Abstract

The traditional vegetable drying (open-air/sun drying) method of harvesting of tomato, potato and onion in the Fogera District in Amhara regional state, Ethiopia, leads to loss of product, reduction in the quality of product and economic loss for the poor farmers. So, this experiment aimed to show the effectiveness of solar dryer technology by increasing the quality of the product in tomato, potato, and onion in Fogera district Northwest Ethiopia, 2018. A simple solar vegetable dryer is experimentally analyzed to alleviate the problem associated with vegetable processing in Woreta city. The first law of thermodynamics energy analysis was carried out to estimate the amount of useful energy gained from solar air dryer and energy utilization ratio of the drying chamber and the energy through drying box. The magnitude of the exergy inflow, outflow and exergy losses in the drying chamber during the drying process was determined by applying the second law of thermodynamics. The average solar drying efficiency was found to be 75.01% to 86.70% for tomato, 75.70% to 87.90% for potato and 58.7% to 85.5% for onion. Regrading the drying period, it took 33 h for tomato, 27 h for potato and 44 h for onion during the experimental test.

Similar content being viewed by others

Introduction

In Ethiopia, especially in Fogera District in Amhara regional state, agricultural vegetable products like onion, potato and tomato share the biggest part of the country’s economy (Wassie. 2016). About 80–90% of the population life depends on vegetable agriculture products (ILRI 2005). Existing evidence shows that vegetable production still does not meet the need of the population, although the production of crops such as onion, tomato and potato is increased from year to year. According to Fogera Agricultural office 2017 report, about 216,788-ton of tomato was produced per year in Fogera District. From this, more than half (55%) of the products had been lost during post-harvest processes. Similarly, 3,661,312.5 ton of onion is produced per year and from this 47% would be lost during post-harvest processes and 122,862.5-ton potato is produced per year and from this 32.3% would be lost during post-harvest processes (Appendix A). The lack of appropriate preservation and storage systems caused considerable losses and reduced the vegetable supply significantly (Karim 2004).

Drying is one of the most prevailing methods of food preservation (Mustayen et al. 2014), where the moisture is removed preventing the growth of microorganisms that causes food damage (Marketing of vegetables thesis first draft). It is also a process which combined heat and mass transfer, where the surface moisture is removed first and the moisture from the interior is forced to move to the surface, which is then removed later (I. S. U. N. Drying 2006). Traditionally, the local farmers utilize open sun drying system which may be responsible for the mentioned large post-harvest loss (Solar Dryer with V-Groove Solar 2013). Therefore, utilization of technology to reduce the post-harvest loss is essential. This can be done by using solar dryer technology. This technology is unique in that the developed dryer has better turbulence effect which helps to remove the hot humidity of the drying system at each tray thereby to improve the preservation of the vegetables such as potato, tomato, and onion.

Solar dryer technology is a cost effective and feasible approached in minimizing the harvest loss and increasing the quality of the products (Soundy and Brutsch 2014, unpublished data). Using this solar vegetable drying technology is also crucial to yield high-quality marketable products which in turn can improve the economic situation of the farmers, assuring food security by minimizing vegetable product loss (Akpinar 2010).The performance of the solar dryer is significantly dependent on the weather condition. Solar dryers located in Fogera District area used solar energy to remove the moisture contained from the product. Therefore, the weather conditions have the biggest influence on the capacity of drying products that can be dried at a certain time. Then measurements of radiation components require expensive equipment that is costly to operate as well as maintain, reliable measurements are undertaken at only a limited number of stations. The solar radiation data can be used as an input variable of solar vegetable dryers. The effects of weather condition data as sources of the solar vegetable dryer before the experimental tests were recording temperature, horizontal radiation and drying humidity and summarized in Table 2 (Appendix B). Thus, data show before the experimental test that is similar to atmospheric condition. During the experimental test (at the loaded condition), the air temperature in the drying chamber, the relative humidity of drying chamber and solar radiation on solar collectors vary between 30 and 72 °C, 8–11% and 485–1165 W/m2, respectively.

Results and discussion

Result of energy analysis

As shown in Figs. 1 , 2 and 3 variations of the energy utilization ratio during the experimental test of tomato, potato and onion were calculated using Eqs. (9). The analysis was conducted depending on the drying chamber flow air temperature as a function of drying time. Moreover, as drying time decreased the energy utilization ratio slightly increased with an increase in drying air temperature. The energy utilization ratio of tomato varied between 4.8 and 19.9% on the first day at drying air temperature of 45 °C, 3.4% to 26.0%, on the second day at drying air temperature of 60 °C and 3.1% to 12.9% on the third day at drying air temperature of 65 °C as shown in Fig. 1.

The energy utilization ratio of potato varied between 4.1 and 19.4% on the first day at drying air temperature of 55.9 °C, 7.4% to 45.6% on the second day at drying air temperature of 57.9 °C and 3.9 to 21.6% on the third day at drying air temperature of 55.3 °C as shown in Fig. 2.

Similarly, the energy utilization ratio of onion varied between 5.2 and 14.5% on the first day at drying air temperature of 39 °C, 6.5% to 26.6% on the second day at drying air temperature of 41.9 °C, 11.8% to 23.5% onion on the third day at drying air temperature of 61.3 °C and 8.3% to 37.4% on the fourth day at drying air temperature of 62.2 °C as shown in Fig. 3.

Result of exergy analysis

Figures 4, 5, 6, 7, 8, 9, 10, 11, 12 and 13 illustrate the maximum and minimum values of exergy inflow, exergy outflow, and exergy losses of the drying chamber at each tray. The rate of exergy inflow as calculated from Eqs. (11) depends on the ambient and inlet air temperature of the drying chamber. The exergy inflow of the first tray was constant since the inlet temperature drying air in the drying chamber and the ambient temperature was kept constant. The exergy inflow of tomato in the drying chamber varied between 0.188 and 1.355 kJ/kg tomato on the first day, 0.331 kJ/kg to 1.21 kJ/kg tomato on the second day and 0.28 kJ/kg to 1.981 kJ/kg tomato on the third day depending on the experimental condition of slices of tomato. The rate of exergy outflow as calculated from Eq. (12) relied on the ambient and outlet air temperature of the drying chamber. The exergy outflow of tomato in the drying chamber varied between 0.165 and 1.240 kJ/kg tomato on the first day, and 0.22 kJ/kg to 1.1134 kJ/kg tomato on the second day, and 0.221 kJ/kg to 1.960 kJ/kg tomato on the third day depending on the experimental test of tomato.

As shown in Figs. 7, 8 and 9, the exergy inflow of potato in the drying chamber varied between 0.187 and 1.987 kJ/kg potato on the first day, 0.41 kJ/kg to 1.49 kJ/kg potato on the second day, 0.35 kJ/kg to 1.511 kJ/kg potato on the third day depending on the experimental test of slices of potato. The exergy outflow of potato in the drying chamber varied between 0.181 and 1.915 kJ/kg potato on the first day, 0.303 kJ/kg to 1.470 kJ/kg potato on the second day and 0.320 kJ/kg to 1.382 kJ/kg potato on the third day depending on the experimental test of slices of potato. In addition, the exergy loss of potato in drying chamber varied between 0.06 and 0.158 kJ/kg potatoes on the first day, 0.02 kJ/kg to 0.236 kJ/kg potatoes on the second day, and 0.012 kJ/kg to 0.19 kJ/kg potatoes on the third day depending on the experimental condition of slices of potato.

Figures 10, 11, 12 and 13 illustrate that the exergy inflow of onion in the drying chamber varied between 0.277 and 1.471 kJ/kg onion on the first day, 0.231 kJ/kg to 0.562 kJ/kg onion on the second day, 0.261 kJ/kg to 1.068 kJ/kg onion on the third day and 0.22 kJ/kg to 1.416 kJ/kg on the fourth day. The exergy outflow of onion in the drying chamber varied between from 0.196 to 1.241 kJ/kg onion on the first day, 0.170 kJ/kg to 0.469 kJ/kg onion on the second day, 0.184 kJ/kg to 0.814 kJ/kg onion on the third day, and 0.172 kJ/kg to 1.283 kJ/kg on the fourth day. Besides, it depends on the experimental condition of onion. And also, the exergy loss of onion in the drying chamber varied between 0.067 kJ/kg to 0.23 kJ/kg onion on the first day, 0.001 kJ/kg to 0.170 kJ/kg onion on the second day, 0.045 kJ/kg to 0.189 kJ/kg onion on the third day, and 0.012 kJ/kg to 0.219 kJ/kg onion on the fourth day.

Figures 14, 15 and 16 show the variation of the exergy output, exergy solar radiation input and exergy efficiency, exergy utilization efficiency and exergy system efficiency in the drying chamber and flat plate solar collector as a function of drying time. The exergy efficiency for each component was calculated by using Eq. (14). It is dependent on the exergy inflow, outflow and loss of exergy in the drying chamber. As shown in Figs. 14, 15 and 16, the exergy efficiency of tomato in the drying chamber varied from 53.35 to 95.60% on the first day, 59.10% to 93.3% on the second day and 61.78% to 98.93% on the third day. It is dependent on the experimental condition of slices of tomato. The rate of exergy output was calculated using Eq. (17) and it is dependent on the ambient and outlet air temperature of the drying chamber. The exergy output of tomato in the drying chamber was found to be 80.20 W to 311.8 W on the first day, 80.9 W to 208.3 W on the second day, and 112.3 W to 182.6 W on the third day. The exergy solar radiation input was calculated by using Eq. (18) and it is dependent on the ambient temperature and the sky temperature, collector area. The exergy solar radiation of tomato varied between 166.3 w to 324.74 W on the first day, 177.44 W to 390 W on the second day and 171.4 W to 387.10 W on the third day depending on the experimental test of tomato. The exergy utilization efficiency was calculated by using Eqs. (16) and it is dependent on the exergy solar radiation input and exergy output. The exergy utilization efficiency of tomato varied between from 43.2 to 95.9% on the first day, 38.7% to 89.1% on the second and 52.9% to 88.7% on the third day depending on the experimental test of tomato. The exergy system (net) efficiency was calculated by using Eq. (15). It was dependent on the exergy utilization efficiency and exergy efficiency. The exergy system (net) efficiency varied between 30.2 and 86.8% tomato on first day, 26.9% to 71.2% tomato on second day and 37.3% to 80.8% tomato on the third day depending on the experimental test of tomato.

Figures 17 and 18 illustrate the exergy efficiency of potato in the drying chamber varied from 54.17% to 96.68% on the first day, 51.1% to 98.64% on the second day and 59.1% to 97.5% on the third day depending on the experimental condition of slices of potato. The rate of exergy output was calculated using Eq. (17). It was dependent on the ambient temperature and outlet air temperature of the drying chamber. Figures 17, 18 and 19 show that the exergy output of potato in the drying chamber varied between 165.5 and 211.7 W on the first day, 122.5 W to 298.6 W on the second day, and 70.71 W to 299.3 W on the third day. The exergy solar radiation input was calculated by using Eq. (18) based on the ambient temperature, the sky temperature and the collector area. Figures 17, 18 and 19 show that the exergy solar radiation input of potato varied between 201.87 and 324.55 W on the first day, 197.9 W to 335.2 W on the second day and 129.5 W to 386.50 W on the third day depending on the experimental test of potato. The exergy utilization efficiency was calculated by using Eq. (16) and it was dependent on the exergy solar radiation input and exergy output. The exergy utilization efficiency of potato varied between 61.6 and 85.6% on the first day, 54.7% to 92.3% on the second day and 53.4% to 92.5% on the third day depending on the experimental condition of potato. The exergy system (net) efficiency was calculated by using Eq. (15) and it was dependent on the exergy utilization efficiency and exergy efficiency. Figures 17, 18 and 19 show that the exergy system (net) efficiency varied between 37.9 and 76.96% on the first day, 27.9% to 91.0% on the second day and 32.3% to 87.5% on the third day depending on the experimental condition of potato.

Figures 20, 21, 22 and 23 show that the exergy efficiency of onion in the drying chamber varied between 53.06 and 87.44% on the first day and 45.45% to 96.64% on the second day, 45.84% to 96.64% on the third day and 56.6% to 98.65% on the fourth day depending on the experimental condition of onion. The rate of exergy output was calculated using Eqs. (17), and it was dependent on the ambient and outlet air temperature of the drying chamber. Figures 20, 21, 22 and 23 show that the exergy output of onion in the drying chamber varied between 156.9 and 310.3 W on the first day, 96.64 W to 133.4 W on the second day, and 126.2 W to 861.5 W on the third day and 119.0 W to 226.08 W on the fourth day depending on the experimental test of onion. The exergy solar radiation input was calculated by using Eqs. (18), based on the ambient temperature, the sky temperature, and the collector area. Figures 20, 21, 22 and 23 show that the exergy solar radiation input of onion varied between 221.5 and 310.3 W on the first day, 179.2 W to 301.8 W on the second day and 171.1 W to 1084.6 W On the third day and 188.2 W to 307.7 W on the fourth day depending on the experimental condition of potato. Figures 20, 21, 22 and 23 show the exergy utilization efficiency calculated by using Eq. (16). It was dependent on the exergy solar radiation input and exergy output. The exergy utilization efficiency of onion varied between from 66.3 to 92.9% on the first day, 50.6% to 90.09% on the second day, 56.0% to 80.1% on the third day and 58.5% to 89% on the fourth day depending on the experimental condition of onion. The exergy system (net) efficiency was calculated by using Eq. (2). It is dependent on the exergy utilization efficiency and exergy efficiency. Figures 20, 21, 22 and 23 show that the exergy system (net) efficiency varied between 35.2 and 80.1% on the first day, 31.8% to 83.8% on the second day and 32.6% to 73.1% on the third day and 40.3% to 76.6% onion the fourth day depending on the experimental condition of onion.

Conclusion

The performance of solar vegetable dryer was analyzed experimentally. The solar vegetable dryer was analyzed based on the 1st and 2nd laws of thermodynamic analysis, viz. energy and exergy analysis. In this study, tomato, potato and onion was used as to dry in the solar dryer. The air temperature required to dry the tomato is from 34.5 to 72.3 °C, for potato is from 37.5 to 66.9 °C and onion is from 36.3 to 63.4 °C. The exergy inflow in drying chamber was found to be 0.188 kJ/kg to 1.981 kJ/kg for tomato, 0.187 kJ/kg to 1.987 kJ/kg for potato, and 0.22 kJ/kg to 1.471 kJ/kg for onion. The exergy outflow in drying chamber was found to be 0.165 kJ/kg to 1.96 kJ/kg for tomato, 0.181 kJ/kg to 1.92 kJ/kg for potato and 0.17 kJ/kg to 1.283 kJ/kg for onion. The average energy utilization ratio in the drying chamber was found to be 3.1 to 26% for tomato, 3.9 to 45.6% for potato and 5.2 to 37.4% for onion. Regarding the drying period, tomato takes 33 h, potato takes 27 h and onion takes 44 h for onion during experimental test. The dried relative humidity ranges from 10.01% to 11%, for tomato, 8.22% to 10.32% for potato and 9.7% to 11.18% for onion. The energy utilization ratio in the drying chamber was found to be 3.1% to 26%, for tomato, 3.9% to 45.6% for potato and 5.2% to 37.4% for onion.

Method/experimental

Experimental set-up

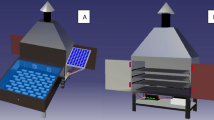

The detailed information on the experimental system and instrumental set-up is given below (Bhardwaj et al. 2017). The collector part and the drying part have an area of 1 × 2 m2 and 1 × 1.07 m2, respectively. The schematic diagram of this dryer is shown in Fig. 24.

Thermocouples were used to measure ambient temperature and the drying air temperature inside the dryer chamber. The range of operational temperature is 20 °C to 150 °C.

Experimental procedure

The daily drying rate was estimated by measuring the weight loss of the product after each day of drying. The relative humidity and solar radiation data were obtained from meteorological and measuring data. All results obtained from the experiments were used to perform the energy and exergy analyses of the solar vegetable drying process. Fresh vegetable products were used in the experiments and the moisture content was recorded as 91% for tomato, 73% for potato and 81% for onion. The drying experiments were carried out at drying air temperature of 35 °C for tomato, 55 °C for potato, and 70 °C for onion and the drying air velocity was 0.5 m/s for tomato, 1.5 m/s for potato and 2 m/s for onion. The final moisture content of samples was calculated based on weight samples of the vegetables and the final drying moisture content was determined as 9%, for tomato, 12%, for potato and 13% for onion based on weight analysis. During the experiments, ambient temperature inlet and outlet temperatures of drying air in the chamber were recorded. To measure drying air temperature, thermocouple and digital thermometer with manually controlled eight (8) channels at the inlet and outlet of the drying chamber during an experimental test was used (Borah et al. 2015). The velocity of air in the drying chamber varied from 0 to 2.5 m/s which was measured from the anemometer.

Steps of drying vegetable

See Fig. 25.

Theoretical analysis

Analysis of solar energy

Energy analysis

The theoretical and derivation of the formulas have been based on first and second laws of thermodynamics principle to determine energy, exergy and utilization ratio of the vegetable drying system (Amjad et al. 2016). These parameters were determined at the inlet, outlet and intermediate section of the drying system based on the empirical formula and measured data on the system (i.e., solar radiation, atmospheric air temperature, drying temperature, outlet temperature, and relative humidity). The air conditioning process throughout the drying of vegetables includes the processes of heating, cooling, and humidification (Akpinar 2010). The air conditioning processes can be modeled as steady-flow processes that were analyzed by applying the steady-flow conservation of mass (for both dry air and moisture) and conservation of energy principle (El-sebaii and Shalaby 2012). General equation of mass conservation of drying air is (Minaei et al. 2014):

General equation of mass conservation of moisture.

General equation of energy conservation.

The changes in kinetic energy of fan were taken into consideration while the potential and kinetic energy in other parts of the process was neglected (Sami et al. 2011). During the energy and exergy analyses of the vegetables drying process, the following equations were generally used to compute the relative humidity and enthalpy of drying air (Arepally et al. 2017):

The relative humidity:

where w is the specific humidity, p atmospheric pressure, \(p_{\text{sat@T}}\) the saturated vapor pressure of drying air.

The enthalpy of drying air:

where \(C_{pda}\) the specific heat of drying air, T is drying air temperature, and \(h_{\text{sat@T}}\) is the enthalpy of saturated vapor.

Determination of fan outlet conditions

where \(h_{fi}\) characterizes the enthalpy of drying air at the inlet of the fan, \(h_{fo}\) the enthalpy at the outlet of the fan vfo the drying air velocity at the outlet of the fan, \(\dot{w}_{f}\) fan energy and \(\dot{m}_{da}\) mass flow of drying air (R. Development. 2016). Considering the values of dry-bulb temperature and enthalpy from Eq. (4), the specific and relative humidity of drying air at the fan were determined by using the psychrometric chart (I. S. U. N. Drying 2006).

Determination of the outlet conditions of the tray

The inlet conditions of the drying chamber were determined depending on the inlet temperatures and specific humidity of drying air (Bolaji and Olalusi 2008). The inlet conditions of the tray were assumed as equal to the inlet conditions of the drying chamber (Celma and Cuadros 2009). Meanwhile, it was considered that the mass flow rate of drying air was equally passed throughout the tray (Kalaiarasi et al. 2016). Thus, the inlet conditions of the tray can be written:

Using Eqs. (1) and (2), the equation of the specific humidity at the outlet of the tray was derived:

where \(w_{\text{tri}}\) is the specific humidity at the inlet of the tray, \(\dot{m}_{\text{vegetable}}\) the mass flow rate of the moisture removed from the vegetable (product). The relative humidity and enthalpy of drying air at the outlet of the tray were, respectively, estimated using Eqs. (4 and 5) (Singh and Kumar 2012). During the humidification process at the tray, the heat transfer can be calculated using the following equations:

where \(h_{\text{tri@T}}\), \(h_{\text{tro@T}}\) are the enthalpies at the inlet and outlet of the tray.

During the experiments, ambient temperature and the relative humidity, inlet and outlet temperature of drying air in the dryer chamber were recorded as shown in Fig. 7 (Arepally et al. 2017) (Fig. 26).

The inlet conditions of the tray were assumed as equal to the inlet conditions of the dry drying chamber (George 2007). In addition, the outlet conditions of trays were assumed as equal to the outlet conditions of the drying chamber (Darvishi et al. 2018). Solar dryer energy analysis based on the first law of thermodynamics never reflects the quality of energy destruction (Bennamoun 2012). During the solar drying process, the energy utilization ratio of the drying chamber is estimated using the following equation (Minaei et al. 2014; Akpinar et al. 2006):

where \(\dot{m}_{ia}\) is the mass flow rate of the dry air (kg/s), \(h_{oa }\) is absolute humidity of the air leaving the drying chamber (%), \(h_{ia}\) is the absolute humidity of the air entering the drying chamber (%), c = specific heat of air (J/kg/°C), and EUR, the energy utilization ratio.

Exergy analysis

Exergy is the maximum amount of work that can be produced by the system or flow of mater or energy reach equilibrium with a reference environment. Energy and exergy analyses of the drying process should be performed to determine the energy interaction and thermodynamics behavior of drying air throughout a drying chamber (Fudholi et al. 2014a). Exergy analysis allows for effective energy resource use because the analysis enables the determination of locations and magnitudes of the losses (Fudholi et al. 2014b).

Exergy analysis is based on the second of law of thermodynamics therefore, the general form of the exergy equation that is applicable to steady-flow systems may be expressed as (Niksiar and Rahimi 2009; Oztop et al. 2013) (Fig. 27):

where \({\text{Ex}}\) is the exergy, \(\dot{m}\) the mass flow rate (kg/s), and \(T_{a}\) the ambient temperature (°C).

Exergy balance (Niksiar and Rahimi 2009)

For the exergy inflow to the drying chamber

where \(T_{\text{dci}}\) is the inflow temperature of the drying chamber.

For the exergy outflow from the drying chamber:

Exergy loss during solar drying is determined by

Exergy efficiency can be defined as the ratio of (No Title. 2004) energy use (investment) in product drying to the exergy of the drying air supplied to the system (No Title. 2004). However, this efficiency can also be defined as the ratio of exergy outflow to exergy inflow in the drying chamber. The exergy efficiencies of the drying chamber can be determined based on this definition (Zohri et al. 2018). Therefore, the general form of exergy efficiency is expressed as follows (Fudholi et al. 2014a):

Given a greenhouse tunnel-type solar dryer system with a chimney that uses solar radiation energy, the given system efficiency is (Bolaji and Olalusi 2008):

For a greenhouse solar dryer system, the exergy utilization efficiency (\(\eta_{{{\text{ex}} . {\text{solar}}}}\)) required to raise internal air temperature is determined as follows (Prommas et al. 2010):

where the exergy output (\({\text{Ex}}_{\text{out}}\)) and the exergy of solar radiation input (\({\text{Ex}}_{\text{rad}}\)) to the dryer was calculated as follows:

where \(T_{at}\) is the air temperature in the dryer (°C) and \(T_{a}\) is the ambient temperature (°C).

where Ts is the sky temperature.

The exergy efficiency of a system or process is maximized when exergy loss (\({\text{Ex}}_{\text{loss}}\)) is minimized.

Experimental analysis of solar vegetable dryer

Solar collectors as heat exchangers transfer the absorbed solar radiation to air passing next to the absorber plate (Akpinar 2010). Thus, hot air is obtained from these collectors and they are used in space heating, agricultural product drying, greenhouse heating and preheating in ventilation systems (Tripathy and Kumar 2009).

Solar air collector is a simple device for air heating by utilizing solar energy for many applications, which require low-to-moderate temperature below 60 °C such as drying and space heating (Arepally et al. 2017; Bennamoun 2012).

The flowchart of the drying process during the experiment is shown in Fig. 28.

Availability of data and materials

When ethics statement was obtained from the Fogera woreda agricultural office, we have agreed and signed not to publish the raw data retrieved from information of the mothers. However, the data sets collected and analyzed for the current study are available from the corresponding author and can be obtained on a reasonable request

Abbreviations

- \(A_{c}\) :

-

Collector area (m2)

- \(D_{R}\) :

-

Drying rate (%)

- EUR:

-

Energy utilization ratio (%)

- \(E_{x}\) :

-

Exergy (w)

- \(Ex_{dci}\) :

-

Exergy inflow to the drying chamber (KJ/kg)

- \(Ex_{dco}\) :

-

Exergy outflow from the drying chamber (KJ/kg)

- \(Ex_{loss}\) :

-

Exergy loss (kJ/kg)

- \(Ex_{out}\) :

-

Exergy out (w)

- \(Ex_{rad}\) :

-

Exergy of solar radiation input (w)

- T:

-

Drying air temperature (°C)

- \(T_{a}\) :

-

Ambient temperature (°C)

- \(T_{o}\) :

-

Outlet air temperature (°C)

- \(T_{i}\) :

-

Inlet air temperature (°C)

- \(T_{dci}\) :

-

Drying air temperature inlet of drying chamber (°C)

- \(T_{dco}\) :

-

Drying air temperature outlet of drying chamber (°C)

- Ts :

-

Sky temperature (°C)

- \(t_{os}\) :

-

Time consumed (s)

- \(t_{sd}\) :

-

Time consumed by solar dryer (s)

- W:

-

Specific humidity

- \(w_{di}\) :

-

Specific humidity of inlet of drying chamber

- \(w_{do}\) :

-

Specific humidity outlet of drying chamber

- \(w_{tri}\) :

-

Specific humidity inlet of the tray

- \(w_{tro}\) :

-

Specific humidity outlet of the tray

- \(W\) :

-

Mass of water removed (kg/s)

- \(x_{2m}\) :

-

Dryer outlet absolute humidity

- \(x_{a}\) :

-

Ambient absolute humidity (%)

- \(\phi\) :

-

Relative humidity (%)

- \(\phi_{dci}\) :

-

Relative humidity inlet of drying chamber (%)

- \(\phi_{dco}\) :

-

Relative humidity outlet of drying chamber (%)

- \(\eta_{c}\) :

-

Collection efficiency (%)

- \(\eta_{S}\) :

-

System drying efficiency (%)

- \(\eta_{d}\) :

-

Drying efficiency (%)

- \(\eta_{Ex.do}\) :

-

Exergy efficiency (%)

- \(\eta_{Ex.nt}\) :

-

System efficiency (%)

- \(\eta_{Ex.solar}\) :

-

Utilization efficiency (%)

References

Akpinar, E. K. (2004). Energy and Exergy Analyses of drying red pepper slices in a convective type dryer. International Communications in Heat and Mass Transfer, 31(8), 1165–1176.

Akpinar, E. K. (2010). Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Conversion and Management,51(12), 2407–2418.

Akpinar, E. K., Midilli, A., & Bicer, Y. (2006). The first and second law analyses of thermodynamic of pumpkin drying process. Journal of Food Engineering.,72(4), 320–331.

Amjad, W., Hensel, O., Munir, A., Esper, A., & Sturm, B. (2016). Thermodynamic analysis of drying process in a diagonal-batch dryer developed for batch uniformity using potato slices. Journal of Food Engineering,169, 238–249.

Arepally, D., Ravula, S. R., Malik, G. K., & Kamidi, V. R. (2017). Mathematical modelling, energy and exergy analysis of tomato slices in a mixed mode natural convection solar dryer. Chemical Science International Journal,20(4), 1–11.

Bennamoun, L. (2012). An Overview on Application of Exergy and Energy for Determination of Solar Drying Efficiency. International Journal of Energy Engineering,2(5), 184–194.

Bhardwaj, A. K., Chauhan, R., Kumar, R., Sethi, M., & Rana, A. (2017). Experimental investigation of an indirect solar dryer integrated with phase change material for drying valeriana jatamansi (medicinal herb). Case Studies in Thermal Engineering,10, 302–314.

Bolaji, B. O., & Olalusi, A. P. (2008). Performance evaluation of a mixed-mode solar dryer. Journal of Agricultural Biotechnology and Sustainable Development,11(4), 225–231.

Borah, A., Hazarika, K., & Khayer, S. M. (2015). Drying kinetics of whole and sliced turmeric rhizomes (Curcuma longa L.) in a solar conduction dryer. Information Processing in Agriculture,2(2), 85–92.

Celma, A. R., & Cuadros, F. (2009). Energy and exergy analyses of OMW solar drying process. Renew. Energy,34(3), 660–666.

Darvishi, H., Azadbakht, M., & Noralahi, B. (2018). Experimental performance of mushroom fluidized-bed drying: Effect of osmotic pretreatment and air recirculation. Renewable Energy,120, 201–208.

El-sebaii, A. A., & Shalaby, S. M. (2012). Solar drying of agricultural products: A review. Renewable and Sustainable Energy Reviews,16(1), 37–43.

Fudholi, A., Sopian, K., Yazdi, M. H., Hafidz, M., Gabbasa, M., & Kazem, H. A. (2014). Performance analysis of solar drying system for red chili. Solar Energy,99, 47–54.

George, C. (2007). Determination of Optimal Surface Area to Volume Ratio for Thin-Layer Drying of Breadfruit (Artocarpus altilis). Humanitarian Engineering and Social Entrepreneurship.,2(2), 76–88.

I. S. U. N. Drying. 2006. 33 Sun and solar dryıng, technıques and equıpment ıı. solar dryıng II. 1. Types of Solar Dryers 1, 1–8.

ILRI. 2005. Fogera Woreda pilot learning site diagnosis and program design.

Kalaiarasi, G., Velraj, R., & Swami, M. V. (2016). Experimental energy and exergy analysis of a flat plate solar air heater with a new design of integrated sensible heat Storage. Energy,111, 609–619.

Karim, M. A. (2004). Development of solar air collectors for drying applications. Energy Conversion and Management,45, 329–344.

Minaei, S., Chenarbon, H. A., Motevali, A., & Hosseini, A. A. (2014). Energy consumption, thermal utilization efficiency and hypericin content in drying leaves of St John’ s Wort (Hypericum perforatum). Journal of Energy in Southern Africa,25(3), 27–35.

Mustayen, A. G. M. B., Mekhilef, S., & Saidur, R. (2014). Performance study of different solar dryers: A review. Renewable and Sustainable Energy Reviews,34, 463–470.

N. Resource and R. Development. 2016. Tropentag 2016, Vienna, Austria September 18–21, 2016.

Niksiar, A., & Rahimi, A. (2009). Energy and exergy analysis for cocurrent gas spray cooling systems based on the results of mathematical modeling and simulation. Energy,34(1), 14–21.

Oztop, H. F., Bayrak, F., & Hepbasli, A. (2013). Energetic and exergetic aspects of solar air heating (solar collector) systems. Renewable and Sustainable Energy Reviews,21, 59–83.

Prommas, R., Rattanadecho, P., & Cholaseuk, D. (2010). Energy and exergy analyses in drying process of porous media using hot air. International Communications in Heat and Mass Transfer,37(4), 372–378.

S. B. Wassie. 2016. Amhara region horticulture development. 2019.

Sami, S., Etesami, N., & Rahimi, A. (2011). Energy and exergy analysis of an indirect solar cabinet dryer based on mathematical modeling results. Energy,36(5), 2847–2855.

Singh, S., & Kumar, S. (2012). Testing method for thermal performance based rating of various solar dryer designs. Solar Energy,86(1), 87–98.

Tripathy, P. P., & Kumar, S. (2009). Modeling of heat transfer and energy analysis of potato slices and cylinders during solar drying. Applied Thermal Engineering,29(5), 884–891.

Zohri, M., Hadisaputra, S., & Fudholi, A. (2018). Exergy and energy analysis of photovoltaic thermal (Pvt)with and without fins collector. ARPN,13(3), 803–808.

Acknowledgements

The authors would like to thank University of Gondar for its support for the achievement of the objective of the research and Fogera woreda agricultural office allowing us to collect the data which was used as input for the research output.

Funding

The research was supported by a grant from University of Gondar, Institute of Technology. The granting agency did not have a role in the design; Collection, analysis, and interpretation of data, or in writing the manuscript.

Author information

Authors and Affiliations

Contributions

YTS: Conception and design, experimental and performance analysis solar dryer of the system and interpretation of data, Drafting the article, Critical revision of the article, final approval of the version of the manuscript. GTA: Conception and design, experimental and performance analysis solar dryer of the system and interpretation of data, Drafting the article, Critical revision of the article, final approval of the version of the manuscript. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Ethical clearance was obtained from Ethical review committee of university of Gondar Department of Mechanical Engineering and letter of permission was obtained from Fogera woreda agricultural office. Then, participants were informed about the purpose of the study, the importance of their participation and their right to withdraw at any time. Informed consent was obtained prior to data collection. Confidentiality of the information was maintained and no identifying information was collected from participants.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Appendix A

See Table 1.

Appendix B

See Table 2.

Appendix C

Tables 3, 4, 5, 6, 7, 8, 9, 10, 11 and 12 show the result of exergy analysis.

Appendix D

Tables 13, 14, 15, 16, 17, 18, 19, 20, 21 and 22 show energy analysis and temperature of drying air at each tray inlet and exit as function of drying period of tomato, potato and onion drying.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sintie, Y.T., Aduye, G.T. Potential assessment and experimental analysis of solar vegetable dryer: in case of northern Ethiopia. Renewables 7, 3 (2020). https://doi.org/10.1186/s40807-020-00059-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40807-020-00059-2