Abstract

The enhancement of the photocatalytic performance of pristine WO3 was systematically adjusted due to its fast recombination rate and low reduction potential. A designed heterostructure photocatalyst was necessarily synthesised by Fe3+ metal ions doping into WO3 structure with and composition modification. In this study, we synthesised a retrievable Fe-doped WO3/SiO2 heterostructure using a surfactant-assisted hydrothermal method. This heterostructure was then employed as an effective photocatalyst for the removal of Cr(VI) under visible light irradiation. Enlarged photocatalytic reduction was observed over a synergetic 7.5 mol% Fe-doped WO3/SiO2-20 nanocomposite, resulting in dramatically increased activity compared with undoped WO3 and SiO2 nanomaterials under visible light illumination within 90 min. The presence of 7.5 mol% Fe3+ ion dopant in WO3 optimised electron–hole recombination, consequently reducing WO3 photocorrosion. After adding SiO2 nanoparticles, the binary WO3-SiO2 nanocomposite played roles as both adsorbent and photocatalyst to increase specific surface area. Thus, the 7.5 mol% Fe-doped WO3/SiO2-20 nanocomposite catalyst had more active sites on the surface of catalyst, and enhanced photocatalytic reduction was significantly achieved. The results showed 91.1% photocatalytic reduction over the optimum photocatalyst, with a photoreduction kinetic rate of 21.1 × 10–3 min−1, which was approximately four times faster than pristine WO3. Therefore, the superior optimal photocatalyst demonstrated reusability, with activities decreasing by only 9.8% after five cycles. The high photocatalytic performance and excellent stability of our photocatalyst indicate great potential for water pollution treatments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Stainless steel manufacturing has seen a rapid increase in the use of chromium (Cr). Most stainless steels contain approximately 18% Cr to harden and toughen the alloys and increase their corrosion resistance, especially when used at high temperatures [1]. This has, however, led to Cr contamination, affecting living organisms in both soil and aqueous environments [2]. Several methods have been employed to remove Cr6+ from industrial wastewater, including chemical and electrochemical precipitation, filtration, and ion exchange [3], prior to waste discharge. Among these, advanced oxidation processes (AOPs) are used in conjunction with semiconductor photocatalysts such as TiO2, ZnO, and WO3. These photocatalysts have been widely considered viable in the treatment of less hazardous organic pollutants, such as azo dyes, and heavy metal contaminants in wastewater effluents. Notably, WO3, an n-type semiconductor with a band gap energy of 2.9–3.2 eV [4], is widely used in photocatalysis owing to its low costs, eco-friendliness, excellent physicochemical stability, electrochromic properties, and ease of synthesis [5,6,7]. Therefore, its use in visible-light-harvesting photocatalysis has become a major focus of research [8, 9]. Various types of controlled WO3 morphologies incorporating single transition metal dopants or two metals as co-dopants can be obtained via different synthetic techniques—these semiconductors (offering different band gap energies) can be combined with supporting materials, such as mesoporous SiO2 nanoparticles (NPs), to form heterostructures that raised the light-harvesting ability of the photocatalyst [10]. In the past decade, several researchers have reported on the superior performance of metal-ion-doped WO3 photocatalysts and (material-supported) W-/metal oxide-based heterostructures in the photocatalytic degradation of wastewater pollutants, including various organic dyes [11,12,13,14] and toxic Cr6+ contaminants, [15,16,17,18], hydrogen production [19, 20], and enhanced gas-sensing performance [21]. Considering the above-mentioned literature sources and the advantages and drawbacks of photocatalysts based on WO3, metal doped WO3, and heterojunctions with SiO2, this work aimed to improve upon the WO3 photocatalyst, implementing heterojunction modifications of the WO3 semiconductor by blending with SiO2 NPs and further doping with Fe3+ ions to improve the photocatalytic reduction efficiency of Cr6+. Notably, SiO2 NPs display high purity and high specific surface areas of 175–225 m2 g−1, not only facilitating the adsorption of organic compounds but also assisting in the dispersal of metal oxide particles [22]. Therefore, the SiO2-supported W-based or WO3 heterostructure photocatalyst in our above-mentioned research has shown superior performance over other photocatalysts in both energy and environmental applications [23], such as the photocatalytic degradation of herbicides and organic dyes and the removal of Cr6+ via photoreductive conversion into the less toxic Cr3+ [24]. Recently, nanosized SiO2 has been utilised in nanomaterial fabrication and semiconductor modification. Further, SiO2 NPs have been used as a support material for W-based photocatalysts due to their cost-effectiveness, easy availability, high mechanical stability, and transparency in the excitation spectral range of WO3 [X]. To the best of our knowledge, our present work is novel in terms of the iron dopant percentage/loading and the combination of a SiO2 support with high-purity WO3, yielding a reproducible method of photocatalyst synthesis for the photoreduction of the hazardous Cr6+ to the less toxic Cr3+ [25]. The superior reusability of the optimal catalyst after five cycles reveals its high efficiency and stability. Moreover, the Fe-doped WO3/SiO2 heterostructure photocatalyst was synthesised via the notably inexpensive CTAB-assisted hydrothermal technique, exhibiting enhanced photocatalytic potential for wastewater treatment under visible light irradiation from a very low-intensity and low-cost halogen lamp.

Thus, the heterostructure Fe-doped WO3/SiO2 nanocomposites were synthesised via hydrothermal treatment with Fe3+ doping in this study. The weight ratio of Fe-doped WO3 to SiO2 was varied. The physicochemical properties of the prepared samples were characterised to describe the effects of the promoted photocatalytic removal of Cr6+. Additionally, the photocatalytic reduction of a toxic Cr6+ solution over the prepared retrievable nanocatalyst was evaluated under visible light illumination (λ > 400 nm), which determined the kinetic rate of Cr6+photoreduction. In addition, the photocatalytic reduction efficiencies (%PE) and kinetic rate (kt) values were also evaluated and compared under the effect of catalyst dosage and the pH of the suspension. Furthermore, the cycling ability of the optimum photocatalyst was also investigated.

Experiments

Chemicals

All chemicals used in our studied are the analytical reagents (AR) grade and used without further purification. Sodium tungsten dihydrate (Na2WO4·2H2O, 99.0%, Sigma-Aldrich), and Iron (III) chloride (FeCl3, 99.0%, Loba Chemie), cetyltrimethylammonium bromide (CTAB, 98%, Sigma-Aldrich), Rhodamine B (C28H31ClN2O3, 99.0%, Loba Chemie), and a chromium (VI) ICP-grade standard solution (99.9%, Sigma-Aldrich) were used. The remaining chemicals and solvents were of purified SiO2 (99.5%) powder (10–20 nm) purchased from Sigma-Aldrich., the Milli Q (Millipore), ultrapure water, or deionised (DI) water having a resistivity of 18.2 MΩ.cm at room temperature and conductivity of 0.054 μS were utilised through the experiments.

Synthesis of Fe-doped WO 3 /SiO 2 heterostructure NPs

Pure WO3, Fe-doped WO3, and Fe-doped WO3/SiO2 heterostructures were prepared via a surfactant-assisted hydrothermal and impregnation procedure. First, monoclinic WO3 nanostructures were synthesised using a CTAB-assisted hydrothermal method. Briefly, a certain amount of Na2WO4⋅2H2O was dissolved in DI water with constant stirring to obtain a clear solution (A). Subsequently, a 0.17 M aqueous CTAB solution was prepared and slowly added to solution (A). The conc. HCl solution was then applied dropwise for pH adjusted to 3.0 ± 0.3 using under vigorously stirring. Thereafter, the mixture was transferred into a Teflon-lined stainless-steel autoclave and kept at 200 °C for 12 h. The precipitate was washed several times and dried at 80 °C for 12 h using an air oven. Finally, the synthesised powder was calcined at 600 °C. The Fe-doped WO3 NPs were prepared via wet impregnation using Fe(III)Cl3 metal ions precursor, with doping concentrations of 2.5, 5.0, 7.5, and 10.0 mol% of Fe3+ contents. The solutions with different concentrations of Fe3+ solution were each added to continuously ground, dried, and sintered at high temperature [26]. Initially, the optimum Fe-doped WO3 sample was evaluated via the photoreduction of Cr6+ prior to prepare the Fe-WO3/SiO2 nanocomposite. The 7.5 mol% Fe-doped WO3 sample displayed the highest photoreduction efficiency as shown in the supporting information (Fig. S1). Therefore, it was used in the further fabrication of the Fe-WO3/SiO2 heterostructure catalyst. Figure 1 schematically demonstrates the synthesis process of the 7.5% Fe-WO3/SiO2-20 composite catalyst nanoparticles. The nominal weight ratio of 7.5 mol% Fe-doped WO3:SiO2 was set at 50:50 and 80:20 wt%. The samples were prepared by directly mixing stoichiometric amounts of Fe-doped WO3 and commercial SiO2 nanopowder (99%, Sigma-Aldrich). The stoichiometric SiO2 powder was sonicated in 90 mL of DI water and then directly mixed with 7.5 mol% Fe-doped WO3 with stirring to obtain a homogeneous mixture with pH adjust of 3.0 by using HCl solution. The mixture was poured into a 350-mL Teflon-line autoclave and kept at 200 °C for 12 h. The precipitates were separated, milled to acquire a dried powder. The calcination characteristics of both ratios of the Fe-doped WO3/SiO2 nanocomposites were investigated at same ambient mention above. The obtained photocatalysts were denoted to SiO2, WO3, 7.5% Fe-WO3, 7.5% Fe-WO3/SiO2-50, and 7.5% Fe-WO3/SiO2-20.

Characterisation

X-ray diffractometer (XRD, PANalytical X’Pert PRO MPD, UK) with λ of Cu Kα radiation (1.541 Angstrom) at 40 kV/30 mA was used for determining the phase confirmation and crystal structures of the as-synthesised NPs samples. The detector was detected a 2θ range of 10–70ο with 0.04° s−1 of scanning rate. Field emission scanning electron microscope (FE-SEM; JEOL JSM 7800F, Japan) was investigated to capture 3D shapes, and particles micrograph, and size of sample. In addition, energy-dispersive X-ray spectroscope (EDX, Horiba–Hitachi, Japan) integrated with of SEM was indicated the dispersing of elements composition. The high-resolution transmission electron microscope (HRTEM; Tecnai G20, USA, 200 kV acceleration) was defined the microstructural details particularly including the precise sizes of 2D NPs, morphology, and polycrystalline nanostructure of the samples. A diffuse reflectance UV–visible spectrophotometer (DRS-UV–Vis spectrophotometer, Shimadzu 3101-PC, Japan) combined with integrating sphere (ISR-260) was recorded the DRS spectra against BaSO4 at λ of 200–1200 nm. X-ray photoelectron spectroscope (XPS; PHOIBOS analyser, Germany) was utilised to evaluate the surface oxidation states and chemical composition of the obtained materials by applying Al Kα radiation at 1400 eV. All absolute binding energy (B.E.) of XPS spectra was calibrated by C 1s at the peak of 284.6. A N2 gas adsorption equipment analyser (Micromeritics 3FleX, USA) was determined the Brunauer–Emmett–Teller (BET) surface area, pore volumes, and pore sizes at the vacuum condition after the degassing of the sorption test. The photoluminescence (PL) spectrophotometer excited with 345 and 525 nm light sources were used for analysing the emission wavelength (PerkinElmer LS-45 photoluminescence, USA) manipulated to report PL spectra of the NPs semiconductors. A zetasizer (ZS Malvern, UK) was used to measure the point of zero charge (PZC) of the optimal photocatalyst.

Photocatalytic reduction experiments

Following the standard procedure, 0.10 g of the catalyst was suspended in 100.0 mL of 20.0 mg·L−1 Cr6+ solution (ICP grade). The solution’s pH was then adjusted to 3.0 using 0.10 M HClO4 and 0.10 M NaOH. Prior to light exposure, the mixture was continuously stirred in the dark for 30 min to reach adsorption–desorption equilibrium. Subsequently, the solutions were irradiated using a 50-W halogen lamp (12 V, Phillips, Netherlands) with a light intensity of 364 W.m−2. At specific time intervals, 4.0 mL of the reaction suspension was withdrawn and filtered through a 0.22-μm micro-syringe nylon membrane (Pro Filter, China). The concentration of Cr6+ after reduction was determined colourimetrically using 1,5-diphenylcarbazide (99.0%, Loba Chemie) by measuring the characteristic UV–Vis absorption peak at 554 nm, detected by a PG-92 + UV–Vis spectrophotometer (Germany). The %PE was calculated using Eq. 1 in our previous work [27]:

where C0 is the initial concentration (mg L−1), and Ct is the concentration at time (mg L−1). The photocatalytic kinetic reaction was investigated using the pseudo-first-order kinetic model of Eq. 2 as follows:

where kt represents the apparent pseudo-first-order rate constant (min−1).

Furthermore, the reusability of superior nanocomposite catalyst compared with other NPs catalysts was also evaluated towards the photoreduction of Cr6+ solution for 5 cycles under the same ambient. In each cycle, to investigate the stability of the binary NPs catalyst. The non-magnetic sample was centrifuged the supernatant after first cycle run, sedimented, and washed by. After each cycle, the catalyst particles were recovered by centrifugation and then washed with 95% ethanol and hot water DI water (70 °C) for 3 several times [28]. The photocatalyst was then dried at 60 °C for 12 h in an air oven and then ground to a fined power. Subsequently, the catalyst was immersed and dispersed into a fresh Cr6+ solution prior to the next run. After 5 cycle tests, the dried precipitate photocatalyst had demonstrated the stability and recyclability against the chemical and photocorrosive property. The structural and phase crystallinity of reused catalyst was confirmed by the FE-SEM and XRD characterisation. In addition, Inductively Coupled Plasma-optical emission spectroscope (ICP-OES; PerkinElmer-4300 DV) was confirmed to determine Fe ions leaching in the supernatant Cr6+ solution.

Results and discussion

Crystal structure

The XRD patterns of all synthesised photocatalysts are shown in Fig. 2a, with the broad peak at 22.19° corresponding to amorphous SiO2 (JCPDS No. 39–1425) [29]. The XRD pattern of WO3 exhibited characteristic peaks at 23.08°, 23.58°, 24.31°, 28.08°, 34.12°, and 49.80°, which could be assigned to the (002), (020), (200), (122), (202), and (132) crystalline planes of monoclinic WO3 (JCPDS No. 43–1035) [30]. Moreover, when loading nanosized SiO2 into the WO3 crystal structure, the three main peaks of (002), (020), and (200)–of WO3 were deconstructed and broadened. Consequently, there were only two peaks at 23.10° while the Fe-WO3 doping sample shifted to the lower angle (− 0.2°). The radii compared with the pristine WO3 pattern could be noticed, as illustrated for 7.5% Fe-WO3/SiO2-20 (Fig. 2b). Additionally, Fig. 2c illustrates the XRD pattern of the (020) peak of WO3 (2θ ~ 33.2°–34.1°). The peaks split into three peaks, and the (202) peak was aligned at 34.10 while the Fe-WO3 doping sample shifted to the lower angle (− 0.2°). The deviation values of the Fe-WO3 samples decreased towards lower angles compared with the pristine WO3 pattern. This could be attributed to the ionic radii of the lattice coordinated Fe3+ and W6+ ions and the substitution of the latter with the former because the ionic radii of Fe3+ (64 pm) and W6+ (62 pm) were very similar [31]. In the meantime, the two broad peaks of the nanocomposite catalysts (20% and 50%) greatly collapsed, causing the (202) peak’s strength to decrease by 10%. Furthermore, when SiO2 was added, the XRD diffractogram of Fe-WO3/SiO2-20 showed noticeably less crystallinity than the pristine monoclinic WO3 diffraction pattern. As 20% and 50% SiO2 loading into the WO3 crystal structure occurred, it was evident that the normalised intensities of various peaks collapsed and disappeared, generating the emerging phase. The presence of SiO2 NPs combination was noticeable in the X-ray diffraction patterns of the Fe-WO3, Fe-WO3/SiO2-20, and Fe-WO3/SiO2-20 composite samples, which demonstrated a decrease in crystallinity degree and a lower peak intensity in the overall diffraction peaks [32]. Consequently, XRD diffraction peak might be attributed to the emergence of recrystallisation between amorphous SiO2 NPs and WO3. Moreover, it supposes that the peaks disappeared, the intensities decreased, and that broadening peaks at 2θ of approximately 23.9° and 33.42°, respectively, formed and initiated the combination of two broadening peaks (Fig. 2b and c). This possibility of SiO2 covering intensity reduced, and some peaks disappear and might be formed to the new phase. Secondly, there is the possibility for SiO2 to impregnate the WO3 surface because the amorphous SiO2 particles might interact or disturb the lattice planes of WO3 crystal structure [33]. The crystallite sizes of the obtained samples calculated from Scherer’s equation [34] are shown in Table 1. Specifically, Fe-WO3/SiO2-50, Fe-WO3/SiO2-20, Fe-WO3, WO3, and SiO2 products have crystallite sizes of 16.4, 18.8, 21.7, 24.3, and 6.47 nm, respectively. It is evident that Fe-WO3/SiO2-20 has a drastically smaller scale compared to pure WO3. This observation supported the above assumption that the loading of Fe3+ ions and SiO2 can inhibit WO3 grain growth, thereby resulting in a smaller crystalline particle size [35].

DRS and UV–Vis spectra study

The Kubelka–Munk (KM) absorption spectra of bare WO3, Fe-WO3, and Fe-WO3/SiO2-20 photocatalysts are shown in Fig. 3. A small shift at the absorption onset and broadening of the absorption tail towards visible light region were observed upon doping WO3/SiO2 with Fe3+. The KM absorption spectra were calculated using Eq. 3:

where R∞ is the absolute diffuse reflectance for an infinitely thick sample. The UV–Vis DRS spectrum of amorphous SiO2 exhibited very weak absorption intensity (Fig. 3a inset), whereas the ionic WO3 NPs samples displayed high absorption intensity, as shown in Fig. 3a. The band gap energy (Eg) of the catalysts can be obtained as illustrated in Fig. 3b and calculated using Eq. 4 as our latest work as follows:

where α is linear absorption coefficient, h is the Planck’s constant, υ is light frequency, A is the proportionality constant, and Eg is the band gap energy. The power of parenthesis is ½ for direct band gap WO3 semiconductor, respectively, reported in Table 1.

Attribution to intrinsic to the band gap absorption can be determined by a linear extrapolation to the energy axis as shown in Fig. 3b. From the band gap energy values obtained by the intercept X–Y of the DR-UV–Vis spectra (Fig. 3b) were ca. 2.83, 2.76, 2.70 eV for WO3, Fe-WO3, and Fe-WO3/SiO2-20, respectively. The lowest band gap energy of photocatalyst is received from 7.5% Fe-WO3/SiO2-20 (2.70 eV). The significant redshift of the light absorption range upon added SiO2 and Fe3+ metal ions amount in the nanocomposite samples corresponds well with the reduced band gap energy. The7.5% Fe-WO3 and 7.5% Fe-WO3/SiO2-20 band gap decrease of ca. 0.7 and 1.3 eV compared with the pure WO3, respectively. These results can be described the effect of Fe3+ ion doping into the WO3 crystal structure on the photocatalytic samples, indicating the visible light response of these samples, which led to the abundant generation of electron–hole pairs and, consequently, improved photocatalytic activity [36]. Moreover, SiO2 might be disturbed Fe-WO3 crystal structure resulting in the drastically decreased the Eg of nanocomposite sample. The calculated crystallite sizes, band gaps, and textural properties of the prepared samples.

In addition, the N2 absorption–desorption curves of the 7.5% Fe-WO3/SiO2-20 nanocomposite and the corresponding pore size distribution are shown in Fig. 4. The isotherms of the Fe-doped WO3 nanostructures can be categorised as a typical type IV [37], with hysteresis loops observed in the relative pressure (P/P0) of 0.99. The total pore volume of the 7.5% Fe-WO3/SiO2-20 sample was calculated as 0.227 cm3 g−1. The pore size distribution of 7.5% Fe-WO3/SiO2-20 obtained from the adsorption branch was placed at ~ 16.0 nm, as shown in the inset of Fig. 4. The 7.5% Fe-WO3/SiO2-20 catalysts were confirmed to be mesoporous materials. SiO2 exhibited a very high BET SSABET of 138.10 m2 g−1, whereas the undoped WO3 had the lowest value of 7.68 m2·g−1 among all the prepared NP products. However, the SSABET of 7.5% Fe-WO3/SiO2-50 became smaller than that of 7.5% Fe-WO3/SiO2-20. As shown in Table 1, the crystallite size of pure WO3 was larger than either 7.5% Fe-WO3, Fe-WO3/SiO2-20, or Fe-WO3/SiO2-50. After doping with Fe3+, the SSABET of 7.5% Fe-WO3 improved slightly to 8.39 m2 g−1. Incorporating 20 wt% of SiO2 into Fe-WO3 significantly increased the SSABET to 50.38 m2 g−1; however, further addition of SiO2 to 50 wt% decreased the SSABET to 21.29 m2 g−1. It might be possibly due to SiO2’s ability inhibited WO3 grain growth and disturbing the crystalline structure of monoclinic WO3 resulting in smaller crystalline particles upon loading Fe3+ and SiO2 [38]. The results suggested that the optimum loading of SiO2 was 20 wt%, as the large specific surface area, the larger pore volume than pure WO3, and the small particle size could enhance the adsorption of Cr6+. Thus, the raising Cr6+ photocatalytic removal performance had revealed [39].

Morphology and microstructure

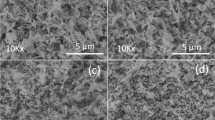

The morphologies and microstructures of selected nanomaterials were imaged as (i) SEM and EDS as shown in Fig. 5a–e and (ii) TEM micrographs in Fig. 6a–i, respectively. The microstructures of the samples are shown in Fig. 5. An agglomeration of small SiO2 NPs is distinguished in the SEM image in Fig. 5a, whereas irregular rod-like WO3 NPs, with an average diameter of 50 nm, can be seen in Fig. 5b. Figure 5e displays the EDS spectra of the 7.5% Fe-WO3/SiO2-20 nanosized catalyst, with the elements W, Si, O, and Fe presenting as expected. Regarding elemental distribution, a binary 7.5% Fe-WO3/SiO2-20 heterojunction nanocomposite comprising the elements described above was homogeneously distributed in the sample. These results indicate the coexistence of Fe, as well as intimate contact between the component materials, confirming the presence of a binary Fe-WO3/SiO2 heterojunction. The SAED and HRTEM images in Fig. 6b–c reveal the non-crystalline nature of SiO2, agreeing with its broad XRD peak in Fig. 2a. By contrast, WO3 (Fig. 5d) exhibited a rod-like shape, with particle sizes in the range of 60–80 nm. Referring to Fig. 6d–f, the polycrystalline characteristic of WO3 was confirmed from the SAED ring pattern and lattice fringes of 0.21, 0.20, and 0.30 nm belonging to the (020), (200), and (110) crystal planes of monoclinic WO3, respectively. Pore size is a component of scaffolds, with the pores providing a region to which cells can adhere or become attached (EDS) [40]. Furthermore, TEM and HRTEM micrographs, as well as SAED patterns (Fig. 6), were obtained to reveal the particle sizes and internal microstructures of the samples (Fig. 6a–f). Regarding 7.5% Fe-WO3/SiO2-20 NPs (Fig. 6g–i) and SiO2 embedded in irregular WO3 NPs, electron diffraction patterns (SAED) revealed the particle sizes and internal microstructures of the NPs of WO3, with an average diameter of 10–20 nm.

XPS analysis

XPS analysis was investigated to obtain the oxidation states and chemical composition of WO3, pure SiO2, and 7.5% Fe-WO3/SiO2-20 nanostructures. Two intense spectra of the W 4f core level of pure WO3 and 7.5% Fe-WO3/SiO2-20 are exhibited in Fig. 7a. As for pure WO3, Fig. 7a displays both main peaks shown at 38.1 and 36.0 eV, corresponding to 4f5/2 and 4f7/2 [41], respectively. A shift of ca. 0.2 − 0.3 eV towards the lower B.E. was observed for the Fe-doped WO3/SiO2 sample. Therefore, this negative shift might have occurred from the increased in electron density due to the substitution of W6+ by Fe3+ ions [42]. The B.E. of O 1s of pristine WO3 and Fe-WO3/SiO2-20 nanocomposite (Fig. 7b) was assigned to two spectra in the comparison purpose. XPS spectra of W 4f and O 1s between the single-phase WO3 (W–O–W) and WO3/SiO2 nanocomposite indicated the different positions of B.E. peaks of couple samples, possibly due to the formation of the W–O–Si bond [43]. A similar negative shifted of the O 1s peak was also observed attributed to the rise of the lower-level occupancy of oxygen conduction band [44]. Figure 7c represents the single Si 2p peaks at 103.9 eV for pure SiO2, corresponding to Si4+ [45]. The lattice oxygen species at ca. 531–532 eV [46] and the adsorbed water/hydroxyl species at ca. 532–533 eV [47] exhibited a negative shift to ~ 530.5 eV in the Fe-WO3/SiO2 catalyst, as revealed in Fig. 7c [48]. Figure 7d reveals the quite spectrum for Fe 2p in Fe-WO3/SiO2. The predominant peaks of 2p1/2 occurred at B.E. of 724.3 eV whereas 2p3/2 marked at 711.7 eV, respectively [49]. The three peaks between 708.0 and 718.0 eV were deconvoluted to Fe 2p3/2. Lattice Fe3+ ions located at the peaks of ~ 710.0, 711.7, and ~ 714.9 eV, whereas for the Fe2+ ions peaks lied at 710.0 eV (2p3/2) and 724.3 eV (2p1/2) in Fe2O3 [50], respectively. The B.E. shift of XPS results could be ascribed to the divergent values between of Fe and W electronegativity (EN) [51]. For the EN of Fe and W comparison, compared with the Fe–O–Fe bond, bonding between Fe and O could have been slightly enhanced in the Fe–O–W bond, hence resulting in the increase the redshift B.E. of the Fe3+ peaks. Conversely, the bonding between W and O was slightly decreased in Fe–O–W opposed to W–O–W. From aforementioned, XPS peak shifts slightly because W6+ cations were replaced by Fe3+. Thus, Fe–O–W bond was formed. Particularly, the metal doping and intercalated doping in WO3 express enhanced crystal structure in preference to surface modification [52].

Photocatalytic reduction activities and kinetics studies

The photocatalytic reduction of the concentrations was performed by varying the overall synthesised photocatalysts. The SiO2, WO3, 7.5% Fe-WO3, 7.5% Fe-WO3/SiO2-20, and 7.5% Fe-WO3/SiO2-50 heterostructures were obtained over 50 ppm of the Cr6+ concentration with a photocatalyst dosage of 1.0 g·L−1 and a pH of 3.0 under 90 min of visible light illumination at room conditions. Figure 8a represents the photoreduction of Cr6+ efficiencies over visible light illumination over overall catalysts, and the first-order rate constants (kt) were calculated and are similarly displayed in Fig. 8b. Moreover, the effect of photocatalyst dosage, pH of the suspension was also evaluated via the optimal result from %PE by using various type of photocatalyst. Furthermore, the usability test of photoreduction via the superior PE photocatalyst had studied together. The deactivation of used catalyst was confirmed by XRD patterns and FE-SEM after 5 cycles run.

The evaluation of the %PE and kt of the Cr6+ reduction with the error bars of the synthesised photocatalysts is illustrated in Fig. 8a and b, respectively. Prior to %PE determination, 7.5% Fe-doped WO3/SiO2-20 demonstrated the highest Cr6+ removal activity of 91.1% within 90 min. The improved photocatalytic efficiency of the WO3/SiO2 nanocomposite was due to the presence of SiO2 NPs. As shown in Fig. 8a, it could be assumed from the evidence that by adding SiO2 to the composite, SiO2 acted as an adsorbent, which sufficiently enlarged the surface area of WO3, representing the main role of SiO2 as a high-surface-area catalyst support to generate well-dispersed Fe-WO3 NPs. The increased surface area of WO3 can facilitate the adsorption of organic pollutants through the formation of more useful adsorption-degradation sites [53]. Additionally, an Fe-WO3/SiO2 nanocomposite is a powerful photocatalyst for separating photogenerated electrons and holes, which is significant for photocatalytic activity. However, further adding SiO2 reduced the activity to 81.0%, presumably since the composite catalyst contained silicon as the main element. Silicon can significantly decrease the crystallinity of WO3 in composite materials by acting as a WO3 grain growth inhibitor [54]. The calculated results of the first-order rate constant (kt) versus irradiation time are shown in Fig. 8b and listed in Table 2. The largest rate constant of 22.5 × 10–3 min−1 was observed for the 7.5% Fe-WO3/SiO2-20 nanocomposite, which was larger than that of 7.5% Fe-WO3 without SiO2 (10.9 × 10–3 min−1). Thus, the 7.5 mol% Fe-doped WO3-20 catalyst was chosen for further investigation of the effects of various parameters on photoreduction efficiency. Furthermore, an evaluation of the photocatalytic reduction of the Cr6+ solution influenced by two factors, namely the photocatalyst dosage and the pH of the suspension, was carried out. Prior to %PE determination, the 7.5% Fe-doped WO3/SiO2-20 demonstrated the highest Cr6+ removal activity at 91.1% within 90 min.

Effect of the photocatalyst dosage

The photocatalytic reduction of Cr6+ was conducted with the 7.5% Fe-WO3/SiO2-20 photocatalyst by varying the catalyst dosages at 0.25, 0.5, 1.0, and 1.5 g L−1, and the rate constant (kt) was also evaluated. As the % PE and kt results in Fig. 9a–b illustrate, the %PE of the Cr6+ solution (50 ppm) decreased in the following order: 1.0 g L−1 (91.2%) > 1.5 g L−1 (86.8%), > 0.5 g L−1 (60.2%), and > 0.25 g L−1 (38.9%). The results revealed that with catalyst loading increments from 0.25 to 1.0 g, an increase in %PE was found, and after further increasing catalyst loading to 1.5 g·L−1, % PE was reduced to 86.6%. This was due to the increase in the catalyst content, which reached a higher quantity of active sites on the photocatalyst surface for the photoreduction reaction. However, upon increasing the catalyst loading to 2.0 g L−1, the photodegradation performance precipitously decreased due to the agglomeration and sedimentation of the catalyst particles, which caused an increase in the particle size and decrease in specific surface area, thus leading to a decrease in the number of active sites [55]. The excess catalyst content may have led to opaqueness and turbidity, possibly blocking the irradiation light, and increasing light scattering of the catalyst particles [56].

Effect of the pH of the suspension

The photocatalytic reduction performance of Cr6+ with the 7.5% Fe-WO3/SiO2-20 photocatalyst by changing the pH of the suspension to 3.0, 5.0, 7.0, and 9.0 was investigated, as shown in Fig. 10a–b. The optimum pH was 3.0, as it reached the highest reduction activity of 91.9% and 22.3 × 10–3 min−1 kt compared with suspensions with higher pH. The zeta potential value versus the pH of the catalyst suspension is displayed in Fig. S2. It can be seen that the PZC value of the 7.5% Fe-WO3/SiO2-20 photocatalyst suspension was approximately − 0.37 mV at pH 5.3. The catalyst surface revealed a negative charge below pH 5.3, and the electrostatic repulsion between the negative charge of the catalyst particles and the positive Cr6+ ions suggested the improvement of photocatalytic reduction activity [57]. Consequently, the surface of the nanocomposite was negatively charged at pH 3; therefore, the adsorption and enhanced photocatalytic reduction of the Cr6+ ions were strongly beneficial because of the strong electrostatic repulsion and charge attraction between the charges of the photocatalyst particles and the Cr6+ cations [58]. Therefore, the optimum condition of photocatalytic reduction of 50 ppm of the Cr6+ solution with the 7.5% Fe-WO3/SiO2-20 photocatalyst and 1.0 g L−1 catalyst loading at pH 3 illustrated the greatest efficiency for 90 min of visible light illumination.

The result from the cycling runs of the photoreduction of the Cr6+ solution with the 7.5% Fe-WO3/SiO2-20 nanocomposite under visible light irradiation and a catalyst loading of 1.0 g L−1 are demonstrated in Fig. 11a. The %PE demonstrated reduced only 9.3% after 5 cycle runs but fresh and but the spent-catalysed and WO3 products were also compared five times of 7.5% Fe-WO3/SiO2-20 sample a prepared fresh sample including the change XRD patterns crystallinity and 3D microstructure result from FE-SEM results. The XRD pattern of 5-spent time catalyst was demonstrated the good crystallinity, and XRD pattern of the used 7.5% Fe-WO3/SiO2-20 nanocomposite was found to decrease in the (202) peak, with an intensity of ~ 14% as shown in Fig. 11b. Meanwhile, Fig. 11c shows a minor change in noise pattern was observed the of the agglomeration of SiO2 NPs together with the rod-like WO3 like the fresh one in comparison with the un-catalysed nanocomposite.

However, the 5-spent times runs of the optimal catalyst observed a minor change of the photoreduction efficiency. There result indicates the 7.5% Fe-WO3/SiO2-20 does not suffer from the photocorrosive and chemical corrosive properties during the reduction towards Cr6+ reactions. Moreover, the leaching of Fe ions from the 7.5% Fe-WO3/SiO2-20 was not found in the supernatant of Cr6+ solution after determined by ICP-OES analysis [31]. These results demonstrate that the heterostructure photocatalyst exhibits stability against both photocorrosion and chemical corrosion in acidic conditions. Consequently, it offers superior stability and efficient reusability for removing Cr6+ effluent by using a retrievable Fe-doped WO3/SiO2-20% nanocomposite catalyst. This enhanced performance can be attributed to the inhibition of electron–hole recombination through the Fe3+ dopant and an increase in the active site surface after SiO2 loading [58]. Typically, the separation of e/h+ pairs occurs upon irradiation; however, e−/h+ is easily recombined without the charge carrier separation properties of a heterojunction. The PL spectra of SiO2, Fe-doped WO3, Fe-doped WO3/SiO2-50%, and 7.5% Fe-WO3/SiO2-20 are illustrated in Fig. S3. It is evident that 7.5% Fe-WO3/SiO2-20 emitted the lowest PL emission intensity in comparison to the other materials. This decrease in the PL spectra intensity indicates that the 7.5% Fe-WO3/SiO2-20 nanocomposite serves as the optimal catalyst, effectively suppressing electron–hole recombination in contrast to Fe-doped WO3, pure WO3, and pure SiO2.

Based on the results presented in Fig. 12, electron generation was observed to increase at the conduction band (CB) of the 7.5% Fe-doped WO3/SiO2-20% heterostructure. Inhibiting electron–hole recombination intensified the photoactivity of the WO3 catalyst. This, in turn, resulted in enhanced photoreduction and modified photocatalysis efficiency [59]. Table 3 compares the photocatalytic reduction of Cr6+ or organic dye activity of the prepared Fe-doped WO3 and WO3/SiO2 in various nanocomposites was compared with previous reports [13, 54, 60,61,62,63].

The photocatalytic reduction performance of a photocatalyst depends on the intrinsic properties of NPs in the photocatalyst, including the band gap energy of each photocatalyst, light source, type of reactant, and the initial concentration of Cr6+ dye [65]. Song et al. [61] had explained that the generated electrons could be excited within the visible light spectrum, contributing to the practical enhancement of photocatalytic performance, as shown in Eqs. 5–8:

The potential mechanism for e−/h+ pairs separation at the 7.5% Fe-WO3-SiO2-20 surface under visible light irradiation is displayed in Fig. 12. As the results from calculated Eg result from Fig. 3b, the conduction band (CB) and valence band (VB) potentials of WO3 and SiO2 can be determined using Eq. 9 in our previous work:

where χ is the absolute electronegativity of the semiconductor (χ is 6.59 and 9.20 eV for WO3 and SiO2, respectively), EC is the scaling factor relating the hydrogen electrode scale (NHE, bulk) to the absolute vacuum scale (AVS) (ca. 4.5 eV vs. NHE), and Eg is the band gap of Fe-WO3/SiO2-20 (2.70 eV) and SiO2 (4.19 eV) obtained in this study. Using the equations mentioned above, the CB position and VB edges of Fe-WO3/SiO2-20 were calculated to be 0.74 and 3.44 eV, respectively. For SiO2, the VB and CB positions potentials were determined to be 2.60 and 6.79 eV, respectively. However, photoreduction was only achievable at the CB of Fe-WO3/SiO2-20 due to visible light generated only a single WO3 semiconductor, which aligned the band gap energy. Moreover, the oxidation of h+ could not oxidised with the hydroxide ions and water molecules in the aqueous Cr6+ solution. Therefore, the potential of the accumulated electrons on CB of WO3 was located at a lower band position than the reduction potential of O2/O2· (0.33 V vs. NHE) [66]. The results indicated an increase in the generation of electrons in the CB of the heterostructure and highlighted its crystallinity, adequate morphology, specific surface area, and extrinsic adsorption capacity [36]. The optimum loading of SiO2 in Fe-doped WO3 involved a concentration of 20 wt%. SiO2 supporter acted great supporter to WO3 NPs alike the type III heterojunction, and migration of charge carriers follows a similar pathway as in type II, resulting in no transference. However, SiO2 could help to trap Cr6+ ions on the interface and around the large surface area and high pore volume consisting of active surface under acidic condition. The photoinduced electrons initially reacted with the Cr6+ present near the periphery of the nanocomposite catalyst, as shown in Eq. 8. As shown in Eq. 6, these highly reactive protons and electrons cumulatively reduce Cr6+ to Cr3+. The purpose of the possible mechanism of the photocatalytic reduction of Cr6+ by the 7.5% Fe-WO3/SiO2-20 nanosized composite catalyst is presented in Fig. 12. The mechanism of (superoxide) radicals [66] involves the generation of Fe3+ ions; consequently, the reduction was controlled by electron capture. Furthermore, a smaller band gap implies a higher quantum efficiency for the material, enabling a greater number of electrons to cross the forbidden energy gap (band gap) into the CB. These electrons can be excited by photons in the visible light region, leading to an enhanced photocatalytic performance and abundant H2O molecules, producing hydroxyl radicals (·OH) and protons (H+).

The relative reduction potential of Fe3+/Fe2+ (Eq. 8) had a higher positive value than W6+/W5+ (Eq. 7). Thus, the Fe3+ doping in WO3 could prevent the self-corrosion of W6+. Then, the three generated e- reduced Cr6+ to Cr3+ as shown in Eq. 6. The standard electrode potential of Fe3+ (E0 cell = 0.77 V NHE) was higher than the CB potential, suggesting that a side photoreduction reaction also did not occur via the capture of e− by Fe3+ ions (Eq. 8). Meanwhile, photocatalytic reduction at the CB of the WO3 surface particles occurred in the presence of visible light, and the transferred electrons from SiO2 generated electrons (e−) and supplied the valence band with holes (h+). In an aqueous system, h+ reacts with the photocatalytic reduction of toxic Cr6+ to less toxic Cr3+. Thus, Cr6+ ions diffused through the medium, representing the proposed mechanism of the photocatalytic reduction of Cr6+ with the 7.5% Fe-WO3/SiO2-20 nanocomposite catalyst [68].

Conclusions

A visible light-driven 7.5% Fe-doped WO3/SiO2 nanocatalyst was successfully synthesised via a facile hydrothermal process coupled with the impregnation method. By applying 1.0 g L−1 of the 7.5% Fe-doped WO3/SiO2 composite catalyst for an illumination time of 90 min, a high pseudo-first-order kinetic rate led to an achievement of 91.1% photocatalytic activity. Photocatalytic activity depends on the intrinsic properties of a photocatalyst, such as a narrowed band gap and a small size. This study demonstrated a high degree of photocatalytic reduction of a hexavalent Cr6+solution was achieved in this study. The reusable catalyst continued to exhibit high activity after a five-cycle run. Thus, we successfully synthesised a composite with enlarged activity, which can be attributed to three factors: (i) an extended visible light absorption region with narrowed band gap energy, (ii) a greater specific surface area (51.38 m2 g−1), and (iii) inhibition of the recombination of e−–h+ pairs, leading to electron charge separation due to the interactions between WO3 and SiO2 in the composite and electron trapping by doped Fe3+ ions. This was confirmed by the lowest absorption values obtained in the PL results. Therefore, the novel modified nanocomposite catalyst reported in this study may be promised for various environmental applications.

Data availability

All generated and analysed data in this research included within the article can be used with no concern or Ethics. Additional Supplement Information 1 is attached file in the system.

References

Mohan D, Pittman CU Jr. Activated carbons and low cost adsorbents for remediation of tri- and hexavalent chromium from water. J Hazard Mater. 2006;137:762–811.

Golonka MC. Toxic and mutagenic effects of chromium (VI) a review. Polyhedron. 1995;15:3667.

Irshad MA, Irfan A, Zaki EM, et al. Enhancing chromium removal and recovery from industrial wastewater using sustainable and efficient nanomaterial: a review. Ecotoxicol Environ Saf. 2023;263: 115231.

Gonzalez-Borrero PP, Sato F, Medina AN, et al. Optical band-gap determination of nanostructured WO3 film. Appl Phys Lett. 2010;96:061909.

Zheng J, Haider Z, Van T, et al. Tuning of the crystal engineering and photoelectrochemical properties of crystalline tungsten oxide for optoelectronic device applications. Cyst Eng Comm. 2015;17:6070.

Khanna A, Shetty V, et al. Solar light induced photocatalytic degradation of reactive Blue 220 (RB-220) dye with highly efficient Ag@TiO2 core–shell nanoparticles: a comparison with UV photocatalysis. Sol Energy. 2014;99:67.

Nasuhoglu D, Yargeau V, Berk D. Photo-removal of sulfamethoxazole (SMX) by photolytic and photocatalytic processes in a batch reactor under UV-C radiation (λmax = 254 nm). J Hazard Mater. 2011;186:67.

Wu Q, Xue S. Photocatalytic reduction of Cr(VI) with TiO2 film under visible light. Appl Catal B. 2013;142–143:142.

Ansari SA, Khan MM, Ansari O, et al. Nitrogen-doped titanium dioxide (N-doped TiO2) for visible light photocatalysis. New J Chem. 2016;40:3000.

Chang X, Sun S, Yin Y, et al. Solvothermal synthesis of Ce-doped tungsten oxide nanostructures as visible-light-driven photocatalysts. Nanotechnology. 2011;22: 265603.

Tianjun N, Yang Z, Liu G, et al. N, Fe-doped carbon dot decorated gear-shaped WO3 for highly efficient UV-Vis-NIR-driven photocatalytic performance. Catalysts. 2020;10:416.

Heri S, Alkian I, Mukholit M, et al. Analysis of Fe-doped ZnO thin films for degradation of rhodamine b, methylene blue, and Escherichia coli under visible light. Mater Res Express. 2021;8: 116402.

Kumari H, Suman S, Ranga R, et al. A review on photocatalysis used for wastewater treatment: dye degradation. Water Air Soil Pollute. 2023;234:349.

Lopez A, Marin M, Bosca F, et al. Synthesis and mechanistic insights of SiO2@WO3@Fe3O4 as a novel supported photocatalyst for wastewater remediation under visible light. Appl Mater Today. 2023;33: 101879.

Balakumar V, Baishnisha A. Rapid visible light photocatalytic reduction of Cr6+ in aqueous environment using ZnO-PPy nanocomposite synthesized through ultrasonic assisted method. Surf Interfaces. 2021;23: 100958.

Zhang G, He H, Lu J, et al. Preparation of ZnIn2S4 nanosheet-coated CdS nanorod heterostructures for efficient photocatalytic reduction of Cr(VI). Appl Catal B. 2018;232:164.

Islam B, Furukawa M, Kaneco S, et al. Formic acid motivated photocatalytic reduction of Cr(VI) to Cr(III) with ZnFe2O4 nanoparticles under UV irradiation. Environ Technol. 2019;42:2740.

Pudkon S, Kaowphong S, Hutchings G, et al. Enhanced visible-light-driven photocatalytic H2 production and Cr(VI) reduction of a ZnIn2S4/MoS2 heterojunction synthesized by the biomolecule-assisted microwave heating method. Catal Sci Technol. 2020;10:2838.

Pinto F, Wilson A, Kafizas A, et al. Systematic Exploration of WO3/TiO2 Heterojunction phase space for applications in photoelectrochemical water splitting. Phys Chem C. 2022;126:871.

Yadav J, Singh JP. WO3/Ag2S type-II hierarchical heterojunction for improved charge carrier separation and photoelectrochemical water splitting performance. J Alloys Compd. 2022;925: 166684.

Yang L, Xiao Y, Liu SN, et al. Photocatalytic reduction of Cr(VI) on WO3 doped long TiO2 nanotube arrays in the presence of citric acid. Appl Catal B: Environ. 2010;94:142.

Babyszko A, Wanag A, Sadłowski M, et al. Synthesis and characterization of SiO2/TiO2 as photocatalyst on methylene blue degradation. Catalysts. 2022;12:1372.

Phanichphant S, Nakaruk A, Chansaenpak K, et al. Evaluating the photocatalytic efficiency of the BiVO4/rGO photocatalyst. Sci Rep. 2019;9:16091.

Paola A, Lopez E, Marci G, et al. A survey of photocatalytic materials for environmental remediation. J Hazard Mater. 2012;211–212:3.

Xie Y, Liu G, Cheng MJ. Crystal facet-dependent photocatalytic oxidation and reduction reactivity of monoclinic WO3 for solar energy conversion. J Mater Chem. 2012;22:6746.

Ramkumar S, Rajarajan GJ. Nitrogen-doped core–shell Fe/Fe3C@C nanocomposites for electromagnetic wave absorption. Mater Sci Mater Electron. 2016;27:1847.

Boonprakob N, Chen J, Inceesungvorn B, et al. Enhanced visible-light photocatalytic activity of g-C3N4/TiO2 films. J Colloid Interface Sci. 2014;417:402.

Mugumo R, Ichipi E, Shepherd M, Tichapondwa NM. Visible-light-induced photocatalytic degradation of rhodamine B dye using a CuS/ZnS p-n heterojunction nanocomposite under visible-light irradiation. Catalysts. 2023;13:1184.

Chang C, Zhu L, Fu Y, et al. Highly active Bi/BiOI composite synthesized by one-step reaction and its capacity to degrade bisphenol A under simulated solar light irradiation. Chem Eng J. 2013;233:305.

Lu R, Zhong X, Tang M, et al. Effects of sintering temperature on sensing properties of WO3 and Ag-WO3 electrode for NO2 sensor. R Soc open sci. 2018;5: 171691.

Chachvalvutikul A, Luangwanta T, Kaowphong S. Double Z-scheme FeVO4/Bi4O5Br2/BiOBr ternary heterojunction photocatalyst for simultaneous photocatalytic removal of hexavalent chromium and rhodamine B. J Colloid Interface Sci. 2011;603:738.

Acosta-Silva YJ, Nava R, Hernandez-Morales V, et al. Methylene blue photodegradation over titania-decorated SBA-15. Appl Catal B: Environ. 2011;110:108–17.

Rasalingam S, Peng R, Koodali R. Enhanced photocatalytic activity of W-doped and W-La-codoped TiO2 nanomaterials under simulated sunlight. J Nanomater. 2014;2014:195.

Kima K, Nam SK, Park JH, et al. Growth of BiVO4 nanoparticles on a WO3 porous scaffold: improved water-splitting by high band-edge light harvesting. J Mater Chem A. 2019;7:4480.

Shpak AP, Korduban AM, Medvedskij MM, et al. XPS studies of active elements surface of gas sensors based on WO3−x nanoparticles. J Electron Spectrosc. 2007;175:156.

Eichhorn SJ, Sampson WW. Relationships between specific surface area and pore size in electrospun polymer fibre networks. J R Soc Interface. 2010;7:641.

Wetchakun N, Wanwaen P, Phanichphant S, et al. Correction: influence of Cu doping on the visible-light-induced photocatalytic activity of InVO4. RSC Advs. 2020;10:37766.

Joseph CG, Taufic YH, Musta B, et al. Application of plasmonic metal nanoparticles in TiO2–SiO2 composite as an efficient solar-activated photocatalyst: a review paper. Front Chem. 2021;8: 568063.

Cui L, Wang Y, Kang S, et al. Facile preparation of Z-scheme WO3/g-C3N4 composite photocatalyst with enhanced photocatalytic performance under visible light. Appl Surface Sci. 2017;391:202.

Hirata S, Inoue A, Inada M, et al. Synthesis and adsorption-photodecomposition properties of mesoporous SiO2-TiO2/WO3 composite. J Ceram Soc Japan. 2021;129:464.

Chen S, Xiao Y, Xie W, et al. Facile strategy for synthesizing non-stoichiometric monoclinic structured tungsten trioxide (WO3−x) with plasma resonance absorption and enhanced photocatalytic activity. Nanomaterials. 2018;8:553.

Gui MS, Zhang WD, Su QX, et al. Preparation and visible light photocatalytic activity of Bi2O3/Bi2WO6 heterojunction photocatalysts. J Solid State Chem. 2011;184:1977.

Tao Y, Luca OD, Singh B. WO3–SiO2 nanomaterials synthesized using a novel template-free method in supercritical CO2 as heterogeneous catalysts for epoxidation with H2O2. Mater Today Chem. 2020;18: 100373.

Ghosh S, Acharya S, Tripathi D, et al. Preparation of silver–tungsten nanostructure materials for selective oxidation of toluene to benzaldehyde with hydrogen peroxide. J Mater Chem A. 2014;2:15726.

DePuccio D, Botella P, O’Rourke B, et al. Degradation of methylene blue using porous WO3, SiO2−WO3, and their Au-loaded analogs: adsorption and photocatalytic studies. ACS Appl Mater Interfaces. 2015;7:3.

Can F, Courtois X, Duprez D. Tungsten-based catalysts for environmental applications. Catalysts. 2021;11:703.

Fernandes E, Gomes J, Martins RC. Semiconductors application forms and doping benefits to wastewater treatment: a comparison of TiO2, WO3, and g-C3N4. Catalysts. 2022;12:1218.

Huang J, Tan G, Ren H, et al. Photoelectric activity of a Bi2O3/Bi2WO6–xF2x heterojunction prepared by a simple one-step microwave hydrothermal method. Appl Mater Interfaces. 2014;6:21041.

Sokolov A, Filatova E, Afanasev V, et al. Interface analysis of HfO2 films on (1 0 0)Si using X-ray photoelectron spectroscopy. J Phys D Appl Phys. 2009;42: 035308.

Wetchakun K, Wetchakun N, Sakulsermsuk S. An overview of solar/visible light-driven heterogeneous photocatalysis for water purification: TiO2- and ZnO-based photocatalysts used in suspension photoreactors. Int J Ind Chem. 2020;11:161.

Channei D, Inceesungvorn B, Wetchakun N, et al. Photocatalytic degradation of methyl orange by CeO2 and Fe-doped CeO2 films under visible light irradiation. Sci Rep. 2017;4:1.

El-Nemr MA, Aigbe UO, Ukhurebor KE, et al. Adsorption of Cr6+ ion using activated Pisum sativum peels-triethylenetetramine. Environ Sci Pollut Res. 2022;29:91036.

Brady RL, Southmayd D, Contescu C, et al. Surface area determination of supported oxides: WO3/Al2O3. J Catal. 1991;129:195.

Wang J, Ren J, Yao H, et al. Synergistic photocatalysis of Cr(VI) reduction and 4-chlorophenol degradation over hydroxylated α-Fe2O3 under visible light irradiation. J Hazard Mater. 2016;311:11.

Channei D, Chansaenpak K, Phanichphant S, et al. Synthesis and characterization of WO3/CeO2 heterostructured nanoparticles for photodegradation of indigo carmine dye. ACS Omega. 2021;6:19771.

Li Y, He H, Li J, et al. Fast photocatalytic degradation of dyes using low power laser-fabricated Cu2O–Cu nanocomposites. RSC Adv. 2015;5:46928.

Yu J, Xiang Q, Zhou M. Preparation characterization and visible-light-driven photocatalytic activity of Fe-doped titania nanorods and first-principles study for electronic structures. Appl Catal B Environ. 2009;90:595.

Samanta S, Srivastava R. Thermal catalysis vs. photocatalysis: A case study with FeVO4/g-C3N4 nanocomposites for the efficient activation of aromatic and benzylic C–H bonds to oxygenated products. Appl Catal B Environ. 2017;218:621.

Shi F, Bai L, Liu J, et al. Preparation and characterization of SiO2–WO3 composite aerogel by ambient pressure drying process. Adv Mat Res. 2012;534:205.

Feng M, Liu Y, Zhao Z, et al. The preparation of Fe doped triclinic-hexagonal phase heterojunction WO3 film and its enhanced photocatalytic reduction of Cr (VI). Mater Res Bull. 2019;109:169.

Song H, Li Y, Lou Z, et al. Synthesis of Fe-doped WO3 nanostructures with high visible-light-driven photocatalytic activities. Appl Catal B Environ. 2015;166–167:112.

Elias N, Ullah S, Perissinotto AP, et al. Thermally stable SiO2@TiO2 core@shell nanoparticles for application in photocatalytic self-cleaning ceramic tiles. Mater Adv. 2021;2:2085.

Luxmi V, Kumar A. Enhanced photocatalytic performance of m-WO3 and m-Fe-doped WO3 cuboids synthesized via sol-gel approach using egg albumen as a solvent. Mater Sci Semicond Process. 2019;104: 104690.

Venkatesh D, Anbalagan K. Interfacial charge transfer of hybrid (Fe3+/Fe2+)/SnO2/TiO2 composites for highly efficient degradation of chromium (VI) under ultra-violet light illumination via Z-scheme. Opt Mater. 2023;135: 113327.

Yu J, Xiang Q, Zhou M. Preparation, characterization and visible-light-driven photocatalytic activity of Fe-doped titania nanorods and first-principles study for electronic structures. Appl Catal B Environ. 2009;90:595.

Wood PM. The two redox potentials for oxygen reduction to superoxide. Trends Biochem Sci. 1987;12:250.

Funding

The research was financially supported by the 2023 Fundamental Fund of Thailand Science Research and Innovation (Grant-TSRI-No. 2168729) and Uttaradit Rajabhat University. The authors acknowledge Dr. Narong Chanlek for accessing and investigating XPS characterisation at the SUT-Nanotec-SLRI joint research facility.

Author information

Authors and Affiliations

Contributions

N. Boonprakob was involved in conceptualisation, investigation of the synthesis and characterisation of photocatalytic reduction studies, writing of the original draft, edition followed the comments and amendments and rewritten the manuscripts at end revision of the manuscript and funding acquisition. D. Channei was involved in conceptualisation, PL characterisation, and revision of the original draft of the manuscript. C. Zhao was involved in conceptualisation and editing of the draft, at end revision of the manuscript.

Corresponding author

Ethics declarations

Competing interests

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Boonprakob, N., Channei, D. & Zhao, C. High-performance photocatalytic reduction of Cr(VI) using a retrievable Fe-doped WO3/SiO2 heterostructure. Discover Nano 19, 22 (2024). https://doi.org/10.1186/s11671-023-03919-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-023-03919-0