Abstract

This paper aims to evaluate the technical efficiency and the total factor productivity change of dairy farms in EU countries. Analyses were carried out in order to determine which countries showed the best performance adaptations when the quota regime was relaxed and to evaluate the technical conditions of European farmers at the starting point of the new regime (milk quota abolition). A data envelopment analysis (DEA) was applied on aggregate data related to 22 European countries for the period from 2004 to 2012. The findings suggest that milk farms show small scope for improving efficiency using their own technical input. The estimation of total factor productivity and its components suggest that the European milk sector has suffered a decline in productivity. This means that external factors, independent of the farmers’ capacity to use technical inputs, can play a greater role than efficiency in conditioning productivity and profitability in the near future.

Similar content being viewed by others

Background

The demand for milk and dairy products has grown dramatically throughout the world during the last decade. Consumption has particularly increased in eastern Asia (China in primis), in middle eastern Asia, and in Africa. As regards cow’s milk, Thiele et al. (2013) forecast that milk consumption would increase with an average growth of 12 million tons per annum until 2022, implying that demand will grow from today’s figure of more than 630 million tons to about 750 million tons. However, even if all the analysts agree that demand will increase in the near future, some estimates of the rate of growth in milk and dairy consumption are lower than others over the next 10 years, mostly because they predict a lower increase in Chinese demand (European Commission 2014).

The greater part of the additional demand over the last 10 years has been satisfied by European producers, and this will continue to be the case. Indeed, the European Union (EU) is the most important supplier of milk and dairy products in the world market. The EU provides 24% of the world’s supply of fresh cow’s milk (Table 1).

The three largest dairy companies (Nestlé, Lactalis, and Danone) operate in Europe. However, they are global companies operating in a dynamic market scenario that is characterized by a high level of mergers and acquisitions throughout the world, and the market is sensitive to price fluctuations (Rabobank 2016). European dairy competitiveness is certainly affected by this market situation. For example, several European producers have delocalized their activity in other Member States, with implications for technological transfer within the EU borders and for competitiveness.

Recently, a new context was created for EU milk producers, because in March 2015, the era of milk quotas—which had characterized milk production for some 30 years—officially ended. The abolition of the milk quota system was not unexpected for producers, because it had been scheduled in the Mid-Term Review more than 10 years earlier (Berkum and Helming 2006; Frascarelli 2012; Lips and Rieder 2005; Rama 2013). Since 2004, a transition regime—involving lower support prices, the weaker protection of domestic supply, more authorized deliveries, and other actions—has been in place.Footnote 1 Since 2007, total milk production in Europe has been lower than the approved quotas, and prices have been more variable than before (European Commission, 2012). In 2009, for the first time, world prices fell below the support price, which was the last chance of shelter for European dairy farmers.

In 2012, the EU produced a series of new instruments aimed at preparing the sector for this new operating environment and ensuring support for milk producers from 2015 onwards. These measures are contained in the so-called “Milk Package,” which takes a longer-term perspective and aims to orient the strategies for the dairy sector towards the market. All the measures established by the Milk Package will apply until mid-2020, and the European Commission is mandated to monitor the implementation of the Milk Package measures, the effects of their application, and the milk market situation.

Several studies have been carried out to assess the impact of the new policy framework on the global dairy market arena. According to the US Dairy Export Council (USDEC), EU milk production will be about 11% higher in 2020 than it was 7 years before (USDEC 2015). The benefits of the growth in supply will be concentrated in six northern European countries: Ireland, the Netherlands, France, Germany, Denmark, and Poland. In the same period, the projected growth of EU dairy export flows is estimated to be about 5–6%. Other studies substantially validate the scenario proposed by USDEC. Jansik et al. (2014) talk about a true “Northern Europe Milk Belt” perspective in the coming years. Bouamra-Mechemache et al. (2008a, 2008b), Chantreuil et al. (2008), Kempen et al. (2011), Réquillart et al. (2008), and Witzke and Tonini (2008) all foresee an increase in the European milk supply of between 2.6 and 5.0%, as well as a price reduction ranging from 5.3 to 10.3%, with respect to the baseline milk quota scenario.

The new institutional dairy regime can reinforce the competitive position of European producers in the global arena, as well as re-distributing the milk supply among the European countries. In this scenario, the efficiency and the productivity capacity of producers could play an important role in expanding production and, as a consequence, profitability. This is because the abolition of milk quotas potentially allows producers to expand their production outside the assigned cap, forcing them to use technical inputs efficiently in their operations to expand production. In other words, when there are no quotas in the market, the ability of milk farmers to produce efficiently might become more relevant than it was in the past.

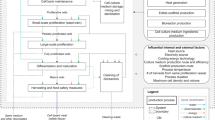

The aim of this paper is to evaluate the technical efficiency and factor productivity change of dairy farms in the EU countries in recent years, in order to determine which countries have shown the best performance adaptations since the quota regime was relaxed, and to evaluate the technical conditions for European farmers at the starting point of the new regime.

A non-parametric efficiency analysis is applied to aggregate data relating to 22 European countries for 2004–2012, to estimate efficiency measures. The analysis allows us to estimate the role of efficiency in conditioning productivity and to understand how much effect efficiency can have on productivity after the abolition of the milk quotas.

The “The empirical model and data” section illustrates the DEA model adopted and the data used. The “Results and discussion” section shows the main research findings and contains a discussion of these results. Finally, the “Conclusions” section provides some general conclusions.

Methods

The empirical model and data

Description of the data envelopment analysis (DEA)

Since Farrell’s (1957) seminal paper, two main approaches have been proposed for calculating efficiency and productivity: stochastic frontier analysis (SFA) and data envelopment analysis (DEA). Both procedures have advantages and disadvantages, and the suitability of the method to the data depends on the industry to be examined (Ruggiero 2007). The literature describes several studies comparing the two approaches (Gong and Sickles 1992; Hjalmarsson et al. 1996; Sickles 2005), and other papers have focused attention on agriculture (Kalaitzandonakes and Dunn 1995; Minh and Long 2009; Sharma et al. 1997; Theodoridis and Psychoudakis 2008; Wadud and White 2000). These studies have mostly investigated the differences between technical efficiency scores and the distribution of the scores over the observed sample, although contradictory results have been found.

Generally speaking, the main advantage of SFA is that it takes into account the stochastic variation of the output, because of its ability to handle the random noise that can affect the output. On the other hand, an SFA model is generally limited to the production of a single output, and some distributional assumptions need to be made on the functional forms of the production frontier and in order to separate the stochastic component from the inefficiency term. Assumptions about the random error component, the fixed nature of the parameters, and the production frontier specification can affect the empirical results.

In contrast, DEA is a non-parametric approach to estimating efficiency; it was originally proposed by Charnes et al. (1978). In the DEA environment, assumptions need to be made about the functional forms for the production or cost frontiers and about the distributions of the errors (Charnes et al. 1978). On the other hand, this method cannot separate the inefficiency component from the noise.

DEA was applied in this study in order to estimate changes in technical efficiency (TE), scale efficiency (SE), and total factor productivity (TFP) in European dairy farms. The decision to apply DEA rather than SFA was suggested by the nature of the database—there were too few observations to estimate a SFA modelFootnote 2—and by the need to deal with TE measures that were not related to an a priori estimated frontier. By solving a linear programming problem, DEA calculates technical efficiency by comparing each production unit against all the others. The best practice frontier is represented by a piecewise linear envelopment surface. The TE scores arising from DEA are therefore invariant to technology, because they are obtained through comparisons between one observation and others and not with respect to an estimated frontier. Furthermore, DEA allows us to adopt a production function that does not make behavioural assumptions about farmers. This is an important specification in our research because we are dealing with a sector for which output quotas have been applied over a long period—therefore confining milk production to a given cap and theoretically limiting the possibility of increasing the quantity produced—and in which price fluctuations have barely affected farmers’ behaviour.

The DEA approach

An output-oriented approach was used for calculating the constant returns to scale (CRS) DEA and variable returns to scale (VRS) DEA measures. This is because, for our hypotheses, we estimated technical efficiency in milk production in terms of farmers’ capacity to maximize production given a certain bundle of inputs. This means that we calculated technical efficiency by hypothesising that, theoretically, production could increase up to the level allowed by technology.

Quotas represent a possible cap on production, so an input-oriented approach (minimizing the use of inputs, given a certain level of output) might be suggested for this sort of problem. However, our choice is derived from the need to highlight the role of technical efficiency in a scenario without milk quotas, and for this reason, we opted for an efficiency measure that was not conditioned by possible caps on production. In other words, since no assumptions on farmers’ behaviour and on technology variation needed to be made in this DEA approach, we opted for an output-oriented approach so as to estimate technical efficiency in terms of the ability of dairy farmers to produce the maximum quantity of milk, given a bundle of inputs at their disposal and with a flexible policy scenario (the presence and afterwards the absence of quotas). We also bore in mind that dairy farmers have not necessarily achieved the maximum production allowed under the quota regime and that therefore production might basically not be strictly handled as a fixed output.

The DEA model

CRS TE for a single output is derived by solving the following linear programming model (Ali and Seiford 1993):

where θ i is the proportional increase in output possible for the ith farm, λ j is an N × 1 vector of weights relative to efficient observations, s is the output slack, and e k is the kth input slack. Banker et al. (1984) suggest that the CRS DEA model should be adapted to account for a variable returns to scale situation. Adding the convexity constraint N1’λ = 1, the model can be modified into VRS DEA.

A farm has efficient results when the values of θ and λ i are equal to 1, and λ j = 0. By contrast, an observation is inefficient when θ > 1, λ i = 0, and λ j ≠ 0. Solving (1), we can obtain a measure of TE that reflects the “distance” between the observed and the optimal output production for a certain input bundle:

where Y i and \( {Y}_i^{\ast } \) are the observed and maximum possible (optimal) outputs, respectively.

A measure of SE can be obtained by comparing the TECRS and TEVRS scores. Any difference between the two TE scores indicates that there is scale inefficiency that limits the achievement of an optimal (constant) scale, which can be calculated as follows (Coelli 1996a):

where SE i = 1 indicates full-scale efficiency and SE i < 1 indicates the presence of scale inefficiency.

Imposing a non-increasing return of scale (NIRS) condition on the DEA model, by changing the convexity constraint N1’λ = 1 of the DEA VRS model into N1’λ ≤ 1, we can estimate whether the observations operate under constant increasing (TENIRS ≠ TEVRS) or decreasing (TENIRS = TEVRS) returns to scale.

In the case of panel data, DEA permits us to calculate the Malmquist Total Factor Productivity (TFP) Index, which serves to estimate productivity change over a period (Berg et al. 1992). This allows us to decompose the TFP into more components: (1) technical efficiency changes; (2) technological changes; (3) pure efficiency changes; and (4) scale efficiency changes (Coelli 1996b). To be more precise, change in technical efficiency is described as the efficiency in reaching the production limit, and technological change as the curve shift in productivity limit (Mahadevan 2002).

Fare et al. (1994) specify an output-based TFP as follows:

which represents the productivity of the production point (x t + 1, y t + 1) relative to the production point (x1, y1). The M 0 index is the geometric mean of the two output-based Malmquist TFP indices described by period t and period t + 1 technology, respectively. M 0 > 1 will indicate positive TFP growth from the period t to the period t + 1. The four components of TFP change reported above are calculated from separate linear programming models similar to those used for calculating the TE measures (Coelli 1996b).

The sample and the data used

DEA was applied to aggregate data related to 22 European countries from 2004 to 2012. We took 2004 as the starting year for the observations, so data were available only for those countries that were part of the EU in that year and for which regime milk quotas were applied from that year onwards. Our analysis can therefore only be focused on 22 EU countries.

Farm Accounting Data Network (FADN) data for specialist milk producers were used (European Commission 2015). Specifically, we introduced average farm data for each country and for each observed year in the model. In other words, the output and input values involved in the analysis correspond to the annual average farm values achieved by each country.

A large amount of literature has been produced in the field of economic efficiency estimation in the dairy sector (see Mareth et al. (2016) for a review of this issue). However, the most of these studies have been based on analyses of farm data rather than aggregate data (Kelly et al. 2012; Mugera 2013; Sauer and Latacz-Lohmann 2015; van der Voort et al. 2014; Zhu et al. 2012). We are conscious that the use of aggregate data creates some limitations.

First, it does not allow us to evaluate the intra-state variability of the outputs and inputs involved in the dairy processes. Secondly, the estimated frontier based on average farms for each country might differ from the real frontier derived from individual farms. On the other hand, aggregate output and input data have been involved in some efficiency analyses in agriculture, especially in case of Malmquist TFP Index estimation among more countries (Coelli and Prasada Rao 2005).

We were dealing with representative farms of each country’s dairy sector, which implies that their decision-making units are the dairy farm sectors of the countries. However, there is a lack of more detailed data (crossing or panel data) for the 22 countries and the nine observation years, and as a consequence, the use of aggregate data represents an opportunity to estimate a milk production frontier for the EU as a whole.

Concerning the use of FADN data, the sample might not necessarily be representative of the dairy farm sector in each country, because the largest and the smallest farms are usually not covered by FADN data. Furthermore, the FADN sample changes every year, with some farms entering the sample and others leaving. On the other hand, this is a common problem when FADN data are used, and despite this, a wide collection of literature has been produced on frontier analysis using this sort of data, explicitly or implicitly assuming that the evolution of the FADN sample is aligned with the evolution of a certain sector in each country (Madau 2011, 2015; Oude Lansink et al. 2002).

The production frontier was described by one output and six technical inputs.Footnote 3 The data involved in the analysis are reported in Table 2.

Milk production was measured in terms of tons produced. Land area corresponds to the average area of arable land at the disposal of the farm and is calculated in hectares. The quantity of livestock is computed in terms of livestock units (LU)Footnote 4 so as to include a standard measure of stock in the model.

At the same time, the standard unit for the labour involved was calculated using the annual work unit (AWU)Footnote 5 as a measure of labour effort. Capital investment, variable costs, and other fixed costs were, obviously, calculated in money values at constant 2005 prices. Machinery and plant were measured in terms of an annual depreciation rate to give a measure of the annual utilization, on average, of the capital stock.

Table 3 shows the average annual value of each variable.

Results and discussion

All efficiency measures were estimated using the DEAP 2.1 program created by Coelli (1996a).

The results indicate that the TE for the CRS and VRS frontiers are, on average, equal to 0.980 and 0.993, respectively (Table 4). Considering the latter measure, the so-called pure efficiency, the results imply that specialist European milk farmers would have been able to increase their output by less than 1% by using their disposable resources more effectively (at the present state of technology) during the period 2004–2012. Therefore, the findings suggest that milk farms show little scope for improving their efficiency using their own technical inputs.

Most of the countries operate under full technical efficiency under the variable returns to scale hypothesis, whereas only six countries—Belgium, Germany, Hungary, Latvia, Austria, and Slovakia—show technical inefficiency. However, the room for improving technical efficiency is very limited in these six countries because all the estimated scores have values greater than 0.900.

Applying the NIRS condition, the scale efficiency was found, on average, to be equal to 0.987, implying that production could increase by 1–2% if farms adjusted their production scale for efficient production. However, the margins for improving efficiency in this direction might exist for nine countries—Belgium, the Czech Republic, Germany, Estonia, Hungary, Latvia, Portugal, Austria, and Slovakia—whereas the most of countries reveal an optimal level of scale efficiency.

The most scale inefficient countries were estimated to be operating under increasing returns to scale conditions. They exhibit a sub-optimal scale, implying that the milk farms need to be expanded in order to achieve full scale efficiency. By contrast, the Czech Republic, Estonia, and Latvia show decreasing returns to scale. These findings suggest that the sizes of the farms are, on average, supra-optimal and should be reduced to reach the optimal scale. This is not a surprising result because the supra-optimal scale countries are also characterized by a strong concentration of dairy livestock (a high value of LU for the farms, on average) and large areas of arable lands on big farms. In other words, the results are evidence that a reduction of the operational scale should be promoted in order to improve efficiency in those countries where the dairy farms are bigger.

The estimation of TFP and its components suggests that the European milk sector has suffered a decline in productivity (Table 5). Indeed, the TFP change (TFPC) is, on average, equal to 0.979, implying that during the period of the observations, there has been a generalized “technological” regression and that TFP has grown by a decreasing amount. The only countries to show values greater than unity for TFPC are Portugal, Finland, and Sweden.

The high efficiency that characterizes the sector plays a neutral role in conditioning the sub-optimal TFPC, since the effects provided by the efficiency components are all, on average, equal or close to unity.

The average score estimated for technical efficiency change is slightly greater than 1, suggesting that the effect on TFPC derived from efficiency change is positive—except in Denmark and Austria—but not very significant. Germany, Hungary, and Latvia show above-average technical efficiency change scores.

The table reveals that the estimated pure efficiency change and scale efficiency change do not affect TFPC (both average scores are equal to 1). Only Denmark exhibits a pure efficiency change score that is below 1, whereas Germany, Hungary, Latvia, Austria, and Slovakia show positive values (although the magnitude is low). Scale efficiency change is negative only for Denmark and Austria, and it is positive, but basically insignificant, for Germany, Estonia, Hungary, Latvia, and Portugal.

Technological change is, on average, negative, and the value substantially corresponds to the TFPC.

A technical efficiency change that is slightly greater than 1 might indicate that the European milk sector is capable of satisfying the production limit. On the other hand, a technological change index of less than 1 means that similar input volumes produce smaller output amounts. This implies that milk producers have to be considered to be efficient and that the reduction in productivity—found especially after 2009—is not the result of the ability of dairy farmers to use their inputs efficiently but might mainly be related to other factors (e.g., market shocks, milk price volatility).

Therefore, the findings partly suggest that exogenous factors might have an influence on both technical efficiency and productivity. This suggestion needs future research that can verify whether there is a strong relationship between, on the one hand, technical efficiency and productivity change and, on the other, certain external factors; this means that the results need to be interpreted with caution, particularly considering the nature of the data. However—even given these inherent methodological limitations—the trend that we have obtained for technical efficiency and productivity change over the period under consideration suggests that market conditions have played a perceptible role in efficiency and productivity.

Table 6 shows that the minimum and maximum TFP and technological change scores were found in 2008 and 2009, respectively. This means that in this interval, we found the greatest increase in technological change whereas, in contrast, the greatest decrease is observed from 2009 to 2010, when the technological change switches from 1.100 to 0.957, indicating that European farmers were not able to raise their efficiency levels (a retrogression of the production frontier).

Comparing the data on world milk price trends with the annual technological change arising from the DEA, a clear relationship comes to light. Indeed, the most relevant reduction in technological change is revealed to have taken place immediately after milk prices showed a remarkable increase (from 2007 and 2008); in contrast, the most sizeable growth in this score was observed in the annual period after world milk prices had dramatically decreased and milk production went down in Europe. The FAO Dairy Price Index, which measures world milk and dairy prices, increased from about 130 points in 2007 to 270 points in 2008 and afterwards fell to 120 points in 2009 (FAO 2016).Footnote 6

On the other hand, in the same period, technical efficiency had a great influence on the change in TFP, rising from 0.994 in 2009 to 1.011 in 2010. This is probably the result of the greater attention paid by farmers to utilizing their own technical inputs to countervail the reductions in milk supply and production capabilities that were probably derived from market shocks.

This is the critical point, because we found that there are only small margins for increasing (technical and scale) efficiency in the European milk production sector. It suggests that external factors, independent of farmers’ capacity to use technical inputs, can play a greater role than efficiency in conditioning productivity and, as a consequence, profitability in the near future. Hence—since an output-oriented approach was adopted—the elimination of the production cap as a result of the abolition of milk quotas may marginally contribute to increasing milk farm productivity, because productivity might basically depend on exogenous factors that affect technology.

Among the policy implications, the findings suggest that the Common Agricultural Policy (CAP) 2014–2020 should generally direct its energy towards promoting policies that are not directly based on improving dairy farm efficiency, because dairy farm efficiency mainly depends on market features. These conclusions are similar to those highlighted by Zhu et al. (2012) for some European countries. These authors found that CAP subsidies granted since 1992 have not had a positive effect on efficiency in the dairy sector and that efficiency is not a factor in conditioning competitiveness.

The general efficiency that was estimated indicates that only small margins for improving technical efficiency might exist and that policies should be addressed towards other tools for guaranteeing competitiveness. Confining price fluctuations within a tunnel and supporting dairy farmers through direct payments may be good tools for containing the expected increase in price volatility, guaranteeing income stability to farmers and ensuring a market scenario in which farms can be competitive. Furthermore, the CAP 2014–2020 should encourage milk farmers to produce milk in a way that covers their costs at the prevailing market prices. Basically, the Milk Package just contains measures aimed at boosting the position of dairy producers in the supply chain and preparing the dairy sector for a more market-oriented future, without directly intervening in the areas of efficiency and productivity.

On the other hand, some countries were found to be not fully efficient, and hence, for these countries, policies can contribute to improving their ability to increase their technical efficiency and productivity. We estimated output-oriented efficiency measures, but the countries estimated to be inefficient revealed their inefficiency even without the DEA approach (i.e., if a farm has inefficient results, this is shown with both an output- and an input-oriented measure). This means that in these countries, both output- and input-oriented policies can be promoted for improving efficiency and can contribute to increasing productivity and/or competitiveness.

Basically, some differences in the estimated efficiency among countries might be due to structural differences in the farms (e.g., farm size, farmer age, or climate conditions) or, on the other hand, to the farms’ management abilities. In the former case, adjusting the structural constraints can improve scale efficiency and, as a consequence, productivity, whereas in the latter case, the improvement of the management systems used in farms should be encouraged in order that farmers become more efficient in using the bundle of resources at their disposal. Where a degree of inefficiency exists, rather than the Milk Package, all the tools available under the second CAP pillar could support inefficient farmers in maintaining or expanding milk production, which is quite often vital for their economies.

Conclusions

This study was carried out in order to estimate technical efficiency and total factor productivity change in the European dairy sector, with the objective being to evaluate whether efficiency can play in a role in the new policy scenario for conditioning productivity and, at the least, profitability. The findings from the analyses are that milk farms show small scope for improving technical efficiency and that the European milk sector has suffered a decline in productivity. These results suggest that the ability of milk farmers to produce efficiently can only increase slightly in the future, implying that other factors might play a crucial role in conditioning economic performance in the absence of milk quotas.

Some normative lessons for the future can be derived from this research. However, it must be underlined that the use of efficiency analysis and the nature of the data used do not allow us to highlight convincing implications from a policy point of view. More research needs to be done to verify whether the margins for improving efficiency in the sector at a European scale are actually small, whether retrogressive behaviour characterizes the milk production function, and more importantly, what the role of technical efficiency is in the economic performance of the sector. This information is certainly useful for obtaining a better understanding of the sort of policies that need to be implemented to give adequate support to a sector that will be subject to great price volatility and foreign competition in the world markets when milk quotas are removed and where there is still a gap between EU countries in their farmers’ ability to use technical factors effectively.

Notes

It must be emphasized that support for dairy farmers has been declining throughout the world, especially in the USA (Wolf and Widmar 2015).

To adopt SFA, with a flexible functional form, we would need to have more data. To impose a more restrictive functional form, with fewer parameters to estimate, can be a limitation on the use of SFA.

According to Nunamaker (1985), the minimum number of observations corresponds to 3 × (number of outputs + number of inputs). In our case, this means that the size of the sample (22 observations) is adequate for handling six input variables (where the minimum is 21 observations).

The livestock unit, abbreviated as LU, is a reference unit that facilitates the aggregation of livestock from various species and of various ages using an agreed convention, via the use of specific coefficients established initially on the basis of the nutritional or feed requirement of each type of animal (Eurostat 2016). The reference unit used for the calculation of livestock units (=1 LSU) is the grazing equivalent of one adult dairy cow producing 3000 kg of milk annually, without additional concentrated foodstuffs.

One annual work unit, abbreviated as AWU, corresponds to the work performed by one person who is occupied on an agricultural holding on a full-time basis (Eurostat 2016). If the national provisions do not indicate the number of hours, then 1800 h are taken to be the minimum annual working hours, which is equivalent to 225 working days of 8 h each.

The FAO Dairy Price Index consists of butter, milk, cheese, and casein price quotations. The average is weighted by world average export trade shares.

References

Ali AI, Seiford LM (1993) The mathematical programming approach to efficiency. In: Fried HO, Lovell CAK, Schmidt SS (eds) The measurement of productive efficiency: techniques and applications. Oxford University Press, Oxford

Banker RD, Charnes A, Cooper WW (1984) Some models for estimating technical and scale inefficiency in data envelopment analysis. Manag Sci 30:1078–1092

Berg SA, Forsund FR, Jansen ES (1992) Malmquist indices of productivity growth during the deregulation of Norwegian banking, 1980–89. Scand J Econ 94:211–228

Berkum VS, Helming JFM (2006) European dairy policy in the years to come: impact of quota abolition on the dairy sector. Agricultural Economics Research Institute (Research report, The Hague

Bouamra-Mechemache Z, Jongeneel R, Réquillart V. (2008a) Removing EU milk quotas, soft landing versus hard landing. Paper presented at the 12th Congress of the European Association of Agricultural Economists, Ghent (Belgium), August 2008

Bouamra-Mechemache Z, Jongeneel R, Réquillart V (2008b) Impact of a gradual increase in milk quotas on the EU dairy sector. Eur Rev Agr Econ 35:461–491

Chantreuil F, Donnellan T, van Leeuwen M, Salamon P, Tabeau A, Bartova L (2008) EU dairy quota reform—AGMEMOD scenario analysis. Paper presented at the 12th Congress of the European Association of Agricultural Economists, Ghent (Belgium), August 2008

Charnes A, Cooper WW, Rhodes E (1978) Measuring the efficiency of decision making units. Eur J Oper Res 2:429–444

Coelli TJ (1996a) A guide to DEAP version 2.1: a data envelopment analysis (computer) program. CEPA working paper, no 8/96, Department of Econometrics, University of New England, Armidale, Australia

Coelli TJ (1996b) Measurement of total factor productivity and biases in technological change in Western Australian agriculture. J Appl Econ 11:77–91

Coelli TJ, Prasada Rao DS (2005) Total factor productivity growth in agriculture: a Malmquist index analysis of 93 countries, 1980–2000. Agric Econ 32:115–134

European Commission (2012) Report from the Commission to the European Parliament and the Council. Evolution of the market situation and the consequent conditions for smoothly phasing-out of the milk quota system—second “soft landing” report, COM (2012) 741 final, http://ec.europa.eu/agriculture/milk/quota-report/com-2012-741_en.pdf. Accessed Sept 2015

European Commission (2014) Prospects for EU agricultural markets and income 2014–2024. http://ec.europa.eu/agriculture/markets-and-prices/medium-term-outlook/2014/fullrep_en.pdf

European Commission (2015) Farm Accounting Data Network (FADN), agricultural and rural development. http://ec.europa.eu/agriculture/rica/. Accessed Oct 2015

Eurostat (2016) Glossary: http://ec.europa.eu/eurostat/statistics-explained/index.php/Glossary. Accessed June 2016

FAO (2016) Trade and markets: milk and dairy http://www.fao.org/economic/est/est-commodities/dairy/en/. Accessed Nov 2016

FAOSTAT (2016) http://faostat3.fao.org/home/E. Accessed May 2016

Fare R, Grosskopf S, Lovell CAK (1994) Production frontiers. Cambridge University Press, Cambridge

Farrell MJ (1957) The measurement of productive efficiency. J R Stat Soc Ser A 120 Part 3:253–290

Frascarelli A (2012) Improving the functioning of the food supply chain: an evaluation of some policy instruments for the post-2013 CAP. Economia Agro-alimentare 14:319–341

Gong B, Sickles R (1992) Finite sample evidence on the performance of stochastic frontiers and data envelopment analysis using panel data. J Econom 51:259–284

Hjalmarsson L, Kumbhakar SC, Hesmati A (1996) DEA, DFA and SFA: a comparison. J Prod Anal 7:303–327

Jansik C, Irz X, Kuosmanen N (2014) Competitiveness of Northern European dairy chains. MTT Agrifood Research Finland, Economic Research, Publications o 116

Kalaitzandonakes NG, Dunn EG (1995) Technical efficiency, managerial ability and farmer education in Guatemalan corn production: a latent variable analysis. Agr Res Econ Rev 24:36–46

Kelly E, Shalloo L, Geary U, Kinsella A, Wallace M (2012) Application of data envelopment analysis to measure technical efficiency on a sample of Irish dairy farms. Irish J Agr Food R 51:63–77

Kempen M, Witzke HP, Perez Dominguez I, Jansson I, Sckokai P (2011) Economic and environmental impacts of milk quota reform in Europe. J Policy Model 33:29–52

Lips M, Rieder P (2005) Abolition of raw milk quota in the European Union: a CGE analysis at the member country level. J Agr Econ 56:1–17

Madau FA (2011) Parametric estimation of technical and scale efficiency in the Italian citrus farming. Agr Econ Rev 12:91–112

Madau FA (2015) Technical and scale efficiency in the Italian citrus farming: a comparison between two methodological approaches. Agr Econ Rev 16:15–27

Mahadevan R (2002) A DEA approach to understanding the productivity growth of Malaysia’s manufacturing industries. Asia Pac J Manag 19:587–600

Mareth T, Thomé AMT, Oliveira FLC, Scavarda LF (2016) Systematic review and meta-regression analysis of technical efficiency in dairy farms. Int J Produc Perform Manag 65:279–301

Minh NK, Long GT (2009) Efficiency estimates for agricultural production in Vietnam: a comparison of parametric and non parametric approaches. Agr Econ Rev 10:62–78

Mugera AW (2013) Measuring technical efficiency of dairy farms with imprecise data: a fuzzy data envelopment analysis approach. Aust J Agr Resour Econ 57:501–517

Nunamaker T.R. (1985). Using Data Envelopment Analysis to Measure the Efficiency of Non-Profit Organizations: A Critical Evaluation. Manage. Decis. Econ. 6:50–58.

Oude Lansink A, Pietola K, Backman S (2002) Efficiency and productivity of conventional and organic farms in Finland 1994–1997. Eur Rev Agr Econ 29:51–65

Rabobank (2016) Global dairy top 20, RaboResearch Food & Agribusiness Research and Advisory, https://www.rabobank.com/en/images/global-dairy-top-20.pdf. Accessed Nov 2016

Rama D (2013) La riforma della Pac per il settore del latte e derivati: criticità e opportunità. Agriregionieuropa 35:50–52

Réquillart V, Bouamra-Mechemache Z, Jongeneel R, Penel C (2008) Economic analysis of the effects of the expiry of the EU milk quota system. Institut d’Economie industrielle, Toulouse

Ruggiero J (2007) A comparison of DEA and the stochastic frontier model using panel data. Int T Oper Res 14:259–266

Sauer J, Latacz-Lohmann U (2015) Investment, technical change and efficiency: empirical evidence from German dairy production. Eur Rev Agr Econ 42:151–175

Sharma KR, Leung P, Zaleski HM (1997) Productive efficiency of the swine industry in Hawaii: stochastic frontier vs data envelopment analysis. J Prod Anal 8:447–459

Sickles R (2005) Panel estimators and the identification of firm-specific efficiency levels in parametric, semiparametric and nonparametric settings. J Econom 126:305–334

Theodoridis AM, Psychoudakis A (2008) Efficiency measurement in Greek dairy farms: stochastic frontier vs. data envelopment analysis. Int J Econ Sci App Res 1:53–67

Thiele HD, Richarts E, Burchardi H (2013) Economic analysis of EU dairy sector development beyond 2015: trade, exports and world market integration. Fachhochschule Kiel, Kiel

USDEC (2015) European Union. The impact of the removal of milk quota in 2015, Arlington VA

van der Voort M, Van Meensel J, Lauwers J, Vercruysse J, Van Huylenbroeck G, Charlier J (2014) A stochastic frontier approach to study the relationship between gastrointestinal nematode infections and technical efficiency of dairy farms. J Dairy Sci 97:3498–3508

Wadud A, White B (2000) Farm household efficiency in Bangladesh: a comparison of stochastic frontier and DEA methods. App Econ 32:1665–1673

Witzke HP, Tonini A (2008) Dairy reform scenarios with CAPSIM acknowledging quota rent uncertainty. Paper presented at the 12th Congress of the European Association of Agricultural Economists, Ghent (Belgium), August 2008

Wolf CA, Widmar NJ (2015) Can insurance provide the US dairy farm safety net? Agr Food Econ 3:1–14

Zhu X, Demeter RM, Lansink AO (2012) Technical efficiency and productivity differentials of dairy farms in three EU countries: the role of CAP subsidies. Agric Econ Rev 13:66–92

Acknowledgments

This paper has been selected as the best paper of the 52nd SIDEA Conference in Rome-Viterbo (17–19 September 2015). It has been accepted for publication in this journal following the usual revision process.

Author information

Authors and Affiliations

Contributions

The study was jointly carried out and written by the authors. All authors read and approve the final manuscript.

Corresponding author

Ethics declarations

Authors’ information

FM is an assistant professor in Agricultural Economics and Policy at the University of Sassari (Italy). RF and PP are full professors in Agricultural Economics and Policy at the same university.

Competing interests

Each author discloses any actual or potential conflict of interest including any financial, personal, or other relationships with other people or organizations that could inappropriately influence, or be perceived to influence, their work.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Madau, F.A., Furesi, R. & Pulina, P. Technical efficiency and total factor productivity changes in European dairy farm sectors. Agric Econ 5, 17 (2017). https://doi.org/10.1186/s40100-017-0085-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40100-017-0085-x