Abstract

Background

The current study was conducted to investigate the individual and combined occurrence of aflatoxin B1 (AFB1), deoxynivalenol (DON) and zearalenone (ZEN) in feeds from various Provinces of China during 2018 to 2020. A total of 3,507 feed samples, including 2,090 feed ingredients and 1,417 complete feed samples, were collected from different areas of China for mycotoxins analysis.

Results

The individual contamination of AFB1, DON and ZEN were present in more than 81.9%, 96.4% and 96.9% of feed samples, respectively, with average concentration ranges of AFB1 between 1.2–27.4 μg/kg, DON between 458.0–1,925.4 μg/kg and ZEN between 48.1–326.8 μg/kg. Notably, 0.9%, 0.5% and 0.1% of feed ingredients, and 1.2–12.8%, 0.9–2.9% and 0–8.9% of complete feeds for pigs, poultry and ruminants with AFB1, ZEN and DON that exceeded China’s safety standards, respectively. Moreover, more than 81.5% of feed ingredients and 95.7% of complete feeds were co-contaminated with various combinations of these mycotoxins.

Conclusion

This study indicates that the feeds in China were universally contaminated with AFB1, DON and ZEN during the past 3 years. These findings highlight the significance of monitoring mycotoxin contaminant levels in the domestic animal feed, and the importance of carrying out feed administration and remediation strategies for mycotoxin control.

Similar content being viewed by others

Introduction

Mycotoxins are naturally toxic secondary metabolites produced by various molds, including Aspergillus, Alternaria, Claviceps, Fusarium and Penicillium [1]. More than 500 mycotoxins have been identified to date [2]. Aflatoxin B1 (AFB1), deoxynivalenol (DON) and zearalenone (ZEN) are recognized as the primary toxins occurring in agricultural commodities, such as maize, peas, peanuts, wheat, barley, millet, nuts, oily feedstuffs, forage, and their by-products [3,4,5]. Mainly generated by Aspergillus, AFB1 is the most lethal toxin, exhibiting hepatotoxic, carcinogenic, mutagenic, and teratogenic properties in animals and humans [6,7,8]. Both DON and ZEN are primarily generated by Fusarium molds. DON is a type B trichothecene, which can cause anorexia, emesis, and impairs intestinal and immune function by inhibiting nucleic acid and protein synthesis in livestock [5, 9,10,11], while ZEN is an estrogenic mycotoxin, that can induce reproductive and fertility disorders by competing with 17 β-estradiol for estrogen receptor binding [11,12,13,14].

Since mycotoxins can affect animal production, as well as product quality and safety, safety standards for mycotoxins in feedstuffs and feed have been established world-wide. For example, the European Commission set limitations of AFB1, DON, and ZEN at 5–20 μg/kg, 900 μg/kg, and 250 μg/kg, respectively, for all kinds of feedstuffs and feed [15, 16]. In 2017, China’s General Administration of Quality Supervision, Inspection and Quarantine released the latest version of safety standards (GB 13078–2017) for AFB1, DON, and ZEN; which are 10–20 μg/kg, 1,000–5,000 μg/kg, and 100–250 μg/kg, respectively, for feedstuffs and complete feeds (Table 1) [17].

Global climate change is increasing crop susceptibility to fungal infection, which is further causing increased mycotoxin contamination of staple cereals [18, 19]. China’s agriculture sector is highly susceptible to mycotoxin contamination in several climatic regions across the country; for example, the warm or humid conditions of the Yangtze, Yellow River basins and northeast region and their numerous rainfall events, are favorable for mold growth and mycotoxin production in crops [20,21,22]. Therefore, monitoring mycotoxin concentrations in the feedstuffs and complete feeds from these and other regions across China is essential to prevent farm animal exposure to mycotoxins and to ensure feed and food safety. Thus, the current study was conducted in order to investigate the individual and combined contamination of AFB1, DON and ZEN in feedstuffs and complete feeds collected from different regions of China.

Materials and methods

Samples collection and preparation

A total of 3,507 feeds samples were collected during 2018 to 2020 from either feed companies or livestock farms in different regions of China. There were 2,090 feedstuff samples including 699 corn, 127 dried distillers grains with soluble, 61 corn germ meal, 68 corn bran, 26 corn gluten meal, 171 wheat, 108 wheat middling, 275 wheat bran, 17 wheat flour, 177 soybean meal, 24 soybean bran, 33 rapeseed meal, 41 peanut meal, 79 fish meal, 125 grass grain, 41 unite bran, 18 rice bran, along with 1,417 complete feed samples including 620 pig feed, 572 poultry feed and 225 ruminant feed. These feed samples were primarily collected from the provinces of Anhui, Beijing, Chongqing, Fujian, Guangdong, Guangxi, Gansu, Henan, Hebei, Hunan, Hubei, Heilongjiang, Inner Mongolia, Jiangsu, Jiangxi, Jilin, Liaoning, Ningxia, Shandong, Sichuan, Shanxi, and Zhejiang. Since few feed samples with insufficient quantity, 3,500, 3,507 and 3,499 samples were analyzed for AFB1, DON and ZEN, respectively. The feed samples were stored in sealing bags at − 20 °C before analysis.

Extraction of mycotoxins from samples

AFB1, DON and ZEN were extracted from the feed samples as previously described [4, 22, 23]. Briefly, 25 g of the mashed feed samples were mixed with a 100 mL solution of methanol: water (80, 20, v/v), methanol: water (60, 40, v/v) and acetonitrile: water (84, 16, v/v) for AFB1, DON and ZEN isolation, respectively. The samples were blended using a commercial blender at high speed for 3 min and filtered using a Mycosep® #226 column (Romer Labs. Inc., Singapore). The solvent extracts were diluted with phosphate-buffered saline solution (PBS, pH 7.4), then washed with PBS and methanol-water solution through immunoaffinity columns; AokinImmunoClean CF AFLA and CF DON (Aokin AG, Germany) for AFB1 and DON, respectively, and ZearaStar (Romer Labs, Austria) for ZEN. Finally, the mycotoxins were eluted from the columns using methanol, and concentrated to dryness under a nitrogen air steam. The mycotoxin residues were then re-dissolved in a mobile phase described below, filtered through a Millex PTFE 0.22 μm filter (Merck, Tianjin, China), and analyzed by high-performance liquid chromatography (HPLC).

HPLC analysis

The mycotoxins were quantified followed the national standard methods as previously described [4, 22,23,24,25]. Briefly, AFB1 concentrations were measured with a reverse-phase HPLC/fluorescence detection system (Agilent 1260, Agilent Technologies, Waldbronn, Germany) with a 360 nm excitation and 440 nm emission fluorescence detector. A C18 column (4.6 mm × 250 mm, 5 μm, Dikma, Shanghai, China) was employed with the limit of detection (LOD) and quantification (LOQ) set at 0.5 μg/kg and 1.5 μg/kg, respectively. A mobile phase of methanol: water: acetonitrile (30, 60, 10, v/v/v) was used for AFB1 analysis at a flow rate of 1 mL/min, and the column temperature was set at 30 °C. DON and ZEN concentrations were measured using a Shimadzu LC-20A binary gradient liquid chromatograph (Shimadzu Europa GmbH, Duisburg, Germany) equipped with a C18 (4.6 mm × 150 mm, 5 μm) reverse-phase column (ZORBAX Eclipse XDB-C18, Agilent Technologies, Waldbronn, Germany). The mobile phase for DON analysis consisted of methanol: water solution (20, 80, v/v) at a flow rate of 0.8 mL/min under UV light at a wavelength of 218 nm [24], and the LOD and LOQ for DON were 100 μg/kg and 260 μg/kg, respectively. A mobile phase of methanol: water: acetonitrile (8, 46, 46, v/v/v) was used for ZEN analysis at a flow rate of 1 mL/min under 274 nm excitation and 440 nm emission wavelengths [25]; the LOD and LOQ for ZEN were 10 μg/kg and 24 μg/kg, respectively. The blank samples are the solvents that were used to dissolve standard samples before HPLC analysis. LOD and LOQ correspond to the amount of analyte for which the signal-to-noise ratio is equal to 3 and 10 [26, 27], respectively, with a minor adjustment according to our previous study [23].

Statistical analysis

All the data were analyzed by the Microsoft Excel 2003 (Microsoft Corporation, Redmond, USA) and expressed as means, median, maximum, or percentages.

Results

Occurrence of AFB1 in feeds

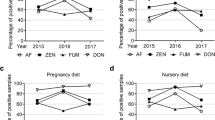

A total of 3,500 feed samples, including 2,083 feedstuff and 1,417 complete feeds, were collected between 2018 and 2020 for analysis of AFB1 (Table 2). AFB1 was detected in 81.9–100% of feedstuff and complete feeds, with the average levels ranging from 1.2–27.4 μg/kg. The highest median concentration of AFB1 was 32.0 μg/kg in peanut meal from the 2019 harvest, followed by 15.6 μg/kg in corn bran from 2020 and 10.8 μg/kg in complete ruminant feed from the 2019 harvest. The maximum levels of AFB1 were 221 μg/kg in corn harvested in both 2018 and 2019, followed by 77.5 μg/kg in both ruminant complete feed from 2018 and wheat middling from 2019, and 68.7 μg/kg in corn bran from 2018. Only 18 raw feed ingredient samples, which account for 0.9% of all the analyzed feedstuffs, were contaminated with AFB1 at concentrations over the Chinese safety standard concentration of 250 μg/kg (Table 1). Notably, 9 samples of complete pig feed, 7 samples of complete poultry feed and 29 samples of complete ruminant feed, which account for 1.5%, 1.2% and 12.8% of all the analyzed samples were contaminated with AFB1 at levels exceeding Chinese safety standard concentrations (Table 1).

Occurrence of DON in feeds

A total of 3,507 samples, including 2090 feedstuffs and 1,417 complete feeds, were collected during 2018–2020 for DON analysis (Table 3). DON was detected in 96.4–100% of feedstuffs and complete feeds, with the mean values ranging from 458.0–1,925.4 μg/kg. The highest median concentration of DON was 1,529.7 μg/kg found in wheat middling harvested during 2018, followed by 1,449.5 μg/kg in grass grain collected in 2018, 1,370.6–1,381.5 μg/kg in wheat bran harvested during 2018 and 2019, and 1,346.6–1,367.8 μg/kg in dried distillers grains with soluble from 2018 and 2020. The maximum contamination of DON was 9,186.4 μg/kg in wheat middlings harvested in 2018, followed by 6,430.6 μg/kg in dried distillers grains with soluble from 2018, 4,985.2 μg/kg in corn bran from 2018, and 4,505.0 μg/kg in rice bran from 2019. Only 2 samples, 1 wheat middling and 1 dried distillers grains with soluble, were contaminated with DON at concentrations over 5,000 μg/kg. However, 55 complete pig feed samples, which account for 8.9% of all the complete pig feed samples, were contaminated with DON at levels over the Chinese safety standard concentration of 1,000 μg/kg (Table 1).

Occurrence of ZEN in feeds

A total of 3,499 samples, including 2,089 feedstuffs and 1,415 complete feeds, were collected during 2018–2020 for ZEN analysis (Table 4). ZEN was detected in 96.9–100% of feedstuffs and complete feeds, with the mean concentrations ranging from 48.1–326.8 μg/kg. The highest median value of ZEN was 326.8 μg/kg in corn gluten meal from 2020, followed by 226.0 μg/kg in corn germ meal from 2020, and 168.5 μg/kg in rice bran from 2019. The maximum concentrations of ZEN were 1,599.0 μg/kg found in both grass grain and complete pig feed from 2019, followed by 956.7 μg/kg in dried distillers grains with soluble from 2019, and 906.9 μg/kg in both wheat middlings and complete ruminant feed from 2018 and 2019. A total of 10 feedstuffs and 27 complete feed samples, which account for 0.5% and 1.9% of all the analyzed feedstuffs and complete feed samples, respectively, were contaminated with ZEN at levels over the Chinese safety standard concentration (Table 1).

Co-occurrence of AFB1, DON and ZEN in feeds

The co-occurrence of AFB1, DON and ZEN in feedstuffs and complete feed samples during 2018–2020 were presented in Table 5. The co–occurrence of AFB1 + DON, AFB1 + ZEN, DON+ZEN, and AFB1 + DON+ZEN in feed ingredients ranged from 81.9–100%, 81.5–100%, 96.1–100% and 81.5–100%, respectively. Notably, the co-contaminates of AFB1 + DON, AFB1 + ZEN, DON+ZEN, along with AFB1 + DON+ZEN in complete feeds ranged from 97.8–100%, 97.8–100%, 95.7–100% and 95.7–100%, respectively.

Discussion

The present study was carried out to investigate the individual and combined contamination of the most prevalent and toxic mycotoxins, AFB1, DON and ZEN, in feedstuffs and complete feeds harvested from various regions of China between 2018 and 2020. In general, the three analyzed mycotoxins displayed a considerably high occurrence in the analyzed feed samples, ranging from 81.9–100%, 96.4–100%, and 96.9–100% for AFB1, DON and ZEN, respectively. The average concentration of AFB1 (1.2–27.4 μg/kg) determined in this study was lower than formerly reported concentrations (0.4–627 μg/kg) from samples harvested between 2013 and 2015 in China [21, 22], while higher than concentrations (1.6–10.0 μg/kg) from samples harvested between 2016 and 2017 in China [4]. Although only 0.9% of the analyzed raw feed ingredients (corn, corn bran, wheat middling, wheat bran, peanut meal, and grass grain) with AFB1 exceeded the Chinese safety standard concentration, 1.5%, 1.2% and 12.8% of all the analyzed final products for pig, poultry and ruminant contained AFB1 over the limitation of Chinese safety standard. These results are much higher than the previously reported that 1.0% analyzed feed samples with AFB1 exceeded China’s safety standards [4]. These divergences could be due to the fact that the analyzed feed samples were randomly gathered from different regions, and weather varies in these areas during the harvest period. Owing to AFB1 is the most toxic mycotoxin [6, 28, 29], it is important to persist in supervising the concentration of AFB1 in the raw feed ingredients and final products in the future.

The occurrence and level of DON in the analyzed feed samples in this study were quite high. The percentage of positive samples of DON was 96.4–100%, which is higher than the previously reported 50.0–100% in feeds collected in China during 2013–2017 [4, 21, 22]. The average concentration of DON in feeds ranged between 458.0–1,925.4 μg/kg, which is relatively lower than the previously reported range of 364.5–4,381.5 μg/kg in the feeds collected in China between 2013 and 2017 [4, 21, 22]. Although only 0.1% of analyzed feed ingredients contaminated with DON exceeded China’s safety standards, 8.9% of the complete pig feed samples that were contaminated with DON over the limitation of the safety standards of China. These findings remind us that we need to be cognizant of the potential for contamination of the raw feed ingredients, including corn bran, dried distillers grains with soluble, wheat middling, wheat bran, and grass grain, which were relatively severely contaminated by DON with an average concentrations more than 1,000 μg/kg.

The occurrence of ZEN (96.9–100%) in the analyzed feed samples in the current study was higher than the previously reported (50.0–100%) from harvests between 2013 and 2017 [4, 21, 22]. However, the concentration of ZEN (48.1–326.8 μg/kg) in the analyzed feed samples was relatively lower in this study than the previously reported (0–729.2 μg/kg) from harvests between 2013 and 2017 [4, 21, 22]. These differences could be due to the various sampling regions and different weather conditions during the harvest periods. Notably, 0.5% of all the analyzed feedstuff samples, including corn, corn gluten meal, corn germ meal and grass grain, were contaminated with ZEN at concentrations that exceeded the Chinese safety standard level. Meanwhile, 2.9%, 1.2% and 0.9% of all the analyzed complete feeds for pig, poultry and ruminant contained ZEN that exceeded the regulatory limits in China; this finding was much lower than previously reported, whereby 10.7% of the complete pig feeds were shown to be contaminated with ZEN exceeding the regulatory limits [4].

Mycotoxins co-contamination can exert additive and synergistic toxic effects, which have been well-documented [3, 30,31,32,33,34]. Unfortunately, co-contamination of mycotoxins in feeds was extremely universal in this study, with more than 81.5% of feed samples containing 2 or more mycotoxins. Notably, corn bran, corn gluten meal, corn germ meal, wheat bran, wheat flour, unite bran, rice bran, soybean bran, rapeseed meal, peanut meal, fish meal and grass grain were 100% co-contaminated with AFB1, DON and ZEN. Meanwhile, more than 97.8%, 98.4% and 95.7% complete feeds for pig, poultry and ruminant, respectively, were also co-contaminated with these three mycotoxins. These results were similar to previous reports which showed that mycotoxin co-contamination is a widespread issue in the feed industry [21, 35,36,37,38]. Since the present feed safety regulations do not consider the potential toxicity of co-contamination of mycotoxins, their combined toxicity on animal health and production may be underestimated, and the combined toxicity of these mycotoxins warrants further study so that it might be considered when new regulatory limits for mycotoxins are set in the future.

It is also worth noting that the average concentrations of AFB1 and DON were not different in the analyzed feeds amongst the three harvest years, while the mean levels of ZEN were much higher in most of the feedstuffs and all the complete feeds in the year 2020 in comparison to years 2018 and 2019. Meanwhile, the raw feed ingredients, corn, dried distillers grains with soluble, corn gluten meal, corn germ meal, corn bran, wheat middling, wheat bran, peanut meal, and grass grain, were seriously contaminated with more than one mycotoxin. Thus, these ingredients need to be regularly monitored. Moreover, strategies for the control of mycotoxins are needed to be seriously considered. Generally, during the pre-harvest, good field and storage management strategies, including crop rotation, variety choice, use of fungicide and antagonistic fungi, temperature, moisture content, humidity of the environment, are important to prevent the mycotoxigenic fungal development and mycotoxin formation [39, 40]. During the post-harvest, physical, chemical and biological approaches have been used to decontaminate mycotoxins from the feedstuffs [39, 40]. So far, the application of binders’ adsorption of mycotoxins from the gastrointestinal tract of animals is the most effective way in practice [40, 41]. While development of novel microorganisms or their enzymes used to biodegradation of the mycotoxins is also a promising approach [39, 40, 42].

Conclusion

In conclusion, this study found that AFB1, DON and ZEN were highly prevalent in all the analyzed feed samples collected from different areas of China between 2018 and 2020. Notably, 0.9%, 0.5% and 0.1% of analyzed raw feed ingredients exceeded China’s safety standards for AFB1, ZEN and DON, respectively. However, much higher ratios of AFB1 (1.2–12.8%), ZEN (0.9–2.9%) and DON (0–8.9%) in complete feeds for pigs, poultry and ruminant exceeded China’s safety standards. Moreover, the co-contamination of AFB1, DON and ZEN was quite common in both the raw feed ingredients (81.5–100%) and complete feed products (95.7–100%). Taken together, these outcomes remind us that, 1) contamination of mycotoxins in feeds needs to be regularly monitored, 2) suitable remediation strategies for mycotoxins need to be applied in the feed industry, and 3) new regulatory limits should consider mycotoxin co-contamination in the feeds.

Availability of data and materials

The datasets used and/or analyzed during the current study are publicly available.

Abbreviations

- AFB1 :

-

Aflatoxin B1

- DON:

-

Deoxynivalenol

- ZEN:

-

Zearalenone

- HPLC:

-

High-performance liquid chromatography

- LOD:

-

Limits of detection

- LOQ:

-

Limits of quantification.

References

Steyn PS. Mycotoxins, general view, chemistry and structure. Toxicol Lett. 1995;82:843–51.

Haque MA, Wang Y, Shen Z, Li X, Saleemi MK, He C. Mycotoxin contamination and control strategy in human, domestic animal and poultry: a review. Microb Pathog. 2020;142:104095. https://doi.org/10.1016/j.micpath.2020.104095.

Sun LH, Lei MY, Zhang NY, Zhao L, Krumm CS, Qi DS. Hepatotoxic effects of mycotoxin combinations in mice. Food Chem Toxicol. 2014;74:289–93. https://doi.org/10.1016/j.fct.2014.10.020.

Ma R, Zhang L, Liu M, Su YT, Xie WM, Zhang NY, et al. Individual and combined occurrence of mycotoxins in feed ingredients and complete feeds in China. Toxins (Basel). 2018;10:113.

Ji X, Zhang Q, Zheng W, Yao W. Morphological and molecular response of small intestine to lactulose and hydrogen-rich water in female piglets fed Fusarium mycotoxins contaminated diet. J Anim Sci Biotechnol. 2019;10(1):9. https://doi.org/10.1186/s40104-019-0320-2.

International Agency for Research on Cancer (IARC). IARC Monographs on the Evaluation of Carcinogenic Risk of Chemicals to Humans—Overall Evaluation of Carcinogenicity: An Updating of IARC Monographs;IARC: Lyon, France, 1987; Volumes 1–42.

Sun LH, Zhang NY, Zhu MK, Zhao L, Zhou JC, Qi DS. Prevention of Aflatoxin B1 Hepatoxicity by dietary selenium is associated with inhibition of cytochrome P450 Isozymes and up-regulation of 6 Selenoprotein genes in Chick liver. J Nutr. 2016;146:655–61.

Zhang NY, Qi M, Zhao L, Zhu MK, Guo J, Liu J, et al. Curcumin prevents Aflatoxin B1 Hepatoxicity by inhibition of cytochrome P450 Isozymes in Chick liver. Toxins (Basel). 2016;8(11):327. https://doi.org/10.3390/toxins8110327.

Shi D, Zhou J, Zhao L, Rong X, Fan Y, Hamid H, et al. Alleviation of mycotoxin biodegradation agent on zearalenone and deoxynivalenol toxicosis in immature gilts. J Anim Sci Biotechnol. 2018;9(1):42. https://doi.org/10.1186/s40104-018-0255-z.

Liu M, Zhang L, Chu XH, Ma R, Wang YW, Liu Q, et al. Effects of deoxynivalenol on the porcine growth performance and intestinal microbiota and potential remediation by a modified HSCAS binder. Food Chem Toxicol. 2020;141:111373. https://doi.org/10.1016/j.fct.2020.111373.

Zhang L, Ma R, Zhu MX, Zhang NY, Liu XL, Wang YW, et al. Effect of deoxynivalenol on the porcine acquired immune response and potential remediation by a novel modified HSCAS adsorbent. Food Chem Toxicol. 2020;138:111187. https://doi.org/10.1016/j.fct.2020.111187.

Gao X, Xiao ZH, Liu M, Zhang NY, Khalil MM, Gu CQ, et al. Dietary Silymarin supplementation alleviates Zearalenone-induced hepatotoxicity and reproductive toxicity in rats. J Nutr. 2018;148(8):1209–16. https://doi.org/10.1093/jn/nxy114.

Takemura H, Shim JY, Sayama K, Tsubura A, Zhu BT, Shimoi K. Characterization of the estrogenic activities of zearalenone and zeranol in vivo and in vitro. J Steroid Biochem Mol Biol. 2007;103(2):170–7. https://doi.org/10.1016/j.jsbmb.2006.08.008.

Gao X, Sun L, Zhang N, Li C, Zhang J, Xiao Z, et al. Gestational zearalenone exposure causes reproductive and developmental toxicity in pregnant rats and female offspring. Toxins (Basel). 2017;9:21.

European Commission. Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. Off J Eur Commun. 2002;10–22.

European Commission. (2006/576/EU) of 17 August 2006 on the Presence of Deoxynivelenol, Zearalenone, Ochratoxin A, T−2 and HT-2 and Fumonisins in Products Intended for Animal Feeding. Official Journal European Community, 2006.

Hygienical Standard for Feeds; GB 13078–2017; National Criterion of China: Beijing, China, 2017.

Magan N, Medina A, Aldred D. Possible climate-change effects on mycotoxin contamination of food crops pre-and postharvest. Plant Pathol. 2011;60(1):150–63. https://doi.org/10.1111/j.1365-3059.2010.02412.x.

Marroquín-Cardona A, Johnson N, Phillips T, Hayes A. Mycotoxins in a changing global environment—a review. Food Chem Toxicol. 2014;69:220–30. https://doi.org/10.1016/j.fct.2014.04.025.

Guan S, Gong M, Yin Y, Huang R, Ruan Z, Zhou T, et al. Occurrence of mycotoxins in feeds and feed ingredients in China. J Food Agric Environ. 2011;9:163–7.

Li R, Wang X, Zhou T, Yang D, Wang Q, Zhou Y. Occurrence of four mycotoxins in cereal and oil products in Yangtze Delta region of China and their food safety risks. Food Control. 2014;35(1):117–22. https://doi.org/10.1016/j.foodcont.2013.06.042.

Wu L, Li J, Li Y, Li T, He Q, Tang Y, et al. Aflatoxin B1, zearalenone and deoxynivalenol in feed ingredients and complete feed from different province in China. J Anim Sci Biotechnol. 2016;7(1):63. https://doi.org/10.1186/s40104-016-0122-8.

Liu J, Sun L, Zhang J, Guo J, Chen L, Qi D, et al. Aflatoxin B1, zearalenone and deoxynivalenol in feed ingredients and complete feed from Central China. Food Addit Contam Part B. 2016;9(2):91–7. https://doi.org/10.1080/19393210.2016.1139003.

National Criterion of China. Determination of deoxynivalenol in food-High performance liquid chromatographic method with immunoaffinitycolumn clean-up. GB 23503-2009. Beijing: Standards Press of China; 2009.

National Criterion of China. Determination of zearalenone in food-high performance liquid chromatographic method with immunoaffinity column clean-up. GB 23504–2009. Beijing: Standards Press of China; 2009.

Kim DH, Hong SY, Kang JW, Cho SM, Lee KR, An TK, et al. Simultaneous determination of multi-mycotoxins in cereal grains collected from south korea by LC/MS/MS. Toxins (Basel). 2017;9:106.

Vial J, Jardy A. Experimental comparison of the different approaches to estimate LOD and LOQ of an HPLC method. Anal Chem. 1999;71(14):2672–7. https://doi.org/10.1021/ac981179n.

Zhao L, Feng Y, Deng J, Zhang NY, Zhang WP, Liu XL, et al. Selenium deficiency aggravates Aflatoxin B1-induced Immunotoxicity in Chick spleen by regulating 6 Selenoprotein genes and redox/inflammation/apoptotic signaling. J Nutr. 2019;149(6):894–901. https://doi.org/10.1093/jn/nxz019.

Deng J, Zhao L, Zhang NY, Karrow NA, Krumm CS, Qi DS, et al. Aflatoxin B1 metabolism: regulation by phase I and II metabolizing enzymes and chemoprotective agents. Mutat Res. 2018;778:79–89. https://doi.org/10.1016/j.mrrev.2018.10.002.

Basso K, Gomes F, Bracarense APL. Deoxynivanelol and fumonisin, alone or in combination, induce changes on intestinal junction complexes and in E-cadherin expression. Toxins (Basel). 2013;5(12):2341–52. https://doi.org/10.3390/toxins5122341.

Smith MC, Madec S, Coton E, Hymery N. Natural co-occurrence of mycotoxins in foods and feeds and their in vitro combined toxicological effects. Toxins (Basel). 2016;8:94.

Sun LH, Lei MY, Zhang NY, Gao X, Li C, Krumm CS, et al. Individual and combined cytotoxic effects of aflatoxin B1, zearalenone, deoxynivalenol and fumonisin B1 on BRL 3A rat liver cells. Toxicon. 2015;95:6–12. https://doi.org/10.1016/j.toxicon.2014.12.010.

Zhou H, George S, Hay C, Lee J, Qian H, Sun X. Individual and combined effects of Aflatoxin B1, Deoxynivalenol and Zearalenone on HepG2 and RAW 264.7 cell lines. Food Chem Toxicol. 2017;103:18–27. https://doi.org/10.1016/j.fct.2017.02.017.

Xu R, Karrow NA, Shandilya UK, Sun LH, Kitazawa H. In-vitro cell culture for efficient assessment of mycotoxin exposure, toxicity and risk mitigation. Toxins (Basel). 2020;12:146.

Binder E, Tan L, Chin L, Handl J, Richard J. Worldwide occurrence of mycotoxins in commodities, feeds and feed ingredients. Anim Feed Sci Technol. 2007;137(3-4):265–82. https://doi.org/10.1016/j.anifeedsci.2007.06.005.

Streit E, Schatzmayr G, Tassis P, Tzika E, Marin D, Taranu I, et al. Current situation of mycotoxin contamination and co-occurrence in animal feed—focus on Europe. Toxins (Basel). 2012;4(10):788–809. https://doi.org/10.3390/toxins4100788.

Chang H, Kim W, Park JH, Kim D, Kim CR, Chung S, et al. The occurrence of zearalenone in South Korean feedstuffs between 2009 and 2016. Toxins (Basel). 2017;9:223.

Kochiieru Y, Mankevičienė A, Cesevičienė J, Semaškienė R, Dabkevičius Z, Janavičienė S. The influence of harvesting time and meteorological conditions on the occurrence of Fusarium species and mycotoxin contamination of spring cereals. J Sci Food Agric. 2020;100(7):2999–3006. https://doi.org/10.1002/jsfa.10330.

Luo Y, Liu X, Li J. Updating techniques on controlling mycotoxins–a review. Food Control. 2018;89:123–32. https://doi.org/10.1016/j.foodcont.2018.01.016.

Zhu Y, Hassan YI, Watts C, Zhou T. Innovative technologies for the mitigation of mycotoxins in animal feed and ingredients–a review of recent patents. Anim Feed Sci and Tech. 2016;216:19–29. https://doi.org/10.1016/j.anifeedsci.2016.03.030.

Guo Y, Zhao L, Ma Q, Ji C. Novel strategies for degradation of aflatoxins in food and feed: a review. Food Res Int. 2020;140:109878.

Zhao L, Feng Y, Wei JT, Zhu MX, Zhang L, Zhang JC, et al. Mitigation effects of bentonite and yeast cell wall binders on AFB1, DON, and OTA induced changes in laying hen performance, egg quality, and health. Toxins (Basel). 2021;13:156.

Funding

This project was supported by the Chinese Natural Science Foundation projects (32072775 and 31772636), National Key Research and Development Program of China (2016YFD0501207), and JiangSu Aomai Bio-Technology Co., Ltd. (Nanjing, China).

Author information

Authors and Affiliations

Contributions

S.L.H. conceptualized and designed this study. Z.L., Z.L., X.Z.J., L.X.D., C.L.Y., and D.J.F. collected and analyzed the data. Z.L., S.L.H., and K.N.A. wrote the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors have approved the final manuscript.

Competing interests

The authors declare no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Zhao, L., Zhang, L., Xu, Z. et al. Occurrence of Aflatoxin B1, deoxynivalenol and zearalenone in feeds in China during 2018–2020. J Animal Sci Biotechnol 12, 74 (2021). https://doi.org/10.1186/s40104-021-00603-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40104-021-00603-0