Abstract

Background

The aim of this study was to develop an oil formulation from a local betabaculovirus. Hyphantria cunea Drury (Lepidoptera: Erebidae) granulovirus (HycuGV-Hc1) was isolated from the infected larvae to test its efficacy on the pest. The oil formulation was prepared by mixing the viral suspension with sunflower oil and some adjuvants and named HycuGV-TR61. Crude virus and the formulations were carried out on third instar H. cunea larvae using 1 × 104–8 OBs /ml concentrations and were exposed to temperatures (28, 35, and 42 °C) and UV-B light at different periods (0, 1, 3, 5 h).

Results

The mortality rate, which was 50% at the lowest concentration (1 × 104 OB/ml), reached 99.86% at the highest concentration (1 × 108 OB/ml). LC50 values of fresh and old forms were calculated as 0.64 × 104 and 0.87 × 104 OBs/ml, respectively. Application of shelf life showed that there was non-significant change in the pathogenic activity of the formulation with time. In the experiments, it was observed that the activity decreased as the temperature and time of exposure increased. Significantly difference in larval mortality was observed when fresh and old formulations were exposed to 0, 1, 3 and 5 h to UV-B, (old: 96.7, 86, 80 and 60%; fresh: 97.1, 90, 85 and 62%, respectively).

Conclusions

The results revealed superior aspects of HycuGV-TR61, which was developed as a local viral biopesticide, its resistance to abiotic factors and its potential to be used in pest control.

Similar content being viewed by others

Background

The fall webworm, Hyphantria cunea (Drury) (Lepidoptera: Erebidae), is a pest of a few ornamental trees and shrubs as well as of several agricultural crops. The larvae feed in huge nests and can completely defoliate trees and shrubs. Native to North America, this species has become an invasive pest throughout Europe and Asia (Johnson and Lyon 1994). Despite the efforts to control, development of resistance to chemicals and extensive damage.

Nucleopolyhedroviruses (NPVs) and granuloviruses (GVs) (Baculoviridae) are important pathogens of a wide range of lepidopteran pests. They have been developed as microbial pesticides (Szewczyk et al. 2009). Several NPVs and GVs have been isolated from H. cunea larvae and considered useful biological control agents (Bayramoglu et al. 2018).

Viral insecticides are emerging as promising alternative control agents to chemicals as they are safe for humans and the environment, suitable for sustainable agricultural practices and the rising market demand (Abd-Alla et al. 2020). Developing formulations can play an important role in stabilize the pathogen during storage and facilitate farmers application of bioinsecticide products (Burges 1998). Viruses must be able to remain intact in environments outside the host insect. Some materials were used as adjuvants to protect the baculoviruses from sunlight and proven to increase the efficacy of Baculovirus formulation (Sajap et al. 2009). The development of viral products may differ depending on the viral strain, formulation type and content, which means that different methods can be used (Roldão et al. 2011). In addition, it has been shown that the oil-based formulations are more stable on the foliage against environmental factors, such as rain and wind and have high shelf life due to low pH levels (Batista et al. 2001).

Formulations should allow the microbial agent to disperse in the environment and remain intact for the time necessary for its action. Laboratory and field studies have shown that the solar radiation (UV) is probably the most important factor affecting the persistence of microbial agents at the environment (Burges 1998). In general, entomopathogenic viruses are quite stable at low temperatures. These viruses can survive for several years in dry powders form or in suspensions stored in the dark and at 0–4 °C (Jacques 1985).

Baculovirus biopesticides are prepared to act as nutritional stimulants with various additives such as sugar, pre-gelatinized flour, starch, ground corncob, corn oil, boric acid and optical brighteners to provide UV protection (Méndez et al. 2002). Resin, alginates, and oils are used to suspend the active ingredient during storage as well as to resuspend it before use (Jones and Burges 1998).

This study aimed to develop an oil-based formulation (HycuGV-TR61) of H. cunea granulovirus (HycuGV-Hc1) isolated from Turkey and to investigate the shelf life of formulations (fresh and old). In addition, it also investigated the sensitivity of the crude virus and two formulations to UV and temperature.

Method

Virus and insect

The Hyphantria cunea granulovirus HycuGV-Hc1strain used in this study was isolated from the larvae of H. cunea in previous studies, and its morphological and molecular characteristics were determined (Bayramoglu et al. 2018). Hyphantria cunea larvae were collected from mulberry trees in Rize, Turkey, in June 2021, reared in the laboratory to adult moths on mulberry leaves in containers (17 × 11 × 7 cm) for oviposition. The newly hatched larvae were fed with fresh mulberry leaves and maintained at 26 ± 1 °C, 50 ± 10% RH and 14:10 (L:D) photoperiod. The third instar larvae were used in the bioassay.

Production and purification of HycuGV-Hc1

For production, a suspension of 1 × 107 occlusion bodies (OBs)/ml HycuGV-Hc1 from pure virus stock in the laboratory was applied to the mulberry leaf and the third instar H. cunea larvae were starved for six hrs and then fed on the leaves in plastic containers. Applications were maintained at 26 ± 1 °C and 50 ± 10% RH on a 14-h light/10-h dark photoperiod. All larvae that die from infection were collected daily, homogenized in 0.1% sodium dodecyl sulfate (SDS), and filtered through cheesecloth to separate the virus from insect body and tissue parts. An equal volume of 0.1% SDS was added to virus suspension, and the filtration was repeated. The resulting filtrate was centrifuged at 7.840× g for 30 min at 4 °C. The supernatant was discarded, and the pellet was suspended in dH2O. The suspension was loaded on 30% sucrose and centrifuged for 30 min at 5000× g. The final pellet was resuspended with dH2O, and the OBs were quantified visually with a Neubauer haemocytometer. The purified HycuGV-Hc1 stock was stored at − 20 °C until the bioassays were conducted.

Development of oil-based viral biopesticide

The formulation was developed by mixing the viral suspension with sunflower oil, surfactant, adjuvant, humectant, solvent, thickener, emulsifier, phagostimulant, lubricant-synergist and sticker (Table 1). After all the ingredients were prepared, the determined final volume (100 ml) was completed with dH2O and mixed homogeneously, and the pH of the mixture was measured. The virus suspension was added to the prepared mixture and pH of the formulation was re-measured. Thus, the formulation was prepared to be contained 20% active ingredient and 80% other fillers and adjuvants. After the old formulation was prepared, it was stored in a glass bottle at 4 °C for 1 year until used in trials. Two formulations, fresh and old, were prepared one year apart and used in bio-test studies.

Efficacy of viral formulation against Hyphantria cunea larvae

The efficacy of the formulation was determined by applying the formulation to third instar larvae of H. cunea in two different forms, fresh (prepared daily) and old. (After preparation, it was kept in a glass bottle at 4 °C for one year under laboratory conditions.) For bioassays, crude virus, fresh and old stock formulations (1 × 109 OB/ml) were firstly diluted from 1 × 108 OB/ml to 1 × 104 OB/ml. One ml of each dilution was contaminated on mulberry leaf of equal size, and leaf expected to dry were placed in the application boxes. Thirty H. cunea larvae starved for six hours were transferred to each box. In the control group, the formulation without the active ingredient (virus) was contaminated on the leaf. All treatments, thirty larvae of H. cunea were used, and the bio-tests were performed in three replicates and were maintained at 26 ± 1 °C and 50 ± 10% RH on a 14-h light/10-h dark photoperiod for 14 days. Larvae were fed on fresh mulberry leaves every day, and symptoms and larval mortality were assessed daily and recorded.

Effects of temperature and ultraviolet on formulations

In this application, the effects were determined crude virus and oil-based HycuGV-Hc1 formulations exposed to different temperatures and UV-B degrees on the pest. Crude virus and two formulation forms were adjusted to 1 × 108 OB/ml in the experiments. Crude virus and both forms were exposed to temperatures of 28, 35, 42 and 60 °C and UV-B radiation (15 watts, G15T8 Germicidal, Japan) at 0, 1, 2, 3 and 5 h. Each character was tested separately with the control group on third instar H. cunea larvae. Application and conditions were carried out as described above. Each treatment was repeated three times. The larval mortality was recorded daily for 10-day post-inoculation.

Statistical analyses

Mortality rates were calculated by Abbott’s formula (Abbott 1925). Mortality data were subjected to probit regression analysis and median lethal concentration (LC50) was estimated (Finney 1971). All analyses were performed using SPSS 25.0 statistical software (IBM, Armonk, NY).

Results

An oil-based biopesticide including 1 × 109 OBs/ml was developed for the first time from the local isolate HycuGV-Hc1 reproduced in H. cunea larvae, and it was named as HycuGV-TR61. The pH of the formulation was measured as 5.3–5.5 as expected. In the insecticidal activity trial, crude virus and both forms (fresh and old) of the formulation produced a very similar mortality plot on H. cunea larvae under laboratory conditions. As expected, concentration–response bioassays showed that larval mortality increased with increasing virus concentrations. The mortality rate, which was 50% at the low concentration (1 × 104 OB/ml), reached 99.86% at the highest concentration (1 × 108 OB/ml) (Fig. 1).

The insecticidal efficacy of the fresh and old forms did not differ much, although there was a period of one year in between. LC50 values of new and old forms of formulation were calculated as 0.64 × 104 (0.09–4.2) and 0.87 × 104 (0.1–5.7) OBs/ml, respectively (Table 2).

Trials of the effect of temperature on the formulation revealed that both formulation forms were equally sensitive at 1 × 108 OBs/ml on H. cunea larvae (Fig. 2). Both the old and the new formulation were showed close efficacy against larvae at all temperature exposures. In the experiments, it was observed that the activity decreased as the temperature and exposure increased. It was determined that there was not much difference in efficacy of crude virus and two formulation forms against H. cunea larvae at all exposure times at temperatures of 28 and 35 °C (Fig. 2A, B).

Mortality rates produced by crude virus, fresh and old forms at 28 °C were determined as 85.45, 88.75 and 81.05%, respectively, at 3 h, intervals. In the same conditions, larval mortality was observed at 35 °C as 76.48, 82.46 and 80%, respectively. At 42 °C, mortality from both forms in 5 h of exposure was approximately 50%, but crude virus had 37.85% mortality at the same conditions (Fig. 2C). It was determined that the mortality rate decreased rapidly with the increase in time at 60 °C and was approximately 15% in both forms at 5 h of exposure (Fig. 2D). The mortality rate of the crude virus at 60 °C for 5 h was determined as 9.48, 85 and 79.42%, respectively.

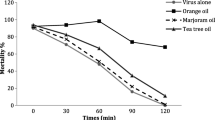

The efficacy of the crude virus, fresh formulation, old formulations (1 × 108 OBs/ml) and the virus-free formulation in third instar H. cunea larvae differed significantly when exposed to UV-B for different durations (Fig. 3). Mortality rates at 1-h exposure to UV-B were recorded as 86 and 90% for the old and new formulations, respectively. Mortality rates on larvae at 3 and 5 h of exposure were calculated as 80 and 60% for the old formulation and 85 and 62% for the new formulation, respectively. The mortality rates decreased as the exposure time to UV-B increased. After 1, 3, and 5 h of exposure to UV-B irradiation, mortality rates of the crude virus on larvae were 72.84, 58.45, and 42.73%, respectively, while mortality values of the fresh and old formulations were above (73%) on the larvae even after 5 h.

Discussion

Studies on the isolation of betabaculovirus from H. cunea in the world date back to very old years and no information about its formulation was found in the literature searches. It is thought that researching the potential of this detected local virus to be used effectively in biological control and thus the development of the virus as a pesticide will provide important contributions to the literature and the use of the virus as a biological control material.

The formulation of granulovirus-containing biological insecticides is the most important part for production. For high volume applications, some factors such as shelf life and UV protection should be considered to create a stable and quality product. The formulation must perform good residual activity in field, and not include any additive with negative effects on virus efficacy (Rashidan et al. 2008). A formulation developed is the result of an active ingredient combined with various components that facilitate the efficacy, stability, and handling of the product (Williams 2001). Liquid formulations are frequently used in the application of biopesticides to larger areas. In a study, it has been shown that oil-based formulations were more advantageous in the field than dry formulations (Batista et al. 2001). So, in the present study, oil-based formulation was preferred. Sunflower oil was used because it is easier and cheaper to obtain. Different oils such as cottonseed oil, corn oil and kaolin are used in oil-based formulations (Shapiro et al. 2012). Additives such as surfactants, adherents, thickeners, binders, binds and phagostimulants and UV protectants were used in baculovirus formulations (Haase et al. 2015). The additives used in the formulation in this study were Tween-80 (surfactant), cotton seed flour (adjuvant), glycerol (humectant), ethyl acetate (solvent), sorbitol (thickener), PEG (emulsifier), sucrose (phagostimulant), boric acid (lubricant-synergist), methyl cellulose (sticker) and lignin sulfate (UV protectant). Some compounds such as boric acid are known to increase the biopesticide properties of baculovirus. A study has shown that boric acid reduces the LT50 of larvae infected with a baculovirus (Morales et al. 1997). Another study showed that lignin sulfonate provides high sun protection (Fernández-Pérez et al. 2014). It has been determined that many products used as adjuvant in studies had an increasing effect on baculovirus infections (Ríos-Velasco et al. 2012). In this study, cotton seed flour was used in the mixture at a rate of 5%.

Baculoviruses break down in alkaline solutions, hence maintaining the pH is particularly important factor. Therefore, the pH value of the formulation with the active ingredient should be between 5 and 7 (Batista et al. 2001). In this study, the pH of the formulation prior to the addition of GV was measured 5.16, while the pH was recorded 5.33 after the GV was added.

In the concentration–response test, no effect of virus-free formulations on H. cunea larvae was observed. Thus, it was determined that the compounds used to prepare the formulation did not have a negative effect on the larvae. LC50 values for these forms (new and old) were calculated as 0.64 × 104 and 0.87 × 104 OBs/ml, respectively. In the previous study, crude form HycuGV-Hc1 virus showed an LC50 value of 2.6 × 104 OBs/ml against H. cunea third instar larvae after 14 days (Bayramoglu et al. 2018). When the LC50 values were compared, it was seen that there was non-significant difference between the HycuGV-Hc1 crude virus and its new and old formulations. The LC50 values of the formulations were calculated slightly lower than crude virus.

Baculoviruses can withstand high temperatures for a short time. They have a OBs (polyhedrin or granulin) that makes them environmentally stable (Funk et al. 1997). Many formulations have been developed to protect baculovirus OBs from environmental factors. In the formulation of any biological agent, it is important that little or no loss of activity (Behle and Birthisel 2014). Temperature and UV-B trials showed that the formulation was protective against the infectivity of the virus but decreased with prolonged exposure.

The mortality of crude virus and formulations differed significantly when exposed to different durations of four temperatures (28, 35, 42 and 60 °C) (Fig. 2). In a study, it was determined that the mortality rate of a baculovirus at three different temperatures for 0, 1, 3 and 5 h decreased as the exposure time increased (Eroglu and Demirbag 2022). There are some studies in the literature that examined the effect of sunlight on the activity of baculoviruses (Sayed et al. 2020). They reported an inverse relationship between exposure to sunlight and larval mortality. In the present study, the mortality rate at the highest (60) temperature exposure was reduced by approximately 60% at 1 h. Hence, the larval mortality decreased with increase in exposure duration of temperature. However, the activity of the fresh and old formulations had similar mortality rates when exposed to heat, while the crude virus had less than 10% mortality. It was detected that the formulations in exposure to temperature was higher mortality than the crude virus.

It has been noted that insect viruses are inactivated by artificial radiation (Cakmak et al. 2021). In the present study, the effect of UV-B exposure of crude virus and formulations, on the virulence of the virus (HycuGV-Hc1) was investigated. Significantly difference in larval mortality was observed when fresh and old formulations were exposed to 0, 1, 3 and 5 h to UV-B (old: 96.7, 86, 80 and 60%; fresh: 97.1, 90, 85 and 62%, respectively). However, it was recorded that the crude virus caused a decrease of approximately 30% in larval mortality on exposure to UV-B (1, 3 and 5 h). Studies have shown that the activity of some baculoviruses of UV light decreases with increasing exposure time (Priyadharshini 2009). The inactivation of virus was directly related to the period of exposure to UV radiation.

Viral insecticides cannot be developed commercially until their formulations are physically, chemically, and environmentally stable in storage and distribution. Use of adjuvants has been found to increase the persistence of the virus in the environment (Mehrvar et al. 2008). The incorporation of adjuvants with microbial insecticides to preserve the virus activity is commonly followed (Rabindra and Jayaraj 1995). Some researchers have noted that the virus can be stable for up to ten years at 4 °C without loss of effectiveness (Gopali and Lingappa 2001). In this study, the larval mortality rates of the formulation kept at 4 °C for one year and the newly prepared formulation were calculated as close to each other. Similarly, Prabhu et al. (2017) stated that virus suspension stored at low temperature causes higher mortality than high temperature.

Although the increase in intensity and time in temperature and UV-B application causes some decrease in insecticidal activity, the formulation is the most effective tool that protects the virus from abiotic factors.

Conclusion

The findings of this study are the first report on the development of a biopesticide originating from betabaculovirus HycuGV, to control of H. cunea and its evaluation for both shelf life and UV/temperature protection under laboratory conditions. The present study demonstrated the advantages of native oil-based HycuGV-TR61 in the laboratory conditions, its resistance to abiotic factors, and its potential for use in pest control. It was shown that the preparation HycuGV-TR61 could be a promising biopesticide; however, further direct investigations are required.

Availability of data and materials

All data and materials are mentioned in the manuscript.

Abbreviations

- OB:

-

Occlusion body

- DNA:

-

Deoxyribonucleic acid

- PCR:

-

Polymerase chain reaction

- MgCl2 :

-

Magnesium chloride

- LC50 :

-

Lethal concentration 50

- μg:

-

Microgram

- ml:

-

Milliliter

- mm:

-

Millimeter

- µl:

-

Microliter

- ng:

-

Nanogram

- UV:

-

Ultraviolet

- RH:

-

Relative humidity

References

Abbott WS (1925) A method of computing the effectiveness of an insecticide. J Econ Entomol 18:265–267

Abd-Alla AM, Meki IK, Demirbas-Uzel G (2020) Insect viruses as biocontrol agents: challenges and opportunities. In: El-Wakeil N, Saleh M, Abu-hashim M (eds) Cottage industry of biocontrol agents and their applications. Springer, Cham, pp 277–295

Batista A, Alves S, Augusto PR (2001) Stability and persistence of two formulations containing Anticarsia gemmatalis nuclear polyhedrovirus (AgMNPV). Neotrop Entomol 30:411–416

Bayramoglu Z, Nalcacioglu R, Demirbag Z, Demir I (2018) Characterization of a Betabaculoviruses from the fall webworm, Hyphantria cunea Drury. (Lepidoptera: Erebidae), in Turkey. Biocontrol Sci Technol 28:1178–1190

Behle R, Birthisel T (2014) Formulations of entomopathogens as bioinsecticides, in Mass Production of Beneficial Organisms. Elsevier, Amsterdam

Burges HD (1998) Formulation of microbial biopesticides-beneficial microorganisms, nematodes and seed treatments. Kluwer Academic Publishers, Dordrecht

Cakmak T, Simón O, Kaydan MB, Tange DA, González Rodríguez AM, Piedra-Buena Díaz A, Caballero Murillo P, Hernández Suárez E (2021) Effects of several UV-protective substances on the persistence of the insecticidal activity of the Alphabaculovirus of Chrysodeixis chalcites (ChchNPV-TF1) on banana (Musa acuminata, Musaceae, Colla) under laboratory and openfield conditions. PLoS ONE 16(5):e0250217

Eroglu GB, Demirbag Z (2022) An environmentally safe and tolerant microbial insecticide utilizing Helicoverpa armigera single nucleopolyhedrovirus (HearNPV-TR). Egypt J Biol Pest Control 32:53

Fernández-Pérez M, Flores-Céspedes F, Daza-Fernández I, Vidal-Peña F, Villafranca-Sánchez M (2014) Lignin and lignosulfonate-based formulations to protect pyrethrins against photodegradation and volatilization. Ind Eng Chem Res 53(35):13557–13564

Finney DJ (1971) Probit analysis. Cambridge Univ press, London

Funk CJ, Braunagel SC, Rohrmann G (1997) Baculovirus structure. In: Miller LK (ed) The baculoviruses. Plenum Press, New York, pp 341–387

Gopali JB, Lingappa S (2001) Evaluation of safety period for field use of virus (HaNPV) under different set of storage conditions. Karnataka J Agric Sci 14(4):1072–1074

Haase S, Sciocco-Cap A, Romanowski V (2015) Baculovirus insecticides in latin america: historical overview, current status and future perspectives. Viruses 7:2230–2267

Jacques RP (1985) Stability of entomopathogenic viruses in the environment. In: Maramorosch K, Sherman KE (eds) Viral insecticides for biological control. Academic Press, New York, pp 285–360

Johnson WT, Lyon HH (1994) Insect that feed on trees and shrubs. Comstock Publishing Associated Cornell University Press, Cornell, pp 166–167

Jones KA, Burges HD (1998) Technology of formulation and application. In: Burges HD (ed) Formulation of microbial pesticides-beneficial microorganisms, nematodes and seed treatments. Kluwer Academic, Dordrecht, pp 7–30

Mehrvar A, Rabindra RJ, Veenakumari K, Narabenchi GB (2008) Evaluation of adjuvants for increased efficacy of HearNPV against Helicoverpa armigera (Hubner) using sunset machine. Int J Biol Sci 8(3):534–541

Méndez WA, Valle J, Ibarra JE, Cisneros J, Penagos DI et al (2002) Spinosad and nucleopolyhedrovirus mixtures for control of Spodoptera frugiperda (Lepidoptera: Noctuidae) in maize. Biol Control 25:195–206

Morales L, Moscardi F, Sosa-Gómez DR, Paro FE, Soldorio IL (1997) Enhanced activity of Anticarsia gemmatalis Hüb. (Lepidoptera: Noctuidae) nuclear polyhedrosis virus by boric acid in the laboratory. An Soc Entomol Brasil 26:115–120

Prabhu S, Mahalingam CA, Krishnamoorthy SV, Shunmugam R (2017) Shelf-life study of Dp NPV (Nuclear Polyhedrosis Virus) suspension and formulation against larval mortality of Diaphania pulverulentalis Hampson. Agric Update 12:234–237

Priyadharshini P (2009) Molecular characterization of NPV of Diaphania pulverulentalis (Hampson) and establishment of phylogenetic relationship with other lepidoptera and baculoviruses. University of Agricultural Sciences, Banglore

Rabindra RJ, Jayaraj S (1995) Management of Helicoverpa armigera with nuclear polyhedrosis virus on cotton using different spray equipment and adjuvants. J Biol Control 9:34–36

Rashidan K, Guertin C, Cabana J (2008) Granulovirus. In: Capinera JL (ed) Encyclopedia of entomology. Springer, Dordrecht

Ríos-Velasco C, Gallegos GM, Berlanga DR, Cambero JC, Romo AC (2012) Mortality and Production of Occlusion Bodies in Spodoptera frugiperda Larvae (Lepidoptera: Noctuidae) Treated with Nucleopolyhedrovirus. Fla Entomol 95(3):752–757

Roldão A, Vicente T, Peixoto C, Carrondo MJT, Alves PM (2011) Quality control and analytical methods for baculovirus-based products. J Invertebr Pathol 107:94–105

Sajap AS, Bakir MA, Kadir HA, Samad NA (2009) Efficacy of selected adjuvants for protecting Spodoptera litura nucleopolyhedrovirus from sunlight inactivation. J Asia-Pac Entomol 12:85–88

Sayed WAA, El-Bendary H, El-Helaly AMA (2020) Increasing the efficacy of the cotton leaf worm Spodoptera littoralis nucleopolyhedrosis virus using certain essential oils. Egypt J Biol Pest Control 30(1):1–7

Shapiro M, El Salamouny S, Jackson DM, Shepard BM (2012) Field Evaluation of a Kudzu/Cottonseed Oil Formulation on the Persistence of the Beet Armyworm Nucleopolyhedrovirus. J Entomol Sci 47(3):197–207

Szewczyk B, Rabalski L, Krol E, Sihler W, de Souza ML (2009) Baculovirus biopesticides: a safe alternative to chemical protection of plants. J Biopestic 2(2):209–216

Williams T, Cisneros J (2001). Formulación y aplicación de los baculovirus bioinsecticidas. In: Caballero P, López Ferber M, Williams T (ed) In Los Baculovirus y Sus Aplicaciones Como Bioinsecticidas (in Spanish)

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

ZB, DG and ID conducted the experiments, collected the data, analyzed the data, collected literature and wrote the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bayramoglu, Z., Gencer, D. & Demir, I. Development of novel betabaculovirus (HycuGV-Hc1) as a biopesticide (HycuGV-TR61) and its efficacy on the fall webworm, Hyphantria cunea Drury (Lepidoptera: Erebidae) larvae. Egypt J Biol Pest Control 33, 21 (2023). https://doi.org/10.1186/s41938-023-00666-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s41938-023-00666-3