Abstract

In this research work, optimized nebivolol-loaded lecithin-chitosan hybrid nanoparticles (NEB-LCNPs) were prepared using sequential screening and optimization designs. The design of experiments software (DoE) was used to obtain a robust formulation that can improve ocular delivery of the NEB in the treatment of glaucoma. The optimized NEB-LCNPs had a mean particle size of 170.5 ± 5.3 nm and drug loading of 10.5 ± 1.2%. These were further loaded in a dual-responsive in situ gel, designed and reported previously by our group. The NEB-LCNPs loaded in situ gel (NEB-LCNPs-ISG) was characterized for physicochemical properties, rheological behavior, stability, in vitro dissolution, and ocular in vivo studies. The ocular pharmacokinetics showed that NEB-LCNPs-ISG had two-fold higher aqueous humor exposure with AUC0–tlast of 375.4 ng × h/mL and sustained drug concentrations for longer durations (1.7-folds higher duration with a mean residence time of 10.6 h) in comparison to a conventional aqueous suspension of NEB (NEB-Susp). Similarly, the pharmacodynamic study showed that NEB-LCNPs-ISG resulted in a higher percentage reduction in intraocular pressure (% ΔIOP) of 28.1 ± 1.8% × h, which was 2.2-times higher reduction compared to NEB-Susp (74.2 ± 3.2% × h). In addition, the pharmacodynamic effect was more sustained with a mean response time of 11.3 ± 0.2 h, a 2.8-times higher response time compared to NEB-Susp (4.06 ± 0.3 h). These results suggest that NEB-LCNPs-ISG was more effective than the conventional aqueous suspension of NEB in the treatment of glaucoma.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Conventional suspension formulations of beta-blockers have limitations, such as short retention times, rapid drainage through the nasolacrimal duct, and entry into the systemic circulation. These shortcomings with conventional formulation not only reduce overall therapeutic efficacy at the target site but also raise systemic safety concerns [1]. Nebivolol (NEB) is a novel third-generation beta-blocker that facilitates the release of nitric oxide and vasodilation through the L-arginine/NO/cGMP pathway. NEB was investigated as a potential candidate in the treatment of glaucoma to address the systemic side effects associated with first-generation beta blockers. NEB modulates the drainage of aqueous humor via the trabecular meshwork and offers neuroprotection, which is an added advantage [2]. The main issue of the extremely low ocular bioavailability of the drug is due to the anatomical and physiological features of the eye, which act as barriers to the absorption and permeation of the drug to reach the target site for effective management of glaucoma. In our earlier published work, we developed NEB-loaded dual-responsive in situ gels using a combination of temperature-responsive polymers, including poloxamer 407 and poloxamer 188, with an ion-sensitive polymer, kappa-carrageenan [3]. The formulation significantly increased the precorneal drug residence time, which led to its improved pharmacokinetic and pharmacodynamic effects over conventional aqueous suspension of NEB.

To further improve the efficiency of ocular delivery and therapeutic efficacy of NEB, we explored the idea of designing nanocarrier formulations for NEB. Nanocarrier formulations delivered through the ocular route offer advantages such as protecting the drug from metabolic degradation or efflux transporters by limiting the exposure of the encapsulated drug to the external environment. In addition, the nanocarrier system also provides controlled release of the loaded drug, increased ocular residence time with the help of mucoadhesive components, and a preferential uptake via direct pathways [4].

In recent years, researchers have explored the use of combining two formulation approaches by loading nanocarrier formulations in the in situ gels to improve drug delivery to intraocular tissues [5]. In situ gels can address the issues associated with tear fluid dilution, nasolacrimal drainage, and short precorneal residence time with conventional ocular drug products. It also maintains dose accuracy and patient convenience compared to semisolid preparations administered through the ocular route [6]. Therefore, in situ gels loaded with nanocarrier formulations can benefit both systems by improving the ocular delivery of drugs, particularly in the treatment of diseases such as glaucoma.

Chitosan is a biodegradable polysaccharide obtained by subjecting chitin to partial deacetylation. It contains repetitive disaccharide units composed of D-glucosamine and N-acetyl-D-glucosamine units linked through glycosidic bonds [7]. It is available in a wide range of molecular masses from 50–400 kDa with different viscosities and with 35–98% deacetylation. The peculiar properties of chitosan, such as corneal mucoadhesion, biodegradability, antimicrobial properties, and nontoxicity, make it an excellent excipient for designing ocular nanoformulations [8]. Chitosan, being a polycation in pH 5.5 to 6.5, exhibits mucoadhesive characteristics due to its ionic interactions with the anionic ocular mucosa. Such mucoadhesive properties help retain the formulation in the precorneal area for a longer duration. Chitosan can also interact with the corneal epithelial by relaxing the tight connections between cells, and increase the drug permeability [9, 10].

Soya lecithin, a phospholipid, contains phosphatidylcholine as the major constituent. It is non-toxic, biodegradable, biocompatible, and non-immunogenic [11]. It is one of the extensively used excipients in the preparation of various lipid-based formulations, including liposomes, nanostructured lipid carriers, solid lipid nanoparticles, etc. The interactions between the negatively charged constituents of lecithin and positively charged constituents of chitosan form a hybrid nanoparticulate system by self-organizing ionic interactions [12]. Saha et al. discussed the development of resveratrol-loaded mucoadhesive lecithin/chitosan nanoparticles for prolonged ocular drug delivery based on the QbD approach [13]. Hassan et al. showed that coating nanoparticles with chitosan enhances the precorneal residence time and transcorneal permeation of hydrophobic compounds [14].

Furthermore, Bhatta et al. developed natamycin-loaded chitosan/lecithin nanoparticles that exhibited high ocular bioavailability at reduced dose and dosing frequency compared to marketed ocular suspension of the drug. Following topical administration, the area under the aqueous humor concentration versus time curve increased up to 1.47-folds while the clearance decreased up to 7.4-folds for the natamycin-loaded chitosan/lecithin nanoparticles in comparison to marketed ocular suspension [15]. Abdelmonem et al. developed chitosan-coated niosomal gel formulations of acetazolamide carvedilol that demonstrated an intraocular pressure (IOP) reduction of up to 50% within 4 h, and this response persisted for 8 h after ocular administration. These results were attributed to the interaction of chitosan with mucin, which prolonged drug absorption via the cornea and eventually enhanced the therapeutic efficacy [16]. The nanocarrier system consisted of a lipid core of soya lecithin and a bio-polymeric shell composed of medium molecular weight chitosan. While the lipid core provided high encapsulation capacity for a lipophilic drug, the bio-polymeric shell of chitosan supports potential targeting by the interaction of amino and hydroxyl groups with the negatively charged mucin in the mucosal epithelium and improving permeability [17].

The objective of our research work is to design a novel lecithin chitosan hybrid nanocarrier system for NEB (NEB-LCNPs) using the design of experiments (DoE) and prepare the formulation of NEB-LCNPs-Susp. The optimized NEB-LCNPs are loaded in the dual-responsive in situ gel (NEB-LCNPs-ISG) to enable efficient ocular delivery with longer precorneal residence time [3]. Developed formulations were characterized for physicochemical properties, rheology, stability, in vitro dissolution, ex vivo ocular irritation, and ocular in vivo evaluations. An ocular pharmacokinetic study was conducted to determine the rate and extent of NEB absorption in aqueous humor, while a pharmacodynamic study was conducted to measure the percent change in intraocular pressure (% ΔIOP) in a male New Zealand rabbit as an animal model [18]. The results from in vivo studies with nanocarrier formulation were compared with those obtained with an aqueous suspension of NEB (NEB-Susp) evaluated for improved therapeutic efficacy in the treatment of glaucoma. The objectives are depicted briefly in the Fig. 1.

2 Experimental section

2.1 Materials and methods

NEB and deuterated NEB (NEB-d4, used as an internal standard in bioanalysis) were obtained from MSN Laboratories (Hyderabad, India) and Bio-organics Limited, Bangalore, India, respectively. Poloxamer 407 (P407) with an average molecular weight of 12,600 Da, kappa-carrageenan (κCRG) with an average molecular weight of 788.65 kDa (viscosity of 0.3% w/v solution is 10–25 mPa at 25 °C), poloxamer 188 (P188) with an average molecular weight of 8400 Da, chitosan with an average molecular weight of 100–300 kDa and polyvinyl alcohol with an average molecular weight of 1,60,000 Da were obtained from Sigma Aldrich Pvt. Ltd., (Mumbai, India). Lecithin (Phospholipon® 90G, soybean lecithin (phosphatidylcholine) was procured from Lipoid Phospholipid GMBH Nattermannallee, Steinhausen, Switzerland. Methanol and acetonitrile of liquid chromatography-mass spectroscopy (LC‐MS) grade were supplied by Thermo Fischer Scientific, Mumbai, India. N-methyl pyrrolidone (NMP) and trehalose SG were procured from Tokyo Chemical Industries (India) Private Limited, Hyderabad, India, and Hayashibara Company Limited, Okayama, Japan, respectively. Ammonium acetate and formic acid were purchased from Sisco Research Laboratories Private Limited, Mumbai, India. Water collected from the Milli‐Q purification system (Millipore®, Massachusetts, USA) was used in all the sample analyses. Male New Zealand white rabbits (age: 10 months; weight: ~ 2.5 kg) were supplied by Vimta Labs, Hyderabad, India.

2.2 Analytical and bioanalytical methods

Various aqueous samples, including the samples from formulation drug loading/entrapment studies and in vitro drug release studies, were analyzed using the high-performance liquid chromatography (HPLC)-UV analytical method. The developed method was based on the method reported for NEB by Zoltan et al., with minor modifications [19]. The proposed method for detecting NEB has a shorter runtime per sample and was linear, precise, and accurate in the calibration range of 100 to 10,000 ng/mL. A Kinetex® C18 reverse-phase column (end-capped; 250 mm × 4.6 mm, particle size 5 μm) (Phenomenex, CA, USA) was used. A mixture of 0.1% (w/v) orthophosphoric acid in water and acetonitrile in 57:43 (v/v) ratio was used as the mobile phase. The flow rate was set at 0.8 mL/min. An LC‐MS/MS method, published by our research group, was employed to analyze the samples obtained in ocular pharmacokinetic studies [20]. The reported method is linear in the calibration range of 0.43 to 750 ng/mL. The samples were analyzed using HPLC (Agilent 1260 Infinity II, Agilent Technologies Inc., CA, USA) combined with a triple quadrupole mass analyzer (API 4500, AB SCIEX, CA, USA). Chromatographic separation was achieved on a Zorbax reversed-phase C18 column (SB‐C18, 4.6 mm × 100 mm, 3.5 μm). A mixture of acetonitrile and methanol in a 30:70 (v/v) ratio was used as organic phase while ammonium acetate buffer (5 mM, pH 3.5 ± 0.05) was used as aqueous phase. Mobile phase containing the above organic and aqueous phases in 75:25 (v/v) was eluted at a flow rate of 0.6 mL/min to analyse the samples. Drug was extracted from the plasma and aqueous humor samples by protein precipitation method. Electron spray ionization, in positive mode, was used to generate the analyte ions. NEB and NEB-d4 were quantified using multiple reaction monitoring mode at Q1/Q3 transitions of 406.2/151.1 and 410.2/151.3, respectively.

2.3 Preparation of NEB-LCNPs

NEB-LCNPs were prepared by a solvent-antisolvent precipitation method [21]. Initially, lecithin (100 mg) and NEB (200 mg) were dissolved in 1.5 mL of NMP in a container to form the organic phase. The aqueous phase was prepared by dissolving chitosan (0.25–0.5% w/v, varied within the range as per the design) in an acetic acid solution (0.5% v/v in water; the pH of the solution was adjusted to 4.0 using 5 M sodium hydroxide). The stabilizer solution of PVA (0.06%-0.4%, varied within the range as per the design) was further added to the aqueous solution of chitosan to form a clear aqueous phase solution. The organic phase containing NEB + lecithin in NMP was slowly added dropwise using a syringe (with a needle having 0.72 mm internal diameter) to 25 mL of the aqueous phase (containing chitosan + PVA) under homogenization (Polytron PT 3100D, Kinematica, Lucerne, Switzerland). The mixture, following the complete addition of the organic phase into the aqueous phase, was further exposed to ultrasonication (Vibra cell, Sonics, CT, USA) to form a dispersion of NEB-LCNPs.

To separate the nanoparticles, the nano suspension was subjected to centrifugation (Model C-24 BL, Remi, Mumbai, India) at 11,000 rpm at 10 °C for 40 min to obtain a pellet of NEB-LCNPs. The pellet containing NEB-LCNPs was separated from the supernatant and was cleansed three times with Milli-Q water to remove any free drug remaining on the surface of nanoparticles. The pellet was re-dispersed in 5 mL of trehalose solution (5% w/v, prepared using MilliQ water as solvent) as a cryoprotectant and frozen at − 80 °C for 8 h before lyophilization. The freeze-dried NEB-LCNPs were stored at 2–8 °C.

2.4 Determination of size and surface charge of NEB-LCNPs

The NEB-LCNPs manufactured in the various experimental runs in DoE were analyzed using the dynamic light scattering technique (Zetasizer nano ZS, Malvern Instruments, Worcestershire, UK) to characterize their particle size (PS), polydispersity index (PDI), and zeta-potential (ZP). The samples were analysed at a backscatter angle of 173°. Laser light with a wavelength of 633 nm was used to irradiate the samples to perform all the particle size measurements. Each sample was diluted with MilliQ water (20× dilution) and equilibrated at 25 °C for 120 s before the measurement. For every sample, three separate measurements were made, and the mean values for PS, PDI, and ZP were determined.

2.5 Application of DoE using a screening design and optimization design for preparation of NEB-LCNPs

The NEB-LCNPs were optimized based on sequential screening and optimization designs. First, a screening design was used to select the critical factors affecting the desired physico-chemical responses of the NEB-LCNPs. PS and DL (%) were taken as the critical responses for NEB-LCNPs. Based on the results, a suitable optimization design was used to determine the design space and, within that, a control space (or solutions) for all the critical factors to manufacture NEB-LCNPs with desired PS and DL (%). The design matrix tables with the compositions of factors in each experimental run, for both screening and optimization experiments, were constructed using Design Expert® (version 10, Stat- Ease Inc., MN, USA).

In the screening design, 6 independent factors were studied. The working ranges of the 6 independent factors are listed in Table 1. A fractional factorial design involving 6 factors studied at two levels, with a resolution of IV, was used to screen the factors (\(2_{{\text{IV}}}^{6 - 2}\) design). In addition, three center point runs were also added to detect the curvature in the relation between responses and independent factors.

In the screening design, 3 factors were found to be statistically significant and, hence, were considered for further optimization studies. The effect of these three critical factors, viz. chitosan-to-lecithin ratio (X1) (weight ratio); homogenization speed (X2), and sonication amplitude (X3) at three levels of low (− 1), medium (0), and high (+ 1), was evaluated on two critical responses of PS and DL (%). The insignificant factors from screening studies were fixed at specific values (which resulted in best value for PS and DL (%) as part of screening studies) in the optimization studies.

Box Behnken design (BBD) was used to optimize the three critical factors. BBD is the most widely used response surface methodology due to its ability to predict the regression equation with a lesser number of experimental runs for a given number of independent factors. In addition, BBD avoids any extremes of the working ranges of the factors in the experimental runs [avoids the experimental runs with factors at (− 1, − 1, − 1) and (+ 1, + 1, + 1)]. The total number of runs performed under this design included 12 factorial runs and 3 center point runs, making a total of 15 runs. After performing the experiments with 15 different combinations of the critical factor values, the data obtained for the critical responses (PS and DL (%)) was fitted into the different regression equations. The statistical evaluations were performed using ANOVA for the individual responses at a significance level of 5%. Numerous solutions were obtained by setting the criteria for the critical factors as well as the responses. The levels of factors that yielded the highest desirability value and that were feasible to employ in the manufacturing process were selected and further validated by checking the difference between the observed and predicted responses. The Wilcoxon signed-rank test was used to validate the optimal solution provided by DoE at a significance level of 5%. The optimized NEB-LCNPs were evaluated for their stability at two different conditions, including controlled room temperature (25 ± 2 °C and 60 ± 5% relative humidity) and refrigerated condition (2–8 °C). The physicochemical properties such as PS, PDI, ZP, DL (%) and EE (%) were evaluated at 0, 15, 30, 45, and 60 days during the stability studies for the optimized NEB-LCNPs at both the storage conditions.

2.6 Determination of the drug loading (DL (%)) and entrapment efficiency (EE (%)) of the NEB-LCNPs

The DL (%) and EE (%) of the NEB-LCNPs were determined by both direct and indirect methods. The pellets obtained from the centrifugation of freshly prepared NEB-LCNP nanosuspensions were used to determine the DL (%) and EE (%) via direct methods. The pellet was washed twice with 5 mL of Milli-Q water and dried under vacuum. The weighed quantity of the dried pellet was dissolved initially in 0.5 mL of acetic acid solution (1% w/v) and vortexed for 5 min. Then, 1.5 mL of NMP was added to the above solution and vortexed again for 5 min to extract the drug from the nanoparticle matrix. The sample was then suitably diluted and analyzed using the HPLC–UV method. In the indirect method, the supernatant obtained after centrifugation of freshly prepared NEB-LCNP nanosuspensions was collected and analyzed after suitable dilution to determine the amount of NEB present in the dissolved state in the continuous phase of the nanosuspension.

Furthermore, the NEB adsorbed on the surface of the NEB-LCNPs was also determined by analyzing the supernatants collected from the pellet washings. The HPLC–UV method described in Sect. 2.2 was used to quantify NEB in all the above samples. The total amount of unentrapped NEB was determined by combining the amount of NEB present in the dissolved state in the supernatant, and the amount of NEB recovered in the two washes. The DL (%) and EE (%) of NEB-LCNPs in the direct method were determined using Eq. (1) and Eq. (2), respectively, and in the indirect method using Eq. (3) and Eq. (4), respectively.

where \(W_{NEB\, in \,Pellet} =\) is the amount of NEB present in the pellet; \(W_{Total \,weight\, of \,Pellet}\) is the total weight of the dried pellet obtained after vacuum drying; \(W_{NEB \,added\, in\, Formulation}\) is the amount of NEB added in the preparation of NEB-LCNPs and \(W_{Unentrapped\, NEB}\) is the total amount of unentrapped NEB recovered from the supernatant and the two washings of the pellet.

2.7 Characterization of size and surface morphology of the optimized NEB-LCNPs

A field emission scanning electron microscope (Apreo LoVac, Thermo Fisher Scientific, MA, USA) was used to characterize the size and surface morphology of the NEB-LCNPs [22]. The sample was prepared by placing 40 μL of the dispersion of optimized NEB-LCNPs on an aluminum stub, followed by air-drying overnight. Sputter coating was done on the dried sample with gold using a sputter coater (Leica EM ACE200, Wetzlar, Germany) in the presence of an inert gas (Argon). The sputter coating chamber was maintained under the vacuum throughout the sputtering process. Multiple SEM images were captured at an acceleration voltage of 5 kV. Different resolutions were also be set to obtain a complete view of the sample.

2.8 Differential scanning calorimetry (DSC) of the optimized NEB-LCNPs

Thermal analysis was performed for NEB, chitosan, lecithin, and a powder mixture of NEB with all the formulation excipients used in the preparation of NEB-LCNPs and lyophilized NEB-LCNPs using DSC-60 (Shimadzu, Kyoto, Japan) [23]. Each sample was weighed accurately and filled in aluminium pans, which were then covered by a flat aluminium plate. The pans were crimped and sealed. A blank aluminium pan (crimped and sealed) was used as a reference. The compartment holding the sample and blank pans was purged with inert gas (nitrogen) at 50 mL/min flow rate. Each sample was first equilibrated at 25 °C for 2 min before the heating cycle. The thermograms were recorded for each sample in the temperature range between 25 °C and 250 °C and at 10 °C/min heating rate.

2.9 X-ray diffractometry of the optimized NEB-LCNPs

To identify the physical state of NEB in the optimized NEB-LCNPs, powder X-ray diffractometry analysis was performed [24]. Rigaku X-ray diffractometer (ULTIMA IV, Texas, USA) with a copper anode (1.54 Å) maintained at 60 kV and 60 mA current was used in the analysis. The X-ray diffractograms of NEB, chitosan, lecithin, a mixture of NEB and the excipients used to prepare the NEB-LCNPs, trehalose (a cryoprotectant used in the lyophilization process), and freeze-dried NEB-LCNPs were captured in the 2θ range of 5–50° at 4° per min scanning rate.

2.10 In vitro drug release studies of the NEB-LCNPs-Susp and NEB-LCNPs-ISG

Drug release studies of the NEB-LCNPs-Susp and NEB-LCNPs-ISG were conducted using the dialysis membrane method [25]. In this study, 40 μL of the test formulation (containing 0.125 mg of NEB) was placed inside a dialysis bag (MWCO: 3500 Da) and sealed from both ends. The dialysis bag was suspended in a beaker containing 100 mL of dissolution media containing simulated tear fluid with Tween 80 (0.5% w/v). The stirring speed was set at 75 rpm. The temperature was maintained at 34 ± 0.5 °C. Samples (2 mL) were collected at specific time points (at 0.5, 1, 2, 4, 6, 8, 12, 16, 18 and 24 h). Fresh dissolution media (preheated to 34 ± 0.5 °C) of equal volume (2 mL) was added to the beaker each time the samples were collected. The samples were subjected to centrifugation at 10,000 rpm, and the clear supernatant was separated. The supernatant was suitably diluted to quantify NEB using the HPLC–UV method described in Sect. 2.2. The data obtained from the in vitro drug release studies was used to determine the cumulative percent drug release of both the NEB-LCNPs-Susp and NEB-LCNPs-ISG. The data was fit into various release kinetic models (i.e., zero‐order, first‐order, Higuchi and Korsmeyer–Peppas models) to understand the order and mechanism of drug release from the formulations. To determine the best-fit model describing the release of NEB from the nanoparticulate systems, R2 values were considered as the standard. The model with the maximum R2 values was selected as the best-fit model [26].

2.11 Ex vivo ocular toxicity using the HET-CAM technique

Hens's egg test—Chorioallantoic membrane (HET-CAM) technique [27] was employed to evaluate the irritation potential of the NEB-LCNPs-Susp and NEB-LCNPs-ISG formulations. Eggs were incubated for 9 days for proper development of CAM. On the 10th day, eggs with developed CAM were carefully broken without rupturing the inner membrane. Four treatment groups: positive control (0.1 N NaOH), group 1; negative control (0.9% w/v NaCl solution), group 2; NEB-LCNPs-Susp, group 3; and NEB-LCNPs-ISG, group 4, were used in the study. The inner membrane of each egg was carefully removed to expose CAM to apply each treatment on the syrface. Three eggs (n = 3) (with a developed and exposed CAM) were utilized for each treatment group. To the egg CAM surface, 200 μL of the treatment was applied, and the level of blood vessel damage was observed for 300 s. Based on the time taken for vascular lysis after treatment, an irritation score (IS) value was determined using below Eq. (5).

where 'H' is the time (in sec) taken to the start of hemorrhage reactions, 'L' is the time (in sec) taken to the start of vessel lysis, and 'C' is the time (in sec) taken to the start of coagulation formation on the CAM.

Based on the level of the hemorrhage of the blood vessels observed, the scores were assigned to each of the treatments applied on the HET-CAM. The treatments were considered as non-irritating for the IS value in the range of 0–0.9, slightly irritating 1–4.9, moderately irritating 5–9.9, and strongly irritating 10–21 [28].

2.12 In vivo studies of the optimized NEB-LCNPs and NEB-LCNPs-ISG

2.12.1 Ocular pharmacokinetic studies

New Zealand white rabbits, weighing approximately 2.5 kg (with clinically normal eyes), were used to compare the pharmacokinetics of the optimized NEB-LCNPs (administered as aqueous suspension, NEB-LCNPs-Susp) and NEB-LCNPs-ISG administered through ocular route. All animal studies were carried out as per the guidelines and regulations provided by the CPCSEA, Ministry of Fisheries, Animal Husbandry and Dairying, and Governments of India. The animal ethics committee of Vimta Labs (Hyderabad, India) examined and approved the protocol for all the in vivo studies (No. VLL/1122/NG/1099R). The rabbits were allowed to acclimatize at a controlled temperature of 22 ± 1 °C and 55 ± 10% relative humidity of 55 ± 10% with 12 h light–dark cycle for one week. In each treatment group, 40 μL of the test formulation (NEB-LCNPs-Susp/NEB-LCNPs-ISG) containing 0.125 mg of the drug was instilled in both eyes (in the lower part) of each rabbit using a calibrated micropipette connected to a blunt tip. To avoid spillover of the treatments, the eyelids were closed for 10 s immediately after administration of the treatments. Freshly prepared formulations (3.125 mg of drug present in 1 mL of NEB-LCNPs-Susp or 1 mL of NEB-LCNPs-ISG) were used in the study. The drug dose was maintained at 0.05 mg/kg per eye for both treatments. Aqueous humor (70 μL) was collected from each rabbit, under mild anesthesia using isoflurane (2% v/v), from both eyes by puncturing them with a sterile hypodermic needle (30-gauge) via paracentesis. A sparse sampling method was followed to collect aqueous humor at predose and at 0.5, 1, 2, 4, 8, 12, and 24 h following ocular administration of the formulations. Predose samples were collected from all rabbits at least 1 h before the study. The samples were collected from rabbits 1 and 3 at 0.5, 2, 8, and 24 h, while from rabbits 2 and 4, the samples were collected at 1, 4, and 12 h. Each data point in the aqueous humor time course is the mean (± SD) of 4 samples collected from both eyes of two different rabbits. The data collected from rabbits 1 and 3 were then pooled with the data from rabbits 2 and 4 to construct the entire aqueous humor time course profile. Blood (0.25 mL) was collected at predose and at 0.5, 1, 2, 4, 8, 12, and 24 h from all the rabbits (via a serial sampling method) by puncturing the ear vein into tubes containing Na-EDTA (200 mM strength, 20 μL per mL of blood). After centrifugation, the plasma was separated and stored in a freezer until analysis [29].

The concentrations of NEB in the samples (both plasma and aqueous humor samples) obtained from the in vivo studies were quantified using the validated LC‐MS/MS method mentioned in Sect. 2.2. Noncompartmental analysis [30] was applied to analyze the pharmacokinetic data of NEB in aqueous humor and plasma.

2.12.2 Ocular pharmacodynamic studies of LCNPs formulations

Pharmacodynamic efficacy studies of the optimized NEB-LCNPs and NEB-LCNPs-ISG (dose of NEB at 0.05 mg/kg per eye) were conducted by determining the time course of the percent reduction in the intraocular pressure [ΔIOP (%)] of the two formulations. In the pharmacodynamic study, six New Zealand white albino rabbits were divided into two groups, with three rabbits in each group. A TONO-PEN XL tonometer (Reichert, Germany) [31] was used to measure the IOP of the rabbits. The baseline IOP was measured in both eyes of all the rabbits just before administering the formulations. The same freshly prepared formulations (with the same dose strength) used in the pharmacokinetic study were also used in the pharmacodynamic study. In the treatment group, 40 μL of the formulation was instilled into the lower cul-de-sac of both eyes of the rabbit and closed immediately for 10 s. The IOP values were measured at 0 h (predose), 1 h, 2 h, 4 h, 6 h, 12 h, and 24 h in both eyes of each rabbit.

The ΔIOP (%) values at each time point were determined using Eq. (6):

where '\(IOP_{Pre}\)' is the intraocular pressure just before administering the treatment. '\(IOP_t\)' is the intraocular pressure at the time 't' after administering the treatment.

The Studentized t-test was used to compare the data of any two treatments (NEB-Susp with NEB-LCNPs; NEB-Susp with NEB-LCNPs-ISG and NEB-LCNPs with NEB-LCNPs-ISG) in the pharmacokinetic and pharmacodynamic studies. The confidence level was set at 95% (α = 0.05) in all the statistical analysis of data.

3 Results and discussion

3.1 Preparation and optimization of NEB-LCNPs using DoE

In the preparation of NEB-LCNPs, NMP was selected as the most suitable organic phase solvent due to its ability to dissolve both NEB and lecithin. Aqueous phase containing chitosan [dissolved in acetic acid (1% w/v, pH = 4.0)] and PVA (as a stabilizer) was used as the antisolvent. Among the various stabilizers (including Tween 80, PVA, HPMC, and PVP K30) screened during initial preparation trials, the nanoparticles prepared using PVA as the stabilizer had smaller PS with narrow PDI and the preparation was consistent and reproducible.

During the addition of the solvent phase to the antisolvent phase, the ionic interaction takes place between positively charged NH3+ ions of chitosan and negatively charged phospholipids present in lecithin. This causes decreased solubility of the complex, and molecules undergo self-aggregation and gelation, which eventually results in the formation of particles with lecithin in the core and chitosan on the surface. Concurrently, due to the diffusion of NMP into the aqueous phase, NEB precipitates (due to its poor solubility in the aqueous phase). The precipitated NEB becomes entrapped in the matrix of lecithin-chitosan self-aggregates and thereby forms NEB-LCNPs. The pH of the aqueous solution had a significant impact on the formation of lecithin-chitosan nanoparticles. At pH ≥ 6, chitosan had less water solubility. As the pH of the aqueous phase decreased below 6, chitosan's solubility increased due to the effective ionization of the amine groups present in it. The aqueous phase solution maintained at pH 4 provides sufficient ionization of chitosan for complexing with lecithin and self-assembly to form nanoparticles by ionic gelation. These findings were in line with the report published by Uppuluri et al., where the researchers recommended to use an aqueous phase with a pH ≤ 6.0 to form nanoparticles by ionic gelation with lecithin.

In the screening design, the factors affecting the critical physicochemical responses, namely, the PS, DL (%), EE (%), and ZP of the NEB-LCNPs, were selected. The 2(6–2) fractional factorial design (resolution IV), which was used for screening the factors, involved 16 factorial runs that provided information on the main factorial effects as well as the two-way interaction effects on the responses. A resolution IV design was selected for screening as the main effects do not show any sort of confounding with other main effects and any of the two-way interaction effects, which is very important in identifying the statistically significant main effects. In addition, the 2(6–2) fractional factorial design with resolution IV involves a lesser number of experimental runs for screening of 6 factors. Additionally, the 3 center point runs in the design were used to determine if the curvature is involved in the relation between the responses and the 6 factors. The observed critical responses across all 19 experimental runs were subjected to regression analysis followed by ANOVA for each regression model. Of the six main effects, three main effects, namely, the chitosan-to-lecithin ratio, homogenization speed, and sonication amplitude, had a significant (P < 0.05) impact on the responses, particularly those of PS and DL (%). The other three factors, i.e., stabilizer concentration, homogenization time, and ultrasonication time, did not show any significant impact on the responses of PS and DL (%) in the screening design.

In the optimization design, BBD, stabilizer concentration was fixed at 0.10% w/v, homogenization time was set at 10 min, and ultrasonication time was set at 5 min in all runs. The three critical factors identified from the screening design varied within a predefined range [32]. The results obtained for various physicochemical properties of NEB-LCNPs across the 15 experimental runs, with the levels of each factor in the optimization design using BBD, are presented in Table 2. The regression analysis was performed only for the data obtained for PS and DL (%) to determine the mathematical equations relating to the effect of the factors on the two critical responses. The responses for EE (%) and ZP did not vary significantly across the 15 experimental runs in the optimization design. Therefore, regression analysis was not performed on the data obtained for EE (%) and ZP.

The data obtained from the BBD was fit into various regression models, including the linear model, 2-factorial interaction model, quadratic model, cubic model, etc. The best-fit model was selected based on the R2 values, and the regression equation of the model was then subjected to ANOVA to test the model's validity and the significant terms of the regression model. The regression equation was further modified by removing the insignificant terms to decrease the error in predicting the responses. The statistical analysis of the effect of different factors on the individual responses is discussed below.

3.1.1 Impact of the critical factors on PS (Y1)

The regression equation relating the effect of critical factors on the PS of NEB-LCNPs in the transformed scale is presented in Eq. (7). A linear model with an inverse transformation function between PS (Y1) and the three critical factors was found to be the best fit.

The ANOVA results of the mathematical equation for PS are presented in Table 3. The mathematical equation for predicting the PS was significant (Fcal = 29.92 and Pcal < 0.0001), and the lack-of-fit for the model was not significant (Fcal = 2.75 and Pcal = 0.2952), suggesting that the insignificant terms do not affect the values predicted by the regression equation.

The regression coefficients of R2Adj and R2PRESS for the regression model for PS were 0.8610 and 0.8112, respectively, with a difference of much less than 0.2 between the two values. Higher R2Adj and R2PRESS values (> 0.8) suggest that the PS of NEB-LCNPs predicted from the regression equation will be closer to the observed PS. The smallest and largest PS were 133.2 nm (6th run) and 265.1 nm (5th run), respectively (Table 2).

The response surface plots for the effects of the chitosan-to-lecithin ratio (X1), sonication amplitude and sonication amplitude (X3) at a fixed homogenization speed (X2 at 0.75% w/v) on the PS of NEB-LCNPs are presented in Fig. 2a. With an increase in the chitosan-to-lecithin ratio from 0.25 to 1, the PS of the NEB-LCNPs decreased at all sonication amplitudes. This could be due to the increase in the positive charge contributed by the protonated amine groups (NH3 +) due to the greater amount of chitosan. A higher positive surface charge resulted in better stability and, thereby, the formation of a smaller PS. Similar results were reported by Uppuluri et al., who studied the effect of the chitosan-to-lecithin ratio on the PS of piribedil-loaded chitosan-lecithin hybrid nanoparticles [33]. The sonication amplitude did not show any significant effect on PS at higher chitosan-to-lecithin ratios (between 0.7 and 1). At lower chitosan-to-lecithin ratios (between 0.25 and 0.55), the PS decreased with increasing sonication amplitude from 20 to 35% due to an increase in the energy output.

3.1.2 Impact of critical factors on DL (%) (Y2)

The mathematical relationship between the three critical factors and the DL (%) of NEB-LCNPs in the transformed scale is presented in Eq. (8). A quadratic equation, primarily involving factor X1, was found to provide the best fit in the regression analysis.

The ANOVA results of the mathematical equation for DL (%) are presented in Table 3. The mathematical equation for predicting the DL (%) was significant (Fcal = 8235.98 and Pcal < 0.00001), and the lack-of-fit for the model was not significant (Fcal = 0.7348 and Pcal = 0.699), suggesting that the insignificant terms do not affect the values predicted by the regression equation. The regression coefficients of R2Adj and R2PRESS for the model for DL (%) were 0.9992 and 0.9988, respectively, with a difference of much less than 0.2. In the optimization design, the highest and lowest DL (%) values were 13.4% (3rd run) and 8.7% (6th run), respectively (Table 2).

Figure 2b shows the effect of the chitosan-to-lecithin ratio (X1) and homogenization speed (X2) at a fixed sonication amplitude (X3 at 27.5%) on the DL (%) of NEB-LCNPs. At all homogenization speeds (7000 to 11,000 rpm), an increase in the chitosan-to-lecithin ratio (from 0.25 to 1) decreased the DL (%) from 13% to 8.7%. An increase in the chitosan-to-lecithin ratio increases the overall amount of polymeric carrier added to the formulation and, thereby, the denominator used in the calculation of DL (%) (for the same drug added to the formulation). This results in a decrease in the DL (%) with an increase in the chitosan-to-lecithin ratio.

3.1.3 Optimum levels of factors to prepare NEB-LCNPs using the desirability function and validation of the solution

The simultaneous optimization method, involving objective functions to minimize PS and maximize DL (%), provided several different solutions with the highest overall desirability (0.9925). The optimum levels for the three critical factors suggested by the Design Expert software in the first solution with an overall desirability of 0.9925 for the preparation of NEB-LCNPs are as follows: X1 (chitosan-to-lecithin ratio) = 0.625; X2 (homogenization speed) = 11,000 rpm; and X3 (sonication amplitude) = 20%. The PS, PDI, DL (%), EE (%), and ZP of the NEB-LCNPs prepared under the optimized conditions were 170.5 ± 5.3 nm, 0.26 ± 0.02, 10.5 ± 1.2%, 97.8 ± 0.8% and 54.6 ± 2.2 mV, respectively.

The observed PS and DL (%) of the optimized NEB-LCNPs of the three independent verification runs were compared with the predicted data [determined from the corresponding mathematical equations of PS and DL (%)]. No significant difference was observed between the predicted and observed data at a 5% level of significance. This suggests the reliability of the mathematical equation for PS and DL (%) to predict the two responses, as well as the validity of the solution provided by the software.

3.2 Physical characterization of the optimized NEB-LCNPs using SEM, DSC, and pXRD

SEM images of the optimized NEB-LCNPs are presented in Fig. 3a. The optimized NEB-LCNPs were found to be spherical with PS in the range of 155 nm to 176 nm, which correlates with the PS measured using a Zetasizer.

DSC thermograms of NEB, chitosan, lecithin, physical mixture of NEB, and the excipients used in the formulation of NEB-LCNPs, freeze-dried powder of NEB-LCNPs and trehalose are shown in Fig. 3b. A sharp peak was observed at 228 °C, which correspond to melting of crystalline form of NEB. However, no sharp/defined endothermic peaks were observed in the thermograms of either chitosan or lecithin, indicating the amorphous nature of the two excipients. The DSC thermogram of the physical mixture of NEB with various excipients showed an endothermic peak (albeit with low intensity) at 228 °C corresponding to the melting point of NEB. The decrease in the intensity of the endothermic peak of NEB in the physical mixture was due to the dilution effect of the various excipients in the physical mixture and the net amount of NEB in the sample analysed via DSC. The thermogram of freeze-dried NEB-LCNPs showed no peak at 228 °C. However, a prominent endothermic peak was observed at 100 °C in the thermogram of NEB-LCNPs due to the melting of trehalose (a cryoprotectant used in the freeze drying of NEB-LCNPs). The absence of the NEB melting peak in the thermogram of NEB-LCNPs may be due to the amorphous nature of NEB entrapped in the nanoparticles.

The pXRD diffractograms of various samples analysed in the study are presented in Fig. 4. Pure NEB showed sharp intensity peaks (that are not overlapping with trehalose) at 2θ values of 13.13°, 16.52°, 20.41°, 21.50°, and 24.82°, indicating the crystalline nature of the NEB powder. The above peaks, which are specific for the crystalline nature of NEB, were missing in the freeze-dried powder of NEB-LCNPs. This indicates that the drug is either loaded in amorphous form or molecular form in the NEB-LCNPs. The pXRD data conforms to NEB-LCNPs with the observations from DSC studies.

3.3 Drug release studies of NEB-LCNP formulations

The drug release studies of NEB-Susp and NEB-LCNPs formulations (NEB-LCNPs-Susp and NEB-LCNPs-ISG) were conducted using STF (pH of 7.4 ± 0.05) containing Tween 80 (0.5% w/v, as a surfactant to increase saturation solubility of the drug) as the dissolution media. NEB has a solubility of 28.62 mg/mL in the dissolution media. Therefore, 100 mL of the above dissolution was used in the drug release studies to maintain the sink conditions. The data obtained from the drug release studies was used to plot the mean cumulative % drug release versus time graphs (Fig. 5). In the case of NEB-Susp, within 30 min, the drug was completely dissolved. In contrast, NEB-LCNPs-Susp and NEB-LCNPs-ISG showed 83% and 72% drug release at 24 h, respectively. In the case of NEB-LCNPs-ISG, the ISG further slowed down the release of NEB, following the release of the drug from the nanoparticles, into the dissolution media due to the viscous gel formed by formulation.

The mean cumulative % drug release released (with standard deviation) of three formulations at each time point is presented in the graph. Note: Data for NEB-Susp were obtained from our previously published work [3]

The dissolution release from NEB-LCNPs-Susp followed the Higuchi kinetic model (R2 = 0.956). The analysis of the dissolution data of NEB-LCNPs was also performed using the Korsmeyer-Peppas model. The 'n' value of 0.561 indicated that the drug followed non-Fickian diffusion as the primary mechanism of release from the nanoparticles. The dissolution data of NEB-LCNPs-ISG was not analysed using any model-dependent methods due to the limitations of applying kinetic models to complex release processes of the drug from NEB-LCNPs-ISG. However, modeling the dissolution data of NEB-LCNPs-ISG using empirical models indicated that the drug release followed the Weibull model (R2 = 0.99).

3.4 Ex vivo ocular toxicity tests for LCNPs formulations using the HET-CAM technique

The images captured from the HET-CAM experiment with four treatment groups: positive control (0.1 N NaOH), group 1; negative control (0.9% w/v NaCl solution), group 2; NEB-LCNPs-Susp, group 3; and NEB-LCNPs-ISG, group 4 are presented in Fig. 6. The positive control (group 1) damaged the CAM substantially within 15 s of treatment, showing rosette-like coagulation, hemorrhage, and lysis of blood vessels. The IS of positive control was 20, indicating its strong irritation properties. In the negative control (group 2), group 3 (NEB-LCNPs-Susp), and group 4 (NEB-LCNPs-ISG), the CAM did not show significant visual changes (for coagulation/hemorrhage/lysis) after exposure for 300 s. The irritation severity scores calculated for negative control, group 3 and group 4 were 0, indicating non-irritant properties. These results of the HET -CAM test to determine ex-vivo irritation potential suggest that the optimized formulations (NEB-LCNPs-Susp and NEB-LCNPs-ISG) are non-irritant, well tolerated to ocular tissues, and thus safe for ocular administration.

3.5 Rheological evaluation of the NEB-LCNP-ISG formulation

The rheological characteristics of NEB-LCNPs-ISG were evaluated by constructing 'loss tangent (tan δ) versus temperature' (Fig. 7a) and 'storage modulus (G,' Pa) versus temperature (Fig. 7b) plots, both with and without the presence of the STF. The rheological properties of NEB-LCNPs-ISG were also compared with those of a blank ISG (blank dual responsive ISG). In the rheological studies without the STF, with an increase in temperature from 20 °C to 27 °C, the loss tangent (tan δ) values of NEB-LCNPs-ISG did not change significantly. However, as the temperature increased from 27 °C up to 31 °C, the tan δ values decreased significantly and reached a plateau above 32 °C. The tan δ values exhibited a sudden inflection, with values decreasing below 1 at temperatures between 29 and 30 °C. This indicates that NEB-LCNPs-ISG exhibited phase transition from solution to gel in the range of 29–30 °C. This can also be confirmed from the storage modulus (G′, Pa) versus temperature (without the STF), where G′ showed a sudden increase at 29–31 °C. This sol-to-gel transition (without the addition of STF) of NEB-LCNPs-ISG in the temperature ramp experiments is due to the thermo-responsive nature of the mixture of P407 + P188 used in the ISG.

Rheological properties of blank ISG and NEB-LCNPs-ISG with temperature sweep experiments. a semi-logarithmic plot of loss tangent (tan δ) versus temperature and b linear plot of storage modulus versus temperature. In both the figures, A represents blank ISG, B represents NEB-LCNPs-ISG, and C represents NEB-LCNPs-ISG in the presence of STF.

In the rheological studies with STF, the tan δ values of NEB-LCNPs-ISG were less than 1 (tan δ = 0.563 at 20 °C), even at 20 °C. A tan δ < 1 indicates a rapid transition of the formulation, from solution to gel, in STF at 20 °C. The NEB-LCNPs-ISG underwent a solution-to-gel conversion due to the interaction of κCRG (ion-sensitive polymer) present in NEB-LCNPs-ISG with the Na+/K+ ions present in STF, even at 20 °C. This can be confirmed by the storage modulus (G') values, which were much greater (> 1140 Pa) even at 20 °C than near '0' values when the study was conducted without the STF.

The tan δ values of NEB-LCNPs-ISG were slightly lower (accordingly, the storage modulus (G') values were slightly greater) than those of the blank ISG at all temperatures in the range of 20 to 38 °C. This could be due to the viscosity imparted by the solid content (i.e., NEB-LCNPs) dispersed in the NEB-LCNPs-ISG compared to the blank ISG.

3.6 Stability studies of LCNPs formulations

Figure 8a and b present the stability data of lyophilized powders of NEB-LCNPs (stored at controlled room temperature; 25 ± 2 °C and 60 ± 5% RH) and NEB-LCNPs-ISG (stored at refrigerated condition; 2–8 °C) for the freshly prepared formulations (t = 0) and samples collected at different time points over the 60-day study period, respectively. The PS, PDI, or ZP of the formulations did not change significantly due to the storage conditions, suggesting that the formulations have good physical stability under their respective storage conditions for at least 60 days. The %RSD values for DL (%) and EE (%) of the freshly prepared formulations and the samples analyzed at different time points during the study period for both formulations did not exceed 5%. This suggests that there is no loss or leaching of the drug from the nanoparticles during storage.

3.7 In vivo studies of the LCNPs formulations

3.7.1 Ocular pharmacokinetic studies of LCNPs formulations

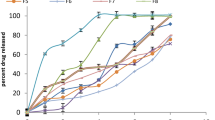

To assess the potential of the optimized NEB-LCNPs in delivering NEB to aqueous humor (target site), various pharmacokinetic parameters were calculated from the ocular administration of NEB-LCNPs in rabbits. The comparative NEB concentration versus time profiles in aqueous humor and plasma obtained by administering NEB-LCNPs-Susp, NEB-LCNPs-ISG, and NEB-Susp (for comparison, data reproduced from our previous published work [3]) through ocular route are presented in Fig. 9a and b, respectively.

Mean concentration of NEB versus time plots constructed using the data obtained from ocular administration of NEB-LCNPs-Susp, NEB-LCNPs-ISG, and NEB-Susp in a aqueous humor and b plasma. Note Data for NEB-Susp are reproduced from our previously published work [3]

Figure 9a and Table 4 show that the NEB concentration (Cmax) in aqueous humor for NEB-LCNPs-Susp (49.8 ± 3.5 ng/mL) was higher compared to NEB-LCNPs-ISG (39.6 ± 2.8 ng/mL) (P < 0.05) and NEB-Susp (28.2 ± 3.1 ng/mL) (P < 0.01). NEB-LCNPs-Susp showed higher Cmax due to possible direct uptake of nanoparticles by the cornea and minimal impact of nasolacrimal drainage on the removal of nanoparticles from the precorneal area than of NEB-Susp.

The Cmax of NEB-LCNPs-ISG was relatively lower than NEB-LCNPs-Susp due to the slow absorption rate of the drug and slow uptake process of the nanoparticles by the cornea due to the rapid formation of viscous gel by ISG. The extent of exposure (AUC0–t value) for NEB-LCNPs-ISG (375.4 ng × h/mL) and NEB-LCNPs-Susp (289.0 ng × h/mL) was found to be greater than NEB-Susp (189 ng × h/mL). MRT0–∞ of NEB in NEB-LCNPs-ISG (10.6 h) and NEB-LCNPs-Susp (7.5 h) was greater than NEB-Susp (6.1 h), indicating that nanoformulations sustained the drug concentrations for more duration in the aqueous humor than conventional NEB-Susp.

The comparative plasma time course profiles presented in Fig. 9b and Table 4 showed plasma exposure (AUC0–t value in plasma) of NEB-LCNPs-ISG (8.38 ± 0.84 ng × h/mL) was significantly lesser than both NEB-LCNPs-Susp (13.6 ± 0.8 ng × h/mL) (P < 0.05) and NEB-Susp (20.2 ± 2.7 ng × h/mL) (P < 0.05). The MRT0–∞ plasma for NEB-LCNPs-ISG (5.0 ± 0.3 h) was less compared to NEB-LCNPs-Susp (11.2 ± 1.3 h) (P < 0.05) compared to NEB-Susp (25.8 ± 1.5 h) (P < 0.05), due to the formation of a gel by ISG, the drug released slowly by diffusing through viscous gel network. In addition, gel formation enhanced the residence time of the formulation in the precorneal area by resisting the nasolacrimal drainage, which reduced the absorption of the drug into the systemic circulation and, thereby, the systemic side effects. Furthermore, the gel made a strong interaction with the corneal epithelium, which enabled the medication to permeate the whole ocular surface.

The ocular pharmacokinetic parameters are listed in Table 4. NEB-LCNPs-ISG resulted in a slower increase in drug concentrations in aqueous humor but prolonged the drug concentrations for more time than compared to NEB-LCNPs-Susp and NEB-Susp. These results suggest that the frequency of dosing can be reduced by administering NEB-LCNPs-ISG in the treatment of glaucoma.

3.7.2 Ocular pharmacodynamic studies

Figure 10 presents the \(\Delta IOP(\% )\) versus time profiles of NEB-LCNPs-ISG and NEB-LCNPs-Susp. Noncompartmental analysis was performed to analyze the pharmacodynamic data [\(\Delta IOP(\% )\) versus time] of the two formulations. The area under the curve in the time interval 't = 0' to 't = 24 h' (AUC0–24 h) and mean response time in the period 't = 0' to 't = 24 h' (MRT0-24 h) were determined for the formulations. The AUC0–24 h for NEB-LCNPs-ISG (386.7 ± 10.2% × h) was higher compared to NEB-LCNPs-Susp (248.3 ± 8.7% × h) (P < 0.05) and NEB- Susp (74.2 ± 3.2% × h) (P < 0.01). The maximum reduction in the IOP of NEB-LCNPs-Susp (peak \(\Delta IOP(\% )\) of 33.5 ± 2.1%) was greater (P < 0.05) than NEB-LCNPs-ISG (peak \(\Delta IOP(\% )\) of 28.1 ± 1.8%). However, the mean response time of NEB-LCNPs-ISG (MRT0-24 h = 11.3 ± 0.2 h) was significantly higher (P < 0.05) compared to NEB-LCNPs-Susp (7.2 ± 0.6 h) and NEB-Susp (4.06 ± 0.3 h) (P < 0.01). These results clearly suggest that compared with that of NEB-LCNPs-Susp, the overall pharmacodynamic effect of lowering IOP for NEB-LCNPs-ISG was much greater and sustained for a longer duration.

Percent reduction in intra‐ocular pressure [ΔIOP (%)] versus time plots of NEB-LCNPs-Susp and NEB-LCNPs-ISG administered through ocular route (dose of 0.05 mg/kg) in rabbits (n = 6). Note Data for NEB-Susp are reproduced from our previously published work [3]

The pharmacokinetic performance of NEB-LCNPs-ISG (in terms of greater exposure and residence time in the aqueous humor) compared to that of NEB-LCNPs-Susp and NEB-Susp was also reflected in its pharmacodynamic performance (overall reduction in the IOP as well as the duration of effect). In the treatment of glaucoma, the drug is expected to reach the aqueous humor, which is in contact with the iris and the ciliary body (the tissues with beta-adrenergic receptors). To reach the site of action, NEB should majorly cross the anatomical and physiological barriers, including the cornea. The reasons for the improvement in the pharmacokinetic parameters and, thereby, the pharmacodynamic performance of the NEB-LCNPs-ISG can be explained as follows: (1) The NEB-LCNPs-ISG which turns into a gel when exposed to the STF, enhanced the overall retention time of the in situ gel loaded nanoparticles on the surface of the eye (in the precorneal area). Due to the enhanced retention of formulation in the precorneal area, the drug released from the nanoparticles provided sufficient time for permeation through the cornea; (2) the NEB-LCNPs, due to their smaller size, can directly enter the anterior chamber of the eye by endocytosis and release the drug from the nanoparticles inside the anterior chamber [34, 35], and (3) Additionally, chitosan (a co-carrier in the LCNPs), exhibits strong mucoadhesive properties towards the corneal epithelium. Chitosan is also known to increase the permeability of drugs through the cornea, acting on the tight intercellular junctions in the corneal epithelium [36]. In contrast, the conventional systems, due to poor residence, get washed away and cannot match the concentrations or the mean residence time achieved by the nanoparticles loaded in situ gels.

4 Conclusion

In this research article, NEB loaded lecithin chitosan hybrid nanoparticles (NEB-LCNPs) were prepared by nanoprecipitation method using the solvent-antisolvent technique. The NEB-LCNPs were optimized for PS and DL (%) using DoE involving a screening design followed by optimization design. The optimized NEB-LCNPs loaded in situ gel (NEB-LCNPs-ISG) showed two-fold increase in aqueous humor availability of NEB and sustained the drug concentrations by 1.7-times compared to NEB-Susp. The pharmacokinetic performance of NEB-LCNPs-ISG was also reflected in its effective pharmacodynamic response over NEB-Susp. NEB-LCNPs-ISG resulted in a 2.2-folds higher percentage reduction in IOP and 2.8-folds higher mean response time compared to NEB-Susp. The study results demonstrate that ocular nanoformulations of NEB (NEB-LCNPs-Susp and NEB-LCNPs-ISG) are effective than the conventional aqueous suspension of NEB (NEB-Susp) in the treatment of glaucoma.

4.1 Future scope of work

In the current research work, the in vivo studies (both pharmacokinetic and pharmacodynamic efficacy studies) of the NEB-loaded nanoparticle formulations (both nanosuspension and nanoparticle loaded in situ gel) are performed in healthy rabbits. It would be interesting to see if there is any difference in the performance of the formulations in glaucomatous rabbit animal model (with increased sample size). NEB is reported to have neuroprotective properties in addition to its ability to modulate the drainage of aqueous humor via the trabecular meshwork. Mechanistic experiments should also be carried out to further investigate the utility of NEB-loaded nanoparticle formulations for their neuroprotective properties in the ocular tissues to claim the dual benefits in the treatment of glaucoma.

4.2 Potential limitations of the study

The major limitation is that the pharmacokinetic and pharmacodynamic studies of the optimized NEB-loaded nanoparticle formulations (both nanosuspension and nanoparticle loaded in situ gel) are conducted only in rabbits. The results obtained in the current study should be validated by performing at least the pharmacodynamic studies (by measuring the IOP) in clinical settings to conclude that the NEB-loaded nanoparticle formulations perform better compared to conventional formulations of the drug in the treatment of glaucoma.

Data availability

Data is provided within the manuscript.

References

Inoue K. Managing adverse effects of glaucoma medications. Clin Ophthalmol. 2014;8:903.

Coats A, Jain S. Protective effects of nebivolol from oxidative stress to prevent hypertension-related target organ damage. J Hum Hypertens. 2017;31:376–81. https://doi.org/10.1038/jhh.2017.8.

Rawat PS, et al. Design, characterization and pharmacokinetic-pharmacodynamic evaluation of poloxamer and kappa-carrageenan-based dual-responsive in situ gel of nebivolol for treatment of open-angle glaucoma. Pharmaceutics. 2023. https://doi.org/10.3390/pharmaceutics15020405.

Kolawole OM, Cook MT. In situ gelling drug delivery systems for topical drug delivery. Eur J Pharm Biopharm. 2023;184(2022):36–49. https://doi.org/10.1016/j.ejpb.2023.01.007.

Wu Y, et al. Research progress of in-situ gelling ophthalmic drug delivery system. Asian J Pharm Sci. 2019;14(1):1–15. https://doi.org/10.1016/j.ajps.2018.04.008.

Khan MS, Ravi PR, Dhavan DS. Design, optimization and pharmacokinetic evaluation of PLGA phosphatidylcholine hybrid nanoparticles of triamcinolone acetonide loaded in situ gel for topical ocular delivery. Int J Pharm. 2023;647: 123530.

Jiménez-Gómez CP, Cecilia JA. Chitosan: a natural biopolymer with a wide and varied range of applications. Molecules. 2020;25(17):3981.

Zamboulis A, et al. Chitosan and its derivatives for ocular delivery formulations: recent advances and developments. Polymers. 2020;12(7):1519.

Chatterjee B, Amalina N, Sengupta P, Mandal UK. Mucoadhesive polymers and their mode of action: a recent update. J Appl Pharm Sci. 2017;7(5):195–203.

Smith J, Wood E, Dornish M. Effect of chitosan on epithelial cell tight junctions. Pharm Res. 2004;21:43–9.

Souza JG, Dias K, Pereira TA, Bernardi DS, Lopez RFV. Topical delivery of ocular therapeutics: carrier systems and physical methods. J Pharm Pharmacol. 2014;66(4):507–30.

Dong W et al. Self-assembled lecithin/chitosan nanoparticles based on phospholipid complex: a feasible strategy to improve entrapment efficiency and transdermal delivery of poorly lipophilic drug. Int J Nanomed. 2020;5629–43.

Saha M, et al. QbD based development of resveratrol-loaded mucoadhesive lecithin/chitosan nanoparticles for prolonged ocular drug delivery. J Drug Deliv Sci Technol. 2021;63: 102480.

Albarqi HA, Garg A, Ahmad MZ, Alqahtani AA, Walbi IA, Ahmad J. Recent progress in chitosan-based nanomedicine for its ocular application in glaucoma. Pharmaceutics. 2023;15(2):681.

Bhatta RS, et al. Mucoadhesive nanoparticles for prolonged ocular delivery of natamycin: in vitro and pharmacokinetics studies. Int J Pharm. 2012;432(1–2):105–12.

Abdelmonem R, Elhabal SF, Abdelmalak NS, El-Nabarawi MA, Teaima MH. Formulation and characterization of acetazolamide/carvedilol niosomal gel for glaucoma treatment: in vitro, and in vivo study. Pharmaceutics. 2021;13(2):221.

A. Harugade, A. P. Sherje, and A. Pethe, "Chitosan: A review on properties, biological activities and recent progress in biomedical applications," React. Funct. Polym., p. 105634, 2023.

Ahn SJ, et al. Use of rabbit eyes in pharmacokinetic studies of intraocular drugs. JoVE J Vis Exp. 2016;113: e53878.

Szabo Z-I, Szabo T, Emőke R, Sipos E. Validated HPLC method for determination of nebivolol in pharmaceutical dosage form and in vitro dissolution studies, Stud Univ Babes-Bolyai Chem, 2014;59(4).

Rawat PS, Ravi PR, Kaswan L, Raghuvanshi RS. Development and validation of a bio-analytical method for simultaneous quantification of nebivolol and labetalol in aqueous humor and plasma using LC-MS/MS and its application to ocular pharmacokinetic studies. J Chromatogr B. 2020;1136: 121908.

Fereig SA, El-Zaafarany GM, Arafa MG, Abdel-Mottaleb MMA. Self-assembled tacrolimus-loaded lecithin-chitosan hybrid nanoparticles for in vivo management of psoriasis. Int J Pharm. 2021;608: 121114.

Dalvi A, Ravi PR, Uppuluri CT. Rufinamide-loaded chitosan nanoparticles in xyloglucan-based thermoresponsive in situ gel for direct nose to brain delivery. Front Pharmacol. 2021;12: 691936.

Murthy A, Ravi PR, Kathuria H, Vats R. Self-assembled lecithin-chitosan nanoparticles improve the oral bioavailability and alter the pharmacokinetics of raloxifene. Int J Pharm. 2020;588: 119731.

Maguire CM, Rösslein M, Wick P, Prina-Mello A. Characterisation of particles in solution–a perspective on light scattering and comparative technologies. In: Science and technology of advanced materials, Vol. 19, Issue 1, Taylor and Francis Ltd. 2018. pp. 732–745 https://doi.org/10.1080/14686996.2018.1517587.

Okur NÜ, Yozgatli V, Okur ME. In vitro–in vivo evaluation of tetrahydrozoline-loaded ocular in situ gels on rabbits for allergic conjunctivitis management. Drug Dev Res. 2020;81(6):716–27.

Singhvi G, Singh M. In-vitro drug release characterization models. Int J Pharm Stud Res. 2011;2(1):77–84.

Moosa RM, et al. In vivo evaluation and in-depth pharmaceutical characterization of a rapidly dissolving solid ocular matrix for the topical delivery of timolol maleate in the rabbit eye model. Int J Pharm. 2014;466(1–2):296–306.

Batista-Duharte A, et al. The hen’s egg test on chorioallantoic membrane: an alternative assay for the assessment of the irritating effect of vaccine adjuvants. Int J Toxicol. 2016;35(6):627–33.

Drahansky M, et al. We are IntechOpen, the world’ s leading publisher of Open Access books Built by scientists, for scientists TOP 1 %. INTECH. 2016;i:13. https://doi.org/10.5772/57353.

Diwan R, Ravi PR, Agarwal SI, Aggarwal V. Cilnidipine loaded poly (ε-caprolactone) nanoparticles for enhanced oral delivery: optimization using DoE, physical characterization, pharmacokinetic, and pharmacodynamic evaluation. Pharm Dev Technol. 2021;26(3):278–90.

Yasser M, El Naggar EE, Elfar N, Teaima MH, El-Nabarawi MA, Elhabal SF. Formulation, optimization and evaluation of ocular gel containing nebivolol Hcl-loaded ultradeformable spanlastics nanovesicles: in vitro and in vivo studies. Int J Pharm X. 2024. https://doi.org/10.1016/j.ijpx.2023.100228I.

Soni PK, Saini TR. Formulation design and optimization of cationic-charged liposomes of brimonidine tartrate for effective ocular drug delivery by design of experiment (DoE) approach. Drug Dev Ind Pharm. 2021;47(11):1847–66.

Uppuluri CT, Ravi PR, Dalvi AV. Design and evaluation of thermo-responsive nasal in situ gelling system dispersed with piribedil loaded lecithin-chitosan hybrid nanoparticles for improved brain availability. Neuropharmacology. 2021;201:108832. https://doi.org/10.1016/j.neuropharm.2021.108832.

Vaneev A, et al. Nanotechnology for topical drug delivery to the anterior segment of the eye. Int J Mol Sci. 2021;22(22):12368. https://doi.org/10.3390/ijms222212368.

Onugwu AL, et al. Nanotechnology based drug delivery systems for the treatment of anterior segment eye diseases. J Controll Release. 2023;354:465–88. https://doi.org/10.1016/j.jconrel.2023.01.018.

Kaiser M, et al. Chitosan encapsulation modulates the effect of capsaicin on the tight junctions of MDCK cells. Sci Rep. 2015. https://doi.org/10.1038/srep10048.

Acknowledgements

We want to acknowledge BITS Pilani Hyderabad campus for providing the laboratory infrastructure and animal house facility to conduct the experiments.

Author information

Authors and Affiliations

Contributions

P.S.R. and P.R.R. conceptualized and wrote the manuscript text. R.M. designed the experiments. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rawat, P.S., Ravi, P.R. & Mahajan, R.R. Design, pharmacokinetic, and pharmacodynamic evaluation of a lecithin-chitosan hybrid nanoparticle-loaded dual-responsive in situ gel of nebivolol for effective treatment of glaucoma. Discover Nano 19, 156 (2024). https://doi.org/10.1186/s11671-024-04109-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-024-04109-2