Abstract

Background

Enzymatic biodegradation of organophosphate pesticides (OPs) is a promising technology to remove these toxic compounds. However, its application in industrial washing was restricted by the lack of efficient immobilized enzymes that can work at high temperatures and high pHs in the presence of various detergents. Therefore, it is necessary to develop a simple method to prepare a robust immobilized enzyme for efficient degradation of OPs.

Results

An organophosphate hydrolase (OPH), PoOPHM9, was conjugated and immobilized with a commercially available polymer, Pluronic F127. The prepared cross-linked enzyme-polymer conjugate (CLEPC) displayed higher pH stability in the range from 7.0 to 11.0 and a higher optimal temperature (50 °C) than that of free PoOPHM9 (30 °C). Its half-life and apparent kcat/KM reached 12.8 h at 50 °C and 390.3 ± 7.8 mM−1 s−1, respectively, which were even better than that of the traditional cross-linked enzyme aggregates (CLEA, 7.2 h and 10.9 ± 1.7 mM−1 s−1). The activity of PoOPHM9 CLEPC was further enhanced up to 2.5-fold by the anionic, nonionic and biocompatible detergents, which was first observed. 0.15 mM Malathion was degraded completely by PoOPHM9 CLEPC after activation within 10 min in the presence of 0.1% (w/w) detergents of all types at pH 9.0 and 25 °C, demonstrating its capability in degrading OPs at practically relevant conditions.

Conclusion

The conjugation of Pluronic F127 in enzyme immobilization could effectively reduce the activity loss of immobilized enzymes and enhance their stability and activity at high temperatures and high pHs. In addition, the activity of CLEPC can be even enhanced in the presence of various detergents. This technology can be extended easily to produce other immobilized polymer-enzyme conjugates due to its simplicity.

Similar content being viewed by others

Background

The accumulation of toxic organophosphate pesticides (OPs) in food and environment has caused an increasing threat to public health (Mostafalou and Abdollahi 2017; Cycon et al. 2017; Hernandez et al. 2017). OPH based biodegradation, which can efficiently hydrolyze OPs to benign molecules, is one of the most attractive technologies for removing OPs (Schenk et al. 2016; Kim et al. 2014a, b; Ramalho et al. 2016; Theriot and Grunden 2011). Many naturally occurring or engineered OPHs have been developed so far (Cherny et al. 2013; Khare et al. 2012; Luo et al. 2014; Abe et al. 2014; Bigley et al. 2016; Chen et al. 2015; Jackson et al. 2009). However, in spite of high activity, free OPHs are difficult to be recovered from aqueous solution, and are often denatured quickly under harsh environments such as high temperatures and high pHs that are usually used in industrial washing and water treatment, hindering its usage in practical applications (Giudice et al. 2016; Bai et al. 2017). Therefore, it is essential to develop a simple and cost-effective method for fully exploiting the potential of OPHs in biodegradation.

Currently, various enzyme immobilization methods to improve the stability and recyclability of OPHs have been extensively explored, including the immobilization of enzymes on nanoparticles (Breger et al. 2015; Hondred et al. 2017), mesoporous silica (Singh et al. 1999), membranes (Yan et al. 2015), textiles (Gao et al. 2014), and encapsulation or complexation of enzymes with amyloid fibrils (Raynes et al. 2011), metal–organic frameworks (Li et al. 2016), polyurethane foam (LeJeune et al. 1997) and polymers (Suthiwangcharoen and Nagarajan 2014; Wei et al. 2013). Carrier-free method, such as cross-linked enzyme aggregate (Zheng et al. 2011; Pan et al. 2011), has been used in the production of value-added chemicals in large quantities (Pan et al. 2014). Although enzyme immobilization gives rise to a better thermostability, it is usually achieved at the expense of the decreased catalytic activity of an enzyme. In addition, the immobilization method should face challenges from practical applications. For example, the immobilized OPHs need to be stable and active at very harsh conditions such as high temperatures and alkaline pH in industrial washing of OP contaminated food. Particularly, they should bear various detergents that can easily denature proteins. Therefore, this special application requirement makes the immobilization of OPHs an extremely difficult task, compared with other immobilized enzymes for traditional biocatalysis.

Recently, a triblock amphiphilic copolymer, poly (ethylene oxide-b-propylene oxide-b-ethylene oxide) F127 (known as Pluronic F127), has been demonstrated to enhance the stability and activity of free OPHs through the interaction between the hydrophobic segments of polymers and the hydrophobic regions of enzyme surface (Suthiwangcharoen and Nagarajan 2014; Kim et al. 2014b). In addition to OPHs, various enzymes can be modified by direct conjugation or covalent binding with Pluronic F127 (Wu et al. 2014, 2015; Zhang et al. 2013). Although advances in the conjugation of Pluronic F127 and free enzymes have been made so far, the application of Pluronic F127 in immobilized enzymes has not been achieved. One possible reason is that the current methods of preparing enzyme-polymer conjugates are performed in aqueous phase (Suthiwangcharoen and Nagarajan 2014; Kim et al. 2014b) and the carrier-immobilized enzymes are not soluble in aqueous solution. More importantly, the improving effect of Pluronic F127 in the catalytic properties of free OPH has not been demonstrated in immobilized OPH yet. Thus, it is of interest to develop a simple method of preparing immobilized OPH-Pluronic F127 conjugates with the expectation of maintaining the high stability and activity of OPH with Pluronic F127 simultaneously.

In the previous study, we engineered a newly discovered phosphotriesterase (PoOPHM9, Luo et al. 2016) with improved catalytic activity and thermostability for efficient malathion degradation, and demonstrated its effectiveness in removing malathion using free PoOPHM9 in the presence of various detergents (Bai et al. 2017), which prompted us to further explore the possibility of preparing immobilized enzymes for potential industrial applications. Herein, we reported a simple method to prepare cross-linked enzyme-polymer conjugates (CLEPC) by directly incorporating Pluronic F127 in the process of carrier-free PoOPHM9 immobilization. The catalytic efficiency and stability of PoOPHM9 CLEPC were systematically investigated, and its capability in degrading malathion in the presence of various detergents under practically relevant conditions were demonstrated.

Materials and method

Chemicals

All chemicals of reagent grade were purchased from Sigma (St. Louis, MO). Malathion (99% purity) was purchased from Shanghai Pesticide Research Center. The P. pastoris strain X33 (Mut+His+) bearing the plasmid of pPICZαA containing PoOPHM9 gene was constructed in our lab. Detergents containing coconut oil derivatives (COD, Komi, Lot 6907974981509), Sodium dodecyl sulphate (SDS, Mama Lemon, Lot 6903624600158) and alkyl polyglycoside (APG, Diaopai, Lot 6910019001841) were purchased from a local supermarket without further treatment.

Preparation of PoOPHM9 CLEPC

PoOPHM9 was produced extracellularly by high-density fermentation of an engineered Pichia pastoris strain described previously (Bai et al. 2017). After fermentation, the broth was centrifuged at 8000 rpm for 20 min, and the supernatant was concentrated and freeze-dried to form lyophilized enzyme powders. The lyophilized enzyme powders were dissolved in a Tris–HCl buffer (pH 7.0) to 20 mg/mL, to which ammonium sulfate was slowly added to 0.5 g/mL. The solution was then stirred at 4 °C for 30 min to precipitate enzymes. Subsequently, Pluronic F127 was slowly added into the suspension to 80 mg/mL and the mixture was continuously stirred at 4 °C for 30 min. Glutaraldehyde of 40 mM was added to cross-link the aggregates and the suspension was stirred at 4 °C for 3 h. Then, the suspension was centrifuged at 12,000 rpm for 3 min, and the precipitate was washed three times and re-suspended in 0.5 mL Tris–HCl buffer (pH 7.0).

Activity assays of PoOPHM9 CLEPC

The catalytic activity of PoOPHM9 CLEPC toward malathion was monitored by determining the increase in absorbance at 412 nm caused by the reaction between the hydrolysis product, mercaptan, and the Ellman reagent, 5,5′-dithiobis-(2-nitrobenzoic acid) (Bai et al. 2017). Each reaction was performed in a 1 mL Tris–HCl buffer (45 mM, pH 9.0) containing 1.8 mM DNTB, 0.5 mM malathion and appropriate amount of the immobilized enzyme. Absorbance readings were taken every min at 30 °C using a PowerWave XS2 spectrophotometer (BioTek, USA). The kinetic parameters were determined by fitting the Michaelis–Menten equation with the substrate concentrations from 0.02 × Km to 10 × Km. The activity recovery of the CLEPC and CLEA was calculated according to Eq. (1).

Enzymatic characterization of PoOPHM9 CLEPC

PoOPHM9 CLEPC and free PoOPHM9 were incubated separately at 10–80 °C for 15 min, respectively, and then their activities were measured to obtain the temperature profile. Similarly, the optimal pH was obtained by incubating the enzymes between pH 7.0 and 11.0 for 15 min before activity assay. The activity of the PoOPHM9 CLEPC and free PoOPHM9 relative to their optimal activity was calculated according to Eq. (2).

To determine the thermostability, PoOPHM9 CLEPC, PoOPHM9 CLEA and free PoOPHM9 were incubated at 50 °C for 7 h. The samples of the enzyme solutions were taken at different time intervals for activity assay. The residual activity of the samples at different time was calculated according to Eq. (3).

The relative activity of immobilized and free enzymes in the presence of various detergents at different time was calculated according to Eq. (3). To determine the reusability, the reaction mixture was centrifuged at 12,000 rpm for 3 min to recover the immobilized enzymes. The collected enzymes were washed for 3 times and the relative activity of PoOPHM9 CLEPC after each round was measured and calculated against the initial activity detected in the first batch.

Degradation of malathion by PoOPHM9 CLEPC in the presence of detergents

Typically, 980 μL of 50 mM Tris–HCl buffer (pH 9.0) containing 0.3 mM DNTB and 0.1% (w/w) of COD, APG and SDS was mixed with 10 μL of 15 mM malathion and 10 μL of 420 U/mL PoOPHM9 CLEPC. The mixture was stirred at 25 °C or 50 °C for 30 min and the absorbance readings were taken every minute. The hydrolysis percentage was calculated by comparing the absorbance at different times with that of the completely hydrolyzed product.

Results and discussion

Preparation of PoOPHM9 CLEPC

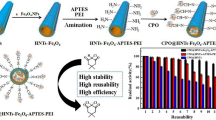

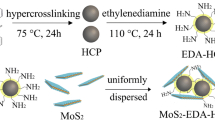

Previous study demonstrated that the hydrophobic PPO blocks of Pluronic F127 can interact with hydrophobic amino acids such as Phenylalanine (Phe) on the surface of OPH, and physically associate with OPH to form a non-covalent binding enzyme-polymer complex (Kim et al. 2014b). PoOPHM9 (PDB: 4O98) is an engineered OPH belonging to the superfamily of phosphotriesterase (Luo et al. 2016), and 10 Phe residues (22 in total) among other hydrophobic residues are located on the surface (Additional file 1: Figure S1). Thus, we modified the process of preparing CLEA and added Pluronic F127 into the reaction mixture after protein precipitation for enzyme-polymer conjugation (Fig. 1). Particularly, the ratio of mass concentration (g/L) of PoOPHM9 to Pluronic F127 was adjusted from 1:0 to 1:6, affording the highest activity recovery of 60% at 1:4, which was used in the following experiments (Fig. 2a). Interestingly, the order of adding Pluronic F127 in the preparation procedure affected the activity recovery of the immobilized enzyme. The polymers can be added into the enzyme solution before protein precipitation (PL–AS–GL, simply for the order of Pluronic F127/ammonium sulfate/glutaraldehyde), after the formation of enzyme aggregates (AS–PL–GL) and after the formation of CLEA (AS–GL–PL). As shown in Fig. 2b, the activity recovery of AS–PL–GL (83%) was higher than that of PL–AS–GL (55%), AS–GL–PL (37%) and CLEA (32%). Notably, all enzyme-polymer conjugates incorporating Pluronic F127 showed higher activity recoveries than that of CLEA, demonstrating Pluronic F127 indeed stabilized enzymes during immobilization. The concentrations of (NH4)2SO4, PoOPHM9 and glutaraldehyde were also optimized to improve the activity recovery (Fig. 2c–e). The prepared catalysts can be easily distributed in aqueous phase during the degradation reaction and recovered by centrifugation for recycle (Fig. 2f). The particles of PoOPHM9 CLEPC were observed in TEM analysis with a mean diameter of 0.66 ± 0.12 μm (Fig. 2g).

The mass ratio of PoOPHM9 to Pluronic F127 (a), the different order of adding Pluronic F127 (b) and the concentrations of ammonium sulfate (c), the free enzyme (d) and glutaraldehyde (e) were optimized for preparing the immobilized catalyst CLEPC. The immobilized enzymes were distributed in aqueous phase during the enzymatic reaction (f, left) and easily recovered by centrifugation (f, right). g The transmission electron microscopy of CLEPC showed the aggregation of immobilized enzymes with the mean diameter of 0.66 ± 0.12 μm

PoOPHM9 CLEPC displayed a higher apparent kcat (49.1 ± 1.2 s−1) than that of PoOPHM9 CLEA (1.1 ± 0.1 s−1, Table 1). Although PoOPHM9 CLEPC had a slightly increased KM (125.7 ± 7.7 μM) compared to that of PoOPHM9 CLEA (103.8 ± 1.7 μM) because of the polymers, its catalytic efficiency (kcat/KM, 390.3 ± 7.8 mM−1 s−1) was much higher that of PoOPHM9 CLEA (10.9 ± 1.7 mM−1 s−1) and also a little bit higher than that of the free enzyme (265.4 ± 2.0 mM−1 s−1). This result suggested that the addition of Pluronic F127 during immobilization can effectively increase the catalytic efficiency of immobilized enzyme, which was consistent with the effect of Pluronic F127 on free enzymes (Kim et al. 2014a, b).

Enzymatic properties of PoOPHM9 CLEPC

As shown in Fig. 3a, PoOPHM9 CLEPC had the same optimal pH of 9.0 as the free PoOPHM9, but it exhibited a better stability in strong alkaline solutions. At pH 8.0, 10.0 and 11.0, it can maintain over 80% of the maximum activity. However, the relative activity of the free enzyme dropped to 32%, 66% and 40%, respectively. In addition, the optimal temperature of CLEPC was 50 °C which was higher than that of PoOPHM9 (30 °C, Fig. 3b). In particular, the immobilized enzyme still maintained 80% activity at 60 °C, but the free enzyme PoOPHM9 was inactivated completely at this temperature. The thermostability of PoOPHM9 CLEPC, PoOPHM9 CLEA and PoOPHM9 was tested and compared at 50 °C in Fig. 3c. PoOPHM9 quickly lost its activity with a half-life of 0.5 h. PoOPHM9 CLEA maintained 68.3% activity after 5 h, yielding a half-life of 7.2 h at 50 °C. Notably, PoOPHM9 CLEPC displayed the best thermostability with a half-life of 12.8 h at 50 °C. This result suggested that Pluronic F127 incorporated in CLEPCs could significantly improve the thermostability of enzymes. The high thermal tolerance of CLEPCs is a prominent advantage for industrial applications because high temperatures facilitate the removal of OPs during washing.

Enzymatic assay of PoOPHM9 CLEPC. The optimal pH (a) and temperature (b) of CLEPC and free enzymes were determined. Thermostability (c) was investigated by measuring the residual activity of different catalysts incubated at 50 °C. d The relative activity of CLEPC and PoOPHM9 incubated in the presence of 0.1% (w/w) detergents were measured at 25 °C. The relative activity of PoOPHM9 CLEPC in the absence of detergents was also measured (red dots)

Effect of detergents on the activity of PoOPHM9 CLEPC

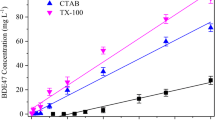

Previously, we found that various commercially available detergents can influence the activity of PoOPHM9 (Bai et al. 2017). For example, the anionic and non-ionic detergents, such as sodium dodecyl sulphate (SDS) and alkyl polyglycoside (APG), decreased the enzyme activity while the biocompatible detergent, coconut oil derivatives (COD), showed a less negative impact on the enzyme activity. In this work, we compared the catalytic activity of PoOPHM9 CLEPC and free PoOPHM9 incubated in the presence of 0.1% (w/w) detergents at 25 °C (Fig. 3d). As observed previously, the activity of free PoOPHM9 decreased to various extent in the presence of COD, APG and SDS. In contrast, the activity of PoOPHM9 CLEPC were all enhanced by 2- to 2.5-fold in the presence of the three detergents after 2 h incubation. It has been reported that SDS can activate phosphotriesterase (PTE) and enhance its activity (Giudice et al. 2016), but inactivate PoOPHM9 (Bai et al. 2017). However, the phenomena that all kinds of detergents can enhance the activity of immobilized enzyme-polymer conjugates was first observed. To confirm this, we compared the activity of PoOPHM9 CLEPC in the absence of detergents under the same condition (red symbols, Fig. 3d). The result showed that the activity of PoOPHM9 CLEPC increased to approximately 154% after 2 h, which was lower than that of CLEPC in the presence of detergents (2- and 2.5-fold). The result suggested that detergents indeed activated and further enhanced the catalytic activity of PoOPHM9 CLEPC.

Effect of Pluronic F127 on the activity of PoOPHM9 CLEPC

First, we prepared and incubated PoOPHM9 CLEA in the absence or presence of detergents. However, the activity in all cases decreased (Additional file 1: Figure S2), indicating that only CLEA cannot enhance the activity of PoOPHM9. Compared with the result in Fig. 3d, it can be concluded that Pluronic F127 is essential in improving the activity of immobilized enzymes. Second, we prepared the conjugate PoOPHM9-PF127 formed between the free PoOPHM9 and Pluronic F127 and measured their activity in the absence of detergents after 2 h incubation (Additional file 1: Figure S3a). The activity of PoOPHM9-PF127 was slightly increased to 105% by 1% and 10% (w/w) Pluronic F127 after 2 h incubation (Additional file 1: Figure S3a). Interestingly, when 0.1% (w/w) detergents were added, the activity of PoOPHM9-PF127 conjugates was all enhanced to approximately 120% relative to that of the free enzyme (Additional file 1: Figure S3b). This result suggested that the activity improvement was achieved by the cooperation between Pluronic F127 and detergents. However, this activity improvement was lower than that of PoOPHM9 CLEPC incubated with detergents (2- and 2.5-fold), indicating that the enzyme aggregation and cross-linkage in PoOPHM9 CLEPC are very important in the activity enhancement (Akbar et al. 2007; Perzon et al. 2017; Wang et al. 2011). In summary, the significant enhancement in the activity of PoOPHM9 CLEPC was caused by the synergic effect of Pluronic F127, enzyme immobilization and detergents.

Degradation of malathion by PoOPHM9 CLEPC

Finally, we tested the effect of malathion degradation by CLEPC in a pH 9.0 solution containing 0.15 mM malathion, 4.2 U PoOPHM9 CLEPC and 0.1% (w/w) detergents (Fig. 4). As shown in Fig. 4a, PoOPHM9 CLEPC degraded 100% malathion after 30 min in the presence of COD, and 92% malathion was removed by CLEPC in the presence of APG and SDS at 25 °C. Next, we increased the temperature to 50 °C and found that 100% malathion was removed within 10 min in the presence of COD, which was faster than that at 25 °C (Fig. 4b). For APG, the washing effect was also enhanced as malathion was completely removed within 15 min, but the effect was almost unchanged in the presence of SDS. As mentioned above, the activity of PoOPHM9 CLEPC can be activated and enhanced after incubation with detergents. Therefore, we tested the degradation effect by incubating PoOPHM9 CLEPC with each of the three detergents (COD, APG and SDS) for 2 h in prior to adding malathion in the buffer at 25 °C (Fig. 4c). To our delight, malathion was totally degraded within 10 min in the presence of the three detergents, which was the best degrading effect compared with the results in Fig. 4a. Finally, the reusability test of CLEPC showed that it still maintained 85.4% activity after 10 cycles (Fig. 4d), demonstrating its potential for practical applications.

Degradation of 0.15 mM malathion by PoOPHM9 CLEPC in the presence of 0.1% (v/v) COD, APG and SDS. The experiments were performed immediately after the addition of detergents at 25 °C (a) and 50 °C (b). c The degradation was performed at 25 °C using PoOPHM9 CLEPC that was incubated with detergents for 2 h in advance. d Recycling CLEPC for malathion degradation. The relative activity of PoOPHM9 CLEPC was measured at 25 °C after each cycle for 10 times

Conclusion

In conclusion, we developed a simple method to prepare an immobilized organophosphate hydrolase (PoOPHM9) conjugated with Pluronic F127 for efficient malathion degradation. Compared to the traditional PoOPHM9-Pluronic F127 CLEA, PoOPHM9-Pluronic F127 CLEPC has a 2.2 times higher activity recovery. It features excellent thermostability with a half-life of 12.8 h at 50 °C, which is 25.6 and 1.7 times higher than that of the free PoOPHM9 and PoOPHM9-Pluronic F127 CLEA CLEA. Particularly, PoOPHM9 CLEPC was not deactivated by detergents; instead, its activity can even be further enhanced by up to 2.5-fold in the presence of detergents such as coconut oil derivatives, sodium dodecyl sulphate and alkyl polyglycoside. Degradation of 0.15 mM malathion with PoOPHM9 CLEPC at 50 °C or 25 °C in the presence of detergents was demonstrated, showing the potential of this new immobilized OPH in practical industrial applications. We believe this technology can be extended easily to produce other immobilized polymer-enzyme conjugates, owing to the simplicity of this technology.

Abbreviations

- OP:

-

organophosphate pesticide

- OPH:

-

organophosphate hydrolase

- CLEPC:

-

cross-linked enzyme-polymer conjugate

- CLEA:

-

cross-linked enzyme aggregate

- SDS:

-

sodium dodecyl sulphate

- APG:

-

alkyl polyglycoside

- COD:

-

coconut oil derivative

References

Abe K, Yoshida S, Suzuki Y, Mori J, Doi Y, Takahashi S, Kera Y (2014) Haloalkylphosphorus hydrolases purified from Sphingomonas sp. strain TDK1 and Sphingobium sp. strain TCM1. Appl Environ Microbial 80:5866–5873

Akbar U, Aschenbrenner CD, Harper MR, Johnson HR, Dordick JS, Clark DS (2007) Direct solubilization of enzyme aggregates with enhanced activity in nonaqueous media. Biotechnol Bioeng 96:1030–1039

Bai YP, Luo XJ, Zhao YL, Li CX, Xu DS, Xu JH (2017) Efficient degradation of malathion in the presence of detergents using an engineered organophosphorus hydrolase highly expressed by Pichia pastoris without methanol induction. J Agric Food Chem 65:9094–9100

Bigley AN, Xiang DF, Ren ZJ, Xue HR, Hull KG, Romo D, Raushel FM (2016) Chemical mechanism of the phosphotriesterase from Sphingobium sp. strain TCM1, an enzyme capable of hydrolyzing organophosphate flame retardants. J Am Chem Soc 138:2921–2924

Breger JC, Ancona MG, Walper SA, Oh E, Susumu K, Stewart MH, Deschamps JR, Medintz IL (2015) Understanding how nanoparticle attachment enhances phosphotriesterase kinetic efficiency. ACS Nano 9:8491–8503

Chen J, Luo XJ, Chen Q, Pan J, Zhou JH, Xu JH (2015) Marked enhancement of Acinetobacter sp. organophosphorus hydrolase activity by a single residue substitution Ile211Ala. Bioresour Bioprocess 2:39–46

Cherny I, Greisen PJ, Ashani Y, Khare SD, Oberdorfer G, Leader H, Baker D, Tawfik DS (2013) Engineering V-type nerve agents detoxifying enzymes using computationally focused libraries. ACS Chem Biol 8:2394–2403

Cycon M, Mrozik A, Piotrowska-Seget Z (2017) Bioaugmentation as a strategy for the remediation of pesticide-polluted soil: a review. Chemosphere 172:52–71

Gao Y, Truong YB, Cacioli P, Butler P, Kyratzis IL (2014) Bioremediation of pesticide contaminated water using an organophosphate degrading enzyme immobilized on nonwoven polyester textiles. Enzyme Microbial Technol 54:38–44

Giudice ID, Coppolecchia R, Merone L, Porzio E, Carusone TM, Mandrich L, Worek F, Manco G (2016) An efficient thermostable organophosphate hydrolase and its application in pesticide decontamination. Biotechnol Bioeng 113:724–734

Hernandez AF, Gil F, Lacasana M (2017) Toxicological interactions of pesticide mixtures: an update. Arch Toxicol 91:3211–3223

Hondred JA, Breger JC, Garland NT, Oh E, Susumu K, Walper SA, Medintz IL, Claussen JC (2017) Enhanced enzymatic activity from phosphotriesterase trimer gold nanoparticle bioconjugates for pesticide detection. Analyst 142:3261–3271

Jackson CJ, Weir K, Herlt A, Khurana J, Sutherland TD, Horne I, Easton C, Russell RJ, Scott C, Oakeshott JG (2009) Structure-based rational design of a phosphotriesterase. Appl Environ Microbiol 75:5153–5156

Khare SD, Kipnis Y, Greisen PJ, Takeuchi R, Ashani Y, Goldsmith M, Song YF, Gallaher JL, Silman I, Leader H, Sussman JL, Stoddard BL, Tawfik DS, Baker D (2012) Computational redesign of a mononuclear zinc metalloenzyme for organophosphate hydrolysis. Nat Chem Biol 8:294–300

Kim CS, Seo JH, Kang DG, Cha HJ (2014a) Engineered whole-cell biocatalyst-based detoxification and detection of neurotoxic organophosphate compounds. Biotechnol Adv 32:652–662

Kim M, Gkikas M, Huang A, Kang JW, Suthiwangcharoen N, Nagarajan R, Olsen BD (2014b) Enhanced activity and stability of organophosphorus hydrolase via interaction with an amphiphilic polymer. Chem Commun 50:5345–5348

LeJeune KE, Mesiano AJ, Bower SB, Grimsley JK, Wild JR, Russell AJ (1997) Dramatically stabilized phosphotriesterase—polymers for nerve agent degradation. Biotechnol Bioeng 54:105–114

Li P, Moon SY, Guelta MA, Lin L, Gomez-Gualdron DA, Snurr RQ, Harvey SP, Hupp JT, Farha OK (2016) Nanosizing a metal-organic framework enzyme carrier for accelerating nerve agent hydrolysis. ACS Nano 10:9174–9182

Luo XJ, Kong XD, Zhao J, Chen Q, Zhou JH, Xu JH (2014) Switching a newly discovered lactonase into an efficient and thermostable phosphotriesterase by simple double mutations His250Ile/Ile263Trp. Biotechnol Bioeng 111:1920–1930

Luo XJ, Zhao J, Li CX, Bai YP, Reetz MT, Yu HL, Xu JH (2016) Combinatorial evolution of phosphotriesterase toward a robust malathion degrader by hierarchical iteration mutagenesis. Biotechnol Bioeng 113:2350–2357

Mostafalou S, Abdollahi M (2017) Pesticides: an update of human exposure and toxicity. Arch Toxicol 91:549–599

Pan J, Kong XD, Li CX, Ye Q, Xu JH, Imanaka T (2011) Crosslinking of enzyme coaggregate with polyethyleneimine: a simple and promising method for preparing stable biocatalyst of Serratia marcescens lipase. J Mol Catal B Enzym 68:256–261

Pan J, Dang ND, Zheng GW, Cheng B, Ye Q, Xu JH (2014) Efficient production of l-menthol in a two-phase system with SDS using an immobilized Bacillus subtilis esterase. Bioresour Bioprocessing 1:12

Perzon A, Dicko C, Cobanoğlu Ö, Yükselen O, Eryilmaz J, Dey ES (2017) Cellulase cross-linked enzyme aggregates (CLEA) activities can be modulated and enhanced by precipitant selection. J Chem Technol Biotechnol 92:1645–1649

Ramalho TC, de Castro AA, Silva DR, Silva MC, Franca TCC, Bennion BJ, Kuca K (2016) Computational enzymology and organophosphorus degrading enzymes: promising approaches toward remediation technologies of warfare agents and pesticides. Curr Med Chem 23:1041–1061

Raynes JK, Pearce FG, Meade SJ, Gerrard JA (2011) Immobilization of organophosphate hydrolase on an amyloid fibril nanoscaffold: towards bioremediation and chemical detoxification. Biotechnol Prog 27:360–367

Schenk G, Mateen I, Ng TK, Pedroso MM, Mitic N, Jafelicci M, Marques RFC, Gahan LR, Olis DL (2016) Organophosphate-degrading metallohydrolases: structure and function of potent catalysts for applications in bioremediation. Coordin Chem Rev 317:122–131

Singh AK, Flounders AW, Volponi JV, Ashley CS, Wally K, Schoeniger JS (1999) Development of sensors for direct detection of organophosphates. part I: immobilization, characterization and stabilization of acetylcholinesterase and organophosphate hydrolase on silica supports. Biosens Bioelectron 14:703–713

Suthiwangcharoen N, Nagarajan R (2014) Enhancing enzyme stability by construction of polymer–enzyme conjugate micelles for decontamination of organophosphate agents. Biomacromol 15:1142–1152

Theriot C, Grunden AM (2011) Hydrolysis of organophosphorus compounds by microbial enzymes. Appl Microbial Biotechnol 89:35–43

Wang MF, Qi W, Jia CX, Ren YF, Su RX, He ZM (2011) Enhancement of activity of cross-linked enzyme aggregates by a sugar-assisted precipitation strategy: technical development and molecular mechanism. J Biotechnol 156:30–38

Wei W, Du JJ, Li J, Yan M, Zhu Q, Jin X, Zhu XY, Hu ZM, Tang Y, Lu YF (2013) Construction of robust enzyme nanocapsules for effective organophosphate decontamination, detoxification, and protection. Adv Mater 25:2212–2218

Wu XL, Wang R, Zhang YF, Ge J, Liu Z (2014) Enantioselective ammonolysis of phenylglycine methyl ester with lipase–Pluronic nanoconjugate in tertiary butanol. Catal Lett 144:1407–1410

Wu XL, Ge J, Zhu JY, Zhang YF, Yong Y, Liu Z (2015) A general method for synthesizing enzyme-polymer conjugates in reverse emulsions using Pluronic as a reactive surfactant. Chem Commun 51:9674–9677

Yan XY, Jiang YJ, Zhang SP, Gao J, Zhang YF (2015) Dual-functional OPH-immobilized polyamide nanofibrous membrane for effective organophosphorus toxic agents protection. Biochem Eng J 98:47–55

Zhang YF, Dai Y, Hou M, Li T, Ge J, Liu Z (2013) Chemo-enzymatic synthesis of valrubicin using Pluronic conjugated lipase with temperature responsiveness in organic media. RSC Adv 3:22963–22966

Zheng GW, Yu HL, Li CX, Pan J, Xu JH (2011) Immobilization of Bacillus subtilis esterase by simple cross-linking for enzymatic resolution of dl-menthyl acetate. J Mol Catal B Enzym 70:138–143

Authors’ contributions

XYZ, JG and YPB designed the experiments; HC, YLZ and XJL performed the research experiments; DSX, QD and XC helped in the experiments. XYZ, JG and YPB analyzed the data; JHX helped in manuscript preparation; HC, XYZ, JG and YPB wrote the manuscript. All authors read and approved the final manuscript.

Acknowledgements

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

All data generated or analyzed during this study are included in this published article and its supplementary information files.

Consent for publication

All of the authors have read and approved to submit it to bioresources and bioprocessing.

Ethics approval and consent to participate

Not applicable.

Funding

This work was financially sponsored by the National Key Research and Development Program of China (2016YFA0204300), National Natural Science Foundation of China (Nos. 21505044, 21536004 and 21506055) and Natural Science Foundation of Shanghai (18ZR1409900).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding authors

Additional file

Additional file 1.

Supplementary information.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cheng, H., Zhao, YL., Luo, XJ. et al. Cross-linked enzyme-polymer conjugates with excellent stability and detergent-enhanced activity for efficient organophosphate degradation. Bioresour. Bioprocess. 5, 49 (2018). https://doi.org/10.1186/s40643-018-0236-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40643-018-0236-2