Abstract

Iron (Fe) and manganese (Mn) are the two most common redox-active elements in the Earth’s crust and are well known to influence mineral formation and dissolution, trace metal sequestration, and contaminant transformations in soils and sediments. Here, we characterized the reaction of aqueous Fe(II) with pyrolusite (β-MnO2) using electron microscopy, X-ray diffraction, aqueous Fe and Mn analyses, and 57Fe Mössbauer spectroscopy. We reacted pyrolusite solids repeatedly with 3 mM Fe(II) at pH 7.5 to evaluate whether electron transfer occurs and to track the evolving reactivity of the Mn/Fe solids. We used Fe isotopes (56 and 57) in conjunction with 57Fe Mössbauer spectroscopy to isolate oxidation of Fe(II) by Fe(III) precipitates or pyrolusite. Using these complementary techniques, we determined that Fe(II) is initially oxidized by pyrolusite and that lepidocrocite is the dominant Fe oxidation product. Additional Fe(II) exposures result in an increasing proportion of magnetite on the pyrolusite surface. Over a series of nine 3 mM Fe(II) additions, Fe(II) continued to be oxidized by the Mn/Fe particles suggesting that Mn/Fe phases are not fully passivated and remain redox active even after extensive surface coverage by Fe(III) oxides. Interestingly, the initial Fe(III) oxide precipitates became further reduced as Fe(II) was added and additional Mn was released into solution suggesting that both the Fe oxide coating and underlying Mn phase continue to participate in redox reactions when freshly exposed to Fe(II). Our findings indicate that Fe and Mn chemistry is influenced by sustained reactions of Fe(II) with Mn/Fe oxides.

Similar content being viewed by others

Introduction

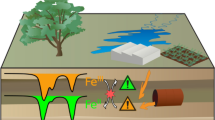

Iron (Fe) and manganese (Mn) are the two most common redox-active elements in the Earth’s crust [1]. Reactions between Fe and Mn species, as well as with other common groundwater constituents, have significant impacts on mineral formation and dissolution [2], trace metal sequestration [3], and contaminant transformations [4, 5]. Our understanding of the health effects of Mn exposure to humans is also evolving, and recent research indicates that elevated Mn concentrations in drinking water may lead to developmental disorders in children, among other adverse health effects [6,7,8,9]. The present study focuses on redox reactions of ferrous iron (Fe(II)) with oxidized Mn(IV) solids at circumneutral pH. Thermodynamics predict that in the presence of Fe(II), all manganese species would exist as reduced Mn(II) as opposed to oxidized Mn(IV). Complex environmental systems, however, do not always adhere to the compositions implied by thermodynamic constraints, especially in complex media such as soil aggregates [10]. For example, microorganisms can significantly impact the speciation of Fe and Mn between reduced and oxidized forms [11, 12] and lead to high local concentrations of dissolved Fe(II) or to Mn(IV) solids that form and persist in the presence of Fe(II) on transient but relevant time scales.

Certain geochemical conditions (low pH, anaerobic zones, presence of organic matter) can stabilize aqueous Fe(II), allowing reduced Fe to travel significant distances and interact with a variety of mineral species. Examples of scenarios where geochemical and kinetic effects dictate the redox interactions observed in field settings are widespread. Studies of both freshwater and marine porewater constituents have observed dissolved Fe(II) in the presence of Mn oxides [13] and implicated Mn oxides as the relevant oxidants of Fe(II) in such systems [14]. Interactions between Fe(II) and Mn oxides have been studied previously under several model geochemical settings, including acid mine drainage [15,16,17] and marine systems [14]. The reaction of Fe(II) with Mn(IV) oxides has previously been described [18] by reaction 1, where Fe(II) is oxidized to Fe(III) with a coupled complete reduction of Mn(IV) to Mn(II).

This reaction was proposed in order to explain locally high concentrations of Mn oxides (e.g. formation of Mn nodules) in sediments [18]. Redox reactions of Fe(II) with Mn(IV) oxides result in an oxidized Fe species, which often occurs as a surface coating on the underlying Mn oxide substrate. The composition of resulting Fe(III) oxide(s) has previously been difficult to ascertain with traditional methods of solid-phase analysis such as X-ray diffraction (XRD) or electron microscopy (Table 1). Postma [18] was unable to clearly define the Fe oxide coating that occurred on birnessite (δ-MnO2) particles reacted with Fe(II), and in later studies chose to model the resulting Fe(III) oxide phase as an amorphous Fe(OH)3 species while identifying it as 6-line ferrihydrite based on XRD [19]. Krishnamurti et al. [20] used a combination of infrared spectroscopy, XRD, and transmission electron microscopy (TEM) to determine that Fe(II) in contact with different Mn oxide substrates (e.g., cryptomelane, hausmannite, and pyrolusite) will react to form different Fe oxide precipitates (akaganeite, magnetite, and lepidocrocite), depending on solution conditions (Table 1).

Formation of an Fe(III) surface coating on Mn oxide solids may impact the rate or overall ability of Mn oxides to remain redox-active phases in environmental systems. In simulated acid-mine drainage systems, Mn(II) production from Mn oxides reacted with Fe(II) decreases with time, suggesting that evolution of a new Fe oxide surface interferes with the ability of underlying Mn oxides to accept electrons from aqueous Fe(II) by creating a passivating Fe-oxide layer [16]. Further studies in this experimental system attributed changing rates of Fe(II) loss and Mn(II) production from batch reactors to Langmuir-type blocking of Mn(IV) surface sites by Fe(III) oxide precipitates using model simulations [17]. In these studies, it was also difficult to concretely ascertain the composition of resulting Fe(III) reaction products. Fe(II)/Mn(IV) redox activity may decrease the oxidation capacity of Mn oxides, which have been demonstrated to be important oxidants for a variety of environmental processes including abiotic release of organic nitrogen in soil [21] and contaminant remediation processes [22, 23]; formation of an amorphous Fe(III) precipitate has previously been shown to inhibit Cr(III) oxidation by birnessite at pH 5.5 [24].

Our guiding hypothesis was that precipitation of Fe(III) minerals at the Mn oxide surface would lead to partial passivation of the Mn oxide reactivity. Thus, we evaluated the effect of aqueous Fe(II) on electron transfer reactions at Mn oxide surfaces by subjecting pyrolusite to successive exposures of Fe(II) at pH 7.5. Pyrolusite was chosen as a model Mn-oxide for this study because it is the most thermodynamically stable Mn mineral phase, and therefore represents the end-member case for Mn(IV) reduction by Fe(II). Many investigations involving Fe(II) and Mn oxides have occurred at lower solution pH values between 3–6 in order to simulate acid mine drainage conditions. Evaluation of Fe/Mn redox chemistry at circum-neutral pH values is also important, as anoxic Fe(II) plumes may persist in neutral pH environments in the presence of Mn oxides [25].

Alongside traditional methods of analysis (XRD, scanning electron microscopy, chemical Fe and Mn analyses), we utilized 57Fe Mössbauer spectroscopy in conjunction with isotopically enriched 57Fe(II) in order to increase the Fe signal (natural Fe contains ~ 2.2 mol% 57Fe). To further examine Fe(III) surface precipitate morphology and what effect this phase has on subsequent redox reactions with Fe(II), we exposed Mn oxide particles to a series of solutions buffered at pH 7.5 which contained either 57Fe(II) (Mössbauer-visible) or 56Fe(II) (Mössbauer-transparent). In this manner, we could subject Mn oxide solids to a series of Fe(II) exposures, but only a particular “pulse” of Fe(II) would be visible with Mössbauer spectroscopy throughout the experiment. Isotope labeling allowed us to track the chemical changes that occurred to a specific set of Fe atoms, even as more Fe(II) was introduced to the reactor.

Experimental

Mn oxide solids characterization

Commercially available MnO2 (Sigma-Aldrich) was used for the entirety of the present study. Mn oxide was ground with a mortar and pestle before sieving (150-µm mesh) to achieve a uniform particle size. X-ray diffraction (XRD) was performed on prepared solids using a Rigaku Miniflex II equipped with a Co X-ray source and indicated pyrolusite (β-MnO2) was the sole Mn oxide phase, and no diffraction peaks indicative of impurities could be detected (Fig. 1). Surface area measurements on sieved Mn oxide powders were made with a Quantachrome BET Nova surface area analyzer using a multipoint measurement and consistently resulted in specific surface area measurements of 1–2 m2 g−1.

Sequential batch experiments with isotopically-enriched aqueous Fe(II)

All reagents were used as received. Experiments were performed in an anoxic chamber with a 95% N2, 5% H2 atmosphere. The chamber contained multiple palladium catalysts to scavenge trace O2 and maintained an O2 level below 1 ppmv. All solutions were made with deionized water (> 18.2 MΩ-cm) that had been deoxygenated by N2 sparging and degassing in the anaerobic chamber. Aqueous Fe(II) stock solutions were prepared by dissolving enriched 56Fe or 57Fe metal (Chemgas, 99 and 96%, respectively) in 0.5 M HCl [26]. To initiate Fe(II) redox experiments, 18 mL of a pH 7.5 buffer solution [25 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (HEPES) + 25 mM KBr] was spiked with either a 57Fe or 56Fe stock solution to yield an initial aqueous Fe concentration of approximately 3 mM. Prior to Fe addition, reactors were counter-spiked with an equivalent volume of 0.5 M NaOH to maintain initial pH. Reactors were equilibrated for 1 h before filtering through a 0.2-µm syringe filter to remove any potential Fe precipitates resulting from trace oxidants. Initial Fe(II) concentration was then measured, and 18 mg of pyrolusite was added to initiate the experiment (solids loading 1 g L−1, Fe/Mn molar ratio ~ 0.26). Reactors were placed on an end-over-end rotator and mixed in the dark. Periodically, small aliquots (~ 150 µL) of suspension were withdrawn, filtered with 0.2-µm nylon syringe filters, and used for chemical Fe and Mn analyses. Experiments were typically allowed to run for ~ 90 min. If solids for a particular experiment were scheduled to receive more than 1 treatment in an aqueous solution, experimental reactors were allowed to stand for a short amount of time to allow Mn solids to settle, where they could be easily removed with a pipette. Solids were placed in a microcentrifuge tube and centrifuged inside the anoxic chamber to pellet solids and facilitate removal of the residual aqueous supernatant. Mn solids were then resuspended in a new buffer solution containing 3 mM 57Fe(II), 56Fe(II), or no Fe, depending on the particular experiment, and an additional experiment was performed to investigate the movement of aqueous Fe and Mn into or out of solution. Solids were resuspended in new buffer solutions with or without additional aqueous Fe(II) from 1 to 9 times.

Acid extractions

To reconcile the amount of Fe(II) lost from solution with the production of Mn(II) into solution, acid extractions were performed on recovered solids to measure total Fe and Mn species. Control reactors with an identical buffer system, Mn solids loading, and Fe/Mn ratio were mixed for 90 min before solids were collected and resuspended in deionized water. 5 M HCl was added to different reactors to obtain a distribution of pH values between ~ 1–2. Extraction reactors were allowed to mix for ~ 150–300 h, periodically removing samples for Fe and Mn analyses. Additional controls of unreacted pyrolusite in HCl resulted in no measurable Mn in solution.

Chemical analyses

Aqueous Fe(II) was measured photometrically using 1,10-phenanthroline at 510 nm [27]. Fluoride was used to remove interferences from aqueous Fe(III) [28]. The amount of Fe(III) in solution was determined by the difference of measured Fe(II) content and the total Fe concentration measured by reducing Fe(III) to Fe(II) with hydroxylamine HCl. Aqueous Mn was determined by modifying the formaldoxime method outlined in Morgan and Stumm [29] and Abel [30] using phenanthroline to complex interfering aqueous Fe.

Solids characterization with SEM and Mössbauer spectroscopy

At the end of each experiment solids were captured by filtration through a syringe filter with a removable 0.45-µm filter disc. A small portion of recovered solids (~ 1 mg) were removed from the filter disc and rinsed with deionized water to remove residual aqueous Fe, Mn, and buffer salts. Rinsed solids were placed on an aluminum microscopy stub and fixed with carbon tape. Imaging of resulting particles and surface precipitates was performed with a Hitachi S-4800 scanning electron microscope (SEM). Remaining Mn/Fe solids recovered after sequential reaction experiments were wrapped in Kapton oxygen-impermeable tape prior to analysis with 57Fe Mössbauer spectroscopy. Mössbauer spectra were collected in transmission mode using a 57Co source and a Janis cryostat with temperature control to 13 K. Mössbauer spectra were collected at room temperature, 140, 77, and 13 K, and data was calibrated to a spectrum of α-Fe foil collected at room temperature. Spectral fitting was performed with the Recoil Software package (http://www.isapps.ca/recoil/) [31].

Results and discussion

Fe(II) oxidation by Mn(IV) oxide and transformation of the secondary Fe oxide

Reaction of aqueous Fe(II) with pyrolusite results in rapid loss of Fe(II) from solution and production of aqueous Mn (Fig. 2). Oxidation of Fe(II) by Mn(IV) oxide is thermodynamically favorable and well documented in the literature, although primarily under acidic pH values simulating acid mine drainage conditions [16, 18,19,20, 32]. At circum-neutral pH, we observed near-complete removal of 2.4 mM Fe(II) after 75 min with release of ~ 0.6 mM aqueous Mn (Fig. 2). No aqueous Mn was observed in aqueous Fe-free control experiments (Fig. 2). According to Eq. 1, loss of Fe(II) should be accompanied by formation of aqueous Mn(II) since reaction stoichiometry predicts production of half as much Mn(II) as Fe(II) oxidized [18]. Although the photometric method used to measure Mn concentrations does not permit speciation of aqueous Mn, it is reasonable to assume that aqueous Mn is most likely Mn(II) based on solubility constraints [29]. Yields of Mn release in the presence of Fe(II) are, however, lower than predicted by Eq. 1, which predicts 1.2 mM Mn released for removal of 2.4 mM Fe(II). Non-stoichiometric production of aqueous Mn has previously been attributed to adsorption or entrainment of newly-produced Mn(II) with mineral surfaces [18, 33], as well as reoxidation of Mn(II) by Mn-oxides [34].

Kinetics of Fe(II) loss from (open markers) and Mn appearance into (closed markers) the aqueous phase. Triangles (Δ) indicate data for the initial suspension of pyrolusite in Fe(II), circles (○) and squares (□) indicate second and third resuspensions, respectively. Initial Fe(II) concentrations for this series of experiments were 2.4 mM. Hatched circles and squares indicate controls where Mn/Fe particles were resuspended in Fe-free buffer to check for Fe and Mn release to solution in the absence of Fe(II)

SEM images of pyrolusite reacted with Fe(II) show dense rod-like precipitates consistent with the oxidation of Fe(II) by pyrolusite and precipitation of an Fe(III) oxide covering the observable pyrolusite surface (Figs. 3, 4a, b). To identify the Fe(III) precipitate, solids were analyzed using powder X-ray diffraction (pXRD) and Mössbauer spectroscopy. Room temperature Mössbauer spectra collected on pyrolusite particles after reaction with Fe(II) were consistent with an Fe(III) oxide doublet with center shift (CS) 0.37 mm s−1 and quadrupole splitting (QS) 0.53 mm s−1 [35]. The Fe doublet magnetically orders into a sextet between 77 and 13 K (Fig. 5), which is characteristic of both lepidocrocite and ferrihydrite [35]. pXRD patterns of the particles after reaction with Fe(II) have reflections consistent with lepidocrocite (Fig. 1) and the rod-like morphology of the precipitates (Figs. 3, 4b) is also indicative of lepidocrocite [36].

Scanning electron micrographs reveal significant changes in particle morphology that occur when unreacted pyrolusite particles (a) are exposed to aqueous Fe(II). After one reaction sequence of pyrolusite with 3 mM aqueous Fe(II) extensive rod-like surface precipitates (b) cover the surface of every particle that was imaged. Images of particles resuspended two (c) and three (d) times in 3 mM aqueous Fe(II) show a morphological transition from rod-like precipitates to spherical particles. Scale bars in all images are 2 µm

Previous work has found that both the identity and morphology of Fe(III) precipitates formed from oxidation of Fe(II) varies depending on the Mn substrate (MnO2, Mn2O3, MnOOH) and solution conditions [pH, ionic strength, Fe(II) concentration] (Table 1). Most studies of Fe(II) reacting with Mn-oxides have been performed at acidic pH, while studies at circumneutral pH focused on biological mechanisms involved with the reaction. Most of these studies identified the formation of discrete Fe phases (only one study reported mixed Mn/Fe jacobsite (MnFe2O4) formation [16]) that were predominantly hydroxylated Fe phases (Fe(OH)3 or FeOOH) with only one study reporting magnetite (Fe3O4) formation [20]. Our observations of lepidocrocite formation from Fe(II) oxidation by pyrolusite are consistent with previous results at pH 6 where lepidocrocite was produced across a range of Mn/Fe molar ratios [20].

To probe the evolution and continued transformation of the Fe-coated pyrolusite particles, we reacted the particles with additional aqueous Fe(II). During the second and third exposure of these particles to Fe(II), Fe(II) loss from and Mn release to solution still occurred, but decreased with each exposure (Fig. 2). Images of particles taken after each Fe(II) exposure reveal changes in particle morphology from rod-like structure (1 exposure) to a mixture of rod-like and spherical structures (Fig. 2). The proportion of spherical particles increases between exposures 2 and 3, and spherical morphology is consistent with magnetite particles [36]. Magnetite formation after reaction of Fe(II) with lepidocrocite has been observed previously [37], although high sulfate concentrations (not present in our study) may inhibit this process [2, 38].

Evolution of secondary Fe oxide

To confirm the secondary formation of magnetite or maghemite (hereafter referred to as magnetite) analysis of pyrolusite particles reacted with different sequences of isotopically-labeled Fe(II) was performed using 57Fe Mössbauer spectroscopy. Mössbauer spectroscopy is specific to the 57-isotope of Fe and we employed both enriched 56Fe(II) and 57Fe(II) in different reaction sequences. Iron isotope labeling allowed for the use Mössbauer spectra to track a specific set of Fe atoms (the 57Fe atoms) through an experiment without spectral contribution from 56Fe atoms. Mössbauer spectra were collected at 77 K to differentiate magnetite from lepidocrocite by minimizing errors due to superparamagnetic behavior of magnetite [39]. At 77 K, lepidocrocite [and most Fe(III) oxides] display doublet spectral features, whereas magnetite exhibits multiple sextets.

We tracked the evolution of initially precipitated Fe atoms by beginning with a reaction between pyrolusite and 57Fe(II). Mössbauer spectra from this sample displayed only doublet spectral features at 77 K, characteristic of Fe(III) oxide (Fig. 6). Upon subsequent addition of 56Fe(II) to these solids, spectra developed sextet characteristics indicative of magnetite in addition to Fe(III) oxide doublets. The reduction of 57Fe(III) could result from reaction with 56Fe(II) via solid-state conversion of lepidocrocite to magnetite, which would result in the presence of magnetite spectral features in Mössbauer spectra. Another pathway resulting in 57magnetite formation is through Fe atom exchange, which has previously been observed between aqueous Fe(II) and goethite [40], magnetite [41], hematite [42], and Fe-bearing clay minerals [43]. Although direct evidence of atom exchange between lepidocrocite and aqueous Fe(II) is not yet available it likely occurs to some extent. In this pathway 57Fe(III) could participate in atom exchange reactions with 56Fe(II) and become solubilized as 57Fe(II), where it would be re-oxidized at the Mn(IV) or Fe(III) surface. Re-oxidation would result in precipitation of either additional lepidocrocite or magnetite through reaction of aqueous 57Fe(II) rather than from solid-state conversion of lepidocrocite to magnetite. Given the current data set, it is not possible to distinguish which process is the dominant pathway for magnetite formation. Most likely atom exchange reactions occur in tandem with direct Fe(II)-catalyzed lepidocrocite to magnetite conversion at the pyrolusite surface. Phase changes in Fe precipitates from oxidized lepidocrocite to mixed-valence magnetite (via net reduction of lepidocrocite) provide evidence that secondary Fe precipitates are able to participate in redox reactions with aqueous Fe(II), suggesting Mn/Fe particle complexes remain important redox-active phases in reactions with constituents like Fe(II).

57Fe Mössbauer spectra of pyrolusite resuspended 1, 2, and 3 times in 3 mM aqueous Fe(II), where the Fe isotope order of addition was 57Fe–56Fe–56Fe. A marked increase in magnetite character can be observed in successive spectra, which is indicative of chemical transformations occurring only in the initial 57Fe atoms oxidized and precipitated on the pyrolusite surface. A summary of lepidocrocite and magnetite ratios obtained from fitting of the Mössbauer spectra is available in Table 2

Next, a similar experiment was performed except the order of Fe isotopes added to the system was switched to investigate the fate of marginal aqueous Fe(II) addition. In these experiments, initial Fe(II) additions were made with Mössbauer invisible 56Fe(II). Pyrolusite particles were suspended in 3 mM 56Fe(II) from 0 to 8 times prior to addition of 57Fe(II), which was always added as the final resuspension and endpoint of reaction. 57Fe(II) addition terminated experiments at 2, 3, 6, and 9 resuspensions [6, 9, 18, and 27 mM total Fe(II) added] and solids were preserved for Mössbauer analysis. Fits of relative peak areas in these spectra reveal that the ratio of magnetite to lepidocrocite increased with the total amount of Fe(II) added to the system, suggesting lepidocrocite was transforming to magnetite (Figs. 7, 8, Table 2). The results are consistent with previous work with hausmannite (Mn3O4) where at low Mn:Fe molar ratios lepidocrocite formation was observed while at higher Mn:Fe ratios magnetite formation occurred instead [20]. Fe(II)-induced conversion of lepidocrocite to magnetite has also been observed for pure lepidocrocite under slightly alkaline conditions similar to our experimental conditions (pH > 7.3) [37]. Under alkaline conditions the conversion of lepidocrocite to magnetite (via a green rust intermediate) in the presence of Fe(II) is rapid and complete after 10 min [44]. Sustained oxidation of Fe(II) confirms that after cumulative addition of 27 mM Fe(II), which exceeds the electron accepting capacity of original pyrolusite particles [1 g L−1 = 23 mM e− for conversion of Mn(IV) to Mn(II)], some of the final Fe(II) added to the system was oxidized. Regardless of whether the relative oxidant in the system is Mn(IV) or Fe(III), redox reactions in Mn/Fe environments continue after the precipitation of oxide layers that have previously been considered passivating.

Relative abundances of lepidocrocite (open markers) and magnetite (closed markers) in marginal Fe(II) additions, as determined by Mössbauer spectral fitting of 57Fe phases at 77 K. Experiments were only exposed to 57Fe during the final Fe(II) resuspension, permitting us to view chemical changes occurring to the marginal Fe(II) addition. After initial reaction of pyrolusite with 3 mM 57Fe(II), only lepidocrocite was detectable in Mössbauer spectra. Increasing 56Fe(II) exposure prior to final 57Fe(II) exposure resulted in marginal 57Fe precipitate formation increasingly dominated by magnetite, as identified by characteristic overlapping sextets in Mössbauer spectra

57Fe Mössbauer spectra of all experimental data collected in which only the final resuspension of Mn particles was done using 57Fe(II). Room temperature (RT, 298 K) spectra are provided for all experiments (left column), with selected 77 K spectra of identical experiments (right column) for comparison. After only one resuspension in 3 mM Fe(II), the resulting spectrum is devoid of multi-sextet character typical of magnetite. As the amount of Fe(II) exposure increases, we can see the final deposition of 57Fe atoms onto the particle surface results in an increasingly large multi-sextet signal and a gradual disappearance of the doublet associated with lepidocrocite formation. Comparing RT spectra with 77 K, magnetite sextets appear to overlap more thoroughly at 77 K, which is commonly observed below the Verwey transition temperature (~ 120 K). Spectra collected at 77 K also contain a visibly higher ratio of sextet: doublet spectral area, possibly indicating the presence of unordered magnetite at room temperature, which orders into a typical sextet at lower collection temperatures

Reaction stoichiometry

Acid extraction (pH 1–2) of Mn/Fe particles resulted in relatively congruent dissolution of Mn and Fe(III), suggesting that Mn was evenly distributed throughout the Fe precipitate phase (Fig. 9 and Additional file 1: Table S1). Regular distribution of Mn within Fe precipitates could be evidence for cation substitution of Mn into lepidocrocite, which may also explain the low ordering temperature observed in 57Fe Mössbauer spectra as was previously observed with Al substitution in lepidocrocite [45]. Mn and Fe(III) dissolution occurred in an approximately 1:1 ratio rather than a 1:2 ratio predicted by Eq. 1 (Fig. 9). Mn and Fe recoveries suggest an apparent reaction stoichiometry of 1:1 between Fe(II) and Mn(IV). This suggests that the average oxidation state of acid-extractable Mn may be Mn3+, although Mn(III) disproportionates into Mn(II) and Mn(IV) at low pH which makes it difficult to definitely determine the reaction stoichiometry. Here we are only able to report on the average observed oxidation state of Mn based on electron balance. Control studies suspending unreacted pyrolusite particles in pH 1.0 buffered solutions, our most extreme extraction condition, did not produce detectable aqueous Mn after several days, ruling out the presence of acid-soluble Mn in the unreacted Mn(IV) solids.

Summary of recovered Fe(III) and Mn after resuspension of Mn/Fe mixed-phase solids in HCl. Theoretical extraction results based on a 1 Fe: 1 Mn (dashed lines) or 2 Fe: 1 Mn (dotted lines) reaction stoichiometry are provided for reference. Data cluster more closely around the 1:1 reaction line, indicating that Fe(II) may be reacting with Mn(IV) to produce Mn(III), which remains in the solid phase. A majority of data points cluster above the 1:1 line, due to the presence of ~ 0.6 mM Mn already existing in solution at the onset of acid addition, as a result of the initial reaction between pyrolusite and Fe(II) (see Fig. 2). Reactions were performed in 60 mL HEPES buffer with 60 mg MnO2

Resuspension of Mn/Fe particles in aqueous Fe(II) initiates a non-stoichiometric release of additional Mn to solution, but no Mn is released into solution when the particles are simply resuspended in pH 7.5 buffer without aqueous Fe(II) (Figs. 4, 10). After 3 exposures to Fe(II) and cumulative exposure time of 225 min (3 × 75-min reaction times), 13% of the initial Mn in MnO2 is mobilized to the aqueous phase (Fig. 10). Sustained Mn release from the solid phase to solution only in the presence of additional Fe(II) indicates further redox reactions between Fe(II) and lepidocrocite coated pyrolusite, resulting in adsorbed or structurally incorporated Mn being released during lepidocrocite transformation to magnetite. Similar release of structurally-substituted Mn from goethite and hematite in the presence of aqueous Fe(II) has been observed previously and been attributed in part to reduction of Mn [46]. Another explanation is direct interaction of Fe(II) with pyrolusite despite the presence of an Fe(III) solid layer. This could involve the conversion of lepidocrocite to magnetite and subsequent coupling of pyrolusite reduction to aqueous Fe(II) oxidation by conduction of electrons through magnetite particles. Kato et al. demonstrated magnetite’s ability to facilitate microbial interspecies electron transfer reactions [47], and we expect magnetite to also be capable of facilitating abiotic electron transfer reactions between spatially disconnected species. Regardless of the mechanism, aqueous Mn release in the presence of Fe(II) appears to occur in the presence of an oxidized Fe surface precipitate despite such precipitates generally thought to prevent Mn redox reactions by acting as a passivating layer [17, 48].

Conclusions

Mn-oxides are powerful natural oxidants, and Mn redox cycling plays a major role in contaminant fate and transport [49]. Here we show that Fe-oxide coatings that form through the abiotic reaction of Fe(II) with Mn-oxide alter the surface properties of the Mn-oxide mineral, but do not shut down the particles’ redox activity. Our findings suggest that surface passivation through the formation of Fe-oxides may not be as extensive or complete as previously thought. In our experiments, we show that the conversion of the initially precipitated Fe-oxide (lepidocrocite) to magnetite is coincident with excess Mn release either from the underlying Mn-oxide or Mn incorporated in the lepidocrocite. These experiments were performed with pyrolusite, the most thermodynamically stable Mn(IV) oxide; thus we expect Mn-oxide reduction by Fe(II) to be a process applicable to a variety of Mn(III/IV)-oxides under environmental conditions. Our findings raise the interesting question of whether sustained redox reactivity in the presence of surface coatings is restricted to Fe(II)/Fe(III) interactions or extends to other environmentally important constituents such as reduced groundwater contaminants.

References

Klein C, Hurlbut CSJ (1999) Manual of mineralogy. Wiley, New York

Hansel CM, Benner SG, Fendorf S (2005) Competing Fe(II)-induced mineralization pathways of ferrihydrite. Environ Sci Technol 39:7147–7153. https://doi.org/10.1021/es050666z

Bowell RJ (1994) Sorption of arsenic by iron oxides and hydroxides in soils. Appl Geochem 9:279–286

Pecher K, Haderlein SB, Schwarzenbach RP (2002) Reduction of polyhalogenated methanes by surface-bound Fe(II) in aqueous suspensions of iron oxides. Environ Sci Technol 36:1734–1741. https://doi.org/10.1021/es011191o

Ulrich HJ, Stone AT (1989) Oxidation of chlorophenols adsorbed to manganese oxide surfaces. Environ Sci Technol 23:421–428

Wasserman GA, Liu X, Parvez F et al (2006) Water manganese exposure and children’s intellectual function in Araihazar, Bangladesh. Environ Health Perspect 114:124–129

Menezes-Filho JA, de Novaes CO, Moreira JC et al (2011) Elevated manganese and cognitive performance in school-aged children and their mothers. Environ Res 111:156–163. https://doi.org/10.1016/j.envres.2010.09.006

Khan K, Wasserman GA, Liu X et al (2012) Manganese exposure from drinking water and children’s academic achievement. Neurotoxicology 33:91–97. https://doi.org/10.1016/j.neuro.2011.12.002

Ljung K, Vahter M (2007) Time to re-evaluate the guideline value for manganese in drinking water? Environ Health Perspect 115:1533–1538. https://doi.org/10.1289/ehp.10316

Ying SC, Masue-Slowey Y, Kocar BD et al (2013) Distributed microbially- and chemically-mediated redox processes controlling arsenic dynamics within Mn-/Fe-oxide constructed aggregates. Geochim Cosmochim Acta 104:29–41. https://doi.org/10.1016/j.gca.2012.08.020

Di-Ruggiero J, Gounot AM (1990) Microbial manganese reduction mediated by bacterial strains isolated from aquifer sediments. Microb Ecol 20:53–63. https://doi.org/10.1007/BF02543866

Lovley DR, Phillips EJP (1988) Novel mode of microbial energy metabolism: organic carbon oxidation coupled to dissimilatory reduction of iron or manganese. Appl Environ Microbiol 54:1472–1480

Widerlund A, Ingri J (1996) Redox cycling of iron and manganese in sediments of the Kalix River estuary, Northern Sweden. Aquat Geochem 2:185–201. https://doi.org/10.1007/BF00121631

van der Zee C, Slomp CP, Rancourt DG et al (2005) A Mossbauer spectroscopic study of the iron redox transition in eastern Mediterranean sediments. Geochim Cosmochim Acta 69:441–453

Stollenwerk KG (1994) Geochemical interactions between constituents in acidic groundwater and alluvium in an aquifer near Globe, Arizona. Appl Geochem 9:353–369. https://doi.org/10.1016/0883-2927(94)90058-2

Villinski JE, O’Day PA, Corley TL, Conklin MH (2001) In situ spectroscopic and solution analyses of the reductive dissolution of MnO2 by Fe(II). Environ Sci Technol 35:1157–1163. https://doi.org/10.1021/es001356d

Villinski JE, Saiers JE, Conklin MH (2003) The effects of reaction-product formation on the reductive dissolution of MnO2 by Fe(II). Environ Sci Technol 37:5589–5596. https://doi.org/10.1021/es034060r

Postma D (1985) Concentration of Mn and separation from Fe in sediments—I. Kinetics and stoichiometry of the reaction between birnessite and dissolved Fe(II) at 10 °C. Geochim Cosmochim Acta 49:1023–1033. https://doi.org/10.1016/0016-7037(85)90316-3

Postma D, Appelo CAJ (2000) Reduction of Mn-oxides by ferrous iron in a flow system: column experiment and reactive transport modeling. Geochim Cosmochim Acta 64:1237–1247. https://doi.org/10.1016/S0016-7037(99)00356-7

Krishnamurti GSR, Huang PM (1988) Influence of manganese oxide minerals on the formation of iron-oxides. Clays Clay Miner 36:467–475

Reardon PN, Chacon SS, Walter ED et al (2016) Abiotic protein fragmentation by manganese oxide: implications for a mechanism to supply soil biota with oligopeptides. Environ Sci Technol. https://doi.org/10.1021/acs.est.5b04622

Laha S, Luthy RG (1990) Oxidation of aniline and other primary aromatic amines by manganese dioxide. Environ Sci Technol 24:363–373. https://doi.org/10.1021/es00073a012

Eary LE, Rai D (1987) Kinetics of chromium(III) oxidation to chromium(VI) by reaction with manganese-dioxide. Environ Sci Technol 21:1187–1193

Amacher MC, Baker DA (1982) Redox reactions involving chromium, plutonium, and manganese in soils. PhD thesis, The Pennsylvania State University

McCobb TD, LeBlanc DR, Walter DA, et al. (1999) Phosphorus in a ground-water contaminant plume discharging to Ashumet Pond, Cape Cod, Massachusetts. US Geological Survey Water Resources Investigations Report 02-4306 70p

Williams AGB, Scherer MM (2004) Spectroscopic evidence for Fe(II)–Fe(III) electron transfer at the iron oxide–water interface. Environ Sci Technol 38:4782–4790. https://doi.org/10.1021/es049373g

Fortune WB, Mellon MG (1938) Determination of iron with o-phenanthroline—a spectrophotometric study. Ind Eng Chem Anal Ed 10:0060–0064

Tamura H, Goto K, Yotsuyanagi T, Nagayama M (1974) Spectrophotometric determination of iron(II) with 1, 10-phenanthroline in the presence of large amounts of iron(III). Talanta 21:314–318

Morgan JJ, Stumm W (1965) Analytical chemistry of aqueous manganese. J (Am Water Works Assoc) 57:107–119

Abel R (1998) Scavenging of particulate and dissolved lead compounds by coprecipitation with manganese oxyhydroxides. Electronic M.S. thesis, Virginia Tech

Rancourt DG, Ping JY (1991) Voight-based methods for arbitrary-shape static hyperfine parameter distributions in Mössbauer spectroscopy. Nucl Instrum Methods Phys Res B58:85–97

Krishnamurti GSR, Huang PM (1987) The catalytic role of birnessite in the transformation of iron. Can J Soil Sci 67:533–543

Morgan JJ, Stumm W (1964) Colloid-chemical properties of manganese dioxide. J Colloid Sci 19:347–359

Elzinga EJ (2011) Reductive transformation of birnessite by aqueous Mn(II). Environ Sci Technol 45:6366–6372. https://doi.org/10.1021/es2013038

Murad E, Cashion J (2004) Mossbauer spectroscopy of environmental materials and their industrial utilization. Kluwer Academic Publishers, Dordrecht

Cornell RM, Schwertmann U (2003) The iron oxides: structure, properties, reactions, occurrences and uses, 2nd edn. Wiley-VCH, Weinheim

Tamaura Y, Ito K, Katsura T (1983) Transformation of γ-FeO(OH) to Fe3O4 by adsorption of iron(II) ion on γ-FeO(OH). J Chem Soc Dalton Trans 2:189–194. https://doi.org/10.1039/DT9830000189

Tamaura Y, Buduan PV, Katsura T (1981) Studies on the oxidation of iron(II) ion during the formation of Fe3O4 and α-FeO(OH) by air oxidation of Fe[OH]2 suspensions. J Chem Soc Dalton Trans 9:1807–1811. https://doi.org/10.1039/DT9810001807

Gorski CA, Scherer MM (2009) Influence of magnetite stoichiometry on Fe(II) uptake and nitrobenzene reduction. Environ Sci Technol 43:3675–3680

Handler RM, Beard BL, Johnson CM, Scherer MM (2009) Atom exchange between aqueous Fe(II) and goethite: an Fe isotope tracer study. Environ Sci Technol 43:1102–1107

Gorski CA, Handler RM, Beard BL et al (2012) Fe atom exchange between aqueous Fe2+ and magnetite. Environ Sci Technol 46:12399–12407. https://doi.org/10.1021/es204649a

Frierdich AJ, Helgeson M, Liu C et al (2015) Iron atom exchange between hematite and aqueous Fe(II). Environ Sci Technol. https://doi.org/10.1021/acs.est.5b01276

Neumann A, Wu L, Li W et al (2015) Atom exchange between aqueous Fe(II) and structural Fe in clay minerals. Environ Sci Technol 49:2786–2795. https://doi.org/10.1021/es504984q

Wang Y, Morin G, Ona-Nguema G, Brown GE (2014) Arsenic(III) and arsenic(V) speciation during transformation of lepidocrocite to magnetite. Environ Sci Technol 48:14282–14290. https://doi.org/10.1021/es5033629

De Grave E, Da Costa GM, I’w LH et al (1996) 57Fe Mossbauer effect study of A1-substituted lepidocrocitest. Clays Clay Miner 44:214–219

Frierdich AJ, Catalano JG (2012) Fe(II)-mediated reduction and repartitioning of structurally incorporated Cu Co, and Mn in iron oxides. Environ Sci Technol 46:11070–11077. https://doi.org/10.1021/es302236v

Kato S, Hashimoto K, Watanabe K (2012) Microbial interspecies electron transfer via electric currents through conductive minerals. PNAS 109:10042–10046. https://doi.org/10.1073/pnas.1117592109

Ying SC, Kocar BD, Griffis SD, Fendorf S (2011) Competitive microbially and Mn oxide mediated redox processes controlling arsenic speciation and partitioning. Environ Sci Technol 45:5572–5579. https://doi.org/10.1021/es200351m

Oze C, Bird DK, Fendorf S (2007) Genesis of hexavalent chromium from natural sources in soil and groundwater. Proc Natl Acad Sci USA 104:6544–6549

Myers CR, Nealson KH (1988) Microbial reduction of manganese oxides: interactions with iron and sulfur. Geochim Cosmochim Acta 52:2727–2732

Authors’ contributions

MMS lead project conceptualization and all authors contributed to the research design. MVS and RMH collected data, all authors analyzed data and contributed to writing the manuscript. All authors read and approved the final manuscript.

Acknowledgements

The authors would like to thank David Cwiertny, Chris Gorski, and Drew Latta for experimental help and Samantha Ying for helpful discussions. Portions of this work were funded by the US National Science Foundation through a Graduate Research Fellowship Program Grant (DGE-114747) and NIRT Grant (EAR-0506679).

Competing interests

The authors declare that they have no competing interests.

Ethics approval and consent to participate

Not applicable.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Schaefer, M.V., Handler, R.M. & Scherer, M.M. Fe(II) reduction of pyrolusite (β-MnO2) and secondary mineral evolution. Geochem Trans 18, 7 (2017). https://doi.org/10.1186/s12932-017-0045-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12932-017-0045-0