Abstract

Background

Due to their widespread use, sulfonamide antibiotics (SAs) have become ubiquitous environmental contaminants and thus a cause of public concern. However, a complete understanding of the behavior of these pollutants in complex environmental systems has been hampered by the unavailability and high cost of isotopically labeled SAs.

Results

Using commercially available uniformly [14C]- and [13C]-labeled aniline as starting materials, we synthesized [phenyl-ring-14C]- and [phenyl-ring-13C]-labeled sulfamethoxazole (SMX), sulfamonomethoxine (SMM), and sulfadiazine (SDZ) in four-step (via the condensation of labeled N-acetylsulfanilyl chloride and aminoheterocycles) or five-step (via the condensation of labeled N-acetylsulfonamide and chloroheterocycles) reactions, with good yields (5.0–22.5% and 28.1–54.1% for [14C]- and [13C]-labeled SAs, respectively) and high purities (> 98.0%).

Conclusion

The synthesis of [14C]-labeled SAs in milligram amounts enables the preparation of labeled SAs with high specific radioactivity. The efficient and feasible methods described herein can be applied to the production of a variety of [14C]- or [13C]-labeled SAs for studies on their environmental behavior, including the fate, transformation, and bioaccumulation of these antibiotics in soils and aqueous systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Background

Sulfonamide antibiotics (SAs) are widely used in the treatment of human disease and in modern animal husbandry. However, due to their poor biodegradation and insufficient removal by wastewater treatment plants [1, 2], high concentrations of sulfadiazine (SDZ), sulfamethoxazole (SMX), and sulfamonomethoxine (SMM) are commonly detected in soils, sediments, rivers and other environmental media [3,4,5]. SAs that enter the environment exert adverse effects on organisms [6,7,8,9], thus raising public concern. A comprehensive understanding of the environmental fate of SAs, including their adsorption, biodegradation, transformation, formation of non-extractable residues (NERs), and transport, is essential to assessing their environment risks.

Studies of the environmental behavior of pollutants often rely on the use of [14C]-radioactive and [13C]-stable isotopes. The advantages of [14C]-tracers include their low detection limit and convenient handling with complex environmental samples. Consequently, they are frequently used to investigate the environmental fate of organic pollutants, especially mineralization and NERs formation. For example, [14C]-tracers have been employed to examine the environmental impacts of pesticides, brominated flame retardants, alkylphenols, and polycyclic aromatic hydrocarbons [10,11,12,13,14]. Stable isotopes (e.g., 13C, 15 N) have been used in mass spectrometry and nuclear magnetic resonance (NMR) spectroscopy studies to quantify and identify metabolites of pollutants in complex matrices [15,16,17,18,19,20]. [13C]-tracers provide powerful tools for investigations of microbial biomass and community composition and have thus been used in phospholipid fatty acid analyses and as DNA stable-isotope probes [21, 22]. This wide range of applications has increased the demand for [14C]- and [13C]-labeled SAs, but these isotopes are either commercially unavailable or too expensive. An efficient, simple method allowing the ‘‘in house’’ synthesis of [14C]- and [13C]-SAs, especially on micro-scales with good yields is therefore needed.

The successful synthesis of [14C]-SAs on a micro-scale requires stable solvents, suitable reaction conditions, and simple purification methods [23]. The conventional method of synthesizing unlabeled SAs consists of four steps: acetylation of aniline using acetic anhydride, chlorosulfonation of N-acetylaniline with ClSO3H, condensation of sulfonyl chloride with nucleophiles such as amines, and alkaline hydrolysis of the acetyl-protecting group [24,25,26,27]. However, the synthetical conditions are suitable for obtaining SAs in gram amounts and cannot be down-scaled to synthesize SAs in milligram quantities, due to the difficulty of mixing under solvent-free conditions and the crystallization of the products. In a previous study, [14C]-SDZ labeled on the heterocyclic ring was prepared via the reaction of N-acetylsulfanilyl chloride with [14C]-2-aminopyrimidine [28]. By contrast, [14C]-labeling of the phenyl ring of SDZ and other common SAs (such as SMM and SMX), required to trace the transformation of phenyl ring of SAs, has yet to be accomplished.

In this study, we report methods for preparation of typical SAs with [14C]- or [13C]-labeling of the phenyl ring with good yields, especially the synthesis of [14C]-labeled SAs on a micro-scale (milligram-level). These methods can be employed to prepare a variety of [14C]- or [13C]-labeled SAs.

Materials and methods

Chemicals

Uniformly [phenyl-ring-14C]-labeled aniline hydrochloride (1a, Fig. 1, 2.96 × 109 Bq/mmol, 99% radiochemical purity) and uniformly [phenyl-ring-U-13C]-labeled aniline hydrochloride (1b, Fig. 1, 99% of 13C atom, 98% chemical purity) were purchased from Moravek Inc. (California, USA) and Alsachim (Illkirch Graffenstaden, France), respectively. Unlabeled SDZ, SMM, SMX, N-acetylaniline, and N-acetylsulfanilyl chloride (purity ≥ 99%) were purchased from J&K Co. (Shanghai, China). All other reagents were obtained from Nanjing Chemical Reagent Co., Ltd. (Nanjing, China) and were of analytical purity grade. Pyridine was dried over a 4 Å molecular sieves for at least 48 h prior to its use.

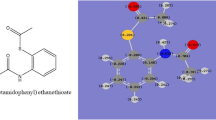

Synthetic pathways of [14C]- and [13C]-labeled SMX (5a, 5b), [14C]- and [13C]-labeled SMM (7a, 7b), and [14C]- and [13C]-labeled SDZ (10a, 10b). I Method: ClSO3H + NaCl in CCl4, 58 °C; purification by flash column chromatography. II Method: ClSO3H + SOCl2 in CCl4, 58 °C; without purification. Yields% (c) and purities% (d) of the synthesized [14C]- or [13C]-labeled compounds are provided. The radiochemical purity of the [14C]-labeled intermediates and [14C]-labeled SAs was determined by TLC coupled to autoradiography and by HPLC coupled to LSC, respectively. The chemical purity of the [13C]-labeled intermediates and SAs was determined by HPLC

Analyses

The reaction products were purified by flash column chromatography (CHEETAH TMMP100; Agela, Tianjin, China) or preparative thin-layer chromatography (TLC) on preparative silica gel plates (GF254, 1 mm, 20 × 20 cm; Huanghai, Shandong, China). The purity of the products was analyzed on analytical silica gel plates (GF254, 0.25 mm, 3 cm × 10 cm, Huanghai, Shandong, China) by analytical TLC coupled to an imaging scanner (Typhoon Trio+; GE Healthcare, U.S.), or by high-performance liquid chromatography (HPLC, 1100 system; Agilent Technology, USA). The synthesized products were identified on an HPLC system (1260; Agilent Technology, USA) coupled to a Q-TOF tandem mass spectrometer (HPLC-Q-TOF–MS/MS, triple TOF 5600 system; AB SCIEX, USA) and by NMR spectroscopy (AVANCE III HD-500; Bruker, Germany). Radioactivity was determined by liquid scintillation counting (LSC, LS6500; Beckman Counter, USA). The specific activities of 5a, 7a, and 10a were calculated from the chemical masses determined by HPLC and the amounts of radioactivity determined by LSC. Details of the instruments used in the purifications and analyses are provided in the Additional file 1.

Syntheses

Synthesis of [14C]-SMX (5a) and [14C]-SMM (7a)

Uniformly [phenyl-ring-14C]-labeled N-acetylaniline (2a)

K2CO3 powder (128 mg, 0.93 mmol) and acetic anhydride (66 μL, 0.70 mmol) were sequentially added to [14C]-labeled aniline hydrochloride (1a, 3.70 × 108 Bq, 2.96 × 109 Bq/mmol, 99.0% purity, 0.125 mmol) in deionized water (10 mL) at 25 °C (Fig. 1). The mixture was further stirred at 25 °C for 1 h and then extracted five times with ethyl acetate (10 mL each). The extract was dried with anhydrous Na2SO4 and evaporated under vacuum to ~ 1 mL. The product in the extract was purified by flash chromatography (for details, see Additional file 1: SI.1) with an elution gradient (Additional file 1: Table S1), resulting in 2a (3.33 × 108 Bq, 2.96 × 109 Bq/mmol) at 90.0% yield. TLC, performed using petroleum ether:ethyl acetate (1:4, v:v) containing 0.2% CH3COOH as the eluent (Rf = 0.45), coupled to autoradiography (Additional file 1: SI.2) showed a radiochemical purity of 99.0%.

Uniformly [phenyl-ring-14C]-labeled N-acetylsulfanilyl chloride (3a)

ClSO3H (45 μL, 0.67 mmol) was added dropwise with stirring in an ice bath to 2a (2.59 × 108 Bq, 2.96 × 109 Bq/mmol, 0.09 mmol, 99.0% purity) in CCl4 (1 mL). The mixture was further stirred at 58 °C for 2 h, after which NaCl (4 mg, 0.07 mmol) was added (Fig. 1, Method I). Following another 2 h of stirring, the mixture was cooled to room temperature. After hydrolysis of the residual chlorosulfonic acid with ice-cold water (10 mL), the mixture was extracted twice with ethyl acetate (35 mL each). The extracts were dried with anhydrous Na2SO4 and evaporated to ~ 1 mL. The product in the extract was purified using flash chromatography (Additional file 1: SI.1) with an elution gradient (Additional file 1: Table S1), resulting in 3a (1.39 × 108 Bq, 2.96 × 109 Bq/mmol) at 53.9% yield. TLC, performed using petroleum ether:ethyl acetate (1:4, v: v) containing 0.2% CH3COOH as the eluent (Rf = 0.35), coupled to autoradiography (Additional file 1: SI.2) showed a radiochemical purity of 96.0%.

Uniformly [phenyl-ring-14C]-labeled N-acetylsulfamethoxazole (4a) and uniformly [phenyl-ring-14C]-labeled N-acetylsulfamonomethoxine (6a)

Synthesis of 4a: 3a (4.07 × 105 Bq, 2.96 × 109 Bq/mmol) in 200 uL of acetone was first diluted with unlabeled 3 (15 mg, 0.064 mmol). Next, 3-amino-5-methylisoxazole (11, 13 mg, 0.130 mmol), anhydrous pyridine (11 μL, 0.130 mmol), and five pieces of molecular sieve (4 Å, diameter: 1 mm) were sequentially added with stirring in an ice bath. After another 5 h of stirring at 60 °C, the mixture was diluted with methanol (200 μL) and separated using preparative TLC, with petroleum ether: ethyl acetate (1:4 / v: v) containing 0.2% CH3COOH as the eluent. The product band of 4a (Rf = 0.53) was scraped from the TLC plate and extracted six times with ethyl acetate (15 mL each). Concentration of the extract by evaporation yielded 4a (2.07 × 105 Bq, 7.40 × 106 Bq/mmol, 51.0% yield) with 95.0% purity as determined by TLC coupled to autoradiography (Additional file 1: SI.2).

Synthesis of 6a: 3a (3.7 × 107 Bq, 2.96 × 109 Bq/mmol) in 200 uL of acetone was first diluted with unlabeled 3 (11.7 mg, 0.05 mmol), followed by the sequential addition of 4-amino-6-methoxypyrimidine (12, 16.1 mg, 0.129 mmol), anhydrous pyridine (10 μL, 0.124 mmol), and five pieces of molecular sieve (4 Å, diameter: 1 mm) with stirring in an ice bath. After an additional 23 h of stirring at 60 °C, 6a (Rf = 0.18) was purified as described for 4a. The purity of 6a (5.77 × 106 Bq, 7.55 × 108 Bq/mmol, 15.6% yield) was 95.0% as determined by TLC coupled to autoradiography (Additional file 1: SI.2).

Uniformly [phenyl-ring-14C]-labeled SMX (5a) and uniformly [phenyl-ring-14C]-labeled SMM (7a)

4a (2.04 × 105 Bq, 7.40 × 106 Bq/mmol) or 6a (4.81 × 106 Bq, 7.55 × 108 Bq/mmol) was heated in NaOH solution (10%, 1 mL) for 3 h at 100 °C and then neutralized with 6 M HCl to pH 6. The products were extracted eight times with ethyl acetate (15 mL each). The extracts were dried with anhydrous Na2SO4, evaporated to ~ 0.5 mL, and purified by preparative TLC using petroleum ether: ethyl acetate (1:4/v:v) containing 0.4% CH3COOH as the eluent. The product band of 5a or 7a (Rf = 0.6 or 0.51, respectively) was scraped from the plates and extracted six times with ethyl acetate (15 mL each). The extracts were evaporated to ~ 0.1 mL, resulting in 5a (1.85 × 105 Bq, 7.40 × 106 Bq/mmol) or 7a (3.18 × 106 Bq, 7.55 × 108 Bq/mmol) at 90.9% or 66.2% yield, respectively, and purities of 98.1% or 98.3%, respectively, as determined by HPLC (Additional file 1: SI.4). The chemical structures of 5a and 7a were elucidated by 1H-NMR, 13C-NMR (Additional file 1: SI.5), and LC-Q-TOF–MS/MS (Additional file 1: SI.6) using the corresponding unlabeled compounds synthesized according to the same procedures.

Synthesis of [14C]-SDZ (10a)

Uniformly [phenyl-ring-14C]-labeled N-acetylsulfanilyl chloride (3a)

2a (1.11 × 109 Bq/mmol, 99.0% purity) was synthesized from 1a (3.70 × 108 Bq, 2.96 × 109 Bq/mmol, 99.0% purity, 0.125 mmol) diluted with unlabeled 1 (26.6 mg, 0.205 mmol) using the method described above. The yield was 90%.

Next, 2a (2.48 × 108 Bq, 0.22 mmol) in CCl4 (0.5 mL) was diluted with unlabeled N-acetylaniline (23.5 mg, 0.17 mmol). ClSO3H (170 μL, 2.52 mmol) was added dropwise with stirring in an ice bath. After the mixture had been stirred at 58 °C for 2 h, SOCl2 (25 μL, 0.34 mmol) was added. The resulting solution was heated for another 2 h at 58 °C (Fig. 1, Method II), cooled to room temperature, and extracted twice with ethyl acetate (35 mL each). The extracts were dried with anhydrous Na2SO4 and evaporated to ~ 1 mL. The purity of the product, 3a (1.98 × 108 Bq), in the mixture was 93.0%, as determined by TLC, using petroleum ether:ethyl acetate (1:4 / v: v) containing 0.2% CH3COOH as the eluent (Rf = 0.35), coupled to autoradiography. The mixture without purification was directly used for the synthesis of 8a. The yield of 3a according to its purity in the mixture was 74.3%.

Uniformly [phenyl-ring-14C]-labeled N-acetylsulfonamide (8a)

Crude 3a (1.98 × 108 Bq, 6.29 × 108 Bq/mmol, 93.0% purity) was mixed with acetone (1 mL), after which ammonium hydroxide (0.5 mL, 28% NH3 in water) was added dropwise at 0 °C. The mixture was vigorously stirred at room temperature for 1 h and the pH was adjusted to 6 with 6 M HCl. It was then extracted eight times with ethyl acetate (15 mL each), dried with anhydrous Na2SO4, and evaporated. The product was purified by flash chromatography with an elution gradient (Additional file 1: Table S1), resulting in 8a (1.81 × 108 Bq) with a 98.3% yield and a purity of 99.0% as determined by TLC, using petroleum ether:ethyl acetate (1:4/v:v), containing 0.2% CH3COOH as eluent, (Rf = 0.26) coupled to autoradiography.

Uniformly [phenyl-ring-14C]-labeled N-acetylsulfadiazine (9a)

2-Chloropyrimidine (13, 48.7 mg, 0.42 mmol) and K2CO3 (58.6 mg, 0.42 mmol) were added sequentially to 8a (1.74 × 108 Bq, 6.29 × 108 Bq/mmol, 0.28 mmol, 99.0% radiochemical purity) in N,N-dimethylacetamide (DMA, 800 μL) with stirring at room temperature. The mixture was heated at 150 °C for 4.5 h, and the solvent N,N-dimethylacetamide was then removed by evaporation. The crude product was dissolved in water, cooled in an ice bath, and the pH was adjusted to 6 with 6 M HCl. The precipitate, comprising 9a (1.10 × 108 Bq), was washed with ice-cold water. The purity of the product was 57%, as determined by TLC (Additional file 1: SI.2), using petroleum ether:ethyl acetate (1:4/v:v) containing 0.2% CH3COOH as the eluent, coupled to autoradiography (Rf = 0.13). The yield of 9a according to its purity was 36.0%.

Uniformly [phenyl-ring-14C]-labeled SDZ (10a)

Crude 9a (9.25 × 107 Bq, 6.29 × 108 Bq/mmol, 57.0% radiochemical purity) was reacted with NaOH solution (10%, 5 mL) for 3 h at 100 °C and neutralized with 6 M HCl to pH 6. The product was extracted eight times with ethyl acetate (15 mL each). The extract was dried with anhydrous Na2SO4, evaporated to ~ 0.5 mL, and the crude product then recrystallized from boiling methanol. The precipitate was centrifuged and washed three times with methanol, resulting in 10a (3.11 × 107 Bq, 6.29 × 108 Bq/mmol). The purity was 98.3% as determined by HPLC (tR = 5.73 min. For details, see Additional file 1). The supernatant was further extracted five times with ethyl acetate (15 mL each). The extract was dried with anhydrous Na2SO4 and evaporated to dryness, resulting in solids containing 10a. These were mixed with unlabeled SDZ (54 mg) and then recrystallized from boiling methanol. The precipitate was washed three times with methanol, resulting in another portion of 10a with a low specific activity (1.10 × 107 Bq, 7.40 × 107 Bq/mmol) and a radiochemical purity of 98.3%. The total amount of 10a was 4.21 × 107 Bq, with a total yield of 79.9%. The chemical structure of 10a was elucidated by 1H-NMR, 13C-NMR (Additional file 1: SI.5), and LC-Q-TOF–MS/MS (Additional file 1: SI.6) using the corresponding unlabeled compounds synthesized according to the same procedures.

Synthesis of [13C]-SMX (5b), [13C]-SMM (7b), and [13C]-SDZ (10b)

Uniformly [phenyl-ring-13C]-labeled N-acetylaniline (2b)

K2CO3 (0.32 g/mL, 30 mL, 69 mmol) and acetic anhydride (4.70 g, 126 mmol) were added sequentially to [13C]-labeled aniline hydrochloride (1b, 3.00 g, 23 mmol, 99% of 13C atom) in a 200-mL flask with stirring at 25 °C. The mixture was further stirred at 25 °C for 1 h and then extracted five times with ethyl acetate (15 mL each). The extract was washed with 20 mL of H2O and then evaporated, resulting in 2b (3.01 g, 99% of 13C atom, 99.0% purity) with a yield of 95.7% (for details, see Additional file 1: SI.4).

Uniformly [phenyl-ring-13C]-labeled N-acetylsulfanilyl chloride (3b)

ClSO3H (19.8 g, 170 mmol) was added dropwise to 2b (3.00 g, 22 mmol, 99% of 13C atom) in CCl4 (5 mL) with stirring in an ice bath. After further stirring at 58 °C for 2 h, SOCl2 (2.67 g, 22 mmol) was added (Fig. 1, Method II). The mixture was heated at 58 °C for another 2 h and cooled to room temperature. The dropwise addition of ice-cold water (10 mL) to the mixture induced the formation of white crystals, which were washed twice with ice-cold water (each 10 mL) by filtration. The yield of the resulting product, 3b (4.29 g, 99% of 13C atom, 96.0% purity) (Additional file 1: SI.4), was 82.8%.

Uniformly [phenyl-ring-13C]-labeled N-acetylsulfamethoxazole (4b), N-acetylsulfamonomethoxine (6b), and N-acetylsulfadiazine (9b)

Synthesis of 4b: 3-amino-5-methylisoxazole (11, 412 mg, 4.2 mmol), anhydrous pyridine (339 μL, 4.2 mmol), and 10 pieces of molecular sieve (4 Å, diameter: 1 mm) were added sequentially to 3b (500 mg, 2.1 mmol, 99% of 13C atom) in acetone (2 mL) with stirring in an ice bath. The mixture was further stirred for 7 h at 60 °C. After removal of the molecular sieves, evaporation of the acetone, and crystallization in ice-cold water, the crude product 4b (470 mg, 99% of 13C atom, 95.0% purity) (Additional file 1: SI.4) was obtained at 73.8% yield.

Synthesis of 6b: 4-amino-6-methoxypyrimidine (12, 526 mg, 4.2 mmol), anhydrous pyridine (339 μL, 4.2 mmol), and 10 pieces of molecular sieve (4 Å, diameter: 1 mm) were added to 3b (500 mg, 2.1 mmol, 99% of 13C atom) in acetone (2 mL) with stirring in an ice bath. The reaction conditions and workup were as described for the synthesis of 4b. The yield of the crude product 6b (286 mg, 99% of 13C atom, 93.0% purity) (Additional file 1: SI.4) was 42.3%.

Synthesis of 8b: Ammonium hydroxide (5 mL, 28% NH3 in water) was mixed vigorously with 3b (1.0 g, 4.3 mmol, 99% of 13C atom) in acetone (10 mL) in an ice bath. After 1 h of stirring at 25 °C, the acetone was removed by evaporation, ice-cold water was added, and the pH was adjusted to 6 with 6 M HCl. Filtration and washing of the mixture with ice-cold water resulted in 8b (672 mg, 99% of 13C atom, 98.0% purity) (Additional file 1: SI.4) with a yield of 73.0%.

Synthesis of 9b: 2-chloropyrimidine (13, 361 mg, 3.1 mmol) and K2CO3 (439 mg, 3.2 mmol) were added with stirring at room temperature to 8b (450 mg, 2.1 mmol, 99% of 13C atom) in N,N-dimethylacetamide (3.5 mL). After 5 h of stirring at 150 °C, the mixture was processed as described above for the synthesis of 9a. The resulting product, 9b (494 mg, 99% of 13C atom, 93.0% purity) (Additional file 1: SI.4), was obtained in 74.8% yield.

Uniformly [phenyl-ring-13C]-labeled SMX (5b), SMM (7b), and SDZ (10b)

4b (300 mg, 99% of 13C atom), 6b (280 mg, 99% of 13C atom), and 9b (350 mg, 99% of 13C atom) were individually hydrolyzed in NaOH solution (10%, 3 mL) for 3 h at 100 °C, then neutralized to pH 6 with 6 M HCl and cooled in an ice bath. The precipitates were washed with ice-cold water six times (1 mL each) and dissolved in boiling methanol (SAs:methanol = 1:1, w:v). The methanol solutions were cooled in an ice bath to recrystallize the products, which were then separated by centrifugation (10 min, 2810 g) and washed twice with ice-cold methanol, resulting in 5b (238 mg, 99.0% purity), 7b (204 mg, 98.0% purity), and 10b (276 mg, 98.0% purity) in 92.5%, 83.7%, and 91.7% yield, respectively(Additional file 1: SI.4).

Results and discussion

SMX, SMM, and SDZ with uniform 13C and 14C labeling on the phenyl ring were prepared from commercially available, labeled aniline in a four-step or five-step synthesis (Fig. 1). The yields and radiochemical or chemical purities of the products are reported in Fig. 1. Three unlabeled SAs and the respective intermediates were similarly synthesized and characterized using HPLC-Q-TOF–MS/MS, and NMR (Additional file 1: Table S2).

Synthesis of [14C]- or [13C]-SMX, [14C]- or [13C]-SMM, and [14C]- or [13C]-SDZ

Chlorosulfonation of aniline on the para-position of the amino group using ClSO3H was the key step in the synthesis of SAs. Prior to this step, the aniline was acetylated to prevent possible oxidation of the amino group and bis-sulfonation on the ring during chlorosulfonation. The acetylation was performed in aqueous solution, and K2CO3 was added to improve nucleophilic activity of aniline (1a), resulting in acetylaniline (2a), with a good yield of 90.0%. Our preparation of 2a with fewer procedures was more convenient than the previously reported method [29].

Chlorosulfonation of 2a with ClSO3H generated the key intermediate 3a, a precursor in the synthesis of a variety of [14C]-SAs labeled on the phenyl ring via reactions with different amino heterocycles and subsequent alkaline hydrolysis. In a previous study, 1.1 g of 2a at a high molar ratio of ClSO3H to 2a (18:1) was used to obtain 3a, which formed a white solid after crystallization in water [29]. However, this method of using a high volume of ClSO3H cannot be applied to synthesize 3a at milligram scale (12 mg of 2a), because the hot H2SO4, derived from the hydrolysis of excess ClSO3H in water, causes the decomposition of 3a, resulting in a very low yield. HPLC-Q-TOF–MS/MS also showed the conversion of a large amount of 3a to N-acetylsulfanilic acid (data not shown). In addition, the solvent-free condition used in previous studies may result in an inhomogeneous mixture of the reactants at a micro-scale. Nguyen-Hoang-Nam et al. [28] also found that it was difficult to synthesize sulfonyl chloride in a small amount and thus failed to obtain micro-quantities (100 mg) of N,N-di(2-chloro-n-propyl)aminobenzenesulfonyl chloride labeled on the phenyl ring by chlorosulfonation with ClSO3H and the corresponding [14C]-sulfonamide derivatives. Therefore, we used a low molar ratio of 1:7.4 in solvent CCl4, and added NaCl to the reaction mixture to consume the by-product H2SO4. These modifications not only completely converted 2a, they also reduced the decomposition of 3a to N-acetylsulfanilic acid by hot H2SO4, such that 3a was produced in a good yield (53.9% after purification; Fig. 1).

Water inhibits the condensation of 3a with amino heterocyclic compounds (e.g., 11 and 12). In our method, water interference was avoided by the inclusion of molecular sieves to adsorb the water during the condensation. With this method, 4a and 6a were obtained in yields of 51.0% and 15.6%, respectively (Fig. 1).

The condensation of 3 with amino heterocycles involved a nucleophilic substitution. Compound 11 had a higher nucleophilic activity than compound 12, according to their electron cloud density, which was in agreement with the higher yield of 4a than 6a (51.0% vs. 15.6%) and of 4b than 6b (73.8% vs. 42.3%) (Fig. 1). The condensation of 3 with other heterocyclic compounds can be used to synthesize other [14C]- or [13C]-labeled sulfonamides, such as the synthesis of SDZ from 2-aminopyrimidine [28]. However, owing to the low nucleophilic activity of 2-aminopyrimidine, the yield of 10a at micro-scale was very low (7.4%; overall yield of 10a from 1a: 2.4%) and the yield of 9b (21.0%) was lower than that of either 4b (73.8%) or 6b (42.3%) (Fig. 1). Therefore, 10a and 10b were synthesized in a five-step synthetic pathway (Fig. 1), in which two steps were used to synthesize 9 instead of one step. First, 8 was synthesized by the condensation of 3 with ammonium hydroxide, which has high nucleophilic activity and is a base capable of neutralizing the by-product H2SO4. Good yields were achieved for both 8a (98.3%) and 8b (73.0%). The coupling of 8 to 13 produced both 9a and 9b in good yields of 36.0% and 74.8%, respectively. The synthesis of 9 from 3 via this two-step pathway not only completely converted 3 to 8 with a high stability, thus avoiding the decomposition of 3, it also resulted in a much higher overall yield than the one-step reaction (35.4% vs. 7.4% for 9a, 54.6% vs. 21.0% for 9b).

13C-NMR of [13C]-SMX, [13C]-SMM, and [13C]-SDZ

The 13C-NMR spectra of three [13C]-SAs and their corresponding unlabeled compounds are shown in Fig. 2. The significant triplet signals allowed the assignment of the signals at 112.53–112.98 ppm, 124.46–125.08 ppm, 129.16–130.16 ppm, and 153.25–153.51 ppm to 13C-atoms of the benzene ring. 13C-tracers can provide more structural information about the fate and behaviors of labeled C-atoms in environmental matrixes than obtained with radioactive [14C]-tracers [30]. The peaks of the C-atoms in 13C-labeled compounds are split into triplets due to 13C–13C coupling and they have a much higher intensity than those in non-labeled compounds containing 13C-atoms in natural abundance (1.1%). Accordingly, the triplet signals can be used to identify the chemical nature of labeled carbon atoms, as demonstrated for the residues of pesticides (e.g., cyprodinil), humus monomers (e.g., catechol), and emerging pollutants (e.g., tetrabromobisphenol A) bound to soil humic substances [31,32,33], thus providing unambiguous information about the incorporation of pollutants (e.g., SDZ, nonylphenol, and chlorophenol) into humic substances [34,35,36].

13C-NMR spectra of [13C]-SMX (5b), [13C]-SMM (7b), and [13C]-SDZ (10b). The positions of the numbered C-atoms are given in the corresponding structure of the [13C]-labeled SAs. The red and black lines represent the spectra of SAs with [13C]-labeling or natural 13C-abundance. The signal of the C-atoms at the [13C]-labeled benzene ring is enlarged. The chemical shifts of the numbered C-atoms with natural abundance are listed

Advantages of the synthetic methods

The main advantage of our synthetic methods over those previously reported is the ability to synthesize [14C]-SAs at micro-scale using commercially available, relatively inexpensive [14C]-labeled 1 (~ 16.2 mg). Unlike the classic synthetic pathway, which proceeds via the condensation of 3 with aminoheterocycles, in our reaction the pathway that includes the condensation of 8 with chloroheterocylces has been optimized for the synthesis of [14C]-labeled SAs using an aminoheterocycle of low nucleophilic activity or of high steric hindrance, either of which results in [13C]-labeled SAs in good yields.

Purification is important for product quality. The methods for purification described herein are appropriate for [14C]-compounds produced in small amounts as they result in a high purity. Both crystallization in water, as a purification procedure, and the direct use of the reaction mixture without further purification are applicable to the synthesis of unlabeled SAs at a gram scale [26, 27], but not to the synthesis of [14C]-labeled SAs at a milligram scale, because impurities may affect the next reaction in the absence of purification, but recrystallization may result in the recovery of smaller amounts of product. In this study, we used classic chromatographic separation methods, such as flash column chromatography and preparative TLC, to purify small amounts of [14C]-products.

Conclusions

This study describes optimized methods for the synthesis of SAs labeled with 14C or 13C on the phenyl ring using commercially available [14C]- or [13C]-aniline, especially the synthesis of [14C]-labeled SAs on a micro-scale (milligram amounts). Three typical sulfonamide antibiotics, SMX, SMM, and SDZ, with [14C]- or [13C]-labeling were prepared in good yields (5.0–22.5% for 14C, 28.1–54.1% for 13C relative to aniline). Both four-step (via the condensation of 3 and aminoheterocycles) and five-step (via the condensation of 8 and chloroheterocycles) reactions were examined. The four-step pathway is suitable for the synthesis of large amount of SAs (e.g., grams) or SAs containing aminoheterocyles of high nucleophilic activity, and the five-step pathway for the synthesis of SAs (e.g., SDZ) in milligram amounts and containing an aminoheterocycle of low nucleophilic activity. Both can be employed to prepare commercially unavailable labeled SAs for use in studies on the fate and behavior of these drugs in natural and engineered environments and biological systems.

Availability of data and materials

The complete dataset of this study is included within the article and the Additional file.

Abbreviations

- SAs:

-

Sulfonamide antibiotics

- SMX:

-

Sulfamethoxazole

- SMM:

-

Sulfamonomethoxine

- SDZ:

-

Sulfadiazine

- NERs:

-

Non-extractable residues

- NMR:

-

Nuclear magnetic resonance

- TLC:

-

Thin-layer chromatography

- HPLC:

-

High-performance liquid chromatography

- LSC:

-

Liquid scintillation counting

- MS:

-

Mass spectrometer

- R f :

-

Retardation factor

- t R :

-

Retention time

- DMA:

-

N,N-Dimethylacetamide

References

Hsieh MK, Shyu CL, Liao JW, Franje CA, Huang YJ, Chang SK, Shih PY, Chou CC (2011) Correlation analysis of heat stability of veterinary antibiotics by structural degradation, changes in antimicrobial activity and genotoxicity. Vet Med 56:274–285

Gros M, Petrović M, Ginebreda A, Barceló D (2010) Removal of pharmaceuticals during wastewater treatment and environmental risk assessment using hazard indexes. Environ Int 36:15–26

Zhang QQ, Ying GG, Pan CG, Liu YS, Zhao JL (2015) Comprehensive evaluation of antibiotics emission and fate in the river basins of China: source analysis, multimedia modeling, and linkage to bacterial resistance. Environ Sci Technol 49:6772–6782

Wei RC, Ge F, Zhang LL, Hou X, Cao YN, Gong L, Chen M, Wang R, Bao ED (2016) Occurrence of 13 veterinary drugs in animal manure-amended soils in Eastern China. Chemosphere 144:2377–2383

Lapworth DJ, Baran N, Stuart ME, Ward RS (2012) Emerging organic contaminants in groundwater: a review of sources, fate and occurrence. Environ Pollut 163:287–303

Wang J, Lin H, Sun W, Xia Y, Ma J, Fu J, Zhang Z, Wu H, Qian M (2016) Variations in the fate and biological effects of sulfamethoxazole, norfloxacin and doxycycline in different vegetable–soil systems following manure application. J Hazard Mater 304:49–57

Wang FH, Qiao M, Chen Z, Su JQ, Zhu YG (2015) Antibiotic resistance genes in manure-amended soil and vegetables at harvest. J Hazard Mater 299:215–221

Feng L, Jinshui W, Guang-Guo Y, Zhuanxi L, Hong F (2012) Changes in functional diversity of soil microbial community with addition of antibiotics sulfamethoxazole and chlortetracycline. Appl Microbiol Biotechnol 95:1615–1623

Liu F, Ying GG, Tao R, Zhao JL, Yang JF, Zhao LF (2009) Effects of six selected antibiotics on plant growth and soil microbial and enzymatic activities. Environ Pollut 157:1636–1642

Liu J, Wang YF, Jiang BQ, Wang LH, Chen JQ, Guo HY, Ji R (2013) Degradation, metabolism, and bound-residue formation and release of tetrabromobisphenol A in soil during sequential anoxic-oxic incubation. Environ Sci Technol 47:8348–8354

Shan J, Jiang BQ, Yu B, Li CL, Sun YY, Guo HY, Wu JC, Klumpp E, Schäffer A, Ji R (2011) Isomer-specific degradation of branched and linear 4-nonylphenol isomers in an oxic soil. Environ Sci Technol 45:8283–8289

Wang Y, Xu J, Shan J, Ma Y, Ji R (2017) Fate of phenanthrene and mineralization of its non-extractable residues in an oxic soil. Environ Pollut 224:377

Barriuso E, Benoit P, Dubus IG (2008) Formation of pesticide nonextractable (bound) residues in soil: magnitude, controlling factors and reversibility. Environ Sci Technol 42:1845

Gevao B, Jones K, Semple K, Craven A, Burauel P (2003) Nonextractable pesticide residues in soil. Environ Sci Technol 37:138a–144a

Stokvis E, Rosing H, Beijnen JH (2005) Stable isotopically labeled internal standards in quantitative bioanalysis using liquid chromatography/mass spectrometry: necessity or not? Rapid Commun Mass Spectrom 19:401–407

Ji R, Chen ZX, Corvini PFX, Kappler A, Brune A, Haider K, Schäffer A (2005) Synthesis of [13C]- and [14C]-labeled phenolic humus and lignin monomers. Chemosphere 60:1169–1181

Bialk HM, Hedman C, Castillo A, Pedersen JA (2007) Laccase-mediated Michael addition of 15N-sulfapyridine to a model humic constituent. Environ Sci Technol 41:3593–3600

Bialk HM, Simpson AJ, Pedersen JA (2005) Cross-coupling of sulfonamide antimicrobial agents with model humic constituents. Environ Sci Technol 39:4463–4473

Berns AE, Philipp H, Lewandowski H, Choi J-H, Lamshoeft M, Narres H-D (2018) Interactions of N-15-sulfadiazine and soil components as evidenced by N-15-CPMAS NMR. Environ Sci Technol 52:3748–3757

Zhang Y, Hu S, Zhang H, Shen G, Yuan Z, Zhang W (2017) Degradation kinetics and mechanism of sulfadiazine and sulfamethoxazole in an agricultural soil system with manure application. Sci Total Environ 607–608:1348–1356

Fang JS, Lovanh N, Alvarez PJJ (2004) The use of isotopic and lipid toluene degradation to specific analysis techniques linking microorganisms: applications and limitations. Water Res 38:2529–2536

Lerner H, Ozturk B, Dohrmann AB, Thomas J, Marchal K, De Mot R, Dehaen W, Tebbe CC, Springael D (2020) Culture-independent analysis of linuron-mineralizing microbiota and functions in on-farm biopurification systems via DNA-stable isotope probing: comparison with enrichment culture. Environ Sci Technol 54:9387–9397

Peeters K, Iskra J, Zuliani T, Ščančar J, Milačič R (2014) The micro-scale synthesis of 117Sn-enriched tributyltin chloride and its characterization by GC-ICP-MS and NMR techniques. Chemosphere 107:386–392

Borges ADL, Del Pointe G, Neto AF, Carvalho I (2005) Synthesis of sulfadiazine and silver sulfadiazine in semi-micro scale, as an experimental practice in drug synthesis. Quim Nova 28:727–731

Sprague JM, Kissinger LW, Lincoln RM (1941) Sulfonamido derivatives of pyrimidines. J Am Chem Soc 11:3028–3030. https://doi.org/10.1021/ja01856a046

Caldwell WT, Kornfeld EC, Donnell CK (1941) Substituted 2-sulfanilamidopyrimidines. J Am Chem Soc 63(8):2188–2190. https://doi.org/10.1021/ja01853a045

Barbosa ML, Melo GM, da Silva YK, Lopes Rde O, de Souza ET, de Queiroz AC, Smaniotto S, Alexandre-Moreira MS, Barreiro EJ, Lima LM (2009) Synthesis and pharmacological evaluation of N-phenyl-acetamide sulfonamides designed as novel non-hepatotoxic analgesic candidates. Eur J Med Chem 44:3612–3620

Hoellinger H, Nguyen-Hoang-Nam PL (1973) Synthesis of sulfadiazine and its derivatives (N4-acetylsulfanilamido)-2-pyridine, (benzenesufonamido)-2-pyrimidine and) para toluenesulfonamide)-2-pyrimidine labeled with C-14 in pyrimidine in pyrimidine nucleus. J Label Compd Radiopharm 9:161–166

Yu NX, Raab CE, Dean DC, Lin LS, Melillo DG (2004) Synthesis of [3,5-dichlorobenzenesulfonamide-U-14C)] labeled VLA-4 antagonists. J Label Compd Radiopharm 47:115–125

Guthrie EA, Bortiatynski JM, van Heemst JDH, Richman JE, Hardy KS, Kovach EM, Hatcher PG (1999) Determination of [13C] pyrene sequestration in sediment microcosms using flash pyrolysis-GC-MS and 13C NMR. Environ Sci Technol 33:119–125

Dec J, Haider K, Benesi A, Rangaswamy V, Schäffer A, Plücken U, Bollag J-M (1997) Analysis of soil-bound residues of 13C-labeled fungicide cyprodinil by NMR spectroscopy. Environ Sci Technol 31:1128–1128

Tong F, Gu X, Gu C, Xie J, Xie X, Jiang B, Wang Y, Ertunc T, Schäffer A, Ji R (2016) Stimulation of tetrabromobisphenol A binding to soil humic substances by birnessite and the chemical structure of the bound residues. Environ Sci Technol 50:6257–6266

Li C, Zhang B, Ertunc T, Schaeffer A, Ji R (2012) Birnessite-Induced binding of phenolic monomers to soil humic substances and nature of the bound residues. Environ Sci Technol 46:8843–8850

Junge T, Meyer KC, Ciecielski K, Adams A, Schäffer A, Schmidt B (2011) Characterization of non-extractable 14C- and 13C-sulfadiazine residues in soil including simultaneous amendment of pig manure. J Environ Sci Health B 46:137–149

Li C, Ji R, Vinken R, Hommes G, Bertmer M, Schäffer A, Corvini PFX (2007) Role of dissolved humic acids in the biodegradation of a single isomer of nonylphenol by Sphingomonas sp. Chemosphere 68:2172–2180

Hatcher PG, Bortiatynski JM, Minard RD, Dec J, Bollag JM (1993) Use of high-resolution carbon-13 NMR to examine the enzymatic covalent binding of carbon-13-labeled 2,4-dichlorophenol to humic substances. Environ Sci Technol 27:2098–2103

Acknowledgements

We gratefully acknowledge Mr. Qingwei Hang, from the School of Chemistry and Chemical Engineering, Nanjing University, for his help in 1H-NMR and 13C-NMR spectroscopy determinations. We also thank Ms. Xiaoran Guo for her suggestions regarding the experiment.

Funding

This study was funded by the National Key Research and Development Program of China (Nos. 2021YFA0910303, 2016YFD0800207), the National Natural Science Foundation of China (Nos. 31861133003, 21661132004, 21607071), the Swiss National Science Foundation (No. IZLCZ2_170272), and the European Horizon 2020 ELECTRA project (No. 826244).

Author information

Authors and Affiliations

Contributions

XW: investigation, methodology, validation, visualization, writing of the original draft; YY: resources; LW and DZ: methodology, supervision; FS: supervision, visualization, funding acquisition, review and editing of the manuscript; JC: supervision, methodology; PC: resources, review and editing of the manuscript, funding acquisition. RJ: conceptualization, supervision, review and editing of the manuscript, funding acquisition; All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

The details of the instruments and analytical methods are provided. Table S1. Purification of [14C]-labeled intermediates and SAs. Table S2. 1H-NMR, 13C-NMR, and HPLC−MS/MS analyses of synthesized unlabeled intermediates and SAs.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, X., Yao, Y., Wang, L. et al. Synthesis of typical sulfonamide antibiotics with [14C]- and [13C]-labeling on the phenyl ring for use in environmental studies. Environ Sci Eur 34, 23 (2022). https://doi.org/10.1186/s12302-022-00598-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-022-00598-z