Abstract

Eugenol is the major component of clove essential oil and has demonstrated relevant biological potential with well-known antimicrobial and antioxidant action. Therefore, this work carried out the synthesis, purification, characterization, and evaluation of the antioxidant and antibacterial potential of 19 eugenol derivatives. The derivatives were produced by esterification reactions in the hydroxyl group (−OH) of eugenol with different carboxylic acids and also by addition reactions in the double bond of the allyl group. The derivatives had a promising antibacterial potential, including a lower minimum inhibitory concentration of 500 μg/mL than eugenol (1000 μg/mL). In addition, the derivatives were active against bacterial strains (Escherichia coli, Staphylococcus aureus) that eugenol itself showed no activity, thus increasing the spectrum of antibacterial action. As for the antioxidant activity, it was observed that the derivatives that involved esterification reactions in the hydroxyl group (−OH) of the eugenol molecule’s phenol resulted in a significant reduction of the antioxidant action (IC50 > 100 μg/mL) when compared with the eugenol precursor molecule (IC50 = 4.38 μg/mL). On the other hand, the structural changes located in the double bond affected much more smoothly the capacity of capturing radicals than the starting molecule, also being obtained derivatives with proximal antioxidant capacity (IC50 = 19.30 μg/mL) to commercial standards such as Trolox (IC50 = 16.00 μg/mL).

Similar content being viewed by others

Introduction

Molecular modification in structures of biologically active substances that occur naturally is one of the main strategies to enhance healthy biological effects, as well as to reduce eventual side effects [1,2,3]. In 1998, it was estimated that 60% of the antitumor and anti-infective drugs that entered the market or under clinical trial originated from natural products [4] via structural modifications. More recent data (December 2014) show that of the 237 drugs used as anti-infectious agents (antibacterial, antifungal, parasitic, and antiviral), excluding vaccines, recognized by public health agencies in the world, 138 (approximately 58.30%) are products of natural origin or derived from natural products. Thus, it is clear that this is a line of research with great potential for obtaining new drugs [5].

Eugenol, a natural substance used as a target molecule for the manufacture of bioactive compounds, was first isolated in 1929 and its commercial production began in 1940 in the United States. It can be produced synthetically; however, it is mainly extracted from Ocimum tenuiflorum, Cassia fistula, Zieria smithii, and Pimenta racemosa. Classified as a phenylpropanoid of the allyl-phenol type, eugenol is a pale yellow oil with clove odor and spicy taste. With numerous applications in the pharmaceutical, food, agricultural, and cosmetics industries [6, 7], it showed promising antimicrobial and antioxidant effects [8,9,10,11,12], when evaluated against the fungi Cladosporium spp. [13]. Other activities are reported in literature, such as antiviral [14, 15], anti-inflammatory [16], and inhibitor of platelet aggregation [17]. In addition, its anti-Leishmania activity together with its low cytotoxicity qualifies it as a promising source of new leishmanicidal [18].

This broad spectrum of biological activity makes eugenol a target molecule for structural modifications in order to produce substances with therapeutic properties. Currently, among the various clinical pathologies, bacterial infections and cellular oxidation stand out, both with serious implications for public health. Due to the acquisition of resistance and the mutational capacity of microorganisms, commercial antibiotics are in many cases incapable of fighting bacterial proliferation, resulting in failures in the treatment associated with multiresistant bacteria. Consequently, bacterial resistance has become a global concern regarding public health [19,20,21].

Aerobic organisms have the ability to produce free radicals that, in excess, can initiate chain reactions that damage cells or cause death to the latter. As a consequence, several diseases arise, especially cardiovascular and neurodegenerative diseases. The fight against the effects resulting from the production of free radicals has been the dietary use of antioxidant substances with a significant effect in the prevention of these diseases [22,23,24,25,26,27,28]. Eugenol, according to reports in literature, combats oxidative stress with beneficial effects on health.

Thus, in view of the broad spectrum of biological activities of eugenol, the present study aimed to obtain its derivatives by means of esterification and addition reactions. All were submitted to the evaluation of the antibacterial and antioxidant potential with very interesting results.

Results and discussion

Structural modifications from eugenol, carried out on the hydroxyl group and the olefinic bond, were represented in reaction Schemes 1 and 2, respectively.

Among the compounds prepared, 3, 13, 15, 17, 18, 19 are unpublished in literature. Compounds 1, 2, 4, 5, 6, 7, 8, 9, 10 and 11 have already been prepared in previous works [11, 29,30,31], however through different synthetic routes.

Evaluation of the antibacterial activity of eugenol derivatives using the inhibition zone technique, measured in millimeter (mm), demonstrates the potential for inhibition of microbial growth by a given substance. According to literature, substances with inhibition halos less than 7 mm, greater than 7 and less than 16 mm, and greater than 16 mm are considered inactive, moderately active, and antibacterial potential, respectively [32, 33]. The results presented in Table 1 show the inhibition zones (halos) presented by the eugenol derivatives against six bacterial strains.

According to the results (Table 1), acetylation of eugenol did not result in any benefit, since esters 1, 2, and 3 showed no antibacterial action against any of the strains. Also, esterification with benzoic acid and its p-substituted derivatives yielded derivatives 4–9 which exhibited random but still insufficient activities relative to eugenol itself.

Regarding derivatives 10–18 resulting from double bond addition, 10–14, 17, and 18 showed random and insufficient activities relative to eugenol. However, according to the classification shown above, derivative 16 showed a strong antibiotic effect against Bacillus cereus and a moderate effect against Staphylococcus aureus, Streptococcus, and Klebsiella pneumoniae, but was inactive in cases of Pseudomonas aeruginosa and Escherichia coli. It was of interest to observe that compound 16, except for the bacterium P. aeruginosa, showed greater activity than eugenol itself. In the case of derivative 15, a triacetyl derivative, it is of particular interest to highlight the high antibacterial activity (inhibition halo 12) against E. coli relative to eugenol (inhibition halo 0). By contrast, 15 was inactive (inhibition halo 0) against P. aeruginosa, whereas eugenol was active (inhibition halo 12).

A recent work [34] revealed antimicrobial activity for eugenol against strains E. coli and S. aureus, exhibiting inhibition halos with diameters of 9.25 and 7.75 mm, respectively. Although the results in the present study did not show activity for these strains, it is worth mentioning that the amounts (3 mg) applied in the first one were 13 times higher than those (0.2 mg) used in the present study. Of the derivatives priorly mentioned, those with inhibition halos greater than 6 mm were subjected to microdilution tests to determine the minimum inhibitory concentration (MIC) which prevents visible growth of the bacteria. Table 2 shows the results for derivatives 4–18 expressed in μg/mL.

Among the compounds tested, 8 and 16 showed the highest activity in inhibiting the strains. Compound 16 had the highest activity of all the derivatives involved in this study, and regarding K. pneumoniae and B. cereus strains, it was two times more active than eugenol. In contrast, compound 8 exhibited, in comparative terms, strong antibiotic activity against the E. coli strain, where the eugenol itself is inactive. Whereas epoxide 16 from eugenol showed strong relative activity, the corresponding acetate 17 showed a marginal effect.

In previous work [35], an MIC of 1200 μg/mL was recorded for eugenol against S. aureus bacteria, consistent with an MIC of 1000 μg/mL determined in the present study. These comparative data show that, like eugenol, several of its derivatives have a promising antimicrobial potential.

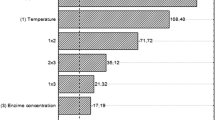

The antioxidant activity of eugenol derivatives was evaluated with DPPH (2,2-diphenyl-1-picrylhydrazyl). Radical scavenging activity is one of the most widely used methods for screening the antioxidant activity of substances. The ability to capture free radicals by the eugenol derivatives (1–19) against DPPH was expressed as IC50, which represents the concentration required to capture 50% of the radicals in the medium. As positive controls, Trolox and gallic acid were used. Phenolic compounds, such as eugenol, have the facility of transferring electrons or hydrogen atoms by neutralizing free radicals, that is, by blocking the oxidative process [10, 36]. The results (Table 3) showed that all the derivatives (1–19) presented higher IC50 than eugenol, that is, the structural modifications resulted in substances with lower antioxidant effects. All derivatives (1–11, 13, 15, 17, 20 and 21) produced by the esterification reaction on the hydroxyl group showed a strong reduction in antioxidant activity, as expected [27, 37, 38].

In the specific case of eugenol, the relationship between the hydroxyl group and the antioxidant action was observed in a previous study [26] through derivatives 2, 4, 5, 6, and 9, in which all presented IC50 is lower than eugenol.

On the other hand, the chemical modification in the double bond, in the case of the derivatives 12, 14, 16, 18, and 19, also caused reduction in the antioxidant capacity against the radical DPPH, however, much lower than that caused by the esterification of the hydroxyl group. Thus, derivatives 16 (IC50 19.3 μg/mL) and 18 (IC50 32 μg/mL), for example, showed antioxidant action close to the Trolox standard (IC50 16 μg/mL).

Derivatives 12, 14, 16, 18, and 19, with higher antioxidant action than the others, have a structural characteristic capable of enhancing this action. Although with IC50 values higher than eugenol, the results reflect the behavior of the substances in vitro; however, in living biological systems, the antioxidant activity varies, among others, with factors such as the reduction potential in the medium, the displacement capacity of the radical structure formed, the ability to complex transition metals involved in the oxidative process, access to the site of action according to hydrophilicity or lipophilicity, and its partition coefficient [39, 40]. The partition coefficient is closely related to the hydrophilic (or hydrophobic) character of the molecule. In the case of derivatives 12, 14, 16, 18, and 19, although less active than eugenol, the hydrophilicity is substantially different, especially for 12 and 14, which have additional hydroxyl groups allowing a higher degree of hydration and, consequently, greater interaction in aqueous media.

Conclusions

It was possible to demonstrate that structural modifications in the eugenol molecule resulted in some potentially antibacterial substances (e.g., 8, 15, 16). In addition, various derivatives (9, 10, 12, 13, 14, 15, 16, 17, and 18) have greater power in inhibiting the growth of certain strains regarding eugenol, as in the case of Streptococcus bacteria.

Regarding the antioxidant capacity of the derivatives, the study contributed to make an empirical evaluation of the structure–activity relationship, being observed that the hydroxyl group is decisive in inhibiting the propagation of free radicals. On the other hand, changes in the olefinic bond, although resulting in a slight reduction in the capacity to capture DPPH radicals, and the increase in the hydrophilic character can compensate and contribute as a differential in the antioxidant action.

Experimental

General methods

GC–MS analyses were performed using a Shimadzu QP2010SE Plus instrument equipped with a Rtx®-5MS (5% phenyl)-dimethylpolysiloxane capillary column (30 m × 0.25 mm) with a film thickness of 0.1 µm using He as carrier gas (1.0 mL/min) in split mode; the injector and detector temperatures were 240 and 280 °C, respectively; column temperature was programmed at 5 °C/min from 60 to 80 °C (3 min), then at 30 °C/min to 280 °C (10 min). Mass spectra were recorded on a Shimadzu QP2010SE apparatus operating in electron impact mode at 70 eV (scan mode analysis). 1H NMR spectra were recorded on a Bruker DPX 300 (300 MHz) and a Bruker DRX 500 (500 MHz) NMR, using CDCl3 solutions and TMS as internal standard.

Synthesis of eugenol derivatives: (1–3)

In separate experiments, eugenol (328 mg, 2 mmol) was mixed with acetic anhydride (712 mg, 6 mmol), butanoic anhydride (948 mg, 6 mmol), and hexanoic anhydride (1284 mg, 6 mmol). In each mixture, 2 mL of pyridine was added, followed by stirring of the resulting solutions for 24 h at room temperature. At the end of this period, EtOAc (20 mL) was added to the reaction medium, which was then partitioned with a 20% (w/v) aqueous solution of CuSO4·5H2O (3 × 30 mL). After separation of the EtOAc and H2O phases, the organic was washed with saturated NaCl solution (3 × 10 mL) and dried with anhydrous Na2SO4. The solvent was evaporated under reduced pressure to obtain the compounds 1 (362 mg, 1.76 mmol, 88% yield), 2 (337 mg, 1.44 mmol, 72% yield), and 3 (314.4 mg, 1.2 mmol, 60% yield). 4–11: In individual experiments, a mixture of eugenol (328 mg, 2 mmol), DMAP (50 mg, 0.4 mmol), and DCC (118 mg, 3 mmol) was added to benzoic acid (366 mg, 3 mmol), 4-methylbenzoic acid (432 mg, 3 mmol), 4-fluorobenzoic acid (420 mg, 3 mmol), 4-chlorobenzoic acid (469.5 mg, 3 mmol), 4-bromobenzoic acid (603 mg, 3 mmol), 4-nitrobenzoic acid (501 mg, 3 mmol), trans-cinnamic acid (444 mg, 3 mmol), and 2-(4-isopropylphenyl)propanoic acid (ibuprofen, 618 mg, 3 mmol) in CH2Cl2 (5 mL). The reaction mixtures were stirred at room temperature for 24 h. At the end of this period, each reaction mixture was filtered and the liquid phases were washed successively with 5% (m/v) HCl (2 × 5 mL), 5% NaHCO3 (w/v; 3 × 5 mL), and H2O (3 × 5 mL). Finally, after drying with anhydrous Na2SO4, the organic phases were evaporated under reduced pressure to afford 4 (353 mg, 1.32 mmol, 66% yield), 5 (350 mg, 1.24 mmol, 62% yield), 6 (457.6 mg, 1.6 mmol, 80% yield), 7 (453 mg, 1.5 mmol, 75% yield), 8 (484 mg, 1.4 mmol, 70% yield), 9 (438 mg, 1.4 mmol, 70% yield), 10 (376 mg, 1.28 mmol, 64% yield), and 11 (422 mg, 1.2 mmol, 60% yield) [41]. 12: To a stirred yellow-colored solution of HgSO4 (1483 mg, 5 mmol) in water (5 mL) and THF (5 mL) was added eugenol (820 mg, 5 mmol). After disappearance of the yellow coloration (ca. 4 h) a mixture of 3 M aqueous NaOH (5 mL) and 0.5 M NaBH4 (5 mL) was added, followed by vigorous stirring for 30 min. At the end of this period, the reaction mixture was poured into a saturated aqueous solution of NaCl (20 mL) and extracted with THF (3 × 5 mL). The combined extracts were dried in anhydrous Na2SO4 and concentrated to give a residue (637 mg) which was chromatographed over Si gel column to give 12 (318 mg, 1.75 mmol, 35% yield) [42]. 13: A solution of 12 (182 mg, 1 mmol) in a mixture of Ac2O (612 mg, 6 mmol) and C5H5N (1 mL) was stirred for 24 h at room temperature. At the end of this period [complete acetylation was indicated by TLC (Si gel, hexane–EtOAc 7:3)], EtOAC (20 mL) was added to the reaction medium, which was then partitioned with a 20% (w/v) aqueous solution of CuSO4·5H2O (3 × 5 mL). After separation of the EtOAc and H2O phases, the organic phase was dried with anhydrous Na2SO4 and the solvent evaporated under reduced pressure 13 (127 mg, 0.48 mmol, 48% yield) [43]. 14: Eugenol (820 mg, 5 mmol) in CH2Cl2 (5 mL) was added dropwise to m-chloroperbenzoic acid (1.30 g) in CH2Cl2 (15 mL) at 25 °C. After stirring for 24 h, 10% aq. Na2SO3 (10 mL) was added to the mixture and the solution was washed two times with 5% NaHCO3 (25 mL). The CH2Cl2 layer was dried (Na2SO4) and concentrated [44]. The reaction product (360 mg, 2 mmol) in 20% NaOH (10 mL) was heated at 80 °C for 2 h. The reaction mixture was cooled (28 °C), diluted with water, and neutralized with 10% HCl to pH 7.0. The water was removed under reduced pressure and the resultant mass was extracted with anhydrous EtOH (5 × 10 mL). The ethanolic solution was filtered, dried with anhydrous Na2SO4, and concentrated under reduced pressure to give a crude product which was subsequently chromatographed over Si gel column 14 (435.6 mg, 2.2 mmol, 44% yield). 15: Product 14 (198 mg, 1 mmol) was treated with Ac2O (1020 mg, 10 mmol) and anhydrous pyridine (3 mL). The resultant solution was stirred at room temperature for 24 h. After this time, the reaction was complete, as indicated by TLC [Si gel, hexane–EtOAc (7:3)], and EtOAC (20 mL) was added to the reaction medium, which was then partitioned with a 20% (w/v) aqueous solution of CuSO4·5H2O (5 × 10 mL). After separation of the EtOAc and H2O phases, the organic was dried with anhydrous Na2SO4 and the solvent evaporated under reduced pressure to afford 15 (110 mg, 0.34 mmol, 34% yield). 16: Eugenol (820 mg) in CH2Cl2 (5 mL) was added dropwise to m-chloroperbenzoic acid (1.30 g) in CH2Cl2 (15 mL) at 25 °C. After stirring for 24 h, 10% aq. Na2SO3 (10 mL) was added to the mixture and the solution was washed two times with 5% NaHCO3 (25 mL). The CH2Cl2 layer was dried with Na2SO4 and concentrated. The residue was purified by silica gel CC with hexane/ethyl acetate (90:10) to give 7 (1.00 g) and 16 (328 mg, 2 mmol, 40% yield). 17: A solution of 16 (180 mg, 1 mmol) in a mixture of Ac2O (306 mg, 3 mmol) and C5H5N (0.5 mL) was stirred under ice bath for 3 h. After this time, the reaction was complete, as indicated by TLC [Si gel, hexane–EtOAc (8:2)], and EtOAc (20 mL) was added to the reaction medium, which was then partitioned with a 20% (w/v) aqueous solution of CuSO4·5H2O (3 × 5 mL). After separation of the EtOAc and H2O phases, the organic was dried with anhydrous Na2SO4 and the solvent evaporated under reduced pressure to afford 17 (138 mg, 0.62 mmol, 62% yield). 18: To a stirred solution of ZnCl2 (0.634 g, 4.95 mmol) in acetone (5 mL) at 0 °C was added over a period of 10 min the compound 14 (396 mg, 2 mmol). The reaction mixture was then warmed at 30 °C, where stirring was continued for an additional time of 24 h. The reaction was quenched by the addition of a mixture of CHCl3 (10 mL) and saturated aqueous NaCl (10 mL) and extracted with CHCl3 (3 × 10 mL). The organic phases were dried with anhydrous Na2SO4 and the solvent evaporated under reduced pressure to afford 18 (285.6 mg, 1.2 mmol, 60% yield) [45]. 19: Compound 18 (238 mg, 1 mmol) was treated with Ac2O (306 mg, 3 mmol) and anhydrous pyridine (1 mL). The resultant solution was stirred at room temperature for 18 h. After this time, the reaction was complete, as indicated by TLC [Si gel, hexane–EtOAc (8:2)], and EtOAC (20 mL) was added to the reaction medium, which was then partitioned with a 20% (w/v) aqueous solution of CuSO4·5H2O (3 × 10 mL). After separation of the EtOAc and H2O phases, the organic was dried with anhydrous Na2SO4 and the solvent evaporated under reduced pressure to afford 19 (196 mg, 0.7 mmol, 62% yield). The characterization of derivatives is detailed in Additional file 1.

Antibacterial activity of eugenol derivatives by inhibition zone (disk diffusion)

Quantitative and qualitative antibacterial screening was performed in the Federal Institute of Education, Science and Technology of Rio Grande do Norte, Apodi campus. The procedure consisted of testing the pure compounds against the following microorganisms, obtained from according to norms approved by the National Sanitary Surveillance Agency32: Pseudomonas aeruginosa, Escherichia coli, Staphylococcus aureus, Streptococcus, Klebsiella pneumoniae, Bacillus cereus. The bacterial strains were replicated in Muller Hilton agar medium (MH) and incubated for 24 h at 35 °C. Plates for the assay were prepared by dispersing the Muller Hilton agar medium in sterile Petri dishes and the bacteria were incubated at 35 °C. Then, with the help of a flame-sterilized platinum handle, the bacterial cells were transferred to a sterile test tube containing 0.85% NaCl solution until reaching an absorption between 0.08 and 0.10 in a spectrophotometer at the wavelength of 625 nm (corresponding to approximately 1 × 108 cells). In the process, a sterile swab was soaked in the bacterial suspension and compressed into the whole assay to avoid excess material. This was then applied in uniform motions on the culture medium until the entire surface was filled. For the disks, 20 µL of the pure compounds was added at concentrations of 10 mg/mL in DMSO/water (1:1). The plates prepared as described were incubated at 35 °C. The antimicrobial activity was recorded as the width (in mm) of the inhibition zone after 24 h of incubation. A standard antibacterial agent (amikacin—30 mcg) was included in each assay as positive control.

Antibacterial activity of eugenol derivatives: minimum inhibitory concentration (MIC)

The antibacterial activity of eugenol derivatives was determined by the microdilution method, recommended by the National Committee for Clinical and Laboratory Standard M7-A632. The procedure consisted of testing the pure compounds in six standard Gram (+) and Gram (−) bacteriological strains: P. aeruginosa, E. coli, S. aureus, Streptococcus, K. pneumoniae, B. cereus). The Muller Hilton Broth (MHB) was used as medium for the bacterial growth (35 °C, 24 h). After this time, the culture of each bacterial species in the MHB was diluted in the same medium to a concentration of approximately 1 × 108 CFU/mL (0.5 NTU—McFarland scale). Each suspension was further diluted to a final concentration of 1 × 106 NTU in NaCl solution (0.85%) with 10% MHB. A volume of 100 μL of each suspension was distributed into the wells of the microplates resulting in a final inoculum concentration of 5 × 105 NTU. The initial solution of the eugenol derivatives was made using 10 mg of each dissolved in 1 mL of DMSO/water (1:1). From this concentration (10 mg/mL), several dilutions were made in distilled water in order to obtain a stock solution of 2000 µg/mL. Further serial dilutions were performed in microplates by addition of MHB (100 µL) to reach a final concentration in the range of 7.8–1000 μg/mL. All the experiments were performed in triplicate and the microdilution trays were incubated in bacteriological oven at 35 °C for 24 h. After this period, the antibacterial activity was detected using a colorimetric method by adding 25 µL of the resazurin staining (0.01%) aqueous solution in each well of the microplate. The minimum inhibitory concentration (MIC) was defined as the lowest extract concentration that can inhibit bacterial growth, as indicated by resazurin staining (dead bacterial cells are not able to change the staining color by visual observation—blue to red).

Free radical scavenging activity (DPPH Assay)

The free radical scavenging activity was determined by the DPPH assay [46, 47]. 2 mL of various concentrations (10, 20, 30, 50, 70, 100 µg/mL) of the compounds in methanol was added to 2 mL of a methanol solution of 6.6 × 10−2 mM DPPH. The decrease in absorbance was determined at 517 nm at room temperature at 0 min, 1 min, and every 5 min for 1 h. For each antioxidant concentration tested, the reaction kinetics was plotted and from these graphs, the absorbance was read after 30 min. Inhibition of the DPPH radical in percent was calculated according to Eq. 1:

Equation 1: Inhibition of the DPPH radical.

where Ablank is the absorbance of the control and Asample is the absorbance of the sample. Sample concentration providing 50% inhibition (IC50) was calculated from the graph plotting inhibition percentage against sample concentration. Tests were carried out in triplicate, and Trolox and gallic acid were used as positive controls.

References

Kodama T, Ito T, Dibwe DF et al (2017) Bioorganic and medicinal chemistry letters syntheses of benzophenone-xanthone hybrid polyketides and their antibacterial activities. Bioorg Med Chem Lett 27:2397–2400

Li G, Jia H, Li J et al (2014) Emission of volatile esters and transcription of ethylene- and aroma-related genes during ripening of “Pingxiangli” pear fruit (Pyrus ussuriensis Maxim). Sci Hortic 170:17–23. https://doi.org/10.1016/j.scienta.2014.03.004

Pang GX, Niu C, Mamat N, Aisa HA (2017) Synthesis and in vitro biological evaluation of novel coumarin derivatives containing isoxazole moieties on melanin synthesis in B16 cells and inhibition on bacteria. Bioorg Med Chem Lett 27:2674–2677. https://doi.org/10.1016/j.bmcl.2017.04.039

Shu YZ (1998) Recent natural products based drug development: a pharmaceutical industry perspective. J Nat Prod 61:1053–1071. https://doi.org/10.1021/np9800102

Newman DJ, Cragg GM (2016) Natural products as sources of new drugs from 1981–2014. J Nat Prod 79:629–661. https://doi.org/10.1021/acs.jnatprod.5b01055

Wanderlan J, Espíndola P, Oliveira L et al (2011) Avaliação da atividade antimicrobiana e citotoxicidade de derivados aril-semicarbazônicos. Rev Bras Farm 92:171–175

Kaufman TS (2015) The multiple faces of Eugenol. A versatile starting material and building block for organic and bio-organic synthesis and a convenient precursor toward bio-based fine chemicals. J Braz Chem Soc 26:1055–1085. https://doi.org/10.5935/0103-5053.20150086

Nam H, Kim MM (2013) Eugenol with antioxidant activity inhibits MMP-9 related to metastasis in human fibrosarcoma cells. Food Chem Toxicol 55:106–112. https://doi.org/10.1016/j.fct.2012.12.050

Kar Mahapatra S, Chakraborty SP, Majumdar S et al (2009) Eugenol protects nicotine-induced superoxide mediated oxidative damage in murine peritoneal macrophages in vitro. Eur J Pharmacol 623:132–140. https://doi.org/10.1016/j.ejphar.2009.09.019

Hidalgo M, De la Rosa C, Carrasco H et al (2009) Antioxidant capacity of eugenol derivates. Quim Nova 32:1467–1470. https://doi.org/10.1590/S0100-40422009000600020

Eyambe G, Canales L, Banik BK (2011) Antimicrobial activity of eugenol derivatives. Heterocycl Lett 1:2231–3087

Awasthi PK, Dixit SC, Dixit N, Sinha AK (2008) Eugenol derivatives as future potential drugs. Drugs 1:215–220

Abbaszadeh S, Sharifzadeh A, Shokri H et al (2014) Antifungal efficacy of thymol, carvacrol, eugenol and menthol as alternative agents to control the growth of food-relevant fungi. Journal de Mycologie Medicale 24:e51–e56. https://doi.org/10.1016/j.mycmed.2014.01.063

Sun W-J, Lv W-J, Li L-N et al (2016) Eugenol confers resistance to Tomato yellow leaf curl virus (TYLCV) by regulating the expression of SlPer1 in tomato plants. New Biotechnol 33:345–354. https://doi.org/10.1016/j.nbt.2016.01.001

Kong X, Liu X, Li J, Yang Y (2014) Advances in pharmacological research of eugenol. Curr Opin Complement Altern Med 1:8–11. https://doi.org/10.7178/cocam.7

Fonsêca DV, Salgado PRR, de Neto H et al (2016) Ortho-eugenol exhibits anti-nociceptive and anti-inflammatory activities. Int Immunopharmacol 38:402–408. https://doi.org/10.1016/j.intimp.2016.06.005

Ma N, Liu XW, Yang YJ et al (2015) Preventive effect of aspirin eugenol ester on thrombosis in κ-carrageenan-induced rat tail thrombosis model. PLoS ONE 10:1–14. https://doi.org/10.1371/journal.pone.0133125

de Morais SM, Vila-Nova NS, Bevilaqua CML et al (2014) Bioorganic and medicinal chemistry thymol and eugenol derivatives as potential antileishmanial agents. Bioorg Med Chem 22:6250–6255. https://doi.org/10.1016/j.bmc.2014.08.020

Kadosaki LL, Falcão De Sousa S, Cibene J, Borges M (2012) Análise do uso e da resistência bacteriana aos antimicrobianos em nível hospitalar Analysis of use and bacterial resistance to antimicrobial in level hospital. Rev Bras Farm 93:128–135

Mota RA, Chaves KP, Silva D et al (2005) Utilização indiscriminada de antimicrobianos e sua contribuição a multirresitência bacteriana. Braz J vet Res anim Sci 42:465–470. https://doi.org/10.1590/S1413-95962005000600010

de Golla S, Faria MGI (2013) Resistência Bacteriana Como Consequência Do Uso Inadequado De Antibióticos Bacterial Resistance As a Result of Use Unsuitable of Antibiotics. Braz J Surg Clin Res BJSCR 5:69–72

Vanin AB (2014) Produção, propriedades biológicas, antioxidantes e toxicidade do bioaromatizante obtido via esterificação enzimática de óleo essencial do cravo-da-índia (Caryophyllus aromaticus). 116

Djurendić EA, Savić MP, Jovanović-Šanta SS et al (2014) Antioxidant and cytotoxic activity of mono- And bissalicylic acid derivatives. Acta Periodica Technologica 45:173–189. https://doi.org/10.2298/APT1445173D

Ben Mohamed H, Duba KS, Fiori L et al (2016) Bioactive compounds and antioxidant activities of different grape (Vitis vinifera L.) seed oils extracted by supercritical CO2 and organic solvent. LWT Food Sci Technol 74:557–562. https://doi.org/10.1016/j.lwt.2016.08.023

Caleja C, Barros L, Antonio AL et al (2017) A comparative study between natural and synthetic antioxidants: evaluation of their performance after incorporation into biscuits. Food Chem 216:342–346. https://doi.org/10.1016/j.foodchem.2016.08.075

D’Avila Farias M, Oliveira PS, Dutra FSP et al (2014) Eugenol derivatives as potential anti-oxidants: is phenolic hydroxyl necessary to obtain an effect? J Pharm Pharmacol 66:733–746. https://doi.org/10.1111/jphp.12197

Wang J, Xia F, Bin Jin W et al (2016) Efficient synthesis and antioxidant activities of N-heterocyclyl substituted coenzyme Q analogues. Bioorg Chem 68:214–218. https://doi.org/10.1016/j.bioorg.2016.08.008

do Nascimento P, Lemos T, Bizerra A et al (2014) Antibacterial and antioxidant activities of ursolic acid and derivatives. Molecules 19:1317–1327. https://doi.org/10.3390/molecules19011317

Horchani H, Ben Salem N, Zarai Z et al (2010) Enzymatic synthesis of eugenol benzoate by immobilized Staphylococcus aureus lipase: optimization using response surface methodology and determination of antioxidant activity. Biores Technol 101:2809–2817. https://doi.org/10.1016/j.biortech.2009.10.082

Rahim NHCA, Asari A, Ismail N, Osman H (2017) Synthesis and antibacterial study of eugenol derivatives. Asian J Chem 29:22–26

Bendre SR, Rajput JD (2016) Outlooks on medicinal properties of eugenol and its synthetic derivatives. Nat Prod Chem Res. https://doi.org/10.4172/2329-6836.1000212

Ribeiro-Santos R, Andrade M, de Melo NR et al (2017) Biological activities and major components determination in essential oils intended for a biodegradable food packaging. Ind Crops Prod 97:201–210. https://doi.org/10.1016/j.indcrop.2016.12.006

Hamed OA, Mehdawi N, Taha AA et al (2013) Synthesis and antibacterial activity of novel curcumin derivatives containing heterocyclic moiety. Iran J Pharm Res 12:47–56

Ribeiro-Santos R, Andrade M, de Melo NR et al (2017) Biological activities and major components determination in essential oils intended for a biodegradable food packaging. Ind Crops Prod 97:201–210. https://doi.org/10.1016/j.indcrop.2016.12.006

Albano M, Alves FCB, Andrade BFMT et al (2016) Antibacterial and anti-staphylococcal enterotoxin activities of phenolic compounds. Innov Food Sci Emerg Technol 38:83–90. https://doi.org/10.1016/j.ifset.2016.09.003

Findik E, Ceylan M, Elmasta M (2011) Isoeugenol-based novel potent antioxidants: synthesis and reactivity. Eur J Med Chem 46:4618–4624. https://doi.org/10.1016/j.ejmech.2011.07.041

Lagha-Benamrouche S, Madani K (2013) Phenolic contents and antioxidant activity of orange varieties (Citrus sinensis L. and Citrus aurantium L.) cultivated in Algeria: peels and leaves. Ind Crops Prod 50:723–730. https://doi.org/10.1016/j.indcrop.2013.07.048

Barroso MF, Ramalhosa MJ, Alves RC et al (2016) Total antioxidant capacity of plant infusions: assessment using electrochemical DNA-based biosensor and spectrophotometric methods. Food Control 68:153–161. https://doi.org/10.1016/j.foodcont.2016.03.029

Manach C, Scalbert A, Morand C et al (2004) Bioavailability, polyphenols: food sources and bioavailability. Am J Clin Nutr 79:727–747. https://doi.org/10.1038/nature05488

Sucupira NR, Da Silva AB, Pereira G, Da Costa JN (2014) Methods for measuring antioxidant activity of fruits. UNOPAR Científica Ciências Biológicas e da Saúde 14:263–269

Hinrichs GBMBPHJ (2002) Asymmetric synthesis of (M)-2-hydroxymethyl-1-(2-Hydroxy-4,6-dimethylphenyl)naphthalene via a configurationally unstable biaryl lactone. Org Synth 79:72. https://doi.org/10.15227/orgsyn.079.0072

Alkenes A, Brown HC, Lynch GJ (2016) Solvomercuration-demercuration. 8. Oxymercuration–demercuration of methoxy-, hydroxy-, and acetoxy-substituted alkenes’. J Org Chem 4537:531–538

da Silva FFM, Ferreira DA, Monte FJQ, de Lemos TLG (2017) Synthesis of chiral esters and alcohols via enantioselective esterification with Citrus aurantium peels as biocatalyst. Ind Crops Prod 96:23–29. https://doi.org/10.1016/j.indcrop.2016.11.013

Burt HHP (1928) Styrene oxide. Org Synth 8:102. https://doi.org/10.15227/orgsyn.008.0102

Citò AM, Araújo BQ, Lopes JAD et al (2009) Síntese de regioisômeros quirais a partir de D-manitol: obtenção de uma mistura de álcoois acetilênicos. Quim Nova 32:2355–2359

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28:25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Sharma OP, Bhat TK (2009) DPPH antioxidant assay revisited. Food Chem 113:1202–1205. https://doi.org/10.1016/j.foodchem.2008.08.008

Authors’ contributions

FFMS: Realization of derivatives synthesis reactions and organization and writing of the manuscript. FJQM: Characterization by Nuclear Magnetic Resonance Spectroscopy of Hydrogen and Carbon of the obtained derivatives. TLGL: Guidance of the work developed and availability of reagents and laboratory equipment for the development of the work. PGGN: Responsible for obtaining the H and C NMR spectra of the obtained derivatives. AKMC: Evaluation of the antioxidant potential of the derivatives obtained. LMMP: Evaluation of the antibacterial potential of the derivatives. All authors read and approved the final manuscript.

Acknowledgements

The authors are grateful to the National Council for Scientific and Technological Development of Brazil (CNPq). We also thank the Northeast Center for the Application and Use of Nuclear Magnetic Resonance (CENAUREMN), at the Federal University of Ceará (UFC), Brazil.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

Manuscript with additional material.

Ethics approval and consent to participate

Not applicable.

Funding

Not applicable.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Additional file

Additional file 1.

Additional material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

da Silva, F.F.M., Monte, F.J.Q., de Lemos, T.L.G. et al. Eugenol derivatives: synthesis, characterization, and evaluation of antibacterial and antioxidant activities. Chemistry Central Journal 12, 34 (2018). https://doi.org/10.1186/s13065-018-0407-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-018-0407-4