Abstract

Background

Contamination of pet foods and infant formula with high levels of melamine has resulted in a number of cases of illness and deaths among pets and children; however, the long-term effects of low dose exposures is poorly understood. Exposure to melamine from the consumption of foods using melamine-based tableware has been identified as a potential source of concern due to the role that melamine may play in human kidney disease, especially among children. In this study, the migration of melamine into solutions of varying pH was characterized in order to better understand the migration risk associated with foods of different chemical characteristics.

Results

Two brands of bowls marketed toward children’s use were tested in pH 3.0, 5.0, 7.0, 9.0, and 11.0 solutions at 95 °C over a series of ten 30 min exposures runs. Melamine migration was significantly greater in the pH 3.0 solution than others and migration was significantly different between the two brands. Migration dropped substantially after the initial run and reached consistent values by the fifth run.

Conclusions

Despite the potential for long term melamine exposure to contribute to human disease, melamine based products are widely available. Exposures to foods cooked in bowls of this type would be less than Tolerable Daily Intake (TDI) levels; however, gaps in the understanding of chronic exposure to melamine may warrant caution among consumers, especially parents of young children. Currently, labeling requirements are inadequate to inform consumers of the potential for exposure to melamine.

Similar content being viewed by others

Background

Melamine is commonly used in the manufacture of a number of different food contact materials ranging from flooring to tableware products. Due to its use in food contact products, the potential for melamine to leach from these products into foods, its demonstrated animal and human toxicity, and unfortunate events where contamination of animal and human foods with melamine has occurred, considerable focus has been placed on the potential risk that melamine poses.

Two large-scale events have brought this issue to the attention of the public. In 2007, pet food manufactured in China and distributed in North America was found to be contaminated with melamine resulting in the recall of over 60 million products from almost 150 brands (Bridges 2007; U.S. FDA 2009a). This incident led to the deaths of more than 1000 household pets (WHO 2009a). In 2008, infants and children in China became ill after ingesting formula tainted with melamine and hospitals in China experienced a flux of ill children with kidney stones with six related fatalities (EFSA 2008; FAO 2012; Guan et al. 2009). More than 294,000 infants and children were affected and infant formula tainted with melamine was identified as the cause (EFSA 2010a). This incident prompted a global recall of the formula as well as other products that contained the tainted milk powder (WHO 2009b).

Exposure to high levels of melamine has long been known to cause kidney damage in animals through controlled studies (Wu and Zhang 2013; Hau et al. 2009) and the occurrence of animal deaths from melamine-contaminated foods points out the hazards from consumption of consumer products. The most widely reported health effects of melamine exposure in humans is the formation of kidney stones although other types of kidney damage have been reported (Skinner et al. 2010; Hau et al. 2009). More closely focused studies have found that melamine induced kidney stones have a different composition, including the presence of melamine (Jia et al. 2011; Liu et al. 2011; Sun et al. 2011). Several epidemiological studies have demonstrated an increased risk for kidney stone formation in children exposed to melamine levels below the WHO standard (Chen et al. 2009; Li et al. 2010) and Liu et al. (2011)) found an increased risk of kidney stone formation in adults with low urinary levels of melamine. Additionally, it has been noted that the effects of chronic melamine exposure are not well known (Ingelfinger 2008).

The main measure used to assess potential exposure to melamine from tableware is the Specific Migration Limit (SML) which is a measure of migration from plates and utensils into foods. The Tolerable Daily Intake (TDI) is an estimate of the daily intake of melamine that can occur over a lifetime without appreciable risk of health effects. The U.S. FDA has established a Tolerable Daily Intake (TDI) of 0.063 mg per kilogram body weight per day (mg/kg bw/day) melamine while the WHO (WHO 2008) and the European Food Safety Authority (EFSA) (EFSA 2010b) set the TDI at 0.2 mg/kg bw/day. Hsieh et al. (2009) argued for a TDI of 0.0081 mg/kg bw/day based on alternative method of analyzing the data from the original animal study (U.S. DHHS 1983). Additional standards for melamine in food include U.S. standards for infant formula (1 mg/kg) and other foods (2.5 mg/kg) (U.S. FDA 2009b) and an EU Specific Migration Limit (SML) of 2.5 mg/kg (EC 2011, 2012).

Melamine is primarily used in resins for plastics, filters, plastic tableware, etc. and its resins are molded and cured in order to achieve the final product. This type of resin is referred to as a thermoset plastic (Tyan et al. 2009). Since this type of plastic can melt when exposed to high levels of heat, manufacturers state that melamine tableware is not oven or microwave safe. Melamine tableware can include plates, cups, bowls, utensils, etc. and it is popular because it is durable and inexpensive. These qualities make melamine tableware a popular choice for household use (Bradley et al. 2010; Lund and Petersen 2006). Due to its durability, melamine tableware is often kept for long periods of time and is used repeatedly (Ishiwata et al. 1986). An area of special concern for chronic melamine exposure has been from melamine migration into foods from melamine tableware, such as bowls and plates. Initial melamine migration may be due to residual monomer while subsequent migration may result from breakdown of the polymer (Hsu et al. 2010).

Several studies have measured the migration of melamine from tableware under various conditions including pH and temperature. Chik et al. (2011)) and Chien et al. (2011), examined the effects of both pH (3 % acetic acid) and temperature (25–100 °C) on melamine migration and found that melamine migration increased with temperature in acetic acid and water solutions and that the acetic acid solution was more effective in leaching melamine than water. Bradley et al. (2010) found a 3 fold increase in melamine migration in an acetic acid (3 %) versus water at 70 °C. Bradley et al. (2010) also found varying results for melamine migration into foods with different pH values with a general trend of higher migration into lower pH foods.

Changes in melamine migration after repeated exposures have also been examined. Bradley et al. (2005) found that measured migration did not significantly change over three exposures to test solutions. Lund and Petersen (2006) also found that melamine migration continued after three or ten successive exposures to test solutions; however, the concentration dropped considerably after the first 2 h exposure period. Ishiwata et al. (1986) found that melamine leached increased with successive exposures.

Based on these studies, it is clear that melamine leaches into foods contained in melamine tableware and that migration varies considerably under different physical conditions and between different products. Since it has also been shown that consumption of foods contained in melamine bowls increases urinary melamine levels (Wu et al. 2013), it can be concluded that melamine from these sources are readily absorbed. Of greatest concern in this regard are the numerous products marketed specifically toward children. For instance, in our local investigation we found melamine tableware to be widely available at large retailers and clearly marketed towards children’s use through the use of graphics. Online sources also offered a wide variety of melamine tableware with similar marketing. With the focus over the past several years that has been placed on the risks of melamine exposure and the identification of melamine tableware as a potential exposure source, it seems prudent for manufacturers to identify production methods that would reduce melamine migration. Bearing this in mind, we sought to determine whether melamine exposure from currently available products continues to present a potential health hazard. In this article, we report the effects of pH and temperature on the migration of melamine from two brands of melamine bowls marketed towards children’s use.

Methods

Melamine migration from tableware available through online commercial sources was measured under controlled pH conditions after repeated exposures at cooking temperatures. Bowls from two different brands from different sources, clearly marketed towards children’s use with colorful graphics (one with a Disney™ character), were tested. Both brands identified the bowls as being made of melamine with their online ordering information; however, neither brand was labeled as such. One brand was labeled for use by children >3 years while the other stated no age restriction. Both brands recommended against microwave use, although one brand employed a symbol to express this message. Neither brand cautioned against using with hot foods and both were manufactured in China.

A total of 50 bowls were tested, 25 for each brand. Sample replicate numbers varied in previous studies from 2 to 3 (Bradley et al. 2010) to 5–6 (Lund and Petersen 2006) We chose 5 bowls per pH solution per brand for testing in order to provide a sound estimate of the variance of results. The two brands were randomly chosen from among the many similar products available. The bowl dimensions for both brands were listed by the manufacturers as 14 cm in diameter and 3.8 cm deep. Average bowl weights and volumes were 61.8 and 138.2 g and 440 and 370 mL for Brand 1 and 2, respectively.

Solutions of pH 3, pH 5, pH 7, pH 9, and pH 11 were prepared using reverse osmosis (RO) treated water, glacial acetic acid (EMD OmniTrace), hydrochloric acid (Fisher Certified ACS Plus), and sodium hydroxide (Fisher ACS Certified). For the two acids, pH solutions were prepared by titration of the concentrated acid into RO water containing a pH probe under slow stirring until the desired pH value was achieved (within 0.1 standard pH units). A sodium hydroxide solution was prepared by dissolving 10 g of sodium hydroxide into 100 mL RO water. This solution was titrated into RO water until the desired pH values were obtained.

The average recommended serving size for children for many foods is 118 to 237 (USDA 2003); therefore, 200 mL approximately represents the amount of food that a child would be expected to consume at one time. Each bowl was filled with 200 mL of the known pH solutions and placed in a convection oven (Precision Scientific Mechanical Convection Oven Model 625) at 95 °C for 30 min. The solution volume from each bowl was measured after cooking to account for losses due to evaporation. This process was repeated ten times per bowl with fresh pH solution each time. Although 10 runs were made for each pH solution, only the 1st, 2nd, 3rd, 4th, 5th, and10th runs were analyzed for melamine. The Abraxis Enzyme-Linked Immunosorbent Assay (No. 50005B) was utilized for melamine analysis using a Biotek Model ELX808LBS plate reader.

Because migration is a contact area mediated process, migration concentrations were normalized to concentration per unit of wetted area (calculated before heating period). For each bowl brand, migration concentrations were divided by the wetted surface area (152.8 cm2 for Brand 1 and 162.3 cm2 for Brand 2), with results expressed in μg/cm2. The 200 mL solution covered each bowl to the 2.2 cm depth or approximately 60 % of the total depth. Cumulative normalized migration concentrations were then calculated for each of the 5 bowls used at each pH condition. The EU guidance for migration testing of plastic materials standardizes the surface-to-volume ratio at 6 for containers with less than 500 mL volume (EC 2014). The bowl types that were tested in this study had surface-to-volume ratios of 7.7 and 8.1 for Brand 1 and 2, respectively.

Results and discussion

Melamine values are examined on a mass per volume (μg/L) and mass per unit area (μg/cm2) (Table 1). Mass per volume measurements are useful for comparison to the EU SML and for calculating exposure scenarios to compare to TDI values while mass per area values are more useful for comparing the bowl brands in this study, as well as other studies, since migration is a surface phenomenon.

The limit of quantification (LOQ) was calculated as 8.28 μg/L using the mean value of blank samples plus 10 standard deviations of the mean value (Gibbons and Coleman 2001). The LOQ is similar to the LOD (9 μg/L) determined by Garber (2008) using similar Abraxis kits. Censored (below the LOQ) values are reported as ½ the LOQ for statistical purposes. The relative standard deviation of duplicate measurements was 11.4 % and the mean accuracy was ± 4.3 %.

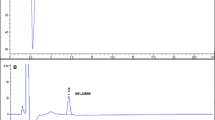

Mean melamine leachate ranged from a high of 76.7 μg/L to below the LOQ (8.28 μg/L) (Table 1). Significant effects on migration concentration were observed for both brand and pH. Melamine concentration dropped by an average of 67 and 71 %, respectively, for Brand 1 and Brand 2 after the first 3 runs (mean of all pH values) and reached consistent values by run 5 (Figs. 1 & 2). Overall, melamine migration dropped 85 % from runs 1 to 10 for both brands with a smaller decrease seen from the pH 3 solution. Initial melamine values were higher for Brand 1 at all pH values for Runs 1 and 2 but became similar to Brand 2 in subsequent runs.

The measured melamine migration is within the range reported in other studies. Chik et al. (2011) measured melamine migration in bowls (100 °C for 30 min) in water and a 3 % acetic solution and found values in bowls between 39 and 140 and 52 and 250 μg/L for water and acetic acid, respectively. Bradley et al. (2010) measured melamine migration (70 °C for 30 min) ranging from 6 to 650 μg/L in water and 13 to 926 μg/L in acetic acid for the melamine items tested. Chien et al. (2011) reported much higher values ranging from 860 to 3430 μg/L for water and 6970 to 19,030 μg/L for a 3 % acetic acid solution in five pieces of melamine tableware (90° for 30 min).

Melamine migration normalized to wetted surface area has varied among previous studies from 0.16 to 0.57 in 3 % acetic acid and 0.02 to 0.10 μg/cm2 in water (both at 90 °C for 30 min) (Chien et al. 2011), 0.34 μg/cm2 (3 % acetic acid for 30 min) (Lund and Petersen 2006), and 1.2 to 8.0 μg/cm2 (70 °C for 2 h.) (Bradley et al. 2005). In our study, the maximum melamine migration was 0.10 μg/cm2 for Brand 1 and 0.06 μg/cm2 for Brand 2 during the first exposure at pH 3 demonstrating that these brands have similar physical characteristics to those tested in other studies.

None of the migration values approached the SML (2.5 mg/L) or the value suggested by Hsieh et al. (2009) (300 μg/L). Potential melamine dose as a percentage of current U.S. FDA and WHO TDI standards was calculated under the worst-case scenario (pH3) using the following formula: (a/b/c) ∗ 100 = % TDI values, where: a = the amount of melamine contained in a single 200 mL serving; b = 20 (representing a 20 kg child); and c = U.S. FDA and WHO TDI values (Table 2). Based on these calculations, a 20 kg child would have to eat a substantial volume of food (100/0.38 = 263 bowls) to approach the recommended TDIs of 0.2 (WHO) and 82 bowls (100/1.22) to reach the 0.063 mg/kg bw/day (USFDA). In the worse-case scenario, a child would have to eat more than ten 200 mL bowls of pH 3 food to reach the most conservative value of 8.1 μg/kg bw/day recommended by Hsieh et al. (2009).

A Levene’s test on the absolute residuals of the cumulative leachate over 10 trials (ppb/cm2) indicated a significant difference in variances across pH (p = 1.42E-05) but not Brand (p = 0.176). Multiple simultaneous pairwise comparisons of the residuals, pooled over Brand, using Tukey’s Minimum Significant Difference test indicated statistically significant differences in variances for pH 3 compared to pH 5, pH 7, and pH 9 but not pH 11. None of the other variances were significantly different from one another.

Cumulative leaching by pH and Brand was modeled using the SAS MIXED procedure with Brand considered as a random effect and pH as a fixed effect, with and without inclusion of a Brand x pH interaction effect. The interaction effect was non-significant and was excluded from further analysis. Modeling with only the main effects indicated both Brand and pH to be statistically significant (p = 0.0027 and p = 0.0005, respectively). Multiple simultaneous comparisons indicated the pH3 mean to be significantly different from (higher than) means at the other pH conditions (p < 0.0043 for all comparisons), but none of the other means were significantly different from one another (Figs. 3 & 4).

We employed a systematic approach to measuring the effects of pH using values from 3 to 11 to reduce the chance of matrix effects associated with food products. In addition, we sought to determine whether there was linear effect of pH on melamine migration. Food pH values can range from as low as 2.2–3.0 for some fruit juices and fruits to 9.0 for egg whites, although most common foods fall in the mid-pH range (U.S. FDA 2012) so the majority of these data are representative of typical foods. The pH 11 value is beyond what would be found in foods so this value was mainly used to determine the effects on migration of a more caustic solution such as found in many household cleaning products. Based on these data and that from other studies reviewed in this paper, it is clear that acidic foods and higher temperatures both increase melamine migration and that first-use of the product presents the greatest risk.

Our study used an exposure temperature of 30 min at 95 °C, both of which are higher than expected during normal food preparation. Although nearly boiling temperature foods could be placed in these bowls and, although not recommended for melamine tableware, foods could be placed in a microwave oven for several minutes allowing the foods to reach boiling temperatures, our exposure scenarios are beyond what would reasonably be encountered during consumer use. The primary purpose for using these scenarios was to generate data that could be compared to that done in other studies, where high temperature exposures for 30 or more minutes have been common. In light of these facts, future studies to estimate melamine exposure would benefit from the use of more realistic time and temperature values.

Consumers needs to be informed that melamine exposure can be reduced by not putting hot or acidic foods into melamine containers or washing them thoroughly in a hot, preferably acidic, solution before first use. This might be a difficult message to convey and probably beyond what is a reasonable expectation for product labeling. Moreover, since the two products tested in this study are not labeled as being made of melamine, it is unlikely that the consumer would know of the potential for melamine exposure from their use. At the very least, melamine tableware should be labeled as such and better guidance should be given for its safe use.

Conclusions

This study measured melamine migration from two brands of melamine bowls under varying pH values over a series of ten 30 min exposures at 95 °C. Migration was greater during the first 30 min exposure and at the lowest pH (3.0) value compared to other higher values up to pH 11. Additionally, there was a significant difference in melamine migration between the two brands of bowls. It should be stressed that the exposure temperature/period is beyond what would be encountered during normal food preparation scenarios so migration values are likely higher than would typically be experienced.

Melamine migration was within the range of that seen in other studies under different test protocols. The fact that migration varies so much according to the brand indicates some inconsistency in the manufacturing process. Melamine migration from the two brands of bowls tested in this study do not exceed any of the known regulatory standards or guidelines, or even the more stringent guidelines suggested by Hsieh et al. (2009). Based on these findings, a child would have to eat an unrealistic amount of food from containers with this construction to be at risk for melamine exposure from these two products. Furthermore, these data indicate that circumneutral pH foods pose a much smaller risk for exposure.

References

Bradley EL, Boughtflower V, Smith TL, Speck DR, Castle L (2005) Survey of the migration of melamine and formaldehyde from melamine food contact articles available on the UK market. Food Addit Contam A 22(6):597–606

Bradley EL, Castle L, Day JS, Ebner I, Ehlert K, Helling R, Koster S, Leak J, Pfaff K (2010) Comparison of the migration of melamine from melamine-formaldehyde plastics (‘melware’) into various food simulants and foods themselves. Food Addit Contam A 27(12):1755–1764

Bridges A (2007) Recall expanded to some dry cat food., http://www.denverpost.com/ci_5556666. Accessed 18 March 2015

Chen B, Liu X, Li S, Zhou Y, Jiang Q (2009) Melamine exposure assessment in children with nephrolithiasis. Pediatr Nephrol 24:2065–2067

Chien C, Wu C, Liu C, Chen B, Huang S, Yi C, Chang A, Lee H, Pan C, Wu W, Shen J, Chang M, Huang C, Shiea J, Hsieh T, Wu M (2011) High melamine migration in daily-use melamine-made tableware. J Hazard Mater 188:350–356

Chik Z, Mohammad Haron DE, Ahmad ED, Taha H, Mustafa AM (2011) Analysis of melamine migration from melamine food contact articles. Food Addit Contam A 28(7):967–973

European Commission (EC) (2011) Commission Regulation (EU) No. 1282/2011 of 28 November 2011. Amending and Correcting Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food

European Commission (EC) (2012) Food and Feed Safety. Food contact materials-EU legislation., http://ec.europa.eu/food/food/chemicalsafety/foodcontact/eu_legisl_en.htm. Accessed 18 March 2015

European Commission (EC) (2014) Union Guidelines on Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food., http://ec.europa.eu/food/food/chemicalsafety/foodcontact/docs/10-2011_plastic_guidance_en.pdf. Accessed 01 June 2015

European Food Safety Authority (EFSA) (2008) Statement of EFSA on risks for public health due to the presences of melamine in infant milk and other milk products in China. EFSA Jl 807:1–10

European Food Safety Authority (EFSA) (2010a) Scientific opinion on melamine in food and feed. EFSA J 8(4):1573

European Food Safety Authority (EFSA) (2010b) EFSA reduces tolerable intake level for melamine., http://www.efsa.europa.eu/en/press/news/contam100413.htm. Accessed 30 April 2015

Food and Agriculture Organization of the United Nations (FAO) (2012) UN strengthens regulations on melamine, seafood, melons, dried figs and labeling., Retrieved from http://www.fao.org/news/story/en/item/150771/icode/. Accessed 18 March 2015

Garber EA (2008) Detection of melamine using commercial enzyme-linked immunosorbent assay technology. J Food Protect 71(3):590–594

Gibbons R, Coleman D (2001) Statistical methods for detection and quantification of environmental contamination. York, John Wiley & Sons New

Guan N, Fan Q, Ding J, Zhao Y, Lu J, Ai Y, Xu G, Zhu S, Yao C, Jiang L, Miao J, Zhang H, Zhao D, Liu X, Yao Y (2009) Melamine-contaminated powdered formula and urolithiasis in young children. N Engl J Med 360(11):1067–1074

Hau HK, Kwan TH, Li PK (2009) Melamine toxicity and the kidney. J Am Soc Nephrol 20:245–250

Hsieh DPH, Chiang CF, Chiang PH, Wen CP (2009) Toxicological analysis points to a lower tolerable daily intake of melamine in food. Regul Toxicol Pharm 55:13–16

Hsu YF, Chen KT, Liu YW, Hsieh SH, Huang HY (2010) Determination of melamine and related triazine by-products ammeline, ammelide, and cyanuric acid by micellar electrokinetic chromatography. Anal Chim Acta 673:206–211

Ingelfinger JR (2008) Melamine and the global implications of food contamination. N Engl J Med 359:2745–2748

Ishiwata H, Inoue T, Tanimura A (1986) Migration of melamine and formaldehyde from tableware made of melamine resin. Food Addit Contam A 3(1):63–70

Jia B, Ouyang Y, Sodhi R, Hu B, Zhang T, Li J, Chen H (2011) Differentiation of human kidney stones induced by melamine and uric acid using surface desorption atmospheric pressure chemical ionization mass spectrometry. J Mass Spectrom 46:313–319

Li G, Jiao S, Yin X, Deng Y, Pang X, Wang Y (2010) The risk of melamine induced nephrolithiasis in young children starts a lower intake level than recommended by the WHO. Pediatr Nephrol 25:135–141

Liu CC, Wu CF, Chen BH, Huang SP, Goggins W, Lee HH, Chou YH, Wu WJ, Huang CH, Shiea J, Lee CH, Wu KY, Wu MT (2011) Low exposure to melamine increases the risk of urolithiasis in adults. Kidney Int 80:746–752

Lund KH, Petersen JH (2006) Migration of formaldehyde and melamine monomers from kitchen- and tableware made of melamine plastic. Food Addit Contam A 23(9):948–955

Skinner CG, Thomas JD, Osterloh JD (2010) Melamine toxicity. J Med Toxicol 6:50–55

Sun X, Shen L, Cong X, Zhu H, Lu J, He L (2011) Infrared spectroscopic analysis of urinary stones (including stones induced by melamine-contaminated milk powder) in 189 Chinese children. J Pediatr Surg 46:723–728

Tyan YC, Yang MH, Jong SB, Wang CK, Shiea J (2009) Melamine contamination. Anal Bioanal Chem 395:729–735

U.S. Department of Agriculture Food and Nutrition Service (2003) Food guide pyramid. Portion sizes and school-age children., http://www.fns.usda.gov/sites/default/files/fgp_sizes.pdf. Accessed 8 May 2015

U.S. Department of Health and Human Services (1983) National Toxicology Program. NTP Technical Report on the Carcinogenesis Bioassay of Melamine (CAS No. 108-78-1) in F344/N Rats and BB6C3F1 Mice (Feed Study)., NTP-81-86. NIH Publication No. 83–2501. NTP TR 245

United States Food and Drug Administration (FDA) (2009a) Melamine pet food recall–frequently asked questions., http://www.fda.gov/AnimalVeterinary/SafetyHealth/RecallsWithdrawals/ucm129932.htm. Accessed 18 March 2015

United States Food and Drug Administration (FDA) (2009b) Update: interim safety and risk assessment of melamine and its analogues in food for humans., http://www.fda.gov/food/foodborneillnesscontaminants/chemicalcontaminants/ucm164520.htm Accessed 30 April 2015

United States Food and Drug Administration (FDA) (2012) Bad bug book, foodborne pathogenic microorganisms and natural toxins, 2nd edn., http://www.fda.gov/downloads/Food/FoodborneIllnessContaminants/UCM297627.pdf Accessed 01 June 2015

World Health Organization (WHO) (2008) Experts set tolerable level for melamine intake., http://www.who.int/mediacentre/news/releases/2008/pr48/en/ Accessed 30 April 2015

World Health Organization (WHO) (2009a) Toxicological and health aspects of melamine and cyanuric acid., http://www.who.int/foodsafety/publications/chem/Melamine_report09.pdf. Accessed 18 March 2015

World Health Organization (WHO) (2009b) Background paper on the chemistry of melamine alone and in combination with related compounds., http://www.who.int/foodsafety/fs_management/Melamine_2.pdf. Accessed 18 March 2015

Wu Y, Zhang Y (2013) Analytical chemistry, toxicology, epidemiology and health impact assessment of melamine in infant formula: Recent progress and developments. Food Chem Toxicol 56:325–335

Wu CC, Hsieh TJ, Chen BH, Liu CC, Wu MT (2013) A crossover study of noodle soup consumption in melamine bowls and total melamine excretion in urine. JAMA Int Med 173(4):317–319

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

RL participated in the design of the study and drafted the manuscript. HH participated in the design of the study and carried out the majority of the laboratory experiment. DJ conducted the statistical analysis of the data and participated in the project design. JB conducted laboratory analysis of samples and assisted in the review of the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lynch, R.A., Hollen, H., Johnson, D.L. et al. The effects of pH on the migration of melamine from children’s bowls. FoodContamination 2, 9 (2015). https://doi.org/10.1186/s40550-015-0017-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40550-015-0017-z