Abstract

The widespread use of sulfonamides can result in the residue of sulfonamides in the foods of animal origin that are the major concerns of consumers and regulatory bodies due to their adverse reaction such as the development of antibiotic resistance. A rapid and efficient multi-residue analytical method was developed to screen and confirm 31 sulfonamides in livestock samples in a single run, using ultra-high-performance liquid chromatography combined with comprehensive mass spectrometric approaches. In this study, a novel sample preparation procedure was used, based on a modified QuEChERS method (Quick, Easy, Cheap, Effective, Rugged, and Safe). The linearity, sensitivity, accuracy, and precision of the method were validated according to the Codex guidelines. The response of the detector was linear for each target compound over a wide concentration range, with a correlation coefficient (r2) greater than 0.98. The limit of detection (LOD) and limit of quantification (LOQ) ranged from 0.3 to 5 ng g−1 and from 1 to 19 ng g−1 and the average recoveries (%) for three laboratories ranged from 85 to 109% with a CV (n = 5) below 22%. The applicability of this screening method was verified using real livestock samples. The proposed analytical method achieves identification and quantification of target sulfonamides at trace levels in a short analysis time. None of the samples contained residues that exceeded the maximum residue limit (MRL).

Similar content being viewed by others

Introduction

Sulfonamides are added in products of animal origin to control and prevent diseases owing to their relatively low cost, low toxicity, and excellent antibacterial activity against common bacteria. Sulfonamides form one of the most widely administered classes of antibiotics [1]. They have a common structure of an unsubstituted amine on the benzene ring and a sulfonamide group parallel to the amine. The nitrogen of the sulfonyl amine group is designated as N1, and the nitrogen in the para-amino group is denoted as N4. Sulfonamides are N-substituted derivatives of sulfanilamide that inhibit bacterial growth by acting as competitive inhibitors of p-aminobenzoic acid during the folate metabolic cycle [2]. This inhibition leads to reduced availability of the reduced folic acid, which is essential for nucleic acid-based systems [3].

The use of sulfonamides can lead to sulfonamide residues in foods of animal origin, causing adverse reactions such as thyroid follicular tumors and the development of antibiotic resistance. Such issues are major concerns among consumers and regulatory bodies, increasing worries on food safety [4, 5]. The emergence of drug residues in animal-derived products have led governments in the United States, European Union, Japan, and other countries to establish surveillance programs [6]. The European Union set a maximum residue limit (MRL) of 100 μg kg−1 for sulfonamides in food of animal origin such as meat, milk, and eggs [7]. The Codex Alimentarius Commission set MRL of 20 and 100 μg kg−1 for sulfonamides in cattle milk and animal origin (muscle, fat, kidney, and liver) products, respectively [8]. Korea set a MRL of 100 μg kg−1 as a total of sulfonamides in livestock products, whereas the same value was set as limit of quantification (LOQ) levels for eggs (Korea Food code, 2022).

Numerous analytical methods have been developed for the screening and quantification of sulfonamides in livestock products [9]. Such analytical methods are mainly based on microbiological assays [10], immunoassays [11], capillary electrophoresis [12], high performance liquid chromatography with diode array detection (HPLC–DAD) [13], gas chromatography-mass spectrometry (GC–MS) [14], liquid chromatography-mass spectrometry (LC–MS) [15], and hydrophilic interaction chromatography-mass spectrometry [16]. A reported GC–MS method required chemical derivatization of the polar sulfonamides owing to their low volatility and extensive cleanup to overcome matrix interference [17]. HPLC-based methods have received considerable attention as analytical methods: HPLC with photodiode array (PDA) detection has been used to measure several sulfonamide residues in foods of animal origin [18]. HPLC combined with ultraviolet detection (UV) is the most widely applied technique for analysis of sulfonamide residues [19]. A common problem arising in the extraction of sulfonamides from biological matrices is the presence of natural organic components in the sample, which reduce the extraction efficiency and interfere with detection. Sample preparation procedures such as solid-phase extraction (SPE), liquid–liquid extraction (LLE), and matrix solid-phase dispersion (MSPD) have been used for the extraction of sulfonamides from meat and milk [20, 21].

In this study, a rapid, sensitive, and reliable method was developed for the simultaneous determination of 31 sulfonamides in livestock products. Ultra-high-performance liquid chromatography was used with tandem mass spectrometry as a detector, equipped with electrospray ionization with a triple quadrupole analyzer. Sample preparation involved a modified QuEChER extraction method and dispersive-solid phase extraction (d-SPE) as well as cleanup with n-hexane saturated with acetonitrile. The developed method was validated based on the Codex guidelines (CAC/GL 71-2009) and tested on real samples to confirm the simultaneous determination of the target compounds.

Previous studies have proposed many simultaneous analytical methods for sulfonamides, but only up to 23 sulfonamides were analyzed in livestock samples, and no analytical methods have analyzed sulfanilamide, succinylsulfathiazole, and phthalylsulfathiazole simultaneously [22, 23]. In order to manage as many sulfonamides as possible in accordance with the implementation of the Positive List System (PLS) by the Ministry of Food and Drug Safety (MFDS) of the Korea, an analytical method that can analyze 31 sulfonamides was developed. Therefore, this is the first study to demonstrate the screening and confirmation of 31 sulfonamides including sulfanilamide, succinylsulfathiazole, and phthalylsulfathiazole, which have been difficult to analyze simultaneously in livestock products.

Materials and methods

Chemicals and reagents

High-purity (> 98%) sulfonamide standards such as succinylsulfathiazole, sulfabenzamide, sulfacetamide, sulfachlorpyrazine, sulfachlorpyridazine, sulfadiazine, sulfadoxine, sulfaguanidine, sulfalene, sulfamerazine, sulfameter, sulfamethazine, sulfamethoxazole, sulfamethoxypyridazine, sulfaperin, sulfaphenazole, sulfapyrazole, sulfathiazole, sulfatroxazole, and sulfisomidine were obtained from Dr. Ehrenstorfer (Augsburg, Germany). Sulfadimethoxine, sulfaethoxypyridazine, sulfamethizole, sulfamonomethoxine, sulfamoxol, sulfanilamide, sulfapyridine, sulfaquinoxaline, sulfisoxazole, and phthalyl sulfathiazole were purchased from Sigma-Aldrich (St. Louis, MO, USA). Sulfanitran was purchased from Santa Cruz Biotechnology (Dallas, TX, USA).

HPLC-grade acetonitrile, methanol, n-hexane, and water were purchased from Merck (Darmstadt, Germany). Formic acid (> 99%), acetic acid (> 99%), sodium chloride (NaCl), and sodium acetate (NaOAc) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Anhydrous sodium sulfate (Na2SO4) and anhydrous magnesium sulfate (MgSO4) were supplied by JUNSEI Chemicals (Tokyo, Japan). Ammonium formate (> 98%) was supplied by Alfa Aesar (Ward Hill, MA). Primary secondary amine (PSA) was purchased from Agilent Technologies (CA, USA). C18 powder (particle size = 55–105 µm, pore size = 125 Å) was purchased from Waters (Milford, MA, USA). Nylon filters (diameter = 15 mm, pore size = 0.2 μm) were purchased from Teknokroma (Barcelona, Spain).

Standard solutions

Sulfonamide standards were accurately weighed and dissolved in methanol to prepare stock standard solutions for each compound at a concentration of 1000 µg mL−1. A working solution (16 µg mL−1) containing 31 sulfonamides was prepared in acetonitrile by mixing the stock standard solutions. The stock and working solutions were stored in glass amber vials at − 20 ℃. Mixed standard solutions varying from 0.05 to 4 µg mL−1 were diluted in ACN and were used to spike the livestock samples.

Sample collection

Livestock product samples were collected between July and November 2022. The collected samples comprised six different types of livestock products [beef (25), pork (54), chicken (25), eggs (13), and milk (12)] commercialized in South Korea. Samples were randomly purchased from different markets in Seoul, Gyeonggi, Gangwon, Chungcheong, Jeolla, and Gyeongsang. All samples were ground using a food blender and were stored in plastic bags in a freezer (− 20 ℃) until analysis.

Sample preparation—method development

Each sample was extracted with 10 mL of (1) ACN, (2) 0.1% Acetic acid in ACN, (3) 1% Acetic acid in ACN upon mixing in a shaker for 10 min and centrifuged at 4700 × g at 4 ℃ for 10 min. As a salt combination, (1) NaCl 1 g, (2) NaCl 1 g, MgSO4 2 g, (3) NaOAc 1 g, MgSO4 2 g, (4) NaCl 1 g, Na2SO4 2 g were added and, after shaking for 10 min, the mix was centrifuged at 4700 × g at 4 ℃ for 10 min. the mixture stands for 30 min at -20 ℃. The supernatant resulting from any of the extraction procedures was transferred to 15 mL centrifuge tube containing (1) C18 500 mg, (2) C18 300 mg, PSA 300 mg, (3) C18 300 mg, PSA 150 mg, (4) C18 150 mg, PSA 150 mg. The tube was shaken for 10 min and centrifuged at 4700 × g at 4 ℃ for 10 min. and 10 mL of hexane saturated with ACN was added and mixed with the extracts. The 5 mL of supernatants was transferred to a centrifuge tube. After that, evaporation and filtration steps were performed. The supernatant was concentrated at 40 ℃ by evaporation with a nitrogen stream to dryness, and the dried samples was reconstituted with (1) 50% MeOH (1:1, v/v), (2) 50% ACN (1:1, v/v), (3) 25 mM AF in water/ACN (3:1, v/v), and (4) 25 mM AF in water/MeOH (3:1, v/v) followed by filtration through a syringe filter of pore size 0.2 µm. Filtration with Nylone cartridge were compared to study filtration loss.

Sample preparation—final method

Livestock products (2.0 g) were placed in 50 mL polypropylene centrifuge tubes and extracted with 10.0 mL of 1% acetic acid in ACN upon mixing in a shaker for 10 min and centrifuging at 4700 × g at 4 ℃ for 10 min. The extracts were transferred to tubes containing 2 g Na2SO4 and 1 g NaOAc. The mixture was mixed in a shaker for 10 min and centrifuged at 4700 × g at 4 ℃ for 10 min. The supernatant was then transferred to a 50 mL centrifuge tube and kept at − 20 ℃ for 30 min to promote protein precipitation. After 30 min, the samples were immediately centrifuged at 4700 × g at 4 ℃ for 10 min and transferred to a 50 mL centrifuge tube containing 300 mg of C18 powder and 150 mg of PSA. Next, 10 mL of hexane saturated with ACN was added and the samples were mixed and centrifuged at 4700 × g at 4 ℃ for 10 min. The supernatant (5 mL) was transferred to a 15 mL centrifuge tube and evaporated under nitrogen stream to dryness at 40 ℃. The residues were reconstituted with 750 µL of 25 mM ammonium formate in water (adjusted to pH 4.0 with a small amount of formic acid) and 250 µL ACN. Finally, the extract was filtered through a 0.2 µm nylon syringe filter and injected to the LC–MS/MS instrument.

LC–MS/MS conditions

The liquid chromatography-electrospray tandem mass spectrometry (LC–ESI–MS/MS) setup consisted of a Shimadzu Nexera X2 system (Kyoto, Japan) connected to a Shimadzu LCMS-8060 (Kyoto, Japan). LC analysis was performed on a C18 column (100 mm × 2.1 mm, particle size = 2.0 μm; Shimadzu, Shim-pack, GIS) at 40 ℃. The flow rate was 0.3 mL min−1 and the mobile phase consisted of (A) 0.1% formic acid in water/ACN (95/5, v/v) and (B) 0.1% formic acid in water/ACN (5/95, v/v). The injection volume was 5 µL and the gradient was set as: 0 min, 20% B; 0–5 min, linear increase to 35% (B); 5–9 min, linear increase to 95% (B); 9–10 min, 95% (B); 10–10.1 min, linear decrease to 20% (B); 10.1–12 min, 20% (B).

The MS/MS detection system included an electrospray ionization (ESI) source. The ESI parameters in the positive or negative ion mode were as follows: positive interface voltage = 3.0 kV, negative interface voltage = − 3.0 kV, interface temperature = 350 ℃, heat block temperature = 300 ℃, desolvation line (DL) temperature = 150 ℃, nebulizing gas flow = 3.0 L min−1, and drying gas flow = 10 L min−1. MS/MS was operated in the multiple reaction monitoring (MRM) mode to achieve highly sensitive and selective analysis for trace residues. The MS/MS parameters of the MRM method were optimized for each compound using automated flow injection analysis of individual standard solutions. The Lab solutions (Ver. 5.99) software was used for instrument control and data processing. Table 1 lists the LC–ESI–MS/MS parameters of sulfonamide analysis.

Method validation

The performance of the proposed method was validated according to the Codex guidelines (CAC/AL 71-2009), using livestock samples (beef, pork muscle, pork fat, chicken, eggs, and milk) as the primary matrix. In case of pork, the fat content can be much higher depending on the meat. In particular, pork fat is separated and used for cooking, and is used for various purposes such as frying, stir-frying, and baking. Thus, validation was performed on pork muscle and fat, separately. The following parameters were evaluated for each sulfonamide: selectivity, linearity, accuracy, precision, limit of detection (LOD), and limit of quantification (LOQ). To test the selectivity of the method, blank livestock samples were analyzed and checked for interference at the retention times of the target compounds. Matrix-matched calibration curves were used to evaluate linearity. Calibration curves were prepared for each matrix at concentrations defined by the response of each analyte. The linearity of the method was evaluated by calculating the regression line and expressed as the coefficient of correlation (r2). The accuracy and precision of the method were determined by repeatedly analyzing livestock samples spiked at concentrations of 0.5 × MRL, 1 × MRL, 2 × MRL or 1 × LOQ, 2 × LOQ, and 10 × LOQ, and by calculating the coefficient of variation (CV %) of five measurements per day for each concentration. The recovery was used to evaluate the accuracy of the method. The sensitivity of the method was evaluated by determining the LOD and LOQ values. The LOD of the method was calculated by multiplying the standard error of the intercept by 3.3 and dividing the resulting number by the slope of the calibration curve. The LOQ was calculated by multiplying the intercept by 10 and dividing the resulting value by the slope. The LOD and LOQ represent the minimum analyte concentrations that could be accurately identified and quantified, respectively, using the proposed method.

To evaluate the ruggedness of the method, an inter-laboratory study was conducted using six livestock materials (beef, pork muscle, pork fat, chicken, egg, and milk), processed in three laboratories in Korea. Each sample was prepared and analyzed following our developed procedure at each of the three participating laboratories using individual LC–ESI–MS/MS systems. The accuracy and precision of five replicate measurements per laboratory were expressed as the recovery (%) and coefficient of variation (CV, %).

Matrix effects

LC–MS/MS techniques allow the matrix components present in the sample to interfere with analytes in the ion source, thereby increasing or decreasing analyte ionization [24]. Matrix effects occur when the ionization of an analyte in a mass spectrometer source is suppressed or enhanced (less frequently) by co-eluting materials. The main sources of matrix effects in samples of animal origin are endogenous components such as lipids, peptides, and metabolites with chemical structures similar to the target compound [25, 26]. A suppression or enhancement of the measured response can be observed, which adversely affects quantification because of the variability in the effect between samples. The matrix effects of each compound were calculated using Eq. (1).

Results and discussion

Optimization of LC–MS/MS conditions

Detection of veterinary drug residues in food, requires powerful tools such as advanced techniques for screening and confirming antibiotic residues combined with LC–MS/MS in multiple reaction monitoring (MRM) mode. In this study, such techniques were used owing to their high sensitivity and selectivity. The instrument parameter settings were optimized using individual standard solutions. The ionization mode (positive/negative ion) and precursor ions were selected according to the chemical ionization characteristics of sulfonamides. The results indicate a considerably higher [M + H]+ abundance for most sulfonamides in the positive-ion mode than in negative-ion mode. Unlike other sulfonamides, sulfanitran (SNT) was more sensitive in negative mode than in positive mode. This was attributed to the acidity of the nitro group making sulfanitran (SNT) more prone to form [M-H]− in the negative mode [27]. From these experiments, breakdown curves were recorded under different collision energy conditions to select the main characteristic fragments for quantification and confirmation. Typical sulfonamide MS/MS fragment patterns, such as m/z 156, 108, and 92 corresponding to [M + H-RNH2]+, [M + H-RNH2-SO]+, and [M + H-RNH2-SO2]+ were observed in this experiment, respectively. The mass of fragmentations of sulfonamides are based on the cleavage of bridge bond (-SO2-) following the loss of sulfonyl group that successively result in the formation of characteristic fragment ions mainly including p-sulfonaniline with m/z 156 and aniline structure m/z 92 [23].

Four solvent mixtures were assessed for reconstitution of the final extract prior to LC–MS/MS injection: (1) 50% MeOH (1:1, v/v), (2) 50% ACN (1:1, v/v), (3) 25 mM AF in water/ACN (3:1, v/v), and (4) 25 mM AF in water/MeOH (3:1, v/v). The retention times, shapes, and responses of the peaks were compared to determine the optimal solvent. Solvent mixture (3) yielded the highest response and best peak shape for most sulfonamides, with sulfanilamide (SNA) presenting an approximately sixfold higher response in this solvent than in the other solvents. Sulfaguanidine (SGA), sulfamethoxypyridazine (SMPD), and sulfameter (SMT) exhibited incomplete separation peaks in the solvent mixture (1).

Although complete separation is unnecessary for MS/MS detection when using the MRM mode, it considerably improves detectability and reduces the ion suppression effect, which is the primary reason for performing these experiments. The optimal separation of the components is highly dependent on the columns and solvent systems used. Separation was performed using reversed-phase chromatography on a C18 column. To obtain optimal separation conditions, three C18 columns (X-select HSS, Acquity BEH, and Shim-pack GIS) were assessed for their separation efficiency and retention times. The Shim-GIS column provided a better peak shape with higher intensity than the other columns. As the effect of the mobile phase composition on the ionization efficiency for LC–MS/MS analysis was significant, four mobile phase combinations were tested: (1) 0.1% formic acid in water/ACN (95:5, v/v) and 0.1% formic acid in water/ACN (5:95, v/v); (2) 0.1% acetic acid in water and 0.1% acetic acid in ACN; and (3) 20 mM ammonium formate in water and 20 mM ammonium formate in water/ACN (90:10, v/v). Mobile phase (1) provided well-resolved peaks. In mass spectrometry, working under acidic conditions (addition of small amounts of acid) is essential for facilitating chromatographic separation and enhancing ionization. Four pairs of isobaric compounds were separated and determined independently: sulfamethoxypyridazine (SMPD) and sulfameter (SMT), sulfamonomethoxine (SMMX) and sulfalene (SFL), sulfamerazine (SMR) and sulfaperin (SPR), and sulfatroxazole (STX) and sulfisoxazole (SSZ). In summary, sulfonamides were separated on a Shim-pack GIS column with reconstitution of 25 mM AF in ACN/water (3:1, v/v) under mobile phase of (A) 0.1% formic acid in water/ACN (95:5, v/v) and (B) 0.1% formic acid in water/ACN (5:95, v/v). As a result of these optimization, Complete separation of 31 sulfonamides was possible within 12 min which is satisfactory results. Figure 1 shows the representative ion chromatograms of the target compounds analyzed by injecting 0.1 µg g−1 of each standard solution.

Representative chromatograms of 31 sulfonamide standard solutions (0.1 µg g−1) in MRM mode; (1) Sulfaguanidine, (2) sulfisomidine, (3) sulfanilamide, (4) sulfacetamide, (5) sulfadiazine, (6) sulfathiazole, (7) succinylsulfathiazole, (8) sulfapyridine, (9) sulfamerazine, (10) sulfamoxole, (11) sulfamethizole, (12) sulfamethoxypyridazine, (13) sulfaperin, (14) sulfamethazine, (15) sulfameter, (16) sulfamonomethoxine, (17) sulfalene, (18) sulfachloropyridazine, (19) phthalylsulfathiazole, (20) sulfadozine, (21) sulfamethoxazole, (22) sulfaethoxypyridazine, (23) sulfatroxazole, (24) sulfisoxazole, (25) sulfabenzamide, (26) sulfachloropyrazine, (27) sulfadimethoxine, (28) sulfaquinoxaline, (29) sulfaphenazole, (30) sulfapyrazole, (31) sulfanitran

Optimization of sample preparation

Many studies have reported modified QuEChERS methods for quantifying veterinary drugs in livestock products. In this study, the developed method was evaluated using pork samples, prior to the optimization of the QuEChERS procedure. However, relatively low extraction recoveries of the target sulfonamides were obtained from the pork samples using previously reported QuEChERS methods. Thus, further research on the different combinations of extraction and clean-up procedures was conducted.

Extraction step

Sulfonamides, which are amphoteric compounds, are readily extracted by organic solvents when present in their molecular form. They exhibit good solubility in polar solvents and are not very soluble in non-polar solvents. Therefore, extraction is generally performed using acetonitrile, chloroform, methylene chloride, acetone, or ethyl acetate [3]. The addition of salt during solvent extraction can increase the solubility of insoluble analytes and the degree of ionization of weakly ionized analytes in the solution [28].

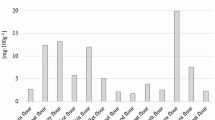

Considering the large physicochemical differences among the monitored veterinary drugs and the unknown influence of complex matrices, several different extraction conditions were designed to investigate the influence of extraction solvents and salt combinations (Fig. 2): (1) ACN/NaCl 1 g, (2) ACN/NaCl 1 g, MgSO4 2 g, (3) ACN/NaOAc 1 g, MgSO4 2 g, (4) 0.1% AA in ACN/NaOAc 1 g, MgSO4 2 g, (5) 1% AA in ACN/NaCl 1 g, Na2SO4 2 g, and (6) 0.1% AA in ACN/NaOAc 1 g, Na2SO4 2 g. The extraction conditions were mainly evaluated based on the recoveries of the selected sulfonamides. Conditions (1–4) exhibited no peaks and low reproducibility for phthalylsulfathiazole (PSTZ) and succinylsulfathiazole (SSTZ), whereas condition (5) exhibited high recoveries for all sulfonamides. The addition of sodium acetate (NaOAc) and sodium sulfate (Na2SO4) afforded acceptable recoveries. Initially, MgSO4 was adopted because of its capacity to bind large amounts of water. However, the experimental results indicated that Na2SO4 was superior to MgSO4. Thus, MgSO4 was replaced with Na2SO4. NaOAc and ACN were used in the salt-out solvent extraction of sulfonamides from livestock products.

Comparison of extraction solvents and salt combination in pork samples at 0.1 μg kg−1. (1) ACN/NaCl 1 g, (2) ACN/NaCl 1 g, MgSO4 2 g, (3) ACN/NaOAc 1 g, MgSO4 2 g, (4) 0.1% acetic acid in ACN/NaCl 1 g, MgSO4 2 g, (5) 1% acetic acid in ACN/NaCl 1 g, Na2SO4 2 g, (6) 1% acetic acid in ACN/NaOAc 1 g, Na2SO4 2 g

Considering the amphoteric properties of sulfonamides, the extraction efficiency can also be affected by the pH of the extraction solvent [29]. When sulfonamides are extracted under basic conditions, the extraction efficiency is lower than that of extraction processes using acidic or neutral conditions, because of the increased H + dissociation of secondary amino groups [3]. The addition of acetic acid to ACN was examined to efficiently target the analytes. Various amounts of acetic acid (0, 0.1, 1, and 2%, v/v) were added to ACN to evaluate the effect on extraction recovery. The highest recoveries were obtained when 1% acetic acid was added to ACN for extraction. The extraction efficiency was investigated using ACN and a mixture of ACN:MeOH (3:1, v/v) under the same conditions, using 1% acetic acid. The addition of methanol to the extraction solution was also evaluated in another study, revealing that the extraction capacity increased in the presence of this solvent. However, in this study, the addition of methanol increased the matrix interference. Given the overall results, the optimum extraction solvents consisted of 1% acetic acid in ACN (v/v) and a combination of 2 g Na2SO4 and 1 g NaOAc.

Cleanup step

Animal-derived matrix compositions are typically richer than those of plant-derived samples such as fruits and vegetables. Therefore, the removal of interfering components in the d-SPE clean-up step is more important when quantifying target analytes in animal products. In this clean-up step, C18 and appropriate d-SPE sorbents were applied to remove unwanted matrix components and improve extraction recovery. In this study, four d-SPE sorbents were tested for removing interfering hydrophobic components and/or fats/lipids from animal tissues (Fig. 3). C18 sorbents are commonly used to remove hydrophobic matrix components from various sample matrices. PSA is usually employed to effectively remove matrix components with polar functional groups, such as fatty acids and sugars from samples [30].

Among the four candidates for d-SPE cleanup, the addition of a C18 (500 mg) sorbent offered not acceptable recoveries for the target sulfonamides, whereas the PSA sorbent (150 mg) significantly improved the extraction recovery. The combination of other d-SPE sorbents was also investigated, however, no improvement in extraction recovery was observed. For subsequent investigations, 300 mg of C18 and 150 mg of PSA were used to perform d-SPE cleanup. In addition, the cooling step and the addition of n-hexane saturated with ACN were used to promote protein precipitation and remove undesirable components in extracts; protein precipitation is needed to extract target compounds and eliminate all major matrix effects. A small proportion of protein was removed owing to the colloidal properties of the sample extracts [31].

Method validation

The selectivity of the method was tested by analyzing blank livestock samples. The absence of any chromatographic peaks at the retention times of the target sulfonamides indicated that matrix compounds producing a false-positive signal were not present in the blank samples. A calibration curve was generated for all sulfonamide standards using matrix-matched calibrations at six concentrations (blank, 0.0125, 0.25, 0.5, 1, 2, and 4 × MRL; blank, 5, 10, 20, 40, 1, and 2 ng g−1 or blank, 2.5, 5, 10, 20, 50, and 100 ng g−1). The results exhibited excellent linear relationships and a favorable coefficient of determination (r2 > 0.98). The recovery and CV of the proposed method were evaluated by assessing the agreement between the three measured and known concentrations (0.5, 1, and 2 × MRL; 10, 20, and 1 ng g−1, and 5, 10, and 50 ng g−1) for all matrices. Additional file 1: Tables S2 and S3 list the average recoveries and CV of the fortified samples from six different matrices. The validated results (n = 5) indicated positive recoveries of sulfonamides ranging from 70 to 110% for all matrices. The precision of the method was analyzed by calculating the CV of repeated measurements (n = 5). The CV range of all sulfonamides was below 15%, indicating the favorable repeatability of the recovery test. The LOD range of sulfonamides was 0.3–4 ng g−1, whereas the LOQ range was 1–19 ng g−1. The achieved LOQs were approximately 1/50 × MRLs, demonstrating the high sensitivity of the method. As a result of the inter-laboratory validation, the average recoveries between the three laboratories ranged from 85 to 109% and CV was also below 22%. All the optimized results satisfied the criteria described in the Codex guidelines. Comparing the performance of the proposed method in this paper with other papers, it showed similar and lower LOD and LOQ compared to the previous paper, despite being able to analyze a large number of sulfonamides in various livestock matrix types [2, 23, 32,33,34,35].

Evaluation of matrix effects

Although LC–MS/MS analyses exhibit many advantages, the matrix effects observed when ESI sources are used can suppress or enhance the MS signals and cause errors during quantification, which is a major drawback. The extracts of livestock matrices typically contain considerable amounts of organic components, such as proteins and lipids. Such compounds increase the viscosity of the sample and the superficial tension of the droplets generated in the ESI source, thereby hindering the evaporation efficiency of the target analytes. To overcome this issue, matrix-matched standards are used instead of solvent standards, but are not always successful. This can affect the ionization efficiency of the analytes due to ionization suppression or enhancement. The matrix effect can be negative or positive and Additional file 1: Table S4 presents the matrix effects grouped into the following categories: high signal suppression (ME < − 50%), moderate signal suppression (ME < − 50 to − 10%), no matrix effect (ME < − 10 to 10%), moderate signal enhancement (ME < 10 to 50%), and high signal enhancement (ME > 50%) [26, 36]. The overall ME (%) was observed in a range of − 71 to 69% in six livestock products. No matrix effects were observed for 14 compounds (45%) in pork fat, 10 compounds (32%) in milk, 9 compounds (29%) in pork muscle, 7 compounds (23%) in chicken and eggs, and 5 compounds (16%) in beef. In beef, 7 compounds (23%) were observed for moderate signal enhancement and 17 compounds (48%) for moderate signal suppression. In pork muscle, moderate signal enhancement was observed for 8 compounds (26%), whereas 11 compounds (35%) showed moderate signal suppression, and 3 compounds (9%) showed high signal enhancement (2 compounds) or suppression (1 compound). In chickens, moderate signal enhancement was observed for 9 compounds (29%), whereas 12 compounds (39%) showed moderate signal suppression, 2 compounds (6%) showed high signal enhancement, and 1 compound (3%) showed high signal suppression. In eggs, 21 compounds (68%) showed moderate signal suppression and no moderate signal enhancement was observed. High signal enhancement was observed for 1 compound, and high signal suppression was observed for 2 compounds. In milk, moderate signal enhancement was observed for 6 compounds (19%), whereas 12 compounds (39%) showed moderate signal suppression. Only 1 compound showed high signal enhancement, whereas 2 compounds (6%) showed high signal suppression. In pork fat, moderate signal enhancement was observed for 6 compounds (19%), whereas 8 compounds (26%) showed moderate signal suppression, 2 compounds (6%) exhibited high signal suppression, and only 1 compound showed high signal enhancement. These results indicate that sulfonamides in livestock product samples exhibit matrix interference due to co-eluting materials. Therefore, matrix-matched standard curves should be used for residue analysis. Considering these matrix effect results, an internal standard is not necessary because matrix-matched calibration samples can be used to efficiently compensate for the differences in recovery across multiple matrices.

Application to real samples

The developed method was applied for the determination of sulfonamides in 129 livestock product samples (beef, pork, chicken, eggs, and milk) obtained from six regions in South Korea. To ensure the quality of the results when the proposed method was applied, internal quality control was performed for every batch of samples. The retention times, quantification and confirmation transitions, and relative ion intensities of the detected ions in the real samples were compared with those of the corresponding calibration standards in the same batch, to identify the detected analytes using the criteria established by the MFDS. Only one sample tested positive for sulfadimethoxine; however, its concentration was below the LOQ (Fig. 4). According to previous studies, sulfadimethoxine is sulfonamide antibiotic used primarily to treat coccidiosis in poultry [35, 37, 38]. In food samples, the target analytes tend to bind more strongly to the matrix in incurred samples than in spiked samples. Unfortunately, there is the absence of repeated analysis in incurred samples that resulted in the extraction efficiency of the developed method. Furthermore, investigation of the incurred samples must be considered to evaluate the extraction efficiency of the developed method.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Xu Y, Ding J, Chen H, Zhao Q, Hou J, Yan J, Wang H, Ding L, Ren N (2013) Fast determination of sulfonamides from egg samples using magnetic multiwalled carbon nanotubes as adsorbents followed by liquid chromatography-tandem mass spectrometry. Food Chem 140:83–90. https://doi.org/10.1016/j.foodchem.2013.02.078

Won SY, Lee CH, Chang HS, Kim SO, Lee SH, Kim DS (2011) Monitoring of 14 sulfonamide antibiotic residues in marine products using HPLC-PDA and LC-MS/MS. Food Control 22:1101–1107. https://doi.org/10.1016/j.foodcont.2011.01.005

Dasenaki ME, Thomaidis NS (2010) Multi-residue determination of seventeen sulfonamides and five tetracyclines in fish tissue using a multi-stage LC-ESI-MS/MS approach based on advanced mass spectrometric techniques. Anal Chim Acta 672:93–102. https://doi.org/10.1016/j.aca.2010.04.034

Littlefield NA, Sheldon WG, Allen R, Gaylor DW (1990) Chronic toxicity/carcinogenicity studies of sulphamethazine in Fischer 344/N rats: Two-generation exposure, Food Chem. Toxicol 28:157–167. https://doi.org/10.1016/0278-6915(90)90004-7

Levin S (1993) The crisis in antibiotic resistance. Infect Dis Clin Pract 2:53. https://doi.org/10.1097/00019048-199301000-00013

Takino M, Yamaguchi K, Nakahara T (2004) Determination of carbamate pesticide residues in vegetables and fruits by liquid chromatography-atmospheric pressure photoionization-mass spectrometry and atmospheric pressure chemical ionization-mass spectrometry. J Agric Food Chem 52:727–735. https://doi.org/10.1021/jf0343377

EU reference laboratory for residues of veterinary drugs., Committee for Veterinary Medicinal Products, 2009. https://doi.org/10.1007/978-3-211-89836-9_245.

FAO (2014) Guidelines for the design and implementation of national regulatory food safety assurance programmes associated with the use of veterinary drugs in food producing animals (CAC/GL 71-2009) http://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXG%2B71-2009%252FCXG_071e_2014.pdf. Accessed 23 April 2020.

Hou XL, Chen G, Zhu L, Yang T, Zhao J, Wang L, Wu YL (2014) Development and validation of an ultra high performance liquid chromatography tandem mass spectrometry method for simultaneous determination of sulfonamides, quinolones and benzimidazoles in bovine milk. J Chromatogr B Anal Technol Biomed Life Sci 962:20–29. https://doi.org/10.1016/j.jchromb.2014.05.005

Pikkemaat MG, Rapallini MLBA, van Dijk SO, Elferink JWA (2009) Comparison of three microbial screening methods for antibiotics using routine monitoring samples. Anal Chim Acta 637:298–304. https://doi.org/10.1016/j.aca.2008.08.023

Hoff RB, Barreto F, Kist TBL (2009) Use of capillary electrophoresis with laser-induced fluorescence detection to screen and liquid chromatography-tandem mass spectrometry to confirm sulfonamide residues: validation according to European Union 2002/657/EC. J Chromatogr A 1216:8254–8261. https://doi.org/10.1016/j.chroma.2009.07.074

Gamba V, Terzano C, Fioroni L, Moretti S, Dusi G, Galarini R (2009) Development and validation of a confirmatory method for the determination of sulphonamides in milk by liquid chromatography with diode array detection. Anal Chim Acta 637:18–23. https://doi.org/10.1016/j.aca.2008.09.022

Rodriguez E, Moreno-Bondi MC, Marazuela MD (2011) Multiresidue determination of fluoroquinolone antimicrobials in baby foods by liquid chromatography. Food Chem 127:1354–1360. https://doi.org/10.1016/j.foodchem.2011.01.098

Reeves VB (1999) Confirmation of multiple sulfonamide residues in bovine milk by gas chromatography-positive chemical ionization mass spectrometry. J Chromatogr B Biomed Sci Appl 723:127–137. https://doi.org/10.1016/S0378-4347(98)00548-9

Yogendrarajah P, Van Poucke C, De Meulenaer B, De Saeger S (2013) Development and validation of a QuEChERS based liquid chromatography tandem mass spectrometry method for the determination of multiple mycotoxins in spices. J Chromatogr A. https://doi.org/10.1016/j.chroma.2013.04.075

Perez N, Gutierrez R, Noa M, Diaz G, Luna H, Escobar I, Munive Z (2002) Liquid chromatographic determination of multiple sulfonamides, nitrofurans, and chloramphenicol residues in pasteurized milk. J AOAC Int 85:20–24. https://doi.org/10.1093/jaoac/85.1.20

Bui LV (1993) Liquid chromatographic determination of six sulfonamide residues in animal tissues using postcolumn derivatization. J AOAC Int 76:966–976. https://doi.org/10.1093/jaoac/76.5.966

Hu L, Zuo P, Ye BC (2010) Multicomponent mesofluidic system for the detection of veterinary drug residues based on competitive immunoassay. Anal Biochem 405:89–95. https://doi.org/10.1016/j.ab.2010.05.034

Granja RHMM, de Lima AC, Salerno AG, Wanschel ACBA (2012) Validation of a liquid chromatography with ultraviolet detection methodology for the determination of sulfonamides in bovine milk according to 2002/657/EC. Food Control 28:304–308. https://doi.org/10.1016/j.foodcont.2012.05.018

Biswas AK, Rao GS, Kondaiah N, Anjaneyulu ASR, Malik JK (2007) Simple multiresidue method for monitoring of trimethoprim and sulfonamide residues in Buffalo meat by high-performance liquid chromatography. J Agric Food Chem 55:8845–8850. https://doi.org/10.1021/jf071140w

Gentili A, Perret D, Marchese S, Sergi M, Olmi C (2004) Accelerated solvent extraction and confirmatory analysis of sulfonamide residues in raw meat and infant foods by liquid. J Agric Food Chem 52:4614–4624

Hou X, Xu X, Xu X, Han M, Qiu S (2020) Application of a multiclass screening method for veterinary drugs and pesticides using HPLC-QTOF-MS in egg samples. Food Chem. https://doi.org/10.1016/j.foodchem.2019.125746

Kung TA, Tsai CW, Ku BC, Wang WH (2015) A generic and rapid strategy for determining trace multiresidues of sulfonamides in aquatic products by using an improved QuEChERS method and liquid chromatography-electrospray quadrupole tandem mass spectrometry. Food Chem 175:189–196. https://doi.org/10.1016/j.foodchem.2014.11.133

Kim YR, Kang HS (2021) Multi-residue determination of twenty aminoglycoside antibiotics in various food matrices by dispersive solid phase extraction and liquid chromatography-tandem mass spectrometry. Food Control 130:108374. https://doi.org/10.1016/j.foodcont.2021.108374

Furey A, Moriarty M, Bane V, Kinsella B, Lehane M (2013) Ion suppression; A critical review on causes, evaluation, prevention and applications. Talanta 115:104–122. https://doi.org/10.1016/j.talanta.2013.03.048

Shin D, Kim J, Kang HS (2021) Simultaneous determination of multi-pesticide residues in fish and shrimp using dispersive-solid phase extraction with liquid chromatography–tandem mass spectrometry. Food Control 120:107552. https://doi.org/10.1016/j.foodcont.2020.107552

Li X, Chi Q, Xia S, Pan Y, Chen Y, Wang K (2020) Untargeted multi-residue method for the simultaneous determination of 141 veterinary drugs and their metabolites in pork by high-performance liquid chromatography time-of-flight mass spectrometry. J Chromatogr A 1634:461671. https://doi.org/10.1016/j.chroma.2020.461671

Hu M, Ben Y, Wong MH, Zheng C (2021) Trace analysis of multiclass antibiotics in food products by liquid chromatography-tandem mass spectrometry: method development. J Agric Food Chem 69:1656–1666. https://doi.org/10.1021/acs.jafc.0c05778

Ji B, Zhao W, Xu X, Han Y, Jie M, Xu G, Bai Y (2021) Development of a modified quick, easy, cheap, effective, rugged, and safe method based on melamine sponge for multi-residue analysis of veterinary drugs in milks by ultra-performance liquid chromatography tandem mass spectrometry. J Chromatogr A. https://doi.org/10.1016/j.chroma.2021.462333

Wen CH, Lin SL, Fuh MR (2017) Determination of sulfonamides in animal tissues by modified QuEChERS and liquid chromatography tandem mass spectrometry. Talanta 164:85–91. https://doi.org/10.1016/j.talanta.2016.11.006

Zhu WX, Yang JZ, Wang ZX, Wang CJ, Liu YF, Zhang L (2016) Rapid determination of 88 veterinary drug residues in milk using automated TurborFlow online clean-up mode coupled to liquid chromatography-tandem mass spectrometry. Talanta 148:401–411. https://doi.org/10.1016/j.talanta.2015.10.037

Lopes RP, De Freitas EE, De Passos JF, Alkimim Filho EA, Vargas DV, Augusti RA (2012) Development and validation of a method for the determination of sulfonamides in animal feed by modified QuEChERS and LC-MS/MS analysis. Food Control 28:192–198. https://doi.org/10.1016/j.foodcont.2012.04.026

Bousova K, Senyuva H, Mittendorf K (2013) Quantitative multi-residue method for determination antibiotics in chicken meat using turbulent flow chromatography coupled to liquid chromatography-tandem mass spectrometry. J Chromatogr A 1274:19–27. https://doi.org/10.1016/j.chroma.2012.11.067

Arroyo-Manzanares N, Gámiz-Gracia L, García-Campaña AM (2014) Alternative sample treatments for the determination of sulfonamides in milk by HPLC with fluorescence detection. Food Chem 143:459–464. https://doi.org/10.1016/j.foodchem.2013.08.008

Mian AA, Ahmad T, Nadeem S, Tanveer ZI, Arshad J (2012) Sulfonamide residues determination in commercial poultry meat and eggs. J Anim Plant Sci 22:473–478

Chatterjee NS, Utture S, Banerjee K, Ahammed Shabeer TP, Kamble N, Mathew S, Ashok Kumar K (2016) Multiresidue analysis of multiclass pesticides and polyaromatic hydrocarbons in fatty fish by gas chromatography tandem mass spectrometry and evaluation of matrix effect. Food Chem 196:1–8. https://doi.org/10.1016/j.foodchem.2015.09.014

Orton LRHCT (1971) Efficacy studies on potentiated sulfadimethoxine as a chicken coccidiostat. Poult Sci 50:1341–1346

B.J.C. Mitrovic M. (1967) Sulfadimethoxine therapy of avian. Poult Sci 46:402–411

Acknowledgements

The authors would like to thank Sung-Yong Ha of Seoul Regional Korea Food & Drug Administration and Youngsik Chae of SGS Korea Co. Ltd. for performing the laboratory experiments.

Funding

This study was supported by the Ministry of Food and Drug Safety of the Republic of Korea (grant no. 22191MFDS317) in 2022.

Author information

Authors and Affiliations

Contributions

YRK: methodology, validation, writing—original draft. SP: validation, formal analysis. JYK: methodology, validation, investigation, writing—review & editing. J-DC and G-IM: review and revising the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Table S1.

The recoveries and coefficient of variation for sulfonamides in three testing levels in beef, pork muscle, and chicken (n=5). Table S2. The recoveries and coefficient of variation for sulfonamides in three testing levels in pork fat, milk and egg (n=5). Table S3. LOD and LOQ (ng g−1) and ME (%) of sulfonamides in livestock products. Fig. S1. Matrix-matched chromatograms of sulfamethoxypyridazine, sulfameter, sulfamonomethoxine, and sulfalene in six livestock matrices at concentration of 0.1 µg kg-1.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, Y.R., Park, S., Kim, J.Y. et al. Simultaneous determination of 31 Sulfonamide residues in various livestock matrices using liquid chromatography-tandem mass spectrometry. Appl Biol Chem 67, 13 (2024). https://doi.org/10.1186/s13765-024-00864-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13765-024-00864-z