Abstract

Quantum dot intermediate band solar cell (QD-IBSC) has high efficiency theoretically. It can absorb photons with energy lower than the bandgap of the semiconductor through the half-filled intermediate band, extending the absorption spectrum of the cell. However, issues in the IBSC, such as the strain around multi-stacking QDs, low thermal excitation energy, and short carrier lifetime, lead to its low conversion efficiency. In recent years, many efforts have been made from different aspects. In this paper, we focus on In(Ga)As QD-IBSC, list the experimental technologies used to improve the performance of the cell and review the recent research progress. By analyzing the effects of different technologies on conversion efficiency, the development direction of the In(Ga)As QD-IBSC in the future is proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sunlight has a spectral range of about 0.5–4 eV, but the traditional solar cells with a single bandgap can only utilize the short wave and the long part is completely wasted. According to a theoretical calculation, the energy conversion efficiency limitation of the single-junction solar cell, which was determined by Shockley and Queisser (SQ limit), is only 40.7% under full concentration light [1]. There are two main reasons why the cells can’t be more efficient. On the one hand, photons with energies lower than the band gap are not absorbed, making this part of energy unavailable. On the other hand, for photons absorbed, only the portion of the energy larger than the band gap of matrix is converted, and the other is wasted as heat [2]. To address the issue and increase the conversion efficiency of solar cells, the IBSC was proposed by A. Luque and A. Marti in 1997 [3]. It can absorb photons with energy lower than the band gap of the matrix through the IB and increases the short-circuit current density (Jsc) of the cells with open-circuit voltage (Voc) preserved, since the Voc is limited by the matrix band gap [4, 5]. The maximum conversion efficiency limit of the IBSC reaches 63.2% [6, 7]. At present, there are three main methods to realize the IB, including QDs, highly mismatched alloys, and bulk materials with deep-level impurities [8]. Among them, the QD-IBSC has received a lot of attention from researchers because it is easy to modify the band structure of the cell by adjusting size and density of QDs. Two conditions must be met to form a QD-IBSC: firstly, the IB must be half-filling to ensure that it can provide holes to the valence band (VB) and electrons to the conduction band (CB) [9]. Secondly, the CB, VB, and IB all have their independent quasi-Fermi levels (QFL), and only in this way will the maximum voltage be limited by the band gap of semiconductors [10, 11].

So far, many materials have been used as substrates for the cells, such as Si, InGaP, GaAs, and so on. For example, research on Si-based cells with Ge QDs shows that the absorption in the infrared region is enhanced, and the Jsc increases [12]. However, the QDs lead to the decrease in the effective band gap and a drop in Voc. More research focuses on III–V compound semiconductors at present, like InGaP, GaAs, etc., since most of them are direct bandgap semiconductors with strong light absorption, good radiation resistance, and low temperature coefficient. For instance, InGaP has a wide band gap, which means that a large energy difference can be obtained between the confined state in QDs and the CB [13, 14]. For InP/InGaP QD-IBSC, the thermal excitation energy is about 0.35 eV and it has a long carrier lifetime of 30 ns, which is more conducive to implement the two-step photon absorption process [15]. In(Ga)As/GaAs QDs based on S-K growth mode have been widely studied in semiconductor lasers, detectors, and other aspects [16,17,18,19], and the growing technology and material properties have been well mastered [20,21,22,23]. Therefore, In(Ga)As/GaAs are suitable to study the properties and performance of QD-IBSC. At present, much attention has been taken to the well-known system In(Ga)As/GaAs. And experimental results proved that there exists the two-step absorption process and the Jsc of the cell with QDs increases [24, 25]. Although it has been proved that it is feasible to absorb low energy photons through the IB and different kinds of QD-IBSCs have been tried, the results are less than satisfactory. The transition rate between the IB and the CB (~ 103 s−1) is typically less than that between the VB and the IB (~ 109 s−1) due to small solar cell power density, optical absorption cross section and density of QDs [26]. The energy difference between the IB and the CB is small, which results in serious thermal excitation at room temperature, so it not only reduces the absorption of long-wavelength photons, but also leads to the thermal coupling of the IB and the CB and the drop of the Voc. Research shows that it can be reduced by low temperatures and concentrated light [27]. There exists strain around QDs grown through Stranski–Krastanov (S–K) mode because of the lattice mismatch between the matrix and the QDs, which limits the growth of multiple layers of QDs. These are the two common problems in QD-IBSC. In addition to these, there are also problems like half-filling, short carrier lifetime and so on [28,29,30,31]. To solve these problems, researchers have made efforts from different aspects.

In this paper, we explain the principle of the IBSC and the process of thermal excitation and non-radiation recombination. Then, various technologies are introduced to solve the problems mentioned above, like Si doping, cap layer, size control, etc. Finally, we summarize the technologies investigated and the future development direction of QD-IBSC is proposed.

Principle of QD-IBSC

The band alignment of the QD-IBSC is shown in Fig. 1a. The QD states form the IB in the substrate band gap, which allows two ways for electrons to transfer from the VB to the CB. One is for the material to absorb photons, and the electrons in the VB are directly transferred to the CB; the other way is for the electrons to absorb sub-bandgap energy photons via transitions from the VB to the IB and then the IB to the CB. By adding an IB between the VB and the CB, the cells are able to absorb photons with low energy via a two-photon absorption process, and the absorption spectrum is expanded, thus improving the conversion efficiency. To achieve the absorption process, the IB must be located at a suitable position to prevent thermal carriers escape and tunneling, and half-filled to ensure that it facilitates carriers to transfer between the VB and the CB. The optimal bandgap for the IBSC is 1.95 eV, which is split by the IB into two sub-bandgaps of approximately 0.71 eV and 1.24 eV [32].

Reproduced from Ref. [32]. b the transition of electrons from the CB to the IB (process1); the thermal electron escape from the IB electrons to the CB (process 1’); the recombination of the IB electrons and the VB holes (process 2); the recombination of the CB electrons and VB holes (process 3); the transition of hole from the VB to the dot (process 4); the thermal hole escape from dot to the VB (process 4’). Reproduced from Ref. [33]

a Band alignment diagram of the IBSC.

The efficiency of solar cells is as follows:

where Pin is the input power, Voc is the open-circuit voltage, Jsc is the short-circuit current density and FF is the fill factor. Therefore, to improve its efficiency, Jsc should be increased as much as possible while the Voc is preserved [34].

Figure 1b shows various excitation and recombination processes in the IBSC [33]. To obtain high efficiency, it is necessary to prevent thermal carriers escape and recombination processes in IBSCs. If the three QFLs separate from each other, the Voc will only be limited by the band gap of the matrix. However, there exists thermal escape which is related to the thermal coupling of the IB and the CB, and the electrons in IB transfer to the CB through the thermal excitation rather than the second-photon absorption, resulting in the drop of Voc. And the excited states of QDs and the confined states of wetting layer will assist the process, which should be avoided as much as possible [35, 36]. For recombination in solar cells, they can be radiative recombination and non-radiative recombination. Radiation recombination is caused by a detailed balance counterpart of the light absorption process, which is inevitable. For non-radiative recombination, it can be Auger recombination transferring the energy to other carriers or SRH recombination to phonons. Auger recombination occurs in highly doped semiconductors, so it is not important in less doped materials. The generally accepted cause of SRH recombination is the lattice relaxation multiple-phonon emission mechanism (MPE). Research shows that SRH recombination can be inhibited by increasing the density of impurities. And this prevents the IB to act as recombination centers [37, 38].

Research progress of In(Ga)As/GaAs QD-IBSC

Doping of Si

Half-filling of the IB is important in QD-IBSCs, which allows the absorption of sub-bandgap photons by the two-step photon absorption. It is proved that the half-filling can be achieved by Si doping, which has little influence on the splitting of the QFLs [39]. There are two doping methods: δ doping and direct doping, both of which have been observed larger thermal excitation energy and improvement in Jsc or Voc (in Fig. 2), it is thought that the doping has an effect on the optical processes and inhibits the non-radiative recombination. And for the heavy doping QDs, the drop in current is attributed to the increased rate of electron capture into QDs since the energy band of QD region becomes more flattened [40, 41]. The Si dopants incorporated in wetting layer supply electrons to QDs, and a potential barrier is formed at the interface of positively charged wetting layer and negatively charged QDs. The barrier suppresses thermal escape from QDs and thus the Voc recovers [42]. Morioka, Takayuki et al. found that recombination process in the QDs region was reduced due to the half-filled IB, leading enhancement in Jsc, Voc and conversion efficiency [43]. Yang, Xiaoguang et al. fabricated an InAs/GaAs QD-IBSC with the Si doping concentration of 5 × 1011 cm−2 and the conversion efficiency reaches 17% [44].

Reproduced from Ref. [40]

a EQE characteristics of InAs/GaAs with δ doping (solid line) or direct doping (dashed line). b J-V characteristics of InAs/GaAs withδdoping (solid line) or direct doping (dashed line).

Size of QDs

The size is an important parameter to consider when growing QDs. The large QDs increase the absorption coefficient and extend the absorption spectra, while the IB is not formed in the band gap of the matrix [45, 46]. Therefore, it is necessary to optimize the size of QDs to obtain a confined electron level in the CB offset, namely the IB. As is shown in Fig. 3, the small QDs allow few excited states inside the CB offset, which is conducive to the splitting of QFLs between the IB and the CB, as well as a better position of the IB, so the thermal excitation energy increases and the voltage is preserved [36, 47, 48]. Also, the reduction of the QD width means that a higher QD density can be obtained, resulting in an increase in photocurrent [49]. For the InAs/GaAs QD-IBSC, it is calculated that the optimal QD size and distance between two QDs are 6–12 nm and 2 nm, respectively [45, 46]. And a low QD size dispersion prevents different confined energy levels to appear, but it may be hard to realize in QD-IBSC operation [50].

Reproduced from Ref. [47]

J–V characteristics of the InAs/GaAs with various sizes of QDs.

Cap layer

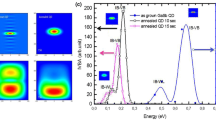

Generally, QDs are grown by S-K mode, which will inevitably produce the wetting layer (WL), and the WL forms continuous confined energy levels below the CB, these energy states assist the thermal excitation of carriers and suppress the second-photon absorption process, leading to the connection of the IB and the CB and a drop of Voc [51]. It is proved that the thin AlAs cap layer (CL) on InAs/GaAs QDs could suppress the formation of the WL and increase the PL intensity (Fig. 4), because the high intermixing between CL and WL results in an InAlGaAs layer with gradual composition [51,52,53]. Also, AlAs CL prevents in segregation and In-Ga intermixing, and reduces QDs decomposition [54, 55]. In addition to AlAs, the CLs commonly used include InGaAs, InAlGaAs, AlGaAsSb and so on, and different CLs have different effects [56,57,58]. Wei-Sheng Liu et al. fabricated an InGaAs/GaAs(Sb) QDs with AlGaAsSb CL. It showed an enlarged band gap with the inserting of AlGaAsSb CL and the Voc is increased from 0.67 to 0.7 V [58]. T. Sugaya et al. found that the In0.2Ga0.8As CLs on In0.4Ga0.6As QD solar cells could reduce the strain around the QDs and 50-stack InGaAs QDs can be grown without defects. The absorption spectra are extended and the conversion efficiency of 10-stack InGaAs QDs reaches 12.2% [56].

Reproduced from Ref. [51]

a TEM image of the InAs/GaAs without AlAs CL. b TEM image of the InAs/GaAs with AlAs CL. c PL spectra of the InAs/GaAs without (red) and with (blue) AlAs CL.

Strain compensation layer

In general, to improve the conversion efficiency, the researchers increase the layers of QDs to realize the high density of QDs. However, there exists a lattice mismatch between the matrix and the QDs. As the QD layers increase, strain will accumulate in the QDs, which will eventually lead to the generation of dislocations [59]. The dislocations clustered in the QDs propagate toward the surface of the cells, and the minority carrier lifetime decreases [60]. In order to solve the problem, strain compensation (SC) is carried out, in the case of the band gap and the lattice constant being considered in the selection of the SC layer. The band gap of the SC layers should not be much smaller than that of the matrix, but it should be similar to that of the matrix [61]. For InAs/GaAs, the layers doped with N, P, and Sb are generally used [29, 62, 63]. For example, no dislocations or coalesced islands were observed in 50-stack InAs QDs with GaNAs SC layers, a high density of QDs was achieved and the Jsc increased without a drop of Voc [64]. S. M. Hubbard et al. used GaP layers to offset compressive strain in stacked InAs QDs and found that without the GaP tensile SC layers, the conversion efficiency of InAs/GaAs QD-IBSC decreased due to the strain-induced dislocations. While there are GaP layers, the conversion efficiency was increased from 3.7 to 10.8%, which indicated that the SC layers result in a reduction of the recombination process [65]. As a surfactant, antimony (Sb) reduces the surface energy, which in turn increases the density of QDs and reduces the coalescence dots [66]. Liu et al. [63] studied ten layers of InAs QDs, and each layer of QDs was grown with a GaAsSb SC layer. They found that the size of QDs became more uniform, and the Jsc was enhanced by 8.8% compared to that without GaAsSb, because it enhanced the absorption of the QDs around 1200 nm.

In addition to the use of SC layers, the composition of the matrix or the QDs can be adjusted to reduce the lattice mismatch and the strain around the QDs. Voicu Popescu et al. fabricated an InyGa1-yAs/GaAs1–xPx QD-IBSC, and the results showed a good lattice match, and the calculations indicated that a maximum thickness of 6 ML could be grown [33]. As shown in Fig. 5, the In0.4Ga0.6As/GaAs structure grown by Sugaya, Takeyoshi et al. was able to grow 400 layers without defects, but the Voc decreases with the increasing of stacking QD layers, which is attributed to the recombination in QDs [67].

Reproduced from Ref. [67]

a SEM images of the surface plane on top of a 200, b 300, c 400-stack In0.4 Ga0.6As QD structures. b I–V characteristics of In0.4Ga0.6As/GaAs QD-IBSCs with different QD layers and a GaAs reference cell.

Increase matrix band gap

Although InAs/GaAs has been studied the most, it is not optimal for the IBSCs, because its effective band gap of 1.066 eV is less than the optimal value of 1.95 eV. Moreover, small QDs are necessary to make sure that the confined states separate from each other, but it will cause the first electron confined state to appear at high energy level. As a consequence, the energy difference between the IB and the CB is usually less than 0.2 eV, and there exists thermal carrier escape from the IB to the CB at room temperature, which results in a drop of the Voc [68]. The theoretical calculation shows that the efficiency limit is only 49.44% for InAs/GaAs QD-IBSC by optimizing the QD size [36]. Thermal excitation energy can be increased by using the wide bandgap substrates, changing the GaAs barrier to AlGaAs, InGaP or GaAsP [69,70,71]. Ramiro et al. [72] increased the band gap of the matrix by doping Al into GaAs and showed that the thermal excitation energy reached 361 meV when the Al content reached 25%, which indicates that, if the energy split between the CB and the IB is large enough, the gap will suppress thermal carrier escape at room temperature. In addition to this, InAs/InGaP QD-IBSC prototypes with a wide bandgap were fabricated by them (Fig. 6), which have a band gap of 1.88 eV, and the energy difference between the IB and the CB is above 0.4 eV, leading to large thermal excitation energy [73].

Reproduced from Ref. [73]

a Band structure diagram of the InAs/AlGaAs/InGaP (left) and an ideal QD-IBSC (right). b Photocurrent response to mid-infrared illumination of InAs/AlGaAs/InGaP at RT (dotted line) and 70 K (solid line).

Type-II IBSC

As shown in Fig. 7a (left), the CB and the VB of QDs are located in the bandgap of the substrate in the type-I QD-IBSC. The effective mass of the heavy holes is large, resulting in a tight arrangement of confined states of QDs around the VB and reducing the effective bandgap [74]. And if the energy levels of the IB and the CB are close, the thermal excitation will dominate the transition from the IB to the CB, which is harmful for the preservation of the Voc. The efficient radiative recombination in type-I IBSC leads to short carrier lifetimes (~ 1 ns) and a small number of photocarriers in QDs, reducing the two-photon absorption process since the second-photon absorption is related to the photocarrier in the IB [75,76,77]. Besides, the huge difference in the two optical transition rates associated with the IB is unfavorable for efficient QD-IBSCs [78]. Although the thermal excitation process can be suppressed by low temperature and concentrated light (Fig. 7b), it is not very realistic in practice [79]. To reduce these effects structurally, A. Marti and A. Luque proposed a type-II IBSC prototype with the band structure shown in Fig. 7a (right). The electrons and holes are spatially separated, so the carrier recombination in QDs is suppressed and the carrier lifetime increases [80]. As distinct from the type-I QDs, the bands of the type-II QDs and the substrate are staggered, so electrons and holes are spatially separated [74, 81]. And the type-II QD-IBSCs have higher thermal excitation energy than the InAs/GaAs, and this suppresses thermal carrier escape in QDs [82]. Besides, the hole confined states of QDs are located in the VB, so it prevents the reduction in the effective band gap.

A theoretical calculation shows that the efficiency of type-II QD-IBSC formed by InAs/GaAsSb can reach 18.4%, which exceeds the efficiency of the InAs/GaAs IBSC (17.8%) [84]. Whether the InAs/GaAsSb forms the type-I or the type-II depends on the component content of Sb in the GaAsSb layer [85]. Hatch et al. [86] found that InAs/GaAsSb showed type-II behavior when the Sb composition reached 12%. As shown in Fig. 8a, with the increase in Sb component, the carrier lifetime increases from 1.8 to 7.4 ns, which is attributed to the formation of the type-II band alignment [87]. In order to reduce the wave function overlap of the electrons and holes as well as prolong the carrier lifetime, a 2-nm GaAs wall is inserted between QDs and GaAsSb layers, and the carrier lifetime reached 480 ns [75]. It is noted that it will prevent the holes from tunneling when the GaAs wall is too thick, leading to carrier recombination in QDs and short carrier lifetime [88].

In addition to In(Ga)As QD-IBSC, GaSb/GaAs is another kind of type-II QD-IBSC, and the GaSb QDs can be grown by the interfacial misfit (IMF) dislocation array growth mode. The misfit array is located at the interface of GaSb/GaAs and is comprised of two 90° dislocations, and the strain energy is relieved by the periodic array misfit dislocations, so there are no visible defects can be observed on the GaSb surface (Fig. 8b)which is conducive to realize high-density QDs and enhances light absorption [89, 90]. GaSb/GaAs QD-IBSC confines holes only, and the IB is 0.49 eV above the VB, larger than energy difference between the IB and the CB of InAs/GaAs [91]. However, the experimental results show that the Jsc increases, but the Voc is still decreased compared with that without QDs, attributing to the IB-VB thermal connection. Nevertheless, there is evidence shows that the half-filling of the IB is beneficial to the two-photon absorption process [83, 92].

From the above analysis, it can be concluded that different technologies have different impact on the performance of the QD-IBSC. The half-filling of the IB can be realized by Si doping; QD-IBSCs with suitable quantum dot size have higher output voltage and photocurrent; the CL suppresses the formation of the wetting layer, so the voltage is preserved; the SC layer reduces the strain around the quantum dots, which means more quantum dots can be grown and the light absorption is enhanced; increasing matrix band gap can reduce the effect of carrier thermal escape; long carrier lifetime can be obtained by the use of type-II quantum dots. Therefore, the effects of each technology must be taken into account in order to obtain high efficiency QD-IBSCs.

The experimental record summary of QD-IBSCs

In this section, we present Table 1, which includes the various experimental results such as the conversion efficiency, Voc, Jsc, and so on. If reported experimental evidence exists, the data are referenced. An oblique line case appears otherwise.

As we can see in Table 1, the high Jsc could be obtained via Si doping and an increase in Voc could be achieved by the use of wide bandgap matrix or CL, but plenty of researches show that high Jsc and Voc are hard to realize at the same time. The low efficiency of the QD-IBSC can be mainly attributed to it that the QDs with the high density, good size homogeneity, and without defects are difficult to grow. As can be seen from Table 1, high-quality QDs obtained through controlling the annealing temperature greatly improve the efficiency. So the research on QD-IBSC should focus on the growth of high quality QDs in the future. Recently a new way to realize the IBSC with colloidal QDs has been developed. Colloidal QD-IBSC has the advantages of a high density of QDs, easy control of the QD size and fabrication, which may be a more promising way to solve this problem [27, 93]

To achieve high conversion efficiency, every factor should be considered and weighed. At present, the highest efficiency of InAs/GaAs reaches 18.7% (1 sun). The high-density QD solar cell with 5 layers stacked is grown by metalorganic chemical vapor deposition which suppresses the degradation of Voc, and a dual-layer anti-reflection coating is used to enhance the light absorption [94]. Therefore, in addition to increasing the number of QDs, light trapping is another way to improve the efficiency through enhancing light absorption. The main technologies used are different trapping structures, which reduce surface light reflection and increase light scattering. The methods commonly used are textures and back reflectors of different shapes, like planar back reflectors, pyramidal back reflectors. All of them show enhanced photocurrent compared with those without back reflectors [95,96,97,98].

Conclusions

In this paper, we have reviewed the progress in In(Ga)As QD-IBSC. A large number of technologies have been used to solve the problems hindering the realization of efficient two-photon absorption with the Voc preserved, including Si doping, cap layer, size control, strain compensation, using the matrix with large bandgap and type-II QDs. Nevertheless, till now, the QD-IBSC with higher energy conversion efficiency than the single-junction solar cell has not been reported yet and plenty of researches show that the high Jsc and Voc are hard to be realized at the same time. To get a high Jsc, multiple layers of QDs need to be grown to increase light absorption, but this in turn causes strain accumulate and voltage drop, which is due to the reason that the QDs with high density, no defects and good size uniformity are difficult to grow. Besides, the low efficiency of the cell is also related to the weak photoabsorption. In the future, researches on In(Ga)As QD-IBSC are supposed to focus on the growth of QD with high quality as well as light trapping technology. The summarized experimental results here may enlighten the further development of the In(Ga)As QD-IBSC.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Shockley W, Queisser H. Detailed balance limit of efficiency of P-N junction solar cells. J Appl Phys. 1961;32:510.

Luque A, Marti A. The intermediate band solar cell: progress toward the realization of an attractive concept. Adv Mater. 2010;22:160–74.

Luque A, Marti A. Increasing the efficiency of ideal solar cells by photon induced transitions at intermediate levels. Phys Rev Lett. 1997;78:5014–7.

Luque A, Marti A, Nozik AJ. Solar cells based on quantum dots: multiple exciton generation and intermediate bands. Mrs Bull. 2007;32:236–41.

Marti A, Lopez N, Antolin E, Canovas E, Stanley C, Farmer C, Cuadra L, Luque A. Novel semiconductor solar cell structures: the quantum dot intermediate band solar cell. Thin Solid Films. 2006;511:638–44.

Luque A, Marti A. A metallic intermediate band high efficiency solar cell. Prog Photovolt. 2001;9:73–86.

Okada Y, Ekins-Daukes NJ, Kita T, et al. Intermediate band solar cells: recent progress and future directions. Appl Phys Rev. 2015;2:021302.

Ramiro I, Marti A, Antolin E, Luque A. Review of experimental results related to the operation of intermediate band solar cells. IEEE J Photovolt. 2014;4:736–48.

Marti A, Cuadra L, Luque A. Partial filling of a quantum dot intermediate band for solar cells. IEEE Trans Electron Devices. 2001;48:2394–9.

Luque A, Marti A, Lopez N, Antolin E, Canovas E, Stanley C, Farmer C, Diaz P. Operation of the intermediate band solar cell under nonideal space charge region conditions and half filling of the intermediate band. J Appl Phys. 2006;99:094503.

Luque A, Marti A, Stanley C, Lopez N, Cuadra L, Zhou D, Pearson JL, McKee A. General equivalent circuit for intermediate band devices: Potentials, currents and electroluminescence. J Appl Phys. 2004;96:903–9.

Liu Z, Zhou T, Li L, Zuo Y, He C, Li C, Xue C, Cheng B, Wang Q. Ge/Si quantum dots thin film solar cells. Appl Phys Lett. 2013;103:082101.

Lam P, Wu J, Tang M, et al. InAs/InGaP quantum dot solar cells with an AlGaAs interlayer. Sol Energy Mater Sol Cells. 2016;144:96–101.

Sugaya T, Takeda A, Oshima R, Matsubara K, Niki S, Okano Y. InGaP-based InGaAs quantum dot solar cells with GaAs spacer layer fabricated using solid-source molecular beam epitaxy. Appl Phys Lett. 2012;101:133110.

Tayagaki T, Sugaya T. Type-II InP quantum dots in wide-bandgap InGaP host for intermediate-band solar cells. Appl Phys Lett. 2016;108:153901.

Shang C, Wan Y, Selvidge J, Hughes E, Herrick R, Mukherjee K, Duan J, Grillot F, Chow WW, Bowers JE. Perspectives on advances in quantum dot lasers and integration with Si photonic integrated circuits. ACS Photonics. 2021;8:2555–66.

Wan Y, Zhang Z, Chao R, et al. Monolithically integrated InAs/InGaAs quantum dot photodetectors on silicon substrates. Opt Express. 2017;25:27715–23.

Tossoun B, Kurczveil G, Zhang C, Descos A, Huang Z, Beling A, Campbell JC, Liang D, Beausoleil RG. Indium arsenide quantum dot waveguide photodiodes heterogeneously integrated on silicon. Optica. 2019;6:1277–81.

Wan Y, Xiang C, Guo J, et al. High speed evanescent quantum-dot lasers on Si. Laser Photonics Rev. 2021;15:2100057.

Chen S, Li W, Wu J, et al. Electrically pumped continuous-wave III-V quantum dot lasers on silicon. Nat Photonics. 2016;10:307-+.

Panda D, Saha J, Balgarkashi A, Shetty S, Rawool H, Singh SM, Upadhyay S, Tongbram B, Chakrabarti S. Optimization of dot layer periodicity through analysis of strain and electronic profile in vertically stacked InAs/GaAs Quantum dot heterostructure. J Alloys Compd. 2018;736:216–24.

Yachmenev AE, Pushkarev SS, Reznik RR, Khabibullin RA, Ponomarev DS. Arsenides-and related III-V materials-based multilayered structures for terahertz applications: various designs and growth technology. Prog Cryst Growth Charact Mater. 2020;66:100485.

Salii RA, Kalyuzhnyy NA, Kryzhanovskaya NV, Maximov MV, Mintairov SA, Nadtochiy AM, Nevedomskiy VN, Zhukov AE. InAs quantum dots grown by MOCVD in GaAs and metamorphic InGaAs matrixes. In: Suris RA, Vorobjev LE, Firsov DA, Shalygin VA, editors. 18th Russian youth conference on physics of semiconductors and nanostructures, opto- and nanoelectronics. Bristol: Iop Publishing Ltd; 2017. p. 012024.

Xiao-Guang Y, Tao Y, Ke-Fan W, et al. Intermediate-band solar cells based on InAs/GaAs quantum dots. Chin Phys Lett. 2011;28:038401.

Kada T, Asahi S, Kaizu T, Harada Y, Kita T, Tamaki R, Okada Y, Miyano K. Two-step photon absorption in InAs/GaAs quantum-dot superlattice solar cells. Phys Rev B. 2015;91:201303.

Wei G, Shiu K-T, Giebink NC, Forrest SR. Thermodynamic limits of quantum photovoltaic cell efficiency. Appl Phys Lett. 2007;91:223507.

Ramiro I, Martí A. Intermediate band solar cells: present and future. Prog Photovolt Res Appl. 2021;29:705–13.

Tutu FK, Sellers IR, Peinado MG, Pastore CE, Willis SM, Watt AR, Wang T, Liu HY. Improved performance of multilayer InAs/GaAs quantum-dot solar cells using a high-growth-temperature GaAs spacer layer. J Appl Phys. 2012;111:046101.

Laghumavarapu RB, El-Emawy M, Nuntawong N, Moscho A, Lester LF, Huffaker DL. Improved device performance of InAs/GaAs quantum dot solar cells with GaP strain compensation layers. Appl Phys Lett. 2007;91:243115.

Shiokawa M, Saputra E, Sakamoto K, Yamaguchi K. Long carrier lifetime in ultrahigh-density InAs quantum-dot sheet of intermediate band solar cells. In: 2013 IEEE 39th Photovoltaic Specialists Conference PVSC. IEEE, New York. 2013, p 311–3.

Tex DM, Kamiya I, Kanemitsu Y. Identification of trap states for two-step two-photon-absorption processes in InAs quantum structures for intermediate-band solar cells. In: 2014 IEEE 40th Photovoltaic Specialists Conference PVSC. 2014; IEEE, New York, pp 3618–3621.

Luque A, Marti A, Stanley C. Understanding intermediate-band solar cells. Nat Photonics. 2012;6:146–52.

Popescu V, Bester G, Hanna MC, Norman AG, Zunger A. Theoretical and experimental examination of the intermediate-band concept for strain-balanced (In, Ga)As/Ga(As, P) quantum dot solar cells. Phys Rev B. 2008;78:205321.

Shao Q, Balandin AA, Fedoseyev AI, Turowski M. Intermediate-band solar cells based on quantum dot supracrystals. Appl Phys Lett. 2007;91:163503.

Cappelluti F, Khalili A, Gioannini M. Open circuit voltage recovery in quantum dot solar cells: a numerical study on the impact of wetting layer and doping. IET Optoelectron. 2017;11:44–8.

Linares PG, Marti A, Antolin E, Luque A. III-V compound semiconductor screening for implementing quantum dot intermediate band solar cells. J Appl Phys. 2011;109:014313.

Krich JJ, Halperin BI, Aspuru-Guzik A. Nonradiative lifetimes in intermediate band photovoltaics—absence of lifetime recovery. J Appl Phys. 2012;112:013707.

Luque A, Marti A, Antolin E, Tablero C. Intermediate bands versus levels in non-radiative recombination. Phys B-Condens Matter. 2006;382:320–7.

Luque A, Marti A, Lopez N, Antolin E, Canovas E, Stanley C, Farmer C, Caballero LJ, Cuadra L, Balenzategui JL. Experimental analysis of the quasi-Fermi level split in quantum dot intermediate-band solar cells. Appl Phys Lett. 2005;87:083505.

Naito S, Yoshida K, Miyashita N, Tamaki R, Hoshii T, Okada Y. Effect of Si doping and sunlight concentration on the performance of InAs/GaAs quantum dot solar cells. J Photonics Energy. 2017;7:025505.

Ban K-Y, Hong W-K, Bremner SP, Dahal SN, McFelea H, Honsberg CB. Controllability of the subband occupation of InAs quantum dots on a delta-doped GaAsSb barrier. J Appl Phys. 2011;109:014312.

Lam P, Hatch S, Wu J, Tang M, Dorogan VG, Mazur YI, Salamo GJ, Ramiro I, Seeds A, Liu H. Voltage recovery in charged InAs/GaAs quantum dot solar cells. Nano Energy. 2014;6:159–66.

Morioka T, Oshima R, Takata A, Shoji Y, Inoue T, Kita T, Okada Y. Multi-stacked InAs/GaNAs quantum dots with direct Si doping for use in intermediate band solar cell. In: 2010 35th IEEE photovoltaic specialists conference. IEEE, Honolulu, HI, USA. 2010, p 001834–7.

Yang X, Wang K, Gu Y, Ni H, Wang X, Yang T, Wang Z. Improved efficiency of InAs/GaAs quantum dots solar cells by Si-doping. Sol Energy Mater Sol Cells. 2013;113:144–7.

Hendra IBP, Rahayu F, Darma Y. Simulation of quantum dots size and spacing effect for intermediate band solar cell application based on InAs quantum dots arrangement In GaAs. In: Djama M, Vierdayanti K, Alamsyah IM, Mukti RR, Indrasari W, Islahuddin M, editors. 4th international conference on mathematics and natural sciences (ICMNS 2012) science for health, food and sustainable energy. Melville: American Institute of Physics; 2014. p. 221–4.

Tomić S, Jones TS, Harrison NM. Absorption characteristics of a quantum dot array induced intermediate band: implications for solar cell design. Appl Phys Lett. 2008;93:263105.

Amine A, Wakif A, Kinani MA, Mir Y, Oukerroum A, Zazoui M. Physical insights into the effects of quantum dots size and temperature on efficiency of InAs/GaAs quantum dots intermediate band solar cell. Phys-Stat Mech Appl. 2020;547:123786.

Mellor A, Luque A, Tobias I, Marti A. The influence of quantum dot size on the sub-bandgap intraband photocurrent in intermediate band solar cells. Appl Phys Lett. 2012;101:133909.

Mellor A, Luque A, Tobias I, Marti A. A numerical study into the influence of quantum dot size on the sub-bandgap interband photocurrent in intermediate band solar cells. Aip Adv. 2013;3:022116.

Biswas S, Chatterjee A, Biswas AK, Sinha A. Spectral response of the intrinsic region of a GaAs-InAs quantum dot solar cell considering the absorption spectra of ideal cubic dots. Phys E-Low-Dimens Syst Nanostruct. 2016;84:108–11.

Tutu FK, Lam P, Wu J, Miyashita N, Okada Y, Lee K-H, Ekins-Daukes NJ, Wilson J, Liu H. InAs/GaAs quantum dot solar cell with an AlAs cap layer. Appl Phys Lett. 2013;102:163907.

Kim D, Tang M, Wu J, Hatch S, Maidaniuk Y, Dorogan V, Mazur YI, Salamo GJ, Liu H. Si-doped InAs/GaAs quantum-dot solar cell with AlAs cap layers. IEEE J Photovolt. 2016;6:906–11.

Ruiz N, Fernandez D, Stanojevic L, Ben T, Flores S, Braza V, Gallego Carro A, Luna E, Ulloa JM, Gonzalez D. Suppressing the effect of the wetting layer through AlAs capping in InAs/GaAs QD structures for solar cells applications. Nanomaterials. 2022;12:1368.

Dorogan VG, Mazur YI, Lee JH, Wang ZM, Ware ME, Salamo GJ. Thermal peculiarity of AlAs-capped InAs quantum dots in a GaAs matrix. J Appl Phys. 2008;104:104303.

Arzberger M, Kasberger U, Bohm G, Abstreiter G. Influence of a thin AlAs cap layer on optical properties of self-assembled InAs/GaAs quantum dots. Appl Phys Lett. 1999;75:3968–70.

Sugaya T, Furue S, Komaki H, Amano T, Mori M, Komori K, Niki S, Numakami O, Okano Y. Highly stacked and well-aligned In0.4Ga0.6As quantum dot solar cells with In0.2Ga0.8As cap layer. Appl Phys Lett. 2010;97:183104.

Hernandez-Saz J, Herrera M, Molina SI, Stanley CR, Duguay S. 3D compositional analysis at atomic scale of InAlGaAs capped InAs/GaAs QDs. Scr Mater. 2015;103:73–6.

Liu W-S, Lin H-C, Liu R-Y. Capping vertically aligned InGaAs/GaAs(Sb) quantum dots with a AlGaAsSb spacer layer in intermediate-band solar cell devices. Prog Photovolt. 2017;25:76–86.

Zheng Z, Ji H, Yu P, Wang Z. Recent progress towards quantum dot solar cells with enhanced optical absorption. Nanoscale Res Lett. 2016;11:266.

Marti A, Lopez N, Antolin E, Canovas E, Luque A. Emitter degradation in quantum dot intermediate band solar cells. Appl Phys Lett. 2007;90:233510.

Pavelescu E-M, Polojarvi V, Schramm A, Tukiainen A, Aho A, Zhang W, Puustinen J, Salmi J, Guina M. Effects of insertion of strain-engineering Ga(In)NAs layers on optical properties of InAs/GaAs quantum dots for high-efficiency solar cells. Opt Mater. 2016;52:177–80.

Oshima R, Takata A, Okada Y. Strain-compensated InAs/GaNAs quantum dots for use in high-efficiency solar cells. Appl Phys Lett. 2008;93:083111.

Liu W-S, Wu H-M, Tsao F-H, Hsu T-L, Chyi J-I. Improving the characteristics of intermediate-band solar cell devices using a vertically aligned InAs/GaAsSb quantum dot structure. Sol Energy Mater Sol Cells. 2012;105:237–41.

Oshima R, Takata A, Shoji Y, Akahane K, Okada Y. InAs/GaNAs strain-compensated quantum dots stacked up to 50 layers for use in high-efficiency solar cell. Phys E-Low-Dimens Syst Nanostruct. 2010;42:2757–60.

Hubbard SM, Cress CD, Bailey CG, Raffaelle RP, Bailey SG, Wilt DM. Effect of strain compensation on quantum dot enhanced GaAs solar cells. Appl Phys Lett. 2008;92:123512.

Guimard D, Nishioka M, Tsukamoto S, Arakawa Y. Effect of antimony on the density of InAs/Sb: GaAs(100) quantum dots grown by metalorganic chemical-vapor deposition. J Cryst Growth. 2007;298:548–52.

Sugaya T, Numakami O, Oshima R, Furue S, Komaki H, Amano T, Matsubara K, Okano Y, Niki S. Ultra-high stacks of InGaAs/GaAs quantum dots for high efficiency solar cells. Energy Environ Sci. 2012;5:6233–7.

Antolin E, Marti A, Farmer CD, Linares PG, Hernandez E, Sanchez AM, Ben T, Molina SI, Stanley CR, Luque A. Reducing carrier escape in the InAs/GaAs quantum dot intermediate band solar cell. J Appl Phys. 2010;108:064513.

Dai Y, Slocum MA, Bittner Z, Hellstroem S, Forbes DV, Hubbard SM. Optimization in wide-band-gap quantum dot solar cells. In: 2016 IEEE 43rd photovoltaic specialists conference PVSC. IEEE, New York. 2016, p 151–4.

Sugaya T, Oshima R, Matsubara K, Niki S. InGaAs quantum dot superlattice with vertically coupled states in InGaP matrix. J Appl Phys. 2013;114:014303.

Shoji Y, Tamaki R, Okada Y. Temperature dependence of carrier extraction processes in GaSb/AlGaAs quantum nanostructure intermediate-band solar cells. Nanomaterials. 2021;11:344–344.

Ramiro I, Antolin E, Steer MJ, et al. InAs/AlGaAs quantum dot intermediate band solar cells with enlarged sub-bandgaps. In: 2012 38th IEEE photovoltaic specialists conference. IEEE, Austin, TX, USA. 2012, p 000652–6.

Ramiro I, Villa J, Lam P, Hatch S, Wu J, Lopez E, Antolin E, Liu H, Marti A, Luque A. Wide-bandgap InAs/InGaP quantum-dot intermediate band solar cells. IEEE J Photovolt. 2015;5:840–5.

Luque A, Linares PG, Mellor A, Andreev V, Marti A. Some advantages of intermediate band solar cells based on type II quantum dots. Appl Phys Lett. 2013;103:123901.

Kim D, Hatch S, Wu J, Sablon KA, Lam P, Jurczak P, Tang M, Gillin WP, Liu H. Type-II InAs/GaAsSb quantum dot solar cells with GaAs interlayer. IEEE J Photovolt. 2018;8:741–5.

Tayagaki T, Sugaya T. Carrier dynamics in type-II quantum dots for wide-bandgap intermediate-band solar cells. In: Freundlich A, Lombez L, Sugiyama M, editors. Physics, simulation, and photonic engineering of photovoltaic devices. Bellingham: Spie-Int Soc Optical Engineering; 2016. p. 974317.

Aihara T, Tayagaki T, Nagato Y, Okano Y, Sugaya T. InGaP-based InP quantum dot solar cells with extended optical absorption range. Jpn J Appl Phys. 2017;56:0406.

Hwang J, Martin AJ, Lee K, Forrest S, Millunchick J, Phillips J. Preserving voltage and long wavelength photoresponse in GaSb/GaAs quantum dot solar cells. In: 2013 IEEE 39th photovoltaic specialists conference (PVSC). IEEE, New York. 2013, p 3191–4.

Linares PG, Marti A, Antolin E, Farmer CD, Ramiro I, Stanley CR, Luque A. Voltage recovery in intermediate band solar cells. Sol Energy Mater Sol Cells. 2012;98:240–4.

Tayagaki T, Nagato Y, Okano Y, Sugaya T. A proposal for wide-bandgap intermediate-band solar cells using type-II InP/InGaP quantum dots. In: 2016 IEEE 43rd photovoltaic specialists conference (PVSC). IEEE, New York. 2016, p 160–2.

Cuadra L, Marti A, Luque A. Type II broken band heterostructure quantum dot to obtain a material for the intermediate band solar cell. Phys E-Low-Dimens Syst Nanostruct. 2002;14:162–5.

Hwang J, Lee K, Teran A, Forrest S, Phillips JD, Martin AJ, Millunchick J. Multiphoton sub-band-gap photoconductivity and critical transition temperature in type-II GaSb quantum-dot intermediate-band solar cells. Phys Rev Appl. 2014;1:051003.

Hwang J, Martin AJ, Millunchick JM, Phillips JD. Thermal emission in type-II GaSb/GaAs quantum dots and prospects for intermediate band solar energy conversion. J Appl Phys. 2012;111:074514.

Xu F, Yang X-G, Luo S, Lv Z-R, Yang T. Enhanced performance of quantum dot solar cells based on type II quantum dots. J Appl Phys. 2014;116:133102.

Lu G, Lv Z, Zhang Z, Yang X, Yang T. Effect of Sb composition on the band alignment of InAs/GaAsSb quantum dots. Chin Phys B. 2021;30:017802.

Hatch S, Wu J, Sablon K, Lam P, Tang M, Jiang Q, Liu H. InAs/GaAsSb quantum dot solar cells. Opt Express. 2014;22:A679–85.

Zhou C, Liang B, Liu J, Wang Y, Guo Y, Wang S, Fu G, Mazur YI, Ware ME, Salamo GJ. Comparative study of photoluminescence for type-I InAs/GaAs0.89Sb0.11 and type-II InAs/GaAs0.85Sb0.15 quantum dots. Opt Mater. 2019;98:109479.

Nishikawa K, Takeda Y, Motohiro T, Sato D, Ota J, Miyashita N, Okada Y. Extremely long carrier lifetime over 200 ns in GaAs wall-inserted type II InAs quantum dots. Appl Phys Lett. 2012;100:113105.

Huang S, Balakrishnan G, Huffaker DL. Interfacial misfit array formation for GaSb growth on GaAs. J Appl Phys. 2009;105:103104.

Laghumavarapu RB, Moscho A, Khoshakhlagh A, El-Emawy M, Lester LF, Huffaker DL. GaSb/GaAs type II quantum dot solar cells for enhanced infrared spectral response. Appl Phys Lett. 2007;90:173125.

Ramiro I, Antolin E, Hwang J, Teran A, Martin AJ, Linares PG, Millunchick J, Phillips J, Marti A, Luque A. Three-bandgap absolute quantum efficiency in GaSb/GaAs quantum dot intermediate band solar cells. IEEE J Photovolt. 2017;7:508–12.

Ramiro I, Villa J, Tablero C, Antolin E, Luque A, Marti A, Hwang J, Phillips J, Martin AJ, Millunchick J. Analysis of the intermediate-band absorption properties of type-II GaSb/GaAs quantum-dot photovoltaics. Phys Rev B. 2017;96:125422.

Hosokawa H, Tamaki R, Sawada T, Okonogi A, Sato H, Ogomi Y, Hayase S, Okada Y, Yano T. Solution-processed intermediate-band solar cells with lead sulfide quantum dots and lead halide perovskites. Nat Commun. 2019;10:43.

Tanabe K, Guimard D, Bordel D, Arakawa Y. High-efficiency InAs/GaAs quantum dot solar cells by metalorganic chemical vapor deposition. Appl Phys Lett. 2012;100:193905.

Aho T, Elsehrawy F, Tukiainen A, Ranta S, Raappana M, Isoaho R, Aho A, Hietalahti A, Cappelluti F, Guina M. Thin-film InAs/GaAs quantum dot solar cell with planar and pyramidal back reflectors. Appl Opt. 2020;59:6304.

Mellor A, Luque A, Tobías I, Martí A. The feasibility of high-efficiency InAs/GaAs quantum dot intermediate band solar cells. Sol Energy Mater Sol Cells. 2014;130:225–33.

Villa J, Ramiro I, Maria Ripalda J, Tobias I, Garcia-Linares P, Antolin E, Marti A. Contribution to the study of sub-bandgap photon absorption in quantum dot InAs/AlGaAs intermediate band solar cells. IEEE J Photovolt. 2021;11:420–8.

Aho T, Tukiainen A, Elsehrawy F, Ranta S, Raappana M, Aho A, Isoaho R, Cappelluti F, Guina M. Back reflector with diffractive gratings for light-trapping in thin-film III-V solar cells. In: 2019 European Space Power Conference ESPC. IEEE, Juan-les-Pins, France. 2019, p 1–4.

Guimard D, Morihara R, Bordel D, Tanabe K, Wakayama Y, Nishioka M, Arakawa Y. Fabrication of InAs/GaAs quantum dot solar cells with enhanced photocurrent and without degradation of open circuit voltage. Appl Phys Lett. 2010;96:203507.

Sablon KA, Little JW, Mitin V, Sergeev A, Vagidov N, Reinhardt K. Strong enhancement of solar cell efficiency due to quantum dots with built-in charge. Nano Lett. 2011;11:2311–7.

Tutu FK, Wu J, Lam P, Tang M, Miyashita N, Okada Y, Wilson J, Allison R, Liu H. Antimony mediated growth of high-density InAs quantum dots for photovoltaic cells. Appl Phys Lett. 2013;103:043901.

Laghumavarapu RB, Liang BL, Bittner ZS, Navruz TS, Hubbard SM, Norman A, Huffaker DL. GaSb/InGaAs quantum dot-well hybrid structure active regions in solar cells. Sol Energy Mater Sol Cells. 2013;114:165–71.

Aihara T, Tayagaki T, Nakamoto T, Okano Y, Sugaya T. Effects of front InGaP layer thickness on solar cell characteristics in InP/InGaP quantum dot solar cells. Jpn J Appl Phys. 2019;58:SBBF09.

Sablon KA, Little JW, Olver KA, Wang ZM, Dorogan VG, Mazur YI, Salamo GJ, Towner FJ. Effects of AlGaAs energy barriers on InAs/GaAs quantum dot solar cells. J Appl Phys. 2010;108:074305.

Weiner EC, Jakomin R, Micha DN, Xie H, Su P-Y, Pinto LD, Pires MP, Ponce FA, Souza PL. Effect of capping procedure on quantum dot morphology: Implications on optical properties and efficiency of InAs/GaAs quantum dot solar cells. Sol Energy Mater Sol Cells. 2018;178:240–8.

Chan S, Kim D, Sanchez AM, Zhang Y, Tang M, Wu J, Liu H. InAs/GaAs quantum dot solar cells with quantum dots in the base region. IET Optoelectron. 2019;13:215–7.

Acknowledgements

This research was financially supported by the National Key R&D Program of China (No. 2019YFB1503602), the Strategic Priority Research Program of Chinese Academy of Sciences (No. XDB43020500) and the Scientific Instrument Developing Project of the Chinese Academy of Sciences (No. YJKYYQ20200002).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

GY collected the documents and wrote the draft of manuscript. WL, YB, XC, CJ and BW prepared the figures and data in the paper. FY and XW provided the indispensable guidance. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, G., Liu, W., Bao, Y. et al. Performance optimization of In(Ga)As quantum dot intermediate band solar cells. Discover Nano 18, 67 (2023). https://doi.org/10.1186/s11671-023-03839-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-023-03839-z