Abstract

Thanks to high performance above room temperature, antimonide laser diodes have shown great potential for broad application in the mid-infrared spectral region. However, the laser`s performance noticeably deteriorates due to the reduction of carrier confinement with increased emission wavelength. In this paper, a novel active region with higher carrier confinements both of electron and hole, by the usage of an indirect bandgap material of Al0.5GaAs0.04Sb as the quantum barrier, was put up to address the poor carrier confinement of GaSb-based type-I multi-quantum-well (MQW) diode lasers emission wavelength above 2.5 µm. The carrier confinement and the differential gain in the designed active region are enhanced as a result of the first proposed usage of an indirect-gap semiconductor as the quantum barrier with larger band offsets in conduction and valence bands, leading to high internal quantum efficiency and low threshold current density of our lasers. More importantly, the watt-level output optical power is obtained at a low injection current compared to the state of the art. Our work demonstrates a direct and cost-effective solution to address the poor carrier confinement of the GaSb-based MQW lasers, thereby achieving high-power mid-infrared lasers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In consideration of the numerous absorption lines for technological and greenhouse gases [1], light emitters operating in the mid-infrared spectral range are in great demand for numerous applications in the field of molecular spectroscopy [2], biomedical diagnostics [3], industrial process control [4], homeland security [5], and so on [6]. These emitters also attract much attention in infrared countermeasure [7], LIDAR [8], and free-space optical communications [9], in consequence of the high transparency atmospheric transmission window in this spectral range. Owing to compactness, scalability, high efficiency, and cost-effectiveness, the semiconductor laser stands as the predominant choice, presenting the most favorable Size-Weight and Power-Cost (SWaP-C) attribute compared to other laser types.

In comparison with other semiconductor materials and structure lasers, GaSb-based type-I multi-quantum-well (MQW) lasers have displayed critical competitiveness in the 1.9–3.3 µm range due to high efficiency, high working temperature and considerable continuous-wave output powers above room temperature [10, 11]. Nonetheless, the GaSb-based type-I MQW laser`s performance explicitly deteriorates with the increasing of emission wavelength on account of reduced carrier confinement, especially for hole confinement [12]. The poor hole confinement leads to an undesirable increase in the density of hole states in the active region including barrier states and waveguide states with higher volume to achieve the separation of electron and hole quasi-Fermi levels at high injection carrier concentration [13]. Worse still, the high threshold carrier concentration remarkably enlarges the non-radiative auger current, limiting the performance of the laser [14]. Additionally, the high concentration of holes leaking into the barrier and waveguide layers causes severe free carrier absorption and reduced injection carrier efficiency.

Previous studies on enhancing the hole confinement mainly focused on using the AlGaInAsSb quinternary alloy lattice-matched to GaSb as quantum barriers [15,16,17]. By adding indium and increasing the arsenic contents in the AlGaAsSb barrier layers, valence bands are pulled down, enlarging the valence band offsets of InGaAsSb/AlGaInAsSb quantum well. Nonetheless, it`s worthy to note that the growth of AlGaInAsSb is much complicated and difficult due to a large and severe thermodynamic miscibility gap [18]. The large differences in Al, Ga, and In atoms mobility and the sensitivity to growth parameters of the ratio of As and Sb in AlGaInAsSb bring many challenges in optimizing the growth of AlGaInAsSb. Although molecular beam epitaxy can achieve growth under far-form-equilibrium condition, the AlGaInAsSb grown is metastable and easy to phase separation [19], which severely restrict the performance of GaSb-based lasers. What is worse, a long time of growth interruptions is required to laboriously change the cell temperatures of Al, Ga, In, and needle valves of As and Sb to precisely control the composition of quinary and quaternary alloys, like AlGaInAsSb, AlGaAsSb, and InGaAsSb. This long time of growth interruptions not only increases the time cost of fabrication but also impacts the quality of interfaces between the quantum well and barrier. Therefore, it`s urgent to search for novel barrier materials or structures to enhance the carrier confinement in GaSb-based type-I MQW lasers. A simple and cost-effective approach is using high Al content of AlGaAsSb as the quantum barrier to address the poor confinement of GaSb-based type-I QW. The AlGaAsSb matched to GaSb is stable and easy to grow in a large growth window. Obviously, the band offsets in conduction and valence bands would be enlarged with the composition of Al further increasing, regardless of whether it is a direct bandgap material or an indirect bandgap material [20]. But there are few studies on the use of indirect bandgap semiconductors as barriers to enhance carrier confinement in GaSb-based quantum-well lasers. Although the GaAs/AlGaAs quantum well has been extensively studied [21, 22], which pointed out that intervalley scattering and Γ-, X-, and L-band would affect the carrier transport characteristics when the AlGaAs changes from direct-gap to indirect-gap material, it is unclear what impact the use of an indirect-gap semiconductor as barriers in quantum-well lasers on laser performance in experiments.

In this research, for the first time, the quaternary alloy of Al0.5GaAs0.04Sb, an indirect-gap semiconductor was used as the quantum barrier to improve the confinements both of electrons and holes and the In0.44GaAs0.18Sb with a compressive strain of 1.5% was used as the quantum well to achieve the lasing wavelength of around 2.5 µm. This designed active region of In0.44GaAs0.18Sb/Al0.5GaAs0.04Sb quantum well with large band offsets in conduction and valence bands not only prevents carrier leakage but also reduces the threshold carrier density and enhances the differential gain of this active region. More specifically, the high quantum well depth can further improve the energy spacings between the first two conduction and valence subbands, and also allow to use of the high indium composition of InGaAsSb as quantum well with smaller carrier mass associated with low carrier density of states [23]. These features can lower the threshold carrier density and improve the differential gain by minimizing the number of states in the conduction and valence bands that are available for the population [24]. Based on theoretical calculations of the variation in optical gain with injected carrier concentration within the active region and specific experimental data of our growth and fabricated GaSb-based type-I MQW laser, this novel active region is demonstrated to possess low threshold and high differential gain characteristics. Furthermore, the watt-level output power is obtained at low injection current compared to the state of the art. Our work demonstrates a direct and simple alternative approach to achieving high-power mid-infrared light emitters.

2 Design and experiments

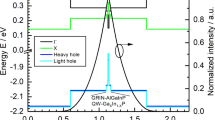

In this paper, the 20 nm-wide Al0.5GaAs0.04Sb matched with GaSb is used as the quantum barrier layer, and the 10 nm-wide In0.44GaAs0.18Sb with 1.5% compressive strain is regarded as the quantum well layer to achieve the lasing wavelength of around 2.5 µm. Figure 1 shows the band structure at the Gamma point, calculated based on the 8-band k · p model [25], and the optical gain spectrum calculated based on Fermi`s Golden Rule [26]. The material data as input parameters for calculation are taken from the review [27] and paper [28]. Figure 1a demonstrates that large conduction and valence band offsets result in more subbands in the quantum wells, preventing pinning of the quasi-Fermi level too early, especially for the hole quasi-Fermi level. That means there are sufficient electron and hole states in QW to achieve population inversion, avoiding carrier leaking into the barrier and waveguide layers. Furthermore, the large band offsets also enlarge the energy spacing between the conduction subbands and valence subbands. As Fig. 1a shows, the energy spacing between the first and second conduction subbands (CC1 and CC2) is 350 meV, and as for valence subbands (HH1 and HH2), it is 50 meV. These high energy spacings force the electrons and holes to occupy the CC1 and HH1 as much as possible to achieve lasing, lowering the threshold carrier density. Figure 1b presents peak optical gain versus injection sheet carrier density, which explicitly proves that the active region of this paper has a much higher differential gain. The details of the calculation method for the gain vs carrier density were clearly described in [23]. And the active region of the reference device [29] is a 14.5-nm In0.41GaAs0.14Sb quantum well with a 200-nm Al0.25GaAs0.02Sb quantum barrier.

a The quantum well structure of 20-nm Al0.5GaAs0.04Sb/10-nm In0.44GaAs0.18Sb. The dashed lines are the results of conduction and valence subbands. b the peak optical gain versus injection sheet carrier density of this paper and reference [29]

Epitaxial growth was performed on N-type GaSb (1 0 0) substrates by solid-source Gen-II molecular-beam epitaxy equipped with valved cracked cells for providing As2 and Sb2. Four multi-quantum-well samples were grown at different temperatures respectively Tc-15 °C, Tc, Tc + 15 °C, and Tc + 30 °C in which the Tc is the reconstruction phase transitions temperature of GaSb (2 × 5 → 1 × 3) based on reflective high energy electron diffraction (RHEED). As Fig. 2a shows, the sample of Tc has the maximum photoluminescence intensity at the same test condition, although there is no obvious difference between these HR-XRD curves in Fig. 2b. The photoluminescence spectra are a more sensitive and elaborate characterization method than high-resolution X-ray diffraction and atomic force microscope to evaluate the crystal quality of samples, especially for optical materials [30]. Thus, the Tc was chosen as the optimal growth temperature of the active region.

Figure 3 depicts the full structure of the laser and the band diagram with the near-field optical fundamental mode distribution. A 366 nm heavily n-type GaSb buffer, enhancing the flatness and electroconductivity, was firstly grown on 2-inch Te doped n-GaSb substrates. Two 10-nm thick 1.5% compressive strained In0.44GaAs0.18Sb QWs spaced by 20-nm thick lattice matched Al0.5GaAs0.04Sb barrier layers were regarded as the active region. The 580-nm waveguide core including the active region and separate confinement layers is sandwiched between 2- and 1.8-µm wide Al0.8GaAs0.06Sb cladding layers with 3.3 × 1017 cm−3 n-type and 6.5 × 1018 cm−3 p-type doping, respectively. It’s worth noting that the indirect-gap material of Al0.5GaAs0.04Sb is also used as the undoped waveguide layer, decreasing the time of growth interruptions to laboriously change the cell temperatures of the Al source cell. Note that after the active region grown over, the rest of the epitaxial layers were grown at the same temperature as the active region to avoid the optical and crystal quality of the active region deteriorating with annealing [31].

The grown wafer was processed into 100-µm-wide FP cavity lasers with different cavity lengths, using standard contact optical lithography in combination with the etching process. A 250-nm thick SiO2 insulation layer was deposited via plasma enhanced chemical vapor deposition. The low-resistance ohmic contacts on the p-type and n-type sides were achieved by magnetron sputtered Ti/Pt/Au and AuGeNi. Finally, a single emitter was chipped and p-side down to a copper heatsink, ready to test its performance. The output power was measured using a Coherent PowerMax PM10 with FieldMaxII.

3 Results and discussion

In order to better compare the performance of our diode laser with state-of-art laser. It`s necessary to provide a brief overview of the advanced characteristics of GaSb-based type-I MQW lasers emitting around 2.5 µm. The most advanced CW output characteristics were reported in 2002 [29], which shows the maximum CW power is 1 W with power conversion efficiency of about 8% at an injection current of 7 A from a 100-µm-wide and 2-mm-long chip at 12 °C with the threshold current density of 250 A/cm2, the low series resistance of 0.1 Ω, the internal losses of 4 cm−1, and the internal quantum efficiency of 0.5. In our work, we guarantee both the high-power output of diode lasers emitting at approximately 2.5 µm and the low threshold characteristics inherent in our designed laser, by the usage of an indirect-gap semiconductor as the quantum barrier, as demonstrated and discussed in the following sections.

The continuous-wave output power (P–I) characteristics of 1.5-mm-long and 100-μm-wide uncoated diode lasers, measured at heatsink temperatures from 10 to 40 °C, are displayed in Fig. 4a. The inset figure shows the characteristic temperatures T0 and T1 are respectively 66 K and 119 K. A maximum power of 1034 mW is obtained at 5 A under heatsink temperature of 10 °C, comparable to the state-of-art performance. And the laser displays a low threshold current density of 170 A/cm2 with a slope efficiency of about 0.275 W/A. Also, the emission spectrum is obtained with a Yokogawa AQ6376 optical spectrum analyzer with a multimode index fiber. Figure 4b shows the laser spectra at 3 A and 10 °C. The internal loss and the internal quantum efficiency are calculated based on the linear regression between the reciprocal of the slope efficiency and the cavity length in Fig. 5a. The internal quantum efficiency of 0.58 surpasses the data of the most high-performing GaSb-based laser reported emitting around 2.5 µm, which exhibits an internal quantum efficiency of 0.5 [29]. Furthermore, the threshold current density at infinite cavity length, the transparent current density, and the effective gain coefficient are extrapolated by the following equations.

a The linear regression between the reciprocal of the slope efficiency and the cavity length. b The linear regression between the logarithm of the threshold current density and the reciprocal of the cavity length. The short vertical lines stand for the error of measured threshold current density. And the uncertainties in the derived quantities are also displayed

The threshold current density can be expressed as

where \({J}_{tr}\) is the transparent current density, \({\eta }_{i}\) is the internal quantum efficiency, \({\alpha }_{i}\) and \({\alpha }_{m}\) are respectively the internal loss and the mirror loss, \(\Gamma\) is the confinement factor of quantum wells, and \({g}_{0}\) is the gain coefficient near threshold. The mirror loss \({\alpha }_{m}\) is given as

By playing logarithmic transformation of both sides, Eq. (1) can be written as

When the cavity length is infinite (\(L\to \infty\)), the threshold density is

So, the effective gain coefficient \(\Gamma {g}_{0}\) of 21.4 cm−1, the transparent current density \({J}_{tr}\) of 44 A/cm2, and the threshold current density at infinite cavity length \({J}_{th,inf}\) of 102 A/cm2 are obtained by implementing the linear regression between the logarithm of the threshold current density and the reciprocal of cavity length, as demonstrated in Fig. 5b. The transparent current density of 44 A/cm2 is much improved than those of antimonide lasers [32], which proves that the active region designed in this paper has a higher differential gain.

For diode lasers, the wall-plug efficiency (WPE) of a single chip is important performance in practical applications. The continuous-wave characteristics of 1.5-mm-long and 100-μm-wide uncoated diode lasers at 10 °C, are shown in Fig. 6. The power conversion efficiency at the maximum output power is relatively low due to the relatively high operated voltage of our lasers. However, the watt-level output power is obtained at a low injection current of 5A compared to the state of the art, even under conditions of relatively high operating voltage and series resistance, which associates with a high heat production capability, preventing a further increase in the CW output power of our laser. In consideration of the first demonstration of this technology, the output power of our lasers would increase obviously with an optimized design to operate with lower voltage and series resistance. In a word, the usage of an indirect-gap semiconductor as the quantum barrier indeed improves the carrier confinement and the differential gain in GaSb-based type-I MQW active region, not only maintains a state-of-the-art high output power but also shows great potential in the future to provide a novel and cost-effective solution to address the issue of insufficient carrier confinement of the GaSb-based MQW lasers, thereby achieving high-power output in mid-infrared lasers.

4 Conclusions

In summary, we have developed high-power 2.5 µm GaSb-based diode laser with a low threshold by designing a novel active region with enhancements in carrier confinement with the usage of an indirect-gap semiconductor as the quantum barrier. The improvements in both electrons and holes confinement lead to an ultralow transparent current density of 44 A/cm2 and high internal quantum efficiency of 0.58. And the watt-class continuous-wave power was obtained with the low threshold current density of 85 A/cm2 per quantum well and slope efficiency of 0.275 W/A in low injection current. We prove that the usage of an indirect-gap semiconductor as the barrier can improves the carrier confinement and the differential gain of the InGaAsSb/AlGaAsSb quantum-well lasers, upgrading the output performance of GaSb-based type-I lasers, thereby achieving high-power output in mid-infrared lasers.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

References

Rothman LS, Gordon IE, Babikov Y, Barbe A, Chris Benner D, Bernath PF, Birk M, Bizzocchi L, Boudon V, Brown LR, Campargue A, Chance K, Cohen EA, Coudert LH, Devi VM, Drouin BJ, Fayt A, Flaud JM, Gamache RR, Harrison JJ, Hartmann JM, Hill C, Hodges JT, Jacquemart D, Jolly A, Lamouroux J, Le Roy RJ, Li G, Long DA, Lyulin OM, Mackie CJ, Massie ST, Mikhailenko S, Müller HSP, Naumenko OV, Nikitin AV, Orphal J, Perevalov V, Perrin A, Polovtseva ER, Richard C, Smith MAH, Starikova E, Sung K, Tashkun S, Tennyson J, Toon GC, Tyuterev VG, Wagner G. The HITRAN2012 molecular spectroscopic database. J Quant Spectrosc Radiat Transf. 2013;130:4–50. https://doi.org/10.1016/j.jqsrt.2013.07.002.

Tittel FK, Richter D, Fried A. Mid-infrared laser applications in spectroscopy. Berlin: Springer; 2003. p. 458–529.

Vizbaras A, Simonyte I, Droz S, Torcheboeuf N, Miasojedovas A, Trinkunas A, Buciunas T, Dambrauskas Z, Gulbinas A, Boiko DL, Vizbaras K. GaSb swept-wavelength lasers for biomedical sensing applications. IEEE J Sel Top Quantum Electron. 2019;25(6):1–12. https://doi.org/10.1109/jstqe.2019.2915967.

Willer U, Saraji M, Khorsandi A, Geiser P, Schade W. Near- and mid-infrared laser monitoring of industrial processes, environment and security applications. Opt Lasers Eng. 2006;44(7):699–710. https://doi.org/10.1016/j.optlaseng.2005.04.015.

Norooz Oliaee J, Sabourin NA, Festa-Bianchet SA, Gupta JA, Johnson MR, Thomson KA, Smallwood GJ, Lobo P. Development of a Sub-ppb resolution methane sensor using a GaSb-Based DFB diode laser near 3270 nm for fugitive emission measurement. ACS Sens. 2022;7(2):564–72. https://doi.org/10.1021/acssensors.1c02444.

Wagner J, Mann C, Rattunde M, Weimann G. Infrared semiconductor lasers for sensing and diagnostics. Appl Phys A Mater Sci Process. 2004;78(4):505–12. https://doi.org/10.1007/s00339-003-2411-2.

Bekman HHPT, Van Den Heuvel JC, Van Putten FJM, Schleijpen R, Development of a mid-infrared laser for study of infrared countermeasures techniques. In: SPIE (2004). https://doi.org/10.1117/12.578214

Yang CA, Xie SW, Zhang Y, Shang JM, Huang SS, Yuan Y, Shao FH, Zhang Y, Xu YQ, Niu ZC. High-power, high-spectral-purity GaSb-based laterally coupled distributed feedback lasers with metal gratings emitting at 2 µm. Appl Phys Lett. 2019;114(2):021102.021101-021102.021105. https://doi.org/10.1063/1.5080266.

Zou K, Pang K, Song H, Fan J, Zhao Z, Song H, Zhang R, Zhou H, Minoofar A, Liu C, Su X, Hu N, McClung A, Torfeh M, Arbabi A, Tur M, Willner AE. High-capacity free-space optical communications using wavelength- and mode-division-multiplexing in the mid-infrared region. Nat Commun. 2022;13(1):7662. https://doi.org/10.1038/s41467-022-35327-w.

Belenky G, Shterengas L, Kisin MV, Hosoda T. Gallium antimonide (GaSb)-based type-I quantum well diode lasers: Recent development and prospects. Semicond Lasers. 2013. https://doi.org/10.1533/9780857096401.3.441.

Stephan S, Frederic D, Markus-Christian A. Novel InP- and GaSb-based light sources for the near to far infrared. Semicond Sci Technol. 2016;31(11):113005. https://doi.org/10.1088/0268-1242/31/11/113005.

Shterengas L, Belenky GL, Kim JG, Martinelli RU. Design of high-power room-temperature continuous-wave GaSb-based type-I quantum-well lasers with λ > 2.5 µm. Semicond Sci Technol. 2004;19(5):655. https://doi.org/10.1088/0268-1242/19/5/016.

Belenky G, Shterengas L, Kipshidze G, Hosoda T. Type-I diode lasers for spectral region above 3 µm. IEEE J Sel Top Quantum Electron. 2011;17(5):1426–34. https://doi.org/10.1109/jstqe.2011.2128300.

Eales TD, Marko IP, Adams AR, Meyer JR, Vurgaftman I, Sweeney SJ. Quantifying auger recombination coefficients in type-I mid-infrared InGaAsSb quantum well lasers. J Phys D Appl Phys. 2021;54(5):055105. https://doi.org/10.1088/1361-6463/abc042.

Grau M, Lin C, Dier O, Lauer C, Amann M-C. Room-temperature operation of 326 µm GaSb-based type-I lasers with quinternary AlGaInAsSb barriers. Appl Phys Lett. 2005;87(24):241104. https://doi.org/10.1063/1.2140875.

Hosoda T, Belenky G, Shterengas L, Kipshidze G, Kisin MV. Continuous-wave room temperature operated 3.0 µm type I GaSb-based lasers with quinternary AlInGaAsSb barriers. Appl Phys Lett. 2008;92(9):091106. https://doi.org/10.1063/1.2890053.

Shterengas L, Belenky G, Kipshidze G, Hosoda T. Room temperature operated 3.1 µm type-I GaSb-based diode lasers with 80 mW continuous-wave output power. Appl Phys Lett. 2008;92(17):171111. https://doi.org/10.1063/1.2919720.

Stringfellow GB. Spinodal decomposition and clustering in III/V alloys. J Electron Mater. 1982;11(5):903–18. https://doi.org/10.1007/bf02658905.

Kuech TF, Babcock SE, Mawst L. Growth far from equilibrium: Examples from III-V semiconductors. Appl Phys Rev. 2016;3(4):040801. https://doi.org/10.1063/1.4944801.

Adachi S. Band gaps and refractive indices of AlGaAsSb, GaInAsSb, and InPAsSb: Key properties for a variety of the 2–4-μm optoelectronic device applications. J Appl Phys. 1987;61(10):4869–76. https://doi.org/10.1063/1.338352.

Alexander MGW, Nido M, Reimann K, Rühle WW, Köhler K. Γ- and X-band contributions to nonresonant tunneling in GaAs/Al0.35Ga0.65As double quantum wells. Appl Phys Lett. 1989;55(24):2517–9. https://doi.org/10.1063/1.101994.

Osotchan T, Chin VWL, Tansley TL. Transport mechanism of Γ- and X-band electrons in AlxGa1−xAs/AlAs/GaAs double-barrier quantum-well infrared photodetectors. Phys Rev B. 1996;54(3):2059–66. https://doi.org/10.1103/PhysRevB.54.2059.

Seki S, Yamanaka T, Lui W, Yoshikuni Y, Yokoyama K. Theoretical analysis of pure effects of strain and quantum confinement on differential gain in InGaAsP/lnP strained-layer quantum-well lasers. IEEE J Quantum Electron. 1994;30(2):500–10. https://doi.org/10.1109/3.283798.

Gain and Current Relations, In: Diode lasers and photonic integrated circuits (2012), pp. 157–246.

Liu G, Chuang S-L. Modeling of Sb-based type-II quantum cascade lasers. Phys Rev B. 2002;65(16):165220. https://doi.org/10.1103/physrevb.65.165220.

Appendix Nine: Fermi's Golden Rule, In: Diode lasers and photonic integrated circuits (2012), pp. 629–638.

Vurgaftman I, Meyer JR, Ram-Mohan LR. Band parameters for III–V compound semiconductors and their alloys. J Appl Phys. 2001;89(11):5815–75. https://doi.org/10.1063/1.1368156.

Donati GP, Kaspi R, Malloy KJ. Interpolating semiconductor alloy parameters: application to quaternary III–V band gaps. J Appl Phys. 2003;94(9):5814–9. https://doi.org/10.1063/1.1613371.

Kim JG, Shterengas L, Martinelli RU, Belenky GL, Garbuzov DZ, Chan WK. Room-temperature 2.5 μm InGaAsSb/AlGaAsSb diode lasers emitting 1 W continuous waves. Appl Phys Lett. 2002;81(17):3146–8. https://doi.org/10.1063/1.1517176.

Vizbaras K, Bachmann A, Arafin S, Saller K, Sprengel S, Boehm G, Meyer R, Amann M-C. MBE growth of low threshold GaSb-based lasers with emission wavelengths in the range of 2.5–2.7 µm. J Cryst Growth. 2011;323(1):446–9. https://doi.org/10.1016/j.jcrysgro.2010.11.139.

Dier O, Dachs S, Grau M, Lin C, Lauer C, Amann M-C. Effects of thermal annealing on the band gap of GaInAsSb. Appl Phys Lett. 2005;86(15):151120. https://doi.org/10.1063/1.1900946.

Rattunde M, Mermelstein C, Schmitz J, Kiefer R, Pletschen W, Walther M, Wagner J. Comprehensive modeling of the electro-optical-thermal behavior of (AlGaIn) (AsSb)-based 2.0 µm diode lasers. Appl Phys Lett. 2002;80(22):4085–7. https://doi.org/10.1063/1.1481979.

Funding

This research was funded by project of National Natural Science Foundation of China under Grant No: 62204238; Innovation Program for Quantum Science and Technology under Grant No: 2021ZD0300801; “Announce the list and take charge” of the major special plan of science and technology in Shanxi Province under Grant No: 202201030201009; Key R&D Program of Shanxi Province under Grant No: 202102030201004; Chinese Academy of Sciences and Changchun City Science and Technology Innovation Cooperation Project under Grant No: 21SH06; Jincheng Key Research and Development Project under Grant No: 20210209.

Author information

Authors and Affiliations

Contributions

HG and CA conceived and designed the research. HG conducted most experiments and data analyzed. YH and JT help with the epitaxial growth. TF, JM, ZQ and ZY help with the device fabraction and characterization. CA and YQ provided useful suggestions in the wirtting. Y, HQ and ZC provided guidance for the optimization of the research. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yu, H., Yang, C., Chen, Y. et al. Watt-level continuous-wave antimonide laser diodes with high carrier-confined active region above 2.5 µm. Discover Nano 19, 44 (2024). https://doi.org/10.1186/s11671-024-03989-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-024-03989-8