Abstract

The direct methanol fuel cell (DMFC) represents a highly promising alternative power source for small electronics and automobiles due to its low operating temperatures, high efficiency, and energy density. The methanol oxidation process (MOR) constitutes a fundamental chemical reaction occurring at the positive electrode of a DMFC. Pt-based materials serve as widely utilized MOR electrocatalysts in DMFCs. Nevertheless, various challenges, such as sluggish reaction rates, high production costs primarily attributed to the expensive Pt-based catalyst, and the adverse effects of CO poisoning on the Pt catalysts, hinder the commercialization of DMFCs. Consequently, endeavors to identify an alternative catalyst to Pt-based catalysts that mitigate these drawbacks represent a critical focal point of DMFC research. In pursuit of this objective, researchers have developed diverse classes of MOR electrocatalysts, encompassing those derived from noble and non-noble metals. This review paper delves into the fundamental concept of MOR and its operational mechanisms, as well as the latest advancements in electrocatalysts derived from noble and non-noble metals, such as single-atom and molecule catalysts. Moreover, a comprehensive analysis of the constraints and prospects of MOR electrocatalysts, encompassing those based on noble metals and those based on non-noble metals, has been undertaken.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

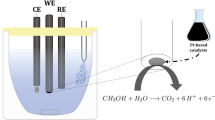

The methanol oxidation reaction (MOR) typically involves complex chemical events that indirectly produce CO2 [1]. This process includes the generation of intermediates through several reaction pathways, as depicted in Fig. 1a, b [2]. As one of the intermediates in the MOR process, CO slows down the reaction and makes it less effective by blocking the electrocatalysts' catalytic active sites [3]. Scientists are searching for efficient electrocatalysts that contain either a single metal or platinum combined with other transition metals (TMs) to enhance catalytic performance and prevent CO poisoning [4]. This occurs because CO can be expelled from the catalyst's active sites by facilitating its oxidation with H2O or OH‒ ions [5, 6]. Although this technique effectively reduces the amount of Pt used in the catalyst ink, investigators are currently trying to substitute Pt-group metals (PGMs) with non-noble metal electrocatalysts for alcohol oxidation processes [7].

a The diagram illustrates a typical CH3OH oxidation reaction, showcasing various reaction intermediates and products. b The diagram illustrates the progressive removal of hydrogen atoms throughout the CH3OH oxidation process. Adapted with permission [1].

It is desirable to assess the reaction mechanism and kinetics of MOR in acidic as well as alkaline mediums along with essential requirements of electrocatalysts before focusing on the effect of carbon-based support on electrocatalysts for MOR of fuel cells. MOR occurs either in acidic or basic environments, however, alkaline electrolyte supports the development of inexpensive as well as potential electrocatalysts for MOR along with the chance of making catalysts suitable for ORR [8]. Figure 2a, b illustrates the general schematic mechanism of MOR in both acidic and alkaline conditions. In the first step, under acidic conditions, the catalyst adsorbs methanol molecules onto its surface. Moreover, the process of methanol dissociation takes place on the catalyst surface by the cleavage of the C‒H bond. Afterward, the catalyst's surface enables the uptake of H2O, leading to the creation of OHad species. In the fourth step, the C‒H bond undergoes oxidation, leading to the creation of the CO species, which serves as an intermediate. The OHads radical subsequently undergo additional oxidation of the CO species, resulting in the formation of a CO2 molecule. Similiarly in alkaline media, during the initial stage, the catalyst's surface undergoes adsorption of both the methanol molecule and OH− species. After the dissociation of methanol, the catalyst generates several carbonaceous intermediates [9, 10]. After that, OHads and OH− (which are formed when surface-adsorbed H2O is activated), oxidize these intermediates and CO2 molecules are formed during the oxidation process. Furthermore, in very acidic environments, the presence of CO intermediates can adversely affect the catalyst's active sites, particularly Pt, [11, 12] resulting in decreased efficiency. Conversely, in a simple setting, intermediate chemicals, like CO, can be easily oxidized due to the heightened reactivity of OH− species. As a result, the catalyst is less susceptible to inefficiency [13,14,15].

Depiction of MOR mechanism on the catalyst's surface under a acidic and b basic conditions. Adapted with permission [16].

Full methanol oxidation in acidic as well as basic electrolytes is a six-electron process to proceeds as follows (Eqs. 1, 2) [17];

Nevertheless, MOR utilizes both indirect and direct CO routes instead of the 6e− procedure. The initial stage of the MOR process entails the adsorption of methanol onto the catalyst's surface [9, 18]. This is followed by either the breaking of the C‒H bond through dehydrogenation or the formation of adsorbed methoxy (CH3O) through dehydrogenation, which occurs by removing acidic hydrogen. Because the C‒H bond breaks, hydroxy-methyl (CH2O)ads are made, which in turn causes the production of COads through an indirect process [19]. When the O‒H bond breaks down, it can lead to the formation of (CH3O)ads and formaldehyde, which either desorb into the solution or undergo further deoxidation. The methanol oxidation reaction (MOR) on platinum (Pt) catalysts considered CO and formate as stable intermediates. These intermediates are considered to influence the efficiency and reaction kinetics of MOR. Regarding MOR, it appears that COads remain stable at low potential within the temperature range of 25–75 °C. This stability can obstruct the active sites of Pt, reducing overall reaction efficiency [20, 21]. Researchers discovered that incorporating Ru with Pt significantly enhances MOR activity, thereby preventing this problem. This is because Ru assists in the oxidation of CO intermediates, which reduces the risk of CO poisoning [22,23,24,25].

2 Pt-group metals-based materials for methanol oxidation reaction

Research has shown that the effectiveness of catalysts developed from Pt-group metals (PGM) based materials in alcohol oxidation depends on the particular type of alcohol fuel utilized. When subjected to electrochemical testing on a Pd electrode in basic media, the rate of oxidation for various alcohols increased in the following sequence: methanol (CH3OH) > glycol (C3H8O3) > ethylene glycol (C2H6O2) > ethanol (C2H5OH) > isopropanol (C3H8O) > n-propanol (C3H8O). On the Pt electrode, the order of reactivity was as follows: methanol (CH3OH) > n-propanol (C3H8O) > ethylene glycol (C2H6O2) > glycol (C3H8O3) > ethanol (C2H5OH) > isopropanol (C3H8O) [26]. The distinct association between adsorption energy and the d-band centers of Pd and Pt metals explains the varying activity trends observed on these metals [27,28,29,30]. When it comes to the interaction between adsorbates and the surface, many molecules and atoms exhibit distinct behaviors. For instance, molecules that include robust π-bonds, such as CO or NO, exhibit a unique mode of interaction in contrast to simpler atoms like H or O. This interaction has an independent effect on the adsorption energy, regardless of the d-band center. As the amount of adsorbates on the surface increases, the interactions between them, whether they repel or attract each other, can greatly alter adsorption energy. This change is not directly related to the d-band center [29, 31]. During the adsorption process, it is common for a charge transfer to occur between the adsorbate and the metal surface. This transfer may involve the metal d-states donating charge back to the adsorbate. The d-band center does not exclusively govern the magnitude and orientation of this electron transfer. Hence, the intricate and multifaceted nature of adsorption events constricts the d-band center's ability to make accurate predictions, despite its usefulness as a theoretical tool for understanding patterns in catalytic activity and adsorption features. For accurate predictions, a thorough analysis of detailed computer models (like density functional theory, DFT) is required that consider the entire electrical structure, the shape of the surface, and how each adsorbate interacts with it. Antibonding is observed above the fermi level, while a substantial bonding effect is shown when the d-band center goes higher. The down-shifting of the d-band center [32] creates the perception of a weak connection. Nevertheless, when the electron density fluctuates around the central metal, the d-band center also shifts accordingly [33]. According to this concept, electrocatalysts that have been designed and produced show enhanced electrocatalytic activity [27]. For instance, the Pt–Sn electrocatalyst undergoes a downward shift in the d-band center of Pt due to the chemo-sorption energy with CO-intermediate. This occurs because Sn transfers electrons to Pt, which is a result of a change in electronegativity. Co and Ni are added to Pt–Co and Pt‒Ni electrocatalysts to decrease the displacement of the d-center of Pt. This, in turn, reduces the chemisorption energy with OH species and increases the number of active sites for ORR, MOR, and EOR [34,35,36]. According to reports, the N-dopant is known to donate electrons to the carbon lattice, increasing the fermi level and charge transfer rate in ORR [37]. The researchers in this study discovered that adding Pt–Rh nanoparticles, tungsten nitride, and carbon nanotubes (CNTs) together improved the catalytic performance and made it less likely that CO would poison the process for EOR. The synergistic effect of tungsten nitride and the nitrogen-doping effect on CNTs are responsible for this improvement [38]. The variation in the loading catalyst step affects the catalytic activity of CNTs, electrocatalysts anchored with charge functional groups. Figure 3a, b shows the impact of constructed polyelectrolytes (PEs) on the surface of CNTs on the charge transfer process and electrocatalytic activity of supported Pt NPs, as reported by Wang et al. [39] Both theoretical analysis and experimental observations indicated that the charged functional group of polymer electrolytes (PEs) had an impact on the d-band center of Pt NPs, which in turn affected their electrocatalytic activity. To enhance the catalytic performance of Pt NPs for MOR, the negatively charged functional groups of polyanions, such as polystyrene sulphonic acid (PSS) and polyacrylic acid (PAA), caused a change in the d-band center of Pt NPs. However, the catalytic activity towards MOR was diminished when Pt NPs blended with the polycations such as polydiallydimethyl-ammonium chloride or polyallylamine hydrochloride, which exhibited an upward shift of the d-band center.

a The diagram demonstrates the electrical properties of Pt nanoparticles (Pt NPs) undergo modification by introducing polyanion (PSS) and polycation (PAA, PAH) functional groups, which act as the electron donor–acceptor. b This illustration displays the relationship between the d-band center and the energy required for O2 adsorption on different Pt slabs. Adapted with permission [39].

Furthermore, ultrathin nanowires, with a diameter of less than 2 nm, are well recognized as highly intriguing catalysts for MOR. This is because they possess a greater number of exposed surface-active areas. For instance, Li et al. synthesized ultrathin nanowires made up of 22% YOx/MoOx-Pt. As depicted in Fig. 4a–e [40], the nanowires exhibited a remarkable mass activity for MOR of 2.10 A mgPt−1 and a specific activity of 3.25 mA cm−2. Researchers have proposed the presence of a decoupling mechanism between adsorbed COads and COOHads. In this process, the catalyst has adsorbed an intermediate species called COOHads, in which the carbon atom is bonded to Pt and the oxygen atom is bonded to an oxophilic element Y. The energy change for the oxidation of COads to COOHads reduces considerably when compared to pure Pt.

Copyright © 2021, Wiley–VCH GmbH. The association between the annealing time and the ordering degree/la ice parameter of Pt3Mn catalysts is demonstrated in (f). g Investigating the correlation between the specific activity at 0.8 V and the degree of ordering in Pt3Mn. Adapted with permission [41]. Copyright © 2022, American Chemical Society

a This picture obtained from a high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) shows very thin nanowires made of 22% YOx/MoOx-Pt. b Illustration of mass-normalized cyclic voltammograms (CVs) of platinum (Pt). d The study investigates the process of adsorption of CO* and COOH* on surfaces made of pure Pt and Pt surfaces adorned with YOx (MoOx). (c–d) The theoretical studies investigated the process of adsorption of *CO and COOH* on surfaces made of pure Pt and Pt surfaces adorned with YOx(MoOx). e This diagram illustrates MOR's catalytic process on a YOx/MoOx-Pt surface, displaying the energy changes involved. Adapted with permission [40].

In their research, Zhang et al. found that the kinetics of MOR reaction can be fasten by adding void structures to the grain boundaries of Pd4Sn wavy nanowires [29]. The numerous flaws present on the surface of Pd4Sn-wavy nanowires create additional possibilities for the adsorption of small molecules. Thermodynamically, the presence of a surface void structure enhances MOR's catalytic activity in the HCOOH (HCOOads) pathway, as opposed to the pathway that leads to CO production. Moreover, the relaxing of the local environment at Pd sites offsets the synergistic effect of significant structural deformation around Sn sites. Chen et al. [41] conducted another study to examine the impact of the annealing period on the MOR (methanol oxidation reaction) activity of L12-phased Pt3Mn@Pt skin. During the annealing process, the degree of order in the Pt3Mn intermetallic core increases, and the lattice parameter decreases as the duration of annealing goes from 1 min to 24 h, as shown in Fig. 4f, g [41]. The presence of a Pt3Mn core induces an increasing compressive strain in the Pt outer layer, resulting in a constant reduction in the distance between adjacent Pt atoms. Following a 24-h annealing process, they successfully produce the most efficient catalyst, exhibiting a specific MOR of 2.71 mA cm−2 and a mass activity of 1.98 AmgPt−1. Further mathematical studies demonstrate that the augmentation in the MOR activity of Pt3Mn@Pt catalysts is mostly attributed to compressive strain rather than the influence of the ligands [42].

3 Non-Pt-group metals based electrocatalysts for methanol oxidation reaction

It would be ideal to create new catalysts that are long-lasting, have high catalytic activity, anti-CO capabilities, and are easy to make if we want to catalyze MOR at a practical level. Consequently, efforts are being made to create catalysts for direct methanol fuel cells (DMFCs) that need a reduced number of noble metals. Within this framework, co-oxides are gaining popularity as HOR catalysts due to their exceptional inherent properties, including electrical and structural flexibility, tunable chemical properties, and redox rich chemistry. Anodic deposition was used by Jafarian et al. [43] to construct a glassy carbon (GC) electrode modified with Co(OH)2. Then, the electrode was examined for activity in the methane oxidation process (MOR). The catalytic reaction demonstrated that cobalt exists in several valence states, with the Co(IV) state serving as the MOR active site. Zafeiratos [44] went a step further by studying how spinel Co3O4 and rock salt CoO's structures affected their HOR activity. Based on the data, spinel Co3O4 could start partial MOR by converting CH3OH into HCHO because it has a more mobile O-lattice. Another study found that Xia et al. [45], created a 3D mesoporous Co3O4 with improved catalytic activity. The enormous surface area of this catalyst (118–121 m2/g) allowed it to exhibit significantly higher MOR activity in comparison to non-porous Co3O4.

A different picture, Fig. 5ai, shows how Shahid et al. [46] made a mix for metal–organic frameworks (MOR) and used nanocarbons like rGO to make Co3O4 more conductor. This catalyst greatly increased the MOR activity compared to bare Co3O4, rGO, and even the typical Pt catalyst. As shown in Fig. 5aii, the catalyst variant with 2% rGO was the best, showing a peak current density of 362 mA/cm2 during MOR. In order to make a catalyst that conducts electricity better, Thamer et al. [47] used an electrospinning method to make N-doped carbon nanofibers (Co/N-CNFs). These nanofibers were very good at absorbing things and didn't block electrons from moving through them. The sample that hasn't been doped (63.56 mA/cm2) in Fig. 5bi–ii has the most activity for Co/N-CNFs at 4% N-content. This is because urea was used as an N-source from 0 to 5% to study how N-content affects the material. In a different study, Han et al. [48] made highly ordered NiZnx@CuO nanoarray structures by heating them up and then using magnetrons to deposit them on a brass mesh base Fig. 6a–h. The researchers discovered that these nanoarrays were highly efficient electrocatalysts for the MOR process. By utilizing different preparation methods for NiZn@CuO nanoarray catalysts, the researchers also discussed about their catalytic activity as electrocatalysts. They discovered that the NiZn1000@CuO electrode, which had been heated to 500 °C for two hours and NiZn alloy film showed a thickness of 1000 nm with a high current density of 449.3 mA/cm2 at 0.8 V for MOR in alkaline media. Furthermore, this electrode exhibited exceptional operational stability, maintaining a retention rate of 92% even after 12 h. The catalysts well-organized hierarchical structure enhances electrocatalytic activity through providing numerous active sites and a synergistic effect, which contributes to its outstanding MOR performance. Additionally, this catalytic structure also promotes efficient mass and electron transfer. It was impressive to show how fractional Zn atoms could be dissolve from the NiZn alloy. This caused the formation of uneven surface nanorods and also increased their specific surface area. The results indicate that the NiZn1000@CuO nanoarray structure has the potential to serve as a viable substitute for Pt-group metals. It has the potential to effectively function as an anode catalyst for DMFCs while also being cost-effective and durable. Mahmoud et al. [25] in another study, use transition metals as the basis for their investigation and present a non-precious group metal (non-PGM) electrocatalyst. (Fig. 6i–k). This electrocatalyst exhibits significant promise in enhancing the efficiency of direct methanol fuel cells (DMFCs). They used a co-precipitation method with different amounts of nickel, cobalt, and tungsten to make a nickel–cobalt mixed tungstate compound. They also tested and validated the materials using a range of characterization techniques. The SEM investigation revealed that the materials contain agglomerated amorphous random circular nanocomposite structures. The electrocatalysts exhibited superior electrochemical performance, with the nanocomposite with a Ni:Co:W ratio of 1:1:1.5 (W1.5) demonstrating the highest performance. When methanol was oxidized at a scan rate of 50 mV s−1 in a 1 molar methanol solution at a potential of 0.6 V, the composite material had a higher current density of 229 mA cm−2. In addition, it exhibited the lowest onset potential of 0.33 V. The results demonstrate the identification of a durable, inexpensive metal material that is suited for direct methanol electro-oxidation procedures. The finding indicates the possibility of creating affordable and eco-friendly electrocatalysts as a replacement for expensive catalysts that are commercially available in the field of catalysts [49, 50].

© 2023, ACS. i–k The graph depicts the comparison between different sample performances in 1 M KOH + 1 M methanol. Adapted with permission [25]. Copyrights© 2024, RSC

a The diagram illustrates the process of creating the NiZnx@CuO nanoarray structures. The obtained pictures are SEM views of NiZnx@CuO nanoarray designs. These architectures consist of NiZn alloy sheets with varying thicknesses: b 1000 nm, c 1500 nm, and d 2000 nm. The CVs of the NiZn1000@CuO and brass mesh catalysts in a KOH solution are shown, with and without 0.5 M methanol. The scan rate used was 50 mV s−1. The CVs of the NiZn1000@CuO catalyst in a KOH solution containing methanol concentrations of 0.25 M, 0.50 M, 1.00 M, and 1.50 M. The scan rate used was 50 mV s−1. The CVs of NiZn1000CuO were measured in a 1 M KOH solution containing 0.5 M methanol at different scan rates. h A chronoamperometry experiment was conducted on the NiZn1000@CuO catalyst at a potential of 0.80 V for a duration of 12 h. Adapted with permission [48]. e The CVs of the NiZn1000@CuO and brass mesh catalysts in a KOH solution are shown, with and without 0.5 M methanol. The scan rate used was 50 mV s−1. f The CVs of the NiZn1000@CuO catalyst in a KOH solution containing methanol concentrations of 0.25 M, 0.50 M, 1.00 M, and 1.50 M. The scan rate used was 50 mV s−1. g The CVs of NiZn1000CuO were measured in a 1 M KOH solution containing 0.5 M methanol at different scan rates. Copyrights

Ghouri et al. [51] evenly spread ZnO(x)CeO2(1−x) nanodots on carbon nanofibers using a template-free method and used it as anode catalysts for the electrooxidation of methanol. The characterization methods revealed that the material consists of carbon nanofibers decorated with ZnO and CeO2 as depicted in Fig. 7a–f. The researchers employed cyclic voltammetry (CV) on a glassy carbon electrode modified with ZnO(x)CeO2(1-x) nanodots on carbon nanofibers to comprehensively investigate the electrochemical oxidation of methanol in alkaline solutions. They conducted a comprehensive analysis to investigate the electrocatalytic oxidation of methanol by altering its concentration. The ZnO (40%) and CeO2 (60%) nanodots exhibited current densities of 5.3 and 16.3 mA/cm2 at CNFs. When ZnO (40%) and CeO2 (60%) nanodots were used on CNFs, the onset potential was − 50 mV lower than when Ag/Ag was used. They consider this value to be higher than that of other non-precious electrocatalysts that have been characterized. In another study, Khalaf et al. [52] conducted another investigation where they created a novel phosphate substance consisting of two metals (Fe and Ni) (Fig. 7g–j). The developed material has shown effectiveness in MOR activity, as illustrated in Fig. 7k–l. The characterization techniques validate that the sol–gel process has shown greater ability to generate nanoscale particles with increased agglomeration, in contrast to the reflux procedure. The electrochemical measurements showed a substantial increase in the current values obtained from both electrodes, FeNiP-R and FeNiP-S. During the electrooxidation of MeOH using FeNiP-S, the current density increased from 0.14 mA/cm2 at 0.402 V to 2.67 mA/cm2 at 0.619 V. This corresponds to an almost 109-fold rise in comparison to the present density measurement of 0.0243 mA/cm.2 at 0.62 V in the absence of MeOH [53]. It was found that the FeNiP-R electrode was better at electrocatalysis than the FeNiP-S electrode at all methanol concentrations up to 80 mmol/L. The increase in anodic current density and charge transfer resistance suggests that the methanol electrooxidation process is occurring on the specially designed Fe/Ni-phosphate bimetallic catalyst [54,55,56]

Copyright © 2015, Elsevier. g–j The diagram depicting the TEM images that are recorded at different magnifications for FeNi-based material, g–l Illustration of chronometric curves for the prepared FeNiP-R, and FeNiP-S catalysts. Adapted with permission [52]. Copyrights © 2022, MDPI

a–d The diagram depicting the TEM images that are recorded at different magnifications for ZnO(x)CeO2(1-x) catalyst, e CV, and f Illustration of chronometric curves that are recorded in methanol containing electrolyte, for the prepared catalysts. Adapted with permission [51].

4 Atomically precise single-atom catalysts for methanol oxidation reaction

Environmental conditions and the geometric arrangement of Pt greatly influence its electrocatalytic performance [57]. Researchers have thoroughly investigated two methods to boost MOR activity and reduce Pt concentration. Changing Pt's structure and/or shape is the main idea behind it. Examples of this include core–shell Pt combinations [31] or hollow or framed Pt structures [58, 59]. Furthermore, combining Pt with Co, Ni, and Sn yields an easily exploitable metal. Unfortunately, the catalysts have poor mass activity because they contain Pt in the form of NPs larger than 1 nm. Furthermore, it is well established that COads in MOR predominantly act as a toxin for Pt NPs, leading to a decrease in their activity [60]. It is therefore very important, both theoretically and practically, to make new electrocatalysts for MOR that are based on Pt, work better, and are less likely to poison. Researchers have discovered a new group of single-atom catalysts (SACs) [61,62,63]. These can help with many electrocatalytic tasks, including alcohol oxidation reactions and reduction reactions for oxygen, carbon dioxide, and nitrogen. The use of Pt is very efficient in Pt SACs, which can greatly speed up the oxidation of carbon monoxide. In MOR, the electrochemical dehydrogenation of methanol to CO necessitates the presence of three adjacent Pt atoms. A single Pt-atom on a CNTs forms SACs [64, 65]. The atomic arrangement significantly influences the catalytic efficiency of each individual atom [66]. Previous studies have shown that changing the connection between the individual atom and substrate can alter the electrical configuration and arrangement of the central individual atom [67, 68]. For instance, Zhiqi Zhang et al. [69], used an easy adsorption-impregnation method to successfully attach single Pt atoms to the surfaces of RuO2 and carbon black (VXC-72) in their study (Fig. 8a–c). They measured the mass activity of the Pt1/RuO2 single-atom catalyst. Figure 8c demonstrates that the stability of these SACs against MOR was significantly higher than that of most previously studied Pt-based catalysts. Density-functional theory (DFT) calculations have greatly contributed to our understanding of the MOR's operation. It involves the electrooxidation of CO and the dehydrogenation of methanol. The results shown in Fig. 8(d–g) back up the experimental findings that the prepared SACs can effectively oxidize alcohol. The findings suggest a potential method for utilizing SACs in direct alcohol fuel cell applications [70,71,72].

a, b HAADF-STEM images, c CV curves, and d–f Diagram illustrating calculated reaction free energy curves of samples. g CO energy barriers, for the prepared Pt-RuO2 samples. Adapted with permission [69]. Copyrights

Single-atom catalysts are highly efficient due to their high Pt content, which significantly enhances electrocatalytic activity. In addition, PtRu alloy nanoparticles demonstrate superior catalytic activity in the methanol oxidation reaction. To leverage the remarkable reactivity of single Pt atom catalysts supported by highly efficient Ru, it is imperative to address the synthetic challenge associated with achieving single Pt atoms on ultrafine noble metal particles. Regarding this discussion, Poerwoprajitno et al. [73] describe a way to create and spread Pt islands on Ru branching nanoparticles that created single Pt-atoms-on-Ru (Fig. 9a). Using in situ TEM, researchers observed that thermodynamics, particularly the formation of strong Pt-Ru bonds and the decrease in surface energy within the Pt islands, drive the production of a stable single-atom structure. The single-atom platinum atom adsorbed on ruthenium has long-term stability and does not exhibit adverse reactivity with carbon monoxide. This suggests that it has the ability to maintain a high level of current density and mass activity while undergoing the methanol oxidation reaction [74,75,76].

© 2022, Nature. b Diagram depicting reaction pathways for MOR. c Illustration of atomic structures of M@N4C. d The number of transferred charges from TM atoms to substrate. e Depiction of energy difference between Ef and Ec of M@N4C. εd means the d-band center of transition metal. f Adsorption energies of CH3OH and H2O on M@N4C. g Limiting potentials and corresponding d-band centers for M@N4C. h Representation of free energy diagrams of Mn@N4C and Co@N4C. Adapted with permission [77]. Copyrights © 2023, ACS

a Graphical illustration showing conversion of Pt islands into single Pt atoms and their promising candidature for MOR. Adapted with permission [73] Copyrights

In another study, Zhang et al. [77] performed a thorough investigation of the activity patterns of electrochemical MOR using DFT calculations. The study focused on a single transition-metal atom embedded in N-coordinated graphene (M@N4C), as shown in Fig. 9(b–h). After examining the free energy diagrams of MOR on M@N4C, they determined that Co@N4C is the most effective catalyst for MOR. This is due to its unique charge transfer and electronic structure result in a low limiting potential of 0.41 V. They conducted an important investigation to figure out how the volcanoes in MOR related to the M@N4C catalysts by analyzing the d-band center and Gibbs free energy of GCH3OH* and GCO* in one and two dimensions, respectively. This study provides theoretical guidelines for improving MOR activity on M@N4C and offers insights for developing MOR electrocatalysts that are both effective and efficient.

In another work, Li et al. [78], also sought to better understand the single atom Ni-Pt nanowire’s (SANi-PtNW) potential as multifunctional electrocatalysts by studying them for MOR and EOR (Fig. 10a). When contrasted with the commercial Pt/C electrocatalyst, the synthetic SANi-PtNW showed higher performance at 3.87 A/mg Pt. The fact that SANi-PtNWs have a lower initial overpotential than Pt/C further supports their lower activation barrier for methanol oxidation on their surface (144 mV). At 1 M ethanol and 1 M KOH, SANi-PtNW outperforms Pt/C for EOR by a factor of 7 and 3, respectively. As shown in Fig. 10(b-g), SANi-PtNW outperforms pure Pt-NWs and Pt/C in terms of long-term dependability in MOR. DFT research revealed all reaction pathways to be exothermic at the experimental potential. SANi-modified Pt top-sites are not as good at absorbing CO2 (by 0.06–0.28 eV) as Pt (111) top-sites in the last step, CO2 production (Fig. 10f). To alter MOR or EOR activity, further new knowledge may be helpful for single-atom tailoring.

a 3D illustration, b, c CVs for MOR and EOR, d MOR Chronoamperometric curves, and f, g Comparison for the MOR and EOR current density, for the SANi-PtNWs material. h Crystal model for the SANi-decorated Pt (111) surface, displaying various active sites for CO adsorption. Adapted with permission [78]. Copyrights

Zhang et al. [79] recently used a hydrothermal method along with nitridation to designed an electrocatalyst for the MOR that works highly efficiently. The process consisted of constructing porous Ni3N nanosheet arrays on a nickel foam (NF) substrate. A straightforward two-step technique can create the highly porous Ni3N nanosheet arrays, as shown in Fig. 11a. The first step is to employed a hydrothermal method to grow the Ni(OH)2 NSAs on a very clean and permeable NF surface, which acts as a conductor. Next, they annealed the Ni(OH)2 NSAs/NF nitride at 400 °C, passing NH3 gas over it to promote the formation of the Ni3N NSAs/NF composite. They further evaluated the Ni3N non-stoichiometric nitride semiconductor/nanofiber electrode for revealing its MOR activity. The TEM image (Fig. 11b) clearly demonstrates the abundance of tiny nanoparticles in the Ni3N-400 nanosheet. The HR-TEM image of Ni3N-400 in Fig. 11c provides a highly detailed view of the lattice fringes. The distance between these fringes, referred to as the interplanar d-spacing, ranges from 0.203 to 0.215 nm. The values are consistent with the hexagonal Ni3N crystal planes (111) and (002). They use CV to analyze the electrochemical properties of the newly created catalyst, Ni3N-400. Prior to that, they perform a comparative test to assess the characteristics of the MOR. In order to determine the catalyst's range, researchers use CV in a 1.0 M KOH solution, with or without methanol. The potential range observed during this process varies from 1.1 to 1.8 V. Figure 11d displays the MOR characteristics of the Ni3N-400 catalyst in a potential range of 1.5–1.7 V. They observe these characteristics following the appearance of the Ni2+ oxidation peak, which happens in the absence of the methanol solution. However, OER occurs on the catalyst at around 1.75 V compared to the RHE, requiring a substantial excess voltage. This indicates the catalyst exhibits superior performance at a lower MOR potential in comparison to OER. As a result, they define a voltage range of 1.1–1.7 V as appropriate for evaluating the MOR activity of Ni3N-400. Despite the significant formation of NiOOH in methanol oxidation, they subject all samples to CV testing. The tests involve 50 cycles performed at a scan rate of 50 mV s−1 in a 1.0 M KOH solution. Initially, they treated the samples to increase the thickness of the electrocatalytic layers and promote the growth of Ni(OH)2/NiOOH on the surface [44, 45]. As depicted in Fig. 11e, all of the catalysts exhibit two redox peaks that correspond to the Ni2+/Ni.3+ redox reaction. Ni3N-400 is the catalyst that stands out due to its superior current density for both oxidation and reduction peaks. This implies that there are a greater number of active sites available to interact with a 1.0 M KOH solution [46].

a Schematic illustration of the process for developing the Ni3N nanosheet arrays on a nickel foam substrate (Ni3N NSAs/NF). b Transmission Electron Microscopy (TEM) and c High-Resolution TEM (HR-TEM) pictures of Ni3N-400 d CV curves of Ni3N-400 in a 1.0 M KOH solution with and without a 1.0 M methanol solution were obtained using a scanning rate of 50 mV s−1. e The CV curves of Ni3N at various temperatures and Ni-400 in 1.0 M KOH were obtained using a scanning rate of 50 mV s−1. Adapted with permission [79]. Copyrights

5 Molecular catalysts for MOR

Methanol oxidation electrochemically is very important due to its close relation to fuel cell and energy research. The extensively utilized molecular catalysts for alcohol oxidation are complexes based on Ruthenium (Ru) and Nickel (Ni) [71, 80]. Besides, Ru and other metal oxo-complexes are also used as suitable oxidizing agent for alcohol [81]. Figure 12 illustrates the proton couple electron transfer by the high valent Ru (IV)-oxo species being generated from corresponding Ru (II)-aquo-complex.

Mechanism of metal oxo-complexes towards alcohol oxidation. Adapted with permission [82]. Copyright @1989, Elsevier

There have been numerous recent reports on novel Ru-oxo compounds that incorporate diamines and modified polypyridyl ligands (Fig. 13). In this study, Lahiri et al. [83] presented evidence of the oxidation process of Ru-aquo species [Ru(tpy)(2,3′-di-imine)(H2O)]2+ (α,α′- di-imine = NC5H4C(H) N(C6H4)nNH2, n = 1 and 2). Ru-oxo acts as a catalyst for the oxidation of benzyl alcohol, resulting in the formation of benzaldehyde [83]. Ru-oxo catalyzes the oxidation of benzyl alcohol to benzaldehyde. Hill et al. [84] conducted a study using a modified polypyridyl ligand (Fig. 13), specifically 4,4′-Me2dppi (3,6-di-(4-methylpyrid-2-yl)pyridazine), to examine the Ru oxo redox reaction. This reaction resulted in the formation of two geometric isomers, both of which could be electrochemically oxidized to produce Ru(IV)-oxo. However, the outer isomer was found to be more reactive due to the instability of the in-isomers. Several benzyl alcohol derivatives, such as 1-phenyl ethanol and 1-phenyl-1-propanol, were examined as substrates in bulk electrolysis. It was shown that the catalytic rate decreased linearly with the increasing steric bulkiness of the alcohol. Furthermore, a study has documented the existence of Ru complexes [Ru(bpea)(bpy)(H2O)]2+ containing a tridentate poly pyridyl ligand called bpea (bpea = (N,N-bis(2-pyridyl)ethylamine))) [85].

Structure of various ligands [84]

Recently, poly-[Ru(bpea-pyr) (bpy-pyr) (H2O)]2 + (Fig. 14) (bpea-pyr = bis-pyridin-2-ylmethyl-(3-pyrrol-l-propyl) amine, bpy-pyr = 4- methyl-4′-(4-pyrrol-1-yl-butyl)-[2,2′]-bipyridine) has been reported in the form of polymer film on the electrode and used towards oxidation of benzyl alcohol electrochemically. The results indicated that the redox cycle of immobilized Ru catalyst increases remarkably upto 922 cycles. Another similar work is [Ru(tpy)(*bpy)(OH)2]2+ (*bpy = 4′-methyl-(2,2′- bipyridine)-4-acetic acid) applicable as adsorbed catalyst on graphite chloride [86, 87].

In majority cases, the catalyst may undergo grafting on graphite felt leading to enhancement of rate of electrooxidation of alcohol. Other than Ru, and In-Sn oxide electrode modified with high valent trans-di-oxorhenium catalyst was demonstrated by Tanaka et al. [88]. The results of the study suggested that catalytic oxidation of 1-phenyl ethanol feel hardship in CH2Cl2 with rhenium (V) complex as catalyst, however, electrocatalytic oxidation could achieved higher catalyst turnover number as well as high current efficiency via immobilization of the rhenium(V) complex onto electrode surface. Figure 15 shows the chemical structure of MOR significance coordination compounds.

Chemical structure of a few metal complexes, which were used to catalyze the alcohol oxidation reaction [88]

While these molecular models aid in the oxidation of various alcohols like methanol, ethanol, and benzyl alcohol, they can also produce additional molecular models for the MOR process [89,90,91]. Alternatively, the combination of redox-active molecule ligands with transition metals can create an additional class of crystalline materials known as monometallic and bimetallic molecular organic frameworks (MOFs) [92]. These materials have the potential to serve as effective electrocatalysts for the MOR process. An additional benefit of using bimetallic MOFs with cobalt (Co) and nickel (Ni) could be helpful in the methanol electro-oxidation process. Liu and his colleagues created the CoNi-ZIF electrode material, which is a NiCo-ZIF@-MoS2 mix, as a change to the GCE (Fig. 16) [93]. When methanol was not present, the electrode exhibited a redox couple at 0.42 V and 0.26 V. The Ni2+/Ni3+ and Co2+/Co3+ redox couples, respectively, facilitated the oxidation and reduction reactions. Furthermore, the proportion of metal ions had a contingent influence on the electrochemical reaction of the bimetallic MOF. The bimetallic CoNi-ZIF (3:1) exhibited the highest current density when compared to other ratios. In addition, the electrode exhibited a proportional reaction to various methanol concentrations ranging from 0.2 to 0.7 M and achieved a peak current density of 72 mA. With an applied potential of 1.55 V, the composite demonstrated its ability to actively facilitate the process of water splitting, resulting in a current density of 10 mA.

Synthesis protocol, and MOR, HER/OER applications of the CoNi-ZIF material. Adapted with permission [93]. Copyrights

A subsequent investigation conducted by Rezaee et al. [94] provided a comprehensive analysis of the alteration of a GCE (Glassy Carbon Electrode) for the electro-oxidation of methanol. This was achieved by utilizing a NiCo-BDC MOF (Metal–Organic Framework) as a sacrificial substance, resulting in the production of a composite material consisting of NiCo/NiO-CoO/nanoporous carbon (as depicted in Fig. 17a). The nanocomposite was made by directly pyrolyzing the bimetallic NiCo-MOF, as depicted in Fig. 11a. When MeOH was present, the composite exhibited a maximum anodic current of 185 mA when measured in alkaline conditions using CV (Fig. 17b, c). The improved catalytic efficiency arises from the formation of metal oxides and the conductive nature of the porous carbon structure. The proposed mechanism for the methanol electro-oxidation process (MOR) entails the direct formation of highly oxidizing MOOH molecules from metal oxides [94].

a Preparation strategy, CVs, b in absence of MeOH, c in presence of MeOH, for NiCo/NiO-CoO/NPCC composites. Adapted with permission [94]. Copyrights

6 Conclusions

To summarize, this review examined the recent progress made in electrocatalysts based on both noble and non-noble metals for the methanol oxidation reaction (MOR), which is a crucial step in direct methanol fuel cells (DMFCs). Moreover, this study underscores the importance of comprehensively understanding the mechanisms of methanol oxidation reactions (MOR) in different types of electrolytes, along with the essential factors that govern electrocatalysts. The research findings demonstrated that Pt-based materials supported on heteroatom-doped carbon matrix exhibited higher activity and stability towards MOR. Furthermore, by anchoring the metallic nanoparticles to nanocarbon supports, it is possible to get a consistent distribution of metallic sites that form strong bonds with heteroatoms (such as N, S, and P), leading to exceptional MOR performance. Since Pt-group metal-based catalysts are expensive in nature, it remains remains a major obstacle despite the effectiveness of this approach for MOR. Besides, the combination of Pt-group metals with affordable metals such as Mn, Fe, Co, Ni, Cu, etc. also exhibited remarkable MOR activity. This method can decrease the amount of noble metal used in the catalyst ink and decrease the overall cost of the catalyst, which is intriguing. On the other hand, atomically precised single-atom and dual-atom catalysts also displayed promise towards MOR. However, it is highly challenging to create catalysts that possess precise spatial arrangements for single or dual atomic sites. These catalysts often offer excellent activity as well as durability towards MOR. Moreover, due to the similarity of these catalysts with molecular systems, they offer a good understanding of catalytic reaction mechanisms at the atomic level.

Although there has been notable advancement in MOR electrocatalysts, there are still practical challenges that need to be addressed. To advance Pt-based catalysts, it is crucial to comprehend the MOR mechanism occurring at the level of individual metal atoms or nanoparticles. The sizes of metal electrocatalysts supported on a carbon substrate might vary within specific boundaries, encompassing individual atoms, nanoparticles, or clusters. Improving the loading and durability of single or dual atomic catalysts is essential for enhancing their performance in direct methanol fuel cells (DMFCs). Some molecular models have been proposed for alcohol oxidation reactions; however, they do not match the practical requirements for MOR due to their susceptibility to deterioration in the electrolyte.

In order to optimize the performance of both noble and non-noble metal electrocatalysts, several future directions should be considered. Firstly, it is important to develop environmentally friendly synthesis protocols for creating innovative electrocatalysts for MOR. Secondly, a variety of catalytic materials, consisting of both single and dual metallic catalysts, should be designed, and manufactured to establish structural and geometrical correlations. Thirdly, systematic in-situ and ex-situ investigations should be conducted to observe the inherent electrical, structural, and surface characteristics. Lastly, based on the findings from these characterizations, it is crucial to develop structural-reactivity descriptors to gain a deeper understanding of the mechanisms involved in MOR.

Data availability

No datasets were generated or analysed during the current study.

References

Wan C-H, Huang Y, Leong YK, Gu Y. Improving the performance of direct methanol fuel cells using a performance-enhancing layer. Fuel. 2024;366: 131366.

Yuda A, Ashok A, Kumar A. A comprehensive and critical review on recent progress in anode catalyst for methanol oxidation reaction. Catal Rev. 2022;64:126–228.

Jin H, Song W, Cao C. An overview of metal density effects in single-atom catalysts for thermal catalysis. ACS Catal. 2023;13:15126–42.

Wang Y, Zhang Y, Yu W, Chen F, Ma T, Huang H. Single-atom catalysts for energy conversion. J Mater Chem A. 2023;11:2568–94.

Huang H, Yang S, Vajtai R, Wang X, Ajayan PM. Pt-decorated 3D architectures built from graphene and graphitic carbon nitride nanosheets as efficient methanol oxidation catalysts. Adv Mater. 2014;26:5160–5.

Cui G, Shen PK, Meng H, Zhao J, Wu G. Tungsten carbide as supports for Pt electrocatalysts with improved CO tolerance in methanol oxidation. J Power Sources. 2011;196:6125–30.

Yin S, Zong K, Ban L, Yin H, Liu X, Ding Y. Design of compressively strained PtRu alloy as anode for high performance DMFC. Inorganic Chem Front. 2024;11:3633–42.

Singh M, Sharma HM, Kaur J, Das DK, Ubaidullah M, Gupta RK, Kumar A. Engineering of electrocatalysts for methanol oxidation reaction: recent advances and future challenges. Mole Catal. 2024;557: 113982.

Yu R, Zhang Y, Deng S, Zhu R, Zhang S, Zhang J, Zhao Y, Xia Z. Platinum alloys for methanol oxidation electrocatalysis: reaction mechanism and rational design of catalysts with exceptional activity and stability. Catalysts. 2024;14:60.

Santos M, Nandenha J, Ayoub J, Assumpção M, Neto A. Methanol oxidation in acidic and alkaline electrolytes using PtRuIn/C electrocatalysts prepared by borohydride reduction process. J Fuel Chem Technol. 2018;46:1462–71.

Zhao L, Wang S-Q, Liang S, An Q, Fu J, Hu J-S. Coordination anchoring synthesis of high-density single-metal-atom sites for electrocatalysis. Coord Chem Rev. 2022;466: 214603.

Shi Q, Hwang S, Yang H, Ismail F, Su D, Higgins D, Wu G. Supported and coordinated single metal site electrocatalysts. Mater Today. 2020;37:93–111.

Tiwari JN, Tiwari RN, Singh G, Kim KS. Recent progress in the development of anode and cathode catalysts for direct methanol fuel cells. Nano Energy. 2013;2:553–78.

Liu H, Song C, Zhang L, Zhang J, Wang H, Wilkinson DP. A review of anode catalysis in the direct methanol fuel cell. J Power Sources. 2006;155:95–110.

Hamnett A. Mechanism and electrocatalysis in the direct methanol fuel cell. Catal Today. 1997;38:445–57.

Tong Y, Yan X, Liang J, Dou SX. Metal-based electrocatalysts for methanol electro-oxidation: progress, opportunities, and challenges. Small. 2021;17:1904126.

Petrii O. The progress in understanding the mechanisms of methanol and formic acid electrooxidation on platinum group metals (a review). Russ J Electrochem. 2019;55:1–33.

Li J, Li L, Wang J, Cabot A, Zhu Y. Boosting hydrogen evolution by methanol oxidation reaction on Ni-based electrocatalysts: from fundamental electrochemistry to perspectives. ACS Energy Lett. 2024;9:853–79.

Phan VTT, Nguyen QP, Wang B, Burgess IJ. Oxygen vacancies alter methanol oxidation pathways on NiOOH. J Am Chem Soc. 2024;146:4830–41.

Li Q, He R, Jensen JO, Bjerrum NJ. Approaches and recent development of polymer electrolyte membranes for fuel cells operating above 100 C. Chem Mater. 2003;15:4896–915.

K.A. Litvintseva, Y.A. Chesalov, A.V. Selivanova, A.A. Saraev, V.V. Kaichev, Mechanistic study of selective oxidation of methanol over a monolayer V2O5/CeO2 catalyst. J Phys Chem C (2024)

Wang K, Gasteiger H, Markovic N, Ross P Jr. On the reaction pathway for methanol and carbon monoxide electrooxidation on Pt-Sn alloy versus Pt-Ru alloy surfaces. Electrochim Acta. 1996;41:2587–93.

Y. Cheng, H. Wang, T.-W. Jiang, X. Guo, F. Kwofie, H. Su, L. Khotseng, W. Zeng, Y. Zhang, Y. Liu, Lutetium-induced ultrafine PtRu nanoclusters with a high electrochemical surface area for direct methanol fuel cells at alleviated temperatures. ACS Appl Mater Interfaces (2024).

Deshpande P, Prasad BL. Alloying with Mn enhances the activity and durability of the CoPt catalyst toward the methanol oxidation reaction. ACS Appl Mater Interfaces. 2023;15:26554–62.

Mahmoud I, Farghali AA, El-Rouby WM, Abdelwahab A. Nickel and cobalt-based tungstate nanocomposites as promising electrocatalysts in alkaline direct methanol fuel cells. Nanoscale Adv. 2024;6:2059–74.

Kavanagh R, Cao XM, Lin WF, Hardacre C, Hu P. Origin of low CO2 selectivity on platinum in the direct ethanol fuel cell. Angew Chem Int Ed. 2012;51:1572–5.

Liang Z, Zhao T, Xu J, Zhu L. Mechanism study of the ethanol oxidation reaction on palladium in alkaline media. Electrochim Acta. 2009;54:2203–8.

Tong Y, Wang L, Hou F, Dou SX, Liang J. Electrocatalytic oxygen reduction to produce hydrogen peroxide: rational design from single-atom catalysts to devices. Electrochem Energy Rev. 2022;5:7.

L. Zhang, T. Wu, Y. Zhan, Y. Dong, F. Wei, D. Zhang, B. Zhou, Z. Tan, C. Zhao, X. Long, Progresses on high-entropy nano-catalysts for electrochemical energy conversion reactions. J Mater Chem A (2024).

Zhang W, Zhao Y, Huang W, Huang T, Wu B. Coordination environment manipulation of single atom catalysts: regulation strategies, characterization techniques and applications. Coord Chem Rev. 2024;515: 215952.

Xin H, Mou T, Pillai HS, Wang S-H, Huang Y. Interpretable machine learning for catalytic materials design toward sustainability, accounts of. Mater Res. 2023;5:22–34.

Hitmi H, Belgsir E, Léger J-M, Lamy C, Lezna R. A kinetic analysis of the electro-oxidation of ethanol at a platinum electrode in acid medium. Electrochim Acta. 1994;39:407–15.

Wang D, Lu S. Tetrahydrofuran-functionalized multi-walled carbon nanotubes as effective support for Pt and PtSn electrocatalysts of fuel cells. Electrochim Acta. 2010;55:2964–71.

Lin J-L, Ren J, Tian N, Zhou Z-Y, Sun S-G. In situ FTIR spectroscopic studies of ethylene glycol electrooxidation on Pd electrode in alkaline solution: the effects of concentration. J Electroanal Chem. 2013;688:165–71.

Xie S-W, Chen S, Liu Z-Q, Xu C-W. Comparison of alcohol electrooxidation on Pt and Pd electrodes in alkaline medium. Int J Electrochem Sci. 2011;6:882–8.

B. Hammer, J.K. Nørskov, Theoretical surface science and catalysis—calculations and concepts. In Advances in catalysis. Elsevier, New York, 2000, pp. 71–129.

Lima FHB, Zhang J, Shao M, Sasaki K, Vukmirovic M, Ticianelli EA, Adzic R. Catalytic activity—d-band center correlation for the O2 reduction reaction on platinum in alkaline solutions. J Phys Chem C. 2007;111:404–10.

Tsunoyama H, Ichikuni N, Sakurai H, Tsukuda T. Effect of electronic structures of Au clusters stabilized by poly (N-vinyl-2-pyrrolidone) on aerobic oxidation catalysis. J Am Chem Soc. 2009;131:7086–93.

Wang S, Yang F, Chen S, Wang X. Tuning the electrocatalytic activity of Pt nanoparticles on carbon nanotubes via surface functionalization. Electrochem Commun. 2010;12:1646–9.

Li M, Zhao Z, Zhang W, Luo M, Tao L, Sun Y, Xia Z, Chao Y, Yin K, Zhang Q. Sub-monolayer YOx/MoOx on ultrathin Pt nanowires boosts alcohol oxidation electrocatalysis. Adv Mater. 2021;33:2103762.

Chen M-X, Luo X, Song T-W, Jiang B, Liang H-W. Ordering degree-dependent activity of Pt3M (M=Fe, Mn) intermetallic nanoparticles for electrocatalytic methanol oxidation. J Phys Chem Lett. 2022;13:3549–55.

Chen YX, Miki A, Ye S, Sakai H, Osawa M. Formate, an active intermediate for direct oxidation of methanol on Pt electrode. J Am Chem Soc. 2003;125:3680–1.

Jafarian M, Mahjani M, Heli H, Gobal F, Khajehsharifi H, Hamedi M. A study of the electro-catalytic oxidation of methanol on a cobalt hydroxide modified glassy carbon electrode. Electrochim Acta. 2003;48:3423–9.

Zafeiratos S, Dintzer T, Teschner D, Blume R, Hävecker M, Knop-Gericke A, Schlögl R. Methanol oxidation over model cobalt catalysts: Influence of the cobalt oxidation state on the reactivity. J Catal. 2010;269:309–17.

Xia Y, Dai H, Jiang H, Zhang L. Three-dimensional ordered mesoporous cobalt oxides: highly active catalysts for the oxidation of toluene and methanol. Catal Commun. 2010;11:1171–5.

Shahid MM, Pandikumar A, Golsheikh AM, Huang NM, Lim HN. Enhanced electrocatalytic performance of cobalt oxide nanocubes incorporating reduced graphene oxide as a modified platinum electrode for methanol oxidation. RSC Adv. 2014;4:62793–801.

Thamer BM, El-Newehy MH, Al-Deyab SS, Abdelkareem MA, Kim HY, Barakat NA. Cobalt-incorporated, nitrogen-doped carbon nanofibers as effective non-precious catalyst for methanol electrooxidation in alkaline medium. Appl Catal A. 2015;498:230–40.

Han L, Li H, Yang L, Liu Y, Liu S. Rational design of NiZn x@ CuO nanoarray architectures for electrocatalytic oxidation of methanol. ACS Appl Mater Interfaces. 2023;15:9392–400.

Alam MW, Aamir M, Farhan M, Albuhulayqah M, Ahmad MM, Ravikumar C, Dileep-Kumar V, Ananda Murthy H. Green synthesis of Ni-Cu-Zn based nanosized metal oxides for photocatalytic and sensor applications. Crystals. 2021;11:1467.

Packiaraj R, Mahendraprabhu K, Devendran P, Nallamuthu N, Palanivel B, Venkatesh K, Karuppannan R. Electrochemical performances of ZnO–NiO–CuO mixed metal oxides as smart electrode material for solid-state asymmetric device fabrication. Energy Fuels. 2021;36:603–17.

Ghouri ZK, Barakat NA, Kim HY, Park M, Khalil KA, El-Newehy MH, Al-Deyab SS. Nano-engineered ZnO/CeO2 dots@ CNFs for fuel cell application. Arab J Chem. 2016;9:219–28.

Khalaf MM, Abd El-Lateef HM, Dao V-D, Mohamed IM. Electrocatalysis of methanol oxidation in alkaline electrolytes over novel amorphous Fe/Ni biphosphate material prepared by different techniques. Nanomaterials. 2022;12:3429.

Abd El Lateef HM, Khalaf MM, Mohamed IM. XPS analysis, voltammetric, and impedance characteristics of novel heterogeneous biphosphates based on Cu/Ni for tri (ammonium) phosphate oxidation: a new direction for material processing in fuel technology. Fuel. 2024;356:129618.

Dao V, Mohamed I. Electrocatalysis of methanol oxidation in alkaline electrolytes over novel amorphous Fe/Ni biphosphate material prepared by different techniques. Nanomaterials. 2022;12:3429–3429.

Yu B, Li Y, Fu X-N, Yu L, Fu H-D, Cao Y-X, Chen Z-H. Preparation and electrocatalytic oxygen evolution of bimetallic phosphates (NiFe) 2P/NF. Green Process Synthesis. 2024;13:20230266.

Pan X, Pu J, Zhang L, Gong X, Luo X, Fan L. Bimetallic iron-nickel phosphide as efficient peroxymonosulfate activator for tetracycline hydrochloride degradation: performance and mechanism. Environ Res. 2024;249:118362.

Kakati N, Maiti J, Lee SH, Jee SH, Viswanathan B, Yoon YS. Anode catalysts for direct methanol fuel cells in acidic media: do we have any alternative for Pt or Pt–Ru? Chem Rev. 2014;114:12397–429.

Chen S, Li M, Gao M, Jin J, van Spronsen MA, Salmeron MB, Yang P. High-performance Pt–Co nanoframes for fuel-cell electrocatalysis. Nano Lett. 2020;20:1974–9.

Huang J, Liu Y, Xu M, Wan C, Liu H, Li M, Huang Z, Duan X, Pan X, Huang Y. PtCuNi tetrahedra catalysts with tailored surfaces for efficient alcohol oxidation. Nano Lett. 2019;19:5431–6.

Huang W, Wang H, Zhou J, Wang J, Duchesne PN, Muir D, Zhang P, Han N, Zhao F, Zeng M. Highly active and durable methanol oxidation electrocatalyst based on the synergy of platinum–nickel hydroxide–graphene. Nat Commun. 2015;6:10035.

Zhou Y, Abazari R, Chen J, Tahir M, Kumar A, Ikreedeegh RR, Rani E, Singh H, Kirillov AM. Bimetallic metal–organic frameworks and MOF-derived composites: recent progress on electro-and photoelectrocatalytic applications. Coord Chem Rev. 2022;451: 214264.

Luo X, Abazari R, Tahir M, Fan WK, Kumar A, Kalhorizadeh T, Kirillov AM, Amani-Ghadim AR, Chen J, Zhou Y. Trimetallic metal–organic frameworks and derived materials for environmental remediation and electrochemical energy storage and conversion. Coord Chem Rev. 2022;461: 214505.

Kumar A, Vashistha VK, Das DK. Recent development on metal phthalocyanines based materials for energy conversion and storage applications. Coord Chem Rev. 2021;431: 213678.

Kumar A, Zhang Y, Liu W, Sun X. The chemistry, recent advancements and activity descriptors for macrocycles based electrocatalysts in oxygen reduction reaction. Coord Chem Rev. 2020;402: 213047.

Qiao B, Wang A, Yang X, Allard LF, Jiang Z, Cui Y, Liu J, Li J, Zhang T. Single-atom catalysis of CO oxidation using Pt1/FeO x. Nat Chem. 2011;3:634–41.

Cuesta A. At least three contiguous atoms are necessary for CO formation during methanol electrooxidation on platinum. J Am Chem Soc. 2006;128:13332–3.

Kim YT, Ohshima K, Higashimine K, Uruga T, Takata M, Suematsu H, Mitani T. Fine size control of platinum on carbon nanotubes: from single atoms to clusters. Angew Chem Int Ed. 2006;45:407–11.

Qin R, Liu K, Wu Q, Zheng N. Surface coordination chemistry of atomically dispersed metal catalysts. Chem Rev. 2020;120:11810–99.

Zhang Z, Liu J, Wang J, Wang Q, Wang Y, Wang K, Wang Z, Gu M, Tang Z, Lim J. Single-atom catalyst for high-performance methanol oxidation. Nat Commun. 2021;12:5235.

Wang K, Zhou T, He J, Cao Z, Jiang Z. Regulating the atomic ratio of Pt/Ru to enhance CO anti-poisoning of Pt based electrocatalysts toward methanol oxidation reaction. Molecular Catalysis. 2024;556: 113927.

Matthews T, Chabalala MP, Mbokazi SP, Maumau T, Mugadza K, Gallenberger J, Hofmann JP, Dolla TH, Maxakato NW. Multi-dimensional PtRu/Co3O4-activated carbon nano-electrocatalyst: metal-Support Interaction, and electronic contributions towards methanol electrooxidation in alkaline fuel cells. Fuel. 2024;359: 130460.

Bayat R, Darabi R, Coguplugil ZK, Akin M, Bekmezci M, Sen F, Karimi F. Synthesis and applications of highly stable silane modified reduced graphene oxide supported cobalt based platinum nanoparticle for anodic part of direct methanol fuel cells. Int J Hydrogen Energy. 2024;52:343–51.

Poerwoprajitno AR, Gloag L, Watt J, Cheong S, Tan X, Lei H, Tahini HA, Henson A, Subhash B, Bedford NM. A single-Pt-atom-on-Ru-nanoparticle electrocatalyst for CO-resilient methanol oxidation, Nature. Catalysis. 2022;5:231–7.

de Sá MH, Moreira CS, Pinto AM, Oliveira VB. Recent advances in the development of nanocatalysts for direct methanol fuel cells. Energies. 2022;15:6335.

Ahmed AA, Al Labadidi M, Hamada AT, Orhan MF. Design and utilization of a direct methanol fuel cell. Membranes. 2022;12:1266.

Milošević D, Stevanović S, Tripković D, Vukašinović I, Maksimović V, Ćosović V, Nikolić ND. Design of Pt-Sn-Zn nanomaterials for successful methanol electrooxidation reaction. Materials. 2023;16:4617.

Zhang J, Yan L, Xue K, Wu J, Ku R, Ding Y-M, Dong H, Zhou L. Understanding trends in electrochemical methanol oxidation reaction activity on a single transition-metal atom embedded in n-coordinated graphene catalysts. J Phys Chem Lett. 2023;14:3384–90.

Li M, Duanmu K, Wan C, Cheng T, Zhang L, Dai S, Chen W, Zhao Z, Li P, Fei H. Single-atom tailoring of platinum nanocatalysts for high-performance multifunctional electrocatalysis, Nature. Catalysis. 2019;2:495–503.

W. Zhang, M. Rafiq, J. Lu, A.R. Woldu, J. Zhou, H. Xia, P.K. Chu, L. Hu, F. Lu, Durable Ni3N porous nanosheets array for non-noble metal methanol oxidation reaction. APL Mater 11 (2023).

Zheng J, Huang K, Hou G, Zhang H, Cao H. A highly active Pt nanocatalysts supported on RuO2 modified TiO2-NTs for methanol electrooxidation with excellent CO tolerance. Int J Hydrogen Energy. 2019;44:31506–14.

Moyer BA, Thompson MS, Meyer TJ. Chemically catalyzed net electrochemical oxidation of alcohols, aldehydes, and unsaturated hydrocarbons using the system (trpy)(bpy) Ru(OH2)2+/(trpy)(bpy) RuO2+. J Am Chem Soc. 1980;102:2310–2.

Khan MT, Ramachandraiah G, Mehata S. trans-Dioxo-bis (dimethylglyoximato) ruthenium (VII) perchlorate: an active oxidation catalyst for the electrochemical epoxidation of olefins. J Mol Catal. 1989;50:123–9.

Chanda N, Mondal B, Puranik VG, Lahiri GK. Ruthenium monoterpyridine complexes incorporating α, α′-diimine based ancillary functions. Synthesis, crystal structure, spectroelectrochemical properties and catalytic aspect. Polyhedron. 2002;21:2033–43.

Catalano VJ, Heck RA, Öhman A, Hill MG. Synthesis, characterization, and electrocatalytic oxidation of benzyl alcohol by a pair of geometric isomers of [Ru (trpy)(4,4′-Me2d ppi)(OH2)]2+ where 4,4′-dppi is 3,6-di-(4-methylpyrid-2-yl) pyridazine. Polyhedron. 2000;19:1049–55.

Rodríguez M, Romero I, Llobet A, Deronzier A, Biner M, Parella T, Stoeckli-Evans H. Synthesis, structure, and redox and catalytic properties of a new family of ruthenium complexes containing the tridentate bpea ligand. Inorg Chem. 2001;40:4150–6.

Geneste F, Moinet C. Electrocatalytic activity of a polypyridyl ruthenium-oxo complex covalently attached to a graphite felt electrode. New J Chem. 2004;28:722–6.

Geneste F, Moinet C, Jezequel G. First covalent attachment of a polypyridyl ruthenium complex on a graphite felt electrode. New J Chem. 2002;26:1539–41.

Sugimoto H, Tsukube H, Tanaka K. Immobilization of a high-valent rhenium complex on an indium-doped tin-oxide electrode: enhanced catalytic activity of a trans-dioxorhenium (v) complex in electrochemical oxidation of alcohols. Eur J Inorg Chem. 2004;2004:4550–3.

Peng Y, Sanati S, Morsali A, García H. Metal–organic frameworks as electrocatalysts. Angew Chem Int Ed. 2023;62: e202214707.

Khan U, Nairan A, Gao J, Zhang Q. Current progress in 2D metal–organic frameworks for electrocatalysis. Small Struct. 2023;4:2200109.

Varsha M, Nageswaran G, Jothi L. Recent advances in metal organic framework derived carbon materials for electrocatalytic applications. J Electrochem Soc. 2022;169: 036503.

Zeeshan M, Shahid M. State of the art developments and prospects of metal–organic frameworks for energy applications. Dalton Trans. 2022;51:1675–723.

Liu Y, Hu B, Wu S, Wang M, Zhang Z, Cui B, He L, Du M. Hierarchical nanocomposite electrocatalyst of bimetallic zeolitic imidazolate framework and MoS2 sheets for non-Pt methanol oxidation and water splitting. Appl Catal B. 2019;258: 117970.

Rezaee S, Shahrokhian S. Facile synthesis of petal-like NiCo/NiO-CoO/nanoporous carbon composite based on mixed-metallic MOFs and their application for electrocatalytic oxidation of methanol. Appl Catal B. 2019;244:802–13.

Acknowledgements

The authors are thankful to GLA University for providing infrastructural support during this work.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

MS and HM wrote the original draft. AK & RKG supervised the project throughout.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Singh, M., Sharma, H.M., Gupta, R.K. et al. Recent advancements and prospects in noble and non-noble electrocatalysts for materials methanol oxidation reactions. Discover Nano 19, 128 (2024). https://doi.org/10.1186/s11671-024-04066-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-024-04066-w