Abstract

Leather is a collagen-based biomass prepared from raw skins or hides by a series of unit operations, in which the unhairing and fiber opening are extremely important operations. However, the conventional Na2S/Ca(OH)2 system used in unhairing and fiber opening has given rise to the pollution to the environment. It is necessary to develop substitute technology for the Na2S/Ca(OH)2. In the present study, 1-allyl-3-methylimidazolium chloride ([AMIm]Cl) was used to cooperate with dispase for cycle unhairing and one-pot beamhouse to recycle waste bovine hides and compared with conventional processing. During those processes, the mechanism of [AMIm]Cl-dispase synergistic unhairing and collagen fibers opening were studied. Besides, plant hazard, organic matter and [AMIm]Cl of wastewater from [AMIm]Cl-dispase process were respectively investigated and separated to evaluate the environmental and economic benefits of the [AMIm]Cl-dispase process. As a result, enzyme activity after unhairing by [AMIm]Cl-diapase system for using 5 times is higher than that by KCl-dispase system, and needs lower unhairing time, which is because of rapid penetration of [AMIm]Cl-dispase solution in bovine hides. For this reason, the tensile strength and elastic modulus of tanned leather from [AMIm]Cl-dispase process are higher than those from the KCl-diapase and conventional processes, and its hydrothermal shrinkage temperature is comparable to that of the conventional one. Because of the 58.13% lower wastewater discharge (WD), 66.60% lower total solids (TS), 97.23% lower ammonia nitrogen (NH3-N), non-toxic wastewater and organic matter recovery in wastewater are reached from [AMIm]Cl-dispase process, which is expected to be an alternative to the conventional process to reduce environmental pollution and realize the sustainable development of technology for leather manufacturing.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.1 Introduction

The bovine hides, a renewable bioresource containing rich collagen, are the waste from slaughterhouses, which are recycled and made into different biomaterials by a series of technologies such as biomedical materials [1,2,3,4,5], food [6, 7], fine chemicals [8], new energy materials [9, 10], textile materials, etc.. However, bovine hides are made into the different biomaterials, which must be removed hairs and opened collagen fiber-bundles first to get pure collagen-based material such as leather making. As a collagen-based material from bovine hides with a natural woven structure [11,12,13,14], leather is obtained through a series of processes including beamhouse, tanning, post tanning and finishing. In beamhouse, non-collagen components (proteoglycans, hairs and cuticles) in bovine hides are removed to open and loose collagen fiber-bundles using chemical and biological reagents and pure collagen fiber woven structure with abundant active reaction sites are obtained for the reaction with tanning agents. However, the sulphide, solid sludge and ammonia nitrogen pollutants are produced, which may account for 60–70% of the total tannery pollution by conventional technology with sodium sulphide and calcium hydroxide system [15, 16]. Additional unit operations such as reliming, deliming and bating are needed in the sodium sulfide/calcium hydroxide system. The more unit operations, the more cost input and pollution loads.

Nowadays, although neutral protease[17, 18], alkaline protease[19,20,21], keratinase[22, 23] and carbohydrase[24,25,26,27,28] have been studied for the purpose of hydrolyzing non-collagen-based elements of bovine hides, the enzymes are only used as an auxiliary reagent or mixed with sodium sulfide and calcium hydroxide system[29,30,31]. The pollution of sulphide and solid sludge does still exist in beamhouse. Even if the enzymes are used as the main materials for removing non-collagen components, there are many problems[31] such as incomplete hair removal [32,33,34] and exfoliation[35], hydrolysis of collagen and grains[36, 37], organic combustible solvents[38], etc., resulting in poor quality of leather materials and limited industrial application. In view of the shortcomings of the conventional and enzymatic processes, the development of high-efficiency and clean biochemical materials to remove the non-collagen components with less environmental pollution and damage to the collagen and collagen fiber woven structure is still urgently needed.

Ionic liquids, new green molten salts, are widely used in various industries owing to lower boiling points[39] (< 100 °), negligible vapor pressure[40], miscibility with water[41, 42] and organic solvents[43,44,45], high chemical and thermal stability, high ion conductivity [46] and wide electrochemical window[47]. The chemical and physical properties of ionic liquids are similar to those of inorganic salts, and the properties of enzymes such as activity, stability, solubility, dispersion and structure might be affected by the use of ionic liquids. The effects of salts on proteins are generally according to the lyotropic series, i.e. Hofmeister series, is described as an ability of the ions to vary the hydrogen bonding network of water to stabilize or destabilize the ability of hydration (salting-out and salting-in) for protein. The theory of ion series is related to the size and surface charge density of anion and cation, e. g. the small size and high surface charge density of ion show a strong ability of hydration to make the network of water (Kosmotropes), and the converse break network of the water (Chaotropes). The anion and cation size of ionic liquids are generally larger than those of inorganic salts, resulting in weak hydration and strong binding to proteins [48], further improving the stability of protein solution.

Ionic liquids have been reported in leather making, such as 1-butyl-3-methylimidazolium chloride ([BMIM][Cl]) [47], 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIM][BF4]) [49], and deep eutectic solvents of choline chloride and carboxylic acids[50, 51] because of their strong chaotropic and environmentally friendly. These ionic liquids related reports for leather making are only limited to a single operation in conventional beamhouse step such as unhairing or fiber opening operation, and few studies have been systematically performed in-depth in simplification of beamhouse, efficient use of ionic liquids/enzyme solution, reducing environmental pollution and wastewater recycling by the designs of cycle unhairing and one-pot beamhouse with ionic liquid combined enzyme technology, which are very key for the practical technical application of ionic liquid combined enzyme in cleaner leather making. Cycle unhairing is the use of unhairing solution to remove hairs multiple times to investigate the unhairing efficiency and effect of unhairing solutions, recycling efficiency of depilatory solution and reduction of environmental pollution. One-pot beamhouse needs only one step to accomplish the operations of unhairing, fiber opening and bating for the hides or skins in the same bath with the same solutions, which was designed based on high-performance materials with excellent effects of unhairing, fiber opening and bating for the hides or skins. One-pot beamhouse simplifies conventional beamhouse multi-step operation, improves efficiency and cost of leather making, and reduces environmental pollution. In this work, dispase, is a renewable resource, preparing from Bacillus subtilis by biological fermentation, which has good ability of hydrolysis to proteoglycans and glycosaminoglycan inside bovine hides in the neutral water solution for unhairing and opening collagen fiber-bundles. 1-allyl-3-methyl imidazolium chloride ([AMIm]Cl), a new ionic liquid with excellent hydrogen bond opening ability, was used to improve the stability, solubility, dispersion of dispase and compared with those of potassium chloride (KCl) from the low lyotropic series. [AMIm]Cl-dispase system firstly was used for cycle unhairing and one-pot beamhouse, and was systematically studied to obtain the various performance and reaction mechanism of [AMIm]Cl-dispase system on the bovine hides and the impact on the environment.

The effects of cycle unhairing and one-pot beamhouse were investigated and evaluated from the viewpoints of dispase activity, the contents of protein, carbohydrate and hydroxyproline (HYP) in wastewater as well as Verhoeff's Van Gieson (EVG) staining technology. The penetration of dispase in bovine hides and the stability of dispase solution were explored by fluorescein isothiocyanate (FITC) labeling, contact angle and zeta potential. The aggregation structure of collagen fibrils, physical properties and hydrothermal stability of tanned leather from both [AMIm]Cl/dispase and KCl/dispase processes were characterized by scanning electron microscopy (SEM), texture analyzer and hydrothermal shrinkage temperature tester, respectively, and compared with those of conventional one. The pollution loads and plant hazard of wastewater were evaluated, in order to extract and reuse the organic matters in wastewater.

2 Experimental procedures

2.1 Materials

1-allyl-3-methylimidazolium chloride ([AMIm]Cl, more than 99% pure) was produced by Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, China. Formalin (4%) and dye liquor of Verhoeff's Van Gieson (EVG) and Van Gieson (VG) were from Wuhan Google Biotechnology Co., Ltd, Wuhan, China. Absolute ethyl alcohol (analytical reagent, AR), xylene (AR) and neutral resins were produced by Sinopharm Chemical Reagent Co., Ltd, Shanghai, Hydroxyproline assay kit (Alkaline) was produced by Nanjing Jiancheng Bioengineering Institute, Nanjing, China. Distilled water (conductivity < 6 μS/cm).

2.2 Experimental and conventional processes

2.2.1 Design of integrated ecological beamhouse

An integrated ecological beamhouse using the [AMIm]Cl-dispase system was designed, with the scheme shown in Scheme 1. [AMIm]Cl-dispase solution was used for cycle unhairing and one-pot beamhouse (unhairing, opening collagen fiber-bundles and bating in same solution and bath), and then the [AMIm]Cl-dispase wastewater from the two processes was recycled for subsequent organic matter recycling to improve environmental and economic benefits.

2.2.2 [AMIm]Cl-dispase synergistic cycle unhairing

40 g of de-salted bovine hide was added into 120 g [AMIm]Cl (0.01 mol)/dispase (0.8 wt%) solution at 32 ℃ for cycle unhairing until its hairs were completely removed, and compared with the synergistic cycle unhairing effects of both processes with dispase (0.8 wt%) and KCl (0.01 mol)/dispase (0.8 wt%) at the same condition. The unhairing complete time and the weight of wastewater was recorded after each cycle of unhairing. The contents of protein, carbohydrates and HYP in wastewater were measured and analyzed, as well as the activity of dispase in wastewater. The recycling was done for 5 cycles in the [AMIm]Cl-dispase synergistic unhairing wastewater under the same condition. Each cycle unhairing result from the processes of dispase, [AMIm]Cl-dispase and KCl-dispase were presented in Additional file 1: Fig. S1.

2.2.3 [AMIm]Cl-dispase synergistic one-pot beamhouse

After being put added into 120 g 0.01 mol [AMIm]Cl/0.8 wt% dispase, another piece of de-salted bovine hide (40 g) was processed for one-pot beamhouse at 32 °C for 30 h, with the synergistic one-pot beamhouse in 0.01 mol KCl/0.8 wt% dispase process at the same condition as a control. The 10 × 10 mm bovine hides sample and 1 mL wastewater were taken out at 4, 6, 12, 18, 24, and 30 h for subsequent study.

2.3 Investigation of the dispase penetration by FITC

The dispase was labeled with FITC, and the labeling operations can be referenced to the reported work [52]. Two de-salted bovine hides (each of 40 g) with uniformity were added into 120 g KCl (0.01 mol)/FITC-dispase (0.8 wt%) and 120 g [AMIm]Cl (0.01 mol)/FITC-dispase (0.8 wt%) solution, respectively, for one-pot beamhouse. The samples (each of 10 × 10 mm) of bovine hides from the two processes were taken out at durations of 4.5, 6, 18, 30 and 38 h, and their cross-sections were observed by the digital slice scanning system (Pannoramic MIDI II, Hungary) at fluorescence environment to investigate the distribution of FITC-dispase in bovine hides with the time increase, further study the effect of the two salts of [AMIm]Cl and KCl on the penetration of dispase in bovine hides.

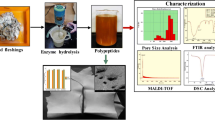

2.4 Organic matter and saline solution separation in wastewater

The wastewater (28 mL) (Additional file 1: Fig. S7(A)) from one-pot beamhouse by the [AMIm]Cl-dispase process was added into ethyl alcohol (125 mL) with sufficient mixing, and then let alone for 24 h. Most of the supernatant was poured out, and the solid organic matter (Additional file 1: Fig. S7(D(1))) in the remaining mixture was collected after centrifuging, which was dried by lyophilizer (GT2-Type-8, LYOTECH, Germany) at − 50 °C for 24 h, and then stored at 4 °C for further analysis. The supernatant was separated into ethyl alcohol (Additional file 1: Fig. S7(F(1))) and [AMIm]Cl solution (Additional file 1: Fig. S7(F(2))) by rotary evaporators at 45 °C under 6 kPa.

2.5 The harm of wastewater to plant growth

Whether the wastewater affects the growth of plants is important for the research and development of clean leather chemicals. The wastewater of one-pot beamhouse from [AMIm]Cl-dispase process contains water, [AMIm]Cl and organic matter (dispase, protein and carbohydrate), which was used for cultivating plants to detect the harm of wastewater to plant growth. 25 mL of wastewater from [AMIm]Cl-dispase process was added into 250 mL water to cultivate a plant of Epipremnum aureum at room temperature with the addition of some pure water to keep the whole volume of nutrient solution not changed, with the comparation of the mixture of 25 mL wastewater from KCl-dispase process and 250 mL water in the same condition, as well as the pure water (275 mL). The growth of Epipremnum aureum was recorded by a digital camera at a duration of 0, 210, 246, 371 and 432 d, with the results shown in Additional file 1: Fig. S9.

3 Results and discussion

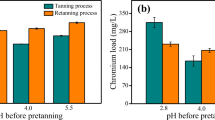

3.1 Effect of [AMIm]Cl-dispase synergistic cycle unhairing

Unhairing is very an important operation for opening fiber-bundles, which increases the specific surface area of bovine hides and provides the channels for the penetration of subsequent chemicals and the dissolution of interfibrillar substance. The proteoglycans that link the hair root to the hair follicle are hydrolyzed by enzyme to realize unhairing. In this work, [AMIm]Cl-dispase was used for cycle unhairing and the results were compared with those by both processes of dispase and KCl-dispase, with each unhairing effect shown in Additional file 1: Fig. S1. The changes of dispase activity and organic matters contents such as protein, carbohydrate and HYP in wastewater from the three processes after each cycle of unhairing were investigated, as well as the changes of wastewater weight and unhairing complete time, with the results shown in Fig. 1. KCl or [AMIm]Cl was added to the dispase solution to synergize with cycle unhairing, which was found to have a better unhairing effect than dispase solution and could be recycled 5 times for cycle unhairing (Additional file 1: Fig. S1). The activity of dispase in the wastewater from [AMIm]Cl-dispase process is more stable than those from the dispase and KCl-dispase processes in cycle unhairing (Fig. 1A). The contents of protein, carbohydrate and HYP in wastewater from [AMIm]Cl-dispase process are all higher than those of both processes of dispase and KCl-dispase after each cycle unhairing (Fig. 1B–D). An appropriate amount of salt can promote the dissolution or stability of dispase (Additional file 1: Fig. S4) and increase the stabilization of dispase activity [52, 53]. In addition, the combining capacity of [AMIm]+ with dispase is stronger than that of K+, more easily destroying the hydrogen and ionic bonds of dispase, which might be because the size of [AMIm]+ is larger than that of K+ in the lyotropic series or Hofmeister series, resulting in more solubilization of dispase in [AMIm]Cl solution. The mixed solution of dissolved [AMIm]Cl-dispase can rapidly penetrate into the hair follicle by external force and osmotic pressure to hydrolyze the proteoglycans of hair roots. Therefore, the content of organic matters in wastewater from [AMIm]Cl-dispase process were the highest (Fig. 1B–D), and the unhairing complete time of [AMIm]Cl-dispase process after each cycle of unhairing was the shortest in the three trials (Fig. 1F). The wastewater weight from the processes of dispase and KCl-dispase gradually increase, while that from [AMIm]Cl-dispase process is gradually decreased (Fig. 1E), which is probably because the lyotropic swelling ability of [AMIm]Cl is stronger than that of KCl to cause easier water absorption of bovine hide at each cycle of unhairing. So the ions of [AMIm]+ and Cl− in solution could maintain the stable activity of dispase, promote the rapid unhairing of dispase, and swell the bovine hide (Fig. 1E). [AMIm]Cl-dispase solution has the best cycle unhairing effect, which could be recycled 5 times in the same solution with the least time in each cycle unhairing (Fig. 1F), as well as keeping the highest activity of dispase at last (Fig. 1A). In this part, basic data used to design infinite cycle of [AMIm]Cl-dispase solution system unhairing is obtained by studying cycle unhairing effect of [AMIm]Cl-dispase system and analyzing their experimental results. According to the changes of dispase activity and [AMIm]Cl-dispase solution weight after each cycle unhairing, suitable weight of [AMIm]Cl-dispase solution might be added by theoretical calculation to keep enough dispase activity for next cycle unhairing to realize cycle unhairing countless times. Besides, the contents of protein, carbohydrate and HYP in the solution does not increase continuously owing to the exchange of organic substances between solution and bovine hides, which greatly reduces the organic pollution and wastewater discharge to improve environmental and economic benefits.

3.2 Effect of [AMIm]Cl-dispase ecological beamhouse

One-pot beamhouse effect of [AMIm]Cl-dispase system was investigated, with its unhairing effect and the changes of dispase activity, protein content, HYP content and carbohydrate content in wastewater shown in Additional file 1: Fig. S2 and Fig. 2, respectively. The hairs of bovine hide were removed completely by [AMIm]Cl-dispase process in 4 h (Additional file 1: Fig. S2(C)), while a small number of hairs still existed on the surface of bovine hide by KCl-dispase process (Additional file 1: Fig. S2(c)) and was not removed completely until 6 h (Additional file 1: Fig. S2(d)). The activity changes of dispase in wastewater from both processes of [AMIm]Cl-dispase and KCl-dispase are not significant, and the significance of dispase activity changes from KCl-dispase process was more obvious than that from [AMIm]Cl-dispase process (Fig. 2A). The results indicated that the stability of dispase activity from [AMIm]Cl-dispase process is better than that from KCl-dispase process during one-pot beamhouse. The contents of protein and HYP in wastewater from [AMIm]Cl-dispase process are higher than those from KCl-dispase process. The time of the maximum content of carbohydrate in wastewater from [AMIm]Cl-dispase process is shorter than that from KCl-dispase solution (Fig. 2D). [AMIm]+ has better ability to bind with dispase than that of K+ because the size of [AMIm]+ is bigger than that of K+, which increase the stability of dispase. So the dispase could rapidly penetrate into the hides to hydrolyze the proteoglycans of hair roots and interfibrillar substance. On the other hand, a large amount of KCl might be bound to the amino acid residues on the surface of collagen fibers due to the poor bond ability with dispase, which could reduce the structural stability of collagen fibrils, resulting in the hydrolysis of collagen. Therefore, [AMIm]Cl-dispase system could effectively hydrolyze the proteoglycans in bovine hides, with less collagen hydrolyzed. The most worth mentioning is that the wastewater after the one-pot beamhouse could still be recycled for cycle unhairing and next one-pot beamhouse because the activity of dispase in wastewater (Fig. 2A) could satisfy the need of activity for cycle unhairing (Fig. 1A) and one-pot beamhouse (the non-significance of dispase activity changes) (Fig. 2 A).

3.3 Hydrolysis of interfibrillar substance in hides

After unhairing and collagen fibers opening by the processes of convention, KCl-dispase and [AMIm]Cl-dispase, the cross-sections of bovine hides were stained with EVG to study the hydrolysis of proteoglycans and elastin in bovine hides, with the results shown in Fig. 3 and Additional file 1: Fig. S3. Elastic fibers (Efs) are dyed black blue, while proteoglycans (PGs) are yellow or clay bank, and collagen fibers are orange-red. The hydrolyzed effects of proteoglycans in bovine hides by both processes of KCl-dispase and [AMIm]Cl-disapse are better than that of conventional one, with the best of [AMIm]Cl-dispase process (Fig. 3C, C1). Both proteoglycans and elastic fibers in bovine hides still are not completely hydrolyzed after unhairing and collagen fibers opening by conventional process with Na2S/Ca(OH)2 system (Fig. 3A, A1), meaning that the operation of bating with trypsin is needed. Both the KCl-dispase and [AMIm]Cl-dispase processes, especially in case of [AMIm]Cl-dispase process, completely hydrolyze the proteoglycans and elastic fibers in bovine hides with the one-pot beamhouse, suggesting an easier and cleaner beamhouse for leather making.

3.4 Distribution of dispase

A moderate amount of inorganic salt was added to dispase solution, which could improve the penetrability of dispase in bovine hides to promote the hydrolysis of proteoglycans in bovine hides. Fluorescence scans of the cross-section of bovine hides during one-pot beamhouse by the processes of KCl/FITC-disapse and [AMIm]Cl/FITC-dispase were conducted, with the results shown in Fig. 4. The penetrability of dispase in bovine hides with [AMIm]Cl-dispase process is better than that of KCl-disapse process at the beginning of the process (Fig. 4a, A). The dispase in both two processes of [AMIm]Cl-dispase and KCl-dispase penetrated into the center of the bovine hides after 30 h, and the proteoglycans in hair follicles are rapidly hydrolyzed. So [AMIm]Cl-dispase process does good for rapid penetration of dispase in bovine hides for the efficient reaction with the components in hides.

3.5 Mechanism of one-pot beamhouse and recovery of organic matter in wastewater

A schematic diagram of [AMIm]Cl-dispase synergistic one-pot beamhouse was proposed as shown in Scheme 2. [AMIm]Cl can promote the solvation of dispase and equably disperse (Additional file 1: Figs. S4 and S5) to the [AMIm]Cl solution duo to ionic electrostatic attraction, which accelerates the penetration of dispase into the bovine hides (Fig. 4) to rapidly hydrolyze the proteoglycans (PGs) of hair roots and collagen fiber-bundles surface and elastic fibers (Efs) to realize one-pot beamhouse (including unhairing, fiber opening and bating). The peptide linkage and hydrogen bond of proteoglycans and elastic fibers in bovine hides were opened by synergy between dispase and [AMIm]Cl to realize one-pot beamhouse due to excellent hydrogen bond opening ability of [AMIm]Cl [5, 54] and good peptide linkage hydrolyzing ability of dispase. In order to avoid the pollution to the environment by organic matter in wastewater, the organic matter in wastewater was recycled after absolute ethanol precipitation and centrifugation, while the ethanol in the separation liquid was recycled by rotary evaporators, with the recycling process shown in Additional file 1: Fig. S7. Besides, the structure of organic matter was analyzed by infrared spectrometer, with the result shown in Additional file 1: Fig. S8. The structure of the organic matter is very similar to those of pure bovine hide collagen and sodium hyaluronate (Additional file 1: Fig. S8). There is a high content of hyaluronic acid in proteoglycans of bovine hides, while the collagen and other protein can be hydrolyzed to glycosaminoglycan (GAG) and polypeptide. So the organic matter in the wastewater is very similar to collagen and hyaluronic acid. From the viewpoint of the structure of the recycled organic matter from the wastewater, the organic matter could be used as a raw material for preparing leather chemicals (such as filling agent, finishing agent, and accessory ingredient, etc.), daily fine chemicals and carbon-based catalytic materials to reduce the environmental pollution as well as reuse of natural resource.

3.6 Grain morphology and collagen fibers aggregation structure of tanned leathers

After being collagen fiber bundles being opened, the bovine hides were fixed with tannic acid to clearly observe the grain morphology and collagen fibers aggregation structure of tanned leather by SEM, with the results shown in Fig. 5 and Additional file 1: Fig. S6. Compared with the grain surface of tanned leathers by conventional process and KCl-dispase, the one by [AMIm]Cl-dispase process is smoother (Fig. 5C), probably owing to the better penetration of [AMIm]Cl-dipase solution inside the leather to less hydrolyze the grain collagen of bovine hides (Fig. 2B, C). The collagen fibril of tanned leather from [AMIm]Cl-dispase is comparable to those from the conventional and KCl-dispase process (Additional file 1: Fig. S6).

3.7 Physical and hydrothermal properties of tanned leather

The tanned leather from the conventional, KCl-dispase and [AMIm]Cl-dispase process were studied by texture analyzer, with the results shown in Table 1. The tensile strength and elastic modulus of tanned leather from [AMIm]Cl-dispae process is the biggest in the samples studied here, which should be probably because [AMIm]Cl-dispase process has the best hydrolysis ability of the proteoglycans in bovine hides and more active sites appeared for subsequent tanning agent of tannin acid (Fig. 3; Additional file 1: Fig. S2D). For this reason, the hydrothermal stability of tanned leather from [AMIm]Cl-dispase process is comparable to those with the conventional and KCl-dispase ones. Therefore, by the one-pot beamhouse with [AMIm]Cl-dispase system, a good tanning result could be reached to improve the properties of leathers.

3.8 Environmental and economic benefits

The wastewater pollution of leather making seriously limits the development of the leather industry. The pollutant loads in wastewater and discharged wastewater from the processes of KCl-dispase and [AMIm]Cl-dispase were investigated and compared with those of the conventional process, with the results shown in Table 2. Compared with the load of COD from the conventional process, those from the salt/dispase system are higher due to their good ability to hydrolyzed the proteoglycans in bovine hides, while the load of COD from [AMIm]Cl-dispase process is highest because the reducibility of the organic cation in [AMIm]Cl might increase the load of COD in wastewater. The protein and proteoglycans in wastewater increase the load of COD, and they are all organic matter with similar structure to collagen or sodium hyaluronate (Additional file 1: Fig. S8), which can be reused (Additional file 1: Fig. S7) to prepare compost for plants, leather chemicals, fine chemicals, biological materials, etc. Besides, the loads of NH3-N and TS from the [AIMm]Cl-dispase process are lower than those from the conventional process due to the use of Na2S/Ca(OH)2 system. What is worth mentioning is that the discharged wastewater from the salt/dispase system is lower than that from the conventional process, and the discharged wastewater can be recycled for unhairing or one-pot beamhouse because the dispase activity of wastewater is high enough (Additional file 1: Fig. S2(A)) to hydrolyze the proteoglycans of the hair root. Salt solution after separating the organic matter can be recycled (Additional file 1: Fig. S7 F(2)) after adding dispase for next unhairing and one-pot beamhouse operations. This way of recycling wastewater from the salt/dispase process, especially for the wastewater from [AMIm]Cl-dispase process, has little effect on plant growth (Additional file 1: Fig. S9) and greatly improves the environmental and economic benefits, which might immensely avoid the use and the pollution loads of sulphide, solid sludge and ammonia nitrogen from the conventional process due to the use of Na2S/Ca(OH)2 system.

4 Conclusions

An application technology of [AMIm]Cl-dispase system is confirmed to rapidly hydrolyze the non-collagen ingredients in bovine hides to realize multiple cycle unhairing and one-pot beamhouse, and the effects of cycle unhairing and one-pot beamhouse are better than those of KCl-dispase because the [AMIm]Cl is better than KCl in improving the dispersion, stable activity and penetration of dispase. The pollutant loads in wastewater and wastewater discharge from [AMIm]Cl-dispase process are lower than those from the conventional one. Besides, the wastewater from [AMIm]Cl-dispase process is recycled, and the organic matter and [AMIm]Cl solution in wastewater is separated, which can be used for other related applications. The tensile strength of tanned leather from [AMIm]Cl-dispase process is higher than those of conventional process, with comparable hydrothermal stability is comparable to that of the conventional one. The recycling of wastewater, separation of organic matter in wastewater and little effect of wastewater on plant growth from the [AMIm]Cl-dispase process greatly reduce the waste of resources, cost and environmental pollution, improving the environmental and economic benefits for leather making.

Availability of data materials

All data generated or analyzed during this study are included in this published article, and its supplementary information files.

Change history

06 May 2023

A Correction to this paper has been published: https://doi.org/10.1186/s42825-023-00121-x

References

Duraipandy N, Lakra R, Vinjimur Srivatsan K, Ramamoorthy U, Korrapati PS, Kiran MS. Plumbagin caged silver nanoparticle stabilized collagen scaffold for wound dressing. J Mater Chem B. 2015;3:1415–25. https://doi.org/10.1039/c4tb01791a.

Yu C, Sharma S, Fang CH, Jeong H, Li J, Joice G, Bivalacqua TJ, Singh A. Aliphatic chain modification of collagen type I: development of elastomeric compliant, and suturable scaffolds. ACS Appl Bio Mater. 2020;3:1331–43. https://doi.org/10.1021/acsabm.9b00781.

Ramanathan G, Seleenmary Sobhanadhas LS, Sekar Jeyakumar GF, Devi V, Sivagnanam UT, Fardim P. Fabrication of biohybrid cellulose acetate-collagen bilayer matrices as nanofibrous spongy dressing material for wound-healing application. Biomacromolecules. 2020;21:2512–24. https://doi.org/10.1021/acs.biomac.0c00516.

Muller WEG, Neufurth M, Ackermann M, Tolba E, Wang S, Feng Q, Schroder HC, Wang X. Fabrication of a new physiological macroporous hybrid biomaterial/bioscaffold material based on polyphosphate and collagen by freeze-extraction. J Mater Chem B. 2017;5:3823–35. https://doi.org/10.1039/c7tb00306d.

Pei Y, Chu S, Zheng Y, Zhang J, Liu H, Zheng X, Tang K. Dissolution of collagen fibers from tannery solid wastes in 1-allyl-3-methylimidazolium chloride and modulation of regenerative morphology. ACS Sustain Chem Eng. 2018;7:2530–7. https://doi.org/10.1021/acssuschemeng.8b05428.

Asai T, Takahashi A, Ito K, Uetake T, Matsumura Y, Ikeda K, Inagaki N, Nakata M, Imanishi Y, Sato K. Amount of collagen in the meat contained in japanese daily dishes and the collagen peptide content in human blood after ingestion of cooked fish meat. J Agric Food Chem. 2019;67:2831–8. https://doi.org/10.1021/acs.jafc.8b06896.

Sato K. The presence of food-derived collagen peptides in human body-structure and biological activity. Food Funct. 2017;8:4325–30. https://doi.org/10.1039/c7fo01275f.

Sato K. Food for skin health: collagen peptides. In: Encyclopedia of food chemistry. 2019; pp. 344–48.

Gao M, Shih C-C, Pan S-Y, Chueh C-C, Chen W-C. Advances and challenges of green materials for electronics and energy storage applications: from design to end-of-life recovery. J Mater Chem A. 2018;6:20546–63. https://doi.org/10.1039/c8ta07246a.

Liu H, Jia M, Yue S, Cao B, Zhu Q, Sun N, Xu B. Creative utilization of natural nanocomposites: nitrogen-rich mesoporous carbon for a high-performance sodium ion battery. J Mater Chem A. 2017;5:9572–9. https://doi.org/10.1039/c7ta01891f.

Basil-Jones MM, Edmonds RL, Cooper SM, Haverkamp RG. Collagen fibril orientation in ovine and bovine leather affects strength: a small angle X-ray scattering (SAXS) study. J Agric Food Chem. 2011;59:9972–9. https://doi.org/10.1021/jf202579b.

Zhang Y, Ingham B, Leveneur J, Cheong S, Yao Y, Clarke DJ, Holmes G, Kennedy J, Prabakar S. Can sodium silicates affect collagen structure during tanning? Insights from small angle X-ray scattering (SAXS) studies. RSC Adv. 2017;7:11665–71. https://doi.org/10.1039/c7ra01160a.

Wells HC, Edmonds RL, Kirby N, Hawley A, Mudie ST, Haverkamp RG. Collagen fibril diameter and leather strength. J Agric Food Chem. 2013;61:11524–31. https://doi.org/10.1021/jf4041854.

Sizeland KH, Basil-Jones MM, Edmonds RL, Cooper SM, Kirby N, Hawley A, Haverkamp RG. Collagen orientation and leather strength for selected mammals. J Agric Food Chem. 2013;61:887–92. https://doi.org/10.1021/jf3043067.

Liu H, Yin Z, Zhang Q, Li X, Tang K, Liu J, Pei Y, Zheng X, Ferah CE. Mathematical modeling of bovine hides swelling behavior by response surface methodology for minimization of sulfide pollution in leather manufacture. J Clean Prod. 2019;237:117800. https://doi.org/10.1016/j.jclepro.2019.117800.

Thanikaivelan P, Rao JR, Nair BU, Ramasami T. Approach towards zero discharge tanning: exploration of NaOH based opening up method. J Am Leather Chem As. 2001;96:222–33.

Jian S, Wenyi T, Wuyong C. Kinetics of enzymatic unhairing by protease in leather industry. J Clean Prod. 2011;19:325–31. https://doi.org/10.1016/j.jclepro.2010.10.011.

Tian J, Long X, Tian Y, Shi B. Eco-friendly enzymatic dehairing of goatskins utilizing a metalloprotease high-effectively expressed by Bacillus subtilis SCK6. J Clean Prod. 2019;212:647–54. https://doi.org/10.1016/j.jclepro.2018.12.084.

Ganesh Kumar A, Swarnalatha S, Sairam B, Sekaran G. Production of alkaline protease by Pseudomonas aeruginosa using proteinaceous solid waste generated from leather manufacturing industries. Bioresour Technol. 2008;99:1939–44. https://doi.org/10.1016/j.biortech.2007.03.025.

George N, Chauhan PS, Kumar V, Puri N, Gupta N. Approach to ecofriendly leather: characterization and application of an alkaline protease for chemical free dehairing of skins and hides at pilot scale. J Clean Prod. 2014;79:249–57. https://doi.org/10.1016/j.jclepro.2014.05.046.

Sivasubramanian S, Manohar BM, Rajaram A, Puvanakrishnan R. Ecofriendly lime and sulfide free enzymatic dehairing of skins and hides using a bacterial alkaline protease. Chemosphere. 2008;70:1015–24. https://doi.org/10.1016/j.chemosphere.2007.09.036.

Fang Z, Yong YC, Zhang J, Du G, Chen J. Keratinolytic protease: a green biocatalyst for leather industry. Appl Microbiol Biotechnol. 2017;101:7771–9. https://doi.org/10.1007/s00253-017-8484-1.

Paul T, Jana A, Mandal AK, Mandal A, Das Mohpatra PK, Mondal KC. Bacterial keratinolytic protease, imminent starter for NextGen leather and detergent industries. Sustain Chem Pharm. 2016;3:8–22. https://doi.org/10.1016/j.scp.2016.01.001.

Pandurangan S, Meganathan I, Ragavan S, Ramudu KN, Shanmugam E, Shanmugam G, Niraikulam A. Engineering of a skin-fiber-opening enzyme for sulfide-free leather beam house operation through xenobiology. Green Chem. 2019;21:2070–81. https://doi.org/10.1039/c8gc03479f.

Pandi A, Ramalingam S, Rao JR, Kamini NR, Gowthaman MK. Inexpensive α-amylase production and application for fiber splitting in leather processing. RSC Adv. 2016;6:33170–6. https://doi.org/10.1039/c5ra26373e.

Murugappan G, Zakir MJA, Jayakumar GC, Khambhaty Y, Sreeram KJ, Rao JR. A novel approach to enzymatic unhairing and fiber opening of skin using enzymes immobilized on magnetite nanoparticles. ACS Sustain Chem Eng. 2016;4:828–34. https://doi.org/10.1021/acssuschemeng.5b00869.

Hammami A, Fakhfakh N, Abdelhedi O, Nasri M, Bayoudh A. Proteolytic and amylolytic enzymes from a newly isolated Bacillus mojavensis SA: characterization and applications as laundry detergent additive and in leather processing. Int J Biol Macromol. 2018;108:56–68. https://doi.org/10.1016/j.ijbiomac.2017.11.148.

Durga J, Ranjithkumar A, Ramesh R, Girivasan KTPV, Rose C, Muralidharan C. Replacement of lime with carbohydrases—a successful cleaner process for leather making. J Clean Prod. 2016;112:1122–7. https://doi.org/10.1016/j.jclepro.2015.07.018.

Durga J, Ramesh R, Rose C, Muralidharan C. Role of carbohydrases in minimizing use of harmful substances: leather as a case study. Clean Technol Envir. 2017;19:1567–75. https://doi.org/10.1007/s10098-016-1321-x.

Fennen J, Herta D, Pelckmans J, Christner J. Reliable and environmentally friendly enzymatic unhairing with low amounts of sulphide. In: Sustainability strategy of leather industry: proceedings of the 10th Asian International conference on leather science and technology workshop on environmental technologies, 2014. pp. 23–26.

Jayanthi D, Victor JS, Chellan R, Chellappa M. Green processing: minimising harmful substances in leather making. Environ Sci Pollut R. 2019;26:6782–90. https://doi.org/10.1007/s11356-018-04111-z.

Andrioli E, Petry L, Gutterres M. Environmentally friendly hide unhairing: enzymatic-oxidative unhairing as an alternative to use of lime and sodium sulfide. Process Saf Environ. 2015;93:9–17. https://doi.org/10.1016/j.psep.2014.06.001.

Jaouadi NZ, Rekik H, A Badis, Trabelsi S, Belhoul M, Hila CG, Irmani A, Khemir H, Toumi A, Bejar S, Jaouadi B. The promising keratin-biodegradation and hide-dehairing activities of the keratinase KERUS from brevibacillus brevis strain US575. In: Recent advances in environmental science from the euro-mediterranean and surrounding regions.2018. pp. 133–35.

Shaikh M, Shafique M, Naz SA, Jabeen N, Rub Nawaz H, Khan Z, Solangi BA, Tahir Ali S. Streptomyces sp. MM-3 from rhizosphere of Psidium guajava: a potential candidate for protease with dehairing properties. Pak J Bot. 2019;51:735–42.

Li SQ, Li J, Yi J, Shan ZH. Cleaner beam house processes trial on cattle sofa leather. J Clean Prod. 2010;18:471–7. https://doi.org/10.1016/j.jclepro.2009.11.010.

Najafi MF, Deobagkar D, Deobagkar D. Potential application of protease isolated from Pseudomonas aeruginosa PD100. Electron J Biotechn. 2005;8:197–203. https://doi.org/10.2225/vol8-issue2-fulltext-5.

Zeng W-C, Sun Q, Zhang W-H, Liao X-P, Shi B. Antioxidant activity in vivo and biological safety evaluation of a novel antioxidant peptide from bovine hair hydrolysates. Process Biochem. 2017;56:193–8. https://doi.org/10.1016/j.procbio.2017.02.022.

Aravindhan R, Monika V, Balamurugan K, Subramanian V, Rao JR, Thanikaivelan P. Highly clean and efficient enzymatic dehairing in green solvents. J Clean Prod. 2017;140:1578–86. https://doi.org/10.1016/j.jclepro.2016.09.211.

Wilkes JS. A short history of ionic liquids—from molten salts to neoteric solvents. Green Chem. 2002;4:73–80. https://doi.org/10.1039/b110838g.

Deferm C, Van de Voorde M, Luyten J, Oosterhof H, Fransaer J, Binnemans K. Purification of indium by solvent extraction with undiluted ionic liquids. Green Chem. 2016;18:4116–27. https://doi.org/10.1039/c6gc00586a.

Riaño S, Binnemans K. Extraction and separation of neodymium and dysprosium from used NdFeB magnets: an application of ionic liquids in solvent extraction towards the recycling of magnets. Green Chem. 2015;17:2931–42. https://doi.org/10.1039/c5gc00230c.

Olkiewicz M, Caporgno MP, Font J, Legrand J, Lepine O, Plechkova NV, Pruvost J, Seddon KR, Bengoa C. A novel recovery process for lipids from microalgæ for biodiesel production using a hydrated phosphonium ionic liquid. Green Chem. 2015;17:2813–24. https://doi.org/10.1039/c4gc02448f.

Zajac A, Kukawka R, Pawlowska-Zygarowicz A, Stolarska O, Smiglak M. Ionic liquids as bioactive chemical tools for use in agriculture and the preservation of agricultural products. Green Chem. 2018;20:4764–89. https://doi.org/10.1039/c8gc01424h.

Dewilde S, Dehaen W, Binnemans K. Ionic liquids as solvents for PPTA oligomers. Green Chem. 2016;18:1639–52. https://doi.org/10.1039/c5gc02185e.

Silva FA, Caban M, Stepnowski P, Coutinho JAP, Ventura SPM. Recovery of ibuprofen from pharmaceutical wastes using ionic liquids. Green Chem. 2016;18:3749–57. https://doi.org/10.1039/c6gc00261g.

Hartmann DO, Shimizu K, Siopa F, Leitão MC, Afonso CAM, Canongia Lopes JN, Silva Pereira C. Plasma membrane permeabilisation by ionic liquids: a matter of charge. Green Chem. 2015;17:4587–98. https://doi.org/10.1039/c5gc01472g.

Jayakumar GC, Mehta A, Rao JR, Fathima NN. Ionic liquids: new age materials for eco-friendly leather processing. RSC Adv. 2015;5:31998–2005. https://doi.org/10.1039/c5ra02167g.

Yang Z. Hofmeister effects: an explanation for the impact of ionic liquids on biocatalysis. J Biotechnol. 2009;144:12–22. https://doi.org/10.1016/j.jbiotec.2009.04.011.

Alla JP, Rao JR, Fathima NN. Integrated depilation and fiber opening using aqueous solution of ionic liquid for leather processing. ACS Sustain Chem Eng. 2017;5:8610–8. https://doi.org/10.1021/acssuschemeng.7b01116.

Andrew DB, Abbott P, Capper G, Davies DL, Rasheed RK. Deep eutectic solvents formed between choline chloride and carboxylic acids: versatile alternatives to ionic liquids. J Am Chem Soc. 2004;126:9142–7.

Abbott AP, Alaysuy O, Antunes APM, Douglas AC, Guthrie-Strachan J, Wise WR. Processing of leather using deep eutectic solvents. ACS Sustain Chem Eng. 2015;3:1241–7. https://doi.org/10.1021/acssuschemeng.5b00226.

Liu H, Li X, Li M, Zhang Y, Tang K, Liu J, Zheng X, Pei Y. A simple and sustainable beamhouse by the recycling of waste-water from KCl-dispase synergistic unhairing in leather making. J Clean Prod. 2021;282:124535. https://doi.org/10.1016/j.jclepro.2020.124535.

Liu H, Zhang Q, Zhang Y, Li X, Tang K, Liu J, Zheng X, Pei Y. Unhairing and fiber bundle-opening of cowhides using KCl and LiBr/[AMIm] Cl assisted neutral protease for leather making. In: Freiberg (Ed.) XXXV congress of IULTCS 2019, Verein für Gerberei-Chemie und -technik e. V., Dresden, Germany, 2019, pp. 1–11.

Zhang H, Wu J, Zhang J, He J. 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules. 2005;38:8272–7.

Acknowledgements

The financial supports from the National Natural Science Foundation of China (No. 51673177) and National Key R & D Program of China (No. 2017YFB0308500) are greatly appreciated.

Funding

National Natural Science Foundation of China (No. 51673177); National Key R & D Program of China (No.2017YFB0308500).

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Fig. S1.

Effects of each cycle unhairing with dispase, KCl/dispase and [AMIm]Cl/dispase processes. Fig. S2. Digital photos of unhairing by KCl/dispase (a, b, c, d) and [AMIm]Cl/dispase (A, B, C, D) processes. Fig. S3. Digital scan images of EVG staining of cross-section of bovine hides ((1) grain layer; (2) reticular layer; (3) subcutis) during one-pot beamhouse by KCl/dispase (a, b, c, d, e, f) and [AMIm]Cl/dispase (A, B, C, D, E, F) processes. Fig. S4. The effect of KCl and [AMIm]Cl concentrations on the Zerta potential dispase solution. Fig. S5. (A) Contact angles of dispase, KCl/dispase and [AMIm]Cl/dispase solutions on the surface of bovine hides; (B) Contact angle digital photos of dispase, KCl/dispase and [AMIm]Cl/dispase solutions on the surface of bovine hides at different time. Fig. S6. SEM images of the cross-section of the tanned leather: (A) conventional process; (B) KCl-dispase process: (C) [AMIm]Cl-dispase process. Fig. S7. Extraction of organic matter in wastewater: (A) Wastewater after one-pot beamhouse; (B) Mixture of wastewater and absolute ethanol; (C) Separation of sediment and solution; (D) Separation of sediment (1) and solution (2); (E) Wastewater extract; (F) Ethanol (1) and containing [AMIm]Cl of water solution (2) after separation. Fig. S8. Infrared spectra of wastewater extract, sodium hyaluronate and pure bovine hide collagen.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, H., Tang, K., Li, X. et al. Efficient and ecological leather processing: replacement of lime and sulphide with dispase assisted by 1-allyl-3-methylimidazolium chloride. J Leather Sci Eng 4, 14 (2022). https://doi.org/10.1186/s42825-022-00086-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-022-00086-3