Abstract

Background

In this research, Two and three-dimensional slope stability analyses of final slope for Miduk copper mine is investigated by using distinct element code. These analyses were repeated in three positions (dry- drained- wet) and were done for four walls of the mine; including eastern wall, northern wall, western wall and southern wall.

Methods

The stability of Miduk copper mine walls were accomplished by distinct element code (UDEC&3DEC). Both 2D and 3D slope stability analyses were performed to establish the representative shear strength parameters to use in the analyses and to examine the differences in the results. The extended Mohr–Coulomb failure criterion was used for analyses. The rock mass was assumed to be permeable and also by the obtained data from surveying, laboratory tests and field observations.

Results

The results are as follows:

- Water and pore pressure in the faults and main joints were the most important destabilizer factors in these analyses.

- The factor of safety after the drainage improved (27–34) % and (20–28) % based on the 3D and 2D slope stability analyses, respectively.

- The difference in factors of safety between the 2D and 3D slope stability analyses for the deeper groundwater table (water level in the elevation 2540 on the walls) is less than 7 %.

Conclusion

The factors of safety obtained from 2D slope stability analyses are not necessarily more conservative than 3D slope stability analyses. Analyses of the slope after lowering of groundwater table by horizontal drains showed that the factor of safety of the slope has improved tremendously. The differences in factors of safety for 2D and 3D slope stability analyses are greater for low groundwater table as compared with those for high groundwater table. The results illustrated how 3D slope stability analyses have become less daunting to perform and can be incorporated into routine slope designs.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Slopes of mines and quarries, some of which may reach several hundred meters deep, must be regarded as "geotechnical works" in the sense that we speak of mine works or civil engineering works. Their design and their implementation must be conducted according to rules of art with the general objective to define the geometry that will ensure the safety of the structure while minimizing the volume of material to be excavated, and therefore the final cost of the project. In addition to these economic issues, specific concerns about the environment must be considered, particularly in the context of procedures for abandonment of mine sites where the problems of long-term slope stability may arise. But these works are, above all, geomechanical objects for which the geological structure, the nature of the constituent materials and their mechanical behavior control the process of deformation and failure considered in the slope design This close connection with the geological structures therefore requires first to identify these structures in order to implement the appropriate means of investigation, modelling and calculation (Fleurisson 2012).

Three-dimensional (3D) slope stability analysis is still not routinely used by geotechnical engineers even though most slope stability problems are three-dimensional. This is due to several reasons. Firstly, it is commonly believed that two-dimensional (2D) slope stability analysis provides a more conservative estimate of the 3D slope stability problem (e.g., (Li et al. 2009; Li et al. 2010; Michalowski 2010)). Secondly a 3D slope stability analysis is more elaborate to conduct as compared with a 2D slope stability analysis. Thirdly, it is more difficult to input data and visualise the output of a 3D slope stability analysis. However, rapid progress in computation and visualisation is making 3D slope stability analysis more accessible to geotechnical engineers (Leong and Rahardjo 2012).

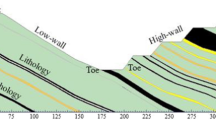

Discontinuum modeling

Discontinuum methods treat the rock slope as a discontinuous rock mass by considering it as an assemblage of rigid or deformable blocks. The analysis includes sliding along and opening/closure of rock discontinuities controlled principally by the joint normal and joint shear stiffness. Discontinuum modeling constitutes the most commonly applied numerical approach to rock slope analysis, the most popular method being the distinct-element method (Itasca 2001). Distinct-element codes such as UDEC and 3DEC (Hart 1993) use a force-displacement law specifying interaction between the deformable joint bounded blocks and Newton’s second law of motion, providing displacements induced within the rock slope. UDEC and 3DEC are particularly well suited to problems involving jointed media and have been used extensively in the investigation of both landslides and surface mine slopes. The influence of external factors such as underground mining, earthquakes and groundwater pressure on block sliding and deformation can also be simulated.

Discontinuities play a major role in the design and maintenance of opencast pits, their presence affecting the mechanical and hydrogeological properties of the rock masses. Scanline surveys were carried out in selected areas of the open pit at Miduk either where failure had occurred or where the potential for failure existed (Sen and Kazi 1984). Numerous parameters were measured for each discontinuity such as roughness, dip and dip direction, spacing, continuity, joint aperture, and the presence of gouge. Joint profile readings were taken (Stimpson 1982) with a carpenters comb and compared with the joint roughness profiles of (Barton 1976). Detailed structural mapping was also undertaken of each face, the data collected including the lithology, dominant joint sets, critical joint spacing, veins and any faults.

The DIPS software program was used to generate the stereonets from the scanline survey data collected. For each region a contoured pole data stereonet with joint set windows was constructed. The stereonets then were analysed according to procedures given in (Hoek and Bray 1981) in order to assess potential modes of failure, thereby allowing potential failure zones to be identified.

Case description

The Miduk porphyry copper deposit is positioned in the Shahr-Babak area in Kerman province, Iran (Fig. 1). Ore in Miduk is fungi-form with 350*400 m dimensions and its upper part consists of oxide-zone (malachite and azurite mineral) and supergene-zone (mostly culcosite). Figure 2 shows Geological map of Miduk Copper mine.

This deposit is located 85 km NW of the Sar Cheshmeh porphyry copper deposit. Preliminary mineral exploration was carried out in 1967–1970 by Parjam and Metallgesellschaft (Hassanzadeh 1993). So far, more than 50 diamond drill holes with a maximum depth of 1013 m have proved the existence of the sizeable and potential porphyry copper mineralization at the Miduk deposit. The orebody contains 170 million tons of ore, with an average grade of 0.86 % Cu, 0.007 % Mo, 82 ppb Au and 1.8 ppm Ag. Supergene enrichment blankets average approximately 50 m thickness and comprise the primary source of Cu ore (Taghipour et al. 2008).

In the course of the study, geotechnical mapping was undertaken to determine the critical orientation of geological discontinuities. Physico-mechanical properties of the rock materials were obtained by laboratory tests conducted on samples cored from exploration drilling and rock blocks taken directly from the mine.

Three major joint sets have been recognized at Miduk, which are related to the regional tectonic history. They have an important influence on slope stability in the open pit, notably in terms of planar and wedge failures. Detailed geological and geotechnical data are often a notable unknown factor in the design and operation of an open pit, the lack of which may pose a significant risk to the mining venture. As data are accumulated and used effectively, so the risk of unforeseen conditions is reduced, and accordingly safety and productivity is increased. Usually, the geotechnical work undertaken at an open pit mine is in connection with improving slope stability (Bye and Bell 2001). At Miduk open pit, geological and geotechnical data have been obtained by face mapping, scan line surveys, from exploration drill holes and from laboratory tests.

Methodology

The first step of site investigation was started in the middle of June 2012, with rock blocks surveying. By the fact that this step is of prime importance, selection of the best specimens is so crucial. The purpose of this is to prepare representative specimens of the rocky walls of the mine. These blocks should have the following properties:

-

Be representative

-

Should have minimum amount of joint and discontinuity

-

Can be carried to the place of coring

Because of high jointing, large amount of discontinuities and accessibility restrictions to the all benches of the mine, this step encountered with limitations. At first, rocky units of every benches and their contacts characterized by an engineering team. After the selection of specific specimen, its coordinates was recorded by a GPS apparatus and the block was characterized by a number. This number and the coordinates of the bench were recorded in a specific form. Figure 3 shows the distribution of sampling blocks points in the area of the mine.

At the end of this step, the process of coring started. In this operation, two or three core were sampled averagely from any of the blocks and attempted to get the cores from the biggest blocks. Total number of 254 cores were prepared and sent to the laboratory. Then the cores were standardized for uniaxial compressive test, triaxial compressive test and indirect tensile strength test. All of the specimens were prepared according to ISRM standards for rock mechanical tests (ISRM 1981). Figure 4 shows a view of all prepared samples.

Geomechanical properties and also effective joint sets in the stability of different division are presented in the Tables 1 and 2, respectively. Dip and dip direction of all the joint sets for different parts of the mine are given in the Table 2.

Discontinuities

Discontinuities play a major role in the design and maintenance of opencast pits, their presence affecting the mechanical and hydrogeological properties of the rock masses. Scanline surveys were carried out in selected areas of the open pit at Maiduk either where failure had occurred or where the potential for failure existed (Sen and Kazi 1984). Numerous parameters were measured for each discontinuity such as roughness, dip and dip direction, spacing, continuity, joint aperture, and the presence of gouge. Joint profile readings were taken (Stimpson 1982) with a carpenters comb and compared with the joint roughness profiles of (Barton 1976). Detailed structural mapping was also undertaken of each face, the data collected including the lithology, dominant joint sets, critical joint spacing, veins and any faults.

The DIPS software program was used to generate the stereonets from the scanline survey data collected. For each region a contoured pole data stereonet with joint set windows was constructed. The stereonets then were analyzed according to procedures given in (Hoek and Bray 1981) in order to assess potential modes of failure, thereby allowing potential failure zones to be identified. Figure 5 shows distribution of all joints in the mine.

In this research, joint study was done by 13 scan line (each with 20 m length). For every joint, its dip and dip direction were determined. The Dips software was used to depict and analyze jointing systems in the mine area. Rose diagram and contour poles of all the surveyed joints in the mine area are shown in Fig. 6.

Slope stability analyses

In the first step, the topography of the mine before its opening was modeled and its in-situ stresses were calculated. Then to test the accuracy, the model was changed to the current available pit.

This analysis was repeated in the following three positions:

-

Assumed that underground water is not available.

-

There is not any drainage network and also water level in the elevation 2540 on the walls.

-

There is a drainage plan to dry the walls to the level of 2250.

These analysis steps were done for four walls of the mine; including east wall, north wall, west wall and south and 3DEC have the capability to perform the analysis of fluid flow through the fractures of a system of impermeable blocks. A fully coupled mechanical-hydraulic analysis is performed, in which fracture conductivity is dependent on mechanical deformation and, conversely, joint fluid pressures affect the mechanical computations (Itasca 2001).

Results

Constructed model of final pit of Miduk mine using 3DEC are shown in Fig. 7. Also Results of the numerical analysis for all the walls are given in Table 3.

Figure 8 shows the tendency vectors of movement toward the inside of the pit for southern-Northern and western-Eastern masses.

Figure 9 shows the In-situ vertical stresses before mining, Mohr-Coulomb safety factor in dry and with water level of 2540 and 2250, respectively for Southern wall of final pit.

Figure 10 shows the difference in factors of safety between the 2D and 3D slope stability analyses in different situations.

Discussion

Analysis of slopes using 3D and 2D slope configurations has led to controversial results over the last four decades showing both the importance and the difficulty to handle the subject. The differences in the obtained results can be attributed to the limited amount of studies and to the limited cases handled in each study.

In practice, different slope stability methods produce different slip surfaces and hence different minimum factors of safety (Duncan and Wright 1980). Therefore, it is important to compare the analysis results with field measurements rather than comparing the factors of safety only. The most critical issue in evaluating different analysis methods is the ability of that method to capture the most critical slip surface. Under a certain critical slip surface, factors of safety from different methods can be different due to the difference in the mathematical formulation and the simplifications used in developing the method.

On the other hand, limitations of slope stability analysis can be noted after extensive use of the method. For example, the presence of a hard cohesive layer at the top of the slope or the presence of a very dense granular layer at the bottom of the slope can produce slip surfaces that are almost vertical. In such cases, good engineering practice and experience suggest the use of tension cracks at the top of the slope to flatten the exit angle at the lower end of the slip surface (Duncan 1996). Such cases are mostly ignored by most engineers due to the lack of solid engineering understanding of slope stability analysis limitations resulting in misleading factors of safety.

End effects in 2D slope stability analysis methods are eliminated by assuming plane strain since the slip surface is assumed to be infinitely wide. This assumption neglects the normal and horizontal side resisting forces along the sides of the sliding mass (end effect), which in turn underestimate the factor of safety leading to more conservative results. On the other hand, backcalculated shear strengths ignoring the end effects tend to be high or unconservative.

Lefebvre et al. (1973) showed that neglecting the end effect can severely affect the factor of safety results especially in narrow slopes with slope surface angles steeper than 20°. Baligh and Azzouz (Baligh and Azzouz 1975) showed that the ignoring the end effect can reduce the factor of safety by 40 %. These studies emphasize the importance of the side and end effects and demonstrate the need for powerful methods that can simulate such conditions accurately.

Conclusion

In this research, the stability of Miduk copper mine walls were accomplished by distinct element code (UDEC&3DEC). Both 2D and 3D were performed to establish the representative shear strength parameters to use in the analyses and to examine the differences in the results. The extended Mohr–Coulomb failure criterion was used for analyses. The rock mass was assumed to be permeable and also by the obtained data from surveying, laboratory tests and field observations. The results are as follows:

-

Water and pore pressure in the faults and main joints were the most important destabilizer factors in these analyses.

-

If the pore pressure omitted by a drainage system for the long life of the mine, there will be stable wall for this period.

-

The factor of safety after the drainage improved (27 − 34) % and (20 − 28) % based on the 3D and 2D slope stability analyses, respectively.

-

The difference in factors of safety between the 2D and 3D slope stability analyses for the deeper groundwater table (water level in the elevation 2540 on the walls) is less than 7 %.

-

According to the mechanical properties of wall rocks and dip direction of faults and main joints and with a drainage system, mining operation with optimized slope can be done.

-

The results illustrated how 3D slope stability analyses have become less daunting to perform and can be incorporated into routine slope designs.

References

Baligh, M, & Azzouz, AS. (1975). End effects on stability of cohesive slopes. Journal of the Geotechnical Engineering Division, ASCE, 101(GT11), 1105–1117.

Barton, N. (1976). The shear strength of rock and rock joints. International Journal of Rock Mechanics and Mining Science and Geomechanics Abstracts, 13, 255–279.

Bye, AR, & Bell, FG. (2001). Stability assessment and slope design at sandsloot open pit, South Africa. International Journal of Rock Mechanics and Mining Sciences, 38, 449–466.

Duncan, JM. (1996). State of the Art: limit equilibrium and finite element analysis of slopes. Journal of Geotechnical Engineering, 122(7), 577596.

Duncan, JM, & Wright, SG. (1980). The accuracy of equilibrium methods of slope stability analysis. Engineering Geology (Amsterdam, Netherlands), 16(1/2), 5–17.

Fleurisson, J-A. (2012). “Slope Design and Implementation in Open Pit Mines: Geological and Geomechanical Approach”. Procedia Engineering, 46, 27–38.

Hart, RD. (1993). An introduction to distinct element modeling for rock engineering. In Comprehensive rock engineering: principles, practice & projects (pp. 245–261). Oxford: Pergamon Press.

Hassanzadeh, J. (1993). Metallogenic and tectono-magmatic events in SE sector of the Cenozoic active continental margin of central Iran (Shahr-Babak, Kerman Province) (PhD Thesis, p. 201). Los Angeles: University of California.

Hoek, E, & Bray, JW. (1981). Rock slope engineering,3rd ed. London: Institution Mining and Metallurgy.

ISRM. (1981). Rock characterizition, testing and monitoring. In ET Brown (Ed.), ISRM suggested methods (p. 211). New-York: Pergamon Press.

Itasca. (2001). Itasca software products - FLAC, FLAC3D, UDEC, 3DEC, PFC. Minneapolis: Itasca Consulting Group Inc.

Lefebvre, G, Duncan, JM, & Wilson, EL. (1973). Three dimensional finite element analysis of dams. Journal of Soil Mechanics and Found Division, ASCE, 99(7), 495–507.

Leong, EC, & Rahardjo, H. (2012). Two and three-dimensional slope stability reanalyses of Bukit Batok slope. Computers and Geotechnics, 42, 81–88.

Li, AJ, Merifield, RS, & Lyamin, AV. (2009). Limit analysis solutions for three dimensional undrained slopes. Computers and Geotechnics, 36, 1330–1351.

Li, AJ, Merifield, RS, & Lyamin, AV. (2010). Three-dimensional stability charts for slopes based on limit analysis methods. Canadian Geotechnical Journal, 47, 1316–1334.

Michalowski, RL. (2010). Limit analysis and stability charts for 3D slope failures. Journal of Geotechnical and Geoenvironmental Engineering, 136(4), 583–593.

Sen, Z, & Kazi, A. (1984). Discontinuity spacing and RQD estimates from finite length scanlines. International Journal of Rock Mechanics and Mining Science and Geomechanics Abstracts, 21, 203–212.

Stimpson, B. (1982). A rapid field method for recording joint roughness profiles. International Journal of Rock Mechanics and Mining Science and Geomechanics Abstracts, 19, 345–346.

Taghipour, N, Aftabi, A, & Mathur, R. (2008). Geology and Re-Os geochronology of mineralization of the maiduk porphyry copper deposit, Iran. Resource Geology, 58(2), 143–160.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

Discontinuities play a major role in the design and maintenance of opencast pits, their presence affecting the mechanical and hydrogeological properties of the rock masses. In this research, Two and three-dimensional slope stability analyses of final slope for Miduk copper mine is investigated by using distinct element code. Modelling of rock slopes using Distinct Element methods can thus simulate movement along major structures, such as faults, as well as the translation and rotation of joint-bounded blocks. While most research has concentrated on the FOS between the LEM and SRM, the present works have compared the locations of the critical failure surfaces from these two methods.

Authors’ contributions

MSS carried out the numerical modeling and laboratory tests. PM drafted the manuscript. EY carried out the rock blocks surveying and face mapping.

I warrant that this manuscript has been read by all co-authors and I have submitted this manuscript on behalf of all the authors with their full consent. The authors declare no conflicts of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Shamsoddin Saeed, M., Maarefvand, P. & Yaaghubi, E. Two and three-dimensional slope stability analyses of final wall for Miduk mine. Geo-Engineering 6, 9 (2015). https://doi.org/10.1186/s40703-015-0009-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-015-0009-0