Abstract

The study investigates the potential of anaerobic co-digestion (AcoD) as a sustainable solution for managing putrescible organic waste generated by leather processing. Three experiments were conducted to assess the impact of various tannery wastes, pretreatment methods, and waste combinations on methane production. Experiment 1 demonstrated that co-digesting tannery wastewater primary sludge (TWPS) and fleshings significantly increased methane yield compared to digesting TWPS alone, though the addition of chromium- and vegetable-tanned leather wastes decreased yield. Experiment 2 explored TWPS pretreatment methods and found that ultrasonic pretreatment increased soluble chemical oxygen demand (SCOD) but did not significantly improve methane yield, suggesting that pretreatment may not be necessary. Experiment 3 revealed that increasing the proportion of fleshings to TWPS resulted in higher methane yield, ranging from 226.52 mL/gVS with 6% fleshings to 395.71 mL/gVS and 538.34 mL/gVS with 12% and 20% of fleshings, respectively. Additionally, this increase in fleshings also led to a reduction in digester volume. These findings highlight the importance of AcoD in addressing both environmental and economic challenges in the leather industry.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.1 Introduction

Industrial processes produce a diverse array of wastes characterized by varying physical properties and chemical compositions throughout different processing stages. Within the tannery industry, leather manufacturing involves a series of mechanical operations and chemical reactions, typically divided into three stages: beamhouse, tanning, and finishing. The beam-house stage, generating approximately 80% of total organic wastes, is composed of dirt, hair, epidermis, non-collagenous proteins, and grease extracted from rawhide and skin [1]. In the tanning process, which contributes to 19% of total organic wastes, tanning agents (e.g., vegetable tannins or chromium sulfate applied at 30% or 3% of the weight of the hide, respectively [2]) cross-link the collagen matrix and stabilize the protein [1, 3]. The global solid wastes generated from processing 15 million tons of hides and skins per year are estimated to be around 6 million tons, with 5 million tons of sludge presenting a significant challenge in many countries [4]. Traditionally, this sludge is disposed of in landfills or incinerated [5]. These wastes, containing organic, inorganic, and nitrogenous compounds, along with ions like chromium, sulfide, and salts, are highly polluting and putrescible [6].

The challenge of global warming and the rise in greenhouse gas emissions have instigated a fundamental shift in the management of industrial waste. Consequently, certain countries engaged in leather production have initiated measures to tackle environmental concerns associated with traditional tannery waste management, proposing cleaner and eco-friendly approaches. In Brazil, for instance, controlled incineration of chromium-tanned wastes and the implementation of constructed wetlands for effluent treatment have been adopted. In China and Spain, membrane bioreactors employing reverse osmosis have been utilized for the recovery and reuse of tannery wastewater [4]. Furthermore, laboratories have conducted studies exploring mechanical, chemical, and biological methods to recycle solid wastes from the tannery industry. For instance, Yoseph et al. [7], successfully recovered elastin from raw trimming wastes using a thermo-chemical process, achieving an impressive 90% yield. Additionally, research indicates the potential for utilizing solid tannery wastes to recover keratin, adhesive, gelatin, protein flavor, and reconstituted collagen [8, 9]. Anaerobic digestion (AD) is an alternative, robust, and cost-effective process for converting organic waste into biogas, a potential energy source. The synergy between bacteria (acidogens and acetogens) and archaea (methanogens) has proven highly effective in treating complex industrial wastes, including but not limited to crude glycerol, meat and bone meal, and food processing wastes [10,11,12]. Despite the presence of AD inhibitors in tannery solid wastes, such as chromium, salts, and tannins, multiple studies have demonstrated the viability of employing AD in the management of tannery solid waste [13,14,15]. As outlined by Agustini et al. [16], AD treatment of tannery solid wastes has proven advantageous for the tannery industry. The AD process has contributed to electricity production, reaching up to 6.8%, and has replaced 1.6% of hot water in leather processing, resulting in significant cost savings related to waste disposal. Tannery organic wastes have been co-digested either with other organic wastes, such as slaughterhouse sludge [17] and vegetable wastes [14], or among themselves [13, 15]. However, it is essential to note that not all tannery solid wastes, such as chromium- and vegetable-tanned leather wastes, may be suitable for anaerobic co-digestion (AcoD) due to their high concentration of AD inhibitors. Therefore, further research is required to elucidate the specific contributions of each tannery solid waste in the context of AcoD.

Tannery wastewater primary sludge (hereinafter referred to as TWPS) accounted for more than 90% of all tannery solid wastes (Table 1). However, this material was challenging to biodegrade, containing a high concentration of inorganic compounds [18]. Thus, effective pretreatment of the TWPS was deemed crucial as a strategy to enhance its soluble chemical oxygen demand (COD). Notably, Kameswari et al. [19] demonstrated that ultrasonic pretreatment of TWPS increased soluble COD and biogas production by 85% and 53%, respectively. Despite its effectiveness, the drawback of ultrasonic pretreatment lies in its high energy consumption [20]. Given this, a comparative study investigating the impacts of ultrasonic and alternative pretreatment methods, such as thermal and thermobaric pretreatments, on TWPS was warranted due to the limited information on TWPS pretreatment. Additionally, achieving a balance between TWPS and fleshings (i.e., animal flesh and natural fats from hides and skins [21]) was crucial for enhancing methane yields, prompting further investigation, as it significantly influenced bioreactor volume and overall investment cost [19]. This study introduces a novel approach by delving into the authentic real-world waste proportions obtained directly from tanneries and conducting various pretreatment methods, considering their financial implications. By incorporating the actual ratios of tannery solid wastes, including TWPS and fleshings, the research aims to provide a more accurate representation of the challenges and opportunities inherent in anaerobic co-digestion (AcoD) processes. Additionally, the study explores the financial impacts associated with different substrates combination scenarios. This emphasis on real-world conditions and financial considerations contributes a practical dimension to the study, offering valuable insights that can guide decision-making processes for sustainable waste management strategies in the leather processing industry. Specifically, this research initiatively focused on identifying the optimal strategy for treating tannery solid wastes in the AcoD process. The research comprised three distinct experiments, each serving a unique purpose. The first experiment sought to determine the suitability of each waste for AcoD, followed by the second experiment, which explored the effects of TWPS pretreatment (thermal, thermobaric, and ultrasonic) on AcoD for both TWPS and fleshings. The third experiment focused on evaluating the impact of the TWPS-to-fleshings mixture ratio on AcoD for both components. By systematically investigating these three scenarios, the study presented key solutions for the AcoD of wastes from leather processing, providing a sustainable tannery processing approach and valuable and applicable insights to inform decision-making processes.

2 Materials and methods

2.1 Feedstock materials and inoculum

The leather processing solid wastes used in this study were tannery wastewater primary sludge (TWPS), leather fleshings (LF), chromium-tanned leather wastes, and vegetable-tanned leather wastes, which were obtained from a leather processing company located in Hyogo Prefecture, Japan. The yearly production of each waste was 182.5 tons, 12 tons, 3.1 tons, and 3.1 tons for TWPS, fleshings, chromium- and vegetable-tanned leather wastes, respectively (Table 1). The characteristics of tannery organic wastes used in this study are listed in Table 1. The inoculum (total solids: 1.37%, volatile solids: 1.13%, pH: 7.71) was collected from an active biodigester treating food waste. The inoculum was conditioned to mesophilic temperatures (35℃) until the cessation of gas production before its utilization in this experiment.

2.2 Experimental setup

In the tannery industry, TWPS represents a significant majority of tannery wastes, accounting for over 90%, according to Table 1. Consequently, our study aimed to explore the optimal conditions for AD of tannery solid wastes, exploring various scenarios of AcoD involving TWPS. To achieve this goal, three sets of batch experiments were conducted. In the first experiment, the AcoD of various tannery solid wastes was compared to the digestion of TWPS alone. Specifically, four treatments (T1, T2, T3, and T4) were tested, where T1 was the control digester fed only with TWPS. In digester T2, TWPS was co-digested with fleshings at a ratio of 15:1. In T3, chromium-tanned leather waste was introduced to TWPS and fleshings at ratios of 0.25:15:1. Ultimately, in T4, vegetable-tanned leather waste was added, resulting in a ratio of 15:1:0.25:0.25 for TWPS: fleshings: chromium-tanned waste: vegetable-tanned waste, respectively. The allocation of each substrate to its respective treatment was determined based on the actual weight ratio of wastes generated in the leather processing industry, as listed in Table 1. The second experiment explored the impact of TWPS pretreatment on the AcoD of both TWPS and fleshings. In this experiment, the biodegradability of TWPS was examined using three pretreatment methods: thermal, thermobaric, and ultrasonic pretreatments. For thermal pretreatment, TWPS was heated at 80℃ for 15 min using a water bath. Thermobaric pretreatment was carried out in an autoclave LBS-352 (Tomy, Japan) at 100 mbar and 121℃ for 15 min. Ultrasonic pretreatment was performed using Yamato 2510 J-MTH (Bransonic, USA) at 40 Hz for 30 min. The pretreated TWPS was subsequently mixed with fleshings at a ratio of 15:1. A control digester (T5) was established where the TWPS underwent no pretreatment. In T6, T7, and T8, fleshings were co-digested with TWPS that had undergone thermal, thermobaric, and ultrasonic pretreatments, respectively.

The third experiment determined the effects of different TWPS-to-fleshings ratios on the AcoD of both TWPS and fleshings, building on the best-performing conditions identified in experiments 1 and 2. In experiment 3, maintaining a consistent organic loading rate, the TWPS-to-fleshings ratios were adjusted to 7:1 and 4:1, based on weight, in T10 and T11, respectively. The control digester (T9) was similar to T2 where the TWPS to fleshings ratio was 15:1.

In all experiments, 500 mL serum bottles sealed with rubber sleeve stoppers were used, each containing a working volume of 300 mL. The digesters were filled with 200 mL of inoculum and 100 mL of diluted substrate, maintaining an inoculum-to-substrate ratio of 2:1 (gVS: gVS), and were kept in water baths at a constant temperature of 35℃.

The experimental design, inclusive of the actual substrate quantities added, is outlined in Table 2. Regular measurements were taken for biogas volumes and compositions. Aliquots of samples were taken from the digesters before and after the digestion process to analyze total solid contents (TS), volatile solid contents (VS), soluble (SCOD) total chemical oxygen demand (TCOD), and pH.

2.3 Analytical procedure

TS and VS measurements were conducted following standard methods (part 2540G) as outlined in APHA (2005). The pH levels were determined using a Horiba D-55 pH meter. COD was assessed using a HACH DR3900 (USA). Biogas compositions were determined using a GC-2014 (Shimadzu, Japan) and Biogas 5000 (Geotech, UK). GC-2014 was equipped with a thermal conductivity detector, featuring a stainless column and Porapak Q packing. Operational temperatures for the injector port, column, and detector were set at 220 °C, 150 °C, and 220 °C, respectively. Argon served as the carrier gas with a flow rate of 50 mL/min.

2.4 Data analysis

2.4.1 Critical retention time

The Chen and Hashimoto model (Eq. (1)) [22] was employed, representing a modified Contois model. This model facilitated the determination of critical hydraulic retention time (T critical, d), the maximum specific growth rate of microorganisms (µ max, d−1), and Chen and Hashimoto kinetic constant (k CH, dimensionless).

where T is the hydraulic retention time (d). From Eq. (1), T can be obtained as a function of M p(t)/(M 0 -M p(t)) (Eq. (2)) with k CH/µ max and 1/µ max are the slope and intercept, respectively. The intercept of Eq. (2) is the same as T critical when biomass washout takes place.

2.4.2 Kinetic studies of methane yields

The first-order kinetic model (Eq. (3)) was introduced to estimate the predicted methane yield (M 0) and hydrolytic rate constant (k) assuming that substrate hydrolysis was the rate-limiting step [23]. When Eq. (3) was logarithmized (Eq. (4)), a straight line would be obtained against time and showed the value of the slope, which was equal to the hydrolysis rate constant.

where t (d) is the time, M 0 (L/gVS) is the cumulative methane yield, M p(t) (L/gVS) is the methane yield obtained at time t, and k is the hydrolysis rate constant.

The modified Gompertz model (Eq. (5)) was developed assuming that bacterial growth was the rate-limiting step of the AD [24]. It was used to estimate M 0, maximum specific methane production rate (R max), and lag phase (λ), which were essential parameters for the design of a biodigester, process improvement, and long-term operation of the AD. All kinetic parameters were estimated using the least squares method of the Solver Function of Microsoft® Office Excel 2016.

where R max is the maximum specific methane production rate (L/gVS); λ is the lag phase time (d); e, the Euler’s number, = 2.71828.

Significant differences were assessed through analysis of variance using STATA version 12.0 (StataCorp, LP, USA). Statistical significance was established at p-values below 0.05.

3 Results and discussions

3.1 Performance of anaerobic co-digestion of solid wastes in tannery processing

Figure 1a and b depict the daily methane yield and the normalized cumulative methane yield concerning the anaerobic mono-digestion of TWPS (T1), while Table 3 displays the overall digestion performances. T1 exhibited the earliest peak in daily methane yield on day 11, with T2 reaching the highest peak on day 17. In contrast, both T3 and T4 experienced peaks on day 23 (Fig. 1a). This observation suggests that the addition of fleshings to the AD of TWPS resulted in a delay in methane production, and the inclusion of chromium- and vegetable-tanned leather wastes (T3 and T4) further extended this delay. This was also confirmed by the increase of T critical from 5.93 d in T1 to 10.56 d in T2, and 12.72 d and 13.53 d in T3 and T4, respectively (Table 3). Despite the delayed daily methane yield in T2, co-digestion of TWPS with fleshings enhanced methane production, reaching the highest daily methane yield of 54.55 mL/gVS in T2, which was 3.11 times higher than that in T1. However, the introduction of chromium- and vegetable-tanned leather wastes resulted in a reduction of daily methane yield peaks by 2.58% in T3 and 10.23% in T4 compared to T2.

The performance of the anaerobic co-digestion of solid wastes produced from a tannery processing industry: daily methane yield (a), normalized cumulative methane yield (b), volumetric production of methane per mass of substrate (c), and volumetric production of methane per cubic meter of reactor (d).

Figure 1b shows that the normalized cumulative methane yield from T1 was surpassed by T2, T3, and T4 on days 13, 17, and 19, respectively. In addition, T2 achieved the highest methane yield (226.52 mL/gVS), which was 5.74 times that of T1 (Table 3). Moreover, Table 4 confirms that T1 exhibited the lowest soluble COD removal compared to T2–T4 digesters. Despite the decrease in methane yield due to the presence of chromium- and vegetable-tanned leather wastes, T3 still exhibited a methane yield comparable to T2, while T4 had a 16% lower methane yield than T2 (Table 3). The volumetric production of methane concerning substrate mass (Fig. 1c) and reactor volume (Fig. 1d) confirmed that TWPS co-digested with fleshings improved digestion performance, while the addition of chromium- and vegetable-tanned leather wastes decreased digestion performance. These findings are confirmed by the volatile fatty acid (VFA) contents shown in Fig. 2. Specifically, the VFA values after AD tests, particularly acetic acid, were lowest in T2 compared to T3 and T4. This residual VFA may indicate a lower conversion of VFA into methane. Furthermore, the soluble COD reduction rate was highest in T2 compared to T3 and T4 (Table 4)

Anaerobic co-digestion has proven to be an effective method for managing solid wastes from tanneries. Typically, TWPS constitutes approximately 90% of the total solid wastes in the leather processing industry, and its biodegradability is limited, as indicated by a VS/TS ratio of 0.62 (Table 1). Consequently, it is often utilized as the primary substrate in combination with fleshings [25]. T1 had a low methane yield due to a high amount of inorganic material, accounting for 60–70% of the TWPS [18]. On the other hand, the improved methane yield in T2 was attributed to the characteristics of fleshings and the potential synergistic effects of the TWPS-fleshings mixture. Fleshings, being an easily biodegradable substrate with a VS/TS ratio of 0.85, consists of protein (7% of dry matter) and lipid (90–92% of dry matter) [18]. Both components have high theoretical methane yields (0.50 L/gVS for protein and 1.01 L/gVS for lipid) [11]. However, the introduction of chromium- and vegetable-tanned materials in T3 and T4 resulted in a reduction in cumulative methane yields. Chromium is known to enhance TWPS biodegradability at low concentrations (below 7.6 mg/L), thus promoting biogas production [25]. However, at high concentrations, chromium becomes detrimental to microorganisms due to its ability to permeate cell membranes and react with intracellular biomolecules [26]. Furthermore, due to the presence of phenolic organic matter (around 22%) [25], vegetable tannin was found to be more toxic to anaerobic microorganisms than chromium. This observation might elucidate the further reduction in methane yield in T4 compared to that in T3.

In this study, the decrease in methane yield with the addition of chromium- and vegetable-tanned leather wastes in T3 and T4 rendered these wastes unsuitable for the AcoD. As a result, chromium- and vegetable-tanned leather wastes were excluded from experiments 2 and 3. However, it is worth noting that further detanning of these wastes may render them suitable for AcoD or they could be repurposed for the production of other leather by-products [18].

3.2 Effects of primary sludge pretreatment on co-digestion with fleshings

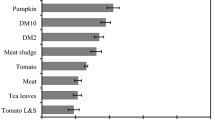

The findings from digester T1 indicated a low methane yield from TWPS. To improve methane production, three pretreatment methods—thermal, thermobaric, and ultrasonic pretreatments—were applied to the TWPS. The results presented in Fig. 3 illustrated that thermal pretreatment reduced soluble COD compared to untreated TWPS, while thermobaric pretreatment showed no significant impact on soluble COD. In contrast, ultrasonic pretreatment led to a 29% increase in soluble COD compared to untreated TWPS (Fig. 3a). This aligns with previous studies indicating that ultrasonic pretreatment enhances TWPS biodegradability in comparison to other methods like alkaline and hydrogen peroxide [27]. The elevated soluble COD following ultrasonic pretreatment could be attributed to cavitation and chemical reactions within the TWPS, causing the disintegration of cell walls and floc matrices and the release of intracellular organic substances [28, 29]. On the other hand, the low soluble COD with thermal pretreatment might be a result of the volatilization of soluble organic matter due to the elevated temperature applied [27].

In successful AD, an increase in methane yield typically correlates with a rise in soluble COD. Figure 4a illustrates that methane production proceeded faster in T7 and T8 compared to T5, while T6 experienced a delay. The accelerated methane production in T8 was attributed to the higher soluble COD of TWPS pretreated with ultrasonic compared to untreated TWPS (Fig. 3; Table 4). Despite thermobaric pretreatment resulting in similar soluble COD levels as untreated TWPS, the faster methane production in T7 suggested a change in the physico-chemical characteristics induced by thermobaric pretreatment. Conversely, the low soluble COD following thermal pretreatment caused the delay in methane production in T6 compared to T5. The soluble COD removal was highest in T5 (65.62%) compared to 63.09% for T6 and 62.96% for T7, as shown in Table 4, indicating better conversion into methane. Additionally, despite the rapid methane production in T8 (Fig. 4a) and a 66.66% reduction in soluble COD in T8 (Table 4), the normalized cumulative methane yield in T5 was 1.07-, 1.12-, and 1.20-fold higher than in T8, T7, and T6, respectively. This suggests that the TWPS pretreatment applied in this study proved ineffective in improving cumulative methane yield. This conclusion is supported by the volumetric methane production depicted in Fig. 4c and d. Furthermore, the VFA results after AD tests in Fig. 2 revealed that T5 had lower values than T6–T8, further supporting the findings of lower methane content, as VFA is partially converted into methane. The differences in pH values for the T5–T8 experiments remained minor over the digestion times, as depicted in Fig. 5. This suggests that these variations likely did not significantly affect the digestion process.

Several studies have demonstrated that pretreatment of TWPS can enhance methane yield by increasing the hydrolysis rate [30]. For instance, in a study by Kameswari et al. [19], ultrasonic pretreatment of sludge improved methane yield by 53%, a result not indicated in this study. The difference may be attributed to variations in the physico-chemical characteristics of the sludge used. Despite the increase in soluble COD with ultrasonic pretreatment (Fig. 3) and soluble COD reduction rate (Table 4), the methane yield was lower compared to that without pretreatment. This suggests that ultrasonic pretreatment did not introduce more biodegradable compounds to the sludge but instead altered the characteristics of organic compounds, leading to an increase in soluble COD. In support of this conclusion, Kim et al. [31] conducted a study utilizing ultrasonic treatment (5–60 min of irradiation) on sludge before anaerobic digestion to assess its impact on methane production. They found that while the solubilization of sludge increased with longer ultrasonic treatment, methane production didn’t consistently rise in correlation. This discrepancy was due to the lower methane yield observed from the soluble fraction. Initially, only 6% of the raw sludge was soluble, with 75.4% of it converted to methane. This contradicts the expectation that most soluble fractions can be converted to methane. However, with 5 min of ultrasonication, methane yield from the soluble fraction increased to 94%, but this decreased with longer treatment times. The authors demonstrated that certain soluble matter generated by pretreatment might not be convertible to methane [31]. Additionally, ultrasound propagation induces both pressure and tension effects. Pressure forces granular sludge to aggregate, while tension separates ions, resulting in the formation of cavitation bubbles within the tension zone. These tiny bubbles progressively expand and eventually collapse, generating shock waves characterized by instantaneous high temperature and pressure [32]. The mechanical shear and jets produced by these shock waves lead to the rupture of sludge cell membranes, concurrently generating free radicals. These highly reactive free radicals readily engage with the organic constituents in sludges, initiating the degradation of macromolecules [32]. However, additional studies are necessary to investigate the impact of ultrasound treatment on solubilizing sludges, the generation of free radicals, and the subsequent methane production from leather sludges. This includes exploring various intensities and durations of irradiation to better understand their effects. Equations 6, 7, 8 and 9 illustrate the reaction mechanism for free radicals generated by ultrasound irradiations [32, 33].

Consequently, the exclusion of TWPS pretreatment in the subsequent experiment underscores a strategic shift in focus. Experiment 3 aims to assess the impact of the TWPS-to-fleshings ratio on methane yield, prioritizing the optimization of the anaerobic digestion process for tannery solid wastes. This approach not only emphasizes environmental sustainability but also strives for increased economic viability, steering the study towards more effective and practical solutions for waste management in the tanning industry.

3.3 Anaerobic co-digestion performance at different sludge-to-fleshings ratios

In general, both the daily methane yield and the normalized cumulative methane yield demonstrated an increase with higher concentrations of fleshings. Specifically, Fig. 6a reveals that daily methane yield peaks occurred uniformly on day 17, with values of 54.55, 74.81, and 118.48 mL/gVS for T9, T10, and T11, respectively. Although T10 exhibited a lower cumulative methane yield than T9 between days 8 and 14 (Fig. 6b), the overall cumulative methane yield for T10 was 395.71 mL/gVS (Table 3), representing a 1.74-fold increase compared to T9. T11 achieved the highest methane yield, surpassing T9 and T10 by 2.38- and 1.36-fold, respectively. This is supported by the findings of VS and soluble COD reduction rates of 64.55%, 69.29%, and 72.37% for T9, T10, and T11, respectively, as illustrated in Table 4. Additionally, the volumetric methane production, based on reactor volume (Fig. 6d), aligned with the cumulative methane yield. However, the highest volumetric methane production per unit mass of substrate (Fig. 6c) was in T10 (63.4 m3/m3 Substrate), marking a 3.05-fold increase over T9 and a 1.10-fold increase over T11.

Anaerobic co-digestion stands out as one of the most prevalent methods for boosting methane yield, offering advantages such as balancing the carbon/nitrogen ratio and fostering substrate synergism. Given the high content of inorganic materials and the presence of tannin agents inhibiting methanogenic activities in TWPS [25], the co-digestion of TWPS with fleshings becomes crucial. This approach not only increases the biodegradable compounds in the digester but also mitigates the inhibitory effects on microorganisms, thus improving the anaerobic digestion (AD) of tannery solid wastes. The observed improvement in methane yield with an increasing fleshings ratio can be attributed to the characteristics of fleshings, known for being generally tannin-free and predominantly composed of lipids and protein [18]. However, at high fleshings concentrations (T11), the volumetric production of methane per mass of substrate decreased, suggesting that a portion of fleshings was likely challenging to digest and required a longer digestion time (T critical was 13.31 d in T10 vs. 13.91 d in T11, as listed in Table 3).

The increased methane yield with adding fleshings is essential for enhancing the economic viability of anaerobic digestion for tannery solid wastes. However, it was worth noting that at a constant fleshings concentration, an increase in fleshings led to a decrease in the quantity of TWPS available for co-digestion. Consequently, the remaining TWPS, which was not utilized in the anaerobic co-digestion (AcoD), necessitated additional treatment. Therefore, further investigation is warranted in continuous feeding experiments, as an elevated fleshings concentration may result in volatile fatty acid accumulation, a phenomenon not observed in batch experiments (total volatile fatty acids after AcoD were less than 100 mg/L).

3.4 Kinetic modeling of methane yields

Table 5 presents the results of kinetic studies on methane yields, The coefficients of determination (R2) for the first-order kinetic model ranged from 0.696 to 0.966, indicating a multiphasic profile in certain methane productions [34], particularly evident in experiments 1 and 3. Co-digestion of TWPS and fleshings reduced k from 0.168 to 0.158 d−1 in experiment 1, with a further decrease observed upon the addition of chromium- and vegetable-tanned leather wastes. In experiment 2, TWPS pretreatment did not influence k, while in experiment 3, the increase in the fleshings ratio decreased k from 0.158 d−1 in T9 to 0.096 and 0.123 d−1 in T10 and T11, respectively.

Methane yield fitting with the modified Gompertz model yielded R2 values between 0.98 and 0.99, indicating a good fit with the regression model. This was further confirmed by the marginal difference (Diff.) between the estimated M 0 and the measured values, which ranged between 1 and 5%. In experiment 1, the shortest λ was 6.78 d in T1, while the addition of fleshings in T2 increased λ to 10.71 d, further extending to 15.05 and 16.94 d in T3 and T4, respectively. This suggests that the addition of fleshings altered the digester environment, necessitating an extended adaptation period for microorganisms to acclimate to the lipid- and protein-rich substrate [18]. The increased protein and lipid contents in the digester might slow down the digestion process, as these components are known to be less digestible compared to elements such as starch [35]. With chromium- and vegetable-tanned leather wastes, the toxic effect of the tannin agents might lead to higher λ. In experiment 2, thermal pretreatment resulted in the longest λ, likely due to the low soluble COD resulting from the volatilization of soluble organic matter. For the thermobaric and ultrasonic pretreatments, the λ was comparable to that in the control indicating that pretreatment did not remarkably improve TWPS hydrolysis. Similarly, in experiment 3, despite the increase in fleshings from 12 to 20% in T10 and T11, λ remained almost similar. This suggests that for up to 20% of fleshings, the hydrolysis of the co-digestion of fleshings with TWPS might not be significantly influenced. Nevertheless, the increase in fleshings ratio significantly elevated Rmax from 13.54 mL/gVS in T9 to 22.85 and 35.71 mL/gVS in T10 and T11, respectively, contributing to enhanced methane yields in these digesters.

In short, the kinetic modeling of methane yields played a crucial role in assessing the suitability of tannery solid wastes for the AcoD process. Furthermore, it offered additional insights into the rationale behind the increased methane yields with a rising fleshings ratio, aligning well with the enhancement observed in R max.

3.5 Key financial strategies for optimizing anaerobic co-digestion in tannery solid waste management

Anaerobic digestion has proven to be a viable alternative for effectively treating tannery solid wastes, offering a sustainable solution to the industry’s waste management challenges. However, the use of tanning agents during leather processing imposes limitations on some tannery solid wastes, particularly chromium and vegetable-tanned leather, due to their adverse effects on anaerobic microbial populations at elevated concentrations. This study reinforces that these specific leather wastes are not suitable for anaerobic digestion treatment. Alternative methods, such as the production of extracted elastin, gelatin, and reconstituted collagen, have been proposed for these wastes [7,8,9]. Additionally, exploring ways to remove chromium from tannery wastes could render them more amenable to anaerobic digestion; however, this requires careful consideration of associated costs and technological applications.

Fleshings, among the various tannery solid wastes, have demonstrated a significant contribution to methane production, with the TWPS/fleshings ratio influencing methane yield. Optimizing the TWPS/fleshings ratio is critical for maximizing methane yield in AcoD of tannery solid wastes. Table 6 outlines three scenarios with varying TWPS/fleshings ratios. In scenario 1, reflecting actual waste production, the entire TWPS and fleshings produced from leather processings were assumed to be treated in anaerobic digestion. Scenarios 2 and 3 increased the concentration of fleshings to 12% and 20%, respectively, while concurrently reducing the concentration of TWPS. In scenario 1, utilizing the entire TWPS and fleshings necessitated an estimated digester volume of 80 m3, resulting in an anticipated biogas production of 5,662 m3/yr. This production could yield a total primary energy output of approximately 34 MWh/yr, given that 1 m3 of biogas possesses a calorific value of 6 kWh [36]. With a conversion rate of 35% for primary energy to electricity and 42% for thermal energy [37], the estimated electricity and thermal energy were 12 and 15 MWh/yr, respectively. Despite reducing the digester volume to 41 m3 in scenario 2, higher biogas production was calculated with a volumetric productivity of biogas (VPB) of 0.53 (m3/m3), which was 2.7 times higher than that of scenario 1. In scenario 3, increasing the fleshings to 20% reduced the digester volume to 25 m3 while increasing the VPB to 0.77 (m3/m3) and the electricity output and thermal energy to 15 and 19 MWh/yr, respectively.

The increase of fleshings in the AcoD of TWPS and fleshings was associated with a reduction in digester volume, significantly impacting the financial considerations of a biogas plant. In fact, Li et al. [38] reported that the installation of a biogas plant could constitute approximately 83% of the overall capital investment. Notably, a larger digester translates to a higher total capital investment. However, it is crucial to highlight that the augmentation of fleshings from 6% (Scenario 1) to 12% (Scenario 2) and 20% (Scenario 3) has led to an increase in unused TWPS in the AcoD, resulting in remaining TWPS quantities of 94 t/yr and 134 t/yr in Scenarios 2 and 3, respectively. Based on the calculation of Agustini et al. [16], with a landfill disposal cost of 50 US$/m3, the associated cost for managing the remaining TWPS was estimated to be US$4,709/yr in Scenario 2 and US$6,716/yr in Scenario 3. Consequently, the integration of AD into tannery solid waste management necessitates further investigation into the environmental impacts, as well as the economic and technical aspects of increasing the TWPS/fleshings ratio in the AcoD. This is essential as achieving a high methane yield may not be imperative when considering the overall financial and environmental benefits of tannery organic waste management.

The tannery industry requires a substantial amount of water, generating between 30 and 35 m3 of wastewater per ton of skin/hide processed [39]. The annual water consumption in the AcoD process amounts to 584, 301, and 181 m3/yr under the three scenarios outlined in Table 6. Considering this, the potential to dilute TWPS and fleshings with tannery wastewater emerges as a significant approach to curbing the consumption of clean water in the AcoD. However, caution is warranted, and further research is imperative to evaluate the potential impacts of calcium, sulfide, sulfate, chloride, chromium, and tannins, all of which are present in tannery wastewater [40]. These compounds pose a potential influence on the AD process and may lead to the inhibition of methane production. This inhibition can occur due to the high production of Free Ammonia Nitrogen (FAN) resulting from elevated levels of NH4 + (from protein-rich substrate) and Cl− (from wastewater), according to the modified Davies Equation [41]. Therefore, a comprehensive understanding of these potential impacts is vital for the successful implementation of wastewater dilution strategies in the AcoD.

4 Overcoming challenges for sustainability

The study on the AcoD of tannery solid wastes offers significant contributions to both the field of waste management and environmental sustainability. Examining AcoD integration strategies offers insights into optimizing methane production and reducing waste disposal impact. Moreover, the study sheds light on the feasibility of AcoD as a cost-effective solution, as evidenced by the minimal impact of TWPS pretreatment on methane production.

To optimize outcomes, several key strategies are proposed:

-

It is necessary to scale up anaerobic digestion processes for comprehensive evaluation using larger industrial-scale digesters with more studies on pretreatment such as alkali.

-

Acknowledging the environmental implications and nutrient runoff of the resulting digestate, particularly in terms of ammonia, alkalinity, sulfate, sulfide, and various elemental compositions including carbon, nitrogen, oxygen, hydrogen, and sulfur, as well as the C/N ratio and chromium content, is crucial. Further analysis is needed to comprehensively evaluate the environmental impact of our findings and ensure regulatory compliance.

-

Understanding the composition and dynamics of microbial communities could provide insights into the efficiency and stability of the AcoD process and inform strategies for optimization.

-

Further studies are required to examine the AD of each substrate individually, particularly fleshings. Examining individual substrate potential would enable a more comprehensive assessment of the specific contributions of various waste streams to methane yield and offer valuable insights for process optimization.

-

The addition of chromium-tanned leather waste and vegetable-tanned leather waste could increase protein content, suggesting potential implications for ammonia nitrogen concentration. Therefore, further study to estimate ammonia nitrogen levels is essential for assessing the environmental impact of the AcoD process and ensuring regulatory compliance.

-

Lastly, the observed reduction in daily methane yield peaks in T3 and T4 could be due to high concentrations of inhibitors, such as chromium and phenolic compounds. Therefore, future research should include measurements of these compounds to support the findings and provide a more robust understanding of their effects on AcoD performance.

Addressing these limitations and challenges enables a more comprehensive evaluation, paving the way for a sustainable and responsible approach to managing tannery wastes and harnessing renewable energy from these valuable resources.

5 Conclusions

Strategies for integrating anaerobic co-digestion (AcoD) to manage tannery solid wastes were explored in this study. The findings revealed that AcoD of tannery sludge and fleshing is more effective than using sludge alone. However, chromium-tanned and vegetable-tanned leather wastes were found to be unsuitable for AcoD of tannery organic wastes. Interestingly, although ultrasonic pretreatment led to an increase in soluble COD in TWPS, there were no significant differences in cumulative methane yields between pretreated and non-pretreated TWPS. This suggests that TWPS pretreatment may not be crucial for maximizing methane production, highlighting the potential efficiency and cost-effectiveness of AcoD.

Moreover, the increase in fleshings concentration in the AcoD of TWPS and fleshings positively correlates with methane production, with the highest methane production observed at 20% fleshings concentration. Specifically, methane yield ranged from 226.52 mL/gVS with 6% fleshings to 395.71 mL/gVS and 538.34 mL/gVS with 12% and 20% of fleshings, respectively. However, the decision-making process should also consider the cost associated with TWPS disposal. Consequently, it is crucial to conduct comprehensive studies evaluating the economic benefits and environmental impacts of AcoD for TWPS and fleshings before committing to biogas plant installation.

Future studies in this area are crucial for several compelling reasons. Firstly, the potential scaling up of AcoD of tannery wastes using large-scale digesters could substantially mitigate the environmental impact of tanneries. By redirecting organic wastes away from landfills and transforming them into valuable resources like methane, this approach offers a practical solution to waste management challenges, promotes economic enhancement, and reduces greenhouse gas emissions. However, a comprehensive examination of the environmental implications and nutrient runoff linked with AcoD processes is imperative to ensure their sustainable implementation. This analysis is crucial for safeguarding ecosystems and human health from potential adverse effects. Additionally, understanding the microbial communities involved in AcoD can enhance process efficiency and stability, leading to increased methane yields and more reliable operation. Furthermore, investigating the impacts of potential inhibitors, such as chromium and phenolic compounds, is necessary for overcoming obstacles and optimizing AcoD processes for maximum effectiveness. By addressing these key areas, future research endeavors will pave the way for a more sustainable approach to managing tannery wastes, benefiting both the environment and society as a whole.

Availability of data and materials

All data generated or analyzed during this study are included in the article.

References

Kanagaraj J, Velappan KC, Chandra Babu NK, Sadulla S. Solid wastes generation in the leather industry and its utilization for cleaner environment - A review. J Sci Ind Res (India). 2006;65:541–8. https://doi.org/10.1002/chin.200649273.

Dhayalan K, Fathima NN, Gnanamani A, Rao JR, Nair BU, Ramasami T. Biodegradability of leathers through anaerobic pathway. Waste Manag. 2007;27:760–7. https://doi.org/10.1016/j.wasman.2006.03.019.

Agustini CB, Spier F, da Costa M, Gutterres M. Biogas production for anaerobic co-digestion of tannery solid wastes under presence and absence of the tanning agent. Resour Conserv Recycl. 2018;130:51–9. https://doi.org/10.1016/j.resconrec.2017.11.018.

Rajamani SG. Recent developments in cleaner production and environment protection in world leather sector. In: 4th International Conference on Advanced Materials and Systems. 2012.

Polizzi C, Alatriste-Mondragón F, Munz G. Modeling the disintegration process in anaerobic digestion of tannery Sludge and fleshing. Front Environ Sci. 2017;5:1–10. https://doi.org/10.3389/fenvs.2017.00037.

Heidarzadeh A, Gu S, Triolo JM. Use of tannery wastewater as an alternative substrate and a pre-treatment medium for biogas production. Bioresour Technol. 2018;258:64–9. https://doi.org/10.1016/j.biortech.2018.02.116.

Yoseph Z, Gladstone J, Assefa B, Selvi AT, Sreeram KJ, Rao JR. Extraction of elastin from tannery wastes: a cleaner technology for tannery waste management. J Clean Prod. 2020;243:118471. https://doi.org/10.1016/j.jclepro.2019.118471.

Sundar VJ, Gnanamani A, Muralidharan C, Chandrababu NK, Mandal AB. Recovery and utilization of proteinous wastes of leather making: a review. Rev Environ Sci Bio/Technology. 2011;10:151–63. https://doi.org/10.1007/s11157-010-9223-6.

Vinicius C, Rigueto T, Rosseto M, Dal D, Krein C, Elisangela B, et al. Alternative uses for tannery wastes: a review of environmental, sustainability, and science. J Leather Sci Eng. 2020;2:21. https://doi.org/10.1186/s42825-020-00034-z.

Andriamanohiarisoamanana F, Yamashiro T, Ihara I, Iwasaki M, Nishida T, Umetsu K. Farm-scale thermophilic co-digestion of dairy manure with a biodiesel byproduct in cold regions. Energy Convers Manag. 2016;128:273–80. https://doi.org/10.1016/j.enconman.2016.09.084.

Andriamanohiarisoamanana FJ, Saikawa A, Tarukawa K, Qi G, Pan Z, Yamashiro T, et al. Anaerobic co-digestion of dairy manure, meat and bone meal, and crude glycerol under mesophilic conditions: synergistic effect and kinetic studies. Energy Sustain Dev. 2017;40:11–8. https://doi.org/10.1016/j.esd.2017.05.008.

Andriamanohiarisoamanana FJ, Yasui S, Yamashiro T, Ramanoelina V, Ihara I, Umetsu K. Anaerobic codigestion: a sustainable approach to food processing organic waste management. J Mater Cycles Waste Manag. 2020. https://doi.org/10.1007/s10163-020-01040-3.

Thangamani A, Rajakumar S, Ramanujam RA. Anaerobic co-digestion of hazardous tannery solid waste and primary sludge: biodegradation kinetics and metabolite analysis. Clean Technol Environ Policy. 2010;12:517–24. https://doi.org/10.1007/s10098-009-0256-x.

Velmurugan B, Ramanujam RA. Co-digestion of Tannery Solid Wastes with primary sewage sludge and vegetable wastes for Biogas Production. J Solid Waste Technol Manage. 2012;8:11–8.

Kanchinadham SBK, Kalyanaraman C, Kumarasamy T. Optimization of organic load for co-digestion of tannery solid waste in semi-continuous mode of operation. Clean Technol Environ Policy. 2015;17:693–706. https://doi.org/10.1007/s10098-014-0826-4.

Agustini C, da Costa M, Gutterres M. Biogas production from tannery solid wastes – scale-up and cost saving analysis. J Clean Prod. 2018;187:158–64. https://doi.org/10.1016/j.jclepro.2018.03.185.

Mpofu AB, Oyekola OO, Welz PJ. Co-digestion of tannery waste activated sludge with slaughterhouse sludge to improve organic biodegradability and biomethane generation. Process Saf Environ Prot. 2019;131:235–45. https://doi.org/10.1016/j.psep.2019.09.018.

Zupančič GD, Jemec A. Anaerobic digestion of tannery waste: semi-continuous and anaerobic sequencing batch reactor processes. Bioresour Technol. 2010;101:26–33. https://doi.org/10.1016/j.biortech.2009.07.028.

Sri Bala Kameswari K, Chitra Kalyanaraman, Thanasekaran K. Effect of ozonation and ultrasonication pretreatment processes on co-digestion of tannery solid wastes. Clean Technol Environ Policy. 2011;13:517–25. https://doi.org/10.1007/s10098-010-0334-0.

Yusaf T, Al-Juboori RA. Alternative methods of microorganism disruption for agricultural applications. Appl Energy. 2014;114:909–23. https://doi.org/10.1016/j.apenergy.2013.08.085.

Pecha J, Kolomaznik K, Barinova M, Sanek L. High quality biodiesel and glycerin from fleshings. J Am Leather Chem Assoc. 2012;107:312–22.

Chen YR, Hashimoto AG. Kinetics of methane fermentation. Biotechnol Bioeng Symp; 1978.

Fernández J, Pérez M, Romero LI. Kinetics of mesophilic anaerobic digestion of the organic fraction of municipal solid waste: influence of initial total solid concentration. Bioresour Technol. 2010;101:6322–8. https://doi.org/10.1016/j.biortech.2010.03.046.

Bolado-Rodríguez S, Toquero C, Martín-Juárez J, Travaini R, García-Encina PA. Effect of thermal, acid, alkaline and alkaline-peroxide pretreatments on the biochemical methane potential and kinetics of the anaerobic digestion of wheat straw and sugarcane bagasse. Bioresour Technol. 2016;201:182–90. https://doi.org/10.1016/j.biortech.2015.11.047.

Agustini CB, Spier F, Costa M, da, Gutterres M. Biogas production for anaerobic co-digestion of tannery solid wastes under presence and absence of the tanning agent. Resour Conserv Recycl. 2018;130:51–9. https://doi.org/10.1016/j.resconrec.2017.11.018.

Priebe GPS, Kipper E, Gusmão AL, Marcilio NR, Gutterres M. Anaerobic digestion of chrome-tanned leather waste for biogas production. J Clean Prod. 2016;129:410–6. https://doi.org/10.1016/j.jclepro.2016.04.038.

Kameswari KSB, Kalyanaraman C, Thanasekaran K. Evaluation of various pre-treatment processes on tannery sludge for enhancement of soluble chemical oxygen demand. Clean Technol Environ Policy. 2014;16:369–76. https://doi.org/10.1007/s10098-013-0632-4.

Wang Q, Kuninobu M, Kakimoto K, I.-Ogawa H, Kato Y. Upgrading of anaerobic digestion of waste activated sludge by ultrasonic pretreatment. Bioresour Technol. 1999;68:309–13. https://doi.org/10.1016/S0960-8524(98)00155-2.

Carrère H, Dumas C, Battimelli A, Batstone DJ, Delgenès JP, Steyer JP, et al. Pretreatment methods to improve sludge anaerobic degradability: a review. J Hazard Mater. 2010;183:1–15. https://doi.org/10.1016/j.jhazmat.2010.06.129.

Khanh Nguyen V, Kumar Chaudhary D, Hari Dahal R, Hoang Trinh N, Kim J, Chang SW, et al. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel. 2021;285:119105. https://doi.org/10.1016/j.fuel.2020.119105.

Kim D-H, Cho S-K, Lee M-K, Kim M-S. Increased solubilization of excess sludge does not always result in enhanced anaerobic digestion efficiency. Bioresour Technol. 2013;143:660–4. https://doi.org/10.1016/j.biortech.2013.06.058.

Zheng K, Wang Y, Wang X, Zhu T, Chen X, Zhao Y, et al. Enhanced methane production from anaerobic digestion of waste activated sludge by combining ultrasound with potassium permanganate pretreatment. Sci Total Environ. 2023;857:159331. https://doi.org/10.1016/j.scitotenv.2022.159331.

Li X, Liu Y, Xu Q, Liu X, Huang X, Yang J, et al. Enhanced methane production from waste activated sludge by combining calcium peroxide with ultrasonic: performance, mechanism, and implication. Bioresour Technol. 2019;279:108–16. https://doi.org/10.1016/j.biortech.2019.01.115.

Liew LN, Shi J, Li Y. Methane production from solid-state anaerobic digestion of lignocellulosic biomass. Biomass Bioenergy. 2012;46:125–32. https://doi.org/10.1016/j.biombioe.2012.09.014.

El-Mashad HM. Kinetics of methane production from the codigestion of switchgrass and Spirulina platensis algae. Bioresour Technol. 2013;132:305–12. https://doi.org/10.1016/j.biortech.2012.12.183.

Bond T, Templeton MR. History and future of domestic biogas plants in the developing world. Energy Sustain Dev. 2011;15:347–54. https://doi.org/10.1016/j.esd.2011.09.003.

Ruffino B, Fiore S, Roati C, Campo G, Novarino D, Zanetti M. Scale effect of anaerobic digestion tests in fed-batch and semi-continuous mode for the technical and economic feasibility of a full scale digester. Bioresour Technol. 2015;182:302–13. https://doi.org/10.1016/j.biortech.2015.02.021.

Li Y, Han Y, Zhang Y, Luo W, Li G. Anaerobic digestion of different agricultural wastes: a techno-economic assessment. Bioresour Technol. 2020;315. https://doi.org/10.1016/j.biortech.2020.123836.

Selvabharathi G, Adishkumar S, Jenefa S, Ginni G, Banu JR, Yeom IT. Combined homogeneous and heterogeneous advanced oxidation process for the treatment of tannery wastewaters. J Water Reuse Desalin. 2016;6:59–71. https://doi.org/10.2166/wrd.2015.139.

Genschow E, Hegemann W, Maschke C. Biological sulfate removal from tannery wastewater in a two-stage anaerobic treatment. Water Res. 1996;30:2072–8. https://doi.org/10.1016/0043-1354(96)00332-6.

Capson-Tojo G, Moscoviz R, Astals S, Robles A, Steyer J-P. Unraveling the literature chaos around free ammonia inhibition in anaerobic digestion. Renew Sustain Energy Rev. 2020;117:109487. https://doi.org/10.1016/j.rser.2019.109487.

Acknowledgements

This research was partially supported by Sanyo Leather Co., Ltd. We also acknowledge the financial assistance provided by the Grant-in-Aid for JSPS Fellows under Grant Numbers 19F19106 and 22KF0257.

Funding

Not available.

Author information

Authors and Affiliations

Contributions

Fetra J. Andriamanohiarisoamanana: Conceptualization, Writing original draft, Formal data analysis, Validation, Methodology. Mohamed Farghali: Writing original draft, Conceptualization, Review & editing, Formal data analysis. Israa M. A. Mohamed: Conceptualization, Review & editing, Validation. Gen Yoshida: Validation, Methodology, Visualization. Kazuya Shiota: Conceptualization, Validation, Visualization. Ikko Ihara: Visualization, Review & editing, Supervision, Project administration.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Andriamanohiarisoamanana, F.J., Farghali, M., Mohamed, I.M.A. et al. Impact of tannery wastes on anaerobic co-digestion: enhancing biogas production and process efficiency. Collagen & Leather 6, 19 (2024). https://doi.org/10.1186/s42825-024-00162-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-024-00162-w