Abstract

Atmospheric plasma processing, which combines the efficacy of chemical processes and the safety of physical processes, has been used to modify the surface characteristics of graphite-based materials. In this work, two distinct plasma source gases, C4F8 and O2, with the addition of a rotary reactor were used. The effectiveness of modifying the basal plane of intercalated graphite nanoplatelets (GnP) was investigated with various analytical techniques and the visual observation of the dispersion of these plasma-treated GnP in solvents was also reported. It is shown that this low-temperature plasma processing technique can be used to successfully modify the GnP surface without significantly changing the intrinsic structure of the GnP, which is desirable in many applications. With the C4F8 plasma treatment, the immersion characteristics in solvents can be tuned and the functional groups present on the surface can be tailored to produce desired bonding environments. This surface chemistry tunability will provide the needed functionalities in creating graphene-containing composite materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

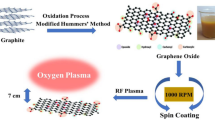

Graphene has remained an attractive material due to its excellent intrinsic mechanical, thermal, and electrical properties [1,2,3]. However, due to the chemically inert nature of the basal plane, significant engineering and/or chemical treatments of graphene are needed for it to be an effective reinforcement in composite materials [4]. The ways to incorporate the attachment points are varied, including chemical treatments and physical processes. Chemical treatments, such as the Hummers’ method to create graphene oxide [5], are batch processes. Harsh chemicals are needed to intercalate and allow oxidation, which can be a time-consuming process and results in the degradation of many properties that make graphene desirable in the first place [6]. The chemicals and reactions involved create exothermic conditions non-conducive to large-scale manufacturing. Physical processes, such as sonication in solvents [7] and mechanical grinding procedures [8], are simple and more environmentally friendly but also less effective in creating strong interfacial bonds. These physical processes can also require large amounts of energy to break bonds within the graphene and ensure an environment where those broken bonds will reform according to the desired bonding schemes [8].

Plasma treatment of graphene surfaces has been shown to successfully modify the basal plane of graphene without the creation of harsh by-products [9,10,11,12]. Plasma modification of graphene utilizes energetic and/or reactive radicals in the plasma to interact with the surface and can have several effects, such as breaking the C–C bonds, removing surface atoms, “cleaning” the surface, and modifying the surface chemistry [13]. The surface reactions are determined by the types of plasma species and energy, which depend on the plasma system, source gas and pressure, and excitation power. Oxygen plasmas have been used to increase bonding between graphene and various matrix materials. Oxygen plasma functionalized graphene has been shown to increase adhesion and stress transfer in metal composites [14]. Oxygen plasmas have also been shown to increase the functionalizability of graphene materials in general, creating more active reaction sites for further functionalization [15]. Oxygen plasma functionalization on nitrogen-doped graphene has been shown to increase supercapacitor performance by inducing pseudo-capacitance incorporating nitrogen and oxygen functional groups [16]. Other carbon-based materials, such as carbon black, have been treated with oxygen plasma; aiming to improve its dispersibility without changing intrinsic structure. Using oxygen plasma functionalization, carbon black was transformed from easily agglomerating nanoparticles to a network with high surface area and hydrophilicity, increasing its usability as a desalination agent [17]. Carbon nanotubes have been modified with plasma for various applications. Treatment with mixtures of oxygen and argon gasses have been shown to increase oxygen content and improve electrochemical sensing performance [18]. Plasma produced using mixtures of carbon dioxide and nitrogen have been shown to alter the nanotubes surface, by producing isocyanate functionalities, and increase the wear resistance of polyurethane-nanotube composites [19]. Amine functionalization using nitrogen plasma has been performed on reduced graphene oxide, with amine functionals providing enhanced interfacial bonding [20]. Nitrogen plasma has been used to produce successful biosensors using graphene as a base material [21]. Mixtures of argon and nitrogen gasses have been used to produce a plasma that can reduce and functionalize graphene oxide simultaneously [22]. Previous reports show that octafluorocyclobutane plasma can functionalize graphite, while oxygen plasma can etch single layer chemical vapor deposited graphene in a few seconds [23, 24]. In this work, radio frequency (RF) power is used to excite gases in a lab-scale plasma reactor, enabling the radicals to interact with graphene nanoplatelets (GnP). The interactions of the plasma species with the GnP create surface disorder, making it possible to introduce covalently bonded functional groups to the graphene surface.

In conventional plasma treatment systems, the sample remains static within the reaction chamber and electrodes are positioned such that the plasma plume interacts with the sample surface. This setup geometry limits the plasma interaction with the sample materials, especially powder samples, to the exposed surfaces. Depending on the energy of the radicals in the plasma, treatment of the bulk material, or at any depth below a few layers of surface atoms, becomes improbable. As radical energy increases, interactions deeper into the surface of the material become possible but implantation and ablation become issues, destroying bonds, and creating disorder within the material. In this work, we report using our patented rotary plasma reactor to overcome these limitations [25]. The rotary plasma reactor is particularly attractive for treating the surface of powders like GnP. The rotation of a tumbler will expose fresh GnP surfaces to the plasma for effective modifications. The goal of the plasma treatments is to modify the GnP surface to allow easy incorporation into solvents and composites, while not significantly changing the structure of the GnP and preserving the intrinsic properties. By utilizing the rotary reactor, lower energy plasma can be utilized to fully treat powder samples, especially large quantities of powders that are difficult to treat in conventional stationary sample set-ups. Using lower energy plasma limits the structural modifications of the GnP, preserving the intrinsic properties, and promoting chemical modification of the surface without implantation or ablation. This minimal change in the GnP structure would allow for more efficient reinforcement in composites.

To verify the plasma treatment effects, X-Ray Photoelectron Spectroscopy (XPS) was used to evaluate the surface functionalization; Raman Microscopy and X-Ray Diffraction (XRD) were used to monitor structural changes of the GnP; and immersion experiments were used to qualitatively visualize the treatment uniformity of the sample batch..

2 Materials and methods

Graphene Nanoplatelets (GnP) of grade M25 were supplied by XG Sciences and used as received. According to XG Sciences, this grade of GnP was produced using a mechanical milling process of acid-assisted intercalated graphite powders. This process is known to leave residual species from the acid intercalation, including oxygen containing groups. These residual oxygen groups are characterized in the raw materials XPS spectra. Grade M particles have thicknesses of approximately 6–8 nm and a surface area of 120–150 m2/g, with M25 having an average particle diameter of 25 microns [26].

A radio frequency plasma system was used to treat the GnP (Fig. 1). The plasma system included a rotary tumbler chamber of 63 mm diameter and 200 mm length that served as the vacuum chamber, a mechanical vacuum pump, a 13.56 MHz RF power supply, a matching network, a vacuum gauge, and a gas flow controller. A schematic of the inner tumbler shows electrode location and tumbling of sample materials (Fig. 2).

First, 1 g of M25 GnP was loaded into the rotary tumbler and the chamber was evacuated to a base pressure of < 20 mTorr. Although no high-vacuum pump was used, the reactor was constructed leak-tight by using magnetic feedthrough for the rotary components. Then the chamber was purged five times with the working gas prior to each plasma treatment. The effects of residual oxygen and water was minimized as evidenced by the consistent results obtained with multiple samples from each treatment as well as from different batches. Next, the gas flow rate was adjusted such that the pressure was stable at 660–680 mTorr (87.9–90.7 Pa), this was achieved at a flow rate of 8 standard cubic centimeters per minute. Octafluorocyclobutane (C4F8) and oxygen (O2) were used separately to generate plasmas and treat samples. Samples treated with C4F8 plasma are referred to as C4F8 Plasma treated M25, samples treated with O2 plasma are referred to as O2 Plasma treated M25. Untreated powders, which were used as-received for comparison, are referred to as As-Received M25. Next RF power was turned on and the matching network was tuned manually to minimize reflected power. The RF power was set at 70 W in all the treatments. The samples were treated for 10 min with reversing rotation direction every 30 s to move the GnP back and forth from one end to the other for uniform treatment. Standard gas flow control and pumping system were used to handle the C4F8 gas and exhaust in an effective venting environment. The components that are directly exposed to the C4F8 plasma were made of aluminum, while the other system components were made of stainless steel. No damage to the reactor components was observed.

X-ray Photoelectron spectroscopy was carried out using a Perkin Elmer Phi 5600 ESCA system with a magnesium Kα x-ray source at a take-off angle of 45°. Survey scans were taken at 1.6 eV step and 187 eV pass energy, detailed region scans were performed with 0.05 eV step and 11.75 eV pass energy. The fitting of peaks was performed using CasaXPS software.

Raman spectroscopy was carried out using LabRAM ARAMIS (HORIBA JOBIN YVON, Inc) in the range of 1200–3000 cm−1 with a 50 × objective lens. The excitation laser wavelength was 532 nm. Scans were performed using 1800 gr/mm grating with a 180-s accumulation time.

X-ray diffraction was carried out using a Bruker D2 Phaser (Bruker Corporation). Scans were collected at 30 kV and 10 mA with a 0.01° step size and 0.5 s dwell time.

Immersion experiments were carried out using deionized water and isopropyl alcohol. Approximately 20 mg of sample materials were added to approximately 60 mL of liquid. As-Received M25, C4F8 Plasma treated M25, and O2 Plasma treated M25 were used to compare how surface treatment affected behavior in water and alcohol. Samples were weighed, then added to a beaker containing the liquid and manually stirred with a glass stir rod. The video recording of the experiments is available in Online Resource 1 and Online Resource 2.

3 Results and discussion

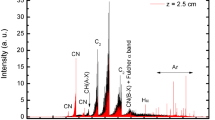

Initial XPS survey scans were performed to identify areas of interest for detailed XPS scans (Fig. 3). Survey scans of the raw materials (Fig. 3a) show only C1s and O1s peaks. We expect to see some residual oxygen species from the GnP exfoliation process, these species are characterized in the detailed C1s scans (Fig. 4a). No detailed scans were performed in the F1s region as no peaks were identified in the survey scans. Oxygen plasma treated materials show a similar survey spectrum to that of the raw materials (Fig. 3b). Detailed scans were performed in the C1s and O1s regions for As-Received M25 and O2 Plasma treated M25. The C4F8 Plasma treated M25 showed C1s and O1s peaks, but also displayed an F1s peak and an associated peak corresponding to the fluorine auger process (F KLL) (Fig. 3c). Detailed scans were performed in the C1s, O1s, and F1s regions for C4F8 Plasma treated M25.

Peak fitting of XPS spectrum was performed using CasaXPS software. Background subtraction was performed, and spectra were charge-referenced to the 284.5 eV C=C peak. A general fitting scheme as suggested by Biesinger [27] for graphitic/graphene/carbon nanotube type materials was modified and used. This fitting scheme was applied to the C1s spectrum from As-Received M25 (Fig. 4a). Full width half max (FWHM) restrictions for the shake-up peak, π–π*, were relaxed to 3.47 eV to allow broadening of the peak to better fit experimental data. The details of the peak assignments and constraints are outlined in Table 1.

This fitting scheme is an appropriate starting point for most graphitic materials. The C=C peak will be the most prominent peak and can be used for charge correction [27]. Adventitious carbon, while useful for samples where other known charge referencing peaks are not available, should be treated differently than graphitic carbon [27]. We are investigating graphene nanoplatelets, so it is expected there will be a large graphitic C1s peak at 284.5 eV, and a large π–π* peak contribution. Any adventitious carbon will be captured in the 285 eV peak, C–C or C–H, and can be characterized as such, but should not be used for charge correction in this case [27]. Data from XG Sciences indicates the presence of ethers, hydroxyl, and carboxyl groups due to residuals from the intercalation process, these are accounted for and characterized in the starting material. Fitting of peaks around 4–6 cm−1 shifts from C=C can be complicated due to overlapping oxygen and fluorine functional group peaks in this region. Notably, O–C=O and C–F can be convoluted and will appear in the same region. This fitting scheme was then applied to spectrum taken from treated materials. When applying the general fitting scheme to the fluorine plasma treated spectrum, two additional peaks are seen (Fig. 4b).

These peaks are a result of the plasma treatment process and are assigned accordingly. The assignment of the CF2 and CF3 peaks are in good agreement with literature values for energy shifting [28]. We do not expect to see many C-F type functionals due to the structure of the C4F8 molecule. It is more likely the ionization process of C4F8 causes a breakdown leading to abundance of CF2 type radicals [29]. However, these C-F functionals would overlap near the π–π* peak and the O–C=O peak. Therefore, broadening and increases in intensity in 290–293 eV region could be due to fluorine functionalization. Oxygen groups, from the residuals left after XG Sciences production process and from quenched reaction sites, are present in the C4F8 Plasma treated M25. When radicals from the plasma interact with the GnP surface, active sites are created through disorder. When the sample materials are removed from vacuum, these sites react with the environment and are passivated, usually through reactions with water producing hydroxyls.

Fitting of the oxygen plasma treated samples did not show any additional peaks, only increases in intensity for the oxygen functional peaks (Fig. 4c).

Fitting of the F1s peak for fluorine plasma treated samples can only be accomplished by fitting with two or more component peaks, shown in Fig. 5 for the C4F8 plasma treated samples.

These results support that more than one type of fluorine species is present at the surface of the GnP after plasma modification. We expect to fit with at least two peaks due to the two extra peaks in Fig. 4b, however due to overlaps in the C1s spectrum of oxygen and fluorine bonded carbons there may be additional peaks convoluting the F1s spectrum. The fluorine treatment did reduce the oxygen content from 3.31 at% in the as received GnP to 2.0 at% after the 10-min fluorine plasma treatment. Peaks at lower binding energies are more indicative of ionically bonded fluorine (< 688 eV), while higher binding energy peaks are more covalent in nature [23, 28]. The peak at 688 eV indicates mainly covalently bonded fluorine, but shoulders can be fit to this peak reducing the residual standard deviation of the fit. This could indicate multiple bonding environments for the fluorine, which would be expected due to the deviation in energy of the radicals encountering the surface. Further treatments should be conducted to study the evolution of the F1s peak to better understand the changing bonding environment. Notably, fluorine peaks are not present in the XPS spectra of the raw material, or the oxygen plasma treated material. Peak fitting of the O1s peaks for oxygen plasma treated samples leads to two peaks being identified (Fig. 6b).

These peaks can be roughly associated with a double bonded oxygen in a carbonyl type carbon group and a single bonded oxygen in a carboxylic type of carbon group [30]. These double bonded carbonyl type oxygen peaks will be located at low eV values (530–533 eV) while single bonded carboxylic type oxygen peaks will be located at high eV values (533–537 eV). These peaks could be further deconvoluted with additional peak assignments, however over-fitting becomes a concern due to the signal to noise ratio. The XPS O1s spectrum for As-Received M25 (Fig. 6a) shows two peaks, one at 530.6 eV and the other at 532.4 eV. Comparing the spectra for As-Received M25 and oxygen plasma treated M25, there was an increase in the ratio of single bonded oxygen species. This supports the evidence from Fig. 4c which shows an increase in the C–H and C–OH peaks as compared to the raw spectrum in Fig. 4a; and a dampening of the C=O and O–C=O peaks. This change in ratio indicates addition of preferable single-bonded oxygen groups as compared to hard to functionalize double-bonded oxygen groups. Notably, the peak positions for oxygen plasma treated samples do not change significantly from that of the raw material. Peaks for the oxygen treated samples were located at 530.6 eV and 532.1 eV, respectively. This indicates that oxygen species present are not changing, only the ratio of the species present. Overall oxygen content has increased for oxygen plasma treatments as compared to the As-Received M25. The density of oxygen increased from 3.31 at% in the as-received GnP to 5.74 at% with 10-min oxygen plasma treatment.

Like the other two samples, the O1s XPS region for C4F8 plasma treated samples can also be fit with two peaks (Fig. 6c). Compared to the untreated sample, both peaks were shifted to slightly higher binding energies, one at 531.1 eV and one at 532.9 eV, respectively. This could indicate the oxygen species present are becoming more carboxylic and single-bonded in nature, or the oxygen species are changing. Fluorine plasma treatments resulted in an oxygen content of 2.0 at% at 10 min. These results indicate that fluorine plasma treatments are either removing oxygen species through sputtering or are functionalizing these oxygen attachment points; changing the binding energies.

Raman microscopy is a powerful tool for the structural characterization of carbon materials [31,32,33,34]. Raman microscopy results show changes in the spectrum for different plasma treatments.

Table 2 summarizes approximate peak position and intensities; these were used to find ratios between peak intensities. The only spectrum containing a D-Peak is the C4F8 plasma treated samples (Fig. 7).

The D-Peak at around 1350 cm−1 is representative of breaking the symmetry of the carbon basal plane by breaking of pi bonded carbons and allows non-symmetrical stretching, a transverse zone boundary phonon interacts with defect to create this shift. The D-Peak can be used to track the amount of “disorder” of the basal plane, specifically the intensity of the D-Peak with respect to the G-Peak [35]. The G-Peak at around 1580 cm−1 represents the symmetric “breathing” of the perfect carbon basal plane, perfect graphene will contain only a G-Peak and a G′ peak. The C4F8 plasma treatment resulted in an Id:Ig of 0.51, which is significantly higher than that of the As-Received M25 and the O2 treated M25 samples. The oxygen plasma treatments did not create an appreciable D-Peak, meaning there is relatively little basal plane disorder. This could be indicative of the addition of functional groups mainly at the edges of the GnP sheets. This is supported by literature from XG sciences indicating that their GnP will be more readily functionalized at the edges [36]. The similarity between the raw material spectrum and the oxygen plasma treated material spectrum indicate no structural changes are occurring during the oxygen plasma treatment, only an increase in the oxygen functionals at the edges of the sheets.

Also seen in the spectrum of the C4F8 treated samples (Fig. 7) is a shoulder at approximately 1605 cm−1, this represents the D′-Peak. The D′-Peak is an intravalley double resonance process where a longitudinal phonon interacts with a defect in a circle around an equivalent k point in the Brillion zone. This is unlike the G′-Peak, which is intervalley, meaning around nonequivalent k points and is a result of two longitudinal phonons interacting, no defects are required to produce a G′-Peak which is why it is present in perfect graphene spectra. Presence of the D′-Peak is further evidence of defects generated during the C4F8 plasma treatment process. The G′-Peak has been shown to be sensitive to both doping and strain in graphene, as well as an indication of the number of layers of graphene with AB Bernal stacking [33]. Decreasing the layer count in few-layer graphene will lead to a redshift in the G′-Peak, increasing strain will tend to redshift the G’-Peak, increasing doping will lead to a dampening in the peak intensity. Graphene produced through mechanical exfoliation will usually have predominantly AB stacking, however the sample material used here was subjected to unknown chemical processes which may have altered the stacking order and produced rotationally random graphene platelet agglomerates. In this case, the G′-Peak could be used to infer about double resonant selection rule relaxation associated with the random stacking [33]. We observe that plasma treatment both redshifts and dampens the G’-Peak (Fig. 7); with fluorine plasma creating more shifting and dampening. This is consistent with the results for the Id:Ig ratio indicating that more disorder was created in the C4F8 treated samples. The peak shape is also changed from a Lorentzian type of peak shape for raw materials to a broader, more convoluted Lorentzian for C4F8 treated samples.

X-ray diffraction can be used in conjunction with Raman to help determine the crystallite size in the c-axis [33]. Diffraction scans are compared in Fig. 8, As-Received M25 samples show a peak at 26.75° with decreasing diffraction angles as treatment occurs. Peak positions, intensities, and full width half maxes (FWHM) are reported in Table 3.

By deconvoluting the G’-Peak and comparing results to XRD scans, empirical formulas have been developed to determine this c-axis crystallite size from certain Raman parameters, R, which is a ratio of the intensities of the deconvoluted G′-Peak. Essentially, the relationship found is that as the G′-Peak becomes more skewed to higher Raman shifts, the crystallite size should increase. From Fig. 7, we see that the As-Received M25 material is the most blue-shifted peak and as we treat with plasma the peak redshifts and changes shape. This is supported by diffraction results (Fig. 8), where the shifting to lower 2\(\theta\) and broadening of the peak FWHM indicates a smaller crystallite size according to the Scherrer equation. Plasma has been shown to exfoliate graphene under certain conditions [37]. Additionally, the plasma processing combined with mechanical tumbling may increase the likelihood of exfoliation. The slight shifting coupled with the increases in FWHM could indicate a peeling of layers due to plasma interactions. The slight shifting could indicate a larger inter-galley spacing for the GnP, but this effect is negligible as the d-spacing remains 0.33 nm.

These results indicate there is minimal structural change occurring to the platelets during plasma treatments. Structural characterization of these platelets will become important when used in composite applications with these functionalized GnP nanoplatelets. For this preliminary study, we are more concerned with the surface chemistry present on these functionalized platelets. Further structural characterization in composites will be the subject of subsequent studies exploring the applications of these functionalized GnP nanoplatelets.

For composite applications, in addition to surface chemistry of the platelet, dispersion of these functionalized GnP nanoplatelets is critical for effective matrix reinforcement [38]. Therefore, immersion experiments were conducted to observe how the plasma treatments changed dispersion behavior in deionized (DI) water and isopropyl alcohol. Images of the immersion experiments are displayed in Figs. 9 and 10, qualitative inspection can be performed. The video recording of the immersion experiments is available in Online Resource 1 and Online Resource 2.

Results of these experiments show that fluorine surface treatments increase the hydrophobicity of the M25 GnP significantly. As seen in Fig. 9, the C4F8 10 Minute Plasma sample does not disperse in the DI water. Increased hydrophobicity is an indicator of the presence of C–F bonds on the surface of graphene [28, 39]. Dispersibility in isopropyl alcohol is comparable to untreated GnP for the fluorine treated samples. Shown in Fig. 10, there is little difference in the appearance of the solutions, with the oxygen plasma sample being slightly more dispersed by visual inspection. Oxygen plasma treated samples show an increase in dispersibility for both water and isopropyl alcohol over nontreated samples. The increase dispersibility in both water and isopropyl alcohol are due to the increased disorder on the basal plane of graphene and presence of oxygen containing functional groups.

4 Conclusions

In this work, commercially available graphene nanoplatelets were modified with low-temperature plasma processes. These plasma processes were performed in a patented rotary reactor system which allowed for increased treatment uniformity for powder samples. The reactor could not only move the powder up and down but also simultaneously transport it through the reactor back and forth using a set of proprietary tumblers. This led to uniform treatment of the samples. Samples randomly taken from each batch, as well as from different batches, showed almost identical Raman spectra. It is worth noting that samples from a static reactor used previously showed pronounced variations in the immersion behaviors, indicating less effective plasma treatment of the stationary powders. Modifications were characterized using XPS, Raman microscopy, and XRD. Immersion experiments were conducted to observe the materials behavior in solvent. All results indicate that C4F8 plasma treatments were successful in attachments of fluorine containing functional groups on the surface of GnP. Addition of F1s peaks on the XPS scans indicate addition of fluorine to the surface of GnP, which modifies the immersion characteristics of the GnP in water and alcohol. Fluorine atomic percentage increased from zero in the as-received materials to 12.6 at% after a 10-min C4F8 plasma treatment. Oxygen plasma treatments were successful in the addition of oxygen containing functionals to the GnP without creation of basal plane disorder. X-ray diffraction and Raman experiments show no appreciable change in the structure of the GnP, which is critical for maintaining the desirable properties of the GnP. These results indicate most oxygen functionalization is occurring on the edges of the GnP, where natural disorder provides dangling bonds. Changes to the interaction of the GnP with solvents is further evidence of a functionalized surface. Surface modification of graphene and graphene-like materials are critical for their future as composite filler materials. Through oxygen functionalization graphene materials can be made more hydrophilic and increase their dispersibility in a variety of solvents. Good dispersion of filler particles is a critical factor in creating efficiently reinforced, high-performance composites. Through fluorine functionalization, these same materials can be made more hydrophobic, creating opportunities for amphiphobicity and biosensing applications. Additionally, fluorinated graphene shows potential in energy conversion and storage devices [39]. This rotary plasma treatment provides enhanced treatment uniformity and throughput capabilities for producing these materials.

Data availability

Raw data as well as plasma processed materials are available upon request.

References

CastroNeto AH, Guinea F, Peres NMR, Novoselov KS, Geim AK. The electronic properties of graphene. Rev Modern Phys. 2009;81:109–62.

Zhu Y, Murali S, Cai W, Li X, Suk JW, Potts JR, Ruoff RS. Graphene and graphene oxide: synthesis, properties, and applications. Adv Mater. 2010;22:3906–24.

Cao K, Feng S, Han Y, Gao L, Hue Ly T, Xu Z, Lu Y. Elastic straining of free-standing monolayer graphene. Nat Commun. 2020. https://doi.org/10.1038/s41467-019-14130-0.

Papgeorgiou DG, Kinloch IA, Young RJ. Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater Sci. 2017;90:75–127.

Hummers WS Jr, Offeman RE. Preparation of graphitic oxide. J Am Chem Soc. 1958;80(6):1339.

Tarcan R, Todor-Boer O, Petrovai I, Leordean C, Astilean S, Botiz I. Reduced graphene oxide today. J Mater Chem C. 2020;8:1198–224.

May P, Khan U, O’Neill A, Coleman JN. Approaching the theoretical limit for reinforcing polymers with graphene. J Mater Chem. 2012;22:1278–82.

Bastwros M, Kim G-Y, Zhu C, Zhang K, Wang S, Tang X, Wang X. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos B Eng. 2014;60:111–8.

Wang X, Fan Q, Chen Z, Wang Q, Li J, Hobiny A, Alsaedi A, Wang X. Surface modification of graphene oxides by plasma techniques and their application for environmental pollution cleanup. Chem Rec. 2015;16:295–318.

Dey A, Chroneos A, Braithwaite N, Gandhiraman R, Krishnamurthy S. Plasma engineering of graphene. Appl Phys Rev. 2016;3(2):1–19.

Bertoti I, Mohai M, Laszlo K. Surface modification of graphene and graphite by nitrogen plasma: determination of chemical state alterations and assignments by quantitative X-ray photoelectron spectroscopy. Carbon. 2015;84:185–96.

Wang Q, Wang X, Chai Z, Hu W. Low-temperature plasma synthesis of carbon nanotubes and graphene based materials and their fuel cell applications. R Soc Chem. 2013;42:8821–34.

Jin C, Huang T, Yang Y, Wu M, Xu Y, Wu Z, Zhuge L, Wu X, Ye C. Synthesis of few-layer graphene-on-insulator films by controllable C4F8 plasma etching SiC. Plasma Process Polym. 2015;12:1061–8.

Dong Z, Zhao S, Zhang Y, Yang J, Xiong D-B. Evaluating and manipulating bonding strength at multilayer graphene-copper interface via plasma functionalization. Mater Sci Eng A. 2022;848:143391.

Jafari A, Mortaheb H, Gallucci F. Plasma treatment for enhanced functionalization of graphene nanosheets by octadecylamine. Chem Eng Res Des. 2022;187:251–60.

Joseph K, Shanov V. Symmetric supercapacitor based on nitrogen-doped and plasma-functionalized 3D graphene. Batteries. 2022;8(12):258.

Cao R, Zhou J, Wang D, Zhang J, Zhang Y, Zhou H, Li J. Improving capacitive deionization performance by using O2 plasma modified carbon black. Chem Eng J. 2023;451(1):138530.

Bohlooli F, Anagri A, Mori S. Development of carbon-based metal free electrochemical sensor for hydrogen peroxide by surface modification of carbon nanowalls. Carbon. 2022;196:327–36.

Ogawa D, Morimune-Moriya S, Nakamura K. Effective polymerization technique for plasma-treated multiwalled carbon nanotubes to maximize wear resistance of composite polyurethane. J Vac Sci Technol B. 2022;40(2): 022803.

Ackermann A, Fischer M, Wick A, Carosella S, Fox B, Middendorf P. Mechanical, thermal and electrical properties of epoxy nanocomposites with amine-functionalized reduced graphene oxide via plasma treatment. J Compos Sci. 2022;6(6):153.

Wang Y, Shao Y, Matson DW, Li J, Lin Y. Nitrogen-doped graphene and its applications in electrochemical biosensing. ACS Nano. 2010;4(4):1790–8.

Akada K, Obata S, Saiki K. Radio-frequency plasma assisted reduction and nitrogen doping of graphene oxide. Carbon. 2022;189:571–8.

Lee C, Han Y-J, Seo YD, Nakabayashi K, Miyawaki J, Santamaria R, Menendez R, Yoon S-H, Jang J. C4F8 plasma treatment as an effective route for improving rate performance of natural/synthetic graphite anodes in lithium ion batteries. Carbon. 2016;103:28–35.

Liu Y, Chang J, Yang H, Lin S, Akhbari S, Zhou Q, Heo K, Lin L. Self-aligned, direct-write graphene channel FETs. In 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain; 2013.

Fan QH, Toomajian M. Rotary Plasma Reactors. United States of America Patent 11,545,343, 3 January 2023.

X. Sciences, Grade M Technical Data Sheet. [Online]. Available: https://xgsciences.us/docs/Grade%20M%20Data%20Sheet.pdf. [Accessed June 2023].

Biesinger MC. Accessing the robustness of adventitious carbon for charge referencing (correction) purposes in XPS analysis: insights from a multi-user facility data review. Appl Surf Sci. 2022;597: 153681.

Cheng L, Jandhyala S, Mordi G, Lucero A, Huang J, Azcatl A, Addou R, Wallace R, Colombo L, Kim J. Partially fluorinated graphene: structural and electrical characterization. ACS Appl Mater Interfaces. 2016;8(7):5002–8.

Miyata K, Hori M, Goto T. Infrared diode laser absorption spectroscopy measurements of CFx (X=1-3) radical densities in electron cyclotron resonance plasmas employing C4F8, C2F6, CF4, and CHF3 gases. J Vac Sci Technol A. 1996;14:2343–50.

Zhou J-H, Sui Z-J, Zhu J, Li P, Chen D, Dai Y-C, Yuan W-K. Characterization of surface oxygen complexes on carbon nanofibers by TPD, XPS and FT-IR. Carbon. 2007;45(4):785–96.

Ferrari AC. Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam Relat Mater. 2002;11:1053–61.

Ferrari AC, Meyer JC, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov KS, Roth S, Geim AK. Raman spectrum of graphene and graphene layers. Phys Rev Lett. 2006;97:1–4.

Malard LM, Pimenta MA, Dresselhaus G, Dresselhaus MS. Raman spectroscopy in graphene. Phys Rep. 2009;473(5–6):51–87.

Ferrari AC, Basko DM. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat Nanotechnol. 2013;8:235–46.

Lucchese MM, Stavale F, MartinsFerreira EH, Vilani C, Moutinho MVO, Capaz RB, Achete CA, Jorio A. Quantifying ion-induced defects and Raman relaxation length in graphene. Carbon. 2010;48:1592–7.

X. Sciences, XG Sciences Multifunctional Nanomaterials. April 2009. [Online]. Available: https://xgsciences.us/docs/XGSOverview09-A.pdf. [Accessed June 2023].

Wang K, Xu M, Gu Y, Gu Z, Liu J, Fan QH. Low-temperature plasma exfoliated n-doped graphene for symmetrical electrode supercapacitors. Nano Energy. 2017;31:486–94.

Kilic U, Sherif MM, Ozbulut OE. Tensile properties of graphene nanoplatelets/epoxy composites fabricated by various dispersion techniques. Polym Testing. 2019;76:181–91.

Feng W, Long P, Feng Y, Li Y. Two-dimensional fluorinated graphene: synthesis, structures, properties and applications. Adv Sci. 2016;3:1–22.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

TJ: Processing of Materials, all characterization experiments and data analysis, and wrote the main manuscript. KW: Setups of plasma processing equipment. QHF: Conceptualization and editing of the manuscript. AL: Conceptualization, project administration, data analysis and editing of the manuscript. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1. This video shows immersion experiments of the as-received M25 (or Raw M25), the O2 Plasma treated M25, and the C4F8 Plasma treated M25 in water. The video shows the three immersion experiments back-to-back with an inset of the top-down view of experiments. At the end of the video, a side-by-side comparison of the three suspensions is shown. Still images were taken from this side-by-side comparison and shown in the manuscript.

Additional file 2. This video shows immersion experiments of the as-received M25 (or Raw M25), the O2 Plasma treated M25, and the C4F8 Plasma treated M25 in Isopropyl Alcohol (IPA). The video shows the three immersion experiments back-to-back with an inset of the top-down view of experiments. At the end of the video, a side-by-side comparison of the three suspensions is shown. Still images were taken from this side-by-side comparison and shown in the manuscript.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Johnson, T., Wang, K., Fan, Q.H. et al. Plasma modification of graphene nanoplatelets surfaces. Discover Nano 18, 144 (2023). https://doi.org/10.1186/s11671-023-03929-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-023-03929-y