Abstract

Background

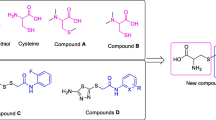

Plants have always played important role in treating human and animal diseases as a therapeutic agent for traditional medicine. Through extensive research throughout the world, potential of natural products have been identified to control the over activity of many enzymes. In-silico screening a library of chlorogenic acid derivatives highlighted some novel compounds which were found effective against urease enzyme and cancer causing H. Pylori bacterium. Selected top ligands possessing minimum binding energy and good docking score were synthesized in wet lab by suitable procedure and evaluated for urease enzyme inhibition and free radical scavenging property. Synthetic scheme includes three step reactions i. e protection of hydroxyl group of quinic acid part of chlorogenic acid with lactonisation process, anilide formation by reaction with substituted anilines followed by extraction with ethyl acetate under vacuum and deprotection of hydroxyl groups by treatment with hydrochloric acid.

Results

In-vitro results of the series concluded that compounds C4a, C4d and C4b (IC50 11.01 ± 0.013, 13.8 ± 0.041 and 15.86 ± 0.004 µM respectively in urease inhibition and 5.10 ± 0.018, 5.34 ± 0.007 and 6.01 ± 0.005 µM in antioxidant property against DPPH) were found to be significantly potent with excellent dock score − 10.091, − 10.603, − 9.833 and binding energy − 62.674, − 63.352, 56.267 kg/mol as compared to standard drugs thiourea and acetohydroxamic acid (− 3.459, − 3.049 and − 21.156 kJ/mol and − 17.454 kJ/mol) whereas compounds C4c, C4(e, h) exhibited moderate in vivo activity when compared to standard.

Conclusions

Selected candidates from the outcome of in vitro urease inhibitory were further examined for anti-H. Pylori activity by well diffusion method against H. pylori bacterium (DSM 4867). Compound C4a showed significant anti-H. Pylori activity with zone of inhibition 10.00 ± 0.00 mm and MIC value 500 μg/mL as compared to standard drug acetohydroxamic acid having zone of inhibition 9.00 ± 0.50 mm and MIC 1000 μg/mL. Molecular docking studies also showed that compounds show strong inhibition by forming strong hydrogen bonding interactions with residues of pocket site in target protein. Hence, the present investigation studies will provide a new vision for the discovery of potent agents against H. Pylori and urease associated diseases.

Similar content being viewed by others

Introduction

Enzyme inhibition studies has been the interesting topic of research today since a large number of diseases are directly or indirectly associated with some enzyme. A hydrolytic enzyme, urease is found abundantly in nature in soil as well as in a large number of microbes like bacteria, algae, fungi. Urease is beneficial for plants as it provides nitrogen to them which is essential for their growth but its excess activity may harm environment by producing excess of ammonia. In human beings it serves the role of a pathogen and responsible for many serious disease like gastric cancer, peptic ulcer, crust formation in catheter, hepatic coma, hepatic encephalopathy, pyelonephritis, [1, 2] ureter obstruction which can lead to kidney fibrosis [3], etc. Among various responsible factors for colonization of H. Pylori presence of urease within bacteria has been found to be most important virulence factor as it causes buffering of stomach acid, produce toxic effect on epithelium cells of stomach, cause disruption of junction of cells tight junctions and sheaths antigens [4,5,6,7]. Furthermore it spreads its virulence by catalyzing urea present in human and animal body into ammonia which causes elevation in pH of gastric media and thereby make comfortable environment for the various pathogenic bacteria containing ureases such as H. pylori to survive there and spread colonies [8,9,10,11,12,13,14,15,16,17].

These infections need attention and proper treatment which can be possible only by inhibiting the responsible enzyme; this compelled us to investigate on urease inhibitors. Drugs used clinically for the treatment of ailments caused by urease producing bacteria includes bismuth complex, phosphoramidates, imidazole derivatives, Antibiotics [18, 19], proton-pump inhibitors [20, 21], H2-blockers [22, 23] and hydroxamic acids with double and triple therapy to eradicate the H. pylori infection [24, 25]. But cost of therapy, antibiotic resistance, and associated side effects like teratogenic effects shown by hydroxamic acid and rapid disintegration of phosphoramidates at low pH [26,27,28] motivated researchers towards natural compounds.

A number of biologically active compounds from natural products have been studied against many diseases [29, 30]. One of the most abundant polyphenol present in human being diet specially consumed in green coffee, fruits and vegetables; chlorogenic acid is a naturally occurring ester of quinic acid and caffeic acid [31]. The name chlorogenic acid was introduced in 1846 in response to explain the major component present in beans of green coffee (Payen 1846) [32]. Chlorogenic acid has antioxidant, antimicrobial, and anxiolytic activity antioxidant, antimicrobial, antibacterial, antiviral and anti-inflammatory capacities, which can contribute in the prevention of chronic and cardiovascular diseases, as described by several studies in-vivo and in-vitro [31, 33,34,35,36,37,38,39,40]. Recent reports indicate that this compound also exerts anti-proliferative effects against some types of cancer cell, such as those from liver, blood, or brain cancer [41,42,43]. Chlorogenic acids not only play a role as antioxidant of coffee, but also contribute to the aroma and taste profile [44, 45]. In pharmaceutical industries it has been in continuous demand because of its beneficial effects [46].

According to literature studies a large number of medicinal plants having phenolic compound and polyphenols as active component have been reported for their anti- H. Pylori activity. Recent findings of many researchers stressed that phenolic compounds having strong antioxidant profile play important role in inhibiting H. pylori. Literature uncovers the antioxidant and H. Pylori urease inhibition profile of chlorogenic acid extracted from Oregano, Cranberry juices as well as extracts of other phytochemical extracts probably by inhibiting urease enzyme [47]. Konstantinopoulou et al. studied phenolic compound chlorogenic acid extracted from plant Anthemis altissima against H. Pylori bacterium and found that it was quite effective in inhibiting the growth of bacteria with MIC value 312.5–1250 μg/mL [48]. In an application for patent for cosmetic and dermatological composition for anti-rash also used chlorogenic acid extracted from aqueous green coffee extract as anti-urease agent [49]. Shang et al. reported that extract of L. japonica containing chlorogenic acid and luteolin glycoside as main component showed good therapeutic potential against H. Pylori [50]. Paun et al. reported urease inhibitory activities of extracts of Geranium spp., Helleborus spp. and Hyssopus spp. polyphenolic extracts having chlorogenic acid as active compound [51]. Furthermore the docking interactions with target protein help in optimization of lead molecules [52] which further help in designing the ligands as potential urease inhibitors. In this regards, targeting urease for treating pathogenic disorders caused by it may open a new line of treatment for infections caused by urease-producing bacteria. This research was conducted in search for newer pharmacophore with emphasis towards urease.

Results and discussion

Chemistry

Chlorogenic acid derivatives C4(a–h) were synthesized by following the procedure given in Scheme 1 [53,54,55]. Evaluation of structure of novel derivatives was confirmed by spectroscopic methods such as IR, 1H NMR, 13CNMR and elemental analysis. Firstly protection of hydroxyl groups of quinic part of chlorogenic acid was done by lactonisation by stirring it with conc. sulphuric acid in acetone for 2 h followed by dilution with ethylacetate and washing with water and brine solution. Anilides of chlorogenic acid was prepared in the second step by refluxing with substituted anilines (Table 1) in presence of dichloromethane for 2–3 h. Finally deprotection of hydroxyl groups of chlorogenic acid was done by reaction with 0.1 M HCl with subsequent washing with ethylacetate in vaccum under pressure. Monitoring of reaction was done by thin layer chromatography and completion of reaction was confirmed by single spot in TLC under UV lamp. Evaluation of structure of novel derivatives was confirmed by spectroscopic methods such as IR, 1H NMR, 13CNMR, elemental analysis. Derivatisation was confirmed by disappearance of peak of saturated acid (C=O) at 1716 cm−1 of chlorogenic acid and appearance of C=O amide peak at 1629–1683 cm−1 in compounds C4(a–h). Moreover peak of N–H amide at 3310–3334 cm−1 in compounds C4(a–h) also confirmed formation of anilides. 1HNMR signals were interpreted by their value of chemical shift for particular protons of synthesized derivatives, coupling constant and multiplicities of signals. Singlet observed at δ 8.5–9.0 was due to NH of secondary amide in all derivatives and in 13C NMR signal of carboxylic acid carbon at δ 180 ppm was shifted to 175 ppm due to formation of amide derivative confirmed formation of compound. Further and final confirmation process involves analyzing their mass spectrum for determination of molecular weight in which Q-ToF Micro instrument was used as ion source. Maximum number of the derivatives showed peak at M+ (molecular ion peak), (M++1), (M++2) in positive chemical ionization and (M+1), (M+2), M+ during negative chemical ionization mode. Elemental analysis of chlorogenic acid derivative was carried out in CHNS analyzer where C, H and N in percent were found within acceptable range.

Biological activity

It has been recommended that phenolic moiety has been found to be important for antioxidant and urease inhibition property of synthesized compounds. The newly synthesized derivatives of chlorogenic acid were examined for their urease enzyme inhibition, free radical scavenging activity and for H. Pylori inhibition. As structure of urease from different sources has common structural features therefore urease inhibition studies were carried out on jack bean urease. Inhibition studies were carried out by indophenol technique described by Weatherburn [56] in which measurement of concentration of ammonia released during the reaction between reagents and compounds were done. Antioxidant property of derivatives was observed by their ability to donate hydrogen or electrons to DPPH [57,58,59]. According to our investigational data almost all the synthesized derivatives showed good potential in both activities than parent drug chlorogenic acid as well as standard drug having IC50 value in range of 11.01–22.02 µM and 5.10–8.48 µM against urease inhibition with competitive mode of inhibition and free radical scavenging activity using thiourea and ascorbic acid as standard drugs respectively (Table 2). According to experimental values derivative C4a, C4d, C4a and C4b bearing nitro and chloro at 2nd and 4th position and C4d bearing only nitro group at 3rd position) were found to possess excellent IC50 value i.e. 11.01 ± 0.013, 13.8 ± 0.041 and 15.86 ± 0.004 µM respectively in urease inhibition (Fig. 1) and 5.10 ± 0.018, 5.34 ± 0.007 and 6.01 ± 0.005 µM in antioxidant property (Fig. 2) against DPPH. It was observed from the experimental data that substitution of electron withdrawing halogen specially chloro and nitro at anilide ring specifically 2nd and 4th position strengthen the potential of candidate towards enzyme inhibition while electron donating groups like methoxy and methyl groups at 3rd and 4 position (C4e, C4f and C4g) does not showed remarkable potential. Antioxidant activity was also highly influenced by addition of electron withdrawing groups in compound C4a and C4b (IC50 5.10 ± 0.018 and 6.01 ± 0.005 µM) chloro and nitro group work synergistically and improves hydrogen releasing capacity of phenolic group of parent chlorogenic acid.

Derivatives C4a, C4b and C4d which were found best in urease inhibition and antioxidant activity as well as in terms of docking score were tested further against antibacterial efficiency against Helicobacter pylori DSM 4867 using AHA as a standard and DMSO as control. MIC50 values, lowest concentration of compound inhibiting microbial growth after 24 h on agar plates in comparison with positive control [60,61,62,63], were calculated for compounds and the results revealed that C4a displayed its excellent potency with good zone of inhibition i.e. 10.00 ± 0.00 mm and MIC value 500 μg/mL as compared to standard drug acetohydroxamic acid having zone of inhibition 9.00 ± 0.50 mm and MIC 1000 μg/mL. In-vitro results concluded that compound C4a bearing nitro and chloro group at 2nd and 4th position indicated excellent antibacterial action against H. Pylori probably by interacting with the target protein efficiently and inhibited the growth of pathogenic bacteria.

Enzyme kinetics

Study of inhibitory effect of chlorogenic derivatives on jack bean urease was performed to check the inhibitory potential, kinetics studies and mechanism of inhibition in phosphate buffer and 1 mM EDTA at pH 8.2. Lineweaver–Burk plots (1/absorbance versus 1/urea) was constructed from kinetic data to determine the mechanism of enzyme inhibition by varying the concentration of substrate urea in the absence and presence of different concentrations of most potent compound C4a (Fig. 3). Inhibition constant (Ki) was determined as the intersection on x-axis of the plot of 1/Vmax and varying concentration of inhibitor obtained from Lineweaver–Burke plot and all experiments were performed in triplicate. Linear lines were formed which intersected at y-axis indicated competitive type of Inhibition as Km was different but Vmax was same at different concentrations of compound. Competitive inhibition infers that compound C4a will probably compete for binding at the site of substrate in enzyme active site pocket. Binding confirmations from molecular simulation studies also confirm the mode of inhibition as shown in Fig. 3.

Structure activity relationship

Studying results from antioxidant nature and urease inhibition activities of newly synthesized morin derivatives, structure activity relationship can be derived (Fig. 4).

-

1.

Incorporation of aromatic ring bearing chloro and nitro group ortho and para position improved urease inhibition and hydrogen donating capacity of compound (compound C4a, C4b and C4d bearing nitro at 3rd position). Nitro and chloro group probably worked synergistically and make the ligands suitable for proper fitting into the active site of protein thereby increased urease inhibition property, also predicted by molecular docking studies (Fig. 5).

-

2.

Presence of Nitro group (C4a, C4b and C4d) improved biological profile of compound.

-

3.

Addition of aromatic ring bearing electron withdrawing groups (C4e, g) did not much improve the urease efficiency of compound might be by stabilizing the molecule.

-

4.

Incorporation of aromatic ring having bromo and fluoro substituents only improved the antioxidant nature of parent compound (C4c, C4h).

Molecular docking study

Molecular docking is an informative tool for investigating affinity between ligand and protein target. With the aim to insight the binding interaction of the compounds with jack bean urease protein [64,65,66], Schrodinger’s maestro package of molecular docking software was used for in-silico studies of newly designed library of chlorogenic acid proposed derivatives. Plant urease jack bean having PDB ID 3LA4 having good resolution about 2.0 Å, crystallographic complex was selected for docking the ligands by induced fit docking (IFD) method. Docking parameters revealed that designed ligands possess excellent docking score and binding energy as compared to standard drugs thiourea and AHA (Table 3). Exhaustive ligand protein interaction studies showed that newly synthesized ligands bind within active site of enzyme firmly by hydrogen bond formation, pi–pi stacking and hydrophobic interaction (Table 4). Position and alignment of particular substituents on molecules was found to be responsible for perfect binding of ligand with enzyme. The docking pose of most active ligand (C4a) showed astonishing interactions among protein complex with five hydrogen bonds between hydroxyl, carbonyl and nitro group of ligand with residues Lys 709, Glu 718, Lys 716, Glu 742, Asn 15 and possessed excellent docking score and binding energy (− 10.091, − 62.674 kcal/mol). Hydrophobic interactions among ligand and residues Phe 712, Tyr 32, Val 36, Ala 37, Pro 743, Val 744, Ala 16, Leu 13, Leu 839, Phe 840 was noticed which firmly hold the molecule within compact substrate cavity (Fig. 6). Polar residues were held as the supporter to anilide bond of the compound C4a. After assessment of best docking pose of second most potent compound (C4d) it was found to form seven hydrogen bonds among Gly 641, Glu 418, Tyr 32, Ser 421, Lys 716, Met 746 with hydroxyl, carboxyl and NH groups. Salt bridge formation was also observed between oxygen and nitrogen atom with Glu 418, Glu 642 residue as shown in Table 4 which additionally provided support to ligand in active site cavity. Hydrogen bond shown by yellow coloured and compounds with green colour with substituents of different coloured. A hydrophobic interaction was also emerged between ligand and surrounding residues Val 640, Pro 717, Tyr 32, Val 36, Phe 712, Val 744, Met 746, Phe 838. Similarly six hydrogen bond formations was observed in inhibitor of third rank (C4b) between Lys 716, Glu 718, Ash 730, Lys 709, Phe 840, Val 844 residues and hydroxyl and keto group of ligand. Docking studies revealed that hydrogen bond interactions fix the ligands firmly and tightly in the active site.

Molecular simulation studies revealed that almost all of the tested inhibitors occupied the same core of enzyme having surrounding residues Lys 709, Glu 718, Lys 716, Glu 742, Asn 15, Phe 712, Tyr 32, Val 36, Ala 37, Pro 743, Val 744, Ala 16, Leu 13, Leu 839 and Phe 840 and every inhibitor showed good hydrogen and hydrophobic interactions. Hydrogen bond formations were considered most important for proper binding of ligand within the enzyme. Almost every molecule have good docking score from − 9.211 to − 10.091 as compared to − 3.459 and − 3.049 of standard thiourea and Acetohydroxamic acid as well as excellent binding energy ranges from − 48.832 kJ/mol to − 63.352 kJ/mol as compared to − 21.156 kJ/mol and − 17.454 kJ/mol of standard thiourea and Acetohydroxamic acid. Docking studies concluded that designed ligands have excellent affinity and binding capability for protein as compared to parent and standard compounds.

Admet studies

In drug discovering the ADME profile of drug like molecules is very important and for this purpose Schrodinger’s maestro molecular modeling package Qikprop module was utilized. The Absorption, distribution, metabolism and excretion descriptors of the designed molecules are given in Table 5. Blood brain barrier partition coefficient (QPlogBB), estimated IC50 value for HERG K+ channels obstruction (log HERG), estimation of human serum albumin binding (QPlogKhsa), permeation through skin estimation (QPlogKp), apparent Caco-2 cell permeability estimation in nm/sec (QPPCaco) and apparent MDCK cell permeability estimation in nm/sec (QPPMDCK), partition coefficient in octanol and water Log P, solubility in aqueous media log S, Lipinski’s rule of five and Percent Human Oral Absorption (%HOA). Results revealed that ADME parameters of each ligand within the bounds of satisfactory range without violating Lipinski’s rules [67,68,69,70].

Experimental

Materials

Chlorogenic acid was purchased from CDH and Jack bean urease from Sigma Aldrich. Analytical grade reagents and solvents were utilized as a part of study and obtained locally. Progression of reaction was observed via. Thin layer chromatography and recrystallization of products was done in order to purify the compounds which were again checked for purity by thin layer chromatography (TLC) performed on precoated plates (0.25 mm) purchased from Merk and visulisation was done under UV lamp. Measurement of melting point was done on Sonar melting point apparatus in open capillary tubes and was uncorrected. The spectral data, IR and 1H NMR, 13CNMR were measured by standard procedures. Brucker 12060280, Germany Software: OPUS 7.2.1394 spectrophotometer in cm−1 was used for recording IR spectra of derivatives and elemental analysis was done on Perkin–Elmer 2400 C, H, N analyzer. The 1HNMR and 13CNMR spectra were recorded in DMSO-d6 on a Bruker DRX-400 FTNMR instrument. Coupling constants (J) were reported in Hertz (Hz) and chemical shifts were depicted as δ (parts per million). Waters Micromass Q-ToF Micro instrument was used for Mass spectra recording.

Synthetic procedure

General synthetic procedure for preparation of derivatives of chlorogenic acid

Synthesis of (1S, 3R)-3-((E)-3-(3,4-dihydroxyphenyl)acryloyloxy)-1-hydroxy-4,5-dimethoxycyclohexane carboxylic acid (2)

In a round bottom flask a solution of chlorogenic acid (0.1 g, 0.52 mmol) in acetone (10 mL) was added with addition of conc. sulphuric acid (2 drops) and the reaction mixture was stirred along with refluxing for 2 h. The progress of the reaction was monitored by TLC, after the completion of the reaction, the solvent was allowed to evaporate, 15 mL ethylacetate was added to dilute the mixture and finally washing was done with water (2 × 30 mL) followed by washing with brine solution (20 mL). Finally yielded crude compound 2 (91%) having melting point 175–177 °C.

General procedure for synthesis of compounds (C3a–h)

Amide derivatives of chlorogenic acid was prepared by refluxing a solution of compound 2 (0.1 g, 0.46 mmol) in dichloromethane (5 mL) with substituted aniline (0.7 mmol) at 80 °C for 2–3 h (scheme 1). Reaction progress was continuously monitored with the help of TLC. After the completion of the reaction as indicated by single spot on precoated plate, the solvent was evaporated and diluted with ethyl acetate (25 mL). Mixture was washed with water (250 mL) followed by brine solution (30 mL). The crude product was obtained which was purified by dichloromethane to afford the pure product (C3a–h).

General procedure for synthesis of compounds (C4a–h)

For deprotecting the hydroxyl groups of synthesized amide derivatives, synthesized compounds C (3a–h) (5.0 g) was dissolved in water (10 mL), then added aq. 1 M HCl (40 mL) at room temperature. The reaction mixture was stirred at room temperature for 1–2 h. Solvent was removed under reduced pressure. The residue HCl was removed by adding EtOEt (20 × 3 mL) under vacuum [53,54,55]. The residue collected was further dried and product was obtained in good yields.

Spectral data

(1R, 5S)-5-((2-chloro-4-nitrophenyl) carbamoyl)-2, 3, 5-trihydroxycyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4a)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.78; (%) Yield = 87.1; m.p (186–188 °C); IR cm−1 3632 (O–H str.), 3328 (N–H str), 3156 (C–H aromatic), 1732 (C=O str ester), 1692 (N–H bending), 1669 (C=O amide), 1636 (C=C str alkene), 1469 (C=C aromatic), 1326 (NO2 sym.), 748 (C–Cl); 1H NMR (400 MHz, DMSO-d6) δ 9.40 (s, 2H), 9.32 (s, 1H), 8.73 (s, 1H), 8.32 (d, J = 1.5 Hz, 1H), 8.24 (d, J = 1.5 Hz, 1H), 8.10 (dd, J = 12.4, 7.0 Hz, 1H), 7.47 (d, J = 1.6 Hz 1H), 7.04–6.97 (m, 3H), 6.30 (d, J = 1.6 Hz, 1H), 5.17 (d, J = 4.5 Hz, 1H), 4.98 (s, 1H), 4.78 (td, J = 7.1 Hz, 1H), 4.40 (d, J = 4.5 Hz 1H), 3.89–3.61 (m, 2H), 2.42 (dt, J = 7.1, 1.6 Hz, 2H), 2.24 (dt, J = 7.1, 1.6 Hz, 1H), 2.13 (dd, J = 12.4, 7.0 Hz, 1H), 2.01 (dd, J = 12.4, 7.0 Hz, 1H); 13C NMR (100 MHz, CDCl3)δ 174.4, 167.2, 147.3, 147.0, 146.2, 140.6, 139.0, 126.1, 120.9, 119.2, 115.6, 77.1, 73.7, 71.1, 69.1, 41.2, 38.1; MS ES + (ToF): m/z 508.09 [M + 1]; CHN: Calc. (C22H21ClN2O10): C, 51.93; H, 4.16; N, 5.51. Found: C, 51.92; H, 4.14; N, 5.50.

(1R, 5S)-5-((4-chloro-2-nitrophenyl) carbamoyl)-2, 3, 5-trihydroxycyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4b)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.75; (%) Yield = 79.8; m.p (182–184 °C); IR cm−1 3636 (O–H str.), 3334 (N–H str), 3167 (C–H aromatic), 1739 (C=O str ester), 1691 (N–H bending), 1642 (C=O amide), 1634 (C=C str alkene), 1484 (C=C aromatic), 1328 (NO2 sym.), 752 (C–Cl); 1H NMR (400 MHz, DMSO-d6) δ 9.76 (s, 1H), 9.40 (s, 1H), 8.73 (s, 1H), 8.05 (s, 1H), 7.66 (dd, J = 12.1, 1.5 Hz, 1H), 7.54 (dd, J = 12.4, 7.0 Hz, 1H), 7.47 (d, J = 1.6 Hz, 1H), 7.02 (d, J = 4.5 Hz, 1H), 6.95 (dd, J = 12.4, 7.0 Hz, 1H), 6.77 (d, J = 1.6 Hz, 1H), 6.30 (d, J = 1.6 Hz, 1H), 5.00 (s, 1H), 4.90–4.77 (m, 2H), 4.69 (d, J = 15.0 Hz, 1H), 3.82 (p, J = 7.0 Hz, 1H), 3.67 (dt, J = 11.5 Hz, 1H), 2.31 (dd, J = 12.1, 5.0 Hz, 1H), 2.13 (dd, J = 12.0, 6.5 Hz, 2H), 1.88 (dd, J = 12.1, 1.0 Hz, 1H); 13C NMR (100 MHz, CDCl3)δ 173.0, 166.2, 148.9, 147.8, 146.8, 136.2, 135.8, 125.5, 125.4, 125.3, 120.3, 116.3, 115.6, 77.7, 71.1, 69.6, 68.9, 41.2, 38.1; MS ES + (ToF): m/z 508.09 [M + 1]; CHN: Calc. (C22H21ClN2O10): C, 51.93; H, 4.16; N, 5.51. Found: C, 51.91; H, 4.17; N, 5.52.

(1R, 5S)-5-((4-bromophenyl)carbamoyl)-2, 3, 5-trihydroxycyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4c)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.69; (%) Yield = 76.5; m.p (190–192 °C); IR cm−1 3614 (O–H str.), 3310 (N–H str), 3142 (C–H aromatic), 1727 (C=O str ester), 1690 (N–H bending), 1637 (C=O amide), 1629 (C=C str alkene), 1477 (C=C aromatic), 518 (C–Br); 1H NMR (400 MHz, DMSO-d6) δ 9.41 (s, 1H), 8.74 (s, 1H), 8.40 (s, 1H), 7.57–7.43 (m, 5H), 7.04 (d, J = 4.5 Hz, 1H), 6.94 (dd, J = 12.4, 7.0 Hz, 1H), 6.75 (d, J = 1.6 Hz, 1H), 6.29 (d, J = 1.6 Hz, 1H), 4.97 (s, 1H), 4.82–4.71 (m, 2H), 4.39 (d, J = 4.8 Hz, 1H), 4.25–4.15 (m, 1H), 3.60 (p, J = 7.0 Hz, 1H), 2.34 (dd, J = 12.4, 7.0 Hz, 1H), 2.24 (dd, J = 12.4, 7.0 Hz, 1H), 2.15 (dd, J = 12.4, 7.0 Hz 1H), 1.95 (dd, J = 12.4, 7.0 Hz,1H); 13C NMR (100 MHz, CDCl3)δ 175.4, 166.9, 149.1, 147.3, 146.7, 146.4, 146.3, 138.2, 132.0, 128.0, 122.4, 122.1, 117.9, 116.0, 115.9, 115.2, 77.3, 73.1, 71.3, 69.0, 41.5, 38.1; MS ES + (ToF): m/z 507.11 [M + 1]; CHN: Calc. (C22H22BrNO8): C, 51.98; H, 4.36; N, 2.76. Found: C, 51.96; H, 4.38; N, 2.75.

(1R, 5S)-2, 3, 5-trihydroxy-5-((3-nitrophenyl)carbamoyl)cyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4d)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.72; (%) Yield = 71.7; m.p (174–176 °C); IR cm−1 3628 (O–H str.), 3330 (N–H str), 3098 (C–H aromatic), 1736 (C=O str ester), 1639 (C=O amide), 1636 (C=C str), 1477 (C=C aromatic), 1326 (NO2 sym.); 1H NMR (400 MHz, DMSO-d6) δ 9.42 (s, 1H), 8.84 (s, 1H), 8.72 (s, 1H), 8.49 (s, 1H), 7.91 (dd, J = 12.4, 7.0 Hz, 2H), 7.53 (t, J = 1.6 Hz, 1H), 7.46 (d, J = 4.8 Hz, 1H), 7.04 (d, J = 4.8 Hz, 1H), 6.96 (dd, J = 12.4, 7.0 Hz, 1H), 6.77 (d, J = 1.6 Hz, 1H), 6.29 (d, J = 1.6 Hz, 1H), 5.66 (d, J = 1.6 Hz, 1H), 5.45 (s, 1H), 4.80 (s, 1H), 4.51 (td, J = 7.5, 4.5 Hz 1H), 3.96–3.71 (m, 2H), 2.30–2.20 (m, 2H), 2.07–2.00 (m, 2H); 13C NMR (100 MHz, CDCl3)δ 174.2, 166.9, 148.9, 148.6, 148.3, 147.3, 146.4, 139.0, 138.9, 138.5, 131.2, 127.4, 125.9, 122.8, 118.4–117.8, 116.6, 115.7, 115.0, 114.7, 114.5, 114.3, 114.2, 77.3, 73.8, 71.6, 69.0, 41.3, 38.4; MS ES + (ToF): m/z 474.14 [M + 1]; CHN: Calc. (C22H22BrNO8): C, 55.70; H, 4.67; N, 5.90. Found: C, 55.73; H, 4.65; N, 5.93.

(1R, 5S)-2, 3, 5-trihydroxy-5-((3-methoxyphenyl)carbamoyl) cyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4e)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.77; (%) Yield = 83.6; m.p (162–164 °C); IR cm−1 3603 (O–H str.), 3321 (N–H str), 3173 (C–H aromatic), 1745 (C=O str ester), 1658 (C=O amide), 1625 (C=C str), 1475 (C=C aromatic), 1134 (C-O str. alkoxy); 1H NMR (400 MHz, DMSO-d6) δ 9.41 (s, 1H), 8.75 (s, 1H), 8.17 (s, 1H), 7.47 (d, J = 1.6 Hz, 1H), 7.37 (t, J = 1.6 Hz, 1H), 7.27–7.17 (m, 2H), 7.06 (d, J = 1.6 Hz, 1H), 6.95 (dd, J = 12.4, 7.0 Hz, 1H), 6.79 (d, J = 1.6 Hz 1H), 6.69 (d, J = 1.6 Hz 1H), 6.30 (d, J = 1.6 Hz 1H), 5.50(t, J = 1.6 Hz, 1H), 5.17 (td, J = 7.1, 1.6 Hz, 1H), 4.99 (s, 1H), 4.54 (s, 1H), 3.97 (d, J = 1.6 Hz, 1H), 3.78 (s, 3H), 3.74–3.69 (m, 1H), 2.39 (dd, J = 12.4, 7.0 Hz, 1H), 2.07 (dd, J = 12.4, 7.0 Hz, 2H), 1.78 (dd, J = 12.4, 7.0 Hz, 1H); 13C NMR (100 MHz, CDCl3)δ 175.5, 166.8, 160.7, 148.5, 147.0, 146.0, 139.4, 139.2, 129.6, 127.2, 122.7, 120.4, 119.6, 118.4, 117.8, 116.5, 115.7, 115.1, 114.7, 114.5, 114.2, 77.4, 73.9, 71.6, 69.0, 41.4, 38.4; MS ES + (ToF): m/z 459.15 [M + 1]; CHN: Calc. (C23H25NO9): C, 60.13; H, 5.48; N, 3.05; Found: C, 60.12; H, 5.50; N, 3.03.

(1R, 5S)-2, 3, 5-trihydroxy-5-((4-methoxyphenyl)carbamoyl)cyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4f)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.81; (%) Yield = 85.4; m.p (160–162 °C); IR cm−1 3611 (O–H str.), 3325 (N–H str), 3194 (C–H aromatic), 1741 (C=O str ester), 1683 (C=O amide), 1627 (C=C str), 1456 (C=C aromatic), 1145 (C-O str. alkoxy); 1H NMR (400 MHz, DMSO-d6) δ 9.40 (s, 1H), 8.73 (s, 1H), 8.30 (s, 1H), 7.60–7.52 (m, 2H), 7.04 (d, J = 1.6 Hz, 1H), 6.99–6.89 (m, 3H), 6.77 (d, J = 1.6 Hz 1H), 6.30 (d, J = 1.6 Hz, 1H), 4.97 (s, 1H), 4.82–4.91 (m, 2H), 4.39 (d, J = 4.5 Hz 1H), 4.26–4.15 (m, 1H), 3.79 (s, 3H), 3.60 (p, 1H), 2.34 (dd, J = 7.5, 5.0 Hz, 1H), 2.24 (dd, J = 7.5, 5.0 Hz, 1H), 2.16 (dd J = 7.5, 5.0 Hz, 1H), 1.97 (dd, 1H); 13C NMR (100 MHz, CDCl3)δ 175.6, 166.8, 157.0, 148.5, 147.0, 146.1, 134.1, 127.3, 122.7, 122.4, 116.3, 115.6, 115.0, 114.7, 114.5, 114.3, 114.1, 77.2, 73.7, 71.1, 69.0, 41.3, 38.4; MS ES + (ToF): m/z 459.22 [M + 1]; CHN: Calc. (C23H25NO9): C, 60.13; H, 5.48; N, 3.05; Found: C, 60.15; H, 5.47; N, 3.07.

(1R, 5S)-2, 3, 5-trihydroxy-5-((2-methylphenyl)carbamoyl)cyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4g)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.66; (%) Yield = 73.9; m.p (166–168 °C); IR cm−1 3611 (O–H str.), 3325 (N–H str), 3194 (C–H aromatic), 1741 (C=O str ester), 1683 (C=O amide), 1627 (C=C str), 1456 (C=C aromatic), 1145 (C-O str. alkoxy); 1H NMR (400 MHz, DMSO-d6) δ 9.42 (s, 1H), 8.74 (s, 1H), 8.41 (s, 1H), 7.95 (dd, dd, J = 7.5, 5.0 Hz, 1H), 7.51–7.37 (m, 2H), 7.27–7.15 (m, 1H), 7.02 (d, J = 1.6 Hz, 1H), 6.95 (dd, dd, J = 7.5, 5.0 Hz, 1H), 6.78 (d, J = 1.6 Hz, 1H), 6.32 (d, J = 1.6 Hz, 1H), 4.98 (s, 1H), 4.79 (td, 1H), 4.50 (dd, dd, J = 7.5, 5.0 Hz, 2H), 4.24–4.14 (m, H), 3.62 (p, 1H), 2.43 (dd, dd, J = 7.5, 5.0 Hz, 1H), 2.33–2.21 (m, 4H), 1.98 (ddd, dd, J = 7.5, 5.0, 2.3 Hz 2H); 13C NMR (100 MHz, CDCl3)δ 175.8, 166.8, 148.5, 147.1, 147.0, 146.9, 146.1, 136.1, 132.5, 132.3, 132.1, 129.9, 127.3, 126.9, 125.0, 122.8, 121.7, 116.7, 115.7, 115.2, 77.1, 73.8, 71.1, 69.0, 41.3, 38.1, 17.7; MS ES + (ToF): m/z 443.16 [M + 1]; CHN: Calc. (C23H25NO8): C, 62.30; H, 5.68; N, 3.16; Found: C, 62.28; H, 5.69; N, 3.14.

(1R, 5S)-5-((2-fluorophenyl)carbamoyl)-2, 3, 5-trihydroxycyclohexyl (2E)-3-(3, 4-dihydroxyphenyl)prop-2-enoate (4h)

Rf TLC mobile phase: Butanol: Water: Acetic acid (6:2:2) = 0.71; (%) Yield = 74.2; m.p (178–180 °C); 1H NMR (400 MHz, DMSO-d6) δ 9.44 (s, 1H), 8.70 (s, 1H), 8.36 (s, 1H), 8.02 (dd, J = 7.5, 5.0 Hz, 1H), 7.47 (d, J = 1.6 Hz, 1H), 7.16 (dd, J = 7.4, 1.6 Hz, 2H), 7.07–6.95 (m, 3H), 6.79 (d, J = 1.6 Hz, 1H), 6.30 (dd, J = 7.4, 1.6 Hz, 1H), 4.97 (s, 1H), 4.82–4.72 (m, 2H), 4.39 (d, J = 1.6 Hz, 1H), 4.20 (dt, J = 7.1, 1.6 Hz, 1H), 3.60 (p, 1H), 2.35 (dd, J = 7.4, 1.6 Hz, 1H), 2.25–2.15 (dd, J = 7.4, 1.6 Hz, 2H), 1.99 (dd, J = 7.4, 1.6 Hz, H); 13C NMR (100 MHz, CDCl3)δ 175.6, 166.8, 156.3, 154.3, 148.5, 147.0, 146.0, 127.2, 126.9, 126. 8, 126.7, 126.3, 125.8, 124.9, 122.8, 122.0, 116.6, 116.4, 116.1, 116.0, 115.7, 115.1, 77.1, 73.8, 71.2, 69.2, 69.0, 68.9, 68.8, 41.3, 38.1; MS ES + (ToF): m/z 447 [M + 1]; CHN: Calc.(C23H25NO8): C, 59.06; H, 4.96; N, 3.13; Found: C, 59.06; H, 4.96; N, 3.13.

175.63, 166.84, 156.36, 154.35, 148.55, 147.02, 146.09, 127.29, 126.93–126.65, 126.65–124.85, 122.76, 122.03, 116.56–116.00, 115.70, 115.09, 77.13, 73.79, 71.16, 69.16–68.80, 41.36, 38.11.

Protocol of in-silico study

In-silico studies of the designed derivatives of chlorogenic acid were done by Induced fit docking protocol of Schrodinger’s Maestro molecular modeling software. Urease from plant source Jack bean having resolution 2.05 Å (PDB code: 3LA4) was retrieved from protein databank online (http://www.rcsb.org) from the Research Collaboratory for Structural bioinformatics (RCSB) and has been used as for the purpose of docking the newly designed ligands in X-ray crystallized structure form for finding the active lead compound.

Protein preparation

With the help of protein preparation wizard named prepwiz, protein was prepared for docking studies. In this process assigning bond orders, partial charges and hydrogens were added, side chains and loops having missing atoms were fabricated, all waters (with exception of those which were coordinated to metals) and unnecessary atoms were expelled and alternate conformations were performed.

Generation of grid

After preparation of protein area for docking interaction with ligands was selected on protein by forming a grid over it. Grid generation was done by grid generation module of Schrodinger Maestro programming according to the conventions.

Ligand preparation

Proposed structure of ligand were drawn by Chemdraw Ultra 8.0 (ChemOffice Package) software which were finally saved as mol. file format and finally prepared by LigPrep module. Addition or removal of hydrogen bond were done for ideal confirmation of ligands, partial charges were computed according to the OPLS-2005 force field with 32 stereo isomers, tautomers, and other options like ionization at the physiological pH 7 ± 2 were set as default options. Ligands were selected for simulation studies after their preparation based upon their minimum potential energy. Geometry of ligand was minimized by application of force field algorithm according to protocol of software.

Molecular docking

Ligand-receptor interaction study using maestro package was done according to the given protocol. While performing Grid-based Ligand Docking ligands were allocated at various positions of grid within range of 1 Å and were rotated in all three angles and glide score (GScore Grid-based Ligand Docking with Energetics) scoring function was obtained as the output for each ligand given in Table 2. Derivatives possessing higher score in terms of glide score and those possessing lower binding energy were selected for further synthesis process [65,66,67,68,69,70].

Urease inhibitory assay

Urease enzyme inhibition investigation studies for all synthesized compounds were done by the method developed by Weatherburn (1967) named Indophenol against Jack Bean Urease [56]. Briefly, incubation of solution of Jack bean protein 25 μL was done at temperature of 30 °C for a period of 15 min with 55 μL of buffers solution having 100 mM urea and 5 μL of test solution in 96-well plates. 45 μL phenol solution composing phenol 1% w/v and solution of sodium nitroprusside 0.005% w/v and alkali reagent 70 μL composed of sodium hydroxide 0.5% w/v and active sodium hypochloride solution 0.1% were mixed to every well. The measurement of increase in absorption at 625 nm was done after 50 min by help of a microplate reader (Molecular Device, USA). Readings were recorded in triplicate set in a final volume of 200 μL using thiourea as standard. Each assay was performed at pH 8.2 (0.01 M K2HPO4.3H2O, 0.01 M LiCl2 and 1 mM EDTA). Calculation of Inhibition in percentage of synthesized derivatives was done by the formula given as:

where, Acontrol is control absorbance; Asample is test absorbance.

Dpph assay for antioxidant activity

Antioxidant nature of the synthesized derivatives was measured by the help of DPPH method. According to this method synthesized compounds were allowed to react for 0.5 h at 37 °C with stable free radical, 1, 1-diphenyl-2-picrylhydrazyl radical (DPPH). The DPPH was taken in a concentration of 300 µM. Decrease in value of absorption at 515 nm was measured after the period of incubation using a microplate reader using ascorbic acid as a standard. Molecule capable of donating proton to DPPH and cause its reduction acts as an antioxidant. Following reduction deep violet coloured DPPH solution changes to yellow depending upon the nature of antioxidant compound, which brings a measurable decrease in value of absorption at 517 nm [57,58,59]. The proton or electron donating capacity of the derivative was estimated from the fading of deep purple colored methanolic solution of 1, 1-diphenylpicrylhydrazyl (DPPH). Incubation of mixture was done at room temperature for 30 min and measurements were done at 517 nm against blank. Calculation of percentage inhibition was done by following formula:

where, Acontrol is control absorbance; Asample is test absorbance.

Anti- H. pylori activity

Since H. Pylori is not acidophilic in nature therefore it requires urease, which produced ammonia by hydrolyzing urea present in stomach, for its survival in acidic gastric medium. Because of virulence nature of urease researchers decided to target its inhibition for anti-H. Pylori drugs. Novel synthesized derivatives were investigated against H. pylori bacterium (DSM 4867, AHA as standard) for their antibacterial activity by using Well diffusion technique. The stock solution of compounds in DMSO (1000 μg/mL) were prepared. Cell suspension was prepared from culture grown on BHI broth. The cell suspensions of all the cultures were adjusted to 1–2 × 105 cells/mL. Helicobacter pylori (100 µL) was inoculated by spread plate technique on agar plates (90 mm). Agar wells (5 mm) were made on H. pylori inoculated media and impregnated with 2500 µg of each sample and standard which were incubated @ 35 °C for 24–48 h with 5% CO2 and observed for zone of inhibition around the well. MIC was determined against Helicobacter pylori by micro broth dilution technique as per NCCLS method [60,61,62,63].

Kinetic studies

Kinetic studies of the derivatives were done to calculate the rate constant Vmax and Michaelis constant Km by plotting Lineweaver bruke plot of 1/[S] (substrate concentration) against 1/[V] velocity. To examine the mode of inhibition compound C4a was solubilized in DMSO and further dilutions were prepared accordingly. Plot was prepared by using varying concentration of substrate (urea) in with varying concentration of inhibitor C4a. Inhibitory constant values (Ki) were determined as the interaction on the X-axis of the plots of the slope against different concentration of derivatives C4a. Mode of inhibition was found to be competitive as value of Km was different but Vmax was same. All experiments were performed in triplicate and kinetic study for interaction of enzyme with inhibitor was computed with Graphpad prism 7.0 software.

Statistical analysis

Output of statistical analysis has been depicted in mean ± SEM whereas statistical examination of data collected experimentally was done by one-way analysis of variance (ANOVA). Considerable difference revealed by ANOVA p < 0.05 was regarded significant. Evaluation of statistical data was done by Graph Pad Prism 7.0 Version for Windows (San Diego, CA, USA).

Conclusion

In conclusion, selected derivatives of chlorogenic acid were synthesized after in silico screening of library of designed derivatives against jack bean urease enzyme. Computational studies helped in selection of potential candidate also shed light into the underlying mechanism of inhibition. Synthetic procedure includes three step reactions which involve lactone formation of chlorogenic acid followed by reaction with substituted anilines. Novel synthesized derivatives were evaluated for their urease inhibitory, DPPH- free radical scavenging and Anti- H. Pylori activity by in vitro method. Among the series all molecules were found effective and specific in their action with good IC50 values and MIC against H. Pylori. Designed candidate C4a was found top most in all parameters and hence can be the potential lead compound in future for treatment of pathologies caused by urease as well as against H. Pylori infection.

Abbreviations

- ADMET:

-

absorption distribution metabolism excretion

- MIC:

-

Minimum Inhibitory Concentration

- HCl:

-

hydrochloric acid

- TLC:

-

thin layer chromatography

- UV:

-

ultra violet

- DPPH:

-

2, 2-diphenyl-1-picrylhydrazyl

- CHLG:

-

chlorogenic acid

- SEM:

-

Standard Error Mean

- ANOVA:

-

analysis of variance

- DMSO:

-

dimethyl sulphoxide

- AHA:

-

acetohydroxamic acid

- EDTA:

-

ethylenediaminetetraacetic acid

- HOA:

-

Human Oral Absorption

- RCSB:

-

Research Collaboratory for Structural bioinformatics

- NCCLS:

-

National Committee for Clinical Laboratory Standards

- EtOEt:

-

ethylacetoacetate

References

Mobley HL, Hausinger RP (1989) Microbial ureases: significance, regulation, and molecular characterization. Microbiol Rev 53(1):85–108

Mobley HL, Island MD, Hausinger RP (1995) Molecular biology of microbial ureases. Microbiol Rev 59(3):451–480

Skibba M, Hye Khan M, Kolb LL, Yeboah MM, Falck JR, Amaradhi R, Imig JD (2017) Epoxyeicosatrienoic acid analog decreases renal fibrosis by reducing epithelial-to-mesenchymal transition. Front Pharmacol 30(8):406

Covacci A, Telford JL, Del Giudice G, Parsonnet J, Rappuoli R (1999) Helicobacter pylori virulence and genetic geography. Science 284(5418):1328–1333

Dundon WG, de Bernard M, Montecucco C (2001) Virulence factors of Helicobacter pylori. Int J Med Microbiol 290:647–658

Mobley HL, Mendz GL, Hazell SL (2001) Helicobacter pylori. ASM Press, Washington (DC), pp 471–498

Yamaoka Y (2010) Mechanisms of disease: Helicobacter pylori virulence factors. Nat Rev Gastroenterol Hepatol. 7:629–641

Tamaddon F, Ghazi S (2015) Urease: a highly biocompatible catalyst for switchable Biginelli reaction and synthesis of 1, 4-dihydropyridines from the in situ formed ammonia. Catal Commun 72:63–67

Gripenberg-Lerche C, Zhang L, Ahtonen P, Toivanen P, Skurnik M (2000) Construction of urease-negative mutants of Yersinia enterocolitica serotypes O: 3 and O: 8: role of urease in virulence and arthritogenicity. Infect Immun 68(2):942–947

Li X, Zhao H, Lockatell CV, Drachenberg CB, Johnson DE, Mobley HL (2002) Visualization of Proteus mirabilis within the matrix of urease-induced bladder stones during experimental urinary tract infection. Infect Immun 70(1):389–394

Olivera-Severo D, Wassermann GE, Carlini CR (2006) Ureases display biological effects independent of enzymatic activity. Is there a connection to diseases caused by urease-producing bacteria. Braz J Med Biol Res. 39(7):851–861

Konieczna I, Kwinkowski M, Kolesi B, Kami Z, Kaca W (2012) Bacterial urease and its role in long-lasting human diseases. Curr Protein Peptide Sci. 13:789–806

Jones NL, Shabib S, Sherman PM (1997) Capsaicin as an inhibitor of growth of the gastric pathogen Helicobacter pylori. FEMS Microbiol Lett 146:223–227

Zeyrek FY, Oguz E (2005) In vitro activity of capsaicin against Helicobacter pylori. Ann Microbiol. 55(2):125–127

Matongo F, Nwodo UU (2014) In vitro assessment of Helicobacter pylori ureases inhibition by honey fractions. Arch Med Res 45(7):540–546

Dowd P, Zheng ZB (1995) On the mechanism of the anticlotting action of vitamin E quinone. Proc Natl Acad Sci 92(18):8171–8175

Sherif TS, Hassan Milan Z (2016) Plant-derived urease inhibitors as alternative chemotherapeutic agents. Arch Pharm Chem Life Sci. 349:507–522

Fera MT, Giannone M, Pallio S, Tortora A, Blandino G, Carbone M (2001) Antimicrobial activity and postantibiotic effect of flurithromycin against Helicobacter pylori strains. Int J Antimicrob Agents 17:151–154

Boyanova L (1999) Comparative evaluation of two methods for testing metronidazole susceptibility of Helicobacter pylori in routine practice. Diagn Microbiol Infect Dis 35:33–36

Park JB, Imamura L, Kobashi K (1996) Kinetic studies of Helicobacter pylori urease inhibition by a novel proton pump inhibitor, rabeprazole. Biol Pharm Bull 19:182–187

Tsuchiya M, Imamura L, Park JB, Kobashi K (1995) Helicobacter pylori urease inhibition by rabeprazole, a proton pump inhibitor. Biol Pharm Bull 18:1053–1056

Susan M, Mou MD (1998) The relationship between Helicobacter infection and peptic ulcer disease. Prim Care Update Ob/Gyns. 5:229–232

Sorba G, Bertinaria M, Di Stilo A, Gasco A, Scaltrito MM, Brenciaglia MI, Dubini F (2001) Anti-Helicobacter pylori agents endowed with H2-antagonist properties. Bioorg Med Chem Lett 11:403–406

Midolo PD, Norton A, von Itzstein M, Lambert JR (1997) Novel bismuth compounds have in vitro activity against Helicobacter pylori. FEMS Microbiol Lett 157:229–232

Worrel JA, Stoner SC (1998) Eradication of Helicobacter pylori. Med Update Psychiat. 4:99–104

Ferrero M, Ducóns JA, Sicilia B, Santolaria S, Sierra E, Gomollón F (2000) Factors affecting the variation in antibiotic resistance of Helicobacter pylori over a 3-year period. Int J Antimicrob Agents 16:245–248

Glupczynski Y, Mégraud F, Lopez-Brea M, Andersen LP (2001) European multicentre survey of in vitro antimicrobial resistance in Helicobacter pylori. Eur J Clin Microbiol Infect Dis 20:820–823

Hirschl A, Andersen LP, Glupczynski Y (2009) Surveillance of Helicobacter pylori resistance to antibiotics in Europe 2008-2009. Gastroenterology 140:S312

Motati DR, Uredi D, Watkins EB (2018) A general method for the metal-free, regioselective, remote C–H halogenation of 8-substituted quinolines. Chem Sci 9(7):1782–1788

Reddy MD, Fronczek FR, Watkins EB (2016) Rh-catalyzed, regioselective, C–H bond functionalization: access to quinoline-branched amines and dimers. Org Lett. 18(21):5620–5623

Santos D, Almeida MC, Lopes NP, De Souza GEP (2006) Evaluation of the anti- inflammatory, analgesic and antipyretic activities of the natural polyphenol chlorogenic acid. Biol Pharm Bull. 29:2236–2240

Koshiro Y, Zheng XQ, Wang ML, Nagai C, Ashihara H (2006) Changes in content and biosynthetic activity of caffeine and trigonelline during growth and ripening of Coffea arabica and Coffea canephora fruits. Plant Science. 171(2):242–250

Nam SH, Ko JA, Jun W, Wee YJ, Walsh MK, Yang KY, Choi JH, Eun JB, Choi J, Kim YM, Han S (2017) Enzymatic synthesis of chlorogenic acid glucoside using dextransucrase and its physical and functional properties. Enzyme Microbial Technol 107:15–21

Feng R, Lu Y, Bowman LL, Qian Y, Castranova V, Ding M (2005) Inhibition of activator protein-1, NF-κB, and MAPKs and induction of phase 2 detoxifying enzyme activity by chlorogenic acid. J Biol Chem 280(30):27888–27895

Sato Y, Itagaki S, Kurokawa T, Ogura J, Kobayashi M, Hirano T, Sugawara M, Iseki K (2011) In vitro and in vivo antioxidant properties of chlorogenic acid and caffeic acid. Int J Pharm 403(1–2):136–138

Zhu X, Zhang H, Lo R (2004) Phenolic compounds from the leaf extract of artichoke (Cynara scolymus L.) and their antimicrobial activities. J Agric Food Chem 52(24):7272–7278

Marinova EM, Toneva A, Yanishlieva N (2009) Comparison of the antioxidative properties of caffeic and chlorogenic acids. Food Chem 114(4):1498–1502

Bajko E, Kalinowska M, Borowski P, Siergiejczyk L, Lewandowski W (2010) 5-OCaffeoylquinic acid: a spectroscopic study and biological screening for antimicrobial activity. Food Sci Technol. 54:158–168. https://doi.org/10.1016/j.lwt.2015.08.024

Butiuk AP, Martos MA, Adachi O, Hours RA (2016) Study of the chlorogenic acid content in yerba mate (Ilex paraguariensis St. Hil.): effect of plant fraction, processing step and harvesting season. J Appl Res Med Aromat Plants. 3:27–33. https://doi.org/10.1016/j.jarmap.2015.12.003

Peng BJ, Zhu Q, Zhong YL, Xu SH, Wang Z (2015) Chlorogenic acid maintains glucose homeostasis through modulating the expression of SGLT-1, GLUT-2, and PLG in different intestinal segments of Sprague–Dawley rats fed a high-fat diet. Biomed Environ Sci 28:894–903. https://doi.org/10.3967/bes2015.123

Belkaid A, Currie JC, Desgagnés J, Annabi B (2006) The chemopreventive properties of chlorogenic acid reveal a potential new role for the microsomal glucose-6-phosphate translocase in brain tumor progression. Cancer Cell Int 6(1):7

Liu YJ, Zhou CY, Qiu CH, Lu XM, Wang YT (2013) Chlorogenic acid induced apoptosis and inhibition of proliferation in human acute promyelocytic leukemia HL-60 cells. Mol Med Rep 8(4):1106–1110

Yagasaki K, Miura Y, Okauchi R, Furuse T (2000) Inhibitory effects of chlorogenic acid and its related compounds on the invasion of hepatoma cells in culture. Cytotechnology 33(1–3):229–235

SiebertM Berger RG, Nieter A (2018) Enzymatic mitigation of 5-O-chlorogenic acid for an improved digestibility of coffee. Food Chem 258:124–128

Moon JK, Shibamoto T (2010) Formation of volatile chemicals from thermal degradation of less volatile coffee components: quinic acid, caffeic acid, and chlorogenic acid. J Agric Food Chem 58:5465–5470

Santana-Gálvez L, Cisneros-Zevallos DA, Velázquez J (2017) Chlorogenic acid recent advances on its dual role as a food additive and a nutraceutical against metabolic syndrome. Molecules 26:1–21

Lin YT, Kwon YI, Labbe RG, Shetty K (2005) Inhibition of Helicobacter pylori and associated urease by oregano and cranberry phytochemical synergies. Appl Environ Microbiol 71(12):8558–8564

Wang YC (2014) Medicinal plant activity on Helicobacter pylori related diseases. World J Gastroenterol 20(30):10368

Huynh-Ba T, Nguyen T, Philippossian G, Vanstraceele A. (1993) Anti-urease cosmetic or dermatological composition. European Patent Application EP0582147A2

Shang X, Pan H, Li M, Miao X, Ding H (2011) Lonicera japonica Thunb: ethnopharmacology, phytochemistry and pharmacology of an important traditional Chinese medicine. J Ethnopharmacol. 138(1):1–21

Paun G, Litescu SC, Neagu E, Tache A, Lucian Radu G (2014) Evaluation of Geranium spp., Helleborus spp. and Hyssopus spp. polyphenolic extracts inhibitory activity against urease and α-chymotrypsin. J Enzyme Inhibit Med Chem. 29(1):28–34

Ganesh T, Banik A, Dingledine R, Wang W, Amaradhi R (2018) Peripherally restricted, highly potent, selective, aqueous-soluble EP2 antagonist with anti-inflammatory properties. Mol Pharm. 15(12):5809–5817

Huang CY, Chen LH, Huang HY, Kao FS, Lee YT, Selvaraju M, Sun CM, Chen HM (2015) Parallel synthesis and biological evolution of quinic acid derivatives as immuno-suppressing agents against T-cell receptors. RSC Adv 5(63):50801–50806

Zeng K, Thompson KE, Yates CR, Miller DD (2009) Synthesis and biological evaluation of quinic acid derivatives as anti-inflammatory agents. Bioorg Med Chem Lett 19:5458–5460

Zeng K. (2010) Discovery of Quinic Acid Derivatives as Oral Anti-inflammatory Agents. Ph.D Thesis University of Tennessee Health Science Center, http://dx.doi.org/10.21007/etd.cghs.2010.0371 https://dc.uthsc.edu/dissertations/314

Weatherburn MW (1967) Phenol-hypochlorite reaction for determination of ammonia. Anal Chem 39(8):971–974

Hanif M, Shoaib K, Saleem M, Hasan Rama N, Zaib S, Iqbal J (2012) Synthesis, urease inhibition, antioxidant, antibacterial, and molecular docking studies of 1, 3, 4-oxadiazole derivatives. ISRN Pharmacol 2012:1–10. https://doi.org/10.5402/2012/928901

Xu Q, Kulkarni AA, Sajith AM, Hussein D, Brown D, Güner OF, Reddy MD, Watkins EB, Lassegue B, Griendling KK, Bowen JP (2018) Design, synthesis, and biological evaluation of inhibitors of the NADPH oxidase, Nox4. Bioorg Med Chem 26(5):989–998

Choudhary MI, Begum A, Abbaskhan A, Musharraf SG, Ejaz A (2008) Two new antioxidant phenylpropanoids from Lindelofia stylosa. Chem Biodivers 5(12):2676–2683

Xiao ZP, Shi DH, Li HQ, Zhang LN, Xu C, Zhu HL (2007) Polyphenols based on isoflavones as inhibitors of Helicobacter pylori urease. Bioorg Med chem. 15(11):3703–3710

Li HQ, Xiao ZP, Yan T, Lv PC, Zhu HL (2009) Amines and oximes derived from deoxybenzoins as Helicobacter pylori urease inhibitors. Eur J Med Chem 44(5):2246–2251

Xiao ZP, Wang XD, Peng ZY, Huang S, Yang P, Li QS, Zhou LH, Hu XJ, Wu LJ, Zhou Y, Zhu HL (2012) Molecular docking, kinetics study, and structure–activity relationship analysis of quercetin and its analogous as Helicobacter pylori urease inhibitors. J Agric Food Chem 60(42):10572–10577

Xiao ZP, Peng ZY, Dong JJ, He J, Ouyang H, Feng YT, Lu CL, Lin WQ, Wang JX, Xiang YP, Zhu HL (2013) Synthesis, structure–activity relationship analysis and kinetics study of reductive derivatives of flavonoids as Helicobacter pylori urease inhibitors. Eur J Med Chem 63:685–695

Maestro, Version 10.2, Schrödinger, LLC, New York, NY, 2015

Friesner RA, Banks JL, Murphy RB, Halgren TA, Klicic JJ, Mainz DT, Repasky MP, Knoll EH, Shelley M, Perry JK, Shaw DE (2004) Glide: a new approach for rapid, accurate docking and scoring. 1. Method and assessment of docking accuracy. J Med Chem 47:1739–1749

Halgren TA, Murphy RB, Friesner RA, Beard HS, Frye LL, Pollard WT, Banks JL (2004) Glide: a new approach for rapid, accurate docking and scoring enrichment factors in database screening. J Med Chem 47:1750–1759

Glide, Version 6.6, Schrödinger, LLC, New York, NY, 2015

Friesner RA, Murphy RB, Repasky MP, Frye LL, Greenwood JR, Halgren TA, Sanschagrin PC, Mainz DT (2006) Extra precision glide: docking and scoring incorporating a model of hydrophobic enclosure for protein-ligand complexes. J Med Chem 49:6177–6196

Cecchelli R, Berezowski V, Lundquist S, Culot M, Renftel M, Dehouck MP, Fenart L (2007) Modelling of the blood-brain barrier in drug discovery and development. Nat Rev Drug Discov. 6:650–661

Lipinski CA, Lombardo F, Dominy BW, Feeney PJ (2012) Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv Drug Deliv Rev 64:4–17

Authors’ contributions

Authors RK and AK have designed, synthesized and executed the work in equal contribution. Both authors have read and approved the final manuscript.

Acknowledgements

Authors are very thankful to Schrödinger team, especially Vinod Devraji Schrodinger, Inc. (New York, USA) for providing necessary help required to complete the computational work and Skanda life sciences Pvt. Ltd, Banglore for carrying out H. Pylori studies.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Funding

No funding received for this research work from outside sources.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Kataria, R., Khatkar, A. In-silico design, synthesis, ADMET studies and biological evaluation of novel derivatives of Chlorogenic acid against Urease protein and H. Pylori bacterium. BMC Chemistry 13, 41 (2019). https://doi.org/10.1186/s13065-019-0556-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-019-0556-0