Abstract

Background

Streptococcus mutans is a bacterium that causes oral diseases. Plaque, a biofilm produced by S. mutans and other bacteria, makes it difficult to remove cariogenic oral microorganisms, including biofilm producers. Glucan synthesis by glucosyltransferase is one of the mechanisms underlying plaque formation. This study demonstrates the effectiveness of inhibiting biofilm formation by interfering with the glucosyltransferase activity of S. mutans using edible herbal medicines.

Methods

This study investigated the inhibitory activity of Glycyrrhizae Radix extract, Rubi Fructus extract, glycyrrhizin from Glycyrrhizae Radix, and ellagic acid from Rubi Fructus against glucosyltransferase activity of S. mutans. Enzyme kinetic analysis identified the mechanism by which glycyrrhizin and ellagic acid inhibit enzyme activity.

Results

The conditions for synergistically inhibiting biofilm formation by combining Glycyrrhizae Radix and Rubi Fructus extracts were identified. Biofilm formation was also synergistically inhibited by mixing their respective active constituents, glycyrrhizin and ellagic acid. Glycyrrhizin and ellagic acid inhibited glucosyltransferase via noncompetitive and uncompetitive mechanisms, respectively, indicating that they inhibit it via distinct mechanisms.

Conclusions

This study presents an effective oral hygiene method using the synergistic activity of two natural plant extracts to inhibit biofilm formation through different inhibitory mechanisms against glucosyltransferase of S. mutans.

Similar content being viewed by others

Background

Dental caries is an infectious oral disease that causes progressive destruction and loss of tooth enamel [1]. Streptococcus mutans is a major cause of dental caries and a representative bacterium that forms biofilm in the oral cavity, which is called plaque [2]. Furthermore, S. mutans glucosyltransferase (GTase) synthesizes sticky glucan from sucrose to promote the formation of dental biofilm and the attachment of oral microorganisms. Oral microorganisms, including S. mutans, produce organic acids from carbohydrates and accelerate the progression of dental caries [3]. Therefore, it is essential to inhibit the formation of dental biofilm to prevent or treat dental caries.

GTase synthesizes water-soluble and/or water-insoluble glucan. Exopolysaccharide-based insoluble glucan is a significant component in the formation of dental biofilm [4] and helps S. mutans adhere to the surface of teeth [5,6,7]. Because GTase uses sucrose to produce insoluble glucans, it has been suggested that sugar alcohols such as xylitol and maltitol [8, 9], alternative carbohydrates such as maltose and fructose [10, 11], and alternative sweeteners such as stevia [12] can substitute sucrose. GTase consists of two functional domains: the amino-terminal catalytic domain (CAT domain), which binds to and hydrolyzes sucrose, and the carboxyl-terminal glucan-binding domain, which binds to glucan and determines the properties of synthesized glucan [13, 14]. Inhibitors that prevent sucrose from binding to the CAT domain of GTase have been proposed to reduce plaque by inhibiting the production of insoluble glucan [15, 16].

In recent decades, chlorhexidine and sodium fluoride have been used to prevent oral diseases; however, they are irritative and have negative consequences, such as the emergence of resistant strains [17,18,19]. Alternatively, plant extracts have been proposed as novel materials for promoting oral health [20, 21] although they require high concentrations to achieve antibiotic-like efficacy. Due to their inherent flavor and aroma, consumers may reject high concentrations of plant extracts. To mitigate these issues without diminishing their efficacy, it is necessary to use plant extracts at lower concentrations. In this context, it has been proposed that extract combinations can be utilized [22,23,24,25,26,27]. However, few studies have examined combinations with the synergistic inhibition of S. mutans biofilm formation. In addition, it is necessary to identify the active constituents of plant extracts that can be used in combination and their biological mechanisms of action.

Our previous studies recently proposed two materials that strongly inhibit S. mutans biofilm formation via different mechanisms [28, 29]. One is a 50% ethanol extract of Glycyrrhizae Radix that inhibits the growth of S. mutans [29]. Its active constituents are glycyrrhizin and glycyrrhetic acid. The other is a methanol extract of Rubi Fructus (fruit of Rubus coreanus) that inhibits GTase activity but not the growth of S. mutans [28].

Glycyrrhizae Radix and Rubi Fructus are sweet, medicinal, or functional foods with a long history of use. In numerous studies, their biological activities and active constituents have also been suggested. Glycyrrhizae Radix is recognized for its anti-inflammatory [30], antioxidant [31], and hepatoprotective [32] properties, as well as its ability to prevent gastrointestinal ulcers [33] and alleviate dry mouth [34]. Meanwhile, Rubi Fructus has been reported to exert anti-inflammatory [35, 36], antioxidant [37, 38], and anticancer effects [39]. A lollipop containing Glycyrrhizae Radix extract has been developed for the prevention of caries [40]. Glycyrrhizae Radix is known to be particularly effective at preventing dental caries.

In this study, a method for inhibiting the biofilm formation of S. mutans by combining the extracts of Glycyrrhizae Radix and Rubi Fructus is proposed. To this end, this study proposes an extraction method for Rubi Fructus in addition to the extraction method for Glycyrrhizae Radix from the previous study [29], as well as a biological mechanism of component compounds that inhibit the biofilm formation of S. mutans in the two proposed extracts.

Methods

Strain, medium, and culture conditions

Streptococcus mutans GS-5, a serotype c strain, was provided by LG Household & Health Care Ltd. [41]. Brain heart infusion (BHI) medium (SKU: 237500) was purchased from Becton, Dickinson and Company Korea Ltd. (Seoul, Korea). BHI-S medium for biofilm formation was made using BHI medium and 1% (w/v) sucrose. BHI agar plates were made with BHI medium and 1.5% (w/v) agar. S. mutans stored in 25% (v/v) glycerol stock at − 80 °C was streaked on a BHI agar plate and incubated at 37 °C for 2 days. The BHI medium was inoculated with a single colony from the BHI agar plates and incubated at 37 °C for 24 h.

Glycorrhizin (catalog number: G0150) and ellagic acid dihydrate (catalog number: E0375) were purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan) and used as standard compounds for the analyses of Glycyrrhizae Radix and Rubi Fructus, respectively. Glycyrrhizin (100 mM) and ellagic acid (5 mM) were dissolved in dimethyl sulfoxide (DMSO) before use.

Preparation of Glycyrrhizae Radix and Rubi Fructus extracts

Dried Glycyrrhizae Radix, purchased from Jiwoondang Herbal Medicine Store (Seoul, Korea), was ground to a powder of ≤1 mm. Then, the extract solution was mixed at 8 mL per 1 g of Glycyrrhizae Radix powder and incubated at 83 °C for 3 h. The solid powder was eliminated by filtration using a 75 μm–pore cartridge filter. The solvent was mixed again at 2 mL per 1 g of Glycyrrhizae Radix powder and incubated at 83 °C for 2 h. The residual powder was removed once more with the use of the same cartridge filter. The powdered mixture of the filtered primary and secondary extracts was produced via spray drying.

Dried Rubi Fructus from Jiwoondang Herbal Medicine Store (Seoul, Korea) was ground to a powder with a particle size of ≤1 mm. Next, the solvent was mixed at 10 mL per 1 g of the Rubi Fructus powder and incubated at 100 °C (water) or 70 °C (50 and 90% ethanol) for 3 h. Following filtration with a cartridge filter, the extract was spray-dried into a powder. The solid yields were 12.7% with water, 21.2% with 50% ethanol, and 10.7% with 90% ethanol.

Glycyrrhizae Radix and Rubi Fructus were formally identified by the Herbal Medicine Store, where they were purchased. All extract powders were vacuum-sealed and stored at − 80 °C until use. Before use, extract powders of Glycyrrhizae Radix and Rubi Fructus were dissolved in distilled water.

Biofilm formation and its quantitative analysis

Microplate biofilm formation was measured using crystal violet staining method [42]. In order to create biofilm, 100 μL of BHI-S medium was dispensed into each well of a 96-well polyvinylchloride microplate, and 5% of the sample was added. S. mutans, with an absorbance of 0.05 at 600 nm, was inoculated into each well. After 24 h of incubation at 37 °C, the absorbance at 595 nm was measured to determine cell growth using an Opsys MR microplate reader (DYNEX Technologies, Chantilly, VA, USA). The planktonic cells were then washed with distilled water. The biofilm was stained with 1% crystal violet and then rinsed with distilled water. For the quantitative analysis of biofilm formation, crystal violet remaining in the biofilm was eluted with 95% ethanol, and the absorbance at 595 nm was measured. The relative amount of biofilm was calculated by comparison with the control value.

Measuring glucosyltransferase activity

Glucosyltransferase activity was measured using a modified version of the method described in previous reports [43, 44]. S. mutans which was stored at − 80 °C, was inoculated on a BHI agar plate and cultured at 37 °C for 2 days. A single colony was inoculated into 40 mL of BHI medium and incubated at 37 °C for 24 h. The preculture cells were inoculated onto 1 L of BHI medium to reach Abs600 = 0.05 and incubated at 37 °C for 24 h. The cells were separated from the supernatant using a centrifuge (Combi-514R; Hanil Science Industrial Co., Ltd., Daejeon, Korea) at 1500×g and 4 °C for 10 min. This cell-free supernatant was combined with cold 95% ethanol and incubated at 4 °C for 24 h. The supernatant was discarded after centrifugation at 1500×g and 4 °C for 10 min to obtain precipitated GTase. Precipitated GTase was washed with 10 mL of 60 mM potassium phosphate buffer (pH 6.8). The GTase was homogenized with an additional 10 mL of 60 mM potassium phosphate buffer (pH 6.8) and stored at − 80 °C.

By analyzing the amount of insoluble glucan produced from sucrose during the enzymatic reaction, the GTase activity was determined. The substrate for the reaction was 1.25% (w/v) sucrose in a 60 mM potassium phosphate buffer at pH 6.8 with 0.025% NaN3. For the reaction, 800 μL of the substrate solution, 50 μL of GTase, 50 μL of the testing sample, and 100 μL of distilled water were mixed and incubated at 37 °C for 24 h. After incubation, insoluble glucan was homogenized for 5 s using a Sonic Dismembrator (model 100; Thermo Fisher Scientific Inc., Waltham, MA, USA) with the power of scale 4. After centrifugation at 1500×g and 4 °C for 10 min, most of the supernatant was removed, leaving ~ 200 μL. The pelleted insoluble glucan was homogenized using sonication under the same conditions mentioned above. After transferring 200 μL into a 96-well polystyrene microplate (catalog number: CLS3628; Corning Inc., New York, NY, USA), absorbance at 540 nm was measured using an Opsys MR™ microplate reader. For the control experiments, distilled water was substituted for the test sample. To calculate the relative GTase activity, the sample value was compared to the control value.

Content analysis of ellagic acid by high-performance liquid chromatography

The concentration of ellagic acid in the Rubi Fructus extract was determined using high-performance liquid chromatography (HPLC) in accordance with the method described in a previous report [45]. Each specimen was filtered using a SEPARA® vial filter (catalog number: MV32ANPPV002FC01; GVS Korea Ltd., Namyangju, Korea). The analytical column was YMC-Triart C18 (catalog number: TA12S05-2546WT; YMC Korea Co., Ltd., Seongnam, Korea). The HPLC instrument was Acme 9000 HPLC, which comprises a vacuum degasser and mixer (catalog number: SDV40A), gradient pump oven (catalog number: CTS30), auto-sampler [catalog number: YL9150 AS (Alias)], solvent delivery pump (catalog number: SP930D), and UV/Vis detector with dual wavelength (catalog number: YL9120) from Young Lin Instrument Co. (Anyang, Korea). The mobile solvents were 1% acetic acid (A) and acetonitrile (B). The following gradient steps were utilized for chemical separation: 90% (A):10% (B) at 0 min; 60% (A):40% (B) at 28 min; 40% (A):60% (B) at 39 min; 10% (A):90% (B) at 50 min; and 90% (A):10% (B) at 55 min. The flow rate of the mobile phase was 0.7 mL/min, and a UV absorbance detector was used to detect the chemicals at 272 nm. The amount of sample injected was 10 μL, and the temperature of the analytical column was 30 °C. The data were analyzed using Autochro-3000 software version 2.0.0 (Young Lin Instrument Co.).

Evaluating synergistic biofilm formation inhibition using a checkerboard microdilution assay

Using a 96-well microplate, the synergistic activity of extract combinations was evaluated [46]. The relative decrease in biofilm formation due to a sample was calculated by comparison with the amount of biofilm formation of the untreated control [47]. Synergistic activity was determined to occur when the relative inhibition value of a combination was more than double the relative inhibition value of each sample.

Kinetic analysis of GTase activity

Michaelis–Menten constants (Km) and maximum reaction rate (Vmax) of GTase were determined using a slightly modified version of a previously described method [48]. At 37 °C for 30 min, GTase activity was measured with sucrose concentrations ranging from 0 to 1%, and the values of Vmax and Km were calculated using the Lineweaver–Burk equation. To determine the type of inhibition, the rate of change of the reaction upon the addition of glycyrrhizin or ellagic acid was compared.

Statistical analyses

To calculate the mean value and standard deviation for all experimental results, the statistical program IBM® SPSS software (Ver. 25.0; SPSS Inc., Chicago, IL, USA) was utilized (SPSS Inc., Chicago, IL, USA). The results were determined using the t-test at the 95% confidence level.

Results and discussion

Inhibitory activity of Rubi Fructus extracts on biofilm formation and glucosyltransferase of S. mutans

Methods for preventing oral diseases caused by S. mutans include 1) inhibiting the growth of S. mutans, 2) inhibiting the biofilm formation of S. mutans (including inhibiting glucan synthesis by GTase), and 3) employing alternative sweeteners that cannot be exploited by S. mutans [49].

In a previous study, ellagic acid rhamnoside from R. ulmifolius was found to inhibit the biofilm formation of Staphylococcus aureus [50], and the R. idaeus extract inhibited the biofilm formation of Candida albicans without antifungal activity [51]. However, Rubi Fructus extract did not inhibit the biofilm formation of seven bacterial strains: Pseudomonas libanensis, Serratia marcescens, Acinetobacter sp., Bacillus amyloliquefaciens, Hafnia paralvei, Obesumbacterium proteus, and Pseudomonas aeruginosa [52]. These findings suggest that the inhibitory activity of Rubus spp. extract against microbial biofilm is strain-specific.

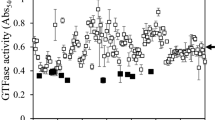

Our previous study found that the methanol extract of Rubi Fructus reduced the GTase activity and biofilm formation of S. mutans [28]. However, methanol is an unsuitable solvent for the production of edible products. This study prepared a Rubi Fructus extract using water and ethanol as extraction solvents. S. mutans biofilm formation (Fig. 1) and GTase activity (Fig. 2) were found to be effectively inhibited by a water extract of Rubi Fructus. Biofilm formation was inhibited in a concentration-dependent manner by all Rubi Fructus extracts, but the growth of S. mutans was not inhibited at any of the concentrations examined (Fig. 1).

Effect of Rubi Fructus extracts on biofilm formation and S. mutans growth. The quantity of biofilm was represented by crystal violet (CV) absorbance at 595 nm. Values that differ from the control with a 95% confidence level are denoted with an asterisk on top of the symbols. A biofilm production with water extract; B cell growth with water extract; C biofilm production with 50% ethanol extract; D cell growth with 50% ethanol extract: E biofilm formation with 90% ethanol extract; F cell growth with 90% ethanol extract

Effect of Rubi Fructus extract on the GTase activity of S. mutans. GTase activity was determined by measuring the amount of insoluble glucan at a wavelength of 540 nm. The tested concentration of all extract was 2.5 g/L. Values that differ from the control with a 95% confidence level are marked with an asterisk on top of the bars

Ellagic acid of Rubi Fructus inhibiting biofilm formation and GTase activity of S. mutans

In previous studies, ellagic acid was shown to inhibit the biofilm formation of Escherichia coli [53], S. aureus [54], and Cutibacterium acnes [55]. In this study, the ellagic acid content of the extract was analyzed based on the solvent used for extraction (Table 1). The ellagic acid concentration in the water extract was the highest at 1.55 mmol/g, whereas it decreased as the ethanol concentration in the extracted solvent increased. The GTase inhibitory activity of Rubi Fructus extract was proportional to its ellagic acid content (Table 1 and Fig. 2).

The 0.25-mM elagic acid concentration decreased biofilm formation by 32% (Fig. 3A) and GTase activity by 63%. (Fig. 3B). However, ellagic acid did not inhibit the growth of S. mutans in the same way that Rubi Fructus extract did (Fig. 3C). According to a previous study, ellagic acid inhibits the GTase activity of S. mutans [56] and S. sobrinus [57]. This study demonstrates that water is a superior extraction solvent for Rubi Fructus to inhibit biofilm formation and GTase activity of S. mutans and that ellagic acid is the active compound responsible for the extract’s inhibitory activity.

Effect of ellagic acid on S. mutans biofilm formation (A), cell growth (B), and GTase activity (C). At a concentration of 0.25 mM, the impact of ellagic acid on GTase activity was examined (B). The amount of biofilm was represented by crystal violet (CV) absorbance at 595 nm. Six (A and C) and three (B) distinct experiments were used to calculate the values. A and B were analyzed statistically using Tukey’s test (A and B) or a paired t-test (C). Values that differ from the control with a 95% confidence level are marked with an asterisk on top of the symbols or bars

Rubi Fructus extract did not inhibit the growth of S. mutans (Fig. 1), nor did ellagic acid up to 0.25 mM (0.076 mg/mL) affect the growth (Fig. 3C). However, it has been reported that the minimum inhibitory concentration (MIC) of ellagic acid against oral bacteria, S. mutans, S. sanguinis, and S. salivarius is < 1 mg/mL, making it more sensitive than Actinomyces viscosus and Lactobacillus rhamnosus [58]. Notably, 30-μg/mL ellagic acid had no effect on the growth of E. coli but it inhibited biofilm formation [53]. Low MIC concentrations and biofilm inhibition for ellagic acid in a previous study suggest that ellagic acid can specifically inhibit the growth of cariogenic oral streptococci, such as S. mutans, S. sanguinis, and S. salivarius.

Synergistic inhibitory activity of Rubi Fructus and Glycyrrhizae Radix extracts

A 50% ethanol extract of Glycyrrhizae Radix inhibited the growth and biofilm formation of S. mutans in a previous study [29] but had no effect on GTase activity (Supplementary Fig. 1). The extract yield of Glycyrrhizae Radix used was 19% in terms of solid content. These findings suggested that Glycyrrhizae Radix extract and Rubi Fructus extract exert different inhibitory effects on the biofilm formation and GTase activity of S. mutans via distinct mechanisms, suggesting that they can be combined for synergistically increased effectiveness. The optimal combination ratio synergistically inhibiting biofilm formation was identified using the checkerboard method (Supplementary Table 1). The combination of Glycyrrhizae Radix extract at 0.3 g/L and Rubi Fructus extract at 0.5 g/L exhibited synergistic activity (Fig. 4A). The activity of this combination was 9.1 times more effective than Glycyrrhizae Radix extract alone and 9.2 times more effective than Rubi Fructus extract alone.

Synergistic inhibition of biofilm formation by extract combinations against S. mutans. The synergistic inhibitory activity of Glycyrrhizae Radix extract and Rubi Fructus extract (A) and glycyrrhizin and ellagic acid (B) against the formation of biofilm by S. mutans. A control was administered, either distilled water (A) or DMSO (B). The amount of biofilm was measured by the absorbance of crystal violet (CV) at 595 nm. Values that differ from the control with a 95% confidence level are marked with an asterisk on top of the bars

Glycyrrhizin of Glycyrrhizae Radix has been reported to inhibit the cell growth, biofilm formation, and GTase activity of S. mutans [29, 59]. The combination of glycyrrhizin and ellagic acid with synergistic inhibition of biofilm formation was also identified using the checkerboard technique (Supplementary Table 2). The activity of inhibiting biofilm formation was increased 13.7-fold and 2.8-fold, respectively, when 2 mM glycyrrhizin and 0.025 mM ellagic acid were combined, compared to the activity of each compound alone (Fig. 4B). Considering the synergistic activity of glycyrrhizin and ellagic acid on S. mutans, they may contribute to the synergistic activity of Glycyrrhizae Radix and Rubi Fructus. MIC for Glycyrrhizae Radix extract against cavity-causing bacteria such as S. mutans, S. sobrinus, and Lactobacillus casei [40] was between 15.6 and 31.2 μg/mL. Lollipops containing Glycyrrhizae Radix extract decreased cavity-causing bacteria in the oral cavity [40]. In addition, Glycyrrhizae Radix extract inhibited the growth of B. subtilis and C. acnes [60], indicating that it selectively inhibited the growth of bacteria and was not limited to oral microorganisms. Glycyrrhizin, a component of Glycyrrhizae Radix, has been demonstrated to have bactericidal activity against E. coli [61], B. subtilis [62], and S. epidermidis [62]. β-Glycyrrhetinic acid had MICs ranging from 16 to 512 μg/mL for cariogenic oral streptococci, such as S. mutans, S. sobrinus, S. anginosus, S. sanguinis, S. salivarius, S. gordonii, and S. oralis [63].

Enzymatic inhibitory mechanism of glycyrrhizin and ellagic acid on GTase

To determine the Michaelis–Menten kinetic constant (Km) and maximum velocity (Vmax) of GTase isolated from S. mutans, the enzymatic activity was measured using various concentrations of sucrose, and the Lineweaver–Burk equation was used to plot the obtained results (Fig. 5). Without any control compounds, the Km and Vmax values of GTase were 0.99 mM and 0.218 Abs540/mL/30 min, respectively. The Km value for glycyrrhizin was 0.93 mM, which was comparable to that of the control GTase. However, the Km value for ellagic acid was 0.57 mM, which was 42% lower than that of the control GTase. Vmax values for glycyrrhizin and ellagic acid were 0135 and 0.105 Abs540/mL/30 min, representing decreases of 38 and 52%, respectively. These results indicated that glycyrrhizin is a noncompetitive inhibitor and ellagic acid is an uncompetitive inhibitor of GTase, indicating that these two compounds inhibit the enzyme in different ways.

Inhibitory effects of glycyrrhizin (A) and ellagic acid (B) on the kinetics of the enzyme GTase. Changes in GTase activity were evaluated without (open square) and with chemicals (filled square). The y-axis represents the inverse of GTase activity, while the x-axis represents the inverse of substrate concentration (mM). GTase activity is measured as the quantity of insoluble glucan produced in 1 mL over a period of 24 h. The Lineweaver–Burk equations for control, glycyrrhizin, and ellagic acid were 1/V = 4.52 × 1/[S] + 4.58, 1/V = 6.90 × 1/[S] + 7.40, and 1/V = 5.38 × 1/[S] + 9.51, respectively. The values were calculated from three independent experiments.

In previous studies, inhibitors of GTase activity with diverse inhibitory mechanisms were described. For instance, polyphenols of oolong tea noncompetitively inhibited the glucan-binding domain of the GTase of S. mutans [64]. Meanwhile, tannic acid, gallic acid, and syringic acid inhibited the GTase activity of S. mutans through mixed-type inhibition [48]. Furthermore, 7-epiclusianone inhibited GTase B activity by mixed-type inhibition while noncompetitively inhibiting GTase C activity [65]. According to our previous research, vanillic acid, ferulic acid, and salicylic acid were uncompetitive, competitive, and noncompetitive inhibitors, respectively [28]. In this experiment, the addition of glycyrrhizin and ellagic acid from Glycyrrhizae Radix and Rubi Fructus did not significantly change pH. This study presents two different inhibitors of GTase, glycyrrhizin, a noncompetitive inhibitor, and ellagic acid, a noncompetitive inhibitor. S. mutans biofilm formation was inhibited synergistically by extracts of Glycyrrhizae Radix and Rubi Fructus containing these two different inhibitors as the main active substances, respectively.

Conclusions

This study revealed the synergistic activity of a combination of two different natural compounds as a potential method for inhibiting S. mutans’ formation of dental biofilm. Rubi Fructus water extract inhibited GTase activity and biofilm formation without inhibiting the growth of S. mutans. Glycyrrhizin and ellagic acid were found to be noncompetitive and uncompetitive inhibitors of S. mutans GTase, respectively. The combination of glycyrrhizin of Glycyrrhizae Radix and ellagic acid of Rubi Fructus synergistically inhibited biofilm formation, and the combination of Rubi Fructus extract with Glycyrrhizae Radix extract exerting different mechanisms of action showed a strong ability to inhibit biofilm formation at low concentrations. Thus, it is possible to develop effective products for preventing oral diseases caused by S. mutans dental biofilm using the proposed combination’s synergistic activity.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- BHI:

-

Brain Heart Infusion

- CAT domain:

-

Catalytic domain

- DMSO:

-

Dimethyl sulfoxide

- GTase:

-

Glucosyltransferase

- HPLC:

-

High-performance liquid chromatography

- K m :

-

Michaelis–Menten constants

- V max :

-

Maximum reaction rate

References

Selwitz RH, Ismail AI, Pitts NB. Dental caries. Lancet. 2007;369(9555):51–9.

Krzyściak W, Jurczak A, Kościelniak D, Bystrowska B, Skalniak A. The virulence of Streptococcus mutans and the ability to form biofilms. Eur J Clin Microbiol Infect Dis. 2014;33(4):499–515.

Klein MI, DeBaz L, Agidi S, Lee H, Xie G, Lin AH, et al. Dynamics of Streptococcus mutans transcriptome in response to starch and sucrose during biofilm development. PLoS One. 2010;5(10):e13478.

Bowen WH, Koo H. Biology of Streptococcus mutans-derived glucosyltransferases: role in extracellular matrix formation of cariogenic biofilms. Caries Res. 2011;45(1):69–86.

Paes Leme AF, Koo H, Bellato CM, Bedi G, Cury JA. The role of sucrose in cariogenic dental biofilm formation--new insight. J Dent Res. 2006;85(10):878–87.

Koo H, Xiao J, Klein MI, Jeon JG. Exopolysaccharides produced by Streptococcus mutans glucosyltransferases modulate the establishment of microcolonies within multispecies biofilms. J Bacteriol. 2010;192(12):3024–32.

Ooshima T, Matsumura M, Hoshino T, Kawabata S, Sobue S, Fujiwara T. Contributions of three glycosyltransferases to sucrose-dependent adherence of Streptococcus mutans. J Dent Res. 2001;80(7):1672–7.

Janakiram C, Deepan Kumar CV, Joseph J. Xylitol in preventing dental caries: a systematic review and meta-analyses. J Nat Sci Biol Med. 2017;8(1):16–21.

Ooshima T, Izumitani A, Minami T, Yoshida T, Sobue S, Fujiwara T, et al. Noncariogenicity of maltitol in specific pathogen-free rats infected with mutans streptococci. Caries Res. 1992;26(1):33–7.

Koepsell HJ, Tsuchiya HM, Hellman NN, Kazenko A, Hoffman CA, Sharpe ES, et al. Enzymatic synthesis of dextran: acceptor specificity and chain initiation. J Biol Chem. 1953;200(2):793–801.

Newbrun E, Finzen F, Sharma M. Inhibition of adherence of Streptococcus mutans to glass surfaces. Caries Res. 1977;11(3):153–9.

Ferrazzano GF, Cantile T, Alcidi B, Coda M, Ingenito A, Zarrelli A, et al. Is Stevia rebaudiana Bertoni a non cariogenic sweetener? A review. Molecules. 2016;21(1):38.

Bujnicki JM, Rotkiewicz P, Kolinski A, Rychlewski L. Three-dimensional modeling of the I-TevI homing endonuclease catalytic domain, a GIY-YIG superfamily member, using NMR restraints and Monte Carlo dynamics. Protein Eng. 2001;14(10):717–21.

Devulapalle KS, Mooser G. Subsite specificity of the active site of glucosyltransferases from Streptococcus sobrinus. J Biol Chem. 1994;269(16):11967–71.

Abachi S, Lee S, Rupasinghe HP. Molecular mechanisms of inhibition of Streptococcus species by phytochemicals. Molecules. 2016;21(2):215.

Monchois V, Willemot RM, Monsan P. Glucansucrases: mechanism of action and structure-function relationships. FEMS Microbiol Rev. 1999;23(2):131–51.

Kaspar JR, Godwin MJ, Velsko IM, Richards VP, Burne RA. Spontaneously arising Streptococcus mutans variants with reduced susceptibility to chlorhexidine display genetic defects and diminished fitness. Antimicrob Agents Chemother. 2019;63(7):e00161–19.

Zanatta FB, Antoniazzi RP, Rosing CK. Staining and calculus formation after 0.12% chlorhexidine rinses in plaque-free and plaque covered surfaces: a randomized trial. J Appl Oral Sci. 2010;18(5):515–21.

Wolff LF. Chemotherapeutic agents in the prevention and treatment of periodontal disease. Northwest Dent. 1985;64(6):15–24.

Shekar BRC, Nagarajappa R, Suma S, Thakur R. Herbal extracts in oral health care - a review of the current scenario and its future needs. Pharmacogn Rev. 2015;9(18):87–92.

Palombo EA. Traditional medicinal plant extracts and natural products with activity against oral bacteria: potential application in the prevention and treatment of oral diseases. Evid Based Complement Alternat Med. 2011;2011:680354.

Veloz JJ, Alvear M, Salazar LA. Antimicrobial and antibiofilm activity against Streptococcus mutans of individual and mixtures of the main polyphenolic compounds found in Chilean propolis. Biomed Res Int. 2019;2019:7602343.

Zou Y, Lee Y, Huh J, Park JW. Synergistic effect of xylitol and ursolic acid combination on oral biofilms. Restor Dent Endod. 2014;39(4):288–95.

Cai JN, Kim MA, Jung JE, Pandit S, Song KY, Jeon JG. Effects of combined oleic acid and fluoride at sub-MIC levels on EPS formation and viability of Streptococcus mutans UA159 biofilms. Biofouling. 2015;31(7):555–63.

Jang E-J, Choi S-M, Cha J-D. Synergistic effects of the methanol extract of Trichosanthes kirilowii with antibiotics against oral pathogens. Dent Oral Craniofac Res. 2018;4(6):1–8.

Hasan S, Singh K, Danisuddin M, Verma PK, Khan AU. Inhibition of major virulence pathways of Streptococcus mutans by quercitrin and deoxynojirimycin: a synergistic approach of infection control. PLoS One. 2014;9(3):e91736.

Lim JH, Song SH, Park HS, Lee JR, Lee SM. Spontaneous detachment of Streptococcus mutans biofilm by synergistic effect between zwitterion and sugar alcohol. Sci Rep. 2017;7(1):8107.

Ham Y, Kim T-J. Inhibitory effect of phenolic acids in Rubus coreanus on glucosyltransferase of Streptococcus mutans. Curr Microbiol. 2020;77(11):3695–703.

Ham Y, Kim T-J. Conditions for preparing Glycyrrhiza uralensis extract for inhibiting biofilm formation of Streptococcus mutans. J Korean Wood Sci Technol. 2019;47(2):178–88.

Yang R, Yuan BC, Ma YS, Zhou S, Liu Y. The anti-inflammatory activity of licorice, a widely used Chinese herb. Pharm Biol. 2017;55(1):5–18.

Hirunpanich V, Utaipat A, Morales NP, Bunyapraphatsara N, Sato H, Herunsale A, et al. Hypocholesterolemic and antioxidant effects of aqueous extracts from the dried calyx of Hibiscus sabdariffa L. in hypercholesterolemic rats. J Ethnopharmacol. 2006;103(2):252–60.

Jung JC, Lee YH, Kim SH, Kim KJ, Kim KM, Oh S, et al. Hepatoprotective effect of licorice, the root of Glycyrrhiza uralensis Fischer, in alcohol-induced fatty liver disease. BMC Complement Altern Med. 2016;16:19.

Momeni A, Rahimian G, Kiasi A, Amiri M, Kheiri S. Effect of licorice versus bismuth on eradication of helicobacter pylori in patients with peptic ulcer disease. Pharm Res. 2014;6(4):341–4.

Agarwal A, Gupta D, Yadav G, Goyal P, Singh PK, Singh U. An evaluation of the efficacy of licorice gargle for attenuating postoperative sore throat: a prospective, randomized, single-blind study. Anesth Analg. 2009;109(1):77–81.

Choi J, Lee K-T, Ha J, Yun S-Y, Ko C-D, Jung H-J, et al. Antinociceptive and antiinflammatory effects of niga-ichigoside F1 and 23-hydroxytormentic acid obtained from Rubus coreanus. Biol Pharm Bull. 2003;26(10):1436–41.

Park JH, Oh S-M, Lim SS, Lee YS, Shin H-K, Oh Y-S, et al. Induction of heme oxygenase-1 mediates the anti-inflammatory effects of the ethanol extract of Rubus coreanus in murine macrophages. Biochem Biophys Res Commun. 2006;351(1):146–52.

Lee S-M, You Y, Kim K, Park J, Jeong C, Jhon D-Y, et al. Antioxidant activities of native Gwangyang Rubus coreanus Miq. J Korean Soc Food Sci Nutr. 2012;41(3):327–32.

Yang JW, Choi IS. Comparison of the phenolic composition and antioxidant activity of Korean black raspberry, Bokbunja, (Rubus coreanus Miquel) with those of six other berries. CyTA-J Food. 2017;15(1):110–7.

Jung J, Son MY, Jung S, Nam P, Sung JS, Lee SJ, et al. Antioxidant properties of Korean black raspberry wines and their apoptotic effects on cancer cells. J Sci Food Agric. 2009;89(6):970–7.

Hu CH, He JA, Eckert R, Wu XY, Li LN, Tian Y, et al. Development and evaluation of a safe and effective sugar-free herbal lollipop that kills cavity-causing bacteria. Int J Oral Sci. 2011;3(1):13–20.

Biswas S, Biswas I. Complete genome sequence of Streptococcus mutans GS-5, a serotype c strain. J Bacteriol. 2012;194(17):4787–8.

Ham Y, Kim T-J. Inhibitory activity of monoacylglycerols on biofilm formation in Aeromonas hydrophila, Streptococcus mutans, Xanthomonas oryzae, and Yersinia enterocolitica. SpringerPlus. 2016;5(1):1526.

Park Y-M, Kim S-J, Jo K-H, Yang E-J, Jung S-T. Anticariogenic and antioxidant activities from medicinal herbs. J Korean Soc Food Sci Nutr. 2006;35(3):284–93.

Fukushima K, Motoda R, Takada K, Ikeda T. Resolution of Streptococcus mutans glucosyltransferases into two components essential to water-insoluble glucan synthesis. FEBS Lett. 1981;128(2):213–6.

Seal T. Quantitative HPLC analysis of phenolic acids, flavonoids and ascorbic acid in four different solvent extracts of two wild edible leaves, Sonchus arvensis and Oenanthe linearis of north-eastern region in India. J Appl Pharm Sci. 2016;6(2):157–66.

Hsieh MH, Yu CM, Yu VL, Chow JW. Synergy assessed by checkerboard a critical analysis. Diagn Microbiol Infect Dis. 1993;16(4):343–9.

Chusri S, Siriyong T, Na-Phatthalung P, Voravuthikunchai SP. Synergistic effects of ethnomedicinal plants of Apocynaceae family and antibiotics against clinical isolates of Acinetobacter baumannii. Asian Pac J Trop Med. 2014;7(6):456–61.

Goyal D, Sharma S, Mahmood A. Inhibition of dextransucrase activity in Streptococcus mutans by plant phenolics. Indian J Biochem Biophys. 2013;50(1):48–53.

Razak FA, Baharuddin BA, Akbar EFM, Norizan AH, Ibrahim NF, Musa MY. Alternative sweeteners influence the biomass of oral biofilm. Arch Oral Biol. 2017;80:180–4.

Fontaine BM, Nelson K, Lyles JT, Jariwala PB, García-Rodriguez JM, Quave CL, et al. Identification of ellagic acid rhamnoside as a bioactive component of a complex botanical extract with anti-biofilm activity. Front Microbiol. 2017;8:496.

Dutreix L, Bernard C, Juin C, Imbert C, Girardot M. Do raspberry extracts and fractions have antifungal or anti-adherent potential against Candida spp.? Int J Antimicrob Agents. 2018;52(6):947–53.

Priha O, Virkajärvi V, Juvonen R, Puupponen-Pimiä R, Nohynek L, Alakurtti S, et al. Quorum sensing signalling and biofilm formation of brewery-derived bacteria, and inhibition of signalling by natural compounds. Curr Microbiol. 2014;69(5):617–27.

Hancock V, Dahl M, Vejborg RM, Klemm P. Dietary plant components ellagic acid and tannic acid inhibit Escherichia coli biofilm formation. J Med Microbiol. 2010;59(4):496–8.

Quave CL, Estévez-Carmona M, Compadre CM, Hobby G, Hendrickson H, Beenken KE, et al. Ellagic acid derivatives from Rubus ulmifolius inhibit Staphylococcus aureus biofilm formation and improve response to antibiotics. PLoS One. 2012;7(1):e28737.

Sivasankar C, Maruthupandiyan S, Balamurugan K, James PB, Krishnan V, Pandian SK. A combination of ellagic acid and tetracycline inhibits biofilm formation and the associated virulence of Propionibacterium acnes in vitro and in vivo. Biofouling. 2016;32(4):397–410.

Sawamura S, Tonosaki Y, Hamada S. Inhibitory effects of ellagic acid on glucosyltransferases from mutans streptococci. Biosci Biotechnol Biochem. 1992;56(5):766–8.

Kuspradini H, Mitsunaga T, Mihara R, Ohashi H. Investigating glucosyltransferase inhibitory activities of polyphenols from kapur (Dryobalanops sp.) heartwood extracts. J Nat Med. 2007;61(4):462–7.

Loo WT, Jin L, Cheung MN, Chow LW. Evaluation of ellagic acid on the activities of oral bacteria with the use of adenosine triphosphate (ATP) bioluminescence assay. Afr J Biotechnol. 2010;9(25):3938–45.

Sela MN, Steinberg D, Segal R. Inhibition of the activity of glucosyltransferase from Streptococcus mutans by glycyrrhizin. Oral Microbiol Immunol. 1987;2(3):125–8.

Kim HJ, Bae JY, Jang HN, Park SN. Comparative study on the antimicrobial activity of Glycyrrhiza uralensis and Glycyrrhiza glabra extracts with various countries of origin as natural antiseptics. Microbiol Biotechnol Lett. 2013;41(3):358–66.

Kim HJ, Jang HN, Bae JY, Ha JH, Park SN. Antimicrobial activity, quantification and bactericidal activities of licorice active ingredients. Microbiol Biotechnol Lett. 2014;42(4):386–92.

Kim HK, Yk P, Kim HN, Choi BH, Jeong HG, Lee DG, et al. Antimicrobial mechanism of β-glycyrrhetinic acid isolated from licorice, Glycyrrhiza glabra. Biotechnol Lett. 2002;24:1899–902.

Dewake N, Ma X, Sato K, Nakatsu S, Yoshimura K, Eshita Y, et al. β-Glycyrrhetinic acid inhibits the bacterial growth and biofilm formation by supragingival plaque commensals. Microbiol Immunol. 2021;65(9):343–51.

Matsumoto M, Hamada S, Ooshima T. Molecular analysis of the inhibitory effects of oolong tea polyphenols on glucan-binding domain of recombinant glucosyltransferases from Streptococcus mutans MT8148. FEMS Microbiol Lett. 2003;228(1):73–80.

Murata RM, Almeida LSB, Yatsuda R, Santos MHD, Nagem TJ, Rosalen PL, et al. Inhibitory effects of 7-epiclusianone on glucan synthesis, acidogenicity and biofilm formation by Streptococcus mutans. FEMS Microbiol Lett. 2008;282(2):174–81.

Acknowledgements

Not applicable.

Funding

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (no. 2021R1F1A1061888).

Author information

Authors and Affiliations

Contributions

YH and TJK conceptualized the study. YH designed the experiments. YH performed the experiments. YH and TJK analyzed the data. YH wrote the first draft of the manuscript. TJK was the major contributor to writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All methods were performed in accordance with the relevant guidelines and regulations.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Supplementary Fig. 1.

Effect of Glycyrrhizae Radix extract at 2.5 g/L on GTase activity of S. mutans.

Additional file 2: Supplementary Table 1.

Synergistic inhibitory activity of extract combination, Glycyrrhizae Radix extract and Rubi Fructus extract, against the biofilm formation of S. mutans with checkerboard assay. This table shows the results for all tested concentration combination of Glycyrrhizae Radix extract and Rubi Fructus extract. After quantitatively analyzing the amount of biofilm with crystal violet, the relative value was calculated by comparing it with the control value. The control value was the amount of biofilm produced without any treatment. The values were calculated from three independent experiments. The shaded cell is a concentration condition that synergistically inhibited biofilm formation. Supplementary Table 2. Synergistic inhibitory activity of compound combination, glycyrrhizin and ellagic acid, against the biofilm formation of S. mutans with checkerboard assay. This table shows the results for all tested concentration combination of glycyrrhizin and ellagic acid. After quantitatively analyzing the amount of biofilm with crystal violet, the relative value was calculated by comparing it with the control value. The control value was the amount of biofilm produced without any treatment. The values were calculated from three independent experiments. Shaded cells are concentration conditions that synergistically inhibited biofilm formation.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Ham, Y., Kim, TJ. Synergistic inhibitory activity of Glycyrrhizae Radix and Rubi Fructus extracts on biofilm formation of Streptococcus mutans. BMC Complement Med Ther 23, 22 (2023). https://doi.org/10.1186/s12906-023-03861-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12906-023-03861-9