Abstract

Background

The aim of the present study is to increase the solubility of dihydroartemisinin (DHA) using the self-emulsifying drug delivery system (SEDDS).

Methods

We first conducted solubility test and ternary phase diagram, then, in order to optimize the formulation of the DHA self-emulsifying agent, the design mixture method was selected in the design expert software. Next, optimal prescription validation and preliminary formulation evaluation were conducted. By comparing the oil–water partition coefficient in vitro, the improvement of the in vivo osmotic absorption of DHA via self-emulsification was evaluated.

Results

The optimal prescription ratio of oleic acid polyethylene glycol glyceride, polyoxyethylene hydrogenated castor oil, and diethylene glycol monoethyl ether in the DHA self-emulsifying preparation = 0.511:0.2:0.289 (w/w/w), with a drug-loading capacity of 26.3634 mg/g, solubility of 2.5448 mg/ml, and self-emulsification time of 230 s. The solubility self-emulsification was approximately 20.52 × higher in DHA than in the crude drug. The self-emulsification could improve DHA permeability and promoting in vivo DHA absorption.

Conclusion

The DHA SEDDS could significantly improve DHA solubility and in vivo absorption.

Similar content being viewed by others

Background

A significant percentage (up to 70%) of chemical substances considered in drug development has poor aqueous solubility problem that will affect gastrointestinal absorption. A renowned alternative approach for delivery of the low water-soluble drug is by formulating as a lipid formulation particularly the self emulsifying drug delivery systems (SEDDS) which deal with low aqueous solubility and poor oral bioavailability [1]. A renowned alternative approach for delivery of the low water-soluble drug is by formulating as a lipid formulation particularly the selfemulsifying drug delivery systems (SEDDS) which deal with low aqueous solubility and poor oral bioavailability [1].

Surfactant, oil-phase, and drug-isotropic mixtures are self-emulsifying drug delivery systems (SEDDS). When they encounter a water-soluble medium, oil-in-water emulsion droplets can be rapidly formed by mild agitation or digestive movement under gastrointestinal conditions [2]. Self-emulsifying drug drops can be divided into two types according to their size: (1) the self-microemulsifying drug delivery system and (2) the self-nanoemulsifying drug delivery system.

There are many advantages to the use of SEDDS, including physical stability, a simple manufacturing process, and oral application via soft or hard gelatin capsules underline the intensive research conducted within the last decades [3,4,5,6].

DHA is soluble in acetone, slightly soluble in methanol or ethanol, and almost insoluble in water. The solubility in water was determined to be 0.124 mg/ mL after shaking for 24 h in a 37 ℃ constant temperature oscillating chamber. Dihydroartemisinin (DHA) is obtained from the reduction of artemisinin using sodium tetrahydroborate. Its structure is characterized by a unique peroxide bridge; this has various advantages (e.g., high potency, micro-toxicity, rapid excretion, metabolism, and absorption by the human body, and wide distribution). In addition, the antimalarial effect of DHA is 4 − 8 × greater than that of artemisinin [7]. However, the solubility of DHA in water is relatively low; thus, the present study aims to improve DHA solubility through self-emulsifying formulation.

Material and methods

Reagents, and drugs

The DHA reference substance (National Institutes for Food and Drug Control, Batch number: 100184–201403); oleic acid polyethylene glycol glyceride (Oleoyl Macrogolglycerides, batch number: M01GS147525, Yuanye Bio-Technology Co. Ltd); polyoxyethylene hydrogenated castor oil (Cremophor RH40, Batch number: Y23M10S83793, Shanghai Yuanye Bio-Technology Co. Ltd); Transcutol P (Batch number: 177546, Tianrun Pharmaceutical Co.); and DHA bulk pharmaceutical chemicals (Chongqing Wulingshan KPC Pharmaceuticals Inc, batch number: C00220181001, content 95%). The methanol was chromatographically pure, and the other items were analytically pure.

Methods

Determination method for DHA content

Chromatographic conditions: Target C18(2) (250 × 4.6 mm, 5 mm), mobile phase: acetonitrile–phosphate buffer solution (1.36 G of monopotassium phosphate was injected, dissolved in 900 ml of water, and pH was adjusted to 3.0 using phosphoric acid. The final volume was obtained and injected with 1000 mL of water) (44:56). Detection: (1) Wavelength: 216 nm; (2) flow rate: 1 mL/min; (3) column temperature: 35 °C; and (4) injection volume: 10 μL.

Reference solution preparation: An appropriate amount of DHA reference control was weighed and dissolved in acetonitrile, and the solution was shaken well.

Test solution preparation: A volume of 0.08 ± 0.01 g of the DHA self-emulsifying preparation was weighed precisely and placed in a 5 mL measuring bottle. Next, the preparation was dissolved in acetonitrile and diluted to the scale. The solution was shaken for further detection using SK-1 quick mixer (Jintan East City Xinrui Instrument Factory).

Blank solution preparation: A volume of 0.08 ± 0.01 g of blank self-emulsifying preparation without DHA was weighed precisely and placed in a 5 mL measuring bottle. Next, the preparation was dissolved in acetonitrile, diluted to the scale, and shaken well.

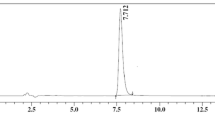

Method specificity inspection: The blank solution, DHA control solution, and test solution, respectively, were taken and determined according to the above chromatographic conditions (Fig. 1). As demonstrated in Fig. 1, the ingredients did not interfere in the detection of DHA.

Determination of linear correlation: The DHA control solution was used to prepare a series of control solutions for the peak area measurement and recording. Linear regression x coordinates (x) were used as the mass concentration (μg/ml), and y coordinates (y) were used as the peak area. The standard curve equation was y = 255.65 x − 1453.9 (r = 0.99999). The results showed that the DHA concentration had a good linear correlation with the peak area within a range of 150.46 ~ 3009.2 μg/mL.

Precision test: The stability, repeatability, and sample recovery of the reference samples were simultaneously tested, and the solution and test solution, respectively, were conducted within 24 h. All parameters met the study requirements, indicating that the method was accurate. Both the reference solution and the test solution became stable within 24 h.

Preparation of the self-emulsifying DHA formulation

Screening of the blank self-emulsification prescription

Determination of DHA solubility in various ingredients

Approximately 2 mL of different oil phases, surfactants, and co-surfactants, respectively, was taken and placed into plug test tubes. Excessive amounts of the crude DHA drug were added and vortexed; the tubes were shaken at 37 °C on a constant temperature oscillation (HZ-881S desktop water bath thermostatic oscillator (Jiangsu Taicang Experimental Equipment Factory)) box for 24 h and centrifuged at 10,000r/min for 10 min (Dongfeng-101 s constant temperature heating collector magnetic stirring instrument (Zhengzhou Greatwall Scientific Industrial and Trade Co, Ltd), RC806 dissolution experimental instrument (Tianjin Tianda Tianfa Technology Co., Ltd)). The required test solution was prepared in accordance with the prescribed procedure.

Ternary phase diagram construction

In the present study, the screening range of each phase in the self-emulsification prescription was limited as follows: (1) the oil phase: 20%–80%; (2) the surfactant phase: 20–80%; and (3) the co-surfactant phase: 0%–30%. Based on the above composition ranges, different proportions of oil phases, surfactants, and co-surfactants were weighed and mixed using a vortex.

The mixtures were then kept at room temperature for 24 h; the occurrence of stratification was observed, and the proportion with stratification was discarded. The emulsifying process was observed and recorded after injecting 100 ML of water into a 0.5 ml non-layered prescription at (37 ± 2) °C during magnetic stirring. With the surfactants, co-surfactants, and oil phases as one side, the proportion that could form clear and transparent oil droplets without floating was determined as the effective self-emulsification region in the phase diagram, and the ternary phase diagram was constructed.

Prescription optimization using the mixture-optimal (custom) design

Based on the ternary phase diagram, the Mixture-Optimal (Custom) design created using Design Expert 11 was adopted for composition optimization. According to the scope of the investigation, the oleic acid polyethylene glycol glyceride (CS, A) range was set at 20–80%, the polyoxyethylene hydrogenated castor oil (EL, B) range was set at 20–80%, and the diethylene glycol monoethyl ether (YP, C) range was set at 0–30%. DHA SEDDS particle size was measured by laser particle size analyzer, DHA SEDDS about 0.2 g, add water to 5 mL, shake well, determination.

Determination of the apparent oil–water partition coefficient

The shaking flask method was used for determination [8, 9]. A proper amount of DHA was dissolved in water-saturated N-octanol, the 1.2 pH hydrochloric acid solution, and the 4.5, 6.8, and 7.4 pH phosphate buffers, respectively.

Thus, a series of drug-saturated N-octanol solutions were prepared. A volume of 1.0 mL of each of the above solutions was measured precisely and put into 5 plug test tubes; next, 4 mL of water and the corresponding N-octanol-saturated pH buffer were successively added. After vortexing for 5 min and shaking at (37 ± 2) °C on a constant temperature oscillation box for 24 h, the tubes were taken out and kept standing still for 30 min. After this, the two phases were separated by 10,000 r/min centrifugation for 10 min. The water intake layer and the alcohol layer were checked. The concentration of DHA and the logPapp were calculated. The calculation formula was as follows:

In the above equation, Papp was the apparent oil–water partition coefficient; C0 was the initial concentration of the drug in N-octanol; and Ct was the concentration measured in the oil phase at the equilibrium partition of the drug.

Results

-

1.

Determination of DHA solubility in various ingredients

The solubility of DHA in different components was determined and shown in Table 1.

-

2.

Ternary phase diagram construction

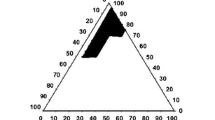

The composition of self-emulsification was as follows: oleic acid polyethylene glycol glyceride (CS)—polyoxyethylene hydrogenated castor oil (EL)—diethylene glycol monoethyl ether (TP). The ternary phase diagram is shown in Fig. 2; the black dots represent the test points, and the area inside the black line represents the effective self-emulsification area. The results showed that emulsification could be achieved within the range of investigation.

-

3.

Prescription optimization using the Mixture-Optimal (Custom) design

The DHA drug load, self-emulsification time, and emulsification time were taken as indicators in the design. The design, experimental factors, and results are shown in Tables 2 and 3. Oleic acid polyethylene glycol glyceride, polyoxyethylene hydrogenated castor oil, and diethylene glycol monoethyl ether were weighed according to the central composite design table. Excessive crude DHA drug was added for mixing and vortexing, and the drug loading was determined. A volume of 200 μL of each test site’s samples was taken and placed into 2 ml of water. Excessive crude DHA drug was added and shaken at 37 °C on a constant temperature oscillation box for 24 h. The mixture was then filtered, and the solubility was measured. At the same time, the 0.2 ml emulsion containing the drug was added to 200 ML of water at a temperature of 37 °C, and the dissolution was determined using the dissolution apparatus. Self-emulsification was achieved by stirring slightly at a rotating speed of 50 r/min with the paddle method, and the emulsification time was recorded with a stopwatch using the visual method.

Model fitting: The Design Expert 11 software was adopted for data model fitting. The fitting model regression equations were as follows: (1) drug loading = 19.22093 A + 17.80913 B + 46.64294 C; (2) solubility = 1.39553 A + 0.61703 B − 7.86810 C + 3.67178 A*B + 17.34126.

A*C + 14.44074 B*C; and (3) time = − 798.47284 A − 801.88714 B + 79.06520 C + 5613.82544 A*B + 1626.57588 A*C − 956.46250 B*C. The fittings of each indicator are illustrated in Table 4.

-

4.

The contour map (Fig. 3) and effect surface 3D diagram (Fig. 4) concerning the three evaluation indicators and the influences of the three kinds of ingredients were obtained from the Mixture-Optimal (Custom) design.

-

5.

Prediction, validation, and preliminary evaluation of the optimal prescription

(1) Prediction and validation of the optimal prescription: In the present study, the prescription composition of the self-emulsification DHA preparation was optimized with a large drug load, maximum solubility, and shortest self-emulsification time.

The predicted optimal prescription ratio was as follows: oleic acid polyethylene glycol glyceride to polyoxyethylene hydrogenated castor oil to diethylene glycol monoethyl ether = 0.511:0.2:0.289 (w/w/w). Predicted drug load = 26.8507 mg/g; solubility = 2.33503 mg/ml; and self-emulsification time = 213.148 s.

The self-emulsifying prescription was prepared with the predicted optimal formula ratio, and the drug load, solubility, and self-emulsification time were determined. The absolute deviation of each indicator was < 10%; this confirmed the good prediction of the mathematical model. The results are demonstrated in Table 5.

-

6.

Other quality evaluations: (1) Appearance: The DHA blank control and the SEDDS containing the drug appeared transparent, with the ingredients slightly yellow in color, and were in the form of oil; (2) physical stability: the DHA SEDDS was centrifuged at 4,000 r·min−1 for 15 min, and no stratification was observed, indicating good physical stability; and (3) particle diameter: the DHA SEEDS was diluted 25 × with water. According to the experimental results, the average particle size of the emulsifier = 136.3 nm. The average Zeta potential of the optimal prescription was -4.13 mV.

-

7.

Results of the oil–water partition coefficient

The influence of prescription composition on each indicator. A Three-dimensional effect diagram of the influence of prescription composition on drug loading. B Three-dimensional effect diagram of the influence of prescription composition on solubility. C Three-dimensional effect diagram of the influence of prescription composition on emulsification time

Theoretically, the logPapp value reflects the lipophilicity and hydrophilia of the drug: the larger the logPapp value, the higher the lipophilicity, the lower the logPapp value, the higher the hydrophilia, and the smaller the hydrophilic. When logPapp < 0, drug absorption in the gastrointestinal tract is very difficult. When 0 < logPapp < 3, drugs can be absorbed by the gastrointestinal tract. When logPapp > 3, drugs have strong lipid solubility and are not conducive to gastrointestinal absorption [10, 11].

As illustrated in Table 6, the logPapp of the crude DHA drug = 0–3 when water was adopted as the medium. The logPapp values of the crude drug were all < 0 when other pH buffers were adopted as the medium. In the solutions with different pH adopted as the medium, the logPapp of the DHA self-emulsifying preparation = 0–3, indicating that the DHA self-emulsifying preparations were more absorbable by the body than the crude drugs.

Discussion

In the preparation of self-emulsifying DHA formulations, the self-emulsifying combinations were conducted according to the solubility of DHA in each phase. The following combinations were investigated: glyceryl mono-oil-Tween 20-glycerol; ethyl oleate, castor oil polyoxyethylene ether, and diethylene glycol ethyl ether; soybean oil, polyethylene glycol monooleate, and isopropanol; oleic acid ethyl ester-Span 85-isopropanol; castor oil-Tween 80-diethylene glycol ethyl ether; ethyl oleate, glyceryl triacetate, and isopropanol; ethyl oleate, isopropyl myristate, and diethylene glycol ethyl ether; medium-chain triglyceride-castor oil polyoxyethylene ether-isopropanol; soybean oil, Tween 40, and glycerin; medium-chain triglyceride-glyceryl triacetate-diethylene glycol ethyl ether; glycerol monooleate-Tween 20-diethylene glycol ethyl ether; ethyl oleate-castor oil polyoxyethylene ether-glycerin; ethyl oleate-Tween 80-diethylene glycol ethyl ether; medium-chain triglycerides-Tween 80-polyethylene glycol 400; medium-chain triglyceride-Tween 40-diethylene glycol ethyl ether; isopropyl myristate-Tween 40-diethylene glycol ethyl ether; ethyl oleate-Tween 40-diethylene glycol ethyl ether; and polyethylene glycol glyceryl oleate-polyoxyethylene hydrogenated castor oil-diethylene glycol monoethyl ether.

However, as the ternary phase diagram in the three phases failed to achieve the formation of emulsification, or the area of the emulsion was too small, ingredients with non-maximum solubility were selected in the investigation. In vivo pharmacokinetic studies, it was found that DHA would be metabolized after entering the body, and artemisinin and artesunate components could be detected simultaneously. The metabolism of DHA in vivo needs further study.

DHA has two peaks in high-performance liquid chromatography; the sum of the two peak areas was adopted to calculate the content [12]. In the follow-up study, investigation of the two peaks’ transformation patterns should be continued in order to provide a basis for further study.

Conclusions

The optimized dosage of DHA SEDDS was 26.3634 mg/g, the solubility was 2.5448 mg/ mL, the self-emulsification time was 230 s, the average particle size was 136.3 nm, and the average Zeta potential was -4.13 mV. Self-emulsification increased the solubility of dihydroartemisinin by about 20.52 times compared with the bulk drug, and the apparent oil–water partition coefficient predicted that SEDDS could improve the absorption of DHA in vivo.

Availability of data and materials

The datasets generated and/or analyzed during the current study are not publicly available due to the authors’ decision but are available from the corresponding author on reasonable request.

Abbreviations

- SEDDS:

-

Self-emulsifying drug delivery systems

- DHA:

-

Dihydroartemisinin

References

Almeida SRD, Tippavajhala VK. A rundown through various methods used in the formulation of solid self-emulsifying drug delivery systems (S-SEDDS). AAPS PharmSciTech. 2019;20(8):323.

Gursoy RN, Benita S. Self-emulsifying drug delivery systems (SEDDS) for improved oral delivery of lipophilic drugs. Biomed Pharmacother. 2004;58:173–82.

Kohli K, Chopra S, Dhar D, et al. Self-emulsifying drug delivery systems: an approach to enhance oral bioavailability. Drug Dis Today. 2010;15(2I–22):958–65.

Gupta S, Kesarla R, Omri A. Formulation strategies to improve the bioavailability of poorly absorbed drugs with special emphasis on self-emulsifying systems. ISRN Pharm. 2013;2013:848043.

Komesli Y, Burak Ozkaya A, Ugur Ergur B, et al. Design and development of a self-microemulsifying drug delivery system of olmesartan medoxomil for enhanced bioavail ability. Drug Dev Ind Pharm. 2019;45(8):1292–305.

Yeom DW, Chae BR, Son HY, et al. Enhanced oral bioavailability of valsartan using a polymer based super saturable self microemulsifying drug delivery system. Int J Nanomed. 2017;12:3533–45.

Xie X, Min Y, Liu L, et al. Progress in the study of antitumor mechanism of dihydroartemisinin. J Jilin Med Coll. 2020;41(2):136–8.

Bao QY, Liu AY, Ma Y, et al. The effect of oil-water partition coefficient on the distribution and cellular uptake of liposome-encapsulated gold nanoparticles. Coll Surf B Biointerfaces. 2016;146:475–81.

Lin J, Zou L, Fu C, et al. Determination of oil-water distribution coefficient of salidroside and tyrosol and absorption kinetics of small intestine in rats. Propr Chin Med. 2013;01:483–6.

Nishida N, Taniyama K, Sawabe T, et al. Development and evaluation of amonolithic drug -in-adhesive patch for valsartan [J]. Int J Phann. 2010;402:103–9.

Sun J. Oral drug absorption and transport [M]. 1st Ed. Beijing: People's Health Report, 2006:322–323.

National Pharmacopoeia Commission. Pharmacopoeia of the People's Republic of China (part two, 2020 edition). Beijing. China Medical Science and Technology Press, 2020:106.

Acknowledgements

We would like to acknowledge the hard and dedicated work of all the staff that implemented the intervention and evaluation components of the study.

Funding

This study was supported by the National Major New Drug Creation Major Science and Technology Projects (2017ZX09101002-002-004), Talent Project of Chongqing Academy of Chinese Materia medica(cqac20190004) and Science and technology project of Chongqing Science and Technology Commission(cstc2019jxjl-jbky10002). The funding body had no role in the design of the study and collection, analysis, and interpretation of data and in writing the manuscript.

Author information

Authors and Affiliations

Contributions

WH and CJ conceived the idea and conceptualized the study. YY, GS and WZ collected the data and analyzed the data. LY, ZX and HL drafted the manuscript, then GY and YY reviewed the manuscript. All authors read and approved the final draft.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Wang, Y., Chen, J., Yang, Y. et al. Oil–water partition coefficient preparation and detection in the dihydroartemisinin self-emulsifying drug delivery system. BMC Biotechnol 22, 16 (2022). https://doi.org/10.1186/s12896-022-00746-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12896-022-00746-6