Abstract

Background

Fungal manganese peroxidases (MnPs) have great potential as bio-remediating agents and can be used continuously in the immobilized form like many other enzymes.

Results

In the present study, purified manganese peroxidase (MnP) enzyme isolated from Ganoderma lucidum IBL-05 was immobilized onto polyvinyl alcohol-alginate beads and investigated its potential for the decolorization and detoxification of new class of reactive dyes and textile wastewater. The optimal conditions for MnP immobilization were 10 % (w/v) PVA, 1.5 % sodium alginate, 3 % boric acid and 2 % CaCl2 solution. The optimum pH, temperature and kinetic parameters (K m and V max ) for free and immobilized MnP were found to be significantly altered after immobilization. The immobilized MnP showed high decolorization efficiency for Sandal reactive dyes (78.14–92.29 %) and textile wastewater (61–80 %). Reusability studies showed that after six consecutive dye decolorization cycles, the PVA coupled MnP retained more than 60 % of its initial activity (64.9 % after 6th cycle form 92.29 % in 1st cycle) for Sandal-fix Foron Blue E2BLN dye. The water quality assurance parameters (BOD, COD and TOC) and cytotoxicity (haemolytic and brine shrimp lethality tests) studies before and after treatment were employed and results revealed that both the dyes aqueous solution and textile wastewater were cytotoxic that reduced significantly after treatment.

Conclusions

The decolorization and cytotoxicity outcomes indicated that immobilized MnP in PVA–alginate beads can be efficiently exploited for industrial and environmental applications, especially for remediation of textile dyes containing wastewater effluents.

Dye decolorizing potential of immobilized MnP

Similar content being viewed by others

Background

No doubt, industrial establishment is necessary for growth, but it always associated with a cost paid in terms of pollution (air, water, soil). The rapid stride in textile industry is one of the major concerns to release toxic chemicals into the environment, especially toxic dyes [1–3]. Reports showed that more than 10,000 different types of dyes with an estimated annual production of 7.105 metric tons are commercially available worldwide [4]. Other than textile industries, dyes are also used in paper and pulp, dye intermediates, pharmaceutical and tannery etc. [3]. Among dyes, reactive dyes are extensively used, fundamentally due to the capacity of their reactive groups to bind on fibers. The discharge of dye-containing effluents into the water bodies is undesirable, because many of dyes are toxic, carcinogenic or mutagenic in nature. Among the damages caused, genotoxic and mutagenic effects have shown to be worrying, due to their capacity to induce genetic damage, which can lead to several health problems and also affect future generations [2].

Due to very stable and xenobiotic nature, reactive dyes are difficult to degrade or exhibit slow degradation [5]. In literature, various physical/chemical methods have been reported by several authors to effectively process the textile effluents such as adsorption, precipitation, chemical reduction, ionizing radiations and ultrafiltration. However, these tested methods are not economically acceptable for application to large-scale effluents due to many drawbacks, such as high operating and equipment costs, low efficiency, secondary pollution, residues waste problems and the inability to treat a wide array of dyes having structural diversity [1, 4]. Although these methods are employed to decolorize the dyes, their capacity to reduce the toxicity is still a matter of major concern. These facts certainly demand the development of an efficient, cost effective and green technique for the detoxification and decolorization of dyes [1]. Biodegradation of toxic dyes is considered best option in this regard and is a key research area in the environmental sciences [6–11].

An advantage of enzymatic approach to treat dye is that enzymes can react with variety of compounds, fast decolorization rate and removal is quite fast at fixed conditions [5]. The major reason that enzymatic treatments have not yet been applied on an industrial scale is due to the huge volume of polluted wastewater demanding remediation. Free enzymes suffer certain drawbacks such as thermal instability, reusability, susceptibility to attack from proteases, activity inhibition and are also sensitive to temperature and pH [6–9, 12–19]. To overcome limitations of free enzymes, the use of immobilized enzyme on various supports has been suggested due to its stability and reusability and previously reported studies regarding dye decolorization highlighted the importance of immobilization since encouraging results were obtained [5, 7, 8, 10, 11, 20–25].

Manganese peroxidase (MnP) is a versatile biocatalyst that gained significant importance in bioremediation, biomass delignification, chemical synthesis, bio-pulping and biosensor development, textile finishing and wine stabilization [5]. Ganoderma lucidum is potent lignin degrading white rot fungus (WRF), able to grow on variety of wastes and have been intensively studied so far to degrade a wide range of pollutants [5]. However, to best our knowledge, the direct application of ligninolytic enzymes for decolorization of textile dyes, especially Sandal reactive dyes has not yet been tried. Sandal dyestuff industries Ltd (Sandal Group) have main offices in Bangladesh and Faisalabad (Pakistan) and has been the agent of BASF AG, Germany, Bayer AG, Germany and Sandoz, Switzerland for their disperse and reactive dyes, but now Sandal, started reactive dyes production locally, and these reactive dyes are exporting to Turkey, Italy, Egypt, Spain, Bangladesh, Morocco, South Africa, Malaysia and Australia.

Therefore, the purpose of the present study was to develop an effective method for immobilization of MnP onto PVA and to decolorize an array of synthetic reactive dyes and real textile wastewater. The treatment efficiency was evaluated on the basis of decolorization, water quality assurance parameters (BOD, COD, TOC, pH) and cytotoxicity (erythrocytes lysis and brine shrimp lethality) reduction. Upon completion of synthetic dye decolorization investigation, wastewater was collected from ten local textile units and tested for decolorization and cytotoxicity reduction by MnP-I-PVAA and F-MnP for the generalization of results.

Experimental

Chemicals and reagents

Coomassie Brilliant Blue G-250, sodium dodecyl sulphate, Sephadex G100, N, N, N′, N′-tetra-methyl ethylene diamine, ß-mercaptoethanol, trizma base, polyvinyl alcohol (Mw = 124–186 kDa), sodium alginate, calcium chloride and boric acid were supplied by Fluka-Sigma-Aldrich (USA) and standard protein markers were purchased from Fermentas (U.K). Triton X-100 and cyclophosphamide were provided by Merck (Germany) and Scharlau (Spain). All other chemicals used in this work were of analytical grade and used without further purification.

Collection and preparation of substrate

Agricultural waste, wheat bran used as growth substrate was collected from Students Farm, University of Agriculture, Faisalabad, Pakistan, washed, sliced, sun dried following oven drying at 60 °C to constant weight. The dried substrate was pulverized to 0.45–0.90 mm (20–40 meshes) by grinder (Ashraf Herbal Laboratories, Faisalabad) and stored in airtight plastic jars.

Fermentative organism and inoculum development

A pure culture of an indigenous fungal strain G. lucidum IBL-05 available in Industrial Biotechnology Laboratory, Department of Biochemistry, University of Agriculture; Faisalabad was raised on potato dextrose agar (PDA) slants at pH 4.5 and 30 °C. Kirk’s basal medium along with 1 % (w/v) Millipore filtered sterile glucose solution was used as inoculum medium. The medium pH was adjusted to 4.5 (HCl/NaOH), sterilized (Sanyo, Japan) at 121 °C and 15 psi for 15 min. G. lucidum IBL-05 spores were transferred to the sterilized inoculum medium under sterile conditions in laminar flow (Dalton, Japan). The inoculated flask was incubated at 30 °C for 5 days in an orbital shaker (Sanyo-Gallenkamp, UK) with continuous shaking (120 rpm) to obtain homogenous spore suspension (~1×107 spore/mL), counted by hemocytometer (Neubauer counting chamber) (Sigma-aldrich, USA) [5].

Solid state fermentation for enzyme production

Cotton plugged Erlenmeyer flasks (triplicate), containing 5 g wheat bran were moistened with Kirk’s basal nutrient medium (66 % w/w) at pH 4.5. The flasks were sterilized, inoculated with 5 mL (1 × 107 spores/mL) freshly prepared G. lucidum IBL-05 spore suspension and placed at 30 °C for fermentation in still culture incubator (Sanyo, Japan) for 5 days. After stipulated time period, 100 mL of distilled water was added into the fermented flasks, shaken for 30 min at 120 rpm (Sanyo-Gallenkamp, UK), filtered, centrifuged (Eppendorf 5415C, Germany) and clear supernatant thus obtained was subjected to ligninolytic enzymes estimation [23] and purified further.

Purification of MnP

Four step purification procedure involving ammonium sulphate fractionation, dialysis, DEAE-cellulose ion exchange and G-100 Sephadex gel permeation chromatography was gradually employed for the purification of MnP. Briefly, crude MnP extract obtained from 5 days old culture of G. lucidum IBL-05 was centrifuged at 3000×g for 15 min to increase clarity using Eppendorfs centrifuge machine (Centrifuge 5415 C, Germany). The supernatant/filtrate was saturated (up to 35 %) by gradual addition of ammonium sulphate, kept overnight at 4 °C and precipitates, thus obtained were recovered (10,000 rpm for 20 min at 4 °C) and supernatant was again saturated by adding ammonium sulfate (up to 65 %), allowed to stand overnight at 4 °C, centrifuged and pellets were dissolved in 50 mM Sodium malonate buffer (pH 4.5), dialyzed and finally, dialyzate was freeze dried. The dialysate obtained was subjected to ion exchange chromatography using diethyl amino ethyl (DEAE) cellulose column. The column was equilibrated with phosphate buffer (pH 6.5) for 24 h and eluted with 0–1.0 M linear gradient of NaCl in 50 mM Na-malonate buffer at a flow rate of 0.5 mL/min. A total 60 fractions, each 1.5 mL were collected and analyzed for enzyme activity and protein contents. The MnP active fractions were concentrated and loaded onto Sephadex-G-100 column (10 × 300 mm). A 50 mM malonate buffer was used for elution at a flow rate of 0.3 mL/min and active fractions (up to 30, 1 mL) were collected and absorbance was measured at 280 nm (CE Cecil 7200, Germany). The purified and concentrated enzyme was stored at −20 °C.

Immobilization of MnP

The PVA solution (8–12 %) and Na-alginate (0.5–4.0 %) were heated at 60 °C to dissolve properly, cooled and mixed with 10 mL of MnP solution. The resultant mixture was extruded drop wise into boric acid (3 % v/v) and CaCl2 (2 % w/v) solution using syringe (nozzle diameter 5 mm) needle to form uniform size beads and stirred for 30–50 min to solidify, thoroughly washed with distilled water and store at 4 °C for 24 h [26]. The immobilization percentage was calculated by relation Eq. (1).

Effect of pH, temperature and substrate concentration on immobilization

In this set of experiment, the MnP-I-PVAA activities were tested at different pH values (3–10). The buffers used were (0.2 M): tartrate buffer, pH 3.0; sodium malonate buffer, pH 4.0; citrate phosphate, pH 5.0 and pH 6.0; sodium phosphate, pH 7.0 and 8.0; carbonate-bicarbonate buffer, pH 9.0 and pH 10.0, whereas temperature effect was checked by incubating the enzyme at varying temperature (30–70 °C) for 1 h at optimum pH before running the routine MnP assay. The effect of substrate concentration was studied by varying the substrate MnSO4 (0.1–1 mM) at optimum pH and temperature. Lineweaver–Burk’s reciprocal plots were constructed between 1/S and 1/V0 and kinetic parameters of Michaelis–Menten (K m and V max) were calculated [23].

MnP assay and protein estimation

For MnP activity determination, 1 mM MnSO4 (1 mL), 50 mM sodium malonate buffer (1 mL, pH 4.5) and enzyme solution (0.1 mL) were thoroughly mixed, followed by the addition of 0.1 mM H2O2 (0.5 mL) as reaction initiator and absorbance was checked at 270 nm (ε270 = 11570 M cm−1) with 10 min interval. For protein estimation, Bradford reagent (1 mL) was added into 100 μL of each solution, mixed well (vortex mixer) and ΔA was monitored at 595 nm (UV double beam spectrophotometer (HALO DB-20) [27].

Dyes and wastewater collection

Five Sandal Reactive dyes namely Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF and Sandal-fix Foron Blue E2BLN were gifted by Dr. Shaukat Ali (consultant-Sandal dye stuffs), Color and Dyes Laboratory, University of Agriculture, Faisalabad, Pakistan. Selected dyes characteristics are shown in Table 1. The textile wastewater sample were collected from Rashid Textile, Arif Textile, Yasser Textile, Mian Chemicals, Taj Mahal Printing, Bashir Printing, M. Shafique Textile Mill, Lili Printing, Amar Bilal Textile Mill, Ali Hajveri Printing industries (numbered 1-10, respectively), located in different areas of Faisalabad, Pakistan.

Decolorization of Sandal reactive dyes and textile wastewater

A set of Sandal reactive dyes was selected to investigate the decolorization potential of MnP-I-PVAA versus F-MnP. For this, the MnP-I-PVAA and F-MnP were transferred to 250 mL cotton plugged Erlenmeyer flasks (triplicate) containing 100 mL of individual dye solution (0.1 mg/mL), prepared in 50 mM sodium malonate buffer (pH 4.5). Flasks were incubated at 30 °C on rotary shaker (Sanyo-Gallenkamp, UK) at 150 rpm for 12 h. After designated time, the flasks contents were filtered, centrifuged (8000×g, 10 min) and residual dye concentration was monitored at respective wavelengths (HALO DB-20).The decolorization efficiency of MnP-I-PVAA and F-MnP for each dye was calculated using relation in Eq. (2). Where Ai and At are representing absorbance at zero and time t. For the decolorization of real textile wastewater samples, same procedure was adopted and before treatment, the samples were filtered to remove debris and suspended particles.

Reusability studies

The MnP-I-PVAA reusability efficiency for the decolorization was monitored up to six cycles. For this, the beads were incubated (Sanyo, Japan) with 1 mM MnSO4 in respective dye solution (0.1 mg/mL) prepared in 50 mM sodium malonate buffer of pH 4.5 at 30 °C for 12 h. At the end of each cycle, the beads were filtered and washed three times with the sodium malonate buffer.

Water quality assurance parameters analysis

The water quality assurance parameters such as BOD, COD, TOC and pH were measured where maximum decolorization was achieved both for synthetic dye solution and textile wastewater. BOD, COD and pH values were measured using BOD, COD and pH meters (Lovibond, water testing systems). For TOC measurement, 2 N K2Cr2O7 (1 mL) and H2SO4 (1.6 mL) were taken in digestion flask containing dyes samples (4 mL) and the contents were digested for 1.5 h at 110 °C, cooled and absorbance was monitored at 590 nm (HALO DB-20).

Cytotoxicity evaluation

To evaluate the MnP-I-PVAA and F-MnP effect on cytotoxicity reduction, erythrocytes lysis and brine shrimp lethality tests were used [2]. The cytotoxicity of samples was measured where maximum decolorization was achieved both for synthetic dye solution and textile wastewater samples.

Results and discussion

MnP production and purification

An indigenous WRF strain, G. lucidum IBL-05 was exploited to produce MnP in solid substrate fermentation (SSF) medium of wheat bran at pre-optimized conditions (moisture, 50 %; substrate, 5 g; pH, 5.5; temperature, 30 °C; carbon source, 2 % glucose; nitrogen source, 0.02 % yeast extract; C: N ratio, 25:1; fungal spore suspension, 5 mL, 5 days fermentation time). A quite significant MnP activity of 717.7 ± 2.3 U/mL was recovered in the culture filtrate after 5 days incubation. The cell-free crude MnP extract thus produced was completely salted out at 65 % saturation with (NH4)2SO4 to 1.73 fold purification with specific activity of 273.01 U/mg. After ion exchange and sephadexG-100 gel filtration chromatography, the specific activity of MnP increased to 539.59 U/mg with 3.43 folds purification. The summary of MnP purification results are presented in Table 2. The purification trend was found comparable with earlier studies e.g. MnP from S. commune IBL-06 was salted out at 55 % (NH4)2SO4 saturation with 1.8 fold purification and specific activity of 394 U/mg [23]. Fractionation of MnP from Phanerochaete chrysosporium by DEAE Sepharose, followed by ion-exchange and UltragelAcA54 gel filtration chromatography resulted in 23.08 % activity yield with 5.8 fold purification [28].

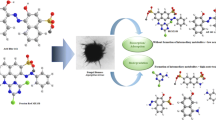

Optimal immobilization of MnP

The purified MnP from G. lucidum IBL-05 was immobilized onto PVA–alginate beads and range of affecting variables such as concentration of immobilization matrix (PVA and Na-alginate) and cross-linkers (boric acid and calcium chloride) were studied (Fig. 1). During preparation of beads, different concentrations of PVA (8–12 %) were tried with the aim to acquire beads with desired mechanical strength. Beads developed using 10 % PVA were found to be most suitable for immobilization exhibiting highest immobilization yield (IY) (Fig. 1a). Below or above this optimal concentration, the immobilization efficiency declined that might be attributed to small pore size of the beads, restricting the diffusibility of the substrate. From the Fig. 1b, it can be observed that sodium alginate at a concentration of 1.5 % (w/v) registered the highest entrapped MnP activity. Low incorporation of Na-alginate at lower and higher concentrations leads to soft, unstable and flaccid beads formation and diffusional limitation of substrate into entrapped enzyme and thus, IY may reduce. Likewise, 3 % boric acid (Fig. 1c) showed better performance but higher concentration beyond this, diminished the IY, which could be due to denser beads formation and restricted substrate diffusion [26]. Furthermore, calcium chloride is used as a cross linking agent, and its concentration affects the activity and the stability of immobilized MnP. Figure 1d shows that calcium chloride at concentration of 2 % furnished better yield and low IY at lower concentration is due to unstable cross-linked gel formation and beads dispersion.

Steady state kinetics

Optimum pH

The pH profile for soluble and immobilized MnP has been presented in Fig. 1f. It can be clearly observed that pH significantly affects the enzyme activity and pH values of 5.0 and 6.0 furnished highest activities for free and immobilized MnP, respectively. Unlike soluble MnP, the immobilized enzyme displayed good activity in broader pH range. It was reported that optimal pH may be altered by as much as 2 pH units. The shift in pH mostly depends on the pH of micro-environment around the immobilized enzyme and also the physico-chemical nature of support material contributes up to some extent. Similar findings were observed for immobilized phospholipase A1 in gelatin hydrogel [29], naringinase in PVA matrices [30], laccase in PVA cryo-gel carrier [31] and dextranase in bovine serum albumin [32].

Optimum temperature

The activity of free and immobilized MnP was checked as the function of varying temperature.

As depicted in Fig. 1e, the free and immobilized MnP activities were found higher at 35 and 65 °C, respectively, which indicates that immobilization, enables the MnP to be active and stable even at higher temperature and is credited to the PVA protective efficiency. The possible reason could be that some covalent linkages (hydrophobic and other secondary interactions of entrapped enzyme) developed, that might impair conformational flexibility requiring higher temperatures for the enzyme to reorganize and attain a proper conformation in order to keep its reactivity. Therefore, immobilized MnP opens the possibility to use it under environmental conditions at higher temperature. Similar observations were described previously [29, 33, 34].

K m and V max

The kinetic constants (K m and V mx) of free and immobilized MnP were computed by intercepting the line on the X-axis and Y-axis of the Lineweaver–Burk plot, using MnSO4 as substrate. The highest activities of free and carrier bound MnP were found to be 859 IU/mL (K m 65.5 mM and V max 640 U/mL) and 896 IU/mL (K m 70 mM and V max 700 U/mL), respectively using non-linear regression analysis (Fig. 2). The change in kinetic parameters of the enzyme is a common manifestation during the process of immobilization. Attachment of enzyme molecules to the supporting matrix generates some hindrance which limits the accessibility of substrate to the enzyme and also the conformational changes in enzyme occurred after immobilization contribute to decreased affinity of enzyme for substrate [5]. Previously, Nunes and coworkers, [30] reported a higher Michaelis–Menten constant (KM) and lower maximum reaction velocity (V max) for immobilized naringinase than that of free enzyme. While the Km values for immobilized lipase was found to be lower as compared to its free counterpart [35].

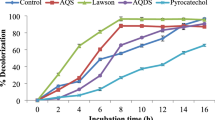

Decolorization of Sandal reactive dyes and textile wastewater

The decolorization efficiencies (%) of F-MnP and MnP-I-PVAA were tested against set of Sandal reactive dyes and results, thus obtained are presented in Fig. 3a–e (UV–Vis spectra) and Fig. 4a (decolorization, %). From results, it was observed that immobilized MnP was more efficient for the decolorization of all investigated reactive dyes as compared to its free counterpart. In case of F-MnP, a decolorization of 57.34, 63.98, 65.66, 65.09 and 74.24 % of Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively were achieved, whereas it increased to 78.14, 86.81, 89.31, 87.63 and 92.29 %, respectively for PVA-I-MnP, which was 26.62, 26.30, 26.48, 25.72 and 19.56 % higher than F-MnP fraction for decolorization of Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively. Similarly, previous data reports regarding dye decolorization [6–8, 12, 15–19] revealed higher decolorization potential of immobilized MnP as compared to soluble MnP treatment. In case of MnP-I-PVAA, the decolorization efficiency was comparable with P. chrysosporium Ca-alginate beads [24], Rhus vernificera-poly (GMA/EGDMA) beads [25], Pleurotus ostreatus-sol‐gel, G. lucidum-Xero-gel [22] and Ca-alginate gel [8], which verified the dye remediation potential of PVA immobilized MnP. Upon completion of decolorization of synthetic dyes, same treatments were applied to investigate the decolorization efficiency for real textile wastewater, containing dyes mixture. Wastewater was collected from ten different textile units, treated by both F-MnP and MnP-I-PVAA systems and results are shown in Fig. 3f (UV–Vis representative spectra) and Fig. 4b (decolorization, %). In case of F-MnP treatment, the decolorization was recorded in the range of 37–63 %, whereas it was 61–80 % for MnP-I-PVAA treatment. The decolorization efficiency for textile wastewater was slightly lower as compared to synthetic dyes aqueous solution and is attributed to the diverse nature of textile wastewater.

MnP-I-PVAA reusability

To demonstrate the reusability properties of PVA entrapped MnP, beads were removed after stipulated reaction time (12 h) and washed thoroughly with distilled water. It was found that even after 6 consecutive dye decolorization cycles, the PVA coupled MnP retained more than 60 % of its initial activity (64.9 % after 6th cycle form 92.29 % in 1st cycle)for Sandal-fix Foron Blue E2BLNdye (Fig. 4c), however, for three cycles, the activity loss was insignificant and then gradually declined. This gradual decline in activity might be the result of plugging of the membrane pore and accumulation of high active free radicals e.g., Mn3+, lipid, hydroxyl, and peroxy-radicals and dimmer in the interior environment of each microsphere which entangled the active site of enzyme led to enzyme inactivation. Similar observations have been documented previously regarding reusability e.g. after 5 cycle, the dye removal efficiency of entrapped CBP-Con A complex was reduced to 67.9 % for DR19 and 63.5 % for dye mixture (DR19 + DB 9) [8] and 50 % loss of initial activity after five cycles for immobilized Horseradish peroxidase [8]. Results indicated that MnP immobilized onto PVA–alginate beads is a better choice with greater reusability efficiency for the removal of toxic pollutants/dyestuffs.

Water quality assurance parameters

The effect of treatment (F-MnP and MnP-I-PVA) for dye degradation was evaluated on the basis of BOD, COD, TOC, and pH, as shown in Fig. 5a–f. Before treatment, the BOD values were in the range of 204–343 mg/L of Sandal reactive dyes and reduced significantly after treatment. In case of F-MnP and MnP-I-PVAA treatments, the BOD values reduced to 21–103 mg/L and 10–17 mg/L, respectively. The percentage reductions in BOD values were 69.95, 84.16, 84.07, 89.66 and 88.77 % (F-MnP) and 95.02, 95.24, 95.44, 94.61 and 95.47 % (MnP-I-PVAA) for Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively. Before treatment, the COD was in the range of 515–752 mg/L and reduced to 110–138 mg/L and 34–45 mg/L for F-MnP and MnP-I-PVAA treated dyes. The percentage reductions were 75.65, 82.75, 78.23, 81.46 and 78.26 % (F-MnP) and 91.18, 94.85, 93.63, 94.09 and 93.75 % (MnP-I-PVAA) for Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively. The TOC values before treatment were in the range of 342–728 mg/L and reduced to 45–187 mg/L (F-MnP) and 32–75 mg/L (MnP-I-PVAA) after treatment. The percentage reductions in TOC were 74.18, 82.3, 90.43, 89.16, 83.23 % (F-MnP) and 89.58, 92.53, 94.21, 95.22, 92.31 % (MnP-I-PVAA) for Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively. The pH was in the range of 8.4–9.0 before treatment, reduced after treatment and fall in the range of 6.0–6.9. The dye samples treated by MnP-I-PVAA showed slightly lower pH values versus F-MnP treatments (Fig. 6a).

The COD, BOD and TOC values of textile wastewater considerably higher as compared to synthetic dyes solution and were beyond the permissible tolerance limit set by National Environmental Quality Standards (NEQS). The COD, BOD, TOC were in the range of 1220–2920 mg/L, 650–2015 mg/L and 1050–2450 mg/L, respectively before treatment. However, after treatment the COD, BOD and TOC values significantly reduced (Fig. 6b, c). In case of F-MnP, the reductions in COD, BOD and TOC were in the range of 47–70 %, 41–61 % and 46–65 %, respectively, whereas 52–86 %, 53–76 % and 54–71 % a reductions were observed in MnP-I-PVAA treated samples. The pH of textile wastewater was in the range of 10.0–11.5 before treatment and after treatment reduced considerably and fall in the range of 6.5–7.00. Here, the improvement in water quality assurance parameters was significantly higher, especially in case of PVA–MnP treatment as compared to previous same sort of studies e.g. BOD (330.8 ppm) and COD (370.1 ppm) removal form textile industry effluents using Irpex lacteus [36], 70 % COD removal by P. ostreatus [37], 75 % COD removal with P. chrysosporium and Coriolus versicolor [38], 67 % COD removal using C. versicolor [39].

Literature survey revealed that although physicochemical techniques were some time effective, quick and compact, but are not generally employed due to the associated high chemical and operational costs and the biodegradation is good option, especially immobilization to hit the target because in most of the cases, the decolorization and improvement in water quality assurance parameters improvement was found significantly higher in comparison to physicochemical treatments.

Cytotoxicity reduction

The cytotoxicity tests (heamolytic and brine shrimp lethality) were performed to check the biological effectiveness of F-MnP and MnP-I-PVA since these tests are used frequently for the toxicity screening of pollutants (air, soil and water) [2]. The order of cytotoxicity of dyes was found in following order before treatment; Sandal-fix Red C4BLN (36 %), Sandal-fix Turq Blue GWF (33 %), Sandal-fix Golden Yellow CRL (31 %), Sandal-fix Foron Blue E2BLN (30 %) and Sandal-fix Black CKF (29 %) for erythrocyte lysis, whereas it was 27, 23, 26, 26, 22 %, respectively in case of brine shrimp. As shown in Fig. 7a, after treatment the cytotoxicity reduced significantly, both for F-MnP and MnP-I-PVAA. Erythrocytes lysis were 27.85, 19.16 and 17.03 %, 23.17 and 21.89 %, whereas 16, 12, 10, 14 and 13 % were observed in case of brine shrimp for Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively for F-MnP treatment. In case of MnP-I-PVAA, the erythrocytes lysis were 5.51, 3.41, 2.07, 3.03 and 2.32 %, whereas 4, 4, 2, 2 and 2 % for brine shrimp of Sandal-fix Red C4BLN, Sandal-fix Turq Blue GWF, Sandal-fix Golden Yellow CRL, Sandal-fix Black CKF, Sandal-fix Foron Blue E2BLN, respectively. The textile wastewater was also subjected to cytotoxicity testing before and after treatment and results, thus obtained are shown in Fig. 7b–d. Before treatment, the cytotoxicity was considerably higher and found in the range of 22.5–84.6 % (erythrocyte lysis) and 21.0–72 % (brine shrimp lethality) for the wastewater collected from ten textile units. After treatment, cytotoxicity reduced significantly and recorded in the range of 15.2–52.1 % (erythrocyte lysis) and 7.63–19.0 % (brine shrimp lethality) in case of F-MnP, whereas 12.1–36.7 % (erythrocyte lysis) and 3.74–11.0 % (brine shrimp lethality) cytotoxicity range was recorded in case of MnP-I-PVAA treatment. The percentage cytotoxicity reductions of 60.0, 38.2, 36.8, 34.8, 42.8, 37.5, 39.7, 47.3, 42.5 and 38.4 (%) (Erythrocytes lysis) and 86.7, 88.0, 88.9, 93.7, 87.3, 89.2, 83.6, 83.6, 86.0 and 88.2 (%) (Brine shrimp lethality) for textile industries wastewater sample from 1 to 10, respectively were observed for MnP-I-PVAA treatments as compared to un-treated samples. As it was highlighted by Rane et al. [1] that several methods have been used for the decolorization of dyes successfully, however, the toxicity is still a matter of major concern because residues/degradation intermediates and end product might be more toxic than the parent compound. Present study showed that MnP-I-PVAA treatment has the ability to detoxify dyes along with decolorization. Previous few studies also revealed that toxicity may be reduced by biodegradation of treated dyes e.g. 98 % toxicity reduction of industrial effluents was observed, treated by WRF ligninolytic enzymes [40] and similar observations were documented by others [23, 41].

Conclusions

The MnP produced from G. lucidum IBL-05 was immobilized onto PVA beads to explore its efficiency for decolorization and detoxification against set of Sandal reactive dyes (new dyes class) and textile wastewater. The MnP was successfully entrapped into PVAA beads with satisfactory immobilization efficiency and resulting, MnP-I-PVAAB showed exciting outcomes for the decolorization and detoxification of Sandal reactive dyes and textile real wastewater. The efficient dye decolorization and cytotoxicity reduction suggests the feasibility of MnP-I-PVAAB for textile wastewater remediation since bio-remediation is a green technique. Future investigations should be focused on more sensible immobilization techniques along with innovative supports for the improvement of enzyme catalytic properties.

References

Rane NR, Chandanshive VV, Khandare RV, Gholave AR, Yadav SR, Govindwar SP (2014) Green remediation of textile dyes containing wastewater by Ipomoea hederifolia L. RSC Adv 4(69):36623–36632

Iqbal M, Bhatti IA, Zia-ur-Rehman M, Bhatti HN, Shahid M (2014) Application of bioassays to evaluate the efficiency of advanced oxidation processes for the detoxification of industrial effluents. Asian J Chem 26(14):4291–4296

Lade H, Govindwar S, Paul D (2015) Mineralization and detoxification of the carcinogenic azo dye congo red and real textile effluent by a polyurethane foam immobilized microbial consortium in an up flow column bioreactor. Int J Environ Res Public Health 12:6894–6918. doi:10.3390/ijerph120606894

Daassi D, Rodriguez-Couto S, Nasri M, Mechichi T (2014) Biodegradation of textile dyes by immobilized laccase from Coriolopsis gallica into Ca-alginate beads. Int Biodeterior Biodegrad 90:71–78

Asgher M, Shahid M, Kamal S, Iqbal HMN (2014) Recent trends and valorization of immobilization strategies and ligninolytic enzymes by industrial biotechnology. J Mol Catal B Enzym 101:56–66

Narkhede M, Mahajan R, Narkhede K (2013) Ligninolytic enzyme production and Remazol Brilliant Blue R (RBBR) decolorization by a newly isolated white rot fungus: Basidiomycota spp. L-168. Int J Pharm Bio Sci 4(1):220–228

Boucherit N, Abouseoud M, Adour L (2013) Degradation of direct azo dye by Cucurbita pepo free and immobilized peroxidase. J Environ Sci 25(6):1235–1244

Jamal F, Singh S, Qidwai T, Singh D, Pandey P, Pandey G, Khan M (2013) Catalytic activity of soluble versus immobilized cauliflower (Brassica oleracea) bud peroxidase-concanavalin A complex and its application in dye color removal. Biocatal Agric Biotechnol 2(4):311–321

Yao J, Jia R, Zheng L, Wang B (2013) Rapid decolorization of azo dyes by crude manganese peroxidase from Schizophyllum sp. F17 in solid-state fermentation. Biotechnol Bioprocess Eng 18(5):868–877

Yanto DHY, Tachibana S, Itoh K (2014) Biodecolorization of textile dyes by immobilized enzymes in a vertical bioreactor system. Procedia Environ Sci 20:235–244

Mirzadeh SS, Khezri SM, Rezaei S, Forootanfar H, Mahvi AH, Faramarzi MA (2014) Decolorization of two synthetic dyes using the purified laccase of Paraconiothyrium variabile immobilized on porous silica beads. J Environ Health Sci Eng 12(1):6

Boer CG, Obici L (2004) Souza CGMd, Peralta RM. Decolorization of synthetic dyes by solid state cultures of Lentinula (Lentinus) edodes producing manganese peroxidase as the main ligninolytic enzyme. Bioresour Technol 94(2):107–112

Gomes E, Aguiar AP, Carvalho CC, Bonfa MRB, Silva RD, Boscolo M (2009) Ligninases production by Basidiomycetes strains on lignocellulosic agricultural residues and their application in the decolorization of synthetic dyes. Braz J Microbiol 40(1):31–39

Parshetti GK, Parshetti S, Kalyani DC, Doong R-A, Govindwar SP (2012) Industrial dye decolorizing lignin peroxidase from Kocuria rosea MTCC 1532. Ann Microbiol 62(1):217–223

Garcia-Galan C, Berenguer-Murcia A, Fernandez-Lafuente R, Rodrigues RC (2011) Potential of different enzyme immobilization strategies to improve enzyme performance. Adv Synth Catal 353:2885–2904

Asgher M, Noreen S, Bhatti HN (2010) Decolorization of dye-containing textile industry effluents using Ganoderma lucidum IBL-05 in still cultures. Water Environ Res 82(4):357–361

Netoa W, Schurmann M, Panella L, Vogel A, Woodley JM (2015) Immobilization of ώ -transaminase for industrial application: screening and characterization of commercial ready to use enzyme carriers. J Mol Catal B Enzym 117:54–61

Kariminiaae-Hamedaani H-R, Sakurai A, Sakakibara M (2007) Decolorization of synthetic dyes by a new manganese peroxidase-producing white rot fungus. Dyes Pigment 72(2):157–162

Singh S, Gogoi BK, Bezbaruah RL (2012) Calcium alginate as a support material for immobilization of L-amino acid oxidase isolated from Aspergillus fumigatus. IIOAB J 3(5):7–11

Khan AA, Husain Q (2007) Decolorization and removal of textile and non-textile dyes from polluted wastewater and dyeing effluent by using potato (Solanum tuberosum) soluble and immobilized polyphenol oxidase. Bioresour Technol 98(5):1012–1019

Uygun M (2013) Preparation of laccase immobilized cryogels and usage for decolorization. J Chem 1:1–7

Asgher M, Iqbal HMN (2013) Enhanced catalytic features of sol-gel immobilized MnP isolated from solid state culture of Pleurotus ostreatus IBL-02. Chin Chem Lett 24(4):344–346

Iqbal HM, Asgher M (2013) Decolorization applicability of sol-gel matrix immobilized manganese peroxidase produced from an indigenous white rot fungal strain Ganoderma lucidum. BMC Biotechnol 13(1):56

Radha K, Regupathi I, Arunagiri A, Murugesan T (2005) Decolorization studies of synthetic dyes using Phanerochaete chrysosporium and their kinetics. Process Biochem 40(10):3337–3345

Arıca MY, Altıntas B, Bayramoglu G (2009) Immobilization of laccase onto spacer-arm attached non-porous poly (GMA/EGDMA) beads: application for textile dye degradation. Bioresour Technol 100(2):665–669

Idris A, Zain NAM, Suhaimi MS (2008) Immobilization of Baker’s yeast invertase in PVA–alginate matrix using innovative immobilization technique. Process Biochem 43(4):331–338

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1):248–254

Urek RO, Pazarlioglu NK (2007) Enhanced production of manganese peroxidase by Phanerochaete chrysosporium. Braz Arch Biol Technol 50(6):913–920

Sheelu G, Kavitha G, Fadnavis NW (2008) Efficient immobilization of lecitase in gelatin hydrogel and degumming of rice bran oil using a spinning basket reactor. J Am Oil Chem Soc 85(8):739–748

Nunes MA, Vila-Real H, Fernandes PC, Ribeiro MH (2010) Immobilization of naringinase in PVA–alginate matrix using an innovative technique. Appl Biochem Biotechnol 160(7):2129–2147

Stanescu MD, Fogorasi M, Shaskolskiy BL, Gavrilas S, Lozinsky VI (2010) New potential biocatalysts by laccase immobilization in PVA cryogel type carrier. Appl Biochem Biotechnol 160(7):1947–1954

El-Tanash A, El-Baz E, Sherief A (2011) Properties of Aspergillus subolivaceus free and immobilized dextranase. Eur Food Res Technol 233(5):735–742

Zang J, Jia S, Liu Y, Wu S, Zhang Y (2012) A facile method to prepare chemically crosslinked and efficient polyvinyl alcohol/chitosan beads for catalase immobilization. Catal Commun 27:73–77

Zhan J, Jiang S, Pan L (2013) Immobilization of phospholipase A1 using a polyvinyl alcohol-alginate matrix and evaluation of the effects of immobilization. Braz J Chem Eng 30(4):721–728

Queiroz AAA, Esdras DP, Sdnei DBA, Gerald SS, Olga ZH, Michele V (2006) Alginate-Poly(vinyl alcohol) core-shell microspheres for Lipase immobilization. J Appl Polym Sci 102:1553–1560

Shin K, Kim YH, Lim J (2005) Purification and characterization of manganese peroxidase of the white-rot fungus Irpex lacteus. J Microbiol Seoul 43(6):503

Malik P, Saha S (2003) Oxidation of direct dyes with hydrogen peroxide using ferrous ion as catalyst. Sep Purif Technol 31(3):241–250

Sanghi R, Dixit A, Guha S (2006) Sequential batch culture studies for the decolorisation of reactive dye by Coriolus versicolor. Bioresour Technol 97(3):396–400

Srikanlayanukul M, Khanongnuch C, Lumyong S (2006) Decolorization of textile wastewater by immobilized Coriolus versicolor RC3 in repeated-batch system with the effect of sugar addition. CMU J 5(3):301

Kulshreshtha S, Mathur N, Bhatnagar P (2013) Mycoremediation of paper, pulp and cardboard industrial wastes and pollutants. In: Fungi as Bioremediators. Springer, pp 77–116

Verma P, Madamwar D (2002) Production of ligninolytic enzymes for dye decolorization by cocultivation of white-rot fungi Pleurotus ostreatus and Phanerochaete chrysosporium under solid-state fermentation. Appl Biochem Biotechnol 102(1–6):109–118

Authors’ contributions

MB (Research Associate of the project) participated in designing of the study and carried out the experimental work on microbial cultivation, MnP production and extraction, purification, polyvinyl alcohol-alginate entrapment immobilization, kinetic characterization, decolorization and detoxification study of free and immobilized MnP. All the research work was carried out under the supervision of MA (Principal Investigator of the project) who designed and coordinated the experiments. MB and MA also interpreted the data and drafted the manuscript. Both authors read and approved the final manuscript.

Acknowledgements

The present study was a part of research project “Development of immobilized ligninase enzymes and their applications in industrial and environmental biotechnology”. We are highly grateful to the Higher Education Commission, Islamabad, Pakistan for financial support. We are also thankful to Dr. Shoukat Ali and Dr. Muhammad shahid, Department of Chemistry and Biochemistry, University of Agriculture, Faisalabad for providing dyes and toxicity study facilities, respectively.

Compliance with ethical guidelines

Competing interests The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Bilal, M., Asgher, M. Sandal reactive dyes decolorization and cytotoxicity reduction using manganese peroxidase immobilized onto polyvinyl alcohol-alginate beads. Chemistry Central Journal 9, 47 (2015). https://doi.org/10.1186/s13065-015-0125-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-015-0125-0