Abstract

Background

The environmental impact of electric scooters has been the subject of critical debate in the scientific community for the past 5 years. The data published so far are very inhomogeneous and partly methodologically incomplete. Most of the data available in the literature suffer from an average bias of 34%, because end-of-life (EOL) impacts have not been modelled, reported or specified. In addition, the average lifetime mileage of shared fleets of e-scooters, as they are operated in cities around the world, has recently turned out to be much lower than expected. This casts the scooters in an unfavourable light for the necessary mobility transition. Data on impact categories other than the global warming potential (GWP) are scarce. This paper aims to quantify the strengths and weaknesses of e-scooters in terms of their contribution to sustainable transport by more specifically defining and extending the life cycle assessment (LCA) modelling conditions: the modelling is based on two genuine material inventories obtained by dismantling two different e-scooters, one based on a traditional aluminium frame and another, for the first time, based on plastic material.

Results

This study provides complete inventory data to facilitate further LCA modelling of electric kick scooters. The plastic scooter had a 26% lower lifetime GWP than the aluminium vehicle. A favourable choice of electric motor promises a further reduction in GWP. In addition to GWP, the scooter's life cycles were assessed across seven other impact categories and showed no critical environmental or health impacts compared to a passenger car. On the other hand, only the resource extraction impact revealed clear advantages for electric scooters compared to passenger cars.

Conclusions

Under certain conditions, scooters can still be an important element of the desired mobility transition. To assure a lifetime long enough is the crucial factor to make the electric scooter a favourable or even competitive vehicle in a future sustainable mobility system. A scooter mileage of more than 5400 km is required to achieve lower CO2eq/pkm emissions compared to passenger cars, which seems unlikely in today's standard use case of shared scooter fleets. In contrast, a widespread use of e-scooters as a commuting tool is modelled to be able to save 4% of greenhouse gas (GHG) emissions across the German mobility sector.

Similar content being viewed by others

Introduction

The European Union has declared a "New Deal" to achieve zero carbon emissions by 2050, which explicitly includes the mobility sector [1]. Reaching zero emissions will require enormous efforts. The mobility sector represents the biggest challenge on the road to zero emissions, or the risk of failure, as it is the only sector in Europe that has so far refused to reduce carbon emissions [2].

Micro-mobility is emerging in this situation as a hope to accompany urban mobility into a period of increased sustainability by reducing urban problems such as congestion, lack of space in traffic areas and emissions [3] through the provision of downsized vehicles. SAE [4] defines powered micro-mobility vehicles as (a) fully or partially powered by an engine, (b) with a curb weight ≤ 500 lb (227 kg), and (c) with a top speed ≤ 30 mph (48 km/h).

This research focuses on electric scooters as an important vehicle in the reign of micro-mobility. However, the term "scooter" is not specific. In an extended classification scheme for micro-mobility vehicles that we have developed, scooters can be found under types 1a, 1b and 3 (Table 1).

This paper focuses on electric vehicles with handlebars, specifically those that are started by kicking/pushing with the foot (hereafter referred to as "e-scooters"), which are included in Group 1b of Table 1. In Switzerland, which provides the main boundary conditions for the LCA modelling, e-scooters are called "Trottinett" (electric and abbreviated: eTrotti).

There is a risk of confounding data from literature sources that do not specifically describe the type of scooter being studied. For example, Chang et al. [6] and Nayak et al. [7] discuss the technological advancement and emissions of 'e-scooters', but this refers to traditional 'step-through scooters' with a seat (vehicle type No. 3, Table 1). New electrified bike-like tricycles (vehicle type 2b, Table 1) have also been modelled for their life cycle emissions (e.g., [8]). However, kick scooters can also have three wheels. The variety of vehicles available today is enormous. Vehicles can change type category (Table 1) due to minor technical variations, also related to different local legislation: for example, a software change can turn a kick-scooter into a step-through scooter (vehicle type 3). Some heavier kick-scooters can easily be fitted with a seat (thus converting them to type 3, Table 1).

In large cities with more than 200,000 inhabitants in Northern America, there were up to 2000 e-scooters in operation per year between 2018 and 2020 according to Badia and Jenelius [9]. The European fleets appear to be larger. Li et al. [10] quantified the fleet sizes in 30 European cities in 2021: on average, there are 4254 scooters per city. Berlin tops the list with 22,948 e-scooters [10]. Extrapolating the number of electric scooters for Europe's 300 largest conurbations [11] gives a figure of over one million. These figures are based entirely on research into shared fleet scooters and not on private scooter use.

Electric scooters as a vision for sustainable transport

Qualitatively, micro-mobility has been associated with a range of positive and negative implications [12]. Kick e-scooters are smartly designed vehicles, because they are light and need little space when driving. In this context, promoting micro-mobility makes sense fundamentally, which is why push and pull strategies need to be developed to increase the uptake of small electric vehicles [13]. E-scooters are seen as vehicles that meet the "last mile" mobility demand [14]. The distances travelled by shared e-scooters are short, averaging 1.81 km, while 13.1 min are spent with a speed of 8.31 km/h, on average [9].

Many studies have attempted to identify possible mode shifts through e-scooter applications such as scooter sharing. However, the reports are inconclusive and show high variability in user behaviour (reviewed in [15, 16]). Nevertheless, likely scenarios for e-scooter uptake have been suggested. For example, Gebhardt et al. [17] found that 13% of daily car trips, or 2% of car kilometres in Germany, are suitable for substitution.

E-scooters are very light (on average only 20 kg without the rider), which makes them easy to transport and results in high energy efficiency in the use phase—energy consumption of electric vehicles depends mainly on the vehicle weight in all vehicle classes [5]. At 1.46 ± 0.42 kWh/100 km, electric stand-up and kick scooters consume 92% less energy in the use phase than electric cars [5]. Therefore, if e-scooters can replace cars on the "last mile", high energy savings can be realised. However, of the 10,487 e-scooter users surveyed in three French and two US cities, only 18% would have used a car instead of an e-scooter for their trip, while the others would have used further environmentally friendly modes of transport if e-scooters had not been available (reviewed in [18]).

Problems associated with shared scooter fleets

In many cities, however, discarded e-scooters block pedestrian routes and are often sabotaged and thrown into rivers, for example. In the city of Zurich, with a population of around 435,000 in 2020, 137 e-scooters were found in the river Limmat in 2020, after another 37 e-scooters were removed from the Limmat in 2019, when sharing platforms started offering their first e-scooters in Zurich [19]. With 2350 e-scooters in Zurich in 2020, around 7% were destroyed by being disposed of in the city's river in this way [20]. A further analysis of comparable figures published in the press showed that in the German city of Cologne (1.1 million inhabitants), around 900 e-scooters were found in or removed from rivers and ponds in 2020 and 2021 alone [21], which means that around 14% of the 6472 e-scooters ([10], figure for 2021) in Cologne were destroyed in this way, in addition to an unknown number of defective e-scooters that were disposed of elsewhere in both of the above cities.

Provoking deterioration, as for example, fleet operators often do not remove e-scooters from the streets during the night, even in winter nights with freezing temperatures.

E-scooters also come with elevated safety risks followed by partly heavy injures among scooter or other road users [22, 23]. Felipe-Falgas et al. [24] studied the environmental impact of shared e-bikes, e-scooters and e-mopeds in Barcelona. The results were very heterogeneous: some vehicles increased greenhouse gas (GHG) and particulate matter (PM) emissions, while others reduced them. All reduced NOx emissions compared to passenger car use [25]. Felipe-Falgas et al. [25] also suggested that the eco-design of micro-mobility vehicles needs to be improved and that they need to be strategically used and deployed as part of a holistic transport policy.

Comparative life cycle global warming potential (GWP) of electric scooters

In contrast to electric passenger cars [26], the GWP of electricity has a comparatively small influence on the total life cycle GWP of e-scooters (in the following referred to as life cycle GWP), according to Moreau et al. [27]. Severengiz et al. [28], on the other hand, reported a clear advantage for the life cycle GWP when the scooters are charged with electricity from wind power instead of the average German net electricity mix. The collection and distribution of scooters by fleet operators (e.g., with diesel vans or cargo bikes) has been attributed with varying impacts on lifetime GWP [29, 30].

However, given the low energy consumption in the use phase, the question arises whether e-scooters are still superior when considering the impacts over the whole life cycle. Specific to electrified vehicles, significant parts of life cycle impacts may belong to the supply chain, such as battery production [26].

Reported life cycle GWP of e-scooters so far shows large variations within the studies published (Fig. 1). This is most of all due to different assumptions when it comes to the lifespan of these vehicles. Whereas mostly temporal lifespans of scooters in terms of months and years are communicated, the LCA analysis behind is based on lifetime mileage assumptions as the vehicles are aging mainly by mileage. Accordingly, the mileages underlying the modelling of the respective literature sources are displayed here in addition (Fig. 1). Fleet operators do not report mileages, making it impossible this way to compare their data. Overall, however, they appear to be similar to the scientific results published up to 2022 (Fig. 1). Operational mileages have a huge influence on the GWP in terms of per g CO2eq/pkm: extending the base case of 284 days of use (equivalent to 1400 km), as specified by Moreau et al. [23], to 2.5 years (equivalent to 11,520 km) would decrease the GWP from 131 to below 50 g CO2eq/pkm (Fig. 1). Severengiz et al. [30, 31] also pointed to a strong influence of lifespan, quantifying impacts for a “6–24 months” use, translated into a kilometre lifespan of 1150–5150 (Fig. 1). Based on even more extended assumptions, only 40 g CO2eq/pkm would result from a lifespan of 5 years but, respectively, 829 g CO2eq/pkm in case the scooter is discarded after already 1 month, due to Moreau et al. [27]. However, these authors did not know statistically, how long a scooter survives in a fleet.

Compilation of life cycle GWP of e-scooters and further passenger traffic modes in g CO2eq per passenger kilometre (pkm) (in red: lifetime mileages of the e-scooters modelled in the respective study). EOL: end-of-life treatment. Electric bicycle data compiled from Weiss et al. [32], Mellino et al. [33], Moreau et al. [27], and Huang et al. [34]. Electric bus data from Helmers et al. [35]. Combustion engine car, lower estimate: mini-size car, higher estimate: mid-size car. Cars modelled with 1.57 persons/car, end-of-life (EOL) modelling based on avoided burden approach [35]. The lower estimates for an electric passenger car are based on a mini-class BEV (battery electric vehicle) operating a 14-kWh battery plus a secondary battery use. The higher estimates for electric passenger cars are based on a mid-range car (52 kWh battery), and without a secondary battery use. All electric cars are charged with reasonable green electricity mix during the use phase (130.6 g CO2eq/kWh, [35]). Conventional city bus data reviewed in Helmers et al. [35]. E-scooter fleet operator’s data from VOI (35 g CO2eq/pkm, [36]), BIRD (97 g CO2eq/pkm, [37]), and LIME, respectively: 165 g CO2eq/pkm [38], but related mileages were not reported (light blue column). Dotted red lines: extrapolation of the modelling of this study to the mileages reported by Reis et al. [39]. Dashed column at the bottom: extrapolation of modelling results from Reis et al. [39] to the mileage assumptions from previous studies

The problem is that a prolonged use about 1–2 years would require a high level of repair activity: economically, it seems rather unlikely that fleet operators invest a lot of efforts in repairs: when ordering thousands of items from e-scooter manufacturers, fleet operators receive a scooter for about 50% of the typical consumer prices between €200 and €1000 (according to an overview on Amazon Germany in December 2023). On top of that, while a private owner receives a 24-month warranty, this is excluded in rental applications. Almost any repair could exceed the replacement cost of 100–500 € for the fleet operator. All this points to (much) shorter periods of use in reality than the up to 24 months (corresponding to 10,000 km of mileage) suggested in reports published between 2019 and 2022 (Fig. 1).

More recently published LCA data can partly be understood as a variation of the above modelling conditions: for example, Ishaq et al. [40] applied the material inventory of Hollingsworth et al. [29] but increased the e-scooter mileage by 1.5 times and, unlike Hollingsworth et al. [29], consider up to "50% use of the recycled aluminium". As would be expected, this significantly reduces the life cycle GWP of the e-scooter from 88 g CO2eq/pkm [29] to 21 g CO2eq/pkm [40]. Extending the lifetime of an e-scooter also depends on whether the battery is replaceable or not [30]. In the early years, scooter batteries were not swappable, so the entire vehicle was wasted after battery failure (the first e-scooter with swappable battery has been introduced in 2019, see Intelligent transport [41]. Finke et al. [42] added the impacts of swappable batteries and self-service battery swapping stations, but also found system-wide emissions of 60–110 g CO2eq/pkm, which is in the order of magnitude of the previous results (Fig. 1).

Moreau et al. [27] reported that in their base case application (284 days of scooter use, corresponding to 1400 km of driving, resulting in 131 g CO2eq/pkm), the GWP of transport activity increases due to the use of e-scooters (Fig. 1). However, Moreau et al. [27] also modelled up to 8 times higher mileages for shared e-scooters (Fig. 1), which seems doubtful given the often poor treatment, such as the fact that many shared e-scooters are left outside for long periods.

These doubts turned out to be justified when the study of Reis et al. [39] was published, changing the picture. Reis et al. [39] for the first time were able to apply real-world mileage/lifetime experiences from an e-scooter fleet in Lisbon (Portugal). Vandalism and high defect rates resulted in an average lifetime of only 1.5 months in Lisbon. Combined with an average mileage of 2–5 km/day, this ended up in a lifetime mileage of only 90–225 km and a resulting footprint of 800–1700 g CO2eq/pkm (Fig. 1). Reis et al. [39] extrapolated their modelling to higher mileages published by earlier authors (Fig. 1), this way resulting in a minimum impact of 112 g CO2eq/pkm (Fig. 1). On the other hand, less favourable assumptions increased emissions to 5300 g CO2eq/pkm for the Lisbon scooter fleet [39]. Although Reis et al. [39] emphasised that the Lisbon application case is an unusually rough one (due to the many steep hills in the city), the question arises whether the previously published impacts (Fig. 1) may have been (much) too optimistic due to the lack of reliable scooter survival data.

All e-scooters modelled so far have been based on an aluminium chassis. Ishaq et al. [40] theoretically discussed several alternative materials. Knowing that aluminium has a high GWP, some fleet operators argue to use up to 99% recycled aluminium [36]. However, removing recycled aluminium for the benefit of e-scooters will result in a shortage of this material at another place. Therefore, this is not a general solution to achieve lower impacts.

The electric scooter industry relies heavily on aluminium as a chassis material: a review of electric scooters (subtype 1b, see Table 1) offered on the Amazon Germany platform on 23 March 2024 found that 76 out of 84 different electric scooters had an aluminium frame (scooters for adults considered only). A further 3 had a steel frame and for 5 of the 84 scooters offered, the frame material was not specified. None of the scooters offered had a plastic frame. All electric scooters offered had only 2 wheels.

Surprisingly, literature sources often did not specify the end-of-life (EOL) choice applied during LCA modelling [29, 43, 44], did not consider recycling credits [31, 45, 46], or excluded EOL treatment from modelling [23], making these sources difficult to use for comparison. Reis et al. [39], in contrast, modelled EOL choices as a particular sensitivity. E-scooter fleet operators have also considered recycling credits (e.g., [36]) during LCA modelling. However, due to the lack of reported lifetime mileage, their data [36,37,38] cannot be seriously compared and are displayed for information only, see Fig. 1.

Purpose of this study

In conclusion, the reported life cycle GWP of e-scooter passenger km travelled, exhibits very heterogenic results. Reported emissions are mostly similar to those of conventional (combustion engine based) transport modes such as cars and buses, and in some cases even higher than those of passenger cars (Fig. 1). Electric bicycles, for example, look more favourable with only 14–26 g CO2eq/pkm (Fig. 1). The recent publication of Reis et al. [39], however, shifted the impact of shared e-scooters very much into an unfavourable region of up to 1700 g CO2eq/pkm and more. This situation is very unsatisfactory, which is why this study investigates measures and factors that enable a reduction in the lifetime emissions of the scooters by applying a cradle-to-grave LCA.

Firstly, missing credits due to recycling indicate a possible overestimation of impacts to date: six out of eight LCA reports do not specify or quantify EOL (Fig. 1). This modelling is designed to carefully assess EOL credits to change the picture.

Another approach to reduce the impact of e-scooters may be the choice of the main material. So far, there are no published LCA data on e-scooters with a chassis material other than aluminium, so the optimisation potential in changing the main material is unknown. This paper therefore compares the life cycle impacts of two different electric scooters with chassis made of different materials (plastic and aluminium).

This study also aims to determine a minimum mileage for the scooters to be advantageous in terms of the GWP compared to passenger cars.

In addition, data on life cycle impacts of e-scooters other than related to the GWP are very scarce. This study therefore attempts to enrich this knowledge by evaluating the impacts of the two e-scooters in about 7 more midpoint and endpoint-related environmental impact categories in order to reveal potential burden shifting. Another new feature of this study is that the impacts of e-scooters are compared directly with those of passenger cars across all impact categories analysed.

This modelling will result in GWP impacts for e-scooters that are valid for a shared fleet application and are therefore compatible with existing literature data. However, as there is still uncertainty about the life expectancy of e-scooters in a shared fleet, this study prefers to determine the potential benefits in terms of reduced GWP of a private e-scooter application for commuting purposes.

Methodology of the life cycle assessment (LCA)

As this study follows the main principles and steps (without critical review) of ISO 14040 [47], it is also based on the structure of goal and scope, life cycle inventory (LCI) analysis, impact assessment and interpretation including transparent documentation.

Goal and scope

Two different e-scooters are assessed and compared in terms of their environmental impact: an aluminium-based e-scooter (Al e-scooter) and a plastic-based e-scooter (plastic e-scooter), which differ mainly in terms of the frame material (aluminium and plastic) and the collection and distribution during their use phases. The plastic e-scooter can drive autonomously via a telematics system and three wheels. More detailed information on the e-scooters in this study can be found in the respective Chapter 2.2 and in the Additional file 1. More details on autonomous e-scooters can be found in the literature ([48,49,50]).

System boundary for both e-scooters

The system boundary of the LCA covers a cradle-to-grave life cycle with a system extension for recycling of the two main materials (aluminium and plastic) for both e-scooters, as shown in Fig. 2. It includes the production and transport of materials and components, the use of the e-scooters including transport, collection and distribution, charging and maintenance, and the end of life (EOL) including recycling or other waste treatment options for the materials used. Although the bill of materials (BOM) was based on own weighting for the Al e-scooter and on a manufacturer’s BOM for the plastic e-scooter, no solid data was available on the final assembly of the e-scooters and its production effort (see “limitations of this study” below). Therefore, this stage was excluded from this study.

Functional unit for both e-scooters

The functional unit (FU) of this study is the distance travelled by a passenger with a reference flow of one passenger-kilometre (pkm) for both e-scooters, in accordance with the standard FU for passenger transportation.

Lifetime and mileage scenarios

This study analyses three different lifetimes: 6, 12, and 24 months (6M, 12M and 24M) based on the lifetimes reported in the literature (see the lifetime discussion in the introduction). The average travel distance per day and e-scooter is 15 km according to the producer and operator of the shared plastic e-scooter. This information is based on usage data in Singapore where the company Floatility operated a fleet of shared scooters with 6 trips/day, 2.5 km/trip [51, 52]. Assuming 360 days of operation and 5 days of out of service due to maintenance within a fleet operation, this daily travel distance results in 2700 km travelled for 6M, 5700 km for 12M, and 10,400 km for 24M lifetime for both e-scooters. For comparison, the much shorter average mileage reported by Reis et al. [39] was modelled in addition (Fig. 1).

Impact assessment methods

Two different impact assessment methods were chosen for comparing the life cycle impacts of both e-scooters:

-

1.

“IPCC 2013 Global Warming Potential (GWP) 100a v1.03”, which presents results in kg CO2eq/pkm [53].

-

2.

“ReCiPe 2016 Endpoint (H) v1.03 / World (2010) H/A” with its subcategories and corresponding units in brackets [54]:

-

a.

Human Health (DALY/pkm),

-

b.

Ecosystems (Species*yr/pkm),

-

c.

Resources (USD2013/pkm).

-

a.

To compare with e-scooters from literature and passenger cars (ICEV = internal combustion engine vehicle, BEV = battery electric vehicles) midpoint indicators from “ReCiPe 2016 Midoint (H) v1.03/World (2010) H” and “ILCD 2011 Midpoint + v1.10/EC-JRC Global, equal weighting” were additionally selected [54, 55]:

-

Fine particulate matter formation (kg PM2.5eq/pkm) from ReCiPe,

-

Terrestrial acidification (kg SO2eq/pkm) from ReCiPe,

-

Human carcinogenic and non-carcinogenic toxicity were combined by addition to “human toxicity” (kg 1.4-DCB/pkm) from ReCiPe,

-

Photochemical ozone formation (kg NMVOCeq/pkm) was taken from ILCD.

Life cycle inventory (LCI)

The life cycle inventory was modelled using SimaPro v9.1.1.1 [56] and ecoinvent v3.5 [57]. For modelling the processes, unit (U) processes and the Allocation-at-point-of-substitution (APOS) model was chosen to account for potential recycling options in the EOL phase. The LCI is described in the following sections, the details are provided in Additional file 1: Tables S1–S3. The LCA model was compiled for Switzerland as a use case.

Production phase

The Al scooter’s chassis is made primarily of aluminium and is not easily dismantled or repaired. In contrast, the plastic e-scooter’s main material is polyamide PA6, commercially known as Ultramid® B3, and is designed to be modular for facilitating repair. Furthermore, the plastic e-scooter has three wheels for improved stability and the ability to drive autonomously to a central loading and maintenance station.

The life cycle inventory (LCI) for the Al e-scooter was based on dismantling and weighing its materials and components. This was done for the specific e-scooter VMAX R25, which weighs 16.31 kg, within a pre-study [58, 59]. The LCI for the plastic e-scooter was based on the Floatility efloater, weighing 17.23 kg. Material and component data were obtained directly from the producer and operator [51, 52].

The materials and components for both e-scooters were modelled, including the respective processing data for each material from ecoinvent 3.5 for the LCI. While detailed data was available for the main production locations of single materials and components for the plastic e-scooters (Singapore, Japan, Thailand, Indonesia and China), global (GLO) or rest of world (RoW) market data sets from ecoinvent 3.5 were mainly used for the Al e-scooter modelling in order to account for the average transportation of materials and components. However, for certain materials and components of the Al e-scooter, production was assumed to take place in China. As a results, Chinese data sets were used and modelled where applicable and appropriate.

Detailed information on materials, components, weights, transportation distances and assumptions as well as corresponding ecoinvent processes for both e-scooters, can be found in Additional file 1: Tables S1–S9.

Use phase

The use phase of both e-scooters includes transportation to their destination in Europe, electricity demand for charging and efforts for collection, distribution and maintenance.

The Al e-scooter is assumed to be transported from China, while most of the plastic e-scooter components are shipped from Jakarta, Indonesia to Europe. Only a few parts are transported from Poland or Germany to the assembly location in Hamburg, Germany. Transportation within Europe is done by lorry.

The Al e-scooter has an electricity consumption of 1.576 kWh/100 km, based on its 20.1 km range and a Li-Ion battery capacity of 316.8 Wh [58]. The range of the Al e-scooter was evaluated by measuring the average of three test drives without standard conditions in a pre-study [58]. Standardised drive conditions for e-scooters have not yet been defined [5] but are the subject of recent research [60]. The plastic e-scooter has a similar electricity consumption of 1.4 kWh/100 km (range: 20 km) (data source: Floatility GmbH [51, 52]). The electricity consumption during the use phase was modelled using a Swiss electricity mix with 105 g CO2eq/kWh [57]. Please refer to Tables S3 and S7 in the Additional file 1 for further process details. According to Severengiz et al. [30], a transportation distance of 1 km per day per e-scooter is assumed for collection and distribution by vans. The lifetime (in months) and related mileages are based on the distance travelled for collection and distribution per day as well as on the e-scooter’s own operating distance of 15 km per day.

As the plastic e-scooter is capable of autonomous driving, the collection and distribution of the plastic e-scooter to a charging station is assumed to be performed without a collection by vans. Therefore, only the additional electricity demand for the autonomous driving is accounted for in the LCI. For this, the electricity demand of 1.4 kWh/100 km was considered as well as the assumption that the e-scooter needs to travel 2 km to the next charging station autonomously per 20 km of battery range, which leads to an electricity demand for collection of 1.4 Wh/pkm, equivalent to only 0.15 g CO2eq/pkm based on the above Swiss electricity mix.

A simplified approach was chosen for maintenance efforts on plastic e-scooters, with 1% of the e-scooter itself requiring maintenance and replacement within 6 months. For lifetimes of 12 and 24 months, maintenance was assumed to increase linearly.

The maintenance efforts for the Al e-scooter were modelled using different approaches for different materials. The assumptions can be found in Additional file 1: Table S7. The LCI of the e-scooter’s use phase is reported in Additional file 1: Table S3.

End-of-Life (EOL) phase

The LCI modelling for the EOL of both e-scooters was based on assumptions or a specific disposal scenario. The only information provided by the producer was that the main chassis material (Ultramid B3®) of the plastic e-scooter is recycled [51].

For both e-scooters, a recycling rate of 90% has been assumed for their main materials, aluminium and plastic (Ultramid B3®). Both recycled materials were modelled using the avoided burden approach. Therefore, a credit with primary material was given according to the recycling rate of the main materials for both e-scooters. The remaining 10% is modelled to be landfilled (refer to Additional file 1: Tables S5 and S8). The recycling rates and EOL treatment options for all other components and materials were adopted from available ecoinvent processes applied. Additional details for the LCI of the EOL can be found in Table S5 for the plastic e-scooter and Additional file 1: Table S8.

Results and discussion

Comparison of the Al and the plastic e-scooter, influence of lifetime mileage and EOL choice

Figure 3 depicts the life cycle impacts of both the aluminium and plastic e-scooters, covering a wide range of operating life cycles, as is usual in published reports. The impacts related to pkm decrease inversely proportional to mileages, as already described (Fig. 1). The high dependence of the impacts on the lifetime mileages of the e-scooters is due to the dominance of production relative to the use phase impacts as shown in Fig. 3. Although we refrain to recommend a shared fleet application of e-scooters in the conclusion, we have also modelled the GWP (IPCC, 100a) for the very low lifetime mileage reported by Reis et al. [39] as one central estimate from a fleet application in Lisbon: 225 km. This highlights the impact of mileage as a sensitivity and allows for evaluation of the comparability of Reis' modelling with ours. Reis et al. [39] reported a GWP of approximately 800 g CO2eq/pkm, while our modelling resulted in a GWP of 640 g CO2eq/pkm for the Al e-scooter and 540 g CO2 eq/pkm for the plastic scooter, respectively, based on a lifetime mileage of 225 km (see Fig. 1). Although Reis et al. [39] considered various variables, this suggest that both LCA models are comparable. This confirms that e-scooters with such a short lifetime are far from being competitive with alternative mobility modes (Fig. 1).

Comparative environmental impacts of the aluminium scooter (Al e-scooter) and the plastic e-scooter based on 6, 12, and 24 months of use, equivalent to 2700, 5400, and 10,800 km of mileage (shared fleet application). Material recycling credits indicated in grey columns. Cradle to cradle impacts (EOL: substitution), overall results depicted by red lines. A IPCC GWP over 100 years. B Summarized human health impacts. C Summarized ecosystem impacts. D Summarized resources impacts (mineral and fossil resource scarcity). A Life Cycle midpoint, B–D endpoints

The Lifetime mileages of e-scooters also strongly affect the impacts on human health, ecosystem, and resources, the comprising endpoints of the ReCiPe LCIA methodology (Fig. 3). Results from these three endpoint impacts were so far reported by de Bortoli [43] only, but without specifying which EOL method was used.

Figure 3 shows that EOL modelling has a significant impact: the credits received when e-scooters materials are returned to the supply chain are high; ranging from 26% to 41% of the life cycle impacts during production plus use phase, as shown in Fig. 3. Recycling yields high credits, particularly for the GWP of the e-scooters (Fig. 3A): material recycling compensated for 34.1–40.6% of the GWP of the Al scooter, and 26.5–29.0% of the GWP of the plastic scooter (6–24 months of use each), for production plus use phase. Based on the medium usage time/mileage (12 months, or 5400 km of mileage), recycling compensates for 38.2% of the production and use phase GWP of the Al scooter, and 28.1% of the production and use phase GWP of the plastic scooter, respectively. These recycling compensations correspond with the findings of Reis et al. [39], who report of 40–52% compensation through recycling credits, depending on the specific EOL scenario. Reis et al. [39] included multiple materials compared to one main material for the avoided burden approach, resulting in a slightly higher compensation compared to the findings of this study.

The plastic e-scooter generally exhibits smaller use phase impacts as shown in Fig. 3 due to its self-driving capability. This capability has been incorporated into the construction of this e-scooter by Floatility [51], but it is not specific to the chassis material, whether it is made of aluminium or plastic.

The plastic scooter, despite having three wheels instead of two generally has lower lifetime impacts than its aluminium chassis counterpart (Fig. 3). The only exception is the 6 months human health impact of the plastic e-scooter, which is 2.7% higher than that of the aluminium e-scooter (Fig. 3). The GWP impact of the plastic e-scooter is 24.9% lower than that of the aluminium e-scooter, based on the medium and most probable operation length of 12M (5.400 km). The Al scooter causes 38.2 g CO2eq/pkm, while the floatility scooter emits 28.1 g CO2eq/pkm, respectively, resulting in a 26% reduction (each modelled for a 12-month = 5.400 km-application). Similarly, the human health impact, the ecosystem impact, and the resources impact of the plastic e-scooter are 1.7%, 16.4% and 12.9% lower, respectively, compared to the Al e-scooter (Fig. 3).

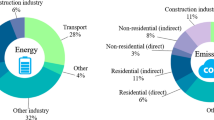

Life cycle impacts inventory breakdown

Figure 4 analyses which inventory components of both the plastic and the aluminium scooter are dominating the lifetime impacts, which were in total depicted in Fig. 3. As shown in Fig. 3, GWP, followed by three endpoint evaluations were modelled: summarized human health and ecosystem impacts, and resources impacts (mineral and fossil resource scarcity).

Share of specific materials and stages of the total global warming potential and three endpoint impact categories (modelling based on 12 months of use equivalent to 5400 km of mileage, EOL credits not considered), shared fleet application. Ultramid®: plastic material from BASF. PC: polycarbonate; PE: polyethylene. HD: high density

The plastic scooter's material inventory is known in more detail. However, not all parts could be depicted in the cake charts. The 'remaining' parts (7.6–11.4% in Fig. 4) consist of Cellasto® foam, brake cable, Ultramid® B3WG13 plastic, Elastollan® (Thermoplastic Polyurethane), a copper solenoid, a magnet, cables, transportation from the factory, maintenance and repair, and partly the throttle (Fig. 4). The impact of the aluminium e-scooter is dominated by the chassis material aluminium across all four impact categories, accounting for 50.5–67.9% (Fig. 4). Although the plastic scooter also contains aluminium, its impact is only around 3.4–7.7% (Fig. 4). The plastic material of the scooter chassis (Ultramid®, made by BASF), the battery, the motor, and rubber account for half of the impacts during the production and use phase of the plastic scooter (Fig. 4). In terms of absolute numbers, the production of the Al chassis results in 2.3 times more CO2eq emissions than the Ultramid® chassis, 5.6 times more impact on human health, 4.1 times more impact on the ecosystem, and removes 1.5 times more resources. Therefore, to reduce the impact of the production phase of e-scooters, the first step should be to replace the Al chassis with plastic materials, which is much more environmentally efficient. The choice of electric motor has a another significant impact on the environment. Depending on the country modelled for production and use phases (Sweden or USA), there may be up to 23% optimization potential [61]. Similarly, the type of battery selected can also affect environmental friendliness, although differences in impacts from varying battery chemistries appear to be small [62, 63].

The power consumption impact of the two e-scooters has already been optimised, as modelled here: Our model utilized relatively 'green' Swiss electricity with 105 g CO2eq/kWh (electricity, low voltage {CH} market for APOS, U), minimizing the use phase impacts (Fig. 3) and share of the electricity impacts (Fig. 4). Regarding the use of scooters in Germany (as shown in the private use case model below), German customers have the option to purchase renewable electricity, which has a carbon footprint comparable to that of Switzerland [35].

The two different e-scooters modelled have a very similar electricity consumption of 1.4–1.5 kWh/100 km. However, the collection & redistribution impact of around 2 g CO2eq/pkm for the Al e-scooter is added to the electricity consumption impact (for the plastic scooter this amounts to 0.15 g CO2eq/pkm only). The respective percentages of the two e-scooters (electricity vs. electricity & collection) are still quite similar, with a difference of only up to 1.4 percentage points, except for the resource impact (Fig. 4).

Analysis of further impact categories

Figure 5 displays the life cycle impacts of e-scooters, excluding GWP. The following questions are posed:

-

Closing knowledge gaps regarding further impacts: are e-scooters critical in selected impact categories as it is typical for electric cars compared to combustion engine cars (e.g., [35])?

-

Is there congruence with previously published e-scooter impact data? These, however, are very scarce so far. In addition, impact categories often have different units, which prevents a direct comparison.

-

How do e-scooters perform in further impact categories compared to passenger cars?

-

Are there any differences between the two chassis materials (aluminium and plastic)?

Further life cycle impact categories of the two electric scooters modelled in this study (Al e-scooter: aluminium scooter, and the plastic e-scooter, respectively) in comparison with literature data and passenger cars (ICEV: internal combustion engine vehicle; BEV: battery electric vehicles). Results for three endpoint categories (resources, ecosystem damage, human health) presented followed by results from four midpoint categories. Dark colours: this study, light colours: comparative literature and passenger car figures. Results are shown in passenger kilometre (pkm). *) = Individual values or averaged values taken from the literature, which are shown in a wider format for better readability. Minimum and maximum of the e-scooters in this study modelled for 6 and 24 months of use each (= 2700–10,800 km of mileage, higher mileages cause smaller impacts in per pkm). Comparative data for passenger car impacts (specified as “BEV”, battery electric vehicle, and “ICEV”: internal combustion engine vehicle) were taken from Helmers et al. [35, 64], the minimum each based on a mini size car (SMART), the maximum based on a midsize car (VW Caddy), respectively, modelled with use phase electricity of 130 g CO2eq/kWh, for all other modelling and inventory parameters see Helmers et al. [35, 64]. Passenger car human toxicity data based on ReCiPe 2016 Midpoint (H) V1.03 / World (2010) H modelling. Human carcinogenic and non-carcinogenic toxicity summarized. ICEV human toxicity minimum and maximum based on small-to-large-sized petrol cars. BEV human toxicity impacts based on the global standardized electric car (result: 0.44 kg 1.4-DCB/pkm shown enlarged). All passenger car pkm data calculated based on 1.57 persons/car (data sources see [35]). Further passenger car endpoint data were taken from Dirnaichner et al. [65]. Smallest columns are based on single data points each [36, 65]. PM10 data for passenger cars (BEV, ICEV) taken from Helmers et al. [35, 64], and converted to PM2.5 based on the factor 0.599 taken from Gronlund et al. [66]. Fleet operators' data taken from EY [36]

The life cycle impacts of the two e-scooters (plastic + aluminium) were modelled and compared to those of passenger cars (Fig. 5). In a previous study comparing electric and combustion engine passenger cars, both technologies showed similar impacts on particulate matter formation and terrestrial acidification [35]. However, the BEV had a lower impact on photochemical oxidant formation and a higher potential for human toxicity [35]. When comparing the environmental impacts of operating a passenger car to that of an e-scooter, it is revealed that the results for both types of vehicles are in the same order of magnitude or even similar in 4 of the impact categories modelled, namely ecosystem damage, human health, acidification potential, and photochemical ozone formation (Fig. 5). This may come as a surprise, as scooters are much lighter than cars. However, this is consistent with the GWP analysis (Fig. 1). According to Helmers et al. [35], passenger cars are typically modelled for lifetime mileages of 100,000 to 200,000 km, which can result in more favourable impacts per passenger-kilometre. Nevertheless, the human toxicity impacts of both e-scooters (averaged) are 43% lower than caused by the battery electric passenger car. Reis et al. [39], as for example, also quantified human health impacts (in another unit); however, did not compare them with passenger cars directly.

As expected, e-scooters consume significantly less resources than passenger cars. On average, the aluminium and plastic e-scooters consume only 20% of the resources per passenger kilometre (pkm) compared to an Internal Combustion Engine Vehicle (ICEV), and 24% of the resources consumed by a Battery Electric Vehicle (BEV) per pkm (Fig. 5). In contrast to the observed advantage in human toxicity, our modelling reveals that e-scooters emit 45% more PM2.5 on average than passenger cars (Fig. 5).

Only three scientific literature reports so far deliver e-scooter LCA data in additional environmental impact categories and quantify them in units compatible with the ReCiPe characterisation method (see Fig. 5). When considering the impacts on ecosystem damage, human health, acidification potential, and particulate matter emissions, the data reported by de Bortoli [43], Hollingsworth et al. [29], and Moreau et al. [27] appear as outliers in the overall picture (see Fig. 5). Once again, this is probably due to the neglect of EOL impacts: Hollingsworth et al. [29] did not specify the end-of-life (EOL) choice applied in modelling, de Bortoli [43] did not consider recycling credits and Moreau et al. [27] excluded EOL treatment from modelling, which may have led to an overestimation of the reported results. However, the resource extraction impact reported by de Bortoli et al. [43] does not appear as an outlier (Fig. 5).

In terms of material comparison between aluminium and plastic, both modelled e-scooters showed similar impacts on resource consumption, ecosystem damage, human health, and acidification (see Fig. 5). However, the e-scooter with an aluminium chassis had significantly higher impacts on photochemical oxidation formation compared to the plastic counterpart, while the plastic e-scooter had higher impacts on human toxicity costs (see Fig. 5).

For the first time, this overview presents a direct comparison of the environmental impacts of passenger cars and e-scooters across a wider range of impact categories. To sum up these results: although e-scooters are not outperforming passenger cars in terms of environmental impacts currently, it is important to consider the resources saved by using e-scooters (Fig. 5). Therefore, they should not be dismissed as a viable mobility option.

Modelling GWP advantages during a personal e-scooter use for commuting purposes

As the fleet use of e-scooters has apparently not yet achieved proven environmental benefits, this remains to be examined for private use. Such an examination is carried out below.

Taking Germany as an example due to better data availability, statistics reveal 16.9 million employees in 2021 who commuted an average of 16.9 km each workday [67, 68]. In 2020, 68% of employees commuted to work by car, despite over 90% of German residents living within 600–1200 m of a bus or train stop with at least 20 daily departures [69]. For our modelling, we have expanded this distance to approximately 2 km to a bus or metro station for both the individuals’ residence and their workplace in another city location. This distance, as already much shorter distances, are too long to walk (four times a day, as shown in Fig. 6), and thus provoking car use for the total distance to and from the workplace. However, with an e-scooter, these individuals could switch to a mixed e-scooter/public transport service scheme (Fig. 6). The commuter could use an e-scooter for the 4 × 2 km/day to reach the bus/train station and then carry the e-scooter (almost all models offered on the market are collapsible) while travelling in the bus or metro train (Fig. 6). After leaving the bus or metro station, the commuter could cover the last 2 km to reach the workplace by scooter again. In order to simplify the modelling of CO2eq-emissions, it is assumed that both alternative routes are of equal length (summed kilometres).

E-scooter enabling the use of public transport during commuting based on an average German workplace distance. E-scooter applied to reach a bus stop or a metro station in about 2 km of distance from home (green column), followed by a bus/metro trip (blue column), followed by 2 km travelled with the scooter to the workplace (green column). Data based on full life cycle impacts and taken from Fig. 1 (averaged for the Al and plastic e-scooter). Other than in Fig. 1, car occupancy here set to 1 person/car. GWP/pkm for public transport (bus + train) averaged for conventional bus + train and electric bus (Fig. 1). BEV: battery electric vehicle. ICEV: internal combustion engine vehicle

When relying solely on a car for commuting, an individual emits 8.3 kg CO2eq/workday when driving an ICEV, or 3.5 kg CO2eq/workday when driving a BEV (upper column, Fig. 6). The mixed e-scooter/public transport-mode (green/blue columns in Fig. 6) emits approximately 1.5 kg CO2eq/workday (4 × 2 × 0.0321 kg CO2eq/km + 2 × 12.9 × 0.049 kg CO2eq/km), providing an 82% reduction in emissions compared to driving an ICEV, or a 57% reduction compared to driving a BEV.

After excluding Sundays and Saturdays, 30 vacation days and 20 days for illness and business trips, a total number of workdays per year is 211. The commuter may not prefer to use the scooter on extremely cold and rainy days. According to DWD [70], Germany has experienced a long-term trend with increasing winter temperatures, resulting in only 17 icy days in 2022 geographically averaged (icy days = days with constant temperatures below the freezing point). The decision of whether or not to use the scooter on a (partly) rainy day, which statistically occurs every third day, is subjective. Additionally, the decision may depend on the distance to be travelled. Assuming, in total, for 155 workdays the e-scooter may be a suitable option, while on the remaining 56 days the car would still be preferred. The average commuter owning a combustion engine car, which is still the vast majority, would emit 1.75 t CO2eq/year based on 100% car use. However, if switching to the mixed scooter/public transport for 155 days and keeping the car for only 56 days, the average commuter would emit only 0.70 t CO2eq/year. This results in a 60% reduction in CO2eq emissions. On the other hand, a commuter already owning an electric car would emit 0.74 t CO2eq/year with a 100% car use. However, if this commuter would take the scooter/public transport on 155 days and use the BEV on 56 days, 0.43 t CO2eq/year would be emitted only for travelling to work, equivalent to a 42% reduction in emissions.

In Germany, an adult emits an average of 11.2 t CO2eq/year for all expenditures [71], number for the year 2016). The modelled e-scooter commuting application can save 2.8% of the average personal annual GHG emissions if the commuter owns an electric car, and 9.4% if a combustion engine car is used, which is the most probable situation. Savings of this magnitude should not be underestimated: in Germany, the mobility system has failed to deliver the desired climate-relevant emission reductions, with emissions remaining at a high level of 143.9 Mio t CO2eq/year recently ([72], number for the year 2023). Assuming that half of the 68% of the 16.9 million employees who currently commute to work by car in Germany [24], switch to the e-scooter/public transport application described above, and given that these commuters own combustion engine cars, a saving of 6.0 Mio t CO2eq/year can be achieved (0.5 × 0.68 × 16.9 million × 0.6 × 1.75 t CO2eq/year). Accordingly, the use of e-scooters in the described model could result in a significant 4.2% reduction of GHG emissions throughout the German mobility system. Passenger transport alone emits 122.8 Mio t of CO2eq/year in Germany ([73], number for 2019). In relation to this, the use of scooters in commuting could save 4.9% of emissions. This modelling does not aim to deliver exact emission saving figures, but rather to indicate the potential magnitude of a GHG emission reduction by e-scooter use.

To achieve lifetime emissions of a low 32 g CO2eq/pkm (averaged for the Al and the plastic scooter), a mileage of 5400 km is required, as this modelling has revealed. The e-scooter commuting application described above comes with an estimated mileage of 1240 km/year. To reach the 5400 km mileage, the private e-scooter use case described would require 4.4 years of continuous use. The feasibility of achieving this mileage needs to be critically discussed. Fortunately, in private use, there will likely be no losses due to vandalism or inappropriate battery treatment. Additionally, unlike fleet operators, private users receive a 2-year warranty, which can be extended to 3 years (e.g., [74]), or the e-scooter can be leased instead. Based on these circumstances, it seems realistic to make a mileage of 5400 years within 4.4 years possible and attain the suggested CO2eq savings.

Limitations of this study and further research

Although the LCI for the LCA model was based on measured material data for the aluminium e-scooter and primary data from the producing company for the plastic e-scooter, the final assembly stage is missing for both e-scooter models due to a lack of solid data. It is assumed that the impact of the final assembly stage for both e-scooter models would be similar, making the comparison of the two models still valid. However, when comparing with other studies, it is important to carefully consider the system boundary of those studies. Although the assembly stage was included in Hollingsworth et al. [29] and Severengiz et al. [30], it only accounted for approximately 1% of the total GWP, so it may be negligible. However, it still had a greater proportion than certain components and materials of the corresponding e-scooter in Hollingsworth et al. [29].

In addition, recent technological advancements in autonomous electric kick-scooters for fleet operators also involve the transfer and processing of data through cloud services and artificial intelligence (AI). An example of this is the Segway® T60 kick scooter (Segway [75]). This study does not cover data processing and storage. However, for future studies, particularly those involving fleet operations with autonomous e-scooters, it is recommended that the carbon footprint of data processing and storage by artificial intelligence and cloud services should be included in LCI modelling [76,77,78].

The decarbonizing potential of e-scooters in commuting was modelled based on a static use case to quantify possible savings. A more dynamic model that considers trip length, weather conditions, and other influencing factors would enhance the significance of this potential.

Conclusions and outlook

As there are large fleets of shared e-scooters operating in major cities around the world, scientific LCA modelling has focused on this application, resulting in very inconsistent GWP in CO2eq/pkm and often no benefit compared to competing mobility modes. This study found that most of the scientific data published to date suffer from high modelling uncertainties, e.g., whether they include recycling and raw material substitution credits, deliberately exclude them or do not model EOL impacts at all. This results in a relatively high bias in the literature data in the range of 26–41%, as shown by the data presented here.

After considering those EOL credits however, e-scooters appear in a slightly better light given a proper recycling strategy is followed at the EOL stage. In principle they can halve the CO2eq/pkm impact of electric passenger cars and of conventional buses and trains. In addition, autonomous e-scooters could reduce the impact of collection and distribution within fleets. However, this would require a three-wheeled design. Unfortunately, our internet search of the world's leading scooter rental companies (Veo, USA; Bolt, Europe, Africa and South America; Voi, Europe; Lyft, USA; Tier, Europe; Bird, 450 cities worldwide; and Lime, USA) did not reveal a single scooter that deviated from the standard two-wheel design. However, autonomous scooters, such as the Segway® T60 kick scooter, have been developed specifically for fleet operators and may be of interest to them in the future to reduce losses due to vandalism and to collection and distribution costs, both economically and environmentally (Segway [75]).

CO2eq emission benefits depend heavily on the mileage the scooters are driven before they are recycled or disposed of. Fleet operators currently argue for 2 years of use (equivalent to 5,400 km of mileage), and so far, LCA modellers have followed this perception. Given the poor maintenance conditions observed in many e-scooter fleets, the high number of scooters lost to vandalism, and the very low cost to fleet operators of simply replacing old scooters with new ones, there have always been questions about how realistic such lifetime expectations are. Traditional assumptions about the average lifetime of e-scooters in shared fleets were then turned on their head by Reis et al. [39]: in a shared e-scooter fleet in Lisbon, these authors found average lifetime mileages of only between 90 and 225 km.

We therefore refrain from recommending a shared fleet application for e-scooters but focus on a private application where a mileage of 5400 km in 4.4 years of use seems realistically achievable. This mileage can be seen as a minimum that needs to be guaranteed by the right circumstances for e-scooters to be competitive with other modes of transport in terms of environmental performance.

Given the precarious situation in many countries where the mobility system refuses to systematically reduce CO2eq emissions, all options must be on the table to bring about change. As modelled here, e-scooters for private commuting, for example, can deliver a 4% reduction in GHG emissions across the German mobility system. Another positive conclusion from this research is that by switching from the traditional aluminium frame material to plastic, a 26% reduction in lifecycle GHG emissions can be achieved. Optimising the type and material of the electric motor promises a further 23% saving [61].

Finally, e-scooters do not emit noise or exhaust when used in urban areas. In addition, they are fun for young people, give them an idea of a new kind of mobility in contrast to car ownership, and can therefore be a stepping stone towards sustainable mobility. However, this may require a redistribution of road space, away from cars and towards more space for pedestrians, bicycles and e-scooters. When it comes to the use of such micro-mobility vehicles in shared fleets, new regulations will need to ensure a much longer average lifetime and appropriate recycling strategies before environmental benefits can be realised. Fleet operators must be forced to systematically monitor vehicles and protect them from destruction and loss. Until legislation addresses this and prevents the current waste of materials, it will be difficult to demonstrate the environmental benefits of shared scooters in commercial fleets.

Ultimately, an autonomous 3-wheeled e-scooter based on climate-friendly materials, such as the Floatility vehicle modelled here, can have the most positive life cycle impact and also increase the social acceptance of this mode of transport: It is safer to ride and it would not block pedestrian walkways, because it can move away by itself.

Availability of data and materials

The original data are published in Additional file 1: Tables S1–S8.

Abbreviations

- Al:

-

Aluminium

- APOS:

-

Allocation at point of substitution

- BASF:

-

Badische Anilin- & Sodafabrik

- BEV:

-

Battery electric vehicle

- CH:

-

Switzerland

- CN:

-

China

- CO2eq:

-

Carbon Dioxide equivalents

- CO2 :

-

Carbon Dioxide emissions

- DALY:

-

Disability-adjusted Life Years

- DCB:

-

Dichlorobenzene

- €:

-

Euro

- EOL:

-

End-of-life

- e-scooter:

-

Electric scooter

- FU:

-

Functional unit

- g:

-

Gram

- GHG:

-

Greenhouse gas

- GLO:

-

Global

- GWP:

-

Global warming potential

- H:

-

Hierarchist

- HD:

-

High density

- HT:

-

Human toxicity

- ICEV:

-

Internal combustion engine vehicle

- ILCD:

-

International Reference Life Cycle Data System

- IPCC:

-

International Panel on Climate Change

- ISO:

-

International Organization for Standardization

- kg:

-

Kilogram

- km:

-

Kilometre

- km/h:

-

Kilometre per hour

- kW:

-

Kilowatt

- kWh:

-

Kilowatt-hour

- lb:

-

Pound

- LCA:

-

Life Cycle Assessment

- LCI:

-

Life Cycle Inventory

- M:

-

Month

- M:

-

Metre

- Mio:

-

Million

- my:

-

Metre and year as functional unit for roads in ecoinvent processes

- NMVOCeq:

-

Non-methane volatile organic compounds equivalents

- No.:

-

Numero; number

- NOx :

-

Nitrogen oxides

- P:

-

Piece as a functional unit for products in ecoinvent processes

- PA6:

-

Polyamid 6

- PC:

-

Polycarbonate

- PE:

-

Polyethylene

- Pkm:

-

Passenger kilometre

- PM2.5eq:

-

Fine Particulate matter (2.5 µm) equivalent

- ReCiPe:

-

Method for LCI assessment developed by three Dutch scientific institutions

- RER:

-

Europe (scope)

- RoW:

-

Rest of World (scope)

- SAE:

-

Society of Automotive Engineers

- SO2eq:

-

Sulfur Dioxide equivalent

- T:

-

Ton

- U:

-

Unit

- USA:

-

United States of America

- USD:

-

United States Dollar

- yr or y:

-

Year

References

EU (2018) The Commission calls for a climate neutral Europe by 2050. https://ec.europa.eu/commission/presscorner/detail/en/IP_18_6543. Accessed 13 Dec 2020

EEA (2018) Transport greenhouse gas emissions. https://www.eea.europa.eu/airs/2018/resource-efficiency-and-low-carbon-economy/transport-ghgemissions. Accessed 13 Dec 2020

EY (2020a) Ernst & Young Global Limited, How micromobility is moving cities into a sustainable future. https://www.ey.com/en_gl/automotive-transportation/how-micromobility-is-moving-cities-into-a-sustainable-future. Accessed 12 Dec 2020

SAE (2019) Taxonomy and classification of powered micromobility vehicles. Society of Automotive Engineers International. Report SAE J3194(tm), summary (2 pp.) https://www.sae.org/binaries/content/assets/cm/content/topics/micromobility/sae-j3194-summary---2019-11.pdf. Accessed 12 Dec 2020

Weiss M, Cloos KC, Helmers E (2020) Energy efficiency trade-off s in small to large electric vehicles. Environ Sci Europe 32:46. https://doi.org/10.1186/s12302-020-00307-8

Chang CC, Wu FL, Lai WH, Lai MP (2016) A cost-benefit analysis of the carbon footprint with hydrogen scooters and electric scooters. Int J hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2016.05.168

Nayak AK, Ganguli B, Ajayan PM (2023) Advances in electric two-wheeler technologies. Energy Rep 9:3508–3530. https://doi.org/10.1016/j.egyr.2023.02.008

Calao J, Marques DL, Completo AG, Coelho MC (2022) Life cycle thinking approach applied to a novel micromobility vehicle. Transp Res Rec 2676(8):514–529. https://doi.org/10.1177/03611981221084692

Badia H, Jenelius E (2023) Shared e-scooter micromobility: review of use patterns, perceptions and environmental impacts. Transp Rev 43(5):811–837. https://doi.org/10.1080/01441647.2023.2171500

Li A, Zhao P, Liu X, Mansourian A, Axhausen KW, Qu X (2022) Comprehensive comparison of e-scooter sharing mobility: evidence from 30 European cities. Transp Res Part D 105:103229. https://doi.org/10.1016/j.trd.2022.103229

Eurostat (2010) Europäische Städte. Eurostat Jahrbuch der Regionen 2010. 46 pp. https://ec.europa.eu/eurostat/documents/3217494/5725037/KS-HA-10-001-02-DE.PDF.pdf/014edfe8-d29b-4c02-896c-acd23f63b809?t=1414775703000. Accessed 26 Mar 2024

Milakis D, Gebhardt L, Ehebrecht D, Lenz B (2020) Is micro-mobility sustainable? An overview of implications for accessibility, air pollution, safety, physical activity and subjective wellbeing. Preprint, 12 pp. The Handbook of Sustainable Transport edited by Curtis, C., forthcoming 2020, Edward Elgar Publishing Ltd. https://elib.dlr.de/134566/1/Milakis%20et%20al_Micromobility%20%28Edward%20Elgar%29_Preprint.pdf. Accessed 13 Dec 2020

Hoerler R, Stoiber T, Del Duce A (2023) Push and pull strategies to increase the uptake of small electric vehicles. Transp Res D 116:103638. https://doi.org/10.1016/j.trd.2023.103638

Baek K, Lee H, Chung J-H, Kim J (2021) Electric scooter sharing: How do people value it as a last-mile transportation mode? Transp Res Part D: Transp Environ 90:102642. https://doi.org/10.1016/j.trd.2020.102642

Orozco-Fontalvoa M, Llerenaa L, Cantillo V (2022) Dockless electric scooters: a review of a growing micromobility mode. Int J Sust Transp. https://doi.org/10.1080/15568318.2022.2044097

Wang K, Qian X, Fitch DT, Lee Y, Malik J, Circella G (2023) What travel modes do shared e-scooters displace? A review of recent research findings. Transp Rev 43(1):5–31. https://doi.org/10.1080/01441647.2021.2015639

Gebhardt L, Ehrenberger S, Wolf C, Cyganski R (2022) Can shared E-scooters reduce CO2 emissions by substituting car trips in Germany? Transp Res D 109:103328. https://doi.org/10.1016/j.trd.2022.103328

Gubman J, Jung A, Kiel T, Strehmann J (2019) E-Tretroller im Stadtverkehr - Handlungsempfehlungen für deutsche Städte und Gemeinden zum Umgang mit stationslosen Verleihsystemen. Agora Verkehrswende report 27–2019-DE, August 2019. 46 pp. https://static.agora-verkehrswende.de/fileadmin/Projekte/2019/E-Tretroller_im_Stadtverkehr/Agora-Verkehrswende_e-Tretroller_im_Stadtverkehr_WEB.pdf. Accessed 13 Dec 2020

NAU (2012) In Zürich landen E-Scooter oft im See und in der Limmat. https://www.nau.ch/news/schweiz/in-zurich-landen-e-scooter-oft-im-see-und-inder-limmat-65947344. Accessed 19 Jan 2022

Auf der Maur M, L Hafner (2019) Shared Mobility 2019 - Collaborative Mobility Services in European cities - a comparison. Zurich University of Applied Science, report, 37 pp., published 20 December 2019. https://www.zhaw.ch/storage/hochschule/medien/news/2020/Shared-Mobility-2019-Study_EN_14012020.pdf. Accessed 6 Jan 2024

Welt (2021) Unfälle, Vandalismus: Grossstädte wollen E-Roller Chaos-beenden. https://www.welt.de/politik/deutschland/article232424421/Unfaelle-Vandalismus-Grossstaedte-wollen-E-Roller-Chaos-beenden.html. Accessed 19 Jan 2022

Jovicic G (2020) E-scooters in inner city Vienna – Deployment prospects and environmental impact. MS thesis, 83 pp., Technical University of Vienna. https://scholar.archive.org/work/3o6j4xcsvjf7fddjtrz7lvcaii/access/wayback/https://repositum.tuwien.at/bitstream/20.500.12708/1106/2/Jovicic%20Goran%20-%202020%20-%20E-Scooters%20in%20Inner%20City%20Vienna%20-%20Deployment%20Prospects...pdf. Accessed 1 Apr 2024

Mitropoulos L, Stavropoulou E, Tzouras P, Karolemeas C, Kepaptsoglou K (2023) E-scooter micromobility systems: review of attributes and impacts. Transp Res Interdiscipl Perspect 21:100888. https://doi.org/10.1016/j.trip.2023.100888

Federal Statistics Office of Germany (2021) 68% of the persons in employment went to work by car in 2020. Press release No. N 054 of 15 September 2021. https://www.destatis.de/EN/Press/2021/09/PE21_N054_13.html. Accessed 25 Dec 2023

Felipe-Falgas P, Madrid-Lopez C, Marquet O (2022) Assessing environmental performance of micromobility using LCA and self-reported modal change: the case of shared E-Bikes, E-Scooters, and E-Mopeds in Barcelona. Sustainability MDPI 14:4139. https://doi.org/10.3390/su14074139

Hawkins TA, Gausen OM, Strømman AH (2012) Environmental impacts of hybrid and electric vehicles — a review. Int J Life Cycle Assess 17:997–1014. https://doi.org/10.1007/s11367-012-0440-9

Moreau H, de Jamblinne de Meux L, Zeller V, D’Ans P, Ruwet C, Achten WM (2020) Dockless E-Scooter: a green solution for mobility? Comparative case study between dockless E-scooters, displaced transport, and personal E-scooters. Sustainability 12:1803. https://doi.org/10.3390/su12051803

Severengiz S, Finke S, Schelte N, Forrister H (2020) Assessing the environmental impact of novel mobility services using shared electric scooters as an example. Procedia Manuf 43:80–87. https://doi.org/10.1016/j.promfg.2020.02.114

Hollingsworth J, Copeland B, Johnson JX, JX, (2019) Are e-scooters polluters? The environmental impacts of shared dockless electric scooters. Environ Res Lett 14:084031. https://doi.org/10.1088/1748-9326/ab2da8

Severengiz S, Finke S, Schelte N, Wendt N (2020) Life Cycle Assessment on the mobility service e-scooter sharing. 2020 IEEE European Technology and Engineering Management Summit (E-TEMS). https://doi.org/10.1109/E-TEMS46250.2020.9111817

Severengiz S, Schelte N, Brake S (2021) Analysis of the environmental impact of e-scooter sharing services considering product reliability and durability. Procedia CIRP 96:181–188. https://doi.org/10.1016/j.procir.2021.01.072

Weiss M, Dekker P, Moro A, Scholz H, Patel MK (2015) On the electrification of road transportation–a review of the environmental, economic, and social performance of electric two-wheelers. Transp Res D 41(2015):348–366. https://doi.org/10.1016/j.trd.2015.09.007

Mellino S, Petrillo A, Cigolotti V, Autorino C, Jannelli E, Ulgiati S (2017) A Life Cycle Assessment of lithium battery and hydrogen-FC powered electric bicycles: searching for cleaner solutions to urban mobility. Int J Hydrogen Energy 42:1830–1840. https://doi.org/10.1016/j.ijhydene.2016.10.146

Huang Y, Jiang L, Chen H, Dave K, Parry T (2022) Comparative life cycle assessment of electric bikes for commuting in the UK. Transp Res D 105:103213. https://doi.org/10.1016/j.trd.2022.103213

Helmers E, Dietz J, Weiss M (2020) Sensitivity analysis in the life-cycle assessment of electric vs. combustion engine cars under approximate real-world conditions. Sustainability MDPI 12:1241

EY (2020b) Ernst & Young Global Limited, Micromobility: Moving cities into a sustainable future. Report, 36 pp. https://assets.ey.com/content/dam/ey-sites/ey-com/en_gl/topics/automotive-and-transportation/automotive-transportation-pdfs/ey-micromobility-moving-cities-into-a-sustainable-future.pdf. Accessed 12 Dec 2020

BIRD (2020) How to (Correctly) Assess the Environmental Impact of an Electric Scooter. Post Published 7/10/20 https://www.bird.co/blog/how-to-correctly-assess-environmental-impact-electric-scooter/. Accessed 12 Dec 2020

Lime (2019) Lime for a sustainable Paris. A study on LIME’s environmental impact in Paris, 2018–2019. https://www.li.me/hubfs/Assets/LIME_ENG_Paris%20Sustainability%20Report_11OCT2019_RGB.pdf. Accessed 15 Feb 2022

Reis AF, Baptista P, Moura F (2023) How to promote the environmental sustainability of shared e-scooters: a life-cycle analysis based on a case study from Lisbon, Portugal. J Urban Mobil 3:100044. https://doi.org/10.1016/j.urbmob.2022.100044

Ishaq M, Ishaq H, Nawaz A (2022) Life cycle assessment of electric scooters for mobility services: a green mobility solutions. Int J Energy Res. https://doi.org/10.1002/er.8009

Intelligenttransport (2019) Wind unveils new e-scooter with “industry-first” swappable battery. News, 9 October 2019. https://www.intelligenttransport.com/transport-news/90161/wind-unveils-new-e-scooter-with-industry-first-swappable-battery/. Accessed 1 Apr 2014

Finke S, Schelte N, Severengiz S, Fortkort M, Kähler F (2022) Can battery swapping stations make micromobility more environmentally sustainable? E3S Web of Confer 349:02007. https://doi.org/10.1051/e3sconf/202234902007

de Bortoli A (2021) Environmental performance of shared micromobility and personal alternatives using integrated modal LCA. Transp Res Part D 93:102743. https://doi.org/10.1016/j.trd.2021.102743

de Bortoli A, Christoforou Z (2020) Consequential LCA for territorial and multimodal transportation policies: method and application to the free-floating e-scooter disruption in Paris. J Clean Prod 273:122898. https://doi.org/10.1016/j.jclepro.2020.122898

Cazzola P, P Crist (2020) Good to Go? Assessing the Environmental Performance of New Mobility. Corporate Partnership Board Report. International Transport Forum. https://www.itf-oecd.org/sites/default/files/docs/environmental-performance-new-mobility.pdf. Accessed 15 Feb 2022

Kazmaier M, Taefi TT, Hettesheimer T (2020) Techno-economical and ecological potential of electric scooters: a life cycle analysis. Eur J Transp Infrastruct Res 20(4):233–251. https://doi.org/10.18757/ejtir.2020.20.4.4912

ISO (2006) ISO 14040:2006. Environmental management — Life cycle assessment — Principles and framework. https://www.iso.org/standard/37456.html. Accessed 28 Feb 2022

Kondor D, Zhang X, Meghjani M, Santi P, Zhao J, Ratti C (2022) Estimating the potential for shared autonomous scooters. IEEE Trans Intell Transp Syst 23(5):4651–4662. https://doi.org/10.1109/TITS.2020.3047141

Luttkus L, Krönes P, Mikelsons L (2020) Scoomatic: simulation and validation of a semi-autonomous individual last-mile vehicle. Sechste IFToMM D-A-CH Konferenz. https://doi.org/10.17185/duepublico/71204

Poojari SS (2023) Outdoor localization and path planning for repositioning a self-driving electric scooter. Master thesis, University of Maryland. https://doi.org/10.13016/dspace/tbvg-9is5

Floatility (2019) Technical data efloater. Personal communication.

Floatility (2020) Efloater, next generation e-scooter. https://www.e-floater.com/echte-nachhaltigkeit?lang=en. Accessed 26 Feb 2022

Munoz I, Schmidt JH (2016) Methane oxidation, biogenic carbon, and the IPCC’s emission metrics. Proposal for a consistent greenhouse-gas accounting. Int J Life Cycle Assess 21:1069–1075. https://doi.org/10.1007/s11367-016-1091-z

Huijbregts MAJ, Steinmann ZJN, Elshout PMF, Stam G, Verones F, Vieira M, Zijp M, Hollander A, van Zelm R (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138. https://doi.org/10.1007/s11367-016-1246-y

JRC (2012) European Commission Joint Research Centre, Institute for Environment and Sustainability. Characterisation factors of the ILCD Recommended Life Cycle Impact Assessment methods. Database and Supporting Information. First edition. February 2012. EUR 25167. Luxembourg. Publications Office of the European Union; 2012. https://eplca.jrc.ec.europa.eu/uploads/LCIA-characterization-factors-of-the-ILCD.pdf. Accessed 28 Feb 2022

Simapro (2022). SimaPro v9.1.1.1. Software. https://simapro.com/. Accessed 07 Jan 2024

Ecoinvent (2022) Ecoinvent v3.5. https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3-5/. Accessed 28 Feb 2022

Adam D (2019) Geteilte Elektro-Trottinetts in der Stadt Zürich - Nachhaltigkeitsbeurteilung mit Schwerpunkt Ökobilanz und Wirtschaftlichkeit. Master thesis, Zurich University of Applied Sciences, School of Engineering.

VMAX Global AG (2022) R25: Stylish, robust, and ready to go. https://www.vmax-escooter.ch/en/e-scooter/r25/. Accessed 28 Feb 2022

Kubik A (2022) The energy consumption of electric scooters used in the Polish shared mobility market. Energies 2022(15):8193. https://doi.org/10.3390/en15218193

Nordelöf A, Grunditz E, Lundmark S, Tillman AM (2019) Life cycle assessment of permanent magnet electric traction motors. Transp Res D 67:263–274. https://doi.org/10.1016/j.trd.2018.11.004

Carranza G, Do Nascimiento M, Fanals J, Febrer J, Valderrama C (2022) Life cycle assessment and economic analysis of the electric motorcycle in the city of Barcelona and the impact on air pollution. Sci Total Environ 821:153419. https://doi.org/10.1016/j.scitotenv.2022.153419

Guo W, Feng T, Li W, Hua L, Meng Z, Li K (2023) Comparative life cycle assessment of sodium-ion and lithium iron phosphate batteries in the context of carbon neutrality. J Energy Storage 72(1):108589. https://doi.org/10.1016/j.est.2023.108589

Helmers E, Dietz J, Hartard S (2017) (2017) Electric car life cycle assessment based on real-world mileage and the electric conversion scenario. Int J Life Cycle Assess 22:15–30. https://doi.org/10.1007/s11367-015-0934-3

Dirnaichner A, Rottoli M, Sacchi R, Rauner S, Cox B, Mutel C, Bauer C, Luderer G (2022) Life-cycle impacts from different decarbonization pathways for the European car fleet. Environ Res Lett. https://doi.org/10.1088/1748-9326/ac4fdb

Gronlund CJ, Humbert S, Shaked S, O’Neill MS, Jolliet O (2015) Characterizing the burden of disease of particulate matter for life cycle impact assessment. Air Qual Atmos Health 8(1):29–46. https://doi.org/10.1007/s11869-014-0283-6

Federal Institute for Research on Building, urban affairs and spatial development (2022) Länge der Arbeitswege unterscheidet sich regional erheblich. Top news, 23.8.2022. https://www.bbsr.bund.de/BBSR/DE/startseite/topmeldungen/pendeln-2021.html. Accessed 25 Dec 2023

Federal Ministry for Housing, Urban Development and Building (2022a) Pendeldistanzen und Pendlerverflechtungen. https://www.deutschlandatlas.bund.de/DE/Karten/Wie-wir-uns-bewegen/100-Pendlerdistanzen-Pendlerverflechtungen.html#_dwmf1prfz. Accessed 25 Dec 2023

Federal Ministry for Housing, Urban Development and Building (2022b) Erreichbarkeit des Öffentlichen Verkehrs (Haltestellen). https://www.deutschlandatlas.bund.de/DE/Karten/Wie-wir-uns-bewegen/103-Erreichbarkeit-Nahverkehr-Haltestellen.html. Accessed 27 Dec 2023

DWD (2023) Klimastatusbericht Deutschland Jahr 2022. Report of the German Meteorological Service, 27 pp. https://www.dwd.de/DE/leistungen/klimastatusbericht/publikationen/ksb_2022.pdf?__blob=publicationFile&v=5. Accessed 26 Mar 2024

UBA (2021) Federal German Environment Agency: Wie hoch sind die Treibhausgasemissionen pro Person in Deutschland durchschnittlich? Published 23.06.2021. https://www.umweltbundesamt.de/service/uba-fragen/wie-hoch-sind-die-treibhausgasemissionen-pro-person. Accessed 25 Dec 2023

UBA (2024) Federal German Environment Agency: Emissionsübersichten KSG-Sektoren 1990–2023. https://www.umweltbundesamt.de/sites/default/files/medien/361/dokumente/2024_03_13_em_entwicklung_in_d_ksg-sektoren_thg_v1.0.xlsx. Accessed 31 Mar 2024

DLR 2022. German Aerospace Center. Personenverkehr in Deutschland: Verkehrsmittel im Vergleich. Daten und Fakten, 8. Februar 2022. https://www.dlr.de/de/aktuelles/nachrichten/daten-und-fakten/personenverkehr-in-deutschland-verkehrsmittel-im-vergleich. Accessed 31 Mar 2024

Lauftech (2023) Die erweiterte 3-Jahres-Garantie - vom Hersteller Veleco autorisiert. https://lauftech.de/die-erweiterte-3-jahres-garantie/. Accessed 25 Dec 2023

Segway Discovery (2021) Kickscooter T60, The world’s first semi-automatic, teleoperating shared scooter. Product Website. https://b2b.segway.com/kickscooter-t60/. Accessed 24 Mar 2024

Bieser JCT, Hintemann R, Hilty LM, Beucker S (2023) A review of assessments of the greenhouse gas footprint and abatement potential of information and communication technology. Environ Impact Assess Rev. https://doi.org/10.1016/j.eiar.2022.107033

Dhar P (2020) The carbon impact of artificial intelligence. Nat Mach Intell 2:423–425. https://doi.org/10.1038/s42256-020-0219-9