Abstract

Background

Bioenergy is re-shaping opportunities and imperatives of forest management. This study demonstrates, through a case study in Scots pine (Pinus sylvestris L.), how forest bioenergy policies affect stand management strategies.

Methods

Optimization studies were examined for 15 Scots pine stands of different initial stand densities, site types, and temperature sum regions in Finland. Stand development was modelled using the PipeQual stand simulator coupled with the simulation-optimization tool OptiFor Bioenergy to assess three forest bioenergy policies on energy wood harvest from early thinnings.

Results

The optimal solutions maximizing bare land value indicate that conventional forest management regimes remain optimal for sparse stands. Energy harvests occurred only when profitable, led to lower financial returns. A forest bioenergy policy which included compulsory energy wood harvesting was optimal for denser stands. At a higher interest rate (4 %), increasing energy wood price postponed energy wood harvesting. In addition, our results show that early thinning somewhat reduced wood quality for stands in fertile sites. For less fertile sites, the changes were insignificant.

Conclusions

A constraint of profitable energy wood harvest is not rational. It is optimal to carry out the first thinning with a flexible forest bioenergy policy depending on stand density.

Similar content being viewed by others

Background

Global interest in bioenergy, defined as energy produced from biomass, has grown rapidly in recent years. In Finland, renewable energy sources account for 24 % of total energy consumption, and wood based fuels, including wood processing residues, account for 20 % of total energy consumption (Hakkila 2006). Modern bioenergy includes liquid biofuels, biogas, and solid biomass for heat and power generation, and forests remain an important source of bioenergy. The substitution of fossil fuels by forest biomass in bioenergy production is an important measure in climate mitigation. Carbon in forest biomass is sequestered through photosynthesis, and released by decomposition and combustion. Therefore, the utilization of forest biomass for energy is carbon-neutral (UN-Energy 2007), and in agreement with the Kyoto Protocol (UNFCCC 1997).

The environmental, social, and economic impacts of bioenergy development depend greatly on local circumstances (UN-Energy 2007). There are several policies and measures in the EU that support bioenergy and stipulate targets (McCormick and Kåberger 2007). For example, Finland aims to increase the annual use of forest chips to 12 million m3 by 2020 (Ministry of Agriculture and Forestry 2008). Current Finnish government incentives and policy measures for energy wood production include: (1) an environmental tax exemption for wood-based fuels used for heat production, (2) a general tax refund for power plants using forest chips as fuel, and (3) a subsidy and financial aid for using small-sized trees from precommercial thinning and for the production and use of forest chips (Hakkila 2006).

Bioenergy provides opportunities to address environmental, social, and economic challenges. The issues raised by bioenergy development, such as energy security, environmental sustainability, food security, and rural development, will mainly be dealt with by bioenergy policy. Nevertheless, bioenergy policy must be designed and managed carefully in order to avoid new environmental and social problems (UN-Energy 2007). Policy design and assessment in climate change are based heavily on models and simulations. At the European level, Wetterlund et al. (2013) developed a techno-economic-geographic optimization model to determine the optimal locations of bioenergy conversion plants with focus on the influence of different carbon cost and biofuel policies. Based on integrated modeling of biomass production and land use, Kraxner et al. (2013) presented an example of global scale assessments for bioenergy production under deforestation, land-use change, and other climate effective aspects to focus on policy design and its implementation. Their studies demonstrated that the integrated assessment approach offers a useful tool for evaluating bioenergy policy.

The source of forest bioenergy may include forest chips and processing by-products. Forest chips, including small diameter wood from young forests, logging residues, and stumps, are from thinnings, and clearcut. The potential utilization of forest biomass has been studied intensively in recent years (Malinen et al. 2001; Bolkesjø et al. 2006; Hakkila 2006; Alam et al. 2010), and diverse energy wood production systems have been proposed (Laitila et al. 2004; Jylhä and Laitila 2007; Nurmi 2007; Laitila 2008). Ahtikoski et al. (2008) investigated the economic viability of energy wood production from young stands based on six thinning methods. By linking energy wood production and forest management, Kärkkäinen et al. (2008) studied the recovery of energy wood in different cutting and climate scenarios in Finland. Their results were based on a linear programming approach (Lappi 1992) which selected the optimum combination of management regimes from a predefined set of alternatives. Kotamaa et al. (2010) integrated energy wood thinning and optimal bucking at stand level. However, their thinning regimes were based on silvicultural recommendations (Finnish Guidelines for Good Silviculture 2006), rather than optimized. There is little integration of energy wood production and forest management optimization for enhancing thinning and rotation regimes.

In contrast to energy wood from commercial thinning and clearcut, the utilization of small diameter wood from precommercial thinning may have important impacts on stand development, and consequently affect thinning and rotation regimes in the long run. Precommercial thinning is a frequently applied silvicultural treatment in conifer stands (Piene 1978; Pothier 2002; Varmola and Salminen 2004; Fahlvik et al. 2005; Huuskonen and Hynynen 2006). Because precommercial thinning increases the spacing between trees, it helps to increase the temperature of surface soil layers and offers more growing space, thus increasing future growth and yield. Precommercial thinning is usually seen as a costly silvicultural treatment. The increasing use of energy wood coupled with forest bioenergy incentives provides additional income that may offset the cost of precommercial thinning (Hakkila 2006; Ministry of Agriculture and Forestry 2006). Therefore, there is a need to investigate the optimal thinning regimes when the energy wood harvest from precommercial thinning is taken into account.

Forest management optimization has been well studied since the 1960s (Amidon and Akin 1968; Haight and Monserud 1990; Valsta 1990; Hyytiäinen et al. 2004; Pukkala 2011). Until recently, most numerical optimization studies in forestry focused on timber production. This study attempts to integrate energy wood harvesting into forest management optimization, and analyses the energy wood harvest from precommercial thinning using a simulation-optimization system for simultaneously optimizing timber and energy wood production.

The objectives of this study were: (1) to integrate bioenergy production into forest management optimization, (2) to develop a simulation-optimization tool OptiFor Bioenergy for optimizing timber and energy wood production, and (3) to demonstrate, through a case study in young Scots pine stands, how various forest bioenergy policies affect optimal thinning regimes, financial returns, as well as wood quality.

Methods

The optimization computations were conducted for 15 simulated pure Scots pine (Pinus sylvestris L.) stands. The initial states (Table 1) are the same as those applied earlier in background calculations made for Silvicultural Recommendations in Finland (Hyytiäinen et al. 2006). The diameter distributions were derived artificially by site type, temperature sum, and initial stand density. The investigated site types are CT (Calluna), VT (Vaccinium), and MT (Myrtillus) (Cajander 1909). The two temperature sum regions are 1100 (T1100) and 1300 (T1300) day degrees (d.d.), and the initial stand densities after completion of the silvicultural operations (tending and slashing) 1500 and 3000 trees∙ha-1, respectively. According to the 10th national forestry inventory in Finland, Scots pine dominant stands are 65 % of total forest land, in which pure Scots pine stands are 59 %. The proportion of forest land on mineral soils by site type are 2, 19 and 47 % for CT, VT, MT sites in the south, and 5, 36 and 54 % for CT, VT, MT sites in the north, respectively (Peltola and Ihalainen 2013). Therefore, the initial states used in the present study are well representative for Scots pine in Finnish conditions.

In this study we employed the process-based growth model, PipeQual (Mäkelä 1997, 2002; Mäkelä and Mäkinen 2003), as the stand growth simulator, and models for predicting sawn wood grading of Scots pine (Lyhykäinen et al. 2009), as the sawing simulator. The process-based model was first linked with an economic optimization model in Hyytiäinen et al. (2004). They demonstrated that the standard Hooke and Jeeves’ direct search algorithm (Hooke and Jeeves 1961) could be successfully applied for the stand level problem formulation that employs a detailed and computationally demanding process-based stand simulator.

The process-based model PipeQual is based on the pipe model theory (Shinozaki et al. 1964) and the theory of crown allometry (Mäkelä and Sievänen 1992). Tree growth simulation by the PipeQual simulator consists of branch, whorl, and tree levels. Tree structure is composed of foliage, fine roots, stem, branches, and transport roots. The whorl module describes the vertical structure of stem and branches. The branch module provides the annual dynamics of individual branches and their properties in each whorl. Annual growth is calculated from tree photosynthesis and respiration. PipeQual is an individual-tree model that describes the stand structure using a list of tree records. For this application the stands were represented by 10 size classes with one representative tree and the number of trees in the class. The number of trees in each sample tree class depends on the initial stand density and other stand characteristics, and evolves over time due to mortality and harvesting. No ingrowth is assumed to occur. The PipeQual is calibrated for different site qualities and temperature sum regions by adjusting the allometric ratio between fine root mass and needle mass (Hyytiäinen et al. 2004) and by comparing the model outcomes for each initial state with those from the empirical Motti simulator (Hynynen et al. 2005). More explicit description of the PipeQual simulator as a dynamic system for stand management optimization was presented in Hyytiäinen et al. (2004).

In this study, multinomial logistic regression models for predicting yields of lumber grades and by-products of individual Scots pine trees developed by Lyhykäinen et al. (2009) were linked with the PipeQual simulator. The sawn wood grading models use stem and crown dimensions as explanatory variables. The proportion of sawn wood grades is a function of the height of the crown, the height of the lowest dry branch, tree diameter at breast height, and stem volume. The end products of Scots pine include centre (grades A, B, C and D) and side (grades A, B, C and D) sawn timber, chips, bark, sawdust, as well as pulpwood.

In order to integrate forest bioenergy production into conventional stand management optimization, we developed a simulation optimization tool OptiFor Bioenergy from an earlier version OptiFor Carbon (Cao et al. 2010). The Hooke and Jeeves’ direct search algorithm used in the OptiFor program has been widely employed in stand management optimization because of the advantage of its robustness (e.g. Haight and Monserud 1990; Valsta 1990). The OptiFor simulation-optimization system was tested by comparing the modified Osyczka’s direct and random search (DRS) (Osyczka 1984) with a random search (RS). The DRS algorithm is clearly more efficient than the random search (Cao 2010). The result of the comparison is consistent with Valsta (1990).

The objective function of the optimization problem is based on the Faustmann (1849) formula. We formulated the optimal thinning regime for energy wood and timber production as a bound-constrained optimization problem (Eqs. 1, 2 and 3). The dynamic problem of stand management is solved as static optimization using control variables. In this formulation, the state variables x(t) (tree diameter, height, etc.) are not used in the optimization algorithm. Instead, the state variable values are computed inside the stand simulator, given initial state x(t 0). The bare land value of a stand is maximized by changing the set of control variables u (time between the i-1th and the ith thinnings, yrs) and H (thinning rate h ij in the jth tree size class at the ith thinning),

where f : E n × E 3 → E 1 is the objective function for the bare land value (BLV) of a thinning regime, E n denotes n-dimensional real Euclidean space, n is the number of thinnings, n + 1 means final felling.

The BLV of a thinning regime for timber production can be expressed as follows (Eq. 4):

where p denotes timber price, v refers to harvested timber volume, l denotes timber categories, c i is the logging cost at the ith harvest, c 0 is the discounted stand establishment cost, r denotes interest rate, and t denotes stand age. The definition of thinning type is defined by three thinning variables, which means thinning rates in the first, the middle and the last tree size classes are selected. The decision variables of thinning type are then defined by linearly interpolating thinning rate h ij in the jth tree size class to other tree sizes.

The logging cost is a function of harvested volume, productivity of felling, and on-site transport. Logging costs are composed of felling and haulage (transportation) costs and a fixed cost. The logging cost model by Kuitto et al. (1994) for timber production from commercial thinning and final felling is based on the time consumption equations for mechanized cutting and forest haulage specification. More detailed description of Kuitto’s logging model was presented in Cao et al. (2006). The productivity of mechanised cutting for energy wood from early thinnings (stem wood) is based on a time consumption model for a thinning harvester equipped with an accumulating felling head (Laitila et al. 2004). Laitila (2008) reported that such a two-machine system (harvester-forwarder) is currently the most cost competitive logging system for energy wood from early thinnings in Finnish conditions. The logging cost parameters were assumed as follows: terrain class one, average travel distance 200 m, felling cost 75.67 €∙h−1, transportation cost 53.35 €∙h−1, and fixed cost 100.00 €∙ha−1 (Cao et al. 2010).

When the first thinning is an energy wood harvest, conventional logging will be applied from the second thinning, and the energy wood logging cost (c E ) and volume v 1j (harvested volume in the jth tree size class at the 1st thinning) will be computed for the first thinning (Eq. 5). The objective function of BLV (Eq. 4) will be modified (III) by adding the net present value of energy wood (NPV E ), where p E denotes the energy wood price.

In this study, the interest rate, costs and roadside prices are expressed in real terms. The roadside prices assumed were 52.98, 26.24 €∙m−3 (Cao et al. 2010), for sawlog, and pulpwood, respectively. The financial returns (bare land value) were computed with a 3 % interest rate. In addition, we assumed the energy wood price of 15 €∙m−3, and conducted sensitivity analyses with energy wood price 15, 20, 25 €∙m−3, and at 2, 3 and 4 % interest rates for stands 10 and 12, respectively.

The unit silvicultural costs assumed were 142, 600, and 276 €∙ha−1 (Cao et al. 2010), for soil preparation, sowing, and other silvicultural operations (tending and slashing), respectively. It was assumed that soil preparation had been done in the first year for all stands. Sowing was carried out in the second year for MT and VT sites. The least fertile CT site was assumed to be regenerated naturally from seeds dispersed from adjacent forest stands. It was also assumed that the tending of the seedling stands had been carried out at ages 20, 18, 15, 16, and 13 for stands 1–3, 4–6, 7–9, 10–12, and 13–15, respectively.

Conventional forest management (Policy 0) was used as a benchmark (the optimal policy for timber production only) to compare with alternative policies for energy wood and timber production. Policy I was designed for profitable energy wood harvesting, which means that the first thinning will be treated as precommercial thinning for energy wood production (small size trees from precommercial thinning) if net income from energy wood harvest is positive. In Policy II it was assumed that the first thinning for energy wood production is compulsory. In other words, no matter how unprofitable energy wood harvesting is, the first thinning is always conducted as precommercial thinning.

Results

The optimal solutions indicate that a conventional forest management regime (Policy 0) was still optimal for sparse stands (Fig. 1a and b). However, Policy II (compulsory energy harvest) turned out to be optimal for denser stands with an initial density of 3000 trees∙ha−1 (Fig. 1c). With Policy II, the number of thinnings was reduced, and the rotation length was shortened slightly. The most significant rotation change was for stand 12 (VT1300, 3000 trees∙ha−1) in which the rotation was shortened by 20 years.

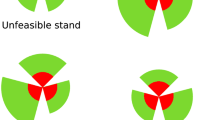

It is somewhat surprising that Policy I (economic harvest), which favours profitable energy wood harvesting, was neither optimal for sparse nor optimal for dense stands (Table 2). For denser stands (3000 trees∙ha−1), Policy I increased the intensity of the first thinning. For sparser stands (1500 trees∙ha−1), Policy I significantly reduced thinning intensity to an unrealistically low level, and brought the first thinning earlier (Table 3).

Thinning from below was optimal at the first thinning for sparser stands (initial density 1500 trees∙ha−1) with Policy 0. With Policy II, thinning from above was optimal at the first thinning for dense stands with an initial density of 3000 trees∙ha−1. The dominant height at the first thinning for the energy wood harvest was lower than eight meters in fertile sites (stands 9, 12 and 15), but higher (9.7 m and 9.2 m for stands 3 and 6, respectively) in less fertile sites. The first thinning with the energy wood harvest was clearly earlier than conventional first thinning. With optimal energy wood harvesting, Policy I resulted in a later first thinning compared to Policy II. The first thinning was postponed by 2–7 years (2, 6, 6 and 7 years for stands 3, 6, 9 and 12, respectively) except stand 15 (Table 3).

The maximized bare land values were higher systematically for lower initial densities from all combinations of site type and temperature region (Table 2). Following Policy 0 (conventional harvest), the higher bare land values were obtained from fertile sites with a greater temperature sum (Tables 1 and 2). Stand 13 from the MT site with a temperature sum of 1300 (d.d.) resulted in the highest bare land value (3714 €∙ha−1). Stand 6 from the VT site with a temperature sum of 1100 (d.d.) led to the lowest bare land value (302 €∙ha−1). On the same sites (the same site type and temperature sum), sparse stands (stands 1, 4, 7, 10 and 13 with an initial density of 1500 trees∙ha−1) resulted in greater financial returns than denser stands.

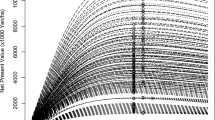

Increasing energy wood price from 15 to 25 €∙m−3 resulted in greater financial returns for the denser stand 12. However, for the sparse stand 10, the financial returns were insensitive to a higher energy wood price (Fig. 2). At a 2 % interest rate, the timing of energy wood harvesting was also insensitive to energy wood price (Fig. 3a). Nevertheless, at a higher interest rate, increasing energy wood price postponed energy wood harvesting (Fig. 3).

Our results reveal that a negative net income from energy wood harvesting might increase financial returns for the whole rotation realized in later thinnings and the final harvest. The net incomes of energy wood harvesting were all negative for optimal solutions with Policy II, even though a relatively high energy wood price of 15 €∙m−3 was applied. The net incomes from energy wood harvesting were − 68.4,−141.1, 224.9,−293.5, and − 287.1 €∙ha1 for stands 3, 6, 9, 12, and 15, respectively. However, the total financial returns increased by 2–16 % compared to Policy 0. With Policy II, financial returns from fertile sites (stands 9, 12, 15) increased by 5 %, but the variation on less fertile sites was large (financial returns increased by 2 and 16 % for stands 3 and 6, respectively).

According to our results, energy wood harvesting somewhat reduced the proportions of sawn wood grades for the most fertile site (stand 15, MT, T1300). However, for the less fertile sites (stands 3, 6, 9, 12), the changes were insignificant (Table 4). The highest reduction (from 63.55 to 51.83 m3∙ha−1), 1.17 % in the proportion of sawn wood grades, was for the centre sawn wood of grade A (the most valuable grade) for stand 15. The side sawn wood of grade A was slightly decreased by 0.06, 0.25, 0.26 and 0.45 % for stands 3, 9, 12, and 15, respectively (Table 4).

Precommercial thinning clearly increased branch diameter growth. Compared to Policy 0, Policy II resulted in thicker branches, a higher crown base, and a lower crown ratio at the second thinning (Fig. 4). Stands 9, 12, and 15 with earlier precommercial thinning (at age 25, 25, and 22, respectively) had more significant differences in branch thickness, crown base, and ratio than stands 3 and 6 with later precommercial thinning (at age 41 and 36, respectively). The most significant changes in branch thickness and crown base appeared in the most fertile site. The thickest dry branch increased by 7 % (0.13 cm), and the height of the crown base increased by 9 % (0.6 m) for stand 15 (H 100 = 27.3 m).

Discussion

Pukkala (2011) developed a simulation-optimization system, in which carbon balances of harvested wood, end use of products, harvesting and processing releases, and substitution effects were incorporated. In his study energy wood was collected only in clearcut, precommercial thinning as energy harvesting was not taken into account. Our results agree that the utilization of forest bioenergy shortened the rotation length slightly as reported in Pukkala (2011), but revealed a more significant change (shortened 20 year) for stand 12 from the VT site in the present study. This was caused by the optimal thinning regimes in which two low thinnings were limited in Pukkala (2011), while the present study allows more frequent thinnings and more flexible thinning types that led to longer rotation.

The requirement of positive harvest profit for the first thinning is common in practical stand management. Ahtikoski et al. (2008) also made this requirement when evaluating the feasibility of energy wood harvests from young stands. However, our optimization results reveal that an energy wood harvest plays a more important role as an investment in early thinnings. The profitability of the first thinning depends on the unit costs of energy wood harvesting and conventional logging technology, as well as the roadside prices of energy wood, pulpwood, and sawlog. As illustrated in Fig. 5, the unit costs of energy wood harvesting and conventional logging decrease with a lower number of stems and higher volume. However, the unit cost of energy wood harvesting is clearly less sensitive to variations in stand density and volume. In other words, energy wood logging is more competitive when more small size stems are removed.

The effects of precommercial thinning on growth and yield have been investigated based on thinning experiments for conifer cultures, such as Scots pine (Ruha and Varmola 1997; Varmola and Salminen 2004; Huuskonen and Hynynen 2006), balsam fir (Pothier 2002), and lodgepole pine (Johnstone 2005). In general, our results on the effects of early thinnings on growth and yield were in line with earlier empirical studies for Scots pine (Mäkinen and Isomäki 2004; Varmola and Salminen 2004; Huuskonen and Hynynen 2006). We contribute to this literature by extending the analysis over the whole rotation period and optimizing the timing and intensity of the thinnings with the option of an energy wood harvest for the first thinning.

Many forest managers expect greater sawlog volume increment and shorter rotations after a stand has been precommercially thinned (Pothier 2002). It has been reported that the strategy of precommercial thinning depends on the aims of stand management, such as even spacing, high yield, or both quality and yield (Vuokila 1972; Ruha and Varmola 1997; Varmola and Salminen 2004). Ruha and Varmola (1997) stated that the intensity of precommercial thinning depends on the aim of the first commercial thinning. Our results confirmed that optimal thinning regimes vary with different forest bioenergy policies. In contrast to Ruha and Varmola (1997), in the present study the whole rotation was taken into account, not only the first commercial thinning. The positive effects of precommercial thinning on diameter and volume growth at the first commercial thinning were reported for balsam fir by Pothier (2002), and for lodgepole pine by Johnstone (2005). However, they pointed out that there were no significant differences in merchantable volume at maturity (Pothier 2002) or, even after 20 years (Johnstone 2005). Meanwhile, Pothier (2002) found that the effect of precommercial thinning on rotation length depends on the management goals. This is supported by the results of the present study. With Policy II, the rotation length was somewhat shortened for dense stands.

Huuskonen and Hynynen (2006) reported that early and light precommercial thinning (H dom 3 m, to a density of 3000 trees∙ha−1) significantly increased the first commercial thinning removal by 40 %. Postponing the first commercial thinning by 10 years, increased the present value of the stumpage revenues by 65 % at a 4 % interest rate (Huuskonen 2008). According to Varmola and Salminen (2004), precommercial thinning to 1600 and 2200 trees∙ha−1 was moderate. Our results confirmed that early energy wood harvesting increased financial returns for dense stands (with an initial density of 3000 trees∙ha−1) by 2–16 % at a 3 % interest rate (Table 2). The intensity of energy wood harvesting was in the range of 40–51 % (Table 3), and the density after energy wood harvesting was close to the target density recommended by Varmola and Salminen (2004).

Precommercial thinning has positive effects on growth and yield. On the other hand, it might also result in negative effects on wood quality. Precommercial thinnings create more growing space and accelerate tree growth and, consequently, branch growth. This lowers timber grades for timber production from commercial thinnings and final felling. Economic analysis of thinning regimes and timber quality has been conducted for Scots pine (Hyytiäinen et al. 2004). Precommercial thinning was excluded in their studies. Positive effects of precommercial thinning on diameter growth and branch development have been reported for jack pine (Tong and Zhang 2005) and Scots pine (Varmola and Salminen 2004; Fahlvik et al. 2005). Their studies lacked financial information. Compared to earlier studies, our optimization results show that the differences in the effects of precommercial thinning on the end products’ distribution were not significant. However, in this study, price differences between sawn wood grades were not considered and an average sawlog price was used.

There are several limitations of the data and models used in this study. In energy wood harvesting practice, young stands from which energy wood is harvested, stand densities clearly exceed 3000 trees∙ha−1. In addition, a significant proportion of removed stem number may comprise broadleaved tree species, especially on fertile sites, but the dynamics of these mixed stands is beyond the scope of the present study of even-aged stand management. The constraint of thinning rate formulated in our optimization problem allows extremely heavy thinning. Such heavy thinning led to a low stand density, and may increase the risks of wind and snow damages. On the other hand, natural regeneration is likely to occur when such low stand density is kept for a long time. Nevertheless, the ingrowth model was excluded in the PipeQual simulator. Future studies which link natural hazard models with the OptiFor system may prevent heavy thinning and improve the applicability of optimization results.

Energy wood production may lead to biomass losses. Interactions between energy wood production and carbon sequestration have been reported recently (Alam et al. 2010; Melin et al. 2010; Mangoyana 2011; Pukkala 2011). These effects are beyond the scope of the present study. Future numerical studies including forest bioenergy production and carbon benefits, and wood quality would be interesting topics as well.

Conclusions

According to our optimization results, it is optimal to carry out the first thinning as an early energy wood harvest (Policy II) for initially dense stands. For sparse stands, it is optimal to follow conventional forest management regimes (Policy 0). In addition, we found that a constraint of profitable energy wood harvest (Policy I) is not rational and may lead to a very early timing and extremely low intensity of the first thinning. This was caused by a thinning strategy that aimed at minimizing the negative outcome of a conventional first thinning.

References

Ahtikoski A, Heikkilä J, Alenius V, Siren M (2008) Economic viability of utilizing biomass energy from young stands–the case of Finland. Biomass Bioenergy 32:988–996

Alam A, Kilpeläinen A, Kellomäki S (2010) Potential energy wood production with implications to timber recovery and carbon stocks under varying thinning and climate scenarios in Finland. Bioenerg Res 3:362–372

Amidon EL, Akin GS (1968) Dynamic programming to determine optimal levels of growing stock. For Sci 14:287291

Bolkesjø TF, Trømborg E, Solberg B (2006) Bioenergy from the forest sector: economic potential and interactions with timber and forest products markets in Norway. Scand J For Res 21:175–185

Cajander AK (1909) Über Waldtypen. Acta For Fenn 1:1–175

Cao T (2010) Silvicultural decisions based on simulation-optimization systems. Dissertationes Forestales 103. pp 48 + 53. ISBN 978-951-651-296-2, ISSN 1795-7389

Cao T, Hyytiäinen K, Tahvonen O, Valsta L (2006) Effects of initial stand states on optimal thinning regime and rotation of Picea abies stands. Scand J For Res 21:388–398

Cao T, Valsta L, Mäkelä A (2010) A comparison of carbon assessment methods for optimizing timber production and carbon sequestration in Scots pine stands. For Ecol Manage 260:1726–1734

Fahlvik N, Ekö PM, Pettersson N (2005) Influence of precommercial thinning grade on branch diameter and crown ratio in Pinus sylvestris in southern Sweden. Scand J For Res 20:243–251

Faustmann M (1849) Berechnung des wertes welchen Waldboden sowie noch nicht haubare Holzbestände für die Waldwirtschaft besitzen. Allgemeine Forst- und Jagd-Zeitung 15:441–455

Finnish Guidelines for Good Silviculture (2006) Metsätalouden kehittämiskeskus Tapio, Helsinki, pp 100 (in Finnish)

Haight RG, Monserud RA (1990) Optimizing any-aged management of mixed-species stands: II. Effects of decision criteria. For Sci 36:125–144

Hakkila P (2006) Factors driving the development of forest energy in Finland. Biomass Bioenergy 30:281–288

Hooke R, Jeeves TA (1961) “Direct search” solution of numerical and statistical problems. J Assoc Comput Mach 8:212–229

Huuskonen S (2008) The development of young Scots pine stands-precommercial and first commercial thinning. Dissertations Forestales pp 61:62

Huuskonen S, Hynynen J (2006) Timing and intensity of precommercial thinning and their effects on the first commercial thinning in Scots pine stands. Silva Fenn 40(4):645–662

Hynynen J, Ahtikoski A, Siitonen J, Sievänen R, Liski J (2005) Applying the MOTTI simulator to analyse the effects of alternative management schedules on timber and non-timber production. For Ecol Manage 207:5–18

Hyytiäinen K, Hari P, Kokkila T, Mäkelä A, Tahvonen O, Taipale J (2004) Connecting a process-based forest growth model to stand-level economic optimization. Can J For Res 34:20602073

Hyytiäinen K, Ilomäki S, Mäkelä A, Kinnunen K (2006) Economic analysis of stand establishment for Scots pine. Can J For Res 36:1179–1189

Johnstone WD (2005) The effects of juvenile spacing on 7-year-old lodgepole pine in central British Columbia. West J Appl For 20(3):160–166

Jylhä P, Laitila J (2007) Energy wood and pulpwood harvesting from young stands using a prototype whole-tree bundler. Silva Fenn 41(4):763–779

Kärkkäinen L, Matala J, Härkönen K, Kellomäki S, Nuutinen T (2008) Potential recovery of industrial wood and energy wood raw material in different cutting and climate scenarios for Finland. Biomass Bioenergy 32:934–943

Kotamaa E, Tokola T, Maltamo M, Packlén P, Kurttila M, Mäkinen A (2010) Integration of remote sensing-based bioenergy inventory data and optimal bucking for stand-level decision making. Eur J Forest Res 129:875–886

Kraxner F, Nordström E, Havlik P, Gusti M, Mosnier A, Frank S, Valin H, Fritz S, Fuss S, Kindermann G, McCallum I, Khabarov N, Böttcher H, See L, Aoki K, Schmid E, Máthé L, Obersteiner M (2013) Global bioenergy scenarios – Future forest development, land-use implications, and trade-offs. Biomass Bioenergy 57:86–96

Kuitto JP, Keskinen S, Lindroos J, Ojala T, Rajamäki J, Räsänen T, Teräväinen J (1994) Mechanized cutting and forest haulage. Metsäteho Report 410. Painovalmiste KY, Helsinki. (In Finnish)

Laitila J (2008) Harvesting technology and the cost of fuel chips from early thinnings. Silva Fenn 42(2):267–283

Laitila J, Asikainen A, Korhonen KT, Nuutienn Y (2004) Cost factors of the production of small-sized wood chips and supply logistics. (Pienpuuhakkeen tuotannon kustannustekijät ja toimituslogistiikka). Finnish Forest Research Institute, Working Papers, 3. pp 57

Lappi J (1992) A linear programming package for management planning. Research Papers 414. The Finnish Forest Research Institute, 134

Lyhykäinen H, Mäkinen H, Mäkelä A, Usenius A (2009) Predicting lumber grade and by-product yields for Scots pine. For Ecol Manage 258:146–158

Mäkelä A (1997) A carbon balance model of growth and self-pruning in trees based on structural relationships. For Sci 43(1):7–23

Mäkelä A (2002) Derivation of stem taper from the pipe theory in a carbon balance framework. Tree Physiol 22:891–905

Mäkelä A, Mäkinen H (2003) Generating 3D sawlog with a process-based growth model. For Ecol Manage 184:337–354

Mäkelä A, Sievänen R (1992) Height growth in open-grown trees. J Theor Biol 159:443–467

Mäkinen H, Isomäki A (2004) Thinning intensity and growth of Scots pine stands in Finland. For Ecol Manage 201:311–325

Malinen J, Pesonen M, Määttä T, Kajanus M (2001) Potential harvest for wood fuels (energy wood) from logging residues and first thinnings in Southern Finland. Biomass Bioenergy 20:189–196

Mangoyana RB (2011) Bioenergy from forest thinning: carbon emissions, energy balances and cost analyses. Renew Energy 36:2368–2373

McCormick K, Kåberger T (2007) Key barriers for bioenergy in Europe: economic conditions, know-how and institutional capacity, and supply chain co-ordination. Biomass Bioenergy 31:443–452

Melin Y, Petersson H, Egnell G (2010) Assessing carbon balance trade-offs between bioenergy and carbon sequestration of stumps at varying time scales and harvest intensities. For Ecol Manage 260:536–542

Ministry of Agriculture and Forestry (2006) Future review for the forest sector — outline of the forest council concerning focuses and aims for the forest sector. 11b/2006. ISBN 978-952-453-309-6. ISSN 1238-2531. pp 36

Ministry of Agriculture and Forestry (2008) Kansallinen mestäohjelma 2015. Lisää hyvinvointia monimuotoisista metsistä - Valtioneuvoston periaatepäätös. Maa- a metsätalousministeriön julkaisuja 3/2008 (Ministry of Agriculture and Forestry, Report 3/2008). Vammalan kirjapaino Oy. pp 45 (In Finnish)

Nurmi J (2007) Recovery of logging residues for energy from spruce (Pices abies) dominated stands. Biomass Bioenergy 31:375–380

Osyczka A (1984) Multicriterion optimization in engineering with FORTRAN programs. Ellis Horwood, Chichester, p 178

Peltola A, Ihalainen A (2013) Forest Resources. In: Ylitalo E (ed) Finnish Statistical Yearbook of Forestry. Finnish Forest Research Institute, Helsinki, p 440

Piene H (1978) Effects of increased spacing on carbon mineralization rates and temperature in a stand of young balsam fir. Can J For Res 8:398–406

Pothier D (2002) Twenty-year results of precommercial thinning in a balsam fir stand. For Ecol Manage 168:177–186

Pukkala T (2011) Optimizing forest management in Finland with carbon subsidies and taxes. For Policy Econ 13:425–434

Ruha T, Varmola M (1997) Precommercial thinning in naturally regenerated Scots pine stands in northern Finland. Silva Fenn 31(4):401–415

Shinozaki K, Yoda K, Hozumi K, Kira T (1964) A quantitative analysis of plant form: the pipe model theory. I. Basic analyses. Jpn J Ecol 14:97–105

Tong QJ, Zhang SY (2005) Impact of initial spacing and precommercial thinning on jack pine tree growth and stem quality. For Chron 81(3):418–428

UN-Energy (2007) Sustainable bioenergy: a framework for decision makers. United Nations. pp 61. http://www.fao.org/docrep/010/a1094e/a1094e00.htm (May 1, 2009)

UNFCCC (1997) The Kyoto protocol to the convention on climate change. United Nations Framework Convention on Climate Change. pp 24. http://unfccc.int/resource/docs/cop3/l07a01.pdf (June 12, 2015)

Valsta L (1990) A comparison of numerical methods for optimizing even aged stand management. Can J For Res 20:961–969

Varmola M, Salminen H (2004) Timing and intensity of precommercial thinning in Pinus sylvestris stands. Scand J For Res 19:142–151

Vuokila Y (1972) Treatment of seedling stands from the viewpoint of production. Folia For 141:36 (In Finnish with English summary)

Wetterlund E, Ledue S, Dotzauer E, Kindermann G (2013) Optimal use of forest residues in Europe under different policies—second generation biofuels versus combined heat and power. Biomass Conv Bioref 3:316

Acknowledgments

This study was partly supported by GSForest in Finland and National Natural Science Foundation of China (NSFC 31170586). We thank Juha Laitila for the opportunity to link their energy wood harvesting model to the OptiFor simulation-optimization system. We also thank Anssi Ahtikoski, Marc Hanewinkel, and Niels Strange for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

TC developed the simulation-optimization tool OptiFor Bioenergy, conducted the calculations and drafted the manuscript. All authors jointly revised the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cao, T., Hyytiäinen, K., Hurttala, H. et al. An integrated assessment approach to optimal forest bioenergy production for young Scots pine stands. For. Ecosyst. 2, 19 (2015). https://doi.org/10.1186/s40663-015-0043-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40663-015-0043-6