Abstract

Background

In Ethiopia, biomass contributes to about 92% of the household fuel consumption. As a result, deforestation rate has alarmingly increased associated with greenhouse gas (GHG) emissions and land degradation. The concerned government agencies have been widely making concerted efforts to reverse the situation by of promotion of improved cookstoves (ICS). However, the performance of these technologies in terms of saving fuelwood and their contribution to CO2 emission reduction in a real kitchen was not studied systematically. Thus, this research was initiated to address the knowledge gap.

Methods

The study was conducted in Tigray region in northern Ethiopia. The study households were selected following cross-sectional and longitudinal study designs. A kitchen performance test (KPT) was carried out based on 3 days of repeated fuelwood use measurements to compare the wood-saving performance of ICS in comparison with the traditional cookstove (TCS). The emission reduction potential of both ICS and TCS was calculated based on the Clean Development Mechanism and United Nation’s Framework of Convention on Climate Change and presented in CO2 equivalent (CO2e).

Results

The result suggests significant differences in total and per capita wood consumption (p < 0.05) between improved and TCS. The use of Mirt and Tikikil compared to the traditional stove has reduced the household wood consumption by 35% and 18%, respectively. Furthermore, ICS stoves also reduced CO2e emission per stove per year by 0.65 and 0.27 tons, respectively.

Conclusion

The study deals with the significant contribution that the shift from TCS to the ICS brought in terms of reducing the amount of fuelwood used at household level and the carbon emission per capita. It addresses the crucial roles of such technologies in reducing forest degradation and the associated ecosystem loss. Therefore, policy aimed at reducing greenhouse gas emissions in developing countries at household level should at least start via promotions of ICS.

Similar content being viewed by others

Background

Biomass is one of the most important sources of energy. In developing countries, 2.8 billion people rely on traditional biomass fuel for cooking and heating [1]. More than 40% of the world’s population depends on biomass as their primary cooking fuel [1, 2], of which approximately 90% live in sub-Saharan Africa [3, 4]. Approximately 1–2.4 Gt CO2e of GHGs are emitted annually due to the production and use of fuelwood and charcoal, which are 2–7% of the global anthropogenic emissions [5]

In Africa, despite the availability of various energy sources, more than 80% of the total population in most countries still use traditional biomass as the main source of energy for cooking [6]. Likewise, biomass is the main form of fuel for approximately 92% of the population in Ethiopia [7, 8]. Although several strategies were designed to increase the performance of fuel by implementing ICS and changing the cooking behavior [9–12], only 6% in sub-Saharan Africa and the least developed countries who use traditional biomass and coal have access to ICS [13].

Carbon dioxide emission to the atmosphere due to deforestation and forest degradation is still immense [14]. Improper use of fuelwood is one of the major anthropogenic activities resulting in land degradation and causing a significant negative impact on forests [3, 15]. The total national consumption of biomass fuel in Ethiopia is 105, 172,465 tons year−1 from total wood (round wood, branch, leaves and twigs) and charcoal equivalent of wood [16]. Moreover, the national per capita consumption of fuelwood for the rural dryland Ethiopia is estimated to be about 272 kg year−1 [16]. In Ethiopia, CO2 emission has increased from 5.1 million tons in 2005 to 6.5 million tons in 2010; and burning of wood and diesel have the largest share for GHG emissions [8].

Ethiopia’s national improved cookstoves program (NICSP) aims to support the distribution of 11 million ICS within 5 years (2016–2020), most of which are designed to bake InjeraFootnote 1 efficiently [17]. The long-term goal is to disseminate 31 million stoves earlier than 2030 [18]. The Ethiopian government has established NICSP to achieve this target. Estimations show that about 8.75 million people have benefited from the program between 2010 and 2015 by using ICS technologies [19]. This program introduced an active ICS production and sales sector with current annual sales of approximately 66,000 ICS (Mirt) and 16,000 rocket-type ICS (Tikikil) [20]. The cost of the stoves varies from 6 to 8 USD, with an average durability of 5 years [18]. For instance, the price of Tikikil and Mirt stoves in Addis Ababa and other parts of Ethiopia is 6–7.4 USD and 6–8 USD, respectively.

The main reason for introducing the ICS was to reduce forest degradation [9, 15, 21, 22], reduce indoor and outdoor pollution [11, 23], improve the quality of health [24,25,26], enhance the socioeconomic benefit [27] and reduce the GHGs emission [7, 8,14, 15]. However, the adoption of ICSs is very slow and context specific [28,29,30]. The GHGs emission from the burning wood also depends on various factors such as kitchen characteristics, stove characteristics, type of fuel, quantity of fuel, method of cooking and cooking time [23].

In dryland of Ethiopia, despite promotions, ICSs empirical evidence based on its performance particularly in regard to saving fuelwood and its CO2 emission reduction potential remains scarce.

Hence, this study was conducted to assess the performance of two ICSs (Mirt and Tikikil) in reducing fuelwood use and CO2 emission in real kitchens of rural households using kitchen performance test (KPT) methods.

Although KPT is a field-based test to assess the performance of improved stove(s) on fuel consumption in the kitchens of real households [1, 31,32,33,34], most of the ICS performance in fuelwood reduction was mainly assessed using water boiling and controlled cooking test [1, 17]. The KPT is the foremost field-based procedure in the kitchen to demonstrate the effect of stove interventions on household fuel consumption.

Methods

Study area

The study was conducted in Asgede Tsimbla district, the northwestern part of Tigray regional state in Ethiopia. The district is situated between 900 and 1800 m above sea level (m.a.s.l) (Fig. 1). The rainfall of the area is bimodal with a short rainy season occurring between January and April, and a long rainy season from June to August. Average annual rainfall is about 550–900 mm. The mean maximum temperature ranges between 20 °C (November and December) and 35 °C (January and March).

In the study area, biomass consisting of dry wood is the major source of energy for rural households. More than 92% of the total energy for household’s cooking is derived from biomass fuels: around 85% from fuelwood, 4% from charcoal and more than 7% from leaves and dung [22]. The dominant dryland woody species used as fuelwood are Acacia sps, Ziziphus spina-christi, Ficus sycomorus and Cordia africana.

Sampling methods

Following the series of discussion with different stakeholders at regional and district levels, multi-stage sampling procedures were employed to select the sample households. In the first stage, Asgede Tsimbla district was selected from the available 34 rural districts of the region due to its diversity of ICS promotion by multiple actors. Second, based on documents obtained from officials at the study site, a list of Kebeles and their status in terms of promotions of ICS was generated using stratified sampling techniques. Those Kebeles involved in the promotions of ICS were included in the study. In the third stage, two potential KebelesFootnote 2 (Lemlem and Hitsats Kebele) which have been using both improved and traditional biomass-based stoves from Asgede Tsimbla district were selected randomly. Lemlem Kebele was selected because most of the improved baking stoves locally called Mirt stoves are found in this village. The second Hitsats Kebele was selected because improved cooking stove locally called Tikikil was widely promoted by Zoa Relief projects is prevalent in Kebele.

Purposefully sampling technique was used to select the study households. Cross-sectional and longitudinal research designs were employed to collect the necessary data. The cross-sectional approach was used to collect data with regard to fuelwood consumption from two separate groups of families, one group using improved baking stoves and another group using the traditional stoves [35]. This approach is selected because of the absence of user households of both improved and traditional baking stoves (TBS) at the same time. On the other hand, the longitudinal approach was used to assess households using both improved (double-skirt Tikikil) and traditional stoves [34]. During cross-sectional testing, both socioeconomic (household income and local farming practices) and environmental factors which may affect the sampling procedure were considered. To avoid environmental variability, ICS and traditional stove users were selected from the same villages and the tests were done at the same time. The number of households covered by this study was more than the rule of thumb (10% of the total number of ICS users) as suggested on KPT protocol [32]. Finally, a total of 86 households from baking stoves (43 Mirt and 43 TBS) and 106 from cooking stoves (53 Tikikil and 53 traditional cookstove) user households were selected. Out of 53 TCS users, only 49 participated up to the end of the KPT. These selected households having multiple stoves agreed to use only one stove until the KPT study was completed.

Regardless of the variation in the frequency of baking of Injera for household consumption, we considered the average use of the stove per week recommended by Beyene and Koch [7]. The households were convinced to bake Injera for 3 days (session), so that the amount of wood consumption was monitored every 3 days for three sections in each type of stove after supplying sufficient amount of wood.

Description of improved and traditional cookstoves

The improved stoves (Mirt and Tikikil) had specified materials and dimensions when first designed by the Ministry of Water and Energy of Ethiopia and Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) in 2011 [35]. The traditional cooking stoves were made up of stone and mud and do not have a uniform structure and design (Fig. 2).

Mirt stove is produced with mortar using a mixture of scoria (red ash) or pumice or river sand with cement to serve for more than 5 years. It is used for baking Injera and/or bread. The stove has six parts that are joined together, four parts fit to make a cylindrically shaped enclosure and two other parts joined one on top of the other and are fitted with the cylindrical enclosure from behind (Fig. 3). The two parts serve as smoke outlet and rest for the cooking pot. There are the classic Mirt stove with 6 cm and the slim Mirt stove with 4 cm of wall thicknesses. Depending on the thickness of the parts as well as the raw materials used, the total weight of Mirt stove ranges from 45 kg to 65 kg. The dimension of Mirt stove for cylindrical enclosure are diameter (64–70 cm), height (22–24 cm), fuel/air inlet (24 cm by 11 cm), smoke outlet (19 cm by 7 cm) and the rear parts (32 cm wide, 26 cm deep and 35 cm high).

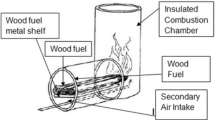

Tikikil is basically a rocket stove, intentionally designed to suit the cooking behavior of Ethiopian households and local production techniques. Tikikil is designed to replace the most inefficient but widely used traditional 3-stone stove. The design parameters considered the households’ pot sizes, ease of production, affordability, use of locally available raw materials and skills. It is designed to accommodate pot sizes of 25 cm (and smaller) in diameter. The stove has two main parts which include the ceramic liner and the metal part (Fig. 3). The metal part contains of the sheet metal cladding and the wood support. The dimensions of Tikikil stove are skirt diameter 27 cm (single-skirt), 29 cm and 33 cm (double-skirt); overall height 36 cm, cylindrical clay liner external diameter 19 cm, cylindrical clay liner internal diameter 11 cm, disc liner diameter 19 cm and combustion chamber opening 11 cm by 11 cm. This stove is used to prepare stew (locally known as Wet), boil water, make coffee and similar activities involve burning a fuel several times a day.

Description of the study household and participants

Except for males with age 15–59 years, the t-test analysis showed that there is no significant difference (p > 0.05) in the number of individuals that participate during mealtime in all age categories between Mirt and TBS. On average, these selected households used Mirt stove for more than 2 years (Table 2), whereas, Tikikil stove is recently distributed (mean age of 7 months). The average family size between traditional and improved baking stove was not significant (p > 0.05).

The entire surveyed households only used fuelwood for baking Injera, cooking a stew and boiling water. The majority of households collected fuelwood from their backyard resource, only a small proportion bought it from the market. The dominant dry woody species used for fuelwood were Ziziphus spina-christi (33%) followed by Ficus sycomorus (22), Cordia africana (19%), Acacia sps. (16%) and others (10%).

Fuelwood use measurement

Our KPTs were based on 3 days of repeated fuelwood use measurements at each sample household. According to the experimental protocol, participants prepared three patches of wood sufficient for 3 days of cooking, and it was based on their typical fuel requirement. The participants were not provided with wood, rather prepared by their own as this may bias the test result [32]. On the 1st day of the tests, the three batches of wood were weighed using pocket balance and recorded. The wood moisture content was measured using two pins type digital wood moisture meter. For moisture content, three pieces of wood samples from the stock were taken randomly and measured using moisture meter at the top, middle and bottom parts. On the 2nd day of the test, the wood that remained from the first day was weighed, and the difference was recorded as the day’s fuel. The moisture content of the randomly selected three pieces of wood was also measured. The same procedure was repeated on day three. Per capita fuelwood consumption was reported based on Standard Adult equivalent. Standard Adult equivalent was determined using the guidelines for wood fuelwood of standard weighted values of FAO (1983): child < 14 years = 0.5, female > 14 years = 0.8, male 15–59 years = 1.0 and male > 59 years = 0.8. The annual fuelwood consumption was extrapolated from the average fuelwood consumption of stove as follows:

where: XStove = average fuelwood consumption per stove (kg) and n = number of days per session.

Estimation of CO2 emission reduction

The contribution of ICS in reducing CO2 emission was determined based on the efficiency of fuelwood saving per stove. CO2 emission was calculated based on the Clean Development Mechanism and the United Nation’s Framework of Convention on Climate Change [15]; Table 1; using the below formula:

where ER = emission reduction in tons of CO2 equivalent (t CO2e); saving = annual fuelwood saved per ICS in tons; fNRB = fraction of non-renewable biomass; NCVbiomass = net calorific value of the non-renewable biomass; EFfuelwood = default emission factor of fuelwood (per unit of energy).

The fraction of non-renewable biomass (88%) was used from the CDM value recommended for Ethiopia [36]. Annual CO2 emission was determined from the estimated annual fuelwood consumption.

Statistical analysis

An excel software-based tool developed by Shell Foundation was used to calculate the daily fuel and energy consumption by a household. It refers to the sessional baking or cooking day, as the fuelwood consumption was not measured daily. Before further statistical analysis, the data were tested for normality using the Shapiro–Wilk test. An independent sample t-test was used to determine if there is a significant difference in average fuelwood consumption between ICS and TCS user households at a 95% level of confidence for cross-sectional testing methods (baking stove users). Likewise, a paired-sample t-test at a 95% level of confidence was used for the paired-sample method of testing (cooking stove users). The data were analyzed using SPSS software (version 21) [37].

Results

Fuelwood consumption

There was a significant difference (p < 0.05) in total and per capita wet and dry wood used between the use of Mirt and TBS stoves. The use of Mirt stove reduced the household’s dry wood consumption by 34.6% compared to the TBS (Table 2). Households with improved Mirt stove consumed less fuelwood than households with TBS users. The household’s consumption of Mirt stove users was 242 ± 169 kg of fuelwood per person per year which was less than the TBS (307 ± 120 kg).

Similar to improved baking stoves, there is significant difference (p < 0.05) between improved and traditional cookstoves in total and per capita wood consumption. Use of Tikikil reduced the household’s dry wood consumption by 18% (Table 2). Households with Tikikil stove users consumed less fuelwood than households with traditional cooking stove users. The household’s consumption of Tikikil stove users was 299 ± 208 kg of fuelwood per person per year which was less than the traditional cooking stoves (340 ± 191 kg).

Moreover, the technologies have been contributing to minimize the burden of rural households’, mainly women and girls during fuelwood collection including traveling long distances and other associated opportunity costs.

Valuation of carbon reductions from improved stoves

The total CO2 emission reduction per stove per year was significantly (p < 0.05) different between traditional and improved stoves. Households with Mirt stove users produce about 1.39 ± 0.88 t CO2 e per year, which was less than the TBS users (2.12 ± 0.72 t CO2 e per year). A Mirt stove saved 34.6% of fuelwood or 438 kg per household per year. Fully adopted Mirt stoves will decrease CO2 emissions by 0.70 tons per stove per year. The emission footprint (t CO2e per capita) of Mirt stove users which is found to be 0.39 ± 0.27 t CO2e per year (95% CI: 0.30, 0.47) was significantly lower (independent t-test; t = 2.053; df = 84; p < 0.05) compared to the TBS users.

The use of Tikikil stove saved 185 kg of wood per year for each user, which corresponds to an emission reduction of 0.296 t CO2 e per year. The amount of CO2e emission per year using TCSs (1.71 ± 0.48 t) was significantly higher than in the case ICSs (1.40 ± 1.71 t), when using (Tikikil) (independent t-test; t = 3.376; df = 100; p < 0.05).

Discussion

The performance of ICSs in fuelwood reduction was commonly measured using experimental methods such as Water Boiling Test and Controlled Cooking Test. However, these methods are misrepresenting the performance of cooking stoves during daily cooking activities [1]. In this study, the KPT protocol was selected because this is a principal field-based procedure that measures fuel use in households under the actual conditions [32]. However, since this test intrudes on people’s daily activities, the measurements taken during the KPT are more uncertain as the potential sources of error are harder to control in comparison to laboratory-based tests [32].

In Ethiopia, Injera baking is the most energy-intensive activity, accounting for over 50% of all primary energy consumption in the country, and over 75% of the total energy consumed in households [7, 15]. In this study, the average amount of fuelwood consumed for baking Injera per session was higher than in studies conducted in southern Ethiopia, the Bale Eco-Region of Ethiopia and the south western part of Ethiopia [16, 38]. This was due to Injera is common traditional food in the study area than the southern and south western parts of Ethiopia. Based on a laboratory test, a Mirt stove has a 50% fuelwood saving as compared to the 3-stone stove, reflecting how lab and field conditions can differ [35, 39]. Likewise, the improved baking stoves of this study saved more fuelwood as compared to the study conducted on Gonzie stoves (33.8–54%), while it was smaller than in a study conducted on Mirt stoves (47.8%) in Southern Ethiopia [38], on Mirt stoves in South western Ethiopia (38.9%) [15] and higher than in the study conducted by Gebreegziabher et al. [17] in four regions of Ethiopia (22–31%), as well as Gizachew’s and Tolera’s [40] study conducted in the Bale Eco-Region of Ethiopia (29%). Besides to the fuel type, calorific values of fuel, cooking behavior, meal types and location specific characteristics, the differences were caused by the variation in the use of TBS (control), i.e., the traditional stoves in the study area (Fig. 2c), which were relatively better than the traditional stoves in other studies (3-stone stoves). We observed that the ICSs were also used for cooking (e.g., Wet) and boiling water activities through its chimney (Fig. 2c). According to Dresen et al.[15], an additional fuelwood saving of about 9% can be achieved from the boiling and cooking activities as it can be done simultaneously with baking Injera. According to the result of this study, if the annual fuelwood saving per household was translated to Ethiopian annual sales of approximately 66,000 Mirt stoves, it implies that the use of Mirt stoves results in an annual wood saving of 28.78 million kg [20].

We found that variation in fuelwood consumption was related to the type of cooking stove used; by which Tikikil stoves consumed substantially less fuelwood than the traditional cooking stoves. The findings of our study were consistent with a study conducted in a rocket mud stove program of Kenya [1], a study in India, Nepal and Peru [41], in Southern Ethiopia [9] and a study conducted in Iran [2]. The amount of fuelwood saving by Tikikil (18%) was lower than in the study conducted in the laboratory (50%) but comparable with the study conducted using ICSs of Kenya (20–50%) and within the range of report in the sub-Saharan Africa 10–60% [42]. The difference in fuelwood consumption among various studies could be attributed to the difference in design and material from which the stoves are made [43]. The design and materials are the most important in affecting fuelwood consumption of stoves [10]. For instance, the traditional cookstove of our study (Fig. 2c) was relatively improved as compared to the other studied traditional 3-stone stoves. The 187 kg per year fuelwood saving per household translates to an annual wood saving of 2.99 million kg from the Ethiopian annual sales of approximately 16,000 Tikikil [20].

Improved cooking and baking stoves reduced carbon emissions to the atmosphere. Our study was consistent with similar studies conducted in the other parts of Ethiopia [9, 15, 42, 44]. The CO2 emission reduction achieved when using Mirt stoves in our study was within the range of the CRGE strategy document, which is the abatement potential of 0.6–1.4 t CO2e per stove per year, depending on the stove type [18], but lower than with that of Dissanayake et al. [44], which is 0.94 tons of CO2 saved per household per year. This was higher than in Gizachew’s & Tolera’s findings presented in [42], representing a reduction of 0.494 tons of CO2e per ICS user. The amount of CO2e reduction using Tikikil cookstoves are lower compared with that of CRGE strategy document. The difference between the control tests and the performances under real household conditions was expected as reported in [32, 42]. If we extrapolate the result of fuelwood consumption and CO2 emission reduction from the Ethiopian target to disseminate 31 million ICSs by 2030 (considering 50% each Mirt and Tikikil), more than 9.7 million tons of wood and 14.2 million CO2e per year will be reduced.

The findings presented in this paper have far-reaching implications for emerging climate-induced energy use challenges. Therefore, in the wake of emission reduction at household level, promotions of efficient ICSs that fits local reality are crucial. The limitation of this study was that several factors listed in the literature which might alter fuel consumption and CO2 emission reductions, are not fully incorporated. Factors that affect the KPT could be types of meal [1], fuelwood type, skill of cooking style [15], accessibility to fuel [9], and seasonal variability [38].

Conclusions

This study presented results regarding the fuelwood saving and emission reduction potential of ICS (namely Mirt and Tikiki stoves), which were widespread in Tigray Regional State, northern Ethiopia. The results showed that the use of ICS significantly reduced the amount of fuelwood used at household level as compared to the use of TCSs. The use of ICSs in the study area resulted in household’s annual fuelwood and CO2 emission reductions of about 438 kg and 0.70 ton of CO2e from Mirt stove users, as well as 185 kg and 0.296 ton of CO2e from Tikikil stove users. Likewise, the technologies have been contributing to minimize the burden of rural households’, mainly women and girls during fuelwood collection including traveling long distances and other associated opportunity costs. Our findings suggest that the use of ICS can be well integrated in the current efforts by governments and people to restore degraded landscapes, thereby contributing to climate change mitigation and adaptation. As there are limited studies on this topic in Ethiopia, further KPT research needs to be conducted across seasons to accommodate seasonal variations in fuelwood use, and how this will be affected by the availability of other sources (e.g., cow dung), as well as the number and type of meals to be prepared and other factors such as household income status.

Availability of data and materials

All data generated or analyzed during this study can be obtained from the corresponding author.

Notes

Injera is a staple food in Ethiopia, sour fermented flatbread with a slightly spongy texture which is made of teff flour.

Kebele is the lowest administrative unit in Ethiopia.

Abbreviations

- CO2e:

-

Carbon dioxide equivalents

- CDM:

-

Clean development mechanism

- fNRB:

-

Fraction of non-renewable biomass

- EFfuelwood :

-

Default emission factor of fuelwood

- GHG:

-

Greenhouse gas

- ICS:

-

Improved cookstoves

- KPT:

-

Kitchen performance test

- NICS:

-

National Improved Cooking Stoves Program

- NCVbiomass :

-

Net calorific value of the non-renewable biomass

- TBS:

-

Traditional Baking Stove

- TCS:

-

Traditional cookstoves

- UNFCCC:

-

United Nation’s Framework of Convention on Climate Change

References

Ochieng CA, Tonne C, Vardoulakis S (2013) A comparison of fuel use between a low cost, improved wood stove and traditional three-stone stove in rural Kenya. Biomass Bioenerg 58:258–266

Rasoulkhani M, Ebrahimi-Nik M, Abbaspour-Fard MH, Rohani A (2018) Comparative evaluation of the performance of an improved biomass cook stove and the traditional stoves of Iran. Sustain Environ Res 28:438–443

Koffi CK, Gazull L, Gautier D (2018) Variability of household fuelwood consumption in a rural Sudano-Sahelian context in Burkina Faso. Energy Sustain Dev 47:75–83

Urmee T, Gyamfi S (2014) A review of improved Cookstove technologies and programs. Renew Sustain Energy Rev 33:625–635

FAO (2017) The charcoal transition: greening the charcoal value chain to mitigate climate change and improve local livelihoods. Rome

Diefenderfer J, assumptions Vipin Arora M, Singer LE (2016) International Energy Outlook 2016 Liquid fuels.

Beyene AD, Koch SF (2013) Clean fuel-saving technology adoption in urban Ethiopia. Energy Econ 36:605–613

Mondal MAH, Bryan E, Ringler C, Mekonnen D, Rosegrant M (2018) Ethiopian energy status and demand scenarios: prospects to improve energy efficiency and mitigate GHG emissions. Energy 149:161–172

Mamuye F, Lemma B, Woldeamanuel T (2018) Emissions and fuel use performance of two improved stoves and determinants of their adoption in Dodola, southeastern Ethiopia. Sustain Environ Res 28:32–38

Adkins E, Tyler E, Wang J, Siriri D, Modi V (2010) Field testing and survey evaluation of household biomass cookstoves in rural sub-Saharan Africa. Energy Sustain Dev 14:172–185

Yip F, Christensen B, Sircar K et al (2017) Assessment of traditional and improved stove use on household air pollution and personal exposures in rural western Kenya. Environ Int 99:185–191

Muralidharan V, Sussan TE, Limaye S, Koehler K, Williams DL, Rule AM, Juvekar S, Breysse PN, Salvi S, Biswal S (2015) Field testing of alternative cookstove performance in a rural setting of Western India. Int J Environ Res Public Health 12:1773–1787

Legros G, Havet I, Bruce N, Bonjour S, Rijal K, Takada M, Dora C (2009) the Energy Access Situation in Developing Countries. UNDP WHO New York 142.

Hosonuma N, Herold M, De Sy V, De Fries RS, Brockhaus M, Verchot L, Angelsen A, Romijn E (2012) An assessment of deforestation and forest degradation drivers in developing countries. Environ Res Lett. https://doi.org/10.1088/1748-9326/7/4/044009

Dresen E, DeVries B, Herold M, Verchot L, Müller R (2014) Fuelwood savings and carbon emission reductions by the use of improved cooking stoves in an afromontane forest, Ethiopia. Land 3:1137–1157

Geissler S, Hagauer D, Horst A, Krause M, Sutcliffe P (2013) Biomass energy strategy: Ethiopia. Energy Dev 41:61476

Gebreegziabher Z, Beyene AD, Bluffstone R, Martinsson P, Mekonnen A, Toman MA (2018) Fuel savings, cooking time and user satisfaction with improved biomass cookstoves: evidence from controlled cooking tests in Ethiopia. Resour Energy Econ 52:173–185

Federal Democratic Republic of Ethiopia (FDRE) (2011) Ethiopia’s Climate-Resilient Green Economy. Addis Ababa, Ethiopia

EFCC (2019) Natinal improved cookstoves program

Economics Vivid (2014) Results-based financing in the energy sector: an analytical guide

Singh G, Rawat GS, Verma D (2010) Comparative study of fuelwood consumption by villagers and seasonal “Dhaba owners” in the tourist affected regions of Garhwal Himalaya, India. Energy Policy 38:1895–1899

Teka K, Welday Y, Haftu M (2018) Analysis of household’s energy consumption, forest degradation and plantation requirements in Eastern Tigray, Northern Ethiopia. Afr J Ecol 56:499–506

Sharma D, Jain S (2019) Impact of intervention of biomass cookstove technologies and kitchen characteristics on indoor air quality and human exposure in rural settings of India. Environ Int 123:240–255

Duguma LA, Minang PA, Freeman OE, Hager H (2014) Energy for Sustainable Development System wide impacts of fuel usage patterns in the Ethiopian highlands: potentials for breaking the negative reinforcing feedback cycles. Energy Sustain Dev 20:77–85

Zhang J, Smith KR, Ma Y, Ye S, Jiang F, Qi W, Liu P, Khalil MAK, Rasmussen RA, Thorneloe SA (2000) Greenhouse gases and other airborne pollutants from household stoves in China : a database for emission factors. 34

Alam SMN, Chowdhury SJ, Begum A, Rahman M (2006) Effect of improved earthen stoves: improving health for rural communities in Bangladesh. Energy Sustain Dev 10:46–53

Onyeneke RU, Nwajiuba CU, Mmagu CJ, Aligbe JO, Uwadoka CO, Igberi CO, Amadi MU (2018) Impact of adoption of improved cook-stove on different components of household welfare in rural communities in Nigeria: the case of Save80 cook-stove in Kaduna. Environ Prog Sustain Energy 37:1327–1338

Kapfudzaruwa F, Fay J, Hart T (2017) Improved cookstoves in Africa: explaining adoption patterns. Dev South Afr 34:548–563

Bielecki C, Wingenbach G (2020) Rethinking improved cookstove diffusion programs: a case study of social perceptions and cooking choices in rural Guatemala. Energy Policy 66:350–358

Rhodes EL, Dreibelbis R, Klasen E, Naithani N, Baliddawa J, Kennedy C, Checkley W (2014) Behavioral attitudes and preferences in cooking practices with traditional open-fire stoves in Peru, Nepal, and Kenya: implications for improved cookstove interventions. 10310–10326.

Smith KR, Dutta K, Chengappa C, Gusain PPS, Berrueta OMV, Edwards R, Bailis R, Shields KN (2007) Monitoring and evaluation of improved biomass cookstove programs for indoor air quality and stove performance: conclusions from the Household Energy and Health Project. Energy Sustain Dev 11:5–18

Bailis R, Thompson R, Lam N, Berrueta V, Muhwezi G, Adams E (2018) Kitchen Performance Test (KPT). 1–16

Wassie YT, Adaramola MS (2020) Analysis of potential fuel savings, economic and environmental effects of improved biomass cookstoves in rural Ethiopia. J Clean Prod 280:124700

Hafner J, Uckert G, Graef F, Hoffmann H, Kimaro AA, Sererya O, Sieber S (2018) A quantitative performance assessment of improved cooking stoves and traditional three-stone-fire stoves using a two-pot test design in Chamwino, Dodoma, Tanzania. Environ Res Lett 13:1–20

GIZ-ECO (Energy Coordination (2011) Mirt Stove Ethiopia. GIZ-ECO Ethiopia, Addis Ababa. Addis Ababa

UNFCCC (2012) Default Values of Fraction of NonRenewable Biomass for Least Developed Countries and Small Island Developing States. United Nations Framework Convention on Climate Change

IBM Corp. Released (2012) IBM SPSS Statistics for Windows,Version 21.0

Fekadu Kedir M, Bekele T, Feleke S (2019) Problems of Mirt, and potentials of improved Gonzie and traditional open cook stoves in biomass consumption and end use emission in rural wooden houses of Southern Ethiopia. Sci Afr. https://doi.org/10.1016/j.sciaf.2019.e00064

Megen Power Ltd (2008) Final Report: Impact Assessment of Mirt Improved Biomass Injera Stoves [sic] Commercialization in Tigray, Amhara and Oromiya National Regional States, Submitted to the MoARD/GTZ SUN Energy Programme, Addis Ababa. https://doi.org/10.1017/CBO9781107415324.004

Gizachew B, Tolera M (2018) Adoption and kitchen performance test of improved cook stove in the Bale Eco-Region of Ethiopia. Energy Sustain Dev 45:186–189

Johnson MA, Pilco V, Torres R et al (2013) Impacts on household fuel consumption from biomass stove programs in India, Nepal, and Peru. Energy Sustain Dev 17:403–411

Zein-Elabdin EO (1997) Improved stoves in Sub-Saharan Africa: the case of the Sudan. Energy Econ 19:465–475

Tryner J, Willson BD, Marchese AJ (2014) The effects of fuel type and stove design on emissions and efficiency of natural-draft semi-gasifier biomass cookstoves. Energy Sustain Dev 23:99–109

Dissanayake STM, Damte Beyene A, Bluffstone R, Gebreegziabher Z, Kiggundu G, Kooser SH, Martinsson P, Mekonnen A, Toman M (2018) Improved Biomass Cook Stoves for Climate Change Mitigation? Evidence of Preferences, Willingness to Pay, and Carbon Savings

Acknowledgements

We acknowledge the financial support provided by Environment, Forest and Climate Change Commission (EFCCC) for field survey. We also acknowledge the logistic and technical support offered from the Tigray Region Agency of Mines and Energy. The authors are grateful to Prof. Emiru Berhane and Dr. Kebede Manjur from Mekelle University, Musse Tesfaye University of Lisbon, Portugal and Haftom Hagos from the University of Twente, Enschede, Netherlands, for their support in language editing which should highly be acknowledged.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

AM is the lead author and made a substantial contribution to the conception and design of the manuscript; SA planned the study and collected the data; YG and BT execute data encoding and editing the draft manuscript; HA supported the data analysis and editing of the draft manuscript; and AW planned the study, edited the manuscript and coordinated the project. All authors have read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Manaye, A., Amaha, S., Gufi, Y. et al. Fuelwood use and carbon emission reduction of improved biomass cookstoves: evidence from kitchen performance tests in Tigray, Ethiopia. Energ Sustain Soc 12, 28 (2022). https://doi.org/10.1186/s13705-022-00355-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13705-022-00355-3