Abstract

La0.67Ca0.33MnOδ nanoparticles of approximate size ∼ 4 nm have been prepared by the chemical solution deposition method to investigate effect of oxygen stoichiometry in the nanoparticles without changing their sizes. Electrochemical oxidation method has been used to change the oxygen stoichiometry \(\delta\) at room temperature, which unlike conventional methods to change oxygen stoichiometry by heating in controlled ambience, does not lead to any significant change in size. This has allowed us to investigate the effects of stoichiometry variations in the nanoparticles with no change in size. The unit cell volume, lattice constants and orthorhombic strains of the as prepared sample (with \(\delta\) = 2.74) are changed by incorporation of oxygen by electrochemical oxidation which in turns affects the magnetic properties. In addition, oxidation leads to change in oxygen stoichiometry of the magnetically “dead” surface layer on the nanoparticles which also affects their magnetization and coercive field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The physical properties of oxides like perovskite oxides can be controlled by changing the oxygen content which is commonly referred as “oxygen stoichiometry”. In the bulks and films of different perovskite oxides, the effect of oxygen nonstoichiometry has been studied rigorously for a long time [1,2,3,4]. There are also investigations of effect of oxygen content on the magnetic properties. For instance in case of manganites, the change in oxygen content brings about a change in its magnetic ordering [5, 6]. This has also been seen in other materials as well [7, 8]. The most common route to change oxygen stoichiometry is heat treatment (typically > 500 °C) in an ambience of controlled oxygen partial pressure [1,2,3,4, 9]. Often, for depleting oxygen, the heat treatment is done in a reducing atmosphere. Such heat treatment is routine for bulks and films, as well as micron-sized powders, but it poses a serious problem when used with nanoparticles, particularly nanoparticles with a diameter of < 10 nm. The heat treatment not only changes the oxygen stoichiometry, it also concomitantly enhances the particle size, mainly by agglomeration. Because of similar impacts on physical properties, the effects of change in particle size and oxygen content variations can often not be clearly separated. This necessitates an athermal method that does not need heat treatment at elevated temperature so that control of the Oxygen stoichiometry can be done without size change.

Electrochemical oxidation/reductionis a tool to change the oxygen stoichiometry at ambient condition [10, 11] particularly for nanoparticles. Previously electrochemical method has been used to change oxygen stoichiometry in Ruddlesden-Popper phase oxides like Lu2CuO4 [12, 13], La4Ni3O10 [14], La2CuO4 [15], SmBaCo2−xMnxO5+δ [16] and double perovskites like BaPrMn1.75Co0.25O5+δ nano sheets [17]. There are also reports of use of this method for stoichiometry control infinite layer oxides like La0.2Sr0.8CoO3-δ [18]. However, the particle size used in the past studies is typically of diameter greater than 10 nm. Control of oxygen stoichiometry by oxidation/reduction to control properties of oxide thin films have been used to make thin film Field Effect Transistors with electrolyte or aqueous gates [19,20,21,22].

In this investigation we used electrochemical method to have a nanoscopic modification of oxygen stoichiometry at ambient condition in a perovskite oxide manganite nanoparticles with average particle diameter < 5 nm. The structural, magnetic and transport properties of nanoparticles of perovskite oxide manganites have critical dependence on both, size as well as oxygen stoichiometry. The oxygen stoichiometry control as well as substitution with divalent cations at A-site in manganites leads to hole doping which in turn leads to important changes in physical properties which are often accompanied by important structural changes [23]. The enabling role of oxygen stoichiometry in LaMnO3+δ has been investigated and the critical role of \(\delta\) has been established in bulk manganites [24, 25], as well as in nanoparticles (diameter ~ 40 nm) [26]. The antiferromagnetic LaMnO3 develops a ferromagnetic order for a small change in oxygen stoichiometry (that leads to hole doping) becoming ferromagnetic for \(\delta \ge 0.1\). Neutron investigations in nanoparticles of LaMnO3+δ (\(\delta \approx 0.03\)) showed that size reduction leads to weakening of the Jahn–Teller distortion leading to canting of spin sublattice which destabilizes the AFM order [26]. Thus in nanoparticles of manganites the issues of stoichiometry as well as size reduction are related due to strong coupling of spin, lattice and change degree of freedoms.

In substituted manganites it has been shown that size reduction below 50 nm stabilizes the ferromagnetic phase. In half doped manganites that show charge ordering and strong lattice distortion at the onset of the charge ordering, the size reduction suppresses the lattice distortion and mitigates charge ordering [27]. Extensive investigation on optimally doped La0.67Ca0.33MnO3 nanoparticles have shown that the paramagnetic insulating (PI) to ferromagnetic metal (FM) transition temperature (TC) varies non-monotonically in the nanomanganite due to the decrease of particle size from bulk to 15 nm [28]. The TC is initially enhanced as the size is reduced and it shows a maximum for a nanoparticle diameter \(d\approx 50 nm\) and then it decreases again along with suppression of the saturation magnetization \({M}_{S}\). It was found that these changes are linked to the bond angle Mn–O–Mn as well as bond length Mn–O [28].

In this report we carry out an investigation of the effect of variation of oxygen stoichiometry in La0.67Ca0.33MnOδ nanoparticles with average diameter in the range of below 5 nm, done in a way that there is no change in size of the nanoparticles during the oxidation/reduction process. This investigation also explores ferromagnetism in such small nanoparticles since; the existence of ferromagnetism in La0.67Ca0.33MnOδ (LCMO) nanoparticles with size below 10 nm has not been investigated before. The present investigation also involves structural analysis to explore how the stoichiometry affects the structure and such properties as variation of transition temperature TC, the saturation magnetization (\({M}_{S}\)) and the Coercive field (HC). As noted before, the effect of variation of \(\delta\) in such small nanoparticles could not be carried out because conventional heating method cannot be employed. In this report we used the enabling technique of electrochemical oxidation/reduction as explained before which allows performance of such critical experiments and permit us to change \(\delta\) in the range 2.74–3.2 without changing the average diameter of the nanoparticles that stay below 5 nm.

2 Method

2.1 Preparation of nanoparticles

La0.67Ca0.33MnOδ nanoparticles were prepared by chemical solution deposition method (CSD) [29]. In CSD method high purity Lanthanum acetate hydrate, Calcium acetate hydrate and Manganese acetate tetrahydrate were mixed with de-ionized (DI) water and Acetic acid in stoichiometric ratio. Appropriate amount of ethylene glycol were added. The polymer (ethylene glycol) was used forming a network of cations which assisted the reaction in phase formation. The solution was heated and stirred at 70 °C for making it in gel formation. The gel was dried for 15 hours at temperature ~ 150 °C. After that pyrolysis process was done at 350 °C and 450 °C. Then finally it was sintered at 650 °C for 3 hours to obtain the proper phase and the desired particle size. The as prepared particles are referred to as S1.

2.2 Change of oxygen content ( \({\varvec{\delta}}\) ) by controlled electrochemical oxidation/reduction:

The oxygen content was changed by electrochemical oxidation/reduction method at ambient temperature (∼ 300 K). A schematic diagram of electrochemical process is given in Fig. 1a. We used a conventional three electrode set-up in which the sample was used as working electrode in the form of a thin disk shape pellet. A rectangular thin Platinum sheet and Hg/HgO were used as counter electrode and reference electrode respectively with 1(M) KOH solution was used as electrolyte. Electrical lead and the contact areas were covered by Polymethyl Methyl Acrylate (PMMA) to avoid any spurious charge deposition at the time of electrochemical process. Fig. 1b shows the current vs. time (I \(-\) t) profile of the oxidation process. The total amount of deposited charge \(Q \left({t}_{tot}\right)\) on the working electrode (i.e., the sample) can be measured by calculating the area under the I \(-\) t curve by integrating the current \(I\) so that \(Q \left({t}_{tot}\right)={\int }_{0}^{{t}_{tot}}Idt\), where \({t}_{tot}\) is the total time of deposition. In this case, the Oxygen ions constitute the current. To change the oxygen stoichiometry in manganite films at room temperature previously we have also used this electrochemical oxidation technique [30, 31].

Inset of Fig. 1b shows the Cyclic Voltametry curve (I \(-\) V) for a complete cycle. This shows the potentials for most efficient oxidation (positive axis) and reduction (negative axis) process. From the Cyclic Voltametry curve we fixed the potential to be used for oxidation (VW) at 0.27 V and that for reduction (VR) at \(-\) 0.15 V. The width of the pellets is in the range of 0.6–1.0 mm. We have oxidized both sides of the pellets. For homogeneous oxygenation we repeated the process at least 4 times by crushing the pellet after the process, palletizing and then repeating the electrochemical process.

2.3 Sample characterization

The crystallographic phase of the LCMO nanoparticles made by CSD method was confirmed by X-ray diffraction (XRD) technique and the composition was checked by Energy dispersive X-ray (EDX) spectroscopy. The particle sizes were measured by High Resolution Transmission Electron Microscope (HRTEM) images. Magnetization measurements were done in vibrating sample magnetometer (VSM) from 80 to 350 K with field range up to 1.6 T.

2.4 Quantitatively fixing the value of \({\varvec{\delta}}\)

One of the crucial parameters that needs be fixed in this experiment is the oxygen stoichiometry \(\delta\) of the LCMO nanoparticles. The efficacy of the electrochemical process (oxidation/reduction) can be quantified by proper fixing of the parameter \(\delta\). This was done using three different methods described below. The incremental change in \(\delta\) can be directly estimated from the Faraday Law of electrochemical deposition. The change in \(\delta\) for the total deposition time \({t}_{tot}\) is given as:

where, \({\delta }_{f}\) and \({\delta }_{i}\) are the final and initial stoichiometries, \(Q\left({t}_{tot}\right)\) is the total deposited charge in the electrochemical process as defined before. Molecular weight and mass of the sample are M and m respectively. Avogadro’s number is NA, e = 1.6 × 10−19 C is the electron charge and n is the valency of the Oxygen ion which is = 2.

While the changes in \(\delta\) can be measured precisely from the Faraday Law, the determination of the absolute value of \(\delta\) needs other techniques. The value of \(\delta\) was measured independently using Iodometric titration and Rietveld refinement of XRD powder patterns. To analyze the crystal structures and for finding out the value of \(\delta\), we used Rietveld refinement method for profile fitting of the XRD data using orthorhombic Pnma space group. The XRD data and the results of the refinements are shown in the next section.

For the as grown sample S1 the initial value of \({\delta }_{i}\) was determined from the iodometric titration method. For other samples that were oxidized /reduced electrochemically the incremental values of \(\Delta \delta\) (= \({\delta }_{f}-{\delta }_{i}\)) were determined from the Farday Law. The \(\delta\) values of all the samples used are shown in Table 1. The agreement of the values of \(\delta\) measured by three methods within their stated accuracy is very good.

3 Results

3.1 Crystal structure and the particle size

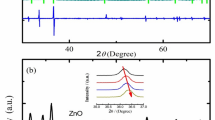

Fig. 2a and b show the XRD patterns (red lines), the Rietveld refined peaks (black lines) and residues (blue lines) for samples S1 and S5 respectively. In Fig. 2c and d we show the TEM images for the same samples S1 and S5. Fig. 2e and f show the particle size distribution of S1 and S5. The insets of Fig. 2e and f show TEM images of a single nanoparticle S1 and S5.

The XRD Rietveld profile fit with residues at 300 K a of sample S1 (δ = 2.74) and b of sample S5 (δ = 3.20). c and d show TEM image of particles S1 and S5 respectively. e and f show particle size distribution of S1 and S5 respectively. Single particle TEM images of S1 and S5 are shown in the insets of e and f

The size distributions of the nanoparticles were checked after each process of electrochemical oxidation and reduction to ascertain that the average size of the particles have not changed by the electrochemical process. In Table 1 the average particle diameters \(<d>\) of all the oxidized and reduced samples are given. Table 1 shows that after the electrochemical process, within the standard uncertainty (± 1 nm), the average particle size remains unchanged. This particular check is important because it validates the claim that the electrochemical process can effectively change \(\delta\) without changing the size.

We note that the average particle size in this investigation has been measured by using TEM images that could ascertain size distribution and the average particle size has been determined from this distribution. Global probe like XRD can also be used for particle size determination but we note the limitations that such a probe has for the size range used in this work. Often use of XRD line width and use of such methods like Williamson-Hall (WH) plot from XRD lead to somewhat larger average particle size compared to that found from TEM analysis primarily due to agglomeration of smaller particles to larger particles (see supplementary section).

The values of the oxygen stoichiometry \(\delta\) have been determined by different methods mainly to check that for a given sample the values of \(\delta\) are internally consistent. The error for the different methods is different due to the nature of measurements. The error bar on the incremental change of value of \(\delta\) as obtained directly From Faraday’s Law is the least and is \(\approx \pm\) 0.002. This least as it depends on measurement of current and time. This error bar is unchanged from sample to sample. The next higher error bar is in Titration (a volumetric method), where the error \(\approx \pm\) 0.021 depends on the accuracy of the apparatus and the accuracy with which the end point is determined. The error bar when one considers sample to sample increase by a factor of 2 at most. The largest error bar in determination of \(\delta \approx \pm 0.035\) occurs for the Rietveld method which is large as it is refinement of profile fitting of all the picks. This is done by taking different sample volumes and thus the sample to sample variation is of the same order. In view of the above discussion, we put a conservative estimate on the absolute value of \(\delta \approx \pm 0.04\). It is also noted that for the incremental change in \(\delta\) as measured by Fraraday’s Law stays at \(\delta \approx \pm\) 0.002.

Crystal structure analysis has been done from x-ray diffraction pattern by Rietveld refinement method as stated earlier. In Table 2 the lattice parameters (a, b and c) are compared with those of the bulk and those of the sample with 15 nm average diameter particle. Results show that all lattice parameters (except c) and unit cell volume (V) are largest for particle with diameter 15 nm, whereas, c maximum for the sample with lowest diameter (∼ 4 nm). This implies that the unit cell is extended along the c-axis which enhances the Orthorhombic distortion strain characterized by the following parameters: orthorhombic strain in ac-plane \({OS}_{\parallel }\) and strain along the b-axis with respect to ac-plane \({OS}_{\perp }\). These parameters are defined as:

It can be seen in Table 2 that in the nanoparticles of average diameter 4 nm, the orthorhombic strain is highest and it also has severe reduction of one of the bond angle Mn-O2-Mn which suppresses the transfer integral and suppresses the \({T}_{C}\) [32].

The results are displayed in the graphs below where the variations of the important structural parameters as a function of the stoichiometry \(\delta\) are shown.

The changes of lattice parameters for different values of \(\delta\) are shown in Fig. 3a–c. At the initial stages of oxidation (\(\delta\) changes from 2.74 to 2.76) lattice constants a, b, c and the unit cell volume V sharply increase. After that the values increase gradually with δ. The initial sharp increment is more prominent for c and V. For the change of \(\delta {\text{on}}\) oxidation from 2.74 to 3.20 (= 0.46) the value of V changes from 228.2 (A0)3 to 229.8 (A0)3 (~ 0.7%). Results on the sample S* which is reduced sample from S5, shows that the electrochemical process can be reversible at least within the limit for which it has been checked. The variations of orthorhombic strains \({OS}_{\parallel }\) and \({OS}_{\perp }\) with \(\delta\) are shown in the inset of Fig. 3b. For the initial change of\(\delta\), \({OS}_{\parallel }\) and \({OS}_{\perp }\) increase sharply and after that change in \({OS}_{\perp }\) saturates, although \({OS}_{\parallel }\) has a gradual increment. The particle size effect on the orthorhombic strain can be clearly visualized from Table 2. From Fig. 3c it can be seen that the bond angle Mn-O1-Mn remains close to the ideal value of 1800, which happens in a cubic structure with orthorhombic distortion \(\to 0.\) However, as the orthorhombic distortion increases on oxidation, the bond angle Mn-O2-Mn decreases substantially after a small initial rise. The change in the bond angle on oxidation is an important parameter.

3.2 Change in magnetic properties after electrochemical oxidation/reduction:

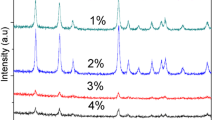

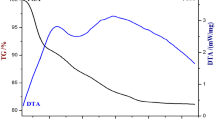

The change in \(\delta\) alter the magnetic properties like the Ferromagnetic Curie Temperature TC, effective moment \({\mu }_{eff}\), saturation magnetization \({M}_{S}\) and the coercive field HC. Development of the effective moment as a function of the stoichiometry \(\delta\) shows that there is qualitative difference with the behaviors observed in the bulk [33]. We also observe large enhancement of the Curie Temperatures \({T}_{C}\) in nanoparticles with average diameter of 4 nm compared to those observed in the bulk. TC and \({\mu }_{eff}\) have been obtained from the Curie–Weiss law χ = C/(T − TC), where χ is the susceptibility measured at a low field of \({\mu }_{0}H=\) 0.01 T in the paramagnetic region \({T>T}_{C}\). The effective magnetic moment \({\mu }_{eff}\) has been obtained from the relation \(C=\frac{{\mu }_{eff}^{2}}{3{k}_{B}}\).The values of \({\mu }_{eff}\) and \({T}_{C}\) are tabulated in Table 3 and the two parameters are plotted as a function of \(\delta\) in Fig. 4a and b.

The magnetization vs. temperature curve shows a ferromagnetic nature (shown in Fig. 4a), where the magnetization \(M\) rises rapidly below the Curie temperature \({T}_{C}\). The Curie temperature TC was determined from the linear fitting of the temperature dependent 1/χ plot. The Curie temperature shows a non-monotonous dependence on \(\delta\) and expectedly reaches the highest TC (324 K) for δ ≈ 3 and decreases by nearly 15 K when \(\delta\) deviates from the optimum value 3 on either side (shown in Fig. 4c). The observed TC of 324 K in nanoparticles of LCMO is the highest reported and is substantially larger than the bulk samples or single crystals and is even larger than TC = 290 K observed in LCMO nanoparticles of diameter ~ 50 nm [28, 34, 35]. The enhanced TC is comparable to 315 K observed in 65 nm LCMO nanowires grown in alumina templates [36].

We also observe that by electrochemical reduction (sample S⋆) it is possible to reverse the oxidation reproducibly thus establishing that the electrochemical route provides a reversible way to control the stoichiometry.

The effective moment \({\mu }_{eff}\) also shows a non-trivial dependence on \(\delta\) as shown in Fig. 4b and Table 3. It shows a sharp drop when the manganite nanoparticles are oxidized till the optimum value of \(\delta =3,\) beyond that \({\mu }_{eff}\) slowly recovers. The reduction in \({\mu }_{eff}\) on oxidation or hole doping (that can also be achieved by substitution in La site by di-valent Ca) has been observed in manganites in bulk form where \({\mu }_{eff}\) shows a peak at hole concentration less than that of optimum hole doping [37] and then gradually decrease mainly due to presence of more Mn4+ that has a lower spin value. The enhancement of \({\mu }_{eff}\) beyond the optimum hole doping as has been observed in nanoparticles have not been observed in the bulk form. This issue will be further discussed later on.

The ferromagnetic nature of the sample is clearly visible in the field dependent magnetization curve (Fig. 5a) that shows hysteresis in the \(M-H\) curve. In Fig. 5b, c and Table 3 we show the saturation magnetization MS at 80 K along with the coercive field (HC). HC shows a maxima close to the stoichiometry \(\delta \approx 3\) and there is small decrease (~ 10%) when \(\delta\) deviated from the optimum value. The \({M}_{S}\) shows a minima around \(\delta \approx 3\) and follows the same trend as the magnetic moment \({\mu }_{eff}\). The ratio \(\frac{{M}_{S}}{{\mu }_{eff}}\) remains almost constant to within \(\approx \pm 7\%\) as \(\delta\) is varied.

We find that the product \({M}_{S}{H}_{C}\), is nearly independent of the value of \(\delta\) and it varies by <\(\pm 5\%\) when \(\delta\) is changed by more than 15%. In the size domain used by us the nanoparticles are monodomains. The size range where the nanoparticles of manganites become mondomain is \(\approx\) 70–75 nm as determined by the exchange constant (0.3 eV) and the saturation magnetization. In absence of agglomeration, in such a system, near independence of the \({M}_{S}{H}_{C}\) product would imply constancy of the anisotropy constant \(\kappa\) as the parameter \(\delta\) is changed (the constant \(\kappa\) is given related to \({H}_{C}\) through the relation \({H}_{C}\propto \frac{2\kappa }{{M}_{S}}\).) We however, note that the above relation may get modified by agglomeration and we exercise caution on the above inference. In the case that \(\kappa\) is nearly independent of \(\delta\), \({H}_{C}\) is tagged to \({M}_{S}\) which in turn is tagged to the magnetic moment \({\mu }_{eff}\) shows a minimum value around \(\delta \approx 3\).

In optimally doped LCMO with δ ≈ 3 the value of \({M}_{S}\) at T = 80 K is around ≈ 3 \(.42{\mu }_{B}\)/Mn [38]. On size reduction the value of \({M}_{S}\) is suppressed and for LCMO nanoparticles with average diameter ~ 50 nm it is ≈ 1.\(5{\mu }_{B}\)/Mn [38] and in the size range of our sample (~ 4 nm) it is further reduced to only ≈ 1.\(0{\mu }_{B}\)/Mn. Similar trend is also seen in the values of magnetic moment \({\mu }_{eff}\). For LCMO with \(\delta \approx 3\), the Mn4+ content is 33.3% while Mn3+ content is 67%. The expected spin only value of \({\mu }_{eff \approx } 4.56{\mu }_{B}\). For the nanoparticle \({\mu }_{eff}\) is much suppressed and is in the range of 0.2 \({\mu }_{B}\).

4 Discussion

The process of oxidation changes the Mn \(-\) O \(-\) Mn bondangles can seen from Fig. 3c.While the bond angle Mn \(-\) O1 \(-\) Mn remains mainly unaltered, the angle Mn \(-\) O2 \(-\) Mn increases sharply on initial oxidation and then decreases. Since the increase of the Mn \(-\) O \(-\) Mn bond angle to 1800 will increase the orbital overlap, this will enhance the band width leading to enhancement of TC which being a double exchange mechanism is directly related to the band-width. However, for \(\delta\) > 2.9, the Mn \(-\) O2 \(-\) Mn angle decreases again but the enhancement of TC continues still higher \(\delta\) (~ 3) and then it decreases again. Thus the enhancement of TC for \(\delta\) ≤ 3 will not only depend on the change in the bond angle but also on other factors like the exchange constant. For \(\delta\) > 3 the suppression of TC is most likely is governed by the large decrease in the bond-angle Mn \(-\) O2 \(-\) Mn.

For nanoparticles, depression of \({M}_{S}\) from the bulk value can arise from surface oxides with lower oxygen content which will suppress their ferromagnetism. This acts as a “dead layer” on the surface of the nanoparticles. This layer would contribute to mass or volume but not to magnetic moment and as a result the effective magnetization/unit volume or unit mass will become smaller than the bulk value [28]. However, \({T}_{C}\) which is an intensive quantity, will not be affected by the “dead layer”. The particle size distribution shows that there is a finite fraction of the nanoparticles have diameter \(\le\) 2 nm. For these particles, the magnetization will be suppressed and may even be paramagnetic. The volume of these nanopartciles will thus be counted in the volume of the “dead layer”.

For a nanoparticle of diameter \(d\), if the surface “dead layer” has a thickness of \(\lambda\) and is assumed to have a zero magnetization, the magnetization will be contained within the core of radius = (d/2-λ). If the magnetization of the nanoparticles is \({M}_{S}\), and that of the ideal nanoparticle with magnetization same as the bulk is \({M}_{0S}\), then the two are related by the relation:

For the optimally doped sample of LCMO with \(\delta \approx\) 3,\({M}_{OS}=\) 3.42 \({\mu }_{B}\) at 80 K [37]. From Eq. (4) the value of \(\lambda\) can be calculated using the relation:

From Eq. (5) we evaluated the dead layer thickness (λ) as a function of \(\delta\). This is shown in Fig. 6. There is a shallow enhancement of \(\lambda\) for the initial stage of oxidation, \(\lambda\) reaches a maximum at \(\delta\)≈ 3. For further increase of \(\delta\) the value of \(\lambda\) reduces sharply by 30% and leads to enhanced \({M}_{S}\) as shown in Fig. 5. The reduction of \(\lambda\) for higher values of \(\delta\) happens because the oxidation process increases the oxygen content in the dead layer as well and thus reduces the effective thickness of the dead layer.

5 Summary

We investigated effect of change in Oxygen stoichiometry (\(\delta\)) in small nanoparticles of La0.67Ca0.33MnOδ with average diameter ~ 4 nm. The stoichiometry \(\delta\) was changed by electrochemical oxidation/reduction without changing the particle size, unlike heating based methods where change in \(\delta\) also leads to change in particle size. The XRD data shows Orthorhombic strain becomes very large in such small particles. The change in \(\delta\) leads to non-monotonous variation of the Mn-O2-Mn bond angle that modifies the physical properties including non-trivial change in ferromagnetism linked properties such as \({T}_{C}, {M}_{S}\) and \({H}_{C}\).Very small particle size makes it possible to carry out large change in oxidation from δ = 2.74 to δ = 3.20 due to faster diffusion.

It is an important observation that the ferromagnetism persists even down to such small sizes, although with strongly suppressed \({M}_{S}\). This suppression of \({M}_{S}\) is linked to existence of a magnetically dead layer on the surface. The process of electrochemical oxidation leads to reduction of thickness of the dead layer.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Trukhanov SV, Lobanovski LS, Bushinsky MV, Khomchenko VA, Pushkarev NV, Troyanchuk IO, Maignan A, Flahaut D, Szymczak H, Szymczak R. Influence of oxygen vacancies on the magnetic and electrical properties of La Sr MnO manganites. Eur Phys J B. 2004;42:51.

Zhang H, Yao X, Zeng XH. Oxygen in-diffusion in LPE thick films of YBCO by electrical resistance relaxation. Phys Stat Solidi (a). 2004;201:2305.

Malavasi L, Flor G. Oxygen chemical diffusion coefficient in manganite thin films by isothermal electric resistivity measurements. J Phys Chem B. 2003;107:13880.

Zhao YG, Cai W, Zhao J, Zhang XP, Cao BS, Zhu MH, Zhang LW, Ogale SB, et al. Electrical transport and magnetic properties of La 05 Ca 05 MnO 3− y with varying oxygen content. Phys Rev B. 2002;65:144406.

Ghosh B, Siruguri V, Raychaudhuri AK, Chatterji T. Effect of size reduction on the structural and magnetic order in LaMnO3+ δ (δ≈ 003) nanocrystals: a neutron diffraction study. J Phys Condens Matter. 2013;26(2):025603.

Mahendiran R, Tiwary SK, Raychaudhuri AK, Ramakrishnan TV, Rao CNR. Structure, electron-transport properties, and giant magnetoresistance of hole-doped LaMnO 3 systems. Phys Rev B. 1996;53:3348.

Awad MA, Mohamed SH, Mohamed SA. Electrical resistivity and magnetic susceptibility of substoichiometric CdO and In doped CdO films. Appl Phys A. 2021;127:343.

Alqahtani MS, Hadia NMA, Mohamed SH. Effects of V doping on magnetic and optical properties of oxygen-deficient In2O3 thin films. Optik. 2017;145:377.

Manzoor A, Hasanain SK, Mumtaz A, Bertino MF, Franzel L. Effects of size and oxygen annealing on the multiferroic behavior of bismuth ferrite nanoparticles. J Nanopart Res. 2012;14:1310.

Zhogin IL, Nemudry AP, Glyanenko PV, Kamenetsky YM, Bouwmeester HJM, Ismagilov ZR. Oxygen diffusion in nanostructured perovskites. Catal Today. 2006;118:151.

Hueso LE, Rivadulla F, Sanchez RD, Caeiro D, Jardon C, et al. Influence of the grain-size and oxygen stoichiometry on magnetic and transport properties of polycrystalline La0.67Ca0.33MnO3±δ perovskites. J Mag Mag Mater. 1998;189:321.

Locquet JP, Arrouy F, et al. Local electrochemical oxidation/reduction: first step towards a new lithography? Appl Phys Let. 1996;68:1999.

Locquet JP. Local electrochemical oxidation/reduction: first step towards a new lithography? Physica C: Superconductivity. 1996;263:160.

Carvalho MD, Wattiaux A, Bassat JM, Grenier JC, Pouchard M, da Silva Pereira MI. Electrochemical oxidation and reduction of La 4 Ni 3 O 10 in alkaline media. Cost J Solid State Electrochem. 2003;7:700.

Feng HH, Li ZG, Hor PH, Bhavaraju S, Di-Carlo JF, Jacobson AJ. Nanoscopic oxygen control of functional oxide nanoparticles by electro-chemical route at ambient temperature. Phys Rev B Rapid Comm. 1995;51:16499.

Olszewska A, et al. Peculiar properties of electrochemically oxidized SmBaCo2− xMnxO5+ δ (x= 0; 05 and 1) a-site ordered perovskites. Crystals. 2020;10:205.

Majee R, Islam QA, Mondal S, Bhattacharyya S. An electrochemically reversible lattice with redox active A-sites of double perovskite oxide nanosheets to reinforce oxygen electrocatalysis. Chem Sci. 2020;11:10180.

Pralong V, Caignaert V, Hebert S, Marinescu C, Raveau B, Maignan A. lectrochemical oxidation and reduction of the La0.2Sr0.8CoO3− δ phases: control of itinerant ferromagnetism and magnetoresistance. Solid State Ionics. 2006;177:815.

Wang D, Meng L, Wei L, Shi P, Chen Y, Yan S, Tian Y, Liu G, Mei L. Reversible phase switching between antiferromagnetic SrCoO2.5 and ferromagnetic SrCoO3− δ by a flexible solid-state electrolyte gate. J Mag Mag Mater. 2020;496:165926.

Katase T, Ohta H. Oxide-based optical, electrical and magnetic properties switching devices with water-incorporated gate insulator. J Appl Phys. 2019;58:090501.

Onozato T, Nezu Y, Cho HJ, Ohta H, Ohta H. Fast operation of a WO3-based solid-state electrochromic transistor. AIP Adv. 2019;9:025122.

Katase T, Suzuki Y, Ohta H. Highly conducting leakage-free electrolyte for SrCoOx-based non-volatile memory device. Adv Electron Mater. 2016;2:1600044.

Mahendiran R, Tiwary SK, Raychaudhuri AK, Ramakrishnan TV, Mahesh R, Rangavittal N, Rao CNR. Structure, Structure, electron-transport properties, and giant magnetoresistance of hole-doped LaMnO 3 systems. Phys Rev B. 1996;53:3348.

Ritter C, Ibarra MR, De Teresa JM, Algarabel PA, Marquina C, Blasco J, García J, Oseroff S, Cheong SW. Influence of oxygen content on the structural, magnetotransport, and magnetic properties of LaMnO 3+ δ. Phys Rev B. 1997;56:8902.

Chatterji T, Ouladdiaf B, Mandal P, Bandyopadhyay B, Ghosh B. Jahn-Teller transition in La 1–x Sr x MnO 3 in the low-doping region (0< x<~ 0. 1). Phys Rev B. 2002;66:54403.

Ghosh B, Siruguri V, Raychaudhuri AK, Chatterji T. Effect of size reduction on the structural and magnetic order in LaMnO3+ δ (δ≈ 003) nanocrystals: a neutron diffraction study. J Phys Condens Matter. 2014;26:025603.

Sarkar T, Ghosh B, Raychaudhuri AK, Chatterji T. Crystal structure and physical properties of half-doped manganite nanocrystals of less than 100-nm size. Phys Rev B. 2008;77:235112.

Sarkar T, Raychaudhuri AK, Bera AK, Yusuf SM. Effect of size reduction on the ferromagnetism of the manganite La1− xCaxMnO3 (x= 0.33). New J Phys. 2010;12:123026.

Shankar KS, Raychaudhuri AK. Low-temperature polymer precursor-based synthesis of nanocrystalline particles of lanthanum calcium manganese oxide (La0.67Ca0.33MnO3) with enhanced ferromagnetic transition temperature. J Mater Res. 2006;21:27.

Chowdhury PM, Raychaudhuri AK. Electromigration of oxygen and resistive state transitions in sub-micron width long strip of La0.85Sr0.15MnO3 connected to an engineered oxygen source. Mat Res Bulletin. 2021;137:111160.

Chowdhury PM. Oxygen diffusion study in manganite films near room temperature. Mat Res Bulletin. 2020;131:110976.

Mahendiran R, Tiwary SK, Raychaudhuri AK, Mahesh R, Rao CNR. Thermopower and nature of the hole-doped states in LaMn O 3 and related systems showing giant magnetoresistance. Phys Rev B. 1996;54:R9604(R).

Trukhanov SV, Kasper NV, Troyanchuk O, Tovar M, Szymczak H, Barner K. Evolution of magnetic state in the La1− xCaxMnO3− γ (x= 0.30, 0.50) manganites depending on the oxygen content. J Solid State Chem. 2002;169:85.

Cheong SW, Monographs in condensed matter science, London: 1999.

Shankar KS, Kar S, Subbanna GN, Raychaudhuri AK. Enhanced ferromagnetic transition temperature in nanocrystalline lanthanum calcium manganese oxide (La0.67Ca0.33MnO3). Solid State Comm. 2004;129:479.

Shantha Shankar K, Kar S, Raychaudhuri AK. Fabrication of ordered array of nanowires of La 0.67 Ca 0.33 MnO 3 (x= 0.33) in alumina templates with enhanced ferromagnetic transition temperature. Appl Phys Lett. 2004;84:993.

Fujishiro H, Fukase T, Ikebe M. Anomalous lattice softening at X= 0.19 and 0.82 in La1-X Ca X MnO3. J Phys Soc Japan. 2001;70:628.

Sarkar T, Tuning of ground state and phase transition in complex oxide nanomaterials, Chapter 3, S. N. Bose National Centre for Basic sciences 2009.

Acknowledgements

P M Chowdhury and A K Raychaudhuri thanks S. N. Bose National Centre for Basic Sciences for providing experimental facilities. P M Chowdhury also would like to thank CSIR Govt. of India for fellowship during experimental work. A K Raychaudhuri wants to thank Science and Engineering Research Board (SERB) for financial support through Distinguished Fellowship Programme (Project number SB/DF/008/2019).

Funding

P M Chowdhury would like to thank CSIR Govt. of India for fellowship. A K Raychaudhuri wants to thank Science and Engineering Research Board (SERB) for financial support through Distinguished Fellowship Programme (Project number SB/DF/008/2019).

Author information

Authors and Affiliations

Contributions

All authors significantly contributed to the study. PMC did the experiment and did part work in data analysis and manuscript preparation. AKR planned the experiment, guided it and did part work in data analysis and manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing fnancial interests or personal relationships that could have appeared to infuence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Malla Chowdhury, P., Raychaudhuri, A.K. Nanoscopic oxygen control of functional oxide nanoparticles by electro-chemical route at ambient temperature. Discover Nano 19, 25 (2024). https://doi.org/10.1186/s11671-024-03969-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-024-03969-y