Abstract

Background

Blackcurrant is a rich source of polyphenols with proven physiological activity, that have lately been classified as emerging prebiotics, making its extracts suitable for application in functional food and bioactive cosmetics. However, these biomolecules are trapped in cell wall structures and nowadays, enzymatic hydrolysis is recognised as powerful tool for extraction efficiency improvement in an environmentally sound manner. This study aimed to optimize enzyme-assisted extraction to maximize yields of blackcurrant polyphenols. In addition, their prebiotic potential was tested by examining their influence on typical skin microbiota representatives as model microorganisms—beneficial coagulase-negative Staphylococcus epidermidis and two opportunistic pathogens, Staphylococcus aureus and Cutibacterium acnes.

Results

Among four examined commercial enzyme preparations, Viscozyme® L and Rohapect® MC, demonstrated the highest potential as extraction enhancers by increasing antioxidant activity, total polyphenol, and flavonoid contents. Furthermore, their synergetic effect enabled 95.3% increase in polyphenol concentration compared to conventional extraction with a maximum of 27.6 mg gallic acid equivalents (GAE)/g dry matter (DM) at a total enzyme concentration of 0.05 mL/g DM (Viscozyme® L to Rohapect® MC ratio 2:1) after 60 min. HPLC profiles of two samples showed differences in polyphenol composition indicating simultaneous extraction–biotransformation. At a concentration of 0.025 mg GAE/mL, PAS (prebiotic activity score) values were 0.096 and 0.172 for conventionally and enzymatically obtained extract, respectively. Moderate inhibitory effect of optimal extract concentration on Cutibacterium acnes was shown, as well. Hydrogel prepared with optimal extract concentration showed improved hydration effect, decreased irritability and increased dermatological compatibility comparing to basic formulation.

Conclusions

Overall results demonstrated that blackcurrant extract obtained under optimized conditions using enzymes possesses an emerging prebiotic potential for selective skin microbiota stimulation.

Graphical Abstract

Similar content being viewed by others

Background

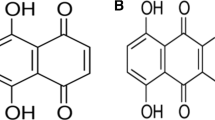

With the growing awareness of producers and consumers about current environmental problems, novel, more efficient technologies for green products with ingredients derived from plant material are becoming indispensable. The plant kingdom is a rich source of phytochemicals with significant physiological activities, desirable for application in food, cosmetics, and pharmaceuticals [1, 2]. Among them, polyphenols are being of particular interest, representing a diverse group of secondary metabolites, divided into several different classes depending on the number of rings and the structural elements associated with the rings, namely, polyphenolic acids, flavonoids, stilbenes and lignin [3]. Their benefits for human health are still being discovered, but the current research indicates that a polyphenols-rich diet protects against the development of certain types of cancer, diabetes, cardiovascular diseases, gastrointestinal disorders, and so on [3, 4]. In addition to improving health, polyphenols are employed in the food industry to prevent the oxidation of other valuable food components, but also as natural colorants and flavorants, enhancing the quality of the final products [5]. The cosmetic and dermatological significance of polyphenolic compounds stems from their application as antioxidants, which minimize oxidative stress-induced skin damage, making them a good alternative for treating and preventing premature skin aging [6, 7].

To isolate and purify these health-promoting bioactives from the raw materials, the extraction process is required. Traditional solvent-based extraction methods are frequently utilized due to easy performance but have a low extraction yield of compounds that are covalently bound to the cell wall matrix [5]. As a result, innovative extraction strategies, such as enzyme-assisted extraction, have been developed to increase the extraction efficiency of phytochemicals from different plant parts. Enzyme-assisted extraction is based on the use of carbohydrate-hydrolysing enzymes (such as cellulases, hemicellulases, pectinases, amylases, and glucanases [8, 9]), which disrupt polysaccharide components of the cell wall (cellulose, hemicellulose, pectin, and glucan), thereby enable the penetration of solvents and facilitate diffusion of biomolecules. The key benefits of this extraction method are the absence of hazardous solvents, the mild reaction conditions, the lower energy consumption, and the ability to achieve the higher recovery of bioactive compounds in a shorter time thanks to high specificity and regioselectivity of enzymatic reactions [5, 8, 9]. The effectiveness of enzyme-assisted extraction is influenced by a number of factors and the optimal conditions for enzyme-assisted extraction should be defined for each plant material to maximize the quantity of polyphenols [5].

In this study, enzyme-assisted extraction was applied and optimized to increase the yield of polyphenolic compounds from blackcurrant, with special attention given to the utilization of the skin prebiotic potential of this plant. The blackcurrant (Ribes nigrum L.) predominantly contains flavonoids, specifically anthocyanins and their aglycone forms, and there are reports that it is a source of the highest amount of phytochemicals with potent antioxidant, antimicrobial, and anti-inflammatory activities capable of improving overall human health, compared to the other berries [10, 11]. Recently, polyphenolic compounds have been recognized as potential gut prebiotics, which stands for substances that are selectively utilized by host microorganisms, exhibiting positive effect on the composition of human microbiota and consequently beneficial influence on human health [12, 13]. Besides gut, skin microbiota composition is attracting increased attention of scientist, companies and consumers; therefore, International Cooperation on Cosmetics Regulation (ICCR) defined cosmetics prebiotics as “substrates added to a cosmetic product to be utilized by the host microbiome, with an intended cosmetic benefit to the host” [14]. There is evidence that blackcurrant is a good candidate to be used as a source of skin prebiotics, since it was observed that it inhibits the inflammation-causing bacteria without affecting beneficial species [15]. For this reason, in addition to selecting enzymes and conditions of enzyme-assisted extraction with optimum effect on polyphenol yield and antioxidant activity of extracts, their potential skin prebiotic activity was also investigated in this study. This was performed by measuring the effect of the obtained blackcurrant extracts on the growth of two skin microbiota representatives, commensal bacterium Staphylococcus epidermidis and an opportunistic pathogen Staphylococcus aureus. Furthermore, the effect of different extracts polyphenol dosage was examined to determine the ideal polyphenol concentration for potential application in prebiotic-containing skin products. Influence of optimized extract concentration on Cutibacterium acnes growth, as another important opportunistic skin pathogen, was examined as well. Finally, skin irritability and hydration potential of the extract incorporated in model formulation was assessed for more detailed evaluation of the prospects for future cosmetic application.

Materials and methods

Materials

Lyophilized blackcurrant was supplied by Drenovac d.o.o., Arilje, Serbia. Analytical grade chemicals, including sodium acetate trihydrate (CH3COONa·3H2O), sodium chloride (NaCl), sodium carbonate (Na2CO3), aluminium chloride (AlCl3), iron(III) chloride hexahydrate (FeCl3·6H2O) and iron(II) sulphate (FeSO4) were obtained from Centrohem (Stara Pazova, Serbia). HPLC grade solvents (methanol and water), formic acid, trifluoroacetic acid (TFA), 3,5-dinitrosalicylic acid and 2,4,6-tris(2-pyridyl)-s-triazine (TPTZ) were purchased from Sigma-Aldrich (Schnelldorf, Germany). Anthocyanin HPLC standards, delphinidin 3-O-rutinoside chloride, cyanidin 3-O-rutinoside chloride and cyanidin 3-O-glucoside chloride, were purchased from Carl Roth (Karlsruhe, Germany). Gallic acid, quercetin, and glucose were obtained from Merck (Darmstadt, Germany). Folin–Ciocalteu phenol reagent was from Carlo Erba (Arese, Italy). Glacial acetic acid (CH3COOH) and hydrochloric acid (HCl) were from Zorka Pharma (Šabac, Serbia). Trypticase soy broth, agar, and yeast extract were purchased from the Institute Torlak (Belgrade, Serbia), while Mueller Hinton broth and brain heart infusion broth were from Becton, Dickinson and Company Sparks (Le Pont de Claix, France) and Xeboic Diagnostics GmbH (Dusseldorf, Germany), respectively. Commercial enzyme preparations Viscozyme® L, Pectinex® Ultra SP-L and Cellic® CTec3 HS were obtained from Novozymes (Bagsvaerd, Denmark), while Rohapect® MC was a kind donation from AB Enzymes (Darmstadt, Germany). Bacterial strains Staphylococcus epidermidis DSM 20044 was from Leibniz Institute DSMZ (German Collection of Microorganisms and Cell Culture GmbH, Braunschweig, Germany), while Staphylococcus aureus ATCC 25923 and Cutibacterium acnes ATCC 11827 were purchased from American-Type Culture Collection (Rockville, Maryland, USA), respectively. Aristoflex AVC (ammonium acryloyldimethyltaurate/VP copolymer; Clariant International Ltd., Basel, Switzerland) was used for the preparation of hydrogels. Zea mays protein, sodium dodecyl sulphate (SDS) and isopropyl myristate were purchased from Sigma-Aldrich Chemie GmbH (Steinheim, Germany) and used for Zein and red blood cell (RBC) assays.

The optimization of enzyme-assisted extraction

The optimization of enzyme-assisted extraction of polyphenols from lyophilized blackcurrant was performed using four commercial enzyme preparations—Viscozyme® L, Pectinex® Ultra SP-L, Rohapect® MC, and Cellic® CTec3 HS. The blackcurrant was mixed with acetate buffer (pH 4.5) at different solid–liquid ratios and various enzyme concentrations, defined for each experiment individually, and incubated at 50 °C with shaking at 150 rpm. The temperature and pH value were selected based on the manufacturer's recommendation. During extraction process, samples were taken for determining total reducing sugar, polyphenol and flavonoid contents, and antioxidant activity. After the hydrolysis, which lasted 60–120 min, the enzymes were deactivated by heating the sample at 100 °C for 5 min. The control sample was prepared in the same manner but without enzymes. All prepared extracts were stored at − 20 °C until analysis.

Total reducing sugars content determination

The total reducing sugar content in extracts was determined by the 3,5-dinitrosalicylic acid (DNS) method [16]. Briefly, 0.25 mL of properly diluted sample was mixed with 0.25 mL of freshly prepared DNS reagent and treated in boiling water for 5 min. After the addition of 2 mL of water, the absorbances were measured at 540 nm against the blank. The blank was prepared in the same manner using water instead of a sample. The concentration of reducing sugars released in extracts was determined using a glucose standard curve and the results were expressed as millimole glucose equivalents (mmol GE) per gram of dry matter (DM) of lyophilized blackcurrant.

Total polyphenol content determination

The total polyphenol content in extracts was determined by the modified Folin–Ciocalteu method [17]. Briefly, 50 µL of the diluted extract was added to 0.25 mL of Folin–Ciocalteu reagent, 1 mL of 15% Na2CO3 solution, and 3.7 mL of distilled water. The mixture was vortexed for 1 min and incubated in the dark for 2 h. The absorbance of samples was measured spectrophotometrically at the wavelength of 750 nm using water incubated with all reagents instead of extracts as a blank sample. Gallic acid was used for the construction of the calibration curve. The results were expressed as milligrams of gallic acid equivalents (GAE) per gram of dry matter (DM) of lyophilized blackcurrant.

Total flavonoid content determination

The total flavonoid content in extracts was determined by the Aluminium chloride colorimetric method [17]. An aliquot of 1 mL of adequate extract dilution was mixed with 1 mL of 2% AlCl3. After 10 min of incubation in dark, the absorbances of samples were measured spectrophotometrically at 410 nm against blank sample containing water instead of extract. A standard graph was plotted for quercetin and the results were expressed as milligrams of quercetin equivalents (QE) per gram of dry matter (DM) of lyophilized blackcurrant.

Ferric reducing antioxidant power (FRAP) assay

For the evaluation of the antioxidant activity of extracts, the FRAP method was used [18]. The FRAP reagent was prepared by mixing 300 mM Na-acetate buffer at pH 3.6, 10 mM TPTZ dissolved in 40 mM HCl and 20 mM FeCl3·3H20 solution in a ratio 10:1:1 (v/v/v), respectively. Then, 30 µL of the diluted extract was added to 900 µL of FRAP reagent and vortexed for 30 s. After 5 min incubation in the dark, the absorbance of samples was measured at 593 nm against blank sample containing FRAP reagent without extract. The calibration curve was plotted using FeSO4 and the results were expressed in millimole of Fe2+ ions per gram of dry matter (DM).

HPLC analysis

Quantitative analyses of samples and anthocyanin standards were done by Dionex Ultimate 3000 Thermo Scientific (Waltham, USA) high-performance liquid chromatography (HPLC) system and a reverse phase column (ZORBAX Eclipse Plus C18, 4.6150 mm, 5 µm). The mobile phase was composed of solvent (A) H2O:TFA = 100:0.1% and solvent (B) MeOH:TFA = 100:0.1%. It was conducted by gradient elution in the following way: 0–5 min isocratic 5% B, 5–45 min gradient from 5% to 50% B, then 45–55 min isocratic 50% B, 55–55.1 min gradient from 50% to 5% B, 55.1–60 min isocratic 5% B.A flow rate of 1 mL/min was used and the column was thermostated at 45 °C. The injection volume of the samples was 15 µL. Detection of products and standards was carried out by a UV detector at 520 nm.

Assessment of extracts impact on the bacterial growth

The effect of investigated extracts was evaluated on three gram-positive bacterial strains: S. epidermidis, S. aureus and C. acnes. For both Staphylococci bacteria, inoculums were prepared by transferring one colony to tryptic soy broth containing 0.6% (w/v) yeast extract (TSBY) and allowed to grow at 37 °C with agitation overnight. The inoculum of C. acnes was prepared in brain heart infusion broth and incubated overnight at 37 °C under anaerobic condition.

The effect of blackcurrant extracts on Staphylococci bacteria growth was tested in liquid cultures spectrophotometrically or using the plate count method. Briefly, extracts were added to the 20 mL of fresh TSBY to obtain final polyphenols concentration of 0.025–0.1 mg GAE per mL of liquid broth. Then, an overnight inoculum of S. epidermidis or S. aureus was added to the growth medium to achieve a final concentration of 107 CFU/mL (based on a standard curve relating colony-forming units and optical density at 600 nm) and incubated at 37 °C with constant shaking at 150 rpm. The TSBY inoculated with bacteria and appropriate volume of buffer used for extraction served as control samples. Samples were taken, diluted, and placed on a tryptic soy agar plate with yeast extract after 24 h. The effect of the extracts on the tested bacteria was evaluated after 24 h of incubation at 37 °C by CFU counting. For optical density determination, aliquots were taken from liquid cultures and absorbance measurements were done at 600 nm against TSBY as control. Experiments with C. acnes were conducted using a spectrophotometric iMark™ microplate reader (Bio-Rad, Hercules, USA). A 96-well microtiter plate was filled with predefined amounts of blackcurrant extract, Mueller Hinton (MH) broth and inoculum, resulting in a final well volume of 200 μL. The positive control was MH broth containing inoculum, while the negative control was only MH broth. The optical density of all wells was measured at 595 nm immediately after inoculation and after 24 h of incubation.

The results of OD measurements were expressed as the percentage change in bacterial growth between the treated and control samples, calculated using Eq. 1. Positive values indicate growth stimulation, while negative values indicate growth inhibition:

The results of CFU counting were used to calculate Prebiotic activity score (PAS) employing Eq. 2, previously reported by Huebner et al., with slight modifications [19]. Although PAS was initially designed for gut microbiota, this approach was adopted to compare the growth of beneficial cutaneous bacteria (S. epidermidis) in the presence and absence of prebiotics, in relation to the growth of skin opportunistic pathogen (S. aureus) under the same conditions. PAS values greater than zero indicate that the examined compound have positive effect on two microorganisms’ ratio, highlighting its prebiotic potential. Conversely, negative PAS values suggest a better growth stimulation of pathogenic bacteria, while values equal to zero indicate that the extract has no effect on bacterial growth:

where SEP24 and SEP0 is log10 CFU/mL of S. epidermidis with extract after 24 h and 0 h of fermentation, respectively. SEC24 and SEC0 is the log10 CFU/mL of S. epidermidis without extracts (control sample), after 24 h and 0 h of fermentation, respectively. SAP24, SAP0 and SAC24, SAC0 are the S. aureus log10 CFU/mL with and without extracts after 24 h and 0 h, respectively.

Preparation of hydrogel

Water solution of commercial hydrogel Aristoflex® AVC in a concentration of 2% (w/v) and predefined amount of blackcurrant extract were mixed on magnetic stirrer at 800 rpm for 5 min until gel formation. Control formulation (without added extract) was prepared in the same way and further analysed in parallel with hydrogels enriched with extract.

Transepidermal water loss (TEWL)

For measuring transepidermal water loss, a condensed-type closed chamber (Aquaflux Biox System Ltd., London, U.K.) was used in accordance with the manufacturer’s instructions. The method determines the evaporation rate of water from the skin surface or a model system based on the following equation:

where dm/dt is the water evaporation rate, D is the diffusion constant, A is the surface, p is the water vapour pressure and x is the distance of the measuring points. The change in water vapor pressure over the surface was measured using a 1 mm Teflon semipermeable membrane, both with applied hydrogel and without applied cream (control sample), every 2 h during the period of 24 h. For the results processing, the surface evaporation–sorption isotherm model was applied and the results are presented as the time curve of the evaporation flux (g/m2 h).

Test of irritability (Zein test)

The Zein irritability test was done according to Invittox Protocol No. 26. [20, 21], in which 1 g of Zea mays protein is solubilized in 10 g/L cosmetics formulation sample (dissolved in demineralized water, 18 MΩ). The protein and hydrogel were mixed using a vibro mixer (SM-30, Edmund Buhler GmbH) for 60 min at 100 rpm. The amount of protein that was dissolved by a sample was determined by Kjeldahl method using a UDK 159 automatic Kjeldahl analyzer (Velp Scientifica, Italy). The results were expressed as Zein numbers—milligrams of nitrogen in 100 mL of sample solution. The values of the Zein number should be less than 5 for skin care products, whereas the products with very low irritability have results lower than 1 [21].

RBC test

The red blood cell (RBC) assay was performed according to the procedure described by Lagarto et al. based on Invittox Protocol No. 37. [22]. To isolate red blood cells, citrated blood samples obtained from rats were centrifuged. Aliquots of RBC suspension with concentrations of the cells ~ 7 × 109 cells/mL and 9.5 g/L test substances were dissolved in PBS pH 7.4 and incubated for 10 min at 25 °C temperature. After incubation, samples were centrifuged during 1 min at 9000 rpm. As an internal standard, SDS to a concentration of 0.75 g/L was used. The degree of haemolysis was determined by comparing supernatants absorbance at 560 nm with that of control samples totally haemolysed with distilled water, while the half-maximal concentration (H50) was calculated based on the concentration–response curve. Haemoglobin release, as an indicator of protein denaturation, was monitored spectrophotometrically (Thermo Scientific Evolution 600 spectrophotometer) in the wavelength range from 450 to 700 nm. Product irritancy classification was done based on the relationship between the haemolytic (H50) and denaturing potential (denaturation index, DI) L/D ratio as non-irritant (> 100), weak irritant (> 10), moderate irritant (> 1), irritant (> 0.19) and very irritant (< 0.1).

Statistical analysis

All experiments were repeated twice, with the exception of the plate count experiment, which was conducted in triplicate. The results of experiments were provided as mean ± standard deviation. To establish the statistical significance of mean value differences for multiple comparisons of the plate count (CFU) results (a one-way analysis of variance (ANOVA) followed by a post hoc Tuckey’s test) OriginPro 8.5 was used. Differences at p < 0.05 were regarded as significant.

Results and discussion

Enzyme-assisted extraction

Selection of enzyme preparations

The enzyme-assisted extraction of blackcurrant was performed using four different commercial enzyme preparations Viscozyme® L, Pectinex® Ultra SP-L, Cellic® CTec3 HS, and Rohapect® MC, all of them being carbohydrate-degrading enzyme mixtures (with different primary and side activities) required for the breakdown of the plant cell wall [23,24,25,26,27]. As indicators of extraction process efficiency, reducing sugar, polyphenol, and flavonoid contents, as well as extract antioxidant activity were monitored and presented in Fig. 1.

Total reducing sugars (a), polyphenol (b), and flavonoid (c) contents and antioxidant activity (d) of blackcurrant extract obtained without enzyme and with four different enzyme preparations: Pectinex® Ultra SP-L, Viscozyme® L, Cellic® CTec3 HS and Rohapect® MC. Enzyme-assisted extraction was performed at 0.4 mL/g DM enzyme concentration. Experiment was conducted in duplicate

The enzymatic hydrolysis increased the reducing sugar content (Fig. 1a) in all of the samples compared to the untreated one (control sample), which confirms that hydrolysis of carbohydrate components of the cell wall occurred. The highest efficiency in cell wall degradation was achieved with Viscozyme® L. Steep increase in reducing sugar concentration occurs during the first hour in all enzyme-assisted extractions, and there were nonsignificant changes in second hour. In addition, the concentration of extracted compounds and antioxidant activities plateaued after 1 h (Fig. 1b–d), hence it was chosen as the optimal extraction time. Thus, after 1 h of enzyme-assisted extraction, the total polyphenol contents were 13.29 mg, 14.77 mg, 17.75 mgand 19.50 mg GAE/g DM with Pectinex® Ultra SP-L SP-Ultra, Cellic® CTec3 HS, Viscozyme® L and Rohapect® MC, respectively, which is 1.4–2.1 times higher than control. The lowest flavonoid amount was achieved by Cellic® CTec3 HS (1.85 mg QE/g DM), while the highest was obtained with Rohapect® MC (2.54 mg QE/g DM), which is 26.7% and 74.0%, respectively, greater than the control (1.46 mg QE/g DM). As result of increased total polyphenol and flavonoid contents, the antioxidant activity in the extracts was increased, as well. It was improved by 100% (from 0.13 to 0.26 mmol Fe2+/g DM) with the most effective enzyme preparation used, Rohapect® MC, while second best was Viscozyme® L with 63.4% increased antioxidant activity. It is worth mentioning that this is the first time that Rohapect® MC was used and proven as an efficient polyphenol extraction enhancer.

The different hydrolytic activities and modes of action of enzyme preparations and the composition of blackcurrant cell wall can be used to explain differences in their efficacy. Blackcurrant cell wall polysaccharides comprise cellulose, hemicellulose (dominated by xylans, xyloglucans, and galactomannans), and a significant amount of pectin (with the ratio of partially methyl esterified homopolygalacturonan being twice that of rhamnogalacturonan I as well as a minor proportion of rhamnogalacturonan II) [28]. The key enzyme activity of Viscozyme® L is endo-β-glucanase that catalyses hydrolysis of (1,3)- or (1,4)-linkages in β-d-glucans present in cellulose and xyloglucans. In addition, it has the side activities of xylanases, hemicellulases, pectinases, and arabinanases, which further increase the degree of cell wall disintegration in blackcurrant [23, 29]. Several studies of various berry pomace subjected to extraction aided by Viscozyme® L revealed significantly greater polyphenol and sugar content yields. In light of this, it was reported that hydrolysis of cranberry pomace under the same extraction conditions as in the current study (solid–liquid ratio 1:10 g/mL, 50 °C, 1 h) and ten times lower concentration of Viscozyme® L (0.04 mL/g DM) resulted in 11% better polyphenol recovery and 3.6 folds higher oligosaccharides content than control [30]. When Viscozyme® L was used for enzyme-assisted extraction of bilberry pomace (at 46 °C, 1 h, and 2 active units of Viscozyme® L/g) 30% and 36.5% more polyphenols and saccharides, respectively, were obtained compared to control [31]. Both studies noted that enzymatic hydrolysis of glucan-type hemicellulose polymers in pomaces increases the level of sugars in extracts indicating that the Viscozyme® L has high cellulase activity. Thus, blackcurrant cell wall (hemi)cellulose degradation seems to be important, but not crucial for high reducing sugar level obtained by Viscozyme® L-assisted extraction, since cellulase and hemicellulase complex, Cellic® CTec3 HS, gave significantly lower reducing sugar concentration. Similarly, two tested pectinolytic enzyme mixtures—Pectinex® Ultra SP-L (primarily endopolygalacturonase [32]) and Rohapect® MC (primarily pectin (methyl)esterase with significant pectin lyase activity [26]) demonstrated different efficiency in blackcurrant cell wall disruption and polyphenols extraction. In general, pectinolytic enzymes aid in the disintegration of the cell middle lamella and primary wall, thereby increasing reducing sugar content and releasing polyphenolic compounds located in the cell vacuoles [29]. Using Rohapect® MC only 15.1% more reducing sugars were liberated compared to Pectinex® Ultra SP-L, but polyphenol content was 46.7% higher. It can be assumed that the main reason for such results is low pectin methylesterase activity (11.5 times lower compared to polygalacturonase) in the Pectinex® Ultra SP-L mixture, as endopolygalacturonase is unable to attack cell wall pectin efficiently without concurrent demethylation of the pectin [32]. Having taken all results into account, it can be concluded that the most efficient preparations for enzyme-aided extraction of blackcurrant are Rohapect® MC and Viscozyme® L, so further optimization was performed with these two enzymes.

Determination of optimal conditions for enzyme-assisted extraction

Further experiments were focused on examining the effect of solid–liquid ratio and enzyme dosage on enzyme-assisted extraction with Rohapect® MC and Viscozyme® L. Three solid–liquid ratios (1:4 g/mL, 1:10 g/mL, and 1:40 g/mL) were tested for extraction efficiency and obtained results are shown in Fig. 2. As can be seen, polyphenol and reducing sugar content increase as the mixture dilution increases. This is in accordance with the mass transfer principles, because a higher solvent amount provides a lower concentration in bulk fluid and consequently higher concentration gradient between the solid and the bulk of the solvent [33]. However, it is notable that the highest flavonoid content and antioxidative capacity were achieved for a solid–liquid ratio 1:10 g/mL with Rohapect® MC, while this solid–liquid ratio enabled highest flavonoid yield with Viscozyme® L. Others observed a similar trend demonstrating that an increase of solid–liquid ratio does not necessarily lead to an increase in the extraction yield when trans-β-carotene was extracted from citrus peels [34]. Interestingly, at a solid–liquid ratio of 1:10 g/mL Rohapect® MC treatment gave higher reducing sugar and polyphenol content, while at 1:40 g/mL ratio, Viscozyme® L-assisted extraction was more efficient. Given that a solid–liquid ratio of 1:10 g/mL yielded satisfactory results and that more concentrated extracts are obtained, it was chosen for further examinations.

Comparison of extraction efficiency assisted by Viscozyme® L and Rohapect® MC at different solid–liquid ratios (1:4 g/mL, 1:10 g/mL, and 1:40 g/mL) on the released total reducing sugar (a), polyphenol (b) and flavonoid (c) contents, and antioxidant activity (d). Experiments were conducted at 0.4 mL/g DM enzyme concentration. Experiment was conducted in duplicate

In terms of the enzyme concentration, the enzyme dose of 0.4 mL/g DM is considerably greater when compared to those used in previous investigations for plant cell wall degradation [30,31,32]. However, it enabled the selection of the most suitable preparations and amount of solvent for which further concentration optimization was performed to increase process cost efficiency. Therefore, the influence of Viscozyme® L and Rohapect® MC dosage (0.001–0.1 mL/g DM) on the course of the blackcurrant polyphenol extraction was examined. The effect of different concentrations of enzyme preparations on the polyphenol levels is shown in Fig. 3.

The results demonstrated that all concentrations of both preparations showed notable effectiveness in enhancing polyphenol extraction efficiency. Regarding Viscozyme® L, it can be noted (Fig. 3a) as the concentration rose from 0.001 to 0.01 mL/g DM, 0.05 mL/g DM, and 0.1 mL/g DM, respectively, after 120 min, polyphenol levels increased by 12.1%, 15.0%, and 15.9%. Very slight variation in yields suggests that the enzyme at a concentration of 0.01 mL/g DM was already saturated with the substrate, and that further increase in concentration was not needed, since it had no effect on enzymatic hydrolysis. When it comes to Rohapect® MC, the polyphenol yield increased with increasing enzyme concentration until a value of 0.01 mL/g DM was reached, after which it stayed almost unchanged.

A comparison of total polyphenol and sugar content in blackcurrant extracts obtained after extraction aided by Viscozyme® L and Rohapect® MC at a concentration of 0.01 and 0.05 mL/g DM is shown in Fig. 4. As it can be seen, both concentrations of the cellulolytic preparation Viscozyme® L exhibited a higher rate of hydrolysis of blackcurrant polysaccharides than Rohapect® MC and attained a similar sugar level of about 1.8 mmol GE/g DM after only 60 min. This leads to the conclusion that Viscozyme® L is superior in breaking down the cell wall even at lower concentrations than Rohapect® MC. On the other hand, when Rohapect® MC was applied higher polyphenol levels were achieved than with Viscozyme® L at both tested concentrations, indicating that the efficiency of active compound extraction is not simply proportional to the extent of cell wall degradation. That may be because plant material also contains insoluble-bound polyphenols, in addition to soluble polyphenols. While soluble phenolics are known to be trapped in plant cell vacuoles and can be successfully extracted after cell wall disintegration, insoluble phenolic compounds are covalently linked to cell wall components, such as cellulose, hemicellulose, arabinoxylans, structural protein, and pectin, through ester, ether or carbon–carbon bond, and it is necessary to break these bonds to liberate the polyphenols [35, 36]. Hence, it can be assumed that the enzyme activities including pectin (methyl)esterase activity of Rohapect® MC are responsible for breaking down pectin as well as covalent bonds between polyphenols and the cell wall contributing to a higher content of polyphenols. Since no notable significant improvement was accomplished using higher amounts of biocatalyst, the application of enzyme concentrations above 0.01 mL/g DM was not justified.

Comparison of total reducing sugar (a) and total polyphenol (b) contents in blackcurrant extracts obtained after enzyme-assisted extraction with Viscozyme® L and Rohapect® MC at a concentration of 0.01 and 0.05 mL/g DM. The extract without enzyme served as control. Experiments were performed at solid–liquid ratio of 1:10 g/mL. Experiment was conducted in duplicate

Since the difference in composition and modes of action of the enzymes included in preparations Rohapect® MC and Viscozyme® L is most probably responsible for the observed result variations, as the last part of this stage of the experiment, the combined effect of two enzymes at a ratio of Viscozyme® L:Rohapect® MC = 1:1, 2:1, 1:2 and a total concentration of enzyme of 0.01 ml/g DM and 0.05 ml/g DM on the course of the extraction were tested. The progress of enzyme-assisted extraction was monitored by the yields of reducing sugar and polyphenol content, which are shown in Fig. 5. According to presented data of the total concentration of reducing sugars, it seems that these enzyme combinations are able to release higher sugar amounts comparing to individual enzymes, especially when it comes to Rohapect® MC at 0.01 mL/g DM concentration. This suggests that the simultaneous breaking of glycoside and ester linkages allows more efficient hydrolysis of the plant cell wall. As already mentioned, the cell wall disruption facilitates the diffusion of molecules, and thus the extraction. It can be seen that combined enzyme application enabled higher polyphenol content compared to single preparations at the same overall concentration, as well. Polyphenol content was additionally increased when two enzymes were used at a total concentration of 0.05 mL/g DM, while prolonged extraction did not lead to significant improvements. In that way, a maximum of 27.6 mg GAE/g DM was extracted at Viscozyme® L to Rohapect® MC 2:1 ratio after 60 min. For comparison, the effect of a cellulase/pectinase mixture on the extraction of polyphenols from blackcurrant press cake was investigated by others. It was reported that the combined effect of cellulases with pectinesterase and polygalacturonase obtained higher polyphenol content than their individual activity, which is in accordance with the results obtained in the current study [37]. Further experiments dedicated to the examination of inhibitory/stimulatory effect on skin microbiota representatives were conducted using blackcurrant extracts obtained after 60 minat a total enzyme concentration of 0.05 mL/g DM (Viscozyme® L:Rohapect® MC = 2:1) as optimal conditions.

Comparison of total sugar (a) and total polyphenol (b) content in blackcurrant extracts obtained after enzyme-assisted extraction with a mixture of Viscozyme® L and Rohapect® MC (at a total concentration of 0.01 and 0.05 mL/g DM and different ratios) and with individual enzyme preparations, after 60 min and 120 min. Experiments were conducted at 1:10 g/mL solid–liquid ratio. Experiment was conducted in duplicate

Investigation of skin prebiotic activity of blackcurrant extracts

After determining the optimal parameters under which the proportions of polyphenolic compounds and antioxidant activity were maximized, the influence of the extracts obtained with Rohapect® MC and Viscozyme® L combination and untreated one, on the growth of two representatives of skin microbiota, S. aureus and S. epidermidis, was examined. Although S. aureus can be found on various locations of healthy skin and mucous membranes (e.g., nasal passages, throat, armpits and groin) without causing any harm, a weakened host immune system may result in an overgrowth of this bacterium, leading to reduced bacterial diversity or exacerbating various dermal diseases, such as atopic dermatitis, requiring antibiotic therapy. On the other hand, S. epidermidis might be regarded as a beneficial bacterium due to its ability to antagonize the pathogenic S. aureus through several biological mechanisms, contributing to the improvement of the skin condition [38,39,40,41]. The latest research indicates that polyphenols can act as prebiotics by increasing the number of beneficial microorganisms while simultaneously reducing pathogens, demonstrating how the interaction between microbiota and polyphenols can influence the host health [13, 42].

The impact of blackcurrant extracts on the growth of both bacteria was tested to select the best-performing polyphenol concentration (in terms of the extract addition as mg GAE per mL of growth medium) and the results are presented in Table 1 as the percentage of inhibition/stimulation of bacterial growth, measured as optical density at 600 nm (OD600). The preliminary screening revealed that both enzymatically treated and untreated extracts suppressed S. aureus at all tested polyphenol doses. The increasing polyphenol concentrations resulted in a dose-dependent inhibition effect on the growth of S. aureus and ranged from 2.7% to 22.7% for untreated sample and 6.1–25.6% for enzymatically treated extract. The antibacterial activity of polyphenols can be explained by several mechanisms of action (e.g., enzyme inactivation, damage of the bacterial cell wall, inhibition of biofilm formation), that may differ depending both on the structure of the polyphenol compounds and bacteria species [43, 44]. On the other hand, the lowest concentration of both extracts had a very mild effect on S. epidermidis, while a polyphenol concentration of 0.025 mg GAE/mL exhibited a notable stimulating effect on S. epidermidis growth, which diminished as polyphenol content increased. According to the analysis of variance (ANOVA followed by a post hoc Tuckey's test), the concentration of 0.025 mg GAE/mL of both extracts exhibited the highest stimulation of S. epidermidis, with simultaneous inhibition of S. aureus, while a further increase in polyphenols led to a significant growth reduction of both bacteria. Hence, based on this, it can be concluded that the polyphenol concentration of 0.025 mg GAE/mL had the most favourable effect on S. aureus and S. epidermidis rebalancing; therefore, it was selected for further testing by viable cell count method.

. Obtained results were expressed as PAS values to establish correlation between extract type and S. epidermidis/S. aureus ratio. ANOVA statistical analysis followed by post-hoc Tukey test showed statistically significant difference between PAS values obtained with two extracts (p < 0.05). Conventionally obtained extract showed moderate effect on S. epidermidis/S. aureus ratio (PAS value 0.096), while extract obtained in enzymatically assisted process demonstrated more pronounced positive effect (PAS value 0.172). The differences in influences between untreated and enzymatically treated extracts could be due to the release of different types and amounts of polyphenols or their possible modification during enzymatic hydrolysis. This assumption was confirmed by RP-HPLC, since chromatograms obtained when untreated and enzymatically treated samples were analysed had different profiles at 520 nm (Additional file 1: Fig. S1) Differences in anthocyanin composition can be seen at 520 nm, where it is evident that diglycosides (cyanidin rutinoside and delphinidin rutinoside) amount decreased, while corresponding monoglucosides concentration increased, indicating that simultaneous extraction and biotransformation occurred. It is possible that glycosyl hydrolases present in enzyme preparations break glycosidic bonds in anthocyanins and that formed monoglucosides demonstrate the altered effect on examined bacterial strains. This is in accordance with literature data, since alteration of several flavonoid glycosides effect on human microbiota representatives after partial deglycosylation was previously reported [45]. Variation in the polyphenol composition (at the same concentration of polyphenols) may, therefore, be responsible for the enhanced stimulation of S. epidermidis compared to the untreated sample, while inhibition of S. aureus growth was not significantly changed. In addition, it was previously proven that released carbohydrates can serve as nutrients for microorganisms and promote bacterial growth [30]. Therefore, the positive value of prebiotic activity score that was demonstrated by blackcurrant extract may be the result of the combined effect of different biomolecules present in the extract.

After determining optimum extract concentration regarding influence on two cutaneous Staphylococci representatives, effect of extract on C. acnes growth was examined as well. Although it is one of the most important members of commensal skin microbiota, overgrowth of C. acnes is associated with acne vulgaris; therefore, influence of perspective cosmetic prebiotics on this bacterium is highly significant. Experiment in which C. acnes growth after 24 h was monitored by OD values in a medium with and without added extract demonstrated that blackcurrant active compounds inhibit microbial growth by 50.0% comparing to control sample. This result implies that blackcurrant extract obtained in enzyme-assisted process not only improves S. epidermidis/S. aureus balance, but also possess inhibitory potential against C. acnes, which altogether can serve as a good basis for further investigations.

Determination of hydration effect, dermatological compatibility and irritability

After maximizing polyphenol content and antioxidant capacity of blackcurrant extract and determining concentration with highest skin microbiota rebalancing potential, its additional cosmetic properties were finally examined. Aristoflex® AVC-based hydrogel was prepared as basic formulation to assess hydration effect, dermatological compatibility and irritability of extract concentration that showed best performance in liquid culture medium (0.025 mg GAE/g formulation), as well as two higher concentrations (0.1 mg and 0.4 mg GAE/g formulation). Such choice of extract concentrations was made due to the fact that future examinations on skin models and clinical studies could reveal concentration optimums alterations. Effect of hydrogels with incorporated extract was compared to control formulation (hydrogel without added extract) in three tests. Regarding TEWL test, results obtained during 24 h of monitoring revealed that enzymatically derived blackcurrant extract demonstrates enhanced hydration effect comparing to control formulation at all tested concentrations (Additional file 1: Table S3). This influence was dose-dependent and reached its maximum at 0.4 mg GAE/g formulation for which no differences in flux density were detected within 24 h. Such result indicates the ability of extract-enriched formulation to compensate water loss during the TEWL process by water from the formulation, namely, surface achieves the dynamic equilibrium of water evaporation and sorption [21]. Moreover, Zein irritability test was performed and obtained results revealed that neither control nor test samples are expected to cause skin irritation (Additional file 1: Table S4). Control sample had Zein number of 4.34, which is close to the acceptable limit for skin care products, while extract enriched formulations showed significantly lower or no irritancy described by Zein number values of 1.23, 1.00 and 0.00 for concentrations of 0.025 mg, 0.1 mg and 0.4 mg GAE/g of hydrogel, respectively. Additional examination of dermatological compatibility for prepared hydrogels was conducted by RBC test. According to results for control and test formulations (Additional file 1: Table S4) blackcurrant extract addition led to dermatological compatibility increase which is presented by the increased hemolytic and denaturing potential ratio of hydrogels. Formulations enriched with two lower extract concentrations were classified as weak irritants, while the one with highest extract concentration was nonirritant. Overall results demonstrated that, besides antioxidant and skin microbiota rebalancing potential, enzymatically derived blackcurrant extract obtained under optimized conditions is suitable for application in skin care cosmetics due to hydration effect, low irritancy and good dermatological compatibility.

Conclusions

Blackcurrant is a good source of polyphenols and enzyme-assisted extraction is a prospective method for their isolation. This study proved that both individual and combined applications of cellulolytic (Viscozyme® L) and pectinolytic (Rohapect® MC) preparations at optimized conditions increase extraction efficiency by enabling increased reducing sugar, total polyphenol, and flavonoid yields, as well as improved antioxidant activity. Moreover, the extract obtained under optimized conditions showed significantly higher potential to be used as a skin prebiotic for the regulation of altered skin microbiota, since it stimulated growth the of S. epidermidis and inhibited S. aureus and C. acnes. Hydrogel with incorporated extract obtained under optimized conditions showed good hydration effect, high dermatological compatibility and low irritancy. Future research will be directed towards the influence of blackcurrant extracts on skin microbiota using adequate in vitro or ex vivo skin models, but also towards establishment of the more detailed structure–function relationship of the extracted compounds.

Availability of data and materials

The data presented in this study will be made openly available on a data repository immediately after publication.

Abbreviations

- DM:

-

Dry matter

- GE:

-

Glucose equivalent

- GAE:

-

Gallic acid equivalent

- QE:

-

Quercetin equivalent

- TSBY:

-

Tryptone soy broth with yeast

- DNS:

-

3,5-Dinitrosalicylic acid

- FRAP:

-

Ferric reducing antioxidant power

- HPLC:

-

High-performance liquid chromatography

References

Altemimi A, Lakhssassi N, Baharlouei A, Watson D, Lightfoot D. Phytochemicals: extraction, isolation, and identification of bioactive compounds from plant extracts. Plants. 2017. https://doi.org/10.3390/plants6040042.

Kanlayavattanakul M, Chaikul P, Kongkow M, Iempridee T, Lourith N. Anti-aging of phenolic-rich Acanthus ebracteatus Vahl. extracts. Chem Biol Techno Agric. 2023. https://doi.org/10.1186/s40538-023-00403-w.

Pandey KB, Rizvicorresponding SI. Plant polyphenols as dietary antioxidants in human health and disease. Oxid Med Cell Longev. 2009. https://doi.org/10.4161/oxim.2.5.9498.

Cory H, Passarelli S, Szeto J, Tamez M, Mattei J. The role of polyphenols in human health and food systems: a mini-review. Front Nutr. 2018. https://doi.org/10.3389/fnut.2018.00087.

Nadar SS, Rao P, Rathod VK. Enzyme assisted extraction of biomolecules as an approach to novel extraction technology: a review. Food Res Int. 2018. https://doi.org/10.1016/j.foodres.2018.03.006.

Cherubim DJ, Martins CV, Fariña L, Lucca RA. Polyphenols as natural antioxidants in cosmetics applications. J Cosmet Dermatol. 2019. https://doi.org/10.1111/jocd.13093.

Zillich OV, Schweiggert-Weisz U, Eisner P, Kerscher M. Polyphenols as active ingredients for cosmetic products. Int J Cosmet Sci. 2015. https://doi.org/10.1111/ics.12218.

Puri M, Sharma D, Barrow CJ. Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol. 2012. https://doi.org/10.1016/j.tibtech.2011.06.014.

Gligor O, Mocan A, Moldovan C, Locatelli M, Crișan G, Ferreira ICFR. Enzyme-assisted extractions of polyphenols—a comprehensive review. Trends Food Sci Technol. 2019. https://doi.org/10.1016/j.tifs.2019.03.029.

Cortez RE, Gonzalez de Mejia E. Blackcurrants (Ribes nigrum): a review on chemistry, processing, and health benefits. J Food Sci. 2019. https://doi.org/10.1111/1750-3841.14781.

Gopalan A, Reuben SC, Ahmed S, Darvesh AS, Hohmann J, Bishayee A. The health benefits of blackcurrants. Food Funct. 2012. https://doi.org/10.1039/c2fo30058c.

Zimmermann C, Wagner AE. Impact of food-derived bioactive compounds on intestinal immunity. Biomolecules. 2021. https://doi.org/10.3390/biom11121901.

Plamada D, Vodnar DC. Polyphenols—gut microbiota interrelationship: a transition to a new generation of prebiotics. Nutrients. 2021. https://doi.org/10.3390/nu14010137.

Report of International Cooperation on Cosmetics Regulation. Microbiome and cosmetics: Working definitions and microbiological assessment considerations; 2022. https://www.iccr-cosmetics.org/topics-documents/14-microbiome. Accessed 21 October 2023.

Bockmühl D, Jassoy C, Nieveler S, Scholtyssek R, Wadle A, Waldmann-Laue M. Prebiotic cosmetics: an alternative to antibacterial products. Int J Cosmet Sci. 2007. https://doi.org/10.1111/j.1467-2494.2007.00355_2.x.

Khatri D, Chhetri SBB, Freire D. Reducing sugar, total phenolic content, and antioxidant potential of nepalese plants. Biomed Res Int. 2020. https://doi.org/10.1155/2020/7296859.

Milutinović M, Radovanović N, Ćorović M, Šiler-Marinković S, Rajilić-Stojanović M, Dimitrijević-Branković S. Optimisation of microwave-assisted extraction parameters for antioxidants from waste Achillea millefolium dust. Ind Crops Prod. 2015. https://doi.org/10.1016/j.indcrop.2015.09.007.

Fernandes RPP, Trindade MA, Tonin FG, Lima CG, Pugine SMP, Munekata PES, et al. Evaluation of antioxidant capacity of 13 plant extracts by three different methods: Cluster analyses applied for selection of the natural extracts with higher antioxidant capacity to replace synthetic antioxidant in lamb burgers. Int J Food Sci Technol. 2015. https://doi.org/10.1007/s13197-015-1994-x.

Huebner J, Wehling RL, Hutkins RW. Functional activity of commercial prebiotics. Int Dairy J. 2007. https://doi.org/10.1016/j.idairyj.2006.10.006.

Blagojević SN, Blagojević SM, Pejić ND. Performance and efficiency of anionic dishwashing liquids with amphoteric and nonionic surfactants. J Surfactants Deterg. 2016. https://doi.org/10.1007/s11743-015-1784-5.

Milivojević AD, Ćorović MM, Simović MB, Banjanac KM, Blagojević SN, Pjanović RV, et al. Novel approach for flavonoid esters production: Statistically optimized enzymatic synthesis using natural oils and application in cosmetics. Ind Eng Chem Res. 2019. https://doi.org/10.1021/acs.iecr.8b06113.

Lagarto A, Vega R, Vega Y, Guerra I, González R. Comparative study of red blood cell method in rat and calves blood as alternatives of Draize eye irritation test. Toxicol in vitro. 2006;20(4):529–33.

Novozymes. Viscozyme® L. https://www.novozymes.com/en/products/juice-fruit-vegetables/olive-oil/viscozyme-l. Accessed 18 June 2023.

Novozymes. Pectinex® Ultra SP-L. https://www.novozymes.com/en/products/juice-fruit-vegetables/vegetables/pectinex-ultra-sp-l. Accessed 18 June 2023.

Novozymes. Cellic® CTec3 HS. https://www.novozymes.com/en/products/bioenergy/cellic-ctec3-hs. Accessed 18 June 2023.

Nuventure. Rohapect® MC Product Data Sheet. https://nuventure.eu/content/uploads/docs/yeast-enzymes/abenzymes/ROHAPECTR%20MC%20Product%20Data%20Sheet%20Rev.%2000%20(ID%202421).pdf. Accessed 18 June 2023.

Enzymes AB. Rohapect® Enzymes for fruit processing. https://www.abenzymes.com/media/2656/ab_enzymes_rohapect.pdf. Accessed 18 June 2023.

Hauke H. Characterisation of cell wall polysaccharides in bilberries and black currants (PhD thesis). Wageningen, The Netherlands: Wageningen University; 2007.

Nguyen C, Nguyen H. The quality of mulberry juice as affected by enzyme treatments. Beverages. 2018. https://doi.org/10.3390/beverages4020041.

Jagelaviciute J, Basinskiene L, Cizeikiene D, Syrpas M. Technological properties and composition of enzymatically modified cranberry pomace. 2022. Foods. https://doi.org/10.3390/foods11152321.

Syrpas M, Valanciene E, Augustiniene E, Malys N. Valorization of bilberry (Vaccinium myrtillus L.) pomace by enzyme-assisted extraction: process optimization and comparison with conventional solid-liquid extraction. Antioxidants. 2021. https://doi.org/10.3390/antiox10050773.

Buchert J, Koponen JM, Suutarinen M, Mustranta A, Lille M, Törrönen R, et al. Effect of enzyme-aided pressing on anthocyanin yield and profiles in bilberry and blackcurrant juices. J Sci Food Agric. 2005. https://doi.org/10.1002/jsfa.2284.

Cacace JE, Mazza G. Mass transfer process during extraction of phenolic compounds from milled berries. Int J Food Eng. 2003. https://doi.org/10.1016/s0260-8774(02)00497-1.

Sun Y, Liu D, Chen J, Ye X, Yu D. Effects of different factors of ultrasound treatment on the extraction yield of the all-trans-β-carotene from citrus peels. Ultrason Sonochem. 2011. https://doi.org/10.1016/j.ultsonch.2010.05.014.

Shahidi F, Yeo J. Insoluble-bound phenolics in food. Molecules. 2016. https://doi.org/10.3390/molecules21091216.

Ghandahari Yazdi AP, Barzegar M, Sahari MA, Ahmadi GH. Optimization of the enzyme-assisted aqueous extraction of phenolic compounds from pistachio green hull. Food Sci Nutr. 2019. https://doi.org/10.1002/fsn3.900.

Granato D, Fidelis M, Haapakoski M, dos Santos LA, Viil J, Hellström J, et al. Enzyme-assisted extraction of anthocyanins and other phenolic compounds from blackcurrant (Ribes nigrum L.) press cake: from processing to bioactivities. Food Chem. 2022. https://doi.org/10.1016/j.foodchem.2022.133240.

Yang Y, Qu L, Mijakovic I, Wei Y. Advances in the human skin microbiota and its roles in cutaneous diseases. Microb Cell Factories. 2022. https://doi.org/10.1186/s12934-022-01901-6.

Pastar I, O’Neill K, Padula L, Head CR, Burgess JL, Chen V, et al. Staphylococcus epidermidis boosts innate immune response by activation of gamma delta t cells and induction of perforin-2 in human skin. Front Imunol. 2020. https://doi.org/10.3389/fimmu.2020.550946.

Petrov A, Ćorović M, Milivojević A, Simović M, Banjanac K, Pjanović R, et al. Prebiotic effect of galacto-oligosaccharides on the skin microbiota and determination of their diffusion properties. Int J Cosmet Sci. 2022. https://doi.org/10.1111/ics.12778.

Jang I-T, Yang M, Kim H-J, Park J-K. Novel cytoplasmic bacteriocin compounds derived from Staphylococcus epidermidis selectively kill Staphylococcus aureus, including methicillin-resistant Staphylococcus aureus (MRSA). Pathogens. 2020. https://doi.org/10.3390/pathogens9020087.

Milutinović M, Dimitrijević-Branković S, Rajilić-Stojanović M. Plant extracts rich in polyphenols as potent modulators in the growth of probiotic and pathogenic intestinal microorganisms. Front Nutr. 2021. https://doi.org/10.3389/fnut.2021.688843.

Bouarab-Chibane L, Forquet V, Lantéri P, Clément Y, Léonard-Akkari L, Oulahal N, et al. Antibacterial properties of polyphenols: characterization and QSAR (Quantitative structure–activity relationship) Models. Front Microbiol. 2019. https://doi.org/10.3389/fmicb.2019.00829.

Makarewicz M, Drożdż I, Tarko T, Duda-Chodak A. The interactions between polyphenols and microorganisms, especially gut microbiota. Antioxidants. 2021. https://doi.org/10.3390/antiox10020188.

Pan L, Ye H, Pi X, Liu W, Wang Z, Zhang Y, et al. Effects of several flavonoids on human gut microbiota and its metabolism by in vitro simulated fermentation. Front Microbiol. 2023. https://doi.org/10.3389/fmicb.2023.1092729.

Acknowledgements

The authors acknowledge and thank to AB Enzymes GmbH (Darmstadt, Germany) for their kind donation of enzyme preparation Rohapect® MC. The authors acknowledge Dr. Patrick Zeeuwen (Department of Dermatology, Radboud University Medical Center, Nijmegen, The Netherlands) for critical reding and advice and Dr. Stevan Blagojević and Dr. Aleksandra Radulović (Institute of general and physical chemistry, University of Belgrade, Belgrade, Serbia) for expert advice in manuscript revision. Icons in graphical abstract made by Freepik and mankik from www.flaticon.com.

Funding

This work was supported by the Ministry of Science, Technological Development and Innovations of the Republic of Serbia (Contract Nos. 451-03-47/2023-01/200287 and 451-03-47/2023-01/200135) and has received funding from Science Fund of the Republic of Serbia, programme IDEAS, Project No. 7750109 (PrIntPrEnzy) and the Horizon Europe 2021–2027 research and innovation programme under grant agreement ID 101060130 (TwinPrebioEnz).

Author information

Authors and Affiliations

Contributions

API performed experiments, data analysis and interpretation, as well as writing original draft. AM contributed to the conception and design of the work, revising and manuscript editing. MĆ contributed to conception and design of the work, supervision and revising and manuscript editing. MS participated in performing analysis and methodology design. KB participated in methodology design and data analysis. PJ participated in experiment design and revising manuscript. AV participated in performing the experiments. EB contributed to design of the work and revising manuscript. DB contributed to the conception and design of the work, supervision and funding acquisition. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1. Table S1

: Raw data of optical density (OD600) of 24 h bacterial growth supplemented with different extracts concentrations. Table S2: Raw data of bacterial colony counts (CFU/mL) obtained after 24 h in media with extracts obtained without enzymes or with enzyme mixtures at a concentration of 0.025 mg GAE/mL. Table S3: Transepidermal water loss (TEWL) analysis. Table S4: Skin irritability (Zein) and dermatological compatibility (RBC) analysis. Fig. S1: Anthocyanin profile of extracts obtained with mixture of Viscozyme® L and Rohapect® MC (black line) and without enzyme (blue line) at 520 nm . Picks identified based on HPLC standards and literature data (10) are: 1—delphinidin 3-O-glucoside, 2—delphinidin 3-O-rutinoside, 3—cyanidin 3-O-glucoside and 4—cyanidin 3-O-rutinoside.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Petrov Ivanković, A., Milivojević, A., Ćorović, M. et al. In vitro evaluation of enzymatically derived blackcurrant extract as prebiotic cosmetic ingredient: extraction conditions optimization and effect on cutaneous microbiota representatives. Chem. Biol. Technol. Agric. 10, 125 (2023). https://doi.org/10.1186/s40538-023-00502-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-023-00502-8