Abstract

Field robots are widely used to accomplish a variety of tasks in many different fields. However, setting of the locomotive ability of these robots at the design phase may prevent the traversal of unknown rough terrain. To address this shortcoming of existing robots, we designed a robot that is able to modify its environment by using polyurethane foam to construct auxiliary structures to facilitate movement across previously impassable terrain. Two robots were implemented with the ability to eject one- and two-part polyurethane foam, respectively. First, we investigated the specifications of the different types of polyurethane foam, specifically the volume expansion and curing time thereof. Two-part polyurethane foam cures in approximately 2 min, compared with 1 h for the one-part foam, but requires more accurate spraying, and its vertical expansion needs to be considered for accurate construction of auxiliary structures. The performance of each robot was tested in two experiments in the field. The first involved filling a deep ditch before crossing over it, while in the second experiment, each robot constructed a slope leading up to a high step, allowing the robot to move onto the step. Both robots succeeded in completing these tasks successfully, with the main difference in performance being the time taken before the robot was able to traverse the obstacles. Using two-part polyurethane foam resulted in much shorter curing times, although the structures constructed were not as even as those for the one-part polyurethane foam, and the robot needed to wait 10 s between the applications of each successive layer of foam to account for the vertical expansion of the material. Our findings demonstrate the effectiveness of our polyurethane foam construction robots in overcoming obstacles in unknown rough terrain.

Similar content being viewed by others

Background

Challenges and limitations of previous locomotion robots on rough terrain

Many field robots have been designed to traverse rough terrain to accomplish a variety of tasks in various fields. In particular, one of the main roles of field robots is rescue and recovery tasks in disaster areas. These robots can be classified into two main types depending on the locomotion mechanics used; that is, the crawler and subcrawler types and the snake-like type.

Crawler and subcrawler type robots are able to move in a seemingly effortless way over rough terrain. Nagatani et al. developed Quince [1], which is equipped with four flipper arms and crawler tracks covering the body. These robots were deployed in Fukushima’s first nuclear plant disaster. Packbot, developed by iRobot Corporation, has two flipper arms, and has been deployed in disaster areas and on the battlefield [2].

These robots have a greater payload and can be equipped with high-resolution cameras or 3D-sensors to construct environmental maps. Recently, this robot design has become the standard for rescue robots.

Similarly, snake-like robot designs have been developed for traversing various types of terrain. Kamegawa et al. developed a snake-like rescue robot, called “KOHGA" [3]. This robot comprised eight linked units (using four active and three passive joints). This mechanism was conceived to passively adapt to rough terrain. Osuka et al. developed “MOIRA", consisting of four units, where all the joints are active [4]. Both robots were designed to crawl through rubble, necessitating the ability to move through small narrow spaces. However, the requisite small body prevented these robots being fitted with high-performance sensors.

To enhance the mobility of the robots discussed above, the main approach has been the integration of robust bodies and strong actuators. However, the mobility of such robots remains somewhat limited. Additionally the degree of mobility is determined at the design stage making it impossible for these robots to traverse unknown terrain. This limitation is inherent in the manufactured product because it is difficult for designers to model unknown environments.

Modification of rough terrain by a robot

In this section, we discuss the accommodation of environmental obstacles using robotics. By accommodation we mean not only the ability of the robot to adapt to the environment, but also its ability to regulate environmental factors for its own benefit. In fact, both subcrawler and snake-like rescue robots are designed to adjust to different ground forms. We approach this consideration in a different way. An alternative to the above-mentioned methods for traversing rough terrain is to equip the robot with the means to reconstruct the terrain itself, so that the modified terrain is more suitable for traversal by the robot.

Recently, various robots have been designed to construct external structures. Lindsey et al. reported aerial robots able to construct a 2.5-D structure [5]. They used quadrotor robots where the quadrotors were equipped with grippers to pick up, transport, and assemble the structural elements. Werfel et al. developed robots that can build a structure, while the system automatically generates low-level rules for independent climbing robots thereby guaranteeing production of that structure [6]. Using only local sensing, these robots coordinated their activity through the shared environment. Napp et al. proposed using construction to change the environment. They tested three kinds of materials for environmental construction; 1) toothpicks, 2) sandbags, and 3) polyurethane foam [7] and concluded that polyurethane foam [8] was the most suitable owing to its wider-ranging usability. They adopted liquid polyurethane foam; however, because this type of foam flows downward before curing, using this method to construct tall structures within a limited area is problematic.

Aim of the study

In this study, we developed robots with the ability to modify the environment through construction using two types of polyurethane foam (one- and two-part foam). Generally, polyurethane foam comprising multiple materials is cured by means of mutual chemical reactions. Using two-part polyurethane foam is expected to be beneficial in the implementation of real robots, since the material solidifies completely in a few seconds. However, despite this advantage, no detailed experiments have been performed to compare the performance of one- and two-part foam for construction. For example, quick curing material requires a more accurate setting of the spray angle, and expansion volume needs to be considered, which is one of the non-negligible specifications of two-part type polyurethane foam.

Thus, to investigate the specifications of the two types of foam used, we carried out preliminary tests focusing on solidification time and the degree of volume expansion of the two types of material. From the results of these tests, we determined appropriate coefficients for the characteristic features of each type of foam for use in the real robot experiments. We designed the actual construction robots paying attention to spray angles. Furthermore, we proposed state transition rules to realize a set of actions involving sensing slopes, movement by actuators, and moving over irregular ground. Finally, the effectiveness of the developed system was evaluated through experiments using actual robots.

Methods

Rigid polyurethane foam as the construction material

The robot builds a structure using rigid polyurethane foam, which is often used as thermal insulation material. This type of foam is commonly hardened by the chemical reaction when isocyanates and polyols are mixed. Both one-and two-part polyurethane foams are available as commercial products. One-part polyurethane foam is available in a single canister filled with isocyanates and polyols mixed with a foaming agent. Two-part foam comprises two separate canisters containing isocyanates and polyols mixed with foaming agents. Both types of polyurethane foam consist of the same materials, but the properties of the respective foams differ. A comparison of the properties of one- (ATF-504, AIRTIGHT, Inc.) and two-part (HYPER #30, ABC TRADING Co., Ltd.) types of rigid polyurethane foam is given in Table 1.

The property that differs most is curing time; that is, the time before the foam is hard enough to be touched. The one-part foam requires more than 18 h to be fully cured, whereas the two-part type requires only 10 min. In our preliminary experiments, we investigated the minimum curing time required to support a robot. The robot was able climb over the foam structure approximately 1 h after construction using one-part type foam and 2 min after using two-part type foam. Moreover, the curing process differs for the two types of foam. The one-part type relies on moisture being present in the atmosphere, because curing occurs as a result of reaction with moisture. This means that the curing process of the one-part type foam depends on volumetric humidity (g/m3). The two-part type cures as a result of an exothermic chemical reaction, induced by mixing the same proportion of isocyanates and polyols.

Both types of polyurethane foam provide a large expansion ratio. According to the manufacturer’s specifications, ATF-504 (one-part foam) has a ×40-50 expansion ratio, which means it can generate a final structure volume of 20–25 liters from a half-liter canister (maximum weight 603 g). HYPER #30 (a two-part foam), however, has a ×30 expansion ratio, which means it can generate a 25-liter final structure volume from 840 ml of foam (total maximum weight 1055 g).

However, the more important property for our research is the total duration of expansion after ejection. Because the structure continues expanding until it is completely cured, if the robot senses the height of the structure immediately after ejection, the sensed data differs from the final volume of the structure. The expansion rates of both types of foam after ejection are specified by the manufacturers; ATF-504 expands ×1.3–1.8 1–60 min after ejection, whereas HYPER #30 expands ×1.5–2.0 until cured completely. Because these metrics were not precise enough for our purposes, we carried out preliminary tests to investigate the expansion rate. Figure 1 shows the properties of vertical expansion for the following sampling periods: 10, 30, 60, 120, and 600 s and 1 day after ejection. In the experiment, humidity and temperature were kept at over 30% and 20°C. The height of the one-part type foam increased continuously until 30 s, and then decreased until 120 s, finally increasing again until fully hardened. Conversely, the two-part type (HYPER #30) increased monotonically until cured, and provided greater expansion than the one-part type.

Vertical expansion properties of different types of polyurethane foam: the blue line shows the expansion rate of one-part type polyurethane foam, while the red line shows that of the two-part type. This test measured foam ejected at a height of 200 mm by our robot. In the experiment, humidity and temperature were kept at over 30% and 20°C.

When used to construct a rigid structure, both types of foam are lighter than water, yet strong enough to support the weight of a human climbing thereon. Additionally, these foams attach to a variety of materials including wood, iron, and concrete, amongst others. Based on these characteristics, this material is suitable for use by a construction robot.

Construction process

We designed an algorithm for construction by the robot, the state transition diagram of which is shown in Figure 2. We explain the algorithm by focusing on two separate tasks of “filling a deep ditch” and “building a slope to a high step”. Figure 3 shows the sequence of actions to fill a deep ditch.

Process overview of traversing a deep ditch. The robot autonomously detects a deep ditch (A, A’), and ejects polyurethane foam (B, B’). After ejecting the foam, the robot re-senses the ditch to determine whether it is completely filled (C, C’). Then, the robot waits until the polyurethane structure has hardened (D, D’), and moves across the structure (E, E’).

The robot injects the foam autonomously. When the robot detects step or ditch, it injects the foam with constant valve opening. And, the internal pressure of canister reduces with foam injection for the task solution. As a result of reduction of inner pressure, the injection of the foam is reduced. Thus, we designed the algorithm which is no considered about an adjustment of amount of polyurethane foam injection.

Filling a deep ditch

At the start of the algorithm, the one-part foam type robot is in the initial state, and moves forward. When it detects a deep ditch as P 1 (Figure 3-A), it transits from internal state S 1 to S 2. The robot in state S 2 ejects polyurethane foam (Figure 3-B), moves backward, and re-senses (using the front PSD sensor) the terrain (Figure 3-C). Filling terminates when the difference between the ground and the filled level of the ditch is less than about 20 to 25 mm; this construction termination threshold is set based on the ability of the robot to climb or descend a 35mm step. The robot waits 1 h for the structure to harden (Figure 3-D), and then re-evaluates whether it can move over the ditch once again using the construction termination threshold. Finally, the robot moves across the structure filling the ditch (Figure 3-D).

The two-part foam type robot acts in the same way as the one-part foam type robot. Having detected a ditch (Figure 3-A’), the robot transits from internal state S 1 to S 2, and carries out the sequence of actions (A2). The only difference between using one- and two-part foam is the waiting time (10 s) for the two-part foam to expand before evaluating whether construction can terminate. Having compared the expansion rates of one and two-part foam types, we defined the required waiting time before evaluating the foam structure.

Building a slope leading to a high step

In the initial state, the one-part foam type robot (S 1) moves forward (A 1). When the robot detects a step that is higher than the robot’s climbing ability, i.e., higher than 35 mm (P 2), it transits from internal state S 1 to S 2. In state S 2 the robot ejects polyurethane foam, moves backward, and re-senses the terrain (A 2). If the robot determines that the structure is sufficient (i.e., the initial step up the slope is less than 35 mm), it transits from internal state S 3 to S 4, and waits for the structure to harden (1 h). Otherwise, the next iteration of foam pouring commences to create a slope less than climbing ability of the robot. Finally, the robot transits back to S 1. The two-part foam type robot behaves in the same way as explained above. One of the differences between using one- and two-part foam is the waiting time (10 s) for the two-part foam to expand in state S 2 before determining whether construction should terminate. In addition, curing time is only 2 min in state S 4.

Hardware design

Complete design of robot system with sensor placement

The developed robot has the following actuators and sensors: 1) four motors for driving each wheel, 2) a rotating actuator to move the head independently, 3) an eject and shutter actuator for foam control, 4) a distance sensor to recognize high steps and deep ditches, and 5) a tilt sensor to detect its own orientation. The robot has a head rotation mechanism to eject polyurethane foam anywhere in the environment. Figure 4 shows the computer-aided design (CAD) models of the robot. The design of the body is the same for both foam types, while the head part differs.

3D-CAD models of the robot: Head part models on the left and right are used with one- and two-part foams, respectively. Individual components of the robot were mostly constructed using ABS board, while the holding jigs for actuators and the canisters were printed by a 3D-printer. Basic specifications of the body part are the following: length 250 mm, width 250 mm, height 158 mm, and wheel width 100 mm. The 2D-size of both head parts is length 350 mm and width 250 mm, while the heights for the one- and two-part foam types are 145 mm and 200 mm, respectively. The turning radius of the nozzle is 213 mm for both head parts. The total weight of the one-part foam robot including canister is approximately 4.3 kg, and that for the two-part foam type robot is approximately 4.6 kg.

The body part consists of distance and tilt sensors, a driving system, and micro-controller. Each sensor sends signals to the micro-controller (TITechSH2 Tiny controller, Hibot Corp.), which controls the actuators. Four motor actuators (Dynamixel MX-28, Robotis Corp.) are used for driving, and a motor (Dynamixel AX-12A, Robotis Corp.) is used to sweep the head part of the robot by means of a timing belt. The average speed of the robot is 11.7 cm/s, and the climbing angle is less than 20°. The robot has high position of the center of gravity by polyurethane foam canister. 20° is limitation of mechanism. The tilt sensor is a 3-axis acceleration sensor (AS-3ACC-3, ASAKUSAGIKEN Ltd, Co.) attached to the rear of the body part to detect the orientation of the robot. The distance sensor module consists of six position-sensitive diode (PSD) sensors (GP2Y0A21YK, Sharp Corp.) with a 10-80 cm distance detection range. A sensor is mounted every 60° on the circumference of the body part with its direction facing 30° downward as shown in Figure 5. The PSD sensor mounted on the front of the body part is used to detect deep ditches or high steps; it can sense the terrain up to 105 mm in front of the robot. The robot is powered by a Li-Ion 18000 mAh battery pack (Energizer XP18000A Tennrich International Corp.), which can simultaneously supply 19 V, 12 V, and 5 V; the 12 V supply is used by the actuators, while the 5 V supply powers the other electronics including the micro-controller and sensors.

The one-part foam type robot has a single tilted foam canister on the body part, which can eject foam vertically downward through a φ6.5 mm silicon tube. The foam ejection is controlled by a servo-motor (Dynamixel MX-28, Robotis Corp.), where the motor pushes the trigger of the canister. We incorporated a shut-off mechanism at the tip of the nozzle, because foam curing occurs in the ejection nozzle. The shut-off mechanism is implemented by a slide-rail action, whereby the silicone tube becomes flat. The slide-rail is linked to the ejection control servo-motor, and shuts down the tube according to the motor rotation. We can therefore realize both a shutdown and ejection mechanism using a single motor by this mechanism.

The two-part foam robot has two canisters on the body part, with both canisters connected to the shutdown mechanism by means of ball valves. The shutdown mechanism, which is controlled by the servo-motor, has a single nozzle at the tip. The inside of the nozzle is shaped as a spiral (AX-CC Nozzle, ABC TRADING Co., Ltd.) to blend the isocyanates and polyols.

Head part motion for construction

The robot builds polyurethane objects using a head-sweeping motion as shown in Figure 6. The rotation radius r is 213 mm. The width of the polyurethane object must be greater than between left and right rim (235 mm). Thus, we configured the sweeping angle as 90°, and numerically determined that L is about 300 mm and d is 63 mm. The initial size of the construction is dependent on the nozzle diameter: 6.5 mm for the one-part type foam robot and 3 mm for the two-part type one. However, the one-part type foam expands immediately after being poured from the silicone tube to approximately 15 mm in diameter from the initial 6.5 mm, while the expansion of the two-part type foam depends on the height of the nozzle from the ground, because it is ejected radially from the nozzle. The height of a one-way sweeping construction is approximately 17 mm using a one-part foam type robot and approximately 21 mm with a two-part foam type one.

Robot experiments

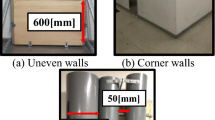

We experimented on 1) filling a ditch (vertical depth: 90 mm, width: 200 mm), and 2) building a slope leading to a step (height: 90 mm), using our developed robot to demonstrate the characteristics of one- and two-part polyurethane foam. This experiment requires the ability to sense a ditch, eject the polyurethane foam correctly, and wait until the foam has cured so that the robot can move onto it.

Humidity and temperature were kept at over 40% and 20°C in each of the experiments using one-part foam, and over 30% and 20°C in experiments using the two-part foam. While the robot waited for the foam to harden, we changed or cleaned the nozzle to prevent it being clogged up from cured foam.

Results

Filling a ditch performance

One-part foam type robot

In this experiment, waiting time until the polyurethane foam cured was configured as 1 h. Details of the construction process are given in the previous section (see Figure 3).

The one-part foam type robot was able to detect the ditch and deposit the polyurethane material by sensing the height of the structure (Figure 7). The robot filled the ditch up to 200 mm wide using one canister, and then crossed the ditch 1 h after the final ejection. The polyurethane structure used to fill the ditch did not cure completely in 1 h, and thus, the structure deformed when the robot moved across it, although the robot did not break the surface. The total time for filling the ditch process was more than 2 h, comprising total ejection time (A2) of 1 min 35 s, total waiting time for curing of 2 h, and moving time.

One-part foam type: Snapshots of the process of filling a 200 mm ditch. The robot autonomously detects the ditch and moves forward slowly (A), and then ejects the polyurethane foam using a head sweeping motion (B). After each foam ejection, the robot moves backward and evaluates whether the ditch has been filled (C). The robot repeatedly ejects polyurethane foam (D). When the robot determines that the ditch has been filled, it moves backward and waits for 1 hour (E). Finally, the robot crosses the ditch (F).

Two-part foam type robot

The experimental conditions were the same as those for the one-part foam type robot. The construction process is detailed in the previous section; note that two-part foam expands greatly in the vertical direction. The two-part foam type robot waits 10 s after each ejection, and detects the distance to the structure. In this experiment, we defined curing time to be 2 min.

The robot filled the deep ditch and crossed it in a shorter time than when using one-part polyurethane foam. The surface of the structure, however, was not smooth, because two-part polyurethane foam expands in a vertical direction. To traverse the 200 mm wide ditch, the robot created two structures, and used approximately 30% of the canisters’ volume. The structures did not, however, deform when the robot moved over them. The total time for filling the ditch was less than 10 min, comprising total ejection time (A2) of 2 min 58 s, total waiting time for curing of 4 min, and moving time (Figure 8).

Two-part foam type: Snapshots of the process of filling a 200 mm ditch. The robot autonomously detects the ditch and moves forward slowly (A), and then pours the polyurethane foam with a head sweeping motion (B). After each pouring, the robot moves back, waits 10 s, and then evaluates whether the ditch is filled (C). The robot repeatedly deposits polyurethane foam (D). After waiting 2 min, the robot pours foam into the next part of the ditch (E). Finally, the robot is able to cross the ditch (F). A thermometer and hygrometer are located on the front of the robot.

Performance of building a slope leading to a step

One-part foam type robot

Waiting time for the polyurethane foam to cure was configured as 1 h. In this experiment, the robot detected that the step was too high to climb using its own mobility and thus, built a slope by depositing polyurethane material (Figure 9). The robot used half a canister of foam to build the slope. The total time for building the slope was over 1 h, comprising total ejection time of 1 min 20 s, total waiting time for curing of 1 h, and moving time.

Two-part foam type robot

The robot was able to build a slope to the high step and climb it (Figure 10). The robot built five structures in constructing the slope with a maximum height of 90 mm, a minimum height of 30 mm, and a length of 370 mm. The total time for building the slope was less than 5 min, comprising total ejection time of 1 min 38 s, total waiting time for curing of 2 min, and moving time.

Two-part foam type robot: Snapshots of the process of building a slope. The robot autonomously detected the step and moved forward slowly (A); then deposited the polyurethane foam with a head sweeping motion (B), moved back slowly, and poured foam repeatedly (C), (D), (E). The robot waited 2 min and moved up the slope (F), thereby finally climbing the step.

Discussion

Comparison of performance of building a structure

In the experiments, the robot was able to traverse the deep ditch and climb the high step using both types of polyurethane foam for construction. The results of these experiments are summarized in Table 2. Each feature is explained as follows. “Curing time" means the elapsed time before the robot can move onto the structure. “Working time efficiency" is dependent on curing time. “Foam accuracy" means the accuracy of shaping the polyurethane structure in terms of nozzle movement. The foam accuracy of the two-part foam type robot is higher than that of the one-part foam type robot. The one-part foam has some viscosity and elasticity, and thus, the nozzle motion after ejection causes a gap in the foam’s placement. The two-part foam has a liquid and misty form just after ejection, which allows it to be placed precisely depending on the movement of the nozzle. However, according to the expansion characteristics, the two-part foam expanded mainly in a vertical direction, which meant that the structure was highly repeatable. The one-part foam expanded horizontally, and the structure deformed under its own weight, causing the foam to expand even more in the horizontal direction. These properties of one-part foam result in low accuracy structures, although for filling large areas the robot does not need a high-precision nozzle control or self-position control, owing to the occurrence of syndetic action of the foam and the environment. Conversely, the requirements for the two-part foam type robot are higher than those for the one-part type; that is, highly accurate ejection position control, precise sensing of the environment, and building with a carefully evaluated interval between each structure.

The one-part foam canister of the robot was almost empty after the ditch-filling experiment despite the higher construction capacity (volume of structures greater than 20 liters). The primary reason for this was the lack of reaction between the foam and the atmosphere, since one-part foam is a moisture-cured material. In both one-part foam experiments, even after 24 h, the foam was not completely cured. There was a slight material loss in the two-part foam process, because it cures by a chemical reaction. Based on the results of the experiments, two-part foam is a more efficient material for construction.

Application of each type of polyurethane foam

From the results of the experiments, the construction process by the one-part foam type robot uses more material and takes longer, mainly because of the curing process and waiting time for curing (1 h). However, it is useful for filling a ditch or a hole. The foam expands in a horizontal direction without any expansion in the vertical direction. Thus, the foam fills the gaps between structures, and the robot can build a composite structure. Although the two-part foam type robot is useful for all building tasks, the two-part foam construction process requires accurate sensing and position control. In addition, each foam structure is built separately, causing the final structure to have an undulating surface. These issues may be considered weaknesses in more complex environments.

Another environment that could be considered for the application of both types of polyurethane foam is a heap of rubble. Because of the self-adhesive nature of the foam, the robot can glue the rubble and traverse across the structure without deforming the ground under foot. One of the most interesting applications for one-part foam is building a road on water. The one-part type foam can cure on water whereas the two-part foam dissolves, and the density of the polyurethane structure is less than that of the water. Thus, a robot may be able to build a road on the surface of water and move over it.

One-part type foam needs 1 h for curing, and this foam type is not useful for quick response task (ex. victim searching). However, one-part type foam can build structure on the wet condition field (ex. water, mud, snow, etc.), and befit with long-term rescue missions (ex. building foothold in Fukushima 1st nuclear power plant). These characteristics are effective on extreme environment. On the other hand, two-part type foam needs 0.5-1 min for curing, and doesn’t befit on wet condition. This foam type is useful for short-term rescue missions.

Applications in swarm robotics: lessons from social insects

Our current system could be extended for use in swarm robotics. The environmental construction ability permits the means for a robot to communicate with other robots in an indirect manner. For example, the presence of modified terrain means that the modification was done by precedent robots (as information senders) and that subsequent robots (or receivers) can move freely across it. We consider this sort of indirect communication as a source of “intelligence," which we call field-mediated intelligence (FMI). It is worth pointing out that FMI is a prominent feature of social insect colonies. Ant workers chemically manipulate the terrain using pheromones to create a trail from their nest to food sources, and some termites collaboratively construct meter-high extended structures, called termite mounds. Moreover, landfill behavior similar to that of our robots is found in social aphids repairing their nests [9]. In other words, they reconstruct their living spaces (niche) by modifying the external environment [10]. In social insects, the self-organizing process of construction behavior is called stigmergy [11]. The term FMI includes stigmergy as a developmental process and niche construction as a consequence of intelligence.

Conclusions

In this study, we experimented with a robot that can modify the environment using one- or two-part polyurethane foam. First, we investigated the properties of both types of polyurethane foam. We also designed robots to use one- and two-part polyurethane foam, with an appropriate ejection mechanism. The reconstruction algorithm was implemented on each robot. In the foam properties section, we focused on the curing mechanism of each type of polyurethane foam. One-part type polyurethane foam needed 1 h to cure before the robot could traverse it. Moreover, the foam expanded in a horizontal direction (and not a vertical direction). Conversely, the two-part type polyurethane foam cured within 2 min, and the foam expanded approximately 2 times in a vertical direction (and not a horizontal direction). To consider these different properties of one- and two-part polyurethane foam, we implemented different algorithms for modifying the environment. The main difference in the algorithms is the waiting time before the robot evaluates the environment after ejection; the two-part foam type robot waits 10 s between evaluations. In the actual experiments, both types of robot could autonomously detect a ditch or step in front, and ejected polyurethane foam with a head sweeping motion. After each ejection, the robot moved backward and re-evaluated the environment. The robot looped through this sequence of actions until the environment was suitable for traversal. After waiting the required time for the structure to harden, the robot traversed the constructed foam structures. From the results of the experiments, the two-part foam appears to be a more efficient material for environmental construction.

We intend to extend our system in a swarm robotics implementation. One idea is to divide the roles of the robots according to the type of robot, where the two-part foam type robots build a strong foundation for construction, and the one-part foam type robots fill the gaps between the structures built by the two-part foam type robots. We feel that such a role-sharing model of a swarm system could improve the construction process making it more efficient. Further goals include using our system to understand the social behavior of insects and indirect communication as a source of “intelligence", which we call FMI.

References

Nagatani K, Kiribayashi S, Okada Y, Tadokoro S, Nishimura T, Yoshida T, Koyanagi E, Hada Y (2011) Redesign of rescue mobile robot quince In: Safety, Security, and Rescue Robotics (SSRR), 2011 IEEE International Symposium On, 13–18.. IEEE. http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber=6106794&url=http\%3A\%2F\%2Fieeexplore.ieee.org\%2Fxpls\%2Fabs_all.jsp\%3Farnumber\%3D6106794.

Yamauchi BM (2004) Packbot: a versatile platform for military robotics In: Defense and Security, 228–237.. International Society for Optics and Photonics. http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=844149.

Kamegawa T, Matsuno F (2007) Development of a remote-controlled double headed snake-like rescue robot kohga. J Robot Soc Japan 25(7): 52.

Osuka K, Kitajima H (2003) Development of mobile inspection robot for rescue activities: Moira In: Intelligent Robots and Systems, 2003.(IROS 2003). Proceedings. 2003 IEEE/RSJ International Conference On, 3373–3377.. IEEE. http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber=1249677&url=http\%3A\%2F\%2Fieeexplore.ieee.org\%2Fxpls\%2Fabs_all.jsp\%3Farnumber\%3D1249677.

Lindsey Q, Mellinger D, Kumar V (2012) Construction with quadrotor teams. Autonomous Robots 33(3): 323–336.

Werfel J, Petersen K, Nagpal R (2014) Designing collective behavior in a termite-inspired robot construction team. Science 343(6172): 754–758.

Napp N, Rappoli OR, Wu JM, Nagpal R (2012) Materials and mechanisms for amorphous robotic construction In: Proceedings of Intelligent Robots and Systems (IROS), 2012 IEEE/RSJ International Conference On, 4879–4885. http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber=6385718&url=http\%3A\%2F\%2Fieeexplore.ieee.org\%2Fxpls\%2Fabs_all.jsp\%3Farnumber\%3D6385718.

Napp N, Nagpal R (2012) Distributed amorphous ramp construction in unstructured environments In: Proceedings of International Symposium on Distributed Autonomous Robotic Systems (DARS12). http://journals.cambridge.org/action/displayAbstract?fromPage=online&aid=9220374&fulltextType=RA&fileId=S0263574714000113.

Kurosu U, Aoki S, Fukatsu T (2003) Proc R Soc Lond Ser B: Biol Sci270((Suppl 1)): 12–14.

Odling-Smee FJ, Laland KN, Feldman MW (2003) Niche Construction: the Neglected Process in Evolution vol. 37. Princeton University Press, Princeton, NJ.

Theraulaz G, Bonabeau E (1999) A brief history of stigmergy. Artif Life 5(2): 97–116.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

RF and NN carried out most of the experiments. SO and RS designed a robot. YI and SD joined discussion. And, YI provided engineering ideas, SD provided biological ideas. All authors have read and approved the manuscript for publication.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Fujisawa, R., Nagaya, N., Okazaki, S. et al. Active modification of the environment by a robot with construction abilities. Robomech J 2, 9 (2015). https://doi.org/10.1186/s40648-015-0030-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40648-015-0030-2