3287–94.

Sun SW, Wang XC, Zhu X, Liu XH, Guo PY, Tian YY. Synthesis of an amphiphilic amphoteric peptide-based polymer for organic chrome-free ecological tanning. J Clean Prod. 2022;330:129880.

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China (22278280). The authors would like to thank Chun Xu for her help with FESEM analysis.

Funding

This work was financially supported by the National Natural Science Foundation of China (22278280).

Author information

Authors and Affiliations

Contributions

YY: Conceptualization, Methodology, Investigation, Writing—original draft. XF: Formal analysis. QL: Validation. YW: Supervision, Funding acquisition, Conceptualization, Writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

Ya-nan Wang serves as the Associate Editor-in-Chief of Collagen and Leather, and he was not involved in the editorial review, or the decision to publish this article. All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yi, Y., Fan, X., Li, Q. et al. Amphiphilic block and random copolymers: aggregation and hydrophobic modification on metal-free tanned collagen fibers. Collagen & Leather 6, 20 (2024). https://doi.org/10.1186/s42825-024-00163-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-024-00163-9