Abstract

This article comprehensively discusses the mechanical and tribological properties of epoxy matrix composites filled with 100μm graphite particulates, at loadings ranging from 0 to 1wt%. The investigation also focuses on the effects of the graphite filler on the wear surface of the specimens, utilizing an optical microscope for analysis. The results revealed a significant decrease in the tensile strength of the composite, with a reduction of more than 50% observed at 1wt% graphite loading. However, the flexural strength exhibited an initial sharp increase at 0.1wt% graphite loading, followed by a decline at higher graphite contents. Moreover, both impact and hardness values demonstrated improvement as the graphite content increased. The addition of graphite particles led to a reduction in the friction coefficient, attributed to the solid lubrication capabilities of graphite. Furthermore, the wear rate exhibited a sharp decrease with an increase in graphite content due to the formation of a lubrication layer at the contact surface, effectively reducing the break-off of the specimen.

Similar content being viewed by others

Introduction

Epoxy as a polymer is known for its unique mechanical properties and high chemical resistance, making it a versatile material for applications in corrosive environments where metals can easily react, and weaker polymers cannot withstand (https://dianhydrides.com/what-is-epoxy/). Fibre-reinforced epoxy matrix composites are extensively used multiphase materials, primarily due to their exceptional strength-to-weight ratio. Epoxy-matrix composites offer remarkable mechanical and tribological properties, dimensional stability, and sufficient chemical and corrosion resistance [1]. Incorporating fillers into the epoxy resin is a common method to enhance matrix properties. Previous literature demonstrates that fillers such as nanoclay [2], silica [3], TiO2 [4], glass beads [5], and fly ash [6] have been utilized as fillers for epoxy matrix composites, resulting in improved stiffness, toughness, hardness, mould shrinkage, heat distortion temperature, wear rate, and fracture mechanisms. Some studies have also reported a significant reduction in processing costs [7].

Composite materials have revolutionized research in advanced materials, offering opportunities to enhance conventional materials in terms of cost-effectiveness and aesthetics, while also enabling the combination of different properties to design materials with multiple functionalities. Polymeric materials filled with strong inorganic substances can exhibit high stiffness, low weight, and excellent wear and corrosion resistance. These characteristics make polymeric composites a promising choice for industrial applications, as they can be tailored with functional fillers [8, 9]. Fibres in polymer matrices have been found to improve the strength and stiffness of composites, while particulates, when homogeneously mixed, enhance hardness and impact properties. Fillers, in general, enhance the mechanical, thermal, and tribological properties of polymer composites [10,11,12]. Various materials such as glass, carbon, and Kevlar have been transformed into fibres for reinforcing polymers, while graphite, graphene, and carbon black particles are employed as fillers. Nanofillers such as silica, alumina, boron nitride, titanium oxide, and carbon are also widely used [13].

The integration of various functional fillers is an essential approach in designing load-bearing and wear-resistant polymer composites. Baptista et al. [14] investigated the mechanical properties of epoxy-matrix composites containing graphite fillers. Graphite fractions ranging from 5 to 30wt% were added to the epoxy matrix, resulting in a substantial decrease in tensile strength and an increase in tensile modulus. These effects were attributed to the high content of graphite particles, leading to agglomeration and the formation of both micro and macro pores. Kulkarni et al. [15] aimed to enhance the mechanical properties of epoxy by incorporating graphite particles with an average size of 75 μm at weight fractions between 3 and 12%. They observed a 100% increase in impact strength, a 59% increase in flexural strength, and a 19% increase in fracture toughness for a graphite content of 12wt%. El-Melegy et al. [16] investigated the synergistic effect of different nanoparticle hybridizations on the mechanical properties of epoxy composites, dispersing nanoparticles such as graphite, silicon carbide, and alumina in an epoxy matrix. The results showed a 37% and 195% increase in tensile and elastic modulus, respectively, for a 2wt% SiC/epoxy composite, 132% and 200% for a 3wt% alumina composite, and 85% and 32% for a 2wt% graphite/epoxy composite. Alajmi et al. [17] explored the tribological characteristics of graphite epoxy composites in adhesive wear experiments. Composites with graphite content ranging from 0 to 7wt% were prepared and tested, and it was determined that the optimal graphite content for minimal wear and friction was between 3-4wt%. Deviating from this range resulted in higher friction and wear rates. Sakka et al. [18] studied the correlation between friction coefficient and temperature for epoxy matrix composites filled with carbon nanotubes, graphite, or a hybrid of both. They concluded that a strong correlation exists between friction and temperature, as the flash temperature measured at the beginning of the experiment exceeded the composite’s degradation temperature, thereby affecting the friction coefficient of the entire system. Researchers have devoted considerable attention to incorporating particles and fibers into polymer matrices to improve mechanical properties, enabling them to compete with metals and other high-strength structural members. Over the past 30 years, numerous investigations have been conducted by researchers such as Shalwan [19], Kaushik [20], Yasmin [21], Novak [22], Suherman [23], and Yao [24], among others.

In this study, epoxy matrix composites filled with varying fractions of approximately 100 μm graphite particulates were fabricated. Layered composites were also developed, followed by an investigation of their mechanical and tribological properties. The adhesion of the layered specimens was also considered. This research aims to explore cost-effective alternatives to fillers in polymers used in friction-intensive systems.

Materials and methods

Materials used

The epoxy resin with commercial name (KEMAPOXY 150) was used in this study. It was obtained from Chemicals for Modern Building (CMB), Cairo, Egypt, along with the corresponding hardener in with 2:1 ratio. Graphite particles from EGYCARBON, Cairo, were sieved and graded to an approximate particle size of 100 μm.

Mixing and preparation

Two types of composite structures were developed for this study: homogeneously mixed composites; where the composite resin and filler were mixed together, and layered structures, where a layer of neat epoxy was poured first, followed by a layer of graphite/epoxy composite. For the homogeneously mixed composite, the epoxy and hardener were mixed in a container according to the manufacturer’s recommended ratio (2:1) and directions. The mixture was mechanically stirred for two minutes using a drilling machine with a coupled metal stirrer head. Graphite particles were slowly added to the mixture while stirring to ensure a homogeneous mixture and prevent agglomeration. The liquid composite was then poured into a mould after 5 min of stirring and gas bubbles are expelled by heating the surface of the specimen with a gas lighter. The specimens were cured for 24 h at room temperature, removed from the mould, and allowed to continue curing for 5 days to reach maximum strength.

For the layered composite, the first layer of neat epoxy was poured into the mould and allowed to cure for 1 h. Subsequently, another layer of either 0.1wt% graphite/epoxy or 1wt% graphite/epoxy composite was poured, and both layers were cured together. Samples were then cut according to the dimensions required for the specific tests. Figures 1 and 2 illustrate the homogeneously mixed and layered specimens, respectively. Tensile and flexural specimens were rectangular with dimensions of 25 mm × 8 mm × 270 mm. Tribological specimens were cut into rectangular cubes measuring 10 mm × 10 mm × 30 mm. Table 1 presents the designation of each specimen. The thickness of the specimens remained consistent due to the uniform utilization of the same volume across all specimens.

Mechanical properties

Tensile and flexural measurements were conducted using a universal tensile testing machine (iBERTEST, Spain, model TESTCOM-100) in accordance with ASTM D638 and D790 standards, respectively. The crosshead speed for both tensile and flexural tests was set at 1 mm/min. Three specimens were tested for each specimen range (Neat, 0.1, 0.5, 1wt%), and the average values were recorded. Hardness values were determined using a Shore D hardness tester, with five random points tested on each specimen to obtain the average hardness value. Impact tests were performed using a Charpy impact testing machine following ASTM D256 standard.

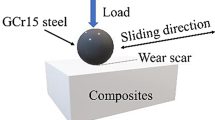

Friction and wear test

A Block-on-Ring (BOR) test setup, as depicted in Fig. 3, was employed for friction and wear testing in this study. The block specimen had dimensions of 10 mm×10 mm×30 mm, while the ring served as the stainless steel counterface (AISI 304, hardness 1250HB). Adhesive wear tests were conducted according to the G-77 ASTM standard under ambient conditions (temperature: 25 °C, humidity: 50 ± 5%). A sliding speed of 200-400 rpm and normal loads of 10 N, 20 N, and 40 N were applied during the tests.

Results and discussion

Tensile behaviour

Tensile tests were conducted on three specimens of each graphite/epoxy composite as well as the neat polymer. Figure 4 presents typical engineering stress-strain curves obtained from these tests. The curves demonstrate the brittle behaviour of all specimens, both with and without graphite filler. It is evident that the mechanical properties of the composites are influenced by the characteristics of the filler used. In this study, all composites exhibited lower tensile strength than the neat epoxy, with the tensile strength decreasing as the graphite filler content increased. The derived tensile properties are presented in Table 2.

The results indicate that the addition of 0.1wt% graphite reduced the tensile properties of the neat epoxy by 32.7% (from 52.11 MPa to 35.05 MPa). This reduction is expected since graphite is a brittle material, and its incorporation into the epoxy matrix renders the epoxy more brittle. A reduction of 43.5% is observed with the addition of 0.5wt% graphite particles, and a final reduction of 56.03% is observed with the specimen containing 1wt% graphite particles. This trend aligns with the findings of Suresha et al. [2] in their study on the role of micro/nano particles in the mechanical and tribological properties of polymer composites.

The strain at break for each specimen, as indicated in Table 2, demonstrates a significant decrease in elongation with the addition of graphite particles. This increased brittleness can be attributed to the amplified stress concentration areas and reduced bonding between the matrix and filler. With higher graphite content, agglomerates are formed, resulting in greater interfacial distance between the matrix and filler, leading to the generation of micro cracks and air bubbles, as illustrated in Fig. 5. Additionally, the presence of graphite micro particles can create obstacles for crack propagation within the composite, resulting in a less favourable crack path and increased brittleness during fracture.

Flexural behaviour

Homogenously mixed composite

Flexural properties play a crucial role in structural elements, as composite materials used in structures often experience bending loads. Therefore, the development of new composites with improved flexural characteristics is essential. Figure 6 illustrates the flexural strength of the homogenously mixed graphite/epoxy composites in comparison to the neat epoxy. It is observed that all graphite/epoxy composites exhibited higher flexural properties than the neat epoxy. This improvement can be attributed to the mechanism of load transfer from the matrix to the high-strength graphite particles during bending. In tension, the stresses are in the opposite direction, which explains the different behaviour.

The most significant enhancement in flexural properties of the graphite/epoxy composite was achieved with the addition of 0.1wt% graphite micro particles. This composition increased the flexural strength of the neat epoxy from 46.8 MPa to 80.08 MPa, corresponding to a remarkable 71.1% increase. With a graphite content of 1wt%, the increase in flexural strength compared to neat epoxy was 59.79 MPa, representing a 27% increase. Although this value was lower than that achieved with 0.1wt% and 0.5wt% graphite content, it still demonstrated an improvement over the neat epoxy.

Figure 7 presents a comparison between the tensile strength and flexural strength of the composites. It is evident that the benefits of using graphite as a filler are more pronounced in flexural loading compared to tensile loading. This finding aligns with previous studies in the literature that have investigated the incorporation of various inorganic fillers in polymer matrix composites [25, 26]. The improved flexural strength can be attributed to the ability of the graphite particles to effectively transfer the applied load from the matrix, resulting in enhanced resistance to bending forces. In contrast, tensile loading primarily relies on the matrix material itself, and the presence of graphite filler may not contribute significantly to the overall tensile strength.

These findings highlight the importance of considering the specific loading conditions and the role of fillers in composite materials. The selection of fillers should be tailored to the desired mechanical performance in the intended application, taking into account the specific loading conditions and the interaction between the filler and the matrix material.

Layered composites

The development of layered composites in this study aimed to explore the potential for successfully bonding different layers of epoxy and graphite/epoxy composites to create a new material with distinct internal and external flexural properties. This investigation aimed to achieve various benefits such as reducing the overall stiffness of the material by combining stiffer and weaker materials, as well as reducing costs by combining cheaper and more expensive materials.

Figure 8 illustrates the flexural strength of the graphite/epoxy layered composites compared to the neat epoxy. The results indicate that the layered composite consisting of a layer of neat epoxy and 0.1wt% graphite/epoxy composite exhibited the highest flexural strength, with a 64.8% increase compared to the plain neat epoxy. This improvement is comparable to the enhancement observed in the homogeneously mixed graphite/epoxy composite. On the other hand, the layered composite with a combination of neat epoxy and 1wt% graphite/epoxy had the lowest flexural strength among the layered specimens, with a value of 49.9 MPa. However, even this specimen showed a 6.6% improvement over the neat epoxy. The layered composite with a triple-layer structure of neat epoxy, 0.1wt% graphite/epoxy, and 1wt% graphite/epoxy exhibited a flexural strength of 61.28 MPa, indicating that flexural properties can be enhanced through the layering of composites with different flexural characteristics. The failure mode observed in the layered specimens was delamination, characterized by interlayer debonding and changes in the crack propagation direction between the layers, as depicted in Fig. 9. This indicates that the bonding between the layers needs further improvement to enhance the overall strength and integrity of the layered composites.

These findings suggest that the layering approach holds promise for improving the flexural properties of composites by combining different materials with distinct mechanical characteristics. However, further optimization of the bonding between the layers is necessary to enhance the overall performance and reliability of the layered composites.

Hardness and impact strength

The hardness and impact strength of the graphite/epoxy composites showed improvement with increasing graphite content. This can be attributed to the higher density, surface hardness, and mechanical strength of the graphite particles compared to the neat epoxy. Table 3 provides the hardness and impact strength of the composites.

In terms of hardness, the neat epoxy had a Shore D hardness of 50 SHD. With the addition of 1wt% graphite, the hardness value increased to 64 SHD, representing a 28% increase. This increase in hardness can be attributed to the load transfer mechanism within the homogeneously dispersed composite, where the surface of the graphite particles becomes load-bearing during compression testing (Shore D hardness testing).

Regarding impact strength, the incorporation of 1wt% graphite resulted in a 29% increase in impact value compared to the neat epoxy. The presence of graphite particles alters the crack propagation path during failure, creating changes in direction that hinder fracture and increase the toughness of the material. Similar enhancements in surface hardness and impact strength have been reported in previous studies [27,28,29] involving the addition of high-density and high-strength inorganic particles to composites.

These results indicate that the inclusion of graphite particles can effectively improve the hardness and impact properties of the epoxy composite. The load transfer mechanism and altered crack propagation behaviour contribute to these enhancements.

Friction and sliding wear results

Friction

The friction coefficient of the neat epoxy and graphite/epoxy composites was investigated under various operating conditions, including different sliding speeds (200 and 600 rpm), applied loads (10, 20, and 40 N), and a constant time of 300 s. The coefficient of friction was determined by dividing the frictional force by the applied load. It was observed that as the applied load increased, the coefficient of friction also increased for all composites, including the neat epoxy. This is expected because higher normal loads result in increased pressure on the specimen and counterface, leading to higher frictional forces in the system.

The specimens with 1wt% graphite content consistently exhibited the lowest coefficient of friction among all applied loads and sliding speeds. For example, when tested at 10 N applied load and 200 rpm sliding speed, a 14% reduction in the coefficient of friction was observed compared to the neat epoxy (Fig. 10). Similarly, at 20 N applied load and 600 rpm sliding speed (Fig. 11), a 12% decrease in the friction coefficient was observed between the neat epoxy and the specimen with 1wt% graphite content. This reduction can be attributed to the ease with which the graphite particles come off the composite and form a lubricating film, as discussed earlier [22]. These findings align with the results reported in previous studies [30, 31].

Similar trends were observed under all other operational conditions, as shown in Fig. 12. The reduction in the coefficient of friction was most significant when the applied load was changed. While the sliding speed had a relatively minor effect on the coefficient of friction of the composites, a noticeable effect was observed with higher applied loads. In fact, a 52% increase in the coefficient of friction was noted when the applied load was changed from 10 to 40 N. It is important to note that increasing the graphite content would lead to lower friction coefficients; however, this could compromise the stability of the composite as the weak bonding between the matrix and the filler may result in the composite becoming weak and prone to crumbling [32].

Overall, the addition of graphite content in the epoxy composite led to a reduction in the coefficient of friction, particularly under higher applied loads. However, it is crucial to strike a balance between achieving low friction coefficients and maintaining the stability and strength of the composite.

Wear

Figure 13 presents the variation in wear rate for the neat epoxy and graphite/epoxy composites under different conditions. The experimental results indicate that the wear rate decreases with an increase in graphite content. Specifically, the specimen with 1wt% graphite exhibited a wear rate reduction of over 75% compared to the neat epoxy. This reduction was also observed at higher sliding speeds of 600 rpm, where the wear rate was reduced by 73%. These findings can be attributed to the solid lubrication abilities of graphite particles, which help to minimize wear [33]. An interesting trend observed in this study is the reduction of wear rate with an increase in sliding speed. This phenomenon can be explained by the faster formation of a sliding film on the specimen and counterface, which subsequently reduces the disintegration of the composite. The generated film stabilizes the stick-slip process, creating a low adhesion region where wear rates are lower. However, this trend may contradict the conclusions drawn in some previous studies [34, 35]. Nevertheless, a study conducted by Tripathy et al. [36] reported that wear rate initially increases with an increase in sliding velocity, but there is a sharp decrease within a velocity range of 3-4 m/s, followed by an exponential increase up to 7 m/s. It could be argued that the reduction in wear rate with an increase in sliding speed observed in this research falls within the range of the initial decrease observed in the aforementioned study, making it an acceptable trend.

Figure 14 specifically depicts the specific wear rate of the graphite/epoxy composite for a 10 N applied load at various sliding distances. Figure 15 provides a comparison of the worn surfaces of the specimens tested during friction, aiming to determine the wear mechanism and surface morphology. It is evident that the worn surface of the neat epoxy composite appears much coarser, exhibiting deep scratches. This can be attributed to the high frictional force and the brittle nature of the epoxy material. In contrast, the composite with 1wt% graphite particles exhibits a smoother surface, although some visible scratches are present. These smooth scratches result from the initial friction and surface break-off of the composite before a lubrication film is generated. This lubrication film subsequently forms a low-friction layer, reducing the generation of debris. These findings align with previous studies on the tribological properties of polymer composites [37].

The worn surface of the specimen with a higher quantity of graphite filler can be described as having a better quality surface [38], as there is no evidence of extreme debonding or high porosity. The presence of microcracks indicates good resistance to shear stresses exhibited by the graphite particles. Similar observations have been reported in studies involving carbon fiber and epoxy polymer composites, where less damage was observed compared to glass fibre epoxy composites [39]. In summary, it can be concluded that graphite demonstrates excellent properties in reducing both friction and wear rates in polymer composites.

Conclusion

Based on the investigation of the mechanical and tribological properties of graphite filler epoxy matrix composites, the following conclusions can be drawn:

-

1.

Successful incorporation of graphite: Graphite can be effectively incorporated into the epoxy resin to produce a particulate filler epoxy composite. It is important to ensure homogenous mixing of the graphite particles to prevent agglomeration, especially at higher percentages.

-

2.

Influence on mechanical properties: The addition of graphite particles significantly affects the mechanical properties of the composite. Tensile strength decreases with an increase in graphite content, with a 1wt% addition resulting in a 56% reduction in tensile strength. Flexural strength, on the other hand, is improved with the addition of graphite particles, although not in a linear manner. The composite with 0.1wt% graphite exhibits the highest flexural strength. Hardness and impact values also show improvement with higher graphite content.

-

3.

Influence on wear and friction properties: The presence of graphite particles influences the wear and friction properties of the composite. The specific wear rate decreases with an increase in graphite content, primarily due to the solid lubrication capabilities of graphite. The friction coefficient is affected by both the graphite content and the applied load. Higher applied loads result in higher friction coefficients, while higher graphite content leads to lower friction coefficients. Microscopic analysis of the wear track reveals that the worn surface of the composite with 1wt% graphite content appears smoother. This is attributed to the development of a lubrication film during friction, which reduces the surface roughness of the system.

Overall, the incorporation of graphite particles in the epoxy matrix composite demonstrates improvements in various mechanical and tribological properties, highlighting the potential of graphite as a beneficial filler material in composite fabrication.

Availability of data and materials

Datasets used in this study are available on a request basis. Further data can be made available on the journal submission page.

References

A. Yasmin, I.M. Daniel, Mechanical and thermal properties of graphite platelet/epoxy composites. Polymer. 45, 8211–8219 (2004)

Z. Xu, X. Tang, J. Zheng, Thermal stability and flame retardancy of rigid polyurethane foams/organoclay nanocomposites. Polym.-Plast. Technol. Eng. 47(11), 1136–1141 (2008)

M.Z. Rong, Q.Y. Zhang, X.H. Zheng, M. Zeng, R. Walter, Friedrich. Structure-property relationship of irradiation grafted nano-inorganic particle filled poly propylene composites. Polymer. 42, 167–183 (2001)

J.F. Tan, Y.J. Jia, L.X. Li, A series–parallel mixture model to predict the overall property of particle reinforced composites. Compos. Struct. 150, 219–225 (2016)

B.R. Raju, B. Suresha, R.P. Swamy, B.S.G. Kanthraju, Investigations on mechanical and tribological behaviour of particulate filled glass fabric reinforced epoxy composites. J. Minerals Mater. Charact. Eng. 1, 160–167 (2013)

R.S. Raja, K. Manisekar, V. Manikandan, Effect of flyash filler size on mechanical properties of polymer matrix composites. Int. J. Min. Metall. Mech. Eng. 1, 34–39 (2013)

A. Khan, P. Savi, S. Quaranta, M. Rovere, M. Giorcelli, A. Tagliaferro, C. Rosso, Jia low-cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers. 9, 1–14 (2017)

I.M. Hutchings, Tribology Friction and wear of Engineering Materials (CRC Press, London, 1992)

S.W. Zhang, State of the art of polymer tribology. Tribol. Int. 3(1–3), 49–60 (1998)

B. Suresha, B.N. Ravi Kumar, M. Venkataramareddy, T. Jayaraju, Role of micro/nano fillers on mechanical and tribological properties of polyamide66/polypropylene composites. Mater. Des. 31, 1993–2000 (2010)

H. Jin, W. Bing, L. Tian, P. Wang, J. Zhao, Combined effects of colour and elastic modulus on antifouling performance: a study of graphene ocide/silicone rubber composite membranes. Materials. 12, 2608 (2019)

J. Beter, B. Schrittesser, B. Lechner, M. Reza, C. Marano, P.F. Fuchs, G. Pinter, Viscoelastic behaviour of glass-fibre-reinforced silicone composites exposed to cyclic loading. Polymers. 12, 1862 (2020)

M. Palabiyik, S. Bahadur, Mechanical and tribological properties of polyamide6 and high density polyethylene polyblends with and without compatibilizer. Wear. 246, 149–158 (2000)

R. Baptista, A. Mendao, M. Guedes, R. Marat-mendes, An experimental study on the mechanical properties of epoxy-matrix composite containing graphite filler. Procedia Struct. Integr. 1, 74–81 (2016)

H.B. Kulkarni, S.S. Mahamuni, P.M. Gaikwad, M.A. Pula, S. Mahamuni, S.H. Bansode, A.A. Kulkarni, Y.B. Shete, A Nehatrao, enhanced mechanical properties of epoxy/graphite composite. Int. J. Adv. Eng. Res. Stud. 6(1), 1–5 (2017)

T.A. El-Melegy, N.S.M. Eltayeb, Synergistic effect of different nanoparticles hybridization on Mechanical Properties of Epoxy Composite. Int. J. Sci. Eng. Res. 5(9), 334–340 (2014)

M. Alajmi, A. Shalwan, Correlation between mechanical properties with specific wear rate and the coefficient of friction of graphite/epoxy composites. Materials. 8, 4162–4175 (2015)

M.M. Sakka, Z. Antar, K. Elluech, J.F. Feller, Tribological response of an epoxy matrix filled with graphite and/or carbon nanotubes. Friction. 5(2), 171–182 (2017)

A. Shalwan, Yousif, influence of date palm fibre on mechanical and wear characteristics of epoxy composite. Mater. Des. 59, 264–273 (2014)

A. Kaushik, P. Singh, Jyoti, mechanical and electrical conductivity study on epoxy/graphite composites. J. Reinf. Plast. Compos. 29(7), 1038–1045 (2010)

A. Yasmin, J.L. Abot, I.M. Daniel, Characterization of structure and mechanical behavior of clay/epoxy nanocomposites, 14th international conference on composite materials, San Diego, CA; (2003)

I. Novak, I. Krupa, Electro-conductive resins filled with Graphite for casting applications. Eur. Polymer J. 40(7), 1417–1422 (2004)

H. Suherman, Y. Mahyoedin, E. Septe, R. Rizade, Properties of graphite epoxy composite: the in-plane conductivity, tensile strength and shore hardness. AIMS Mater. Sci. 6(2), 165–173 (2019)

X. Yao, X. Gao, J. Jiang, C. Xu, C. Deng, J. Wang, Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos. part B: Eng. 132(1), 170–177 (2018)

S. Chatterjee, J.W. Wang, W.S. Kuo, N.H. Tai, C. Salzmann, W.L. Li, R. Hollertz, F.A. Nüesch, B.T.T. Chu, Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites. Chem. Phys. Lett. 531, 6–10 (2012)

S. Vijoya, K.G. Kornev, A method for wet spinning of alginate fibers with a high concentration of single-walled carbon nanotubes. Carbon. 49, 1859–1868 (2011)

J. Wei, T. Vo, Inam, epoxy/graphene nanocomposites- processing and properties: a review. Royal Soc. Chem. Adv. 5, 7351 (2015)

S. Bal, S.S. Samal, U.K. Mohanty, Mechanical and microstructural analysis of Carbon nanotube Composites pretreated at different temperatures. Am. J. Mater. Sci. 1(1) 5–11 (2011)

S. Jana, W.H. Zhong, Curing characteristics of an epoxy resin in the presence of ball-milled graphite particles. J. Mater. Sci. 44, 1987–1997 (2009)

M.Q. Zhang, M.Z. Rong, S.L. Yu, B. Wetzel, K. Friedrich, Improvement of tribological performance of epoxy by the addition of irradiation grafted nano-inorganic-particles. Macromol. Mater. Eng. 28(7), 5–11 (2002)

A. Khanam, B. Mordina, Tiwari, statistical evaluation of the effect of carbon nanofibre content on the Tribological properties of epoxy composites. J. Compos. Mater. 0(0), 1–11 (2014)

M. Sudheer, K. Hemanth, K. Raju, T. Bhat, Enhanced mechanical and wear performance of epoxy/glass composites with PTW/Graphite hybrid fillers. procedia Mater. Sci. 6, 975–987 (2014)

W.J. Anthony, R.A. Bideaux, K.W. Bladh, M.C. Nichols, Graphite: Handbook of Mineralogy. Vol. I (Elements, Sulfides, Sulfosalts). Chantilly, VA: Mineralogical Society of America. (1990). ISBN 978-0962209703

K. Kato, Friction and wear of passive metals and coatings, Metals and Surface Engineering, Tribocorrosion of Passive Metals and Coatings, Woodhead Publishing, 65–99, (2011). ISBN 9781845699666

J. Zhang, L. Chang, S. Deng, L. Ye, Z. Zhang, Some insights into effects of nanoparticles on sliding wear performance of epoxy nanocomposites. Wear. 304, 138–143 (2013)

B.S. Tripathy, M.J. Furey, Tribological behaviour of unidirectional graphite-epoxy carbon-PEEK composites. Wear. 162, 385–396 (1993)

B.J. Briscoe, P.J. Tweedale, A review of polymer composite tribology. p. 15. Am. Soc. Met. (1990)

B. Shivamurthy, K.U. Bhat, S. Anandhan, Mechanical and sliding wear properties of multi-layered laminates from glass fabric/graphite/epoxy composites. Mater. Des. 44, 136–143 (2013)

K.M. Subbaya, Grey-based Taguchi approach for wear assessment of SiC filled carbon–epoxy composites. Mater. Des. 41, 124–130 (2012)

Acknowledgements

Engineer Omar Mohasen and Engr Wesam Sedik of the CAM centre and the materials lab respectively are duly acknowledged here due to their immense contribution to the experimental setup and analysis of results from the beginning of the research till the end.

Funding

I declare that no external funding was used in this research. All financial obligations relied on the author(s).

Author information

Authors and Affiliations

Contributions

A, B and C did the research, wrote the manuscript and edited. D proofread the manuscript and checked for corrections.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibrahim, M.M., El-Tayeb, N., Shazly, M. et al. An experimental study on the effect of graphite microparticles on the mechanical and tribological properties of epoxy matrix composites. Functional Composite Mater 5, 2 (2024). https://doi.org/10.1186/s42252-023-00046-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42252-023-00046-y