Abstract

The archaeological site of Adulis lays on the Red Sea Coast of Eritrea and during Late antiquity played a significant role in interregional commerce among the Mediterranean, the Red Sea and the Indian Ocean coasts. Contacts with the Eastern Mediterranean, Arabian Peninsula and the Sasanian world have been attested from different classes of pottery that were brought to light from on-going excavations at the site. Transport vessels have attracted particular attention as they testify the extent of trades and exchange networks. Transport vessels were coated by organic materials to seal porosity and make them suitable to transport different liquids and/or food. The characterisation of coating materials helped shedding light on their function, and support the attribution to different classes of transport vessels found in the Indian Ocean and Red Sea worlds. Here, the characterisation of the organic lining detected on a set of samples identified as Late Roman Amphora 1 is discussed. Results from the chemical analyses, performed preliminarily by FT-IR and then by GC–MS, revealed that bitumen was used for lining the jars, thus leading to set the classification of the amphorae within the wide class of the so- called Torpedo jars. By overcoming the question of typological complexity posed from macroscopic examination of the sherds, the chemical investigation contributed here crucial information for the interpretation of past trading in the Indian Ocean. The research gave clues to broaden the distribution of the Torpedo jars to Adulis, giving an unexpected insight into the trading routes of the past.

Similar content being viewed by others

Introduction

Fourier Transform InfraRed spectroscopy (FT-IR) and Gas Chromatography—Mass Spectrometry (GC–MS) play a relevant role in the characterization of organic residues found in archaeological vessels. In particular, the chemical nature of the layers spread on the porous pottery to make it suitable to conserve and to transport liquid foodstuff can be elucidated [1,2,3,4,5,6,7,8,9]. In addition to recognising lining materials, the versatility of archaeometric approaches has been proved to be quite significant to tackle vessel function: by investigating organic residues in transport vessels, analytical techniques can contribute further information that support the archaeological approach in shedding light on past trades [2, 3, 5, 10,11,12,13].

Contacts among settlements on the Mediterranean, Red Sea and Indian Ocean coasts have been widely discussed in the archaeological community and archaeological records show evidence of the Roman control and influence of trades in these regions. The Red Sea, East Africa, the Persian Gulf, Southern Arabia, and India were integrated in a net of exchanges between Rome and India, where connections to all the coasts of the Indian Ocean and beyond were established to support the trade of a wide range of commodities [9, 14,15,16,17].

The trade networks increased particularly during the Hellenistic and Roman times, when traders from the Mediterranean reached the Indian Ocean through the Persian Gulf and the Red Sea [9]. Studies on the extent of these trade networks are growing and ceramics have largely contributed to our understanding of the trades involving the Mediterranean, Red Sea, and Indian Ocean worlds.

The Late Roman Amphora 1 (LRA1) and the Torpedo jars, which were produced broadly in the same chronological period, proved to be excellent proxies for understanding the Indian Ocean trade, as these transport vessels are spread over much of the Indian Ocean and the Red Sea.

The LRA 1 is one of the seven varieties of Late Roman Amphoras, which are indicated with numbers from 1 to 7. The classification is based on the comparisons of the standardised shapes and sizes of the varieties [18]. The production of LRA 1 is evidenced from the 4th to 7th Century in the Eastern Mediterranean, including Rhodes, western Anatolia, the Cilician coast, and Cyprus [18,19,20]. LRA1 were made in a multitude of centres, and the shape pinpoints a standardized production during these periods. It is generally agreed that high uniformity found in LRA1, and in other LRA types, attests a close cultural or administrative connection between the regions of production [20].

LRA1 have been found throughout the Roman world including the British Isles, along the Mediterranean coast of southern Europe, North Africa, and Western Asia, and the Black Sea region [18, 21]. Moreover, the vessels have been identified on the Indian sub-continent beyond the frontiers of the Mediterranean maritime trade [14]. The distribution of the LRA1 across the Mediterranean and beyond testifies an expansive trade network connecting many parts of the late Roman and early Byzantine worlds. The vessels are therefore an important proxy for these intangible social and economic connections [20].

It has been suggested that LRA1 vessels were used to transport liquids such as wine and—possibly—oil. Some examples of LRA 1 from Cyprus, Marseille, and the Yassi Ada wreck were found coated on the inside [18]. The chemical characterization of organic residues from Roman amphorae highlighted the use of pitch as the main sealing material, further supporting their function as containers for liquids [22,23,24].

Another material that was used to seal pottery porosity was bitumen, and fragments of vessels coated with this sealing material were often found in archaeological sites in Mesopotamia and in the Arabian Gulf [8, 9, 16, 17, 25,26,27,28,29,30].

The so-called Torpedo jars have, among others, caught the attention of multidisciplinary studies in recent years as they can be considered a marker for tracing maritime trade connections during the Sasanian and early Islamic periods. These vessels are tall elongated or round bodied handle-less ceramic transport containers characterized by a narrow mouth and a pointed base, and they are often coated with bitumen to seal their porosity [16, 17, 29]. Ceramic vessels classified as Torpedo jars were produced during the Sasanian (c. 3rd to mid-seventh centuries CE) to Early Islamic (mid-7th to tenth centuries CE) periods. The distribution of the Torpedo jars has been attested mainly from sites throughout the Persian Gulf and western Indian Ocean, and rarely as far west as the Egyptian Red Sea coast at Berenike [8] and to the east in Thailand [7]. No kilns directly related to production of Torpedo jars have been identified yet, hindering the exact recognition of their provenance. Like the Mediterranean amphorae, Torpedo jars may have been primarily used for the long-distance transport of wine, oil, or other high-priced liquid foodstuffs [9].

The classification of Torpedo jars has been until recently mainly limited to typological studies [8, 25, 28, 31,32,33,34]. Lately, a distinction between Torpedo-S (TORP-S) and Torpedo-C (TORP-C) varieties has been indicated in the literature based both on the macroscopic characteristics of the vessels and on the microscopic features of the ceramic body [7, 9, 16, 28]. The TORP-S fabric—classified by Tomber et al. [16]—is characterized by thinner walls and by the presence of well-sorted sandy inclusions in a buff, pink or orange-coloured matrix. It has been indicated that this fabric corresponds to an earlier production and its distribution has been testified at the Sasanian site of Bushehr in southern Iran [35], with finds from the 5th to late 8th century in the assemblages at Kush [30], in the late Sasanian assemblage at Jazirat al-Ghanam [36] and in the mid-7th to mid 8th century assemblages from Sir Bani Yas [34]. In addition, numerous finds are documented in India and Sri-Lanka [37] as well as in the early 5th to late 7th century occupation of Fulayj in Oman [27].

On the other hand, TORP-C fabric is related to the buff or cream-coloured body and characterized by lower amounts of sand inclusions and thicker walls [16]. The recovery of assemblages related to this fabric has been exclusively associated with contexts dated from the mid 8th century, or later, including those from Sohar, Manda and Siraf [16]. Recently they have been also found in Southeast Asia, namely in the late 8th century Phanom Surin wreck in Thailand and the mid 9th century Belitung wreck off the coast of Java in Indonesia [7].

In the absence of complete specimens found in Adulis, non-morphologically diagnostic wall fragments considered in this study were attributed, doubtfully, to LRA1 [9]. Yet, Torpedo jars have been distinguished from coeval Roman pottery through the internal brownish-blackish coating which, differently from the resin that characterises LRA 1, is formed by bitumen [9, 16]. The chemical signature of the lining has become a fingerprint for the identification of Torpedo jars, and allowed researchers to shed further light on their origin and trade over long distances [7, 9, 33].

Based on these premises, FT-IR and GC–MS analyses were performed on residues of the original coating found on a set of fragments attributed to LRA1, with the aim of contributing some knowledge to the investigation of the axes of distribution of transport vessels in the Eastern Mediterranean, Red Sea, and Indian Ocean Worlds.

Archaeological context and sampling

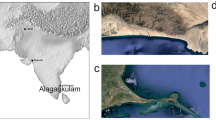

The site of Adulis (Fig. 1) is located on the Eritrean coast and was the most important port for trade in the northern Horn of Africa during late antiquity, linking the early urban settlements of the Eritrean and Ethiopian highlands to the coastal people. It also played a significant role in the policy within the Red Sea area during its long history, which spanned for some 800 years. Based on the comparative analysis of architectural features, as well as on dating of coinage and pottery [38, 39], it was in fact determined that the site was continuously inhabited from the 2nd–1st century BCE up to the 6th and early 7th century CE, and intensely occupied in the 5th–6th century CE.

The extent of the trade exchanges that involved the ancient port city of Adulis could be traced by comparing the Late Roman and Byzantine transport and common wares that have been uncovered by archaeological excavations at Adulis with wares recovered from the adjacent Arabian Peninsula and Indian Ocean [39,40,41,42,43].

The samples considered for this archaeometric work were collected from the on-going excavations at the archaeological site at Adulis and were retrieved as part of a comprehensive archaeometric characterization of different pottery classes. A group of six pottery fragments was selected with the aim of characterising—by means of analytical chemistry techniques—the (more or less evident) deposits, which were possibly interpreted as organic residues of the internal coating. The selection was mainly based on stratigraphic reliability, in order to link each fragment to a well-defined chronological sequence. Since extensive fragmentation of the finds is very common in urban contexts, morphologically diagnostic specimens were not available in the archaeological site, therefore the shards were classified as LRA1 based on the available knowledge on the trade of this type of amphorae in Adulis and on similarities of the ceramic paste with LRA1. The analysed samples, with details on the stratigraphic units, are listed in Table 1.

The chemical composition of the organic residues was preliminarily investigated by FT-IR. Then, GC–MS was employed to obtain more detailed information on the composition of the organic compounds extracted from the inorganic substrate.

Materials and methods

Chemicals

Dichloromethane, acetone, and methanol were used for the preparation of extracts for FT-IR analysis. n-hexane, dichloromethane and methanol were used for the GC–MS analyses. All the solvents were analytical grade from Sigma-Aldrich.

FT-IR analysis

In order to provide a first chemical screening of the composition of the organic fraction of the shards, FT-IR was employed. Powdered samples were collected from the ceramic fragments and subdivided into three 100 mg aliquots for each sample. Each aliquot was treated with one solvent, namely acetone, methanol or dichloromethane, in order to exploit the different extraction capability of solvents with different polarity [4, 44, 45]. Extraction was performed in a glass vial. 2 mL of the solvent was added to the powder, favouring the interaction between the solid and the solvent by a Vortex lab shaker. After 2 min of treatment, the system was allowed to settle for about 4 h, then the liquid fraction was transferred into another vial and left to dry in a fume hood. The resulting deposits were collected, set in a diamond anvil cell and analysed in transmission mode using a Vertex 70 FT-IR benchtop spectrometer by Bruker, equipped with a Hyperion 3000 Microscope. Spectra were collected in the range from 4000 cm−1 to 400 cm−1, with a resolution of 4 cm−1 and 64 scan acquisitions.

GC–MS analysis

An insight into the chemical nature of the organic material extracted from the inorganic ceramic substrate was then performed by GC–MS following a procedure previously validated [6]. Briefly, about 10 mg of each sample were treated with 1 mL of n-hexane, dichloromethane and methanol (80:15:5 v:v:v) in microwave extractor MLS-1200 MEGA Milestone (Italy) for 5 min at 500 W and 60 °C. The extract was centrifuged at 4000 rpm (1780×g Relative Centrifugal Force) for 5 min and the supernatant was dried under a nitrogen stream. 300 μL of n-hexane were added and the solution was sonicated for 10 min at 40 °C in order to allow asphaltene precipitation; the extraction with n-hexane was repeated 3 times and the supernatant from each of the three steps was collected in a vial. Deasphalted solution was subjected to separation of saturated and aromatic hydrocarbons from the polar fraction using column chromatography with silica gel activated at 400 °C prior to use. After conditioning the column with 1 mL of n-hexane, the sample was loaded in the column and then it was eluted with 3 mL of a n-hexane-dichloromethane mixture (1:1 in volume). The collected hydrocarbon fraction was dried under a nitrogen flow and then added with 50 μL of isooctane. The fraction containing the saturated and aromatic hydrocarbons was dried under a nitrogen stream and re-dissolved in 50 mL of isooctane. 2 mL of the final solution were analyzed by GC–MS. The GC–MS system consists of a 6809 N-Network gas chromatograph with a PTV injector and a 5975 single quadrupole mass spectrometer (Agilent Technologies, Palo Alto, USA). The PTV injector was used in splitless mode at 280 °C. The chromatographic separation was performed on a HP-5MS chromatographic capillary column (5% phenyl/95% dimethylpolysiloxane, inner diameter: 0.25 mm, length: 30 m, film: 0.25 m, J&W Scientific Agilent Technologies, Palo Alto, CA), coupled with a deactivated fused silica guard column (inner diameter: 0.32 mm, length: 2 m, J&W Scientific Agilent Technologies, Palo Alto, CA). The chromatographic oven was set with the following temperature program: initial temperature 80 °C for 2 min, a first ramp rate of 20 °C/min up to 200 °C, 200 °C for 1 min, a second ramp rate of 4 °C/min up to 300 °C, 300 °C for 60 min. The mass spectrometer ionization source was set at 230 °C, the quadrupole was kept at 150 °C. The mass spectrometer was used in the EI mode (70 eV), acquiring in the range 50–700 m/z. The relative percentages of the peak areas of principal biomarkers obtained from extracted ion chromatograms (m/z 191) were used to estimate the relative abundance of the various compounds.

Results and discussion

FT-IR analysis

The preliminary screening with FT-IR of the extracts from all the samples showed clear evidence of the presence of organic components. The spectra obtained on extracts from the same solvent were essentially comparable for all the samples, as were the spectra acquired on the three different solvents extracts of a same sample. However, a slightly higher complexity of the spectroscopic pattern in the 3600–3000 cm−1 region and in the low wave number interval (below 900 cm−1) was observed for the methanol and dichloromethane extracts. As an example, Fig. 2 reports the FT-IR spectra obtained for the three different solvents extracts from sample C07, and Table 2 summarizes the features of the spectroscopic patterns obtained from the extracts.

The broad band in the 3600–3000 cm−1 interval is ascribable to the O–H stretching vibration, being recorded in many of the materials which could be used for lining the ceramic surface such as pitch or tar [46, 47], charred organic residues [48], diterpenoid resins from Pinaceae family trees [49] and bitumen [46]. On the contrary, the absorption around 3400 cm−1 can be specifically attributed to adsorbed water in silicates. This signal, together with the broad, complex and quite strong peak in the 1100–1000 cm−1 range, can be explained by the presence, in the extract, of some residual clay particles from the powdered ceramic fragments. Moreover, in this spectroscopic range, a contribution of signals due to the presence of aromatic compounds (ring deformations) cannot be excluded.

The 2950, 2925 and 2855 cm−1 peaks are characteristics of the methyl and methylene groups stretching vibrations in the spectroscopic patterns of all the already-cited materials. The 1705 and 1670 cm−1 signals have been attributed to the C=O stretching vibration corresponding to different chemical environments, but—according to literature data—only the band at 1705 cm−1 is ascribed to the C=O bond in the spectra of pitch or tar [2, 46]. The same band was observed, but not assigned, in the bitumen spectrum [46], whereas both the peaks were recognized in the spectroscopic pattern of diterpenoid resins and ascribed to the C=O stretching signals in organic acids and esters, although slightly shifted towards higher wavenumbers: 1715 and 1688 cm−1, respectively [49].

The signal at 1590 cm−1 was recognised in the spectra of pitch or tar [2, 47], charred organic residues [48] and bitumen [46], while the peaks at 1455 and 1375 cm−1 were highlighted not only in both pitch or tar [46, 47] and bitumen [47] spectra, but also in the spectroscopic patterns of diterpenoid resins [4, 49]. Lastly, the signals at 875 and 835 cm−1 were observed in bitumen spectra [46], while aromatic ring C-H deformation in pitch or tar generate higher wavenumbers peaks in the spectroscopic patterns (886 and 881 cm−1).

Therefore, FT-IR spectra suggest that the organic components extracted from all the investigated sherds are residues of some kind of material employed for sealing the internal porosity of the ceramic. Nevertheless, the FT-IR spectroscopic patterns did not allow us to confidently recognise the nature of this material. As this information is crucial for contributing new knowledge for interpreting the role of Adulis in past trades, a more selective approach with GC–MS analyses was employed to pursue the identification of the specific substance/s used for lining.

GC–MS

The chromatographic profile obtained from the analysis of all the archaeological samples is typical of a bituminous material (Fig. 3), attested from the presence of the terpane compounds including the hopane and homo-hopane series (H28-H35). The most abundant peaks, identified in the extracted ion m/z 191 chromatograms by the examination of their mass spectra [6, 9, 50] are ascribable to H29 (17α(H),21β(H)-30-norhopane) and to H30 (17α(H),21β(H)-30-hopane), both belonging to the hopane class. In sample C06 a tricyclic terpane (TR23), a tetracyclic terpane (TET24) and the several homo-hopanes (H32-H35) were detected as minor components. Only in sample C02 gammacerane (GAM) was not identified. Steranes (m/z 217), monoaromatic steranes (m/z 253) and triaromatic steranes (m/z 231) are below the detection limit of the employed procedure.

Sample C06 extracted ion (m/z 191) chromatogram (see Table 3 for the list of compounds)

The relative percent distribution of the detected compounds is illustrated in Fig. 4 and they are listed in Table 3.

The identification of a bituminous substance in all the investigated samples allows us to give a new classification for the ceramic sherds: they were initially attributed to LRA 1, but they shall be instead interpreted as fragmentary Torpedo jars [9, 37]. The typological complexity due to the similarities between Torpedo jars and LRA1 is resolved here by the chemical information obtained from the residues of the lining agents.

It is well-known that bitumen was used from the Palaeolithic or early Neolithic periods for several purposes. Long distance commercial networks were eventually established to provide different settlements with bitumen, where the bitumen trade expanded in the Middle-Bronze Age and continued until the Early Islamic period and beyond [51, 52].

Bitumen sources from Mesopotamia, Iran and the Dead Sea have been widely discussed in the literature, where different sites across the Persian Gulf, Indian Ocean and the Mediterranean were included in the long-distance trade of the material. It is known that settlements under Mesopotamian influence used exclusively bitumen from Hit in Iraq, whereas bitumen sources in northern Iraq and Iran supplied other settlements [9, 52]. Moreover, it is mentioned that bitumen from Iran played a bigger role in the Gulf starting from the second half of the first millennium BCE, as is attested from settlements in Southeast Arabia, the Oman coast and as far as across the Indian Ocean at Anuradhapura in Sri Lanka [33]. While bitumen from Mesopotamia and Iran were widespread across the Near East, many sites in the Eastern Mediterranean were provided with bitumen from the Dead Sea [52,53,54]. Therefore, the reconstruction of bitumen trade in antiquity is framed within the framework of comparing the biomarkers (GC–MS profiles, chemical compositions, source of the bitumen rocks) of these known sources.

Archaeometric work on Torpedo jar samples from 3rd to ninth century levels at Anuradhapura (Sri Lanka) indicated that the source of most of the bitumen could be in the region within the vicinity of Dehluran and Susa in southern Ilam or northeast Khuzestan in Iran [33]. Similarly, a recent publication by Connan et al.[7] on fabrics belonging to TORP-S and TORP-C fragments from Phanom-Surin wreck has attributed the source of the bitumen from a set of deposits near Dehluran and Khuzestan [7]. Furthermore, the analysis of two sets of Torpedo jars from Alagankulam in southern India and the site of Al Hamr al-Sharqiya1 in Oman by Lischi et al. [9] has attested to sources in Iraq.

Tracing the source of the bitumen is beyond the scope of the present work. Moreover, it should be noted, that it remains unclear whether Torpedo jars were manufactured in the same location in which the bitumen was obtained, or if the vessels were lined with a bituminous material imported from elsewhere [16].

This leaves open the need to consider both the characterization of the clay paste and the source of the bitumen for approaching the provenance of the vessels. We demonstrated that similarities in the macroscopic features of the clay body and other archaeological inferences supported the identification of the investigated fragments from Adulis as LRA1, whereas the chemical characterization of their organic lining identified them as Torpedo jars.

The similarities possibly suggest production areas exploiting materials from similar geological basins in the wider geographical areas from Eastern Mediterranean to Mesopotamia.

In fact, two main geological features, namely the Tigris-Euphrates basin of Iraq (Mesopotamia) and the continuous mountain range stretching from Troodos, Cyprus to Semail, Oman, dominate the area where Torpedo jars are most likely to originate [16]. On the other hand, the possibilities of the transport of solid bitumen to production centres can pinpoint multiple production for the vessels.

Conclusion

The characterization of organic residues of lining carried out in this study—with the detection of a bituminous coating—allowed the archaeologists to securely recognize as fragments of Torpedo jars some sherds that were initially interpreted as LRA1 due to both the similarities between fabrics and the present knowledge on past trades in the area. This unexpected information revealed a new scenario on the role of Adulis in the framework of the distribution of transport vessels to the African shores of the Red Sea and broadens the themes revolving around the provenance, production, and distribution of the Torpedo jars on the wider Indian Ocean and Red Sea Worlds.

Trade connections in the Indian Ocean involved a very large area, including the Red Sea, East Africa, the Persian Gulf, Southern Arabia, and India. The scope of regional exchanges involving the Red Sea and Indian Ocean Worlds encompassed multiple routes [9] and the one going from Oman to the Red Sea could have contributed to the distribution of transport vessels from the Indian Ocean to the Eritrean Coast. The extent of these contacts is further attested by the expansion of the Sasanian trade into the Red Sea by late antiquity. By the chemical characterization of the pottery fragments considered in this work, the role played by Adulis in the trading in textiles, spices, precious stones, essential oils and a range of other commodities can be further enhanced in a new perspective of commercial interactions within the wider Indian Ocean.

However, the analysis undertaken in this study represents a starting point, as only a small number of fragments was considered. Nevertheless, the result is relevant as the presence of Torpedo jars has never been testified in Red Sea contexts. As far as the contribution given by Torpedo jars to the archaeological research is considered, it is evident that the study of the bitumen lining using archaeometric approaches proves to be of paramount relevance when the macroscopic observation does not evidence any diagnostic clue for typological attribution.

The present work places Adulis within the growing archaeometric discussion on the production, distribution and use of the Torpedo jars. The information from Adulis further supports the fact that these jars provide a direct proxy for trade and exchange throughout the Indian Ocean. Moreover, it should be noted that a closer examination of the ceramic fabric, form and lining of the jars needs to be systematically approached in the future, and sherds already found in the past should be possibly reconsidered in a new perspective. Chemical analyses of the lining—and minero-petrographic and geochemical analyses of the clay body—of samples obtained from archaeological sherds found in sites of the Red Sea and Indian Ocean should be considered for an exhaustive typo-chronological framework and provenance evaluation to build the picture of the past connections in the area.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the authors upon request.

Abbreviations

- FT-IR:

-

Fourier Transform InfraRed spectroscopy

- GC–MS:

-

Gas Chromatography—Mass spectrometry

- LRA:

-

Late Roman Amphora

- CE:

-

Common Era

- BCE:

-

Before Common Era

References

Derrick M. Fourier transform infrared spectral analysis of natural resins used in furniture finishes. J Am Inst Conserv. 1989;28(1):43–56. https://doi.org/10.2307/3179466.

Font J, Salvadó N, Butí S, Enrich J. Fourier transform infrared spectroscopy as a suitable technique in the study of the materials used in waterproofing of archaeological amphorae. Anal Chim Acta. 2007;598(1):119–27. https://doi.org/10.1016/j.aca.2007.07.021.

Dimitrakoudi E, Mitkidou S, Urem-Kotsou D, Kotsakis K, Stephanidou-Stephanatou J, Stratis J. Characterization by gas chromatography—mass spectrometry of diterpenoid resinous materials in roman-age amphorae from northern Greece. Eur J Mass Spectrom (Chichester). 2011;17(6):581–91. https://doi.org/10.1255/ejms.1155.

Lettieri M. Infrared spectroscopic characterization of residues on archaeological pottery through different spectra acquisition modes. Vib Spectrosc. 2015;76:48–54. https://doi.org/10.1016/j.vibspec.2014.12.002.

Roffet-Salque M, Dunne J, Altoft DT, Casanova E, Cramp LJE, Smyth J, Whelton HL, Evershed RP. From the inside out: upscaling organic residue analyses of archaelogical ceramics. J Archaeol Sci Rep. 2017;16:627–40. https://doi.org/10.1016/j.jasrep.2016.04.005.

Nardella F, Landi N, Degano I, Colombo M, Serradimigni M, Tozzi C, Ribechini E. Chemical investigations of bitumen from Neolithic archaeological excavations in Italy by GC/MS combined with principal component analysis. Anal Methods. 2019;11:1449–59. https://doi.org/10.1039/C8AY02429D.

Connan J, Priestman S, Vosmer T, Komoot A, Tofighian H, Ghorbani B, Engle MH, Zumberge A, Van de Velde T. Geochemical analysis of bitumen from West Asian Torpedo Jars from the c. 8th Century Phanom Surin Shipwreck in Thailand. J Archaeol Sci. 2020;117:105111. https://doi.org/10.1016/j.jas.2020.105111.

Tomber R. Rome and Mesopotamia—importers into India in the first millennium AD. Antiquity. 2007;81(314):972–88. https://doi.org/10.1017/S0003598X00096058.

Lischi S, Odelli E, Perumal JL, Lucejko JJ, Ribechini E, Mariotti Lippi M, Selvaraj T, Colombini MP, Raneri S. Indian Ocean trade connections: characterization and commercial routes of torpedo jars. Herit Sci. 2020;8(1):76. https://doi.org/10.1186/s40494-020-00425-9.

Colombini MP, Giachi G, Modugno F, Ribechini E. Characterisation of organic residues in pottery vessels of the Roman age from Antinoe (Egypt). Microchem J. 2005;79(1–2):83–90. https://doi.org/10.1016/j.microc.2004.05.004.

Hjulstrom B, Isaksson S, Hennius A. Organic geochemical evidence for pine tar production in Middle Eastern Sweden during the Roman Iron Age. J Archaeol Sci. 2006;33(2):283–94. https://doi.org/10.1016/j.jas.2005.06.017.

Pecci A, Domínguez-Bella S, Buonincontri MP, Miriello D, De Luca R, Di Pasquale G, Cottica D, Casasola DB. Combining residue analysis of floors and ceramics for the study of activity areas at the Garum Shop at Pompeii. Archaeol Anthropol Sci. 2018;10(2):485–502. https://doi.org/10.1007/s12520-017-0573-7.

Manhita A, Martins S, Gomes da Silva M, Lopes MC, Barrocas Dias C. Transporting olive oil in Roman times: chromatographic analysis of Dressel 20 Amphorae from Pax Julia Civitas, Lusitania. Chromatographia. 2020;83(9):1055–64. https://doi.org/10.1007/s10337-020-03927-7.

Tomber R. Indo-Roman trade: the ceramic evidence from Egypt. Antiquity. 2000;74(285):624–31. https://doi.org/10.1017/S0003598X00059986.

Seland EH. Archaeology of trade in the Western Indian Ocean, 300 BC–AD 700. J Archaeol Res. 2017;22(4):367–402. https://doi.org/10.1007/s10814-014-9075-7.

Tomber R, Spataro M, Priestman S. Early Islamic Torpedo Jars from Siraf: scientific analyses of the clay fabric and source of Indian Ocean transport containers. Iran. 2020. https://doi.org/10.1080/05786967.2020.1792797.

Durand C. From ‘ovoid jars’ to ‘torpedo jars’: Investigations into bitumen- lined transport containers in the Gulf and the Indian Ocean in antiquity (second century BCE– third century CE). Arab Arch Epig. 2021;32(1):21–32. https://doi.org/10.1111/aae.12186.

Reynolds P. Levantine amphorae from Cilicia to Gaza: a typology and analysis of regional production trends from the 1st to 7th centuries. In: Gurt Esparraguerra JM, Buxeda I Garrigòs J, Cau Ontiveros MA editors. LRCW I. Late Roman Coarse Wares, Cooking Wares and Amphorae in the Mediterranean: Archaeology and Archaeometry. British Archaeological Reports. International Series, Vol. 1340. Oxford, Archeopress. 2005. p 563–611.

Bezeczky T, Scherrer P, Sauer R. The amphorae of Roman Ephesus. Wien: Verlag der Österreichischen Akademie der Wissenschaften; 2013.

Karagiorgou O. Mapping Trade by the Amphora. In: Mango MM, editor. Byzantine Trade 4th-12th Centuries. London: Routledge; 2009. p. 37–58.

Williams DF. An integrated archaeometric approach to ceramic fabric recognition: A study case on late Roman amphora 1 from the eastern Mediterranean. In: Gurt Esparraguerra JM, Buxeda I Garrigòs J, Cau Ontiveros MA editors. LRCW I. Late Roman coarse wares, cooking wares and amphorae in the Mediterranean. Archaeology and archaeometry. British Archaeological Reports. International Series, Vol. 1340. Oxford, Archeopress. 2005. p 613–624.

Dorrego F, Carrera F, Luxán MP. Investigations on Roman amphorae sealing systems. Mater Struct. 2004;37(269):369–74. https://doi.org/10.1617/13702.

Romanus K, Baeten J, Poblome J, Accardo S, Degryse P, Jacobs P, De Vos D, Waelkens M. Wine and olive oil permeation in pitched and non-pitched ceramics: relation with results from archaeological amphorae from Sagalassos. Turkey J Archaeol Sci. 2009;36(3):900–9. https://doi.org/10.1016/j.jas.2008.11.024.

Colombini MP, Modugno F, Ribechini E. Direct exposure electron ionization mass spectrometry and gas chromatography/mass spectrometry techniques to study organic coatings on archaeological amphorae. J Mass Spectrom. 2005;40(5):675–87. https://doi.org/10.1002/jms.841.

Tomber R, Carter RA, Priestman SMN. Report on Torpedo Jars from the Williamson Collection. British Inst Persian Stud Newsl. 2010;38:6–7.

Tomber R. Beyond the Boundaries of the Periplus: The Persian Gulf Route in the Supply to Myos Hormos and Berenike. In: Manzo A, Zazzaro C, De Falco DJ, editors. Stories of Globalisation: The Red Sea and the Persian Gulf from Late Prehistory to Early Modernity. Leiden: Brill; 2019. p. 394–407.

Al-Jahwari NS, Priestman SMN, Sauer E. Fulayj: A Late Sasanian fort on the Arabian coast. Antiquity. 2018;92(363):724–41. https://doi.org/10.15184/aqy.2018.64.

Priestman SMN. A Quantitative Archaeological Analysis of Ceramic Exchange in the Persian Gulf and Western Indian Ocean, AD c. 400–1275. PhD Thesis, University of Southampton (UK). 2013.

Priestman SMN. Ceramic Exchange and the Indian Ocean Economy. London: British Museum Research Publication; 2021.

Tofighian H. Ancient Torpedo Jars of Iran (Persian Gulf). In: Krist G, Zhang L, editors. Archaeology and Conservation Along the Silk Road. Vienna: Bohlau Verlag Gmbh U Co Kg; 2018. p. 63–82.

Kennet D. Sasanian and Islamic Pottery from Ras al-Khaimah: Classification, Chronology and Analysis of Trade in the Western Indian Ocean. Oxford: Archaeopress; 2004.

Priestman SMN. Settlement & ceramics in Southern Iran: an analysis of the Sasanian & Islamic periods in the Williamson Collection. PhD Thesis, University of Durham (UK). 2005

Stern B, Connan J, Blakelock E, Jackman R, Conningham RAE, Heron C. From Susa to Anuradhapura: reconstructing aspects of trade and exchange in bitumen-coated ceramic vessels between Iran and Sri Lanka from the third to the ninth centuries AD. Archaeometry. 2008;50(3):409–28. https://doi.org/10.1111/j.1475-4754.2007.00347.x.

Carter RA, Connan J, Priestman SMN, Tomber R. Torpedo Jars from Sir Bani Yas, Abu Dhabi. Tribulus J Emir Nat Hist Group. 2011;19:162–3.

Whitehouse D, Williamson AG. Sasanian Maritime Trade. Iran. 1973;11(1):29–49.

de Cardi B. Archaeological Survey in Northern Oman, 1972. In: Tucci G, Faccenna D, Lanciotti L, Taddei M (eds). East and West. Istituto Italiano per l’Africa e l’Oriente (IsIAO); 1975. Vol 25, p. 9–75.

Tomber R. Indo-Roman trade: from pots to pepper. London: Bristol Classical Press; 1998.

Zazzaro C. The Ancient Red Sea Port of Adulis and the Eritrean Coastal Region. Previous investigations and museums collections. BAR International series 2569. Oxford: Archaeopress; 2013.

Zazzaro C, Cocca E, Manzo A. Towards a chronology of the Eritrean Red Sea port of Adulis (1st—Early 7th Century AD). J Afr Archaeol. 2014;12(1):43–73. https://doi.org/10.3213/2191-5784-10253.

Peacock D, Blue L. The Ancient Red Sea Port of Adulis, Eritrea Report of the Eritro-British Expedition, 2004–5. Oxford: Oxbow Books; 2007.

Phillipson DW. Archaeology at Aksum, Ethiopia, 1993–7, vol. 2. London: The Society of Antiquaries; 2000.

Fattovich R. From community to state: the development of the Aksumite Polity (Northern Ethiopia and Eritrea), c. 400 BC-AD 800. J Archaeol Res. 2019;27:249–85. https://doi.org/10.1007/s10814-018-9122-x.

Schmidt PR, Curtis MC. The archaeology of Ancient Eritrea. Trenton: The Red Sea Press; 2007.

Izzo FC, Zendri E, Bernardi A, Balliana E, Sgobbi E. The study of pitch via gas chromatography-mass spectrometry and Fourier-transformed infrared spectroscopy: the case of the Roman amphoras from Monte Poro, Calabria (Italy). J Archaeol Sci. 2013;40(1):595–600. https://doi.org/10.1016/j.jas.2012.06.017.

Koupadi K, Boyatzis SC, Roumpou M, Kalogeropoulous N, Kotzamani D. Organic remains in early Christian Egyptian metal vessels: investigation with fourier transform infrared spectroscopy and gas chromatography-mass spectrometry. Heritage. 2021;4(4):3611–29. https://doi.org/10.3390/heritage4040199.

Shearer GL. An evaluation of Fourier transform infrared spectroscopy for the characterization of organic compounds in art and archaeology. PhD Thesis, University of London (UK). 1989.

Fujii H, Mazzitelli JB, Adilbekov D, Olmer F, Mathe C, Vieillescazes C. FT-IR and GC-MS analyses of Dressel IA amphorae from the Grand Congloué 2 wreck. J Archaeol Sci Rep. 2019;28: 102007. https://doi.org/10.1016/j.jasrep.2019.102007.

Oudemans TFM, Boon JJ, Botto RE. FTIR and solid-state 13C CP/MAS NMR spectroscopy of charred and non-charred solid organic residues preserved in Roman Iron Age vessels from the Netherlands. Archaeometry. 2007;49(3):571–94. https://doi.org/10.1111/j.1475-4754.2007.00321.x.

Ribechini E, Colombini MP, Giachi G, Modugno F, Pallecchi P. A multi-analytical approach for the characterization of commodities in a ceramic jar from Antinoe (Egypt). Archaeometry. 2009;51(3):480–94. https://doi.org/10.1111/j.1475-4754.2008.00406.x.

Armonius C, Alexander R, Kagi RI, Sosrowidjojo IB. Fractionation of sedimentary higher plant derived pentacyclic triterpanes using molecular sieves. Org Geochem. 1994;21(5):531–43. https://doi.org/10.1016/0146-6380(94)90104-X.

Connan J. Use and trade of bitumen in antiquity and prehistory: molecular archaeology reveals secrets of past civilizations. Philos Trans R Soc Lond B Biol Sci. 1999;354(1379):33–50. https://doi.org/10.1098/rstb.1999.0358.

Van de Velde T. Black magic bitumen: an archaeometrical approach to 5000 years of bitumen imports in the Persian Gulf. PhD Thesis, University of Ghent (Belgium). 2015.

Spiro B, Welte DH, Rullkötter J, Schaefer RG. Asphalts, oils, and bituminous rocks from the Dead Sea area–a geochemical correlation study. AAPG Bull. 1983;67(7):1163–75. https://doi.org/10.1306/03B5B71D-16D1-11D7-8645000102C1865D.

Rullkötter J, Nissenbaum A. Dead sea asphalt in Egyptian mummies: molecular evidence. Naturwissenschaften. 1988;75(12):618–21. https://doi.org/10.1007/BF00366476.

Acknowledgements

The authors wish to warmly thank the Commission of Culture and Sports of the State of Eritrea, Northern Red Sea Museum of Massawa, and Centro Ricerche sul Deserto Orientale (Ce.R.D.O.) for supporting this research. The funding from the EU Horizon 2020 RI programme under the Marie Skłodowska-Curie grant agreement No 754511 (PhD Technologies Driven Sciences: Technologies for Cultural Heritage – T4C) is acknowledged. The sole responsibility of this publication lies with the authors. The European Union is not responsible for any use that may be made of the information contained therein.

Funding

The present work has received financial support from EU Horizon 2020 RI programme under the Marie Skłodowska-Curie grant agreement No 754511 (PhD Technologies Driven Sciences: Technologies for Cultural Heritage–T4C).

Author information

Authors and Affiliations

Contributions

AZ, TM, SM, CM provided the studied sample set and drafted the archaeological context of the study. AZ, SM, ALG, AR, MG, PD designed the research plan. AP, PD, AZ performed the FT-IR analysis and interpretation. CG, JŁ, ER performed the GC- MS analysis and interpretation. MG, PD, JŁ, ER, AP, AZ, SM, ALG, AR prepared the draft of the manuscript. MG, ALG, PD and AR supervised the scientific analysis. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Zerai, A., Guerrini, C., Łucejko, J.J. et al. The organic residues of lining in transport vessels from the Red Sea coast of Eritrea: a further element to understand past commercial relations. Herit Sci 10, 162 (2022). https://doi.org/10.1186/s40494-022-00801-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-022-00801-7