Abstract

Background

Physical and chemical properties of feedstuffs can be changed by feed processing. Moreover, through various mechanisms, feed processing can affect growth performance and feed efficiency of swine, nutrition value of the feed. Weaning-to service-intervals (WSI), subsequent farrowing rates, and total-born litter sizes were determined by feed intake and metabolic state during lactation.

Methods

A total of 20 sows (Landrace × Yorkshire) with an average body weight (BW) of 266.1 kg 4 d before farrowing were used to determine the effect of feed processing on the performance of lactating sows and their offspring. The following two dietary treatments were used: 1) Crumble diet (C); and 2) Mash diet (M). Ten replications were used for each treatment. Back fat thickness of sows was measured 6 cm off the midline at the 10th rib using a real-time ultrasound instrument at 4 d before farrowing, 1 d after farrowing, and during weaning. Sow BW were also checked at 4 d before farrowing, 1 d after farrowing, and during weaning. Fecal score of sows were assessed on d 14. Fecal score of piglets were observed on d 7, 15, and 24. Data were analyzed using t-test procedure of SAS (2014) with sow as experimental unit.

Results

No significant (p > 0.05) difference was observed in the reproduction performance of sows between the two treatments. In addition, there was no significant (p > 0.05) difference in the growth performance of piglets between the two treatments. Fecal score of sows or piglets showed no significant (p > 0.05) difference either.

Conclusions

In conclusion, different feed processing (mash or crumble) did not make any significant difference on the performance of lactation sow or their piglets.

Similar content being viewed by others

Background

Feed intake and metabolic state during lactation can influence WSI, subsequent farrowing rates, and total-born litter sizes [1]. Therefore, insufficient feed intake of sows during lactation is a serious problem because sows require large amount of energy for high milk production during lactation. A low feed intake during lactation can lead to great body weight (BW) loss, decreased milk production, and reproductive problems that may lead to culling of the sows [2, 3]. However, genetic selection for large litter size can lead to heavy burden of milk production [4].

Feed processing can change the physical and chemical properties of feedstuffs. In addition, it can also improve the nutrition value of the feed through various mechanisms. Feed processing of diets has been extensively used in commercial feed production. Compared to mashed diet, expanded crumble diet can decrease feed cost per kg weight gain by 15 % [5]. It is known that pelleting feed can improve the growth performance and feed efficiency in swine [6–9]. However, to our knowledge, few studies have evaluated the use of crumble diets and mashed diets in lactating sows. Therefore, the objective of this study was to evaluate the effect of crumbled and mashed diets on the performance of lactation sows and their offspring.

Methods

The experimental protocols describing the management and care of animals were reviewed and approved by the Animal Care and Use Committee of Dankook University.

Experimental design, animals, housing and diets

A total of 20 sows (Landrace × Yorkshire) with an average BW of 266.1 kg (measured 4 days before farrowing) were used in this experiment. Gestating sows were fed with basal gestation diet until farrowing. The diet was changed to experimental feed during the lactating period. On d 107 of gestation, sows were moved into farrowing crates in an environmentally regulated farrowing house and assigned to one of the following two dietary treatment groups: 1) Crumble diet (C), and 2) Mashed diet (M). Ten replications were used for each treatment. Diets were formulated to meet or exceed the NRC [10] nutrient requirements for sows (Table 1) . Farrowing crates (2.1 m × 0.6 m) included an area (2.1 m × 0.6 m) for newborn pigs on each side. Supplemental heat was provided for pigs using heat lamps (500 W) to keep the temperature constant at 35 °C for newborn piglets.

On the day of parturition, sows were not offered any feed. On the first day after farrowing, sows were fed with 1.5 kg lactation diet and 2.0 kg on the second day. The daily feed allowance was increased gradually by 0.5 kg per day. One week after farrowing, sows were provided experimental lactation feed and water ad libitum. All diets were provided in crumbled form or mashed form.

Sampling and measurements

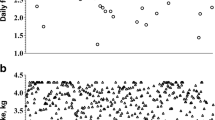

The back fat thickness of sows was measured 6 cm off the midline at the 10th rib using a real-time ultrasound instrument (Piglot 105, SFK Technology, Herlev, Denmark) 4 d before farrowing, 1 d after farrowing, and during weaning. The BW of sows were checked at 4 d before farrowing, 1 day after farrowing, and during weaning. Individual piglet BW was assessed on d 0 (birth weight), 7, 14, 21, and 28 (weanling). The number of piglets for every sow was recorded on the farrowing day and the weaning day to evaluate the survival rate of piglets. The number of birth piglet and live piglets were recorded on the farrowing day to calculate the rate of stillbirth. Feed intake of sows were recorded daily to determine the daily feed intake during lactation.

Detection of estrus was conducted twice per day from weaning onward at 08:30 and 16:00 daily. A sow was considered to be in estrus when it exhibited a standing response induced by a back pressure test when in the presence of a boar. Fecal score of sows was observed and recorded on d 14. The fecal score of piglets was observed and recorded on d 7, 15, and 24. To assess the fecal score, feces from each pig were scored by determining the moisture content according to the method described by Hu et al. [11]. Briefly, the following scoring system was used. Score of 1 indicated hard feces. Score of 2 was used for feces that were firm and well formed. Score of 3 indicated soft and partially formed feces. Score of 4 was for loose and semi-liquid feces. Score of 5 indicated watery feces.

Statistical analysis

Data were analyzed using t-test procedure of SAS [12] with sow as experimental unit and farrowing group as block. The back fat thickness of sow and changes during lactation were analyzed using fat depth at farrowing as covariates. Piglet birth weight was used as a covariate for weaning weights during lactation. Lactation length was used as a covariate for the number of pigs weaned, survivability, weaning weights of sows and piglets, sow ADFI, and back fat change. Difference with p value level less than 0.05 was considered as statistically significant.

Results

Litter performance

The two dietary treatments had no significantly (p > 0.05) different effect on the reproduction performance of sows (Table 2).

Growth performance

The two dietary treatments had no significantly (p > 0.05) different effect on the growth performance of piglets (Table 3).

Fecal score

The two dietary treatments had no significantly (p > 0.05) different effect on fecal scores of sows or piglets (Table 4).

Discussion

For the past several decades, nutritionists have attempted to further improve the nutritional value of swine feeds. Extruder and expander processing has been introduced. According to previous studies, the nutritional value of feeds may be altered by extruder/expander conditions such as the degree of cooking, preconditioning, and temperature [13, 14]. On the other hand, it is widely accepted that pelleting of diets could improve average daily gain and feed conversion ratio in pigs. Based on 16 trials, Ohh [15] has summarized that pelleted diet could improve the growth of swine by 3–4 % compared to mashed diet. In addition, it has been reported that pelleting could increase ADG while reducing pelleting and particle size could improve FCR [16].

Currently, much interest has been focused on the extruding/expanding technology for the manufacturing of swine feeds. In pig feed processing, expander processing method was introduced to improve pellet quality. Several researchers have reported that the expander processing has little effect on the performance of growing-finishing pigs fed on common diet [17]. There was no significant difference between mashed diet and heat-processed diet (pellet and expanded crumble) in improving ADG and ADFI. It has been previous reported that feeding pelleted diets could significantly increase FCR [5]. Increased nutrient digestibility and decreased feed wastage might have improved feed utilization in pigs feeding with pelleted diets [18]. Burnham et al. [19] have emphasized extrusion of soybean can improve rate and efficiency of gain when fed to nursery pigs in the place of soybean meal. While Kim t al. demonstrated that extrusion yielded a full-fat soy product had greater nutritional value than roasting [13]. of Furthermore, it has been reported that pelleting feed could improve gain/feed ratio by 7 % compared to mashed feed [20]. Many previous studies have also demonstrated that the efficiency of growth is improved when pigs are fed pelleted diets [17, 18, 21, 22]. Reducing diet particle size can improve the efficiency of growth in growing-finishing and nursery pigs [23, 24]. In addition, reduced diet particle size could increase digestibility of nutrients which may lead to improve the lactation performance in sows [25, 26]..

Wondra et al. [16] have reported that pelleting diet can increase ADG and gain/feed ratio by 5 and 7 %, respectively. Baird [27] has reported that pelleting corn-soybean meal diet can improve ADG and gain/feed ratio of growing pigs by 5 and 8 %, respectively. However, several experiments including the NCR-42 Committee on Swine Nutrition [28] failed to demonstrate that pelleting could consistently improve ADG. The mechanisms on how pelleted diets could increase ADG of pigs is currently unclear.

Several researchers have reported that the expander processing has little effect on the performance of growing-finishing pigs fed with common diets [17]. Previous studies have demonstrated that dressing percentage and back fat thickness are not affected by expander processing of pig diets [14, 29]. In addition, Yang et al. [5] have reported that expanding process may not be suitable for growing and finishing pigs because the expanding process will increase feed cost without improving the performance of pigs compared to the pelleting process. Our results showed that crumbled feed failed to significantly improve the litter performance compared to mashed feed. This might be due to the fact that the sows used in our study might have higher feed intake than sows used in other lactation experiments [30, 31]. Therefore, lactation sows might have obtained enough nutrients such as protein and energy regardless which type of feed processing was used.

Conclusions

In conclusion, different feed processing did not make any significant difference on the performance or growth performance of lactation sows or their piglets.

References

Bilkei G. Herd health strategy for improving the reprovductive-performance of pigs. Magyar Agyar Allatorvosok Lapja. 1995;50:766–8.

Baidoo SK, Aherne FX, Kirkwood RN, Foxcroft GR. Effect of feed intake during lactation and after weanling on sow reproductive performance. Can J Anim Sci. 1992;72:911–7.

Eissen JJ, Kanis E, Kemp B. Sow factors affecting voluntary feed intake during lactation. Livest Prod Sci. 2000;64:147–65.

Auldist DE, Morrish L, Eason P, King RH. The influence of litter size on milk production of sows. Anim Sci. 1998;67:333–7.

Yang JS, Jung HJ, Xuan ZN, Kim JH, Kim DS, Chae BJ, et al. Effects of feeding and processing methods of diets on performance, morphological changes in the small intestine and nutrient digestibility in growing-finishing pigs. Asian-Aus J Anim Sci. 2001;10(14):1450–9.

Hansen JA, Nelssen JL, Tokach MD, Goodband RD, Kats LJ, Friesen KG. Effects of a grind and mix high nutrient density diet on starter pig performance. J Anim Sci. 1992;70 Suppl 1:59. Abstr.

Wondra KJ, McCoy RA, Hancock JD, Behnke KC, Hines RH, Fahrenholz CH, et al. Effect of diet form (pellet vs meal) and particle size on growth performance and stomach lesions in finishing pigs. J Anim Sci. 1992;70 Suppl 1:239. Abstr.

Traylor SL, Behnke KC, Hancock JD, Sorrell P, Hines RH. Effect of pellet size on growth performance in nursery and finishing pigs. J Anim Sci. 1996;74 Suppl 1:67. Abstr.

Hongtrakul K, Goodband RD, Behnke KC, Nelssen JL, Tokach MD, Bergstrom JR, et al. The effects of extrution processing of carbohydrate sources on weanling pig performance. J Anim Sci. 1998;76(12):3034–42.

NRC. Nutrient requirements of swine. 11th ed. Washington, DC: Natl. Acad. Press; 2012.

Hu CH, Xiao K, Song J, Luan ZS. Effects of zinc oxide supported on zeolite on growth performance, intestinal microflora and permeability, and cytokines expression of weaned pigs. Anim Feed Sci Tech. 2013;181(1):65–71.

SAS, 2013. In: SAS/STAT User Guide SAS Inst. Inc., Cary, NC.

Kim IH, Hancock JD, Jones DB, Reddy PG. Extrusion processing of low-inhibitor soybeans improves growth performance of early-weaned pigs. Asian-Aus J Anim Sci. 1999;12:1251–7.

Johnston SL, Hancock JD. Effects of expander conditioning of complex nursery diets on growth performance of weaniling pigs. Asian-Aus J Anim Sci. 1999;12:395–9.

Ohh SJ. Past and future of feed manufacturing and processing industry. Seoul: Manual of Short Course on Feed Technology; 1991. p. 138.

Wondra KJ, Hancock JD, Behnke KC, Hines RH, Stark CR. Effects of particle size and pelleting on growth performance, nutrient digestibility, and stomach morphology in finishing pigs. J Anim Sci. 1995;73:757–63.

Johnston SL, Trayler SL, Hines RH, Hancock JD, Behnke KC, Sorrel SP, et al. Effects of expanders on growth performance in finishing pigs Swine Day. Kansas State University. 1996. p. 149–51.

Hanke HE, Rust JW, Meade RJ, Hanson LE. Influence of source of soybean protein, and of pelleting, on rate of gain/feed of growing swine. J Anim Sci. 1972;35:958–62.

Burnham LL, Kim IH, Kang JO, Rhee HW, Hancock JD. Effects of sodium sulfite and extrusion on the nutritional value of soybean products for nursery pigs. Asian-Aus J Anim Sci. 2000;13(11):1584–92.

Park JS, Kim IH, Hancock JD, Wyatt CL, Behnke KC, Kennedy GA. Effects of expander processing and enzyme supplementation of wheat-based diets for finishing pigs. Asian-Aust J Anim Sci. 2003;16:248–56.

Harris DD, Tribble LF, Orr Jr DE. The effects of meal versus different size pelleted forms of sorghum-soybean meal diets for finishing swine. Proc. 27th Annual Swine Short Course, Texas Tech University, Agric. Sci. Tech, 1979; p. 57.

Tribble LF, Lennon AM. Meal versus pelleted sorghum-soybean meal rations for growing-finishing swine. Proc. 23rd annual Swine short Course, Texas Tech Univ. Agric. Sci. Tech, 1975; p. 31.

Giesemann MA, Lewis AJ, Hancock JD, Peo Jr ER. Effect of particle size of corn and grain sorghum on growth and digestibility by growing pigs. J Anim Sci. 1990;68(Suppl1):104. Abstr.

Healy BJ, Hancock JD, Kennedy GA, Bramel-Cox PJ, Behnke KC, Hines RH. Optimum particle size of corn and hard and soft sorghum grain for nursery pigs. J Anim Sci. 1994;72:2227–36.

Wondra KJ, Hancock JD, Kennedy GA, Behnke KC, Wondra KR. Effects of reducing particle size of corn in lactation diets on energy and nitrogen metabolism in second-parity sows. J Anim Sci. 1995;73:427.

Wondra KJ, Hancock JD, Kennedy GA, Hines RH, Behnke KC. Reducing particle size of corn in lactation diets from 1,200 to 400 micrometers improves sow and litter performance. J Anim Sci. 1995;73:421–6.

Baird DM. Influence of pelleting swine diets on metabolizable energy, growth and carcass characteristics. J Anim Sci. 1973;36:516–21.

NCR-42 Committee on Swine Nutrition. Cooperative regional studies with growing swine: effects of source of ingredients, form of diet and location on rate and efficiency of gain of growing swine. J Anim Sci. 1969;29:927.

Johnston SL, Hancock JD. Effects of expander conditioners on pellet quality and growth performance in nursery and finishing pigs. Asian-Aus J Anim Sci. 1999;12:558–64.

Hu YJ, Gao KG, Zheng CT, Wu ZJ, Yang XF, Wang L, et al. Effect of dietary supplementation with glycitein during late pregnancy and lactation on antioxidative indices and performance of primiparous sows. J Anim Sci. 2015;95:2246–54.

Zhang Y, Gao R, Liu M, Shi B, Shan A, Cheng B. Use of modied halloysite nanotubes in the feed reduces the toxic effects of zearalenone on sow reproduction and piglet development. Theriogenology. 2015;83:932–41.

Acknowledgment

This work was supported by a grant (PJ.011212) of “Cooperative Research Program for Agriculture Science & Technology Development” funded by Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

SCK participated in the paper writing and the whole sample collection with HLL. JHP did the chemical analyzed and helped to modify manuscript together with HLL. Prof IHK helped with the whole trial and manuscript. All authors read and approved the final manuscript.

Author details

Present address: Department of Animal Resource & Science, Dankook University No. 29 Anseodong, Cheonan, Choongnam, 330-714, South Korea.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Kim, S.C., Li, H.L., Park, J.H. et al. Crumbled or mashed feed had no significant effect on the performance of lactating sows or their offspring. J Anim Sci Technol 57, 45 (2015). https://doi.org/10.1186/s40781-015-0078-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40781-015-0078-9