Abstract

Biomass-based membranes have attracted increasing attentions due to their cheap and sustainable advantages. In this work, a novel thin-film composite (TFC) nanofiltration (NF) membrane was fabricated through a facial interfacial polymerization (IP) process by initiate the crosslinking reaction between collagen fibers (CFs) and tannic acid (TA). The increased TA concentrations endowed the TFC membrane with a higher crosslinking degree, a thicker active layer and a rougher top surface. At optimized condition with 0.60 mg TA decoration, the TFC-3 membrane exhibited a high water permeability of 23.49 L m−2 h−1 bar−1 with high rejections above 98.0% for congo red, reactive blue 19, coomassie blue G-250, and methyl blue. Furthermore, the membrane preserved remarkable salt retentions (93.3% for Na2SO4, 83.4% for MgSO4, 36.2% for MgCl2, and 26.4% for NaCl) and satisfying operation stability. This facial fabrication method offered a new insight to employ biomass for molecular precise separation.

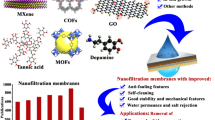

Graphical abstract

Similar content being viewed by others

1 Introduction

Nanofiltration (NF) membranes have revolutionized the hyperhaline dye wastewater separation with remarkable superiorities of higher separation efficiency, convenient operation and less energy consumption [1, 2]. Generally, NF membranes are mainly thin-film composite (TFC) membranes composed by a dense active layer and a thick porous support [3, 4]. The active layer, supplying considerable separation property, is created between the aqueous and organic interface through an interfacial polymerization (IP) reaction [5]. A variety of reactive aqueous monomers (polyamines, polyols and polyphenols) have been utilized to prepare the TFC membranes with polyamide, polyester and polyurethane active layer [6, 7]. These unique TFC membranes, with molecular weight cut-offs ranging from 200 to 2000 Da, can be effectively deployed to reject dyes and multivalent salts [8]. However, the TFC membranes with high crosslinking degree always suffers the “trade-off” issues between water permeability and selectivity [9]. Thus, it remains a challenge to develop novel TFC NF membrane with excellent water permeability and high retention towards organic dyes and inorganic salts.

To pursuit TFC membrane with desired properties, novel materials are continuously adopted during the membrane fabrication process. Among them, biomass have displayed a great potential due to their abundant amine (–NH2) and hydroxyl (–OH) groups, which can be served to modify membrane and integrate nanomaterials [10, 11]. For example, silk nanofibrils can be utilized to construct membrane with an ultra-low surface layer around 40 nm. The reduced thickness and the narrowed pore size distribution of the achieved membrane exhibited a high water flux of 13,000 L h−1 m−2 bar−1 and an excellent dye separation efficiency [12]. Cheng et al. compared the difference of applying soybean lecithin as an interlayer material, an additive for polyamine and a post-treatment agent for the fabrication of TFC NF membranes. The results revealed that soybean lecithin as an additive could provide additional water channels to enhance the separation performance [3].

Collagen fibers (CFs), a typical structural protein derived from animal skins, presents distinctive viscoelasticity, tensile strength and tear strength properties [13, 14]. Previous research has proved the modeling ability of collagen fiber and the feasibility of molecules separation. Li et al. [15] synthesized a skin-simulated TFC membrane via a vacuum-assisted IP method for dye/salt separation. With the decoration of collagen fibril, the optimized membrane possessed a water permeability up to 84.7 L h−1 m−2 bar−1 and outstanding dyes rejections (> 98.5%). However, the obtained CF-based TFC membrane presented comparatively low salt rejections for NaCl and Na2SO4. This was mainly attributed to the loosen structure and poly-dispersed pore size of the active layer. Thus, constructing CFs-based membranes with reliable membrane permeability and selectivity is still fundamental for membrane industry.

Tannic acid (TA), a typical natural polyphenol, has been employed to the construction and modification of the membrane matrix [16, 17]. Recently, tannic acid-based TFC membrane is reported to possessed an enhanced separation performance due to their abundant phenolic hydroxyl groups [18, 19]. By utilizing TA as an interlayer, reverse osmosis membrane possessed a higher NaCl rejection [19]. Meantime, oligomer TA could also be introduced as aqueous monomer of IP to achieve a highly crosslinked TFC membrane with an ultra-high stability in harsh solvent environment [20].

Herein, CFs and TA were applied to initiate the IP reaction to endow the polyacrylonitrile (PAN) ultrafiltration (UF) substrate a dense active layer. The effect of TA concentrations on the separation performance were also detected, including the pure water permeability, rejection towards salts and dyes. Meanwhile, the physical and chemical information of the obtained membranes were revealed. Furthermore, the pure water permeability, dye and salt rejection, operation stability were investigated. These results were expected to provide some guidance for the fabrication and application of biomass-based TFC NF membrane to treat textile wastewater.

2 Materials and methods

2.1 Materials

Bovine skin was offered from Qiushi Agriculture Development Co., LTD (Beijing, China). Citric acid (99.5% purity), sodium citrate (99.5% purity) and hydrochloric acid (HCl, 37.0% purity) were obtained by Sigma-Aldrich. Polyacrylonitrile (PAN) ultrafiltration (UF) membrane (Molecular weight cut-off = 100 kDa) was achieved from Beijing Separate Equipment Co., Ltd (China). Tannic acid (TA, 95.0 purity), trimesoyl chloride (TMC, 98.0% purity) and n-hexane (97.0% purity) were received from Sigma-Aldrich. Congo red (CR, 99.5% purity), reactive blue 19 (RB19, 100.0% purity), coomassie blue G-250 (CB-G250, 99.0% purity), methyl blue (MB, 99.5% purity), sodium chloride (NaCl, 99.0% purity), sodium sulfate (Na2SO4, 99.0% purity), magnesium chloride (MgCl2, 99.0% purity), and magnesium sulfate (MgSO4, 99.0% purity) were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

2.2 Preparation of CFs and TFC membranes

The CF dispersions were obtained based on the previous literatures [21]. Specifically, bovine skins were rinsed repeatedly by distilled water and softened with a mixed solution of 4.35 g/L citric acid and 5.89 g/L sodium citrate until pH was around 4.8. The prepared skins of 1 cm × 1 cm strip were then ground with ice at a 1:2 (w/w) ratio. The obtained skin slurries were mingled with a same amount of distilled water, and stored at a hydrochloric acid solution with pH adjusted to 3 at 4 °C for 24 h to get the CF paste. Ultimately, CF dispersions were homogenized to obtain a mixed solution and the concentration was measured using a BCA assay (0.5 wt%, pH = 3.0).

A vacuum filtration-based IP reaction was employed to construct the TFC membrane, as displayed in Fig. 1. Specifically, 0.1 mL CF with various content of TA were diluted to 10.0 mL and the according membrane were labeled in Table 1. The mixture was filtrated on the PAN support for positioning the CF/TA. After being drained, the pretreated membrane was immersed in a TMC/n-hexane solution (5 mL, 0.1 wt%) for 5 min. The resultant TFC membranes were dried naturally and then placed in distilled water for further usage.

2.3 Characterization of TFC membranes

Fourier transform infrared (FTIR, AVATRA-FTIR-360, Thermo Nicolet, USA) and X-ray photoelectron spectroscopy (XPS, Thermo Fisher Scientific K-Alpha, USA) were employed to detect the chemical composition of membranes. Scanning electron microscope (SEM, Hitachi SU8010, Japan) and atomic force microscopy (AFM, Bruker Dimension Icon, Germany) were adopted to detect the morphologies of membranes. Contact angle meter (OCA20, Dataphysics Instruments, Germany) was used to evaluate the hydrophilicity. The membrane surface charge properties were monitored by an electrokinetic analyzer (Surpass 3, Anton Paar GmbH, Austria) at neutral condition (pH = 7.0).

2.4 Separation performance of TFC membranes

The separation performances of the obtained TFC membranes were detected through a cross-flow device. Obtained membranes were pre-pressurized at 4.0 bar for 60 min and the membrane permeability (J) and rejections (R) towards salts (1000 mg/L) and dyes (200 mg/L) were calculated as Eqs. (1–2):

where V, A, Δt, P, Cp, and Cf represents the volume of the permeate (L), the membrane effective area (m2), time (h), operation pressure (bar), solute concentration (mg/L) of the permeate and feed solutions, respectively. The concentration of salts and dyes were detected by electrical conductivity (a-AB23EC ZH, Ohaus) and microplate reader (SpectraMax Mini, Molecular Devices), respectively.

The molecular weight cut-off (MWCO) for different membranes were evaluated by polyethylene glycol (PEG) rejection at different molecular weights (200–100 kDa) [22] and the concentrations of PEG were measured by a TOC analyzer (Envir TOC, Elementar Analysensysteme GmbH, Germany).

3 Results and discussions

3.1 Morphologies of membranes

The surface and cross-sectional SEM images of the membranes were exhibited in Figs. 2 and 3. As shown in Fig. 2a–b, the PAN UF substrate displayed a smooth surface with uniformly distributed micropores. After the IP reaction, visible stripes around 350 nm (Additional file 1: Fig. S1) on the PAN surface for TFC-0 membrane was observed and the surface nanopores was covered entirely by the CF (Fig. 2c) [15]. As shown in Fig. 2d, the incorporation of TA bring the TFC-1 membrane a portion of granular structures, which was consistent with the previous results [17]. With the increased incorporation of TA, more pellets appeared on the membrane surface from TFC-1 to TFC-5 membranes (Fig. 2d–h). The cross-sectional morphologies of the fabricated membranes were presented in Fig. 3. An enhanced thickness of the active layer could be seen after the introduction of TA.

Figure 4a–f showed the AFM results of different TFC membranes. As expected, the TFC-0 membrane covered by the CF active layer displayed a relatively smooth surface with a Ra value of 3.95 nm. After incorporation of TA, the roughness of the fabricated layer increased continuously up to Ra = 15.46 nm for the TFC-5 membrane. Consequently, TFC membranes decorated with TA molecules possessed a more dense, thicker and rougher selective layer.

3.2 Chemical composition of membranes

FTIR and XPS were employed to measure the chemical information of different membranes. As exhibited in Fig. 5a, characteristic peak at 1552 cm−1 for TFC-0 and TFC-3 membranes was assigned to the stretching vibration of amide groups, which confirmed the cross-linking reaction between –NH2 of CFs and acyl chloride groups of TMC [23]. Meantime, TFC membranes presented a broad band of hydroxyl groups (–OH) at 3000–3400 cm−1, which was originated from the unreacted –OH on the CFs. Comparatively, the introduction of TA (Fig. 5b) enhanced the bending vibration of -OH for TFC membranes [24]. Meantime, TFC membranes displayed an enhanced peak intensity at 1700 cm−1, which belonged to the stretching vibration of ester groups (C=O) formed via the cross-linking of –OH of TA with acyl chloride of TMC [25].

The XPS spectra of TFC membranes were provided in Fig. 6 to further analyses its chemical composition. As depicted in Fig. 6a, the characteristic peaks at 286.5 eV, 399.0 eV, and 532.5 eV were corresponded to the C 1s, N 1s and O 1s, respectively [26, 27]. Obviously, the introduction of TA enhanced the intensity of O 1s for the TA-based TFC membranes. Meantime, with the formation of the active layer on the PAN membrane, the atomic nitrogen content significantly reduced (Table 2) [28]. From Fig. 6b–c, N 1s deconvoluted spectrum for TFC-0 and TFC-3 membranes were consisted with two peaks, which were –NH2 (399.2 eV) and N–C=O (398.5 eV) respectively. The constant chemical bonds concentration indicated a steady cross-linking degree of CFs. The O 1s spectra were branched as N–C=O (530.9 eV), O–C=O (532.5 eV), and O–H (531.2 eV) as exhibited in Fig. 6d–i [29]. It could be found that O–H and O–C=O concentrations enhanced gradually with the addition of TA, which were derived from the extensive hydroxyl and ester groups.

Furthermore, high-resolution spectra of C 1s were investigated in Additional file 1: Fig. S2. C 1s peak were divided into several peaks located at 284.6 eV, 286.1 eV, 287.5 eV, 289.1 eV, which were corresponded to C–C, C–N/C–O, C=O and O–C=O, respectively [30, 31]. Compared to TFC-0 membrane, membranes decorated by TA presented an intenser peak for O–C=O, which was due to the formed ester groups after IP reaction [32]. The obvious upward trend for the O–C=O concentration and the stable cross-linking degree between –NH2 with TMC demonstrated a higher crosslinking degree between –OH and TMC.

The hydrophilicity of TFC membrane surface was evaluated by the contact angle results in Fig. 7a. The deposition of CFs on the PAN membrane endowed the membrane a higher water contact angel, which suppressed the hydrophilicity of the membranes [33]. As hydrophilic –OH groups of TA were introduced to the TFC membranes, the increased free hydrophilic groups declined the water contact angle [34]. Nevertheless, an obvious increase of water contact angle was obtained for TFC-4 and TFC-5 membranes. The generated ester groups were derived from the reaction between hydroxyl groups of TA molecules and acyl chloride groups of TMC [35]. The Zeta potential results in Fig. 7b revealed a strong negatively charged surface of TFC-0 membrane due to the presence of carboxyl groups [36]. Moreover, the incorporation of negatively charged TA molecules (Additional file 1: Fig. S3) decreased the Zeta potential value of TFC-3 membrane from − 53.52 to − 58.21 mV.

3.3 Separation performance of membranes

A crossflow setup (effective membrane area of 7.07 cm2) was utilized to monitor the filtration performance of the obtained membranes with different molecules (NaCl, Na2SO4, MgCl2, MgSO4, CR, RB 19, CB-G250, MB, and PEGs). As depicted in Fig. 8a–c, PEG rejection and the pore size distribution confirmed that TFC-3 membrane possessed a MWCO around 1.5 × 103 Da and a pore size (µp) of 0.62 nm. Comparatively, TFC-0 membrane exhibited a MWCO around 9.2 × 104 Da and a pore size of 5.53 nm. The smaller pore size and higher crosslinking degree of TFC-3 membrane exhibited a reduced water permeability from 93.45 to 23.49 L m−2 h−1 bar−1 (Fig. 8d). This is due to the increased TA molecules on the membrane surface exaggerated the transfer resistance, which finally be reflected by the water permeance.

Form Fig. 8e, dye rejections of TFC membranes showed an enhanced trend with the increasing TA loading. TFC-3 membrane with 0.60 mg TA decoration possessed excellent dye rejections above 98.0%. It could be explained by the negatively charged surface and the smaller pore size of TFC-3 membrane. More TA molecules involved in the IP process presented an un-changed rejections towards dyes for TFC-4 and TFC-5 membranes.

Figure 8f presented the rejections of inorganic salts with the order of Na2SO4 > MgSO4 > MgCl2 > NaCl. Specially, size exclusion and electrostatic repulsion mainly determined the salts rejection of membrane [37]. As revealed before, hydrated radius of Na+, Mg2+, SO42−, Cl− were 0.72, 0.86, 0.76 and 0.66 nm, respectively [38]. The larger hydrated radius of ions led to higher rejections of Na2SO4 and MgSO4 than that of MgCl2 and NaCl. Similarly, size exclusion played a dominant role in MgCl2 and NaCl rejection as Na+ with lower hydrated radius could penetrate membranes more easily than Mg2+ ions [39]. Despite the larger hydrated radius of Mg2+ ions, the negatively charged surface suffered a stronger attraction to the divalent cation Mg2+ ions than that of Na+ ions, inducing a comparatively higher permeance of MgSO4 [40]. Consequently, the optimized TFC-3 membrane with 0.6 mL 0.1 wt% TA possessed a pure water permeance of 23.49 L m−2 h−1 bar−1, an exceptional high dye rejections (> 98.0%), and a presentable repulsion for salts (93.3%, 83.4%, 36.2%, 26.4% for Na2SO4, MgSO4, MgCl2 and NaCl, respectively).

Membrane stability is of vital important for practical applications. The stability of the membrane in the acid and base condition were evaluated by immersing the membrane in a 0.1 M HCl and a 0.1 NaOH solutions for 12 h. The obtained membrane possessed an outstanding operational stability after acidic and neutral solutions treatment. However, a deteriorate separation performance with improved water permeance and decreased rejection was obtained after a base solution treatment (Fig. 9a). As TA could be oxidized to TA-quinone though a Michael addition/Schiff base reaction, the destroyed the polyester layer on the membrane surface finally caused an enhanced water permeance [41]. Moreover, the larger molecular weight (Additional file 1: Table S1) and enhanced negative charge of CR and CB G-250 (Additional file 1: Fig. S4), TFC-3 membrane treated with alkaline solution possessed comparatively higher rejections. Meantime, the water permeability and MB rejection of TFC-3 membrane was maintained for 100 h (Fig. 9b) and the chemical structure and surface morphology of TFC-3 membrane remained unchanged after the long-term filtration (Additional file 1: Fig. S5), indicating a good operation stability. Figure 9c outlined the filtration performance of dye/salt mixed solution. No obvious variation can be found while comparing the mixed solution to individual dye or salt solution. Furthermore, MB/NaCl mixtures with different NaCl concentrations (1.0–6.0 g/L) were utilized to detect its practical stability. As exhibited in Fig. 9d, TFC-3 membrane maintained a stable MB rejection around 98.5%, while the retention of NaCl declined to 20.0% with the increased NaCl concentration. As the vacancy of negatively charged functional groups were held by the abundant Na+ ions, the weakened electrostatic shielding effect the electro-repulsion force finally resulted in a lower NaCl rejection [42]. Additional file 1: Table S2 and Fig. 9e–f compared the separation performance of TFC-3 membrane with other reported membranes. Obviously, TFC-3 membrane displayed superiority concerning both water permeability and molecule rejections. These results demonstrated that TFC-3 membrane possessed a superior water permeability, exceptional dye and salt rejections, and excellent durability during the long-term operation.

4 Conclusion

This research offered a facile method to construct TFC NF membranes via a filtration-assisted IP reaction with CFs and TA molecules. With the continuous addition of TA, TFC membranes possessed a higher crosslinking degree, a thicker active layer, a rougher surface and a tinier pore size, which ensured a better dye and salt separation performance. The optimized TFC-3 membrane displayed an outstanding rejection of dyes (above 98.0%) with a water permeability around 23.49 L m−2 h−1 bar−1. In addition, the membrane possessed remarkable salt rejections of 93.3%, 83.4%, 36.2%, 26.4% for Na2SO4, MgSO4, MgCl2 and NaCl, respectively. Besides, TFC-3 membrane displayed superior stability in acid/neural conditions and maintained its separation performance during the long-term operation. This simple strategy, assembled with CFs and TA, offers a novel material for membrane fabrication and provides some guidance for the applications of biomaterial-based NF membrane in dyeing industry.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Hu MY, Yang SQ, Liu XW, Tao R, Cui ZY, Matindi C, et al. Selective separation of dye and salt by PES/SPSf tight ultrafiltration membrane: roles of size sieving and charge effect. Sep Purif Technol. 2021;266:118587.

Gong XW, Zhang GM, Dong HF, Wang HT, Nie J, Ma GP. Self-assembled hierarchical heterogeneous MXene/COF membranes for efficient dye separations. J Membr Sci. 2022;657:120667.

Cheng LLT, Xie YS, Li X, Liu F, Wang Y, Li J. Lecithin decorated thin film composite (TFC) nanofiltration membranes for enhanced sieving performance. J Membr Sci. 2023;677:121632.

Tian JY, Chang HL, Gao SS, Zhang RJ. How to fabricate a negatively charged NF membrane for heavy metal removal via the interfacial polymerization between PIP and TMC? Desalination. 2020;491:114499.

Wang KY, Chung TS, Amy G. Developing thin-film-composite forward osmosis membranes on the PES/SPSf substrate through interfacial polymerization. AIChE J. 2012;58:770–81.

Zhang Y, Su YL, Peng JM, Zhao XT, Liu JZ, Zhao JJ, et al. Composite nanofiltration membranes prepared by interfacial polymerization with natural material tannic acid and trimesoyl chloride. J Membr Sci. 2013;429:235–42.

Khorshidi B, Soltannia B, Thundat T, Sadrzadeh M. Synthesis of thin film composite polyamide membranes: effect of monohydric and polyhydric alcohol additives in aqueous solution. J Membr Sci. 2017;523:336–45.

Marchetti P, Jimenez Solomon MF, Szekely G, Livingston AG. Molecular separation with organic solvent nanofiltration: a critical review. Chem Rev. 2014;114:10735–806.

Jiang LJ, Chen L, Zhu L. Minimize the trade-off between wetting resistance and water permeance in membrane distillation with ion-sieving coating layer. Chem Eng J. 2022;430:133165.

Ling SJ, Qin ZQ, Huang WW, Cao SF, Kaplan DL, Buehler MJ. Design and function of biomimetic multilayer water purification membranes. Sci Adv. 2017;3:e1601939.

Lin XG, Chen L, Chen C, Rao JQ, Chen JQ, He YS. Carboxylated-covalent organic frameworks and chitosan assembled membranes for precise and efficient dye separation. J Membr Sci. 2022;663:121075.

Ling SJ, Jin K, Kaplan DL, Buehler MJ. Ultrathin free-standing bombyx mori silk nanofibril membranes. Nano Lett. 2016;16:3795–800.

Li HF, Zheng W, Xiao HZ, Hao BC, Wang YJ, Huang X, et al. Collagen fiber membrane-derived chemically and mechanically durable superhydrophobic membrane for high-performance emulsion separation. Collagen Leather. 2021;3:1–10.

Woessner AE, Jones JD, Witt NJ, Sander EA, Quinn KP. Three-dimensional quantification of collagen microstructure during tensile mechanical loading of skin. Front Bioeng Biotech. 2021;9:642866.

Li J, Xiao P, Xu YL, Dong LL, Wang ZY, Liu F, et al. Collagen fibril-assembled skin-simulated membrane for continuous molecular separation. Acs Appl Mater Inter. 2022;14:7358–68.

Yan WT, Liu LF, Dong CX, Xie SJ, Zhao XT, Gao CJ. Surface modification of reverse osmosis membrane with tannic acid for improving chlorine resistance. Desalination. 2021;498:114639.

Li Q, Liao ZP, Fang XF, Wang DP, Xie J, Sun XY, et al. Tannic acid-polyethyleneimine crosslinked loose nanofiltration membrane for dye/salt mixture separation. J Membr Sci. 2019;584:324–32.

Zhang X, Liu C, Yang J, Zhu CY, Zhang L, Xu ZK. Nanofiltration membranes with hydrophobic microfiltration substrates for robust structure stability and high water permeation flux. J Membr Sci. 2020;593:117444.

Shi MQ, Yan WT, Zhou Y, Wang Z, Liu LF, Zhao S, et al. Combining tannic acid-modified support and a green co-solvent for high performance reverse osmosis membranes. J Membr Sci. 2020;595:117474.

Pérez-Manríquez L, Neelakanda P, Peinemann KV. Tannin-based thin-film composite membranes for solvent nanofiltration. J Membr Sci. 2017;541:137–42.

Xu J, Liu F, Wang T, Goff HD, Zhong F. Fabrication of films with tailored properties by regulating the swelling of collagen fiber through pH adjustment. Food Hydrocoll. 2020;108:106016.

Li Y, Wong E, Mai ZH, Van der Bruggen B. Fabrication of composite polyamide/Kevlar aramid nanofiber nanofiltration membranes with high permselectivity in water desalination. J Membr Sci. 2019;592:117396.

Li J, Li L, Li X, Dong LL, Wang ZY, Shen JN, Van der Bruggen B. Membranes with ZIF-8 regulated MXene nanosheet stacks for efficient molecular sieving. Desalination. 2023;546:116184.

Yao QS, Li SX, Zhang RR, Han LH, Su BW. High-throughput thin-film composite membrane via interfacial polymerization using monomers of ultra-low concentration on tannic acid: copper interlayer for organic solvent nanofiltration. Sep Purif Technol. 2021;258:118027.

Li J, Xie YS, Cheng LLT, Li X, Liu F, Wang ZY. Photo-Fenton reaction derived self-cleaning nanofiltration membrane with MOFs coordinated biopolymers for efficient dye/salt separation. Desalination. 2023;553:116459.

Chen DD, Liang QQ, Gao F, Liu TY, Wu YQ, Zheng Z, et al. Design of high-performance biomimetic reverse osmosis membranes by introducing loose liposome as an artificial water channel. Chem Eng J. 2022;431:133878.

Ng ZC, Lau WJ, Kartohardjono S, Ismail AF. Comprehensive studies of membrane rinsing on the physicochemical properties and separation performance of TFC RO membranes. Desalination. 2020;491:114345.

Zhu JY, Yuan SH, Uliana A, Hou JW, Li J, Li X, et al. High-flux thin film composite membranes for nanofiltration mediated by a rapid co-deposition of polydopamine/piperazine. J Membr Sci. 2018;554:97–108.

Wang L, Lin YK, Tang YH, Ren D, Wang XL. Fabrication of oppositely charged thin-film composite polyamide membranes with tunable nanofiltration performance by using a piperazine derivative. J Membr Sci. 2021;634:119405.

Kang Y, Obaid M, Jang J, Kim IS. Sulfonated graphene oxide incorporated thin film nanocomposite nanofiltration membrane to enhance permeation and antifouling properties. Desalination. 2019;470:114125.

Xu SJ, Shen Q, Luo LH, Tong YH, Wu YZ, Xu ZL, et al. Surfactants attached thin film composite (TFC) nanofiltration (NF) membrane via intermolecular interaction for heavy metals removal. J Membr Sci. 2022;642:119930.

Jin PR, Zhu JY, Yuan SS, Zhang G, Volodine A, Tian M, et al. Erythritol-based polyester loose nanofiltration membrane with fast water transport for efficient dye/salt separation. Chem Eng J. 2021;406:126796.

Socrates R, Prymak O, Loza K, Sakthivel N, Rajaram A, Epple M, et al. Biomimetic fabrication of mineralized composite films of nanosilver loaded native fibrillar collagen and chitosan. Mat Sci Eng C-Mater. 2019;99:357–66.

Zhu XW, Zhang XY, Li JY, Luo XS, Xu DL, Wu DJ, et al. Crumple-textured polyamide membranes via MXene nanosheet-regulated interfacial polymerization for enhanced nanofiltration performance. J Membr Sci. 2021;635:119536.

Venault A, Hsu CH, Ishihara K, Chang Y. Zwitterionic bi-continuous membranes from a phosphobetaine copolymer/poly(vinylidene fluoride) blend via VIPS for biofouling mitigation. J Membr Sci. 2018;550:377–88.

Li J, Li L, Xu YL, Zhu JY, Liu F, Shen JN, et al. MXene nanosheet stacks with tunable nanochannels for efficient molecular separation. Chem Eng J. 2022;427:132070.

Ormanci-Acar T, Tas CE, Keskin B, Ozbulut EBS, Turken T, Imer D, et al. Thin-film composite nanofiltration membranes with high flux and dye rejection fabricated from disulfonated diamine monomer. J Membr Sci. 2020;608:118172.

Dehghanpour SB, Parvizian F, Vatanpour V, He T. Enhancing the flux and salt rejection of thin-film composite nanofiltration membranes prepared on plasma-treated polyethylene using PVA/TS-1 composite. React Funct Polym. 2022;177:105329.

Wei XZ, Huang JH, Cao SY, Chen Y, Yang RY, Wang Z, et al. Preparation of graphene oxide/polyamide composite nanofiltration membranes for enhancing stability and separation efficiency. J Appl Polym Sci. 2021;138:50902.

Borjigin B, Yu L, Xu L, Zhao C, Wang J. Influence of incorporating beta zeolite nanoparticles on water permeability and ion selectivity of polyamide nanofiltration membranes. J Environ Sci. 2020;98:77–84.

Li Q, Liao ZP, Fang XF, Xie J, Ni LH, Wang DP, et al. Tannic acid assisted interfacial polymerization based loose thin-film composite NF membrane for dye/salt separation. Desalination. 2020;479:114343.

Guo Q, Wu X, Ji Y, Hao Y, Liao S, Cui Z, et al. pH-responsive nanofiltration membrane containing chitosan for dye separation. J Membr Sci. 2021;635:119445.

Acknowledgements

The financial supports from the National Natural Science Foundation of China (Grant Nos: 21908076).

Funding

National Natural Science Foundation of China (Grant No: 21908076).

Author information

Authors and Affiliations

Contributions

YX: Writing, experiments. ZG: Date analysis. XL: Manuscript modification. WY: General supervision of the research. FL: Cauterization. JL: Organization of the experiment, manuscript modification, the funding and resources.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Written informed consent is obtained from all the participants prior to the publication of this study.

Consent for publication

The Author confirms:·that the work described has not been published before;·that it is not under consideration for publication elsewhere; ·that its publication has been approved by all co-authors; that its publication has been approved (tacitly or explicitly) by the responsible authorities at the institution where the work is carried out.

Competing interests

All authors declare that there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1

. Supporting Information.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xie, Y., Ge, Z., Li, X. et al. Composite nanofiltration membrane with tannic acid coordinated collagen fibers for enhanced molecule separation. Collagen & Leather 5, 28 (2023). https://doi.org/10.1186/s42825-023-00133-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-023-00133-7