Abstract

Blue staining on rubberwood (Hevea brasiliensis) is a common kind of defect. There currently exists much research focused on the prevention and control of blue staining. However, little research has been concentrated on the utilization of blue staining for green dyeing. The research conveyed in this paper primarily used Lasiodiplodia theobromae to dye rubberwood, and used scanning electron microscope (SEM), energy-dispersive spectrometer (EDS), X-ray diffraction (XRD), and fourier transform infrared spectrometer (FTIR) to analyze the commission internationale eclairage (CIE) L*a*b* value of color, the contact angle, the pH value, 24-h water absorption, mass loss ratio, and compressive strength in increments between 5 and 40 days. The results found that the color of rubberwood became darker and more uniform, and that the surface dyed with fungi can reach a super-hydrophobic state. With the increase of time, the pH value of rubberwood changed from acidic to alkaline. Furthermore, hyphae entered the wood mainly through vessels for their large pore diameter, and reduced water absorption. Mass loss ratio increased gradually between 5 and 40 days. The research in this paper concludes that the microorganism was an effective method of wood dyeing, and lays a foundation for further research.

Similar content being viewed by others

Introduction

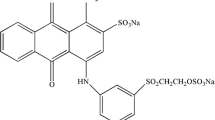

Coloring of wood is a significant processing technology that can improve surface decoration properties and reduce wood defects, thereby increasing the value of wood [1]. Currently, wood staining primarily depends on physical, chemical and biological methods. Physical method such as thermal modification mainly uses high temperature to induce discoloration. In this process, there also exist chemical changes, for thermal modification can change the content and structure of wood chemical composition, such as cellulose, hemicellulose, lignin, and extractives [2,3,4]. However, thermal modification requires significant electrical and thermal energy [5]. The chemical dyeing method mainly uses chemical agents such as chitosan, metal, and pigment dyes to dip or brush the wood, and the dyes either cover the wood surface or enter into the wood cell to change the wood color; however, chemical dyes still have problems with colorfastness, water-fastness, and so on [6,7,8]. Furthermore, the chemical method may be harmful to the environment and to human health [9]. Biological method usually utilizes stains to change the color of wood, such as extractives in trees and pigment in microorganism, and that is an effective way on wood staining [10, 11].

Biotechnology is a possible solution for wood processing, and microorganisms have the potential to dye wood. Above all, microorganisms have a close relationship with wood because both are living organisms, and there are many kinds of fungi that live in wood [12]. With the appropriate temperature, humidity, light, and pH, microorganisms can live in wood and change the wood into a variety of colors. However, these discolorations have mostly been regarded as defects of wood [13, 14]. Researchers have proposed a variety of methods to prevent against the discoloration [15,16,17]. Wood discoloration is usually caused by decaying fungi, mold, and stain fungi [18, 19]. Mold is unsuitable for utilization in wood dyeing as it is unsafety for human and uncontrollability [20]. Decaying fungi have been investigated for its application for wood decoration, such as in the case of spalting wood [21]. Spalting wood is formed by the metabolic processes of fungi, whereby fungi produce zone lines and pigment inside the wood [22]. In recent years, research on spalting wood mainly concentrated on the screening of fungi, the extraction of pigment, the properties of spalted wood, and production design. The relevant results have indicated that fungal pigments have superior colorfastness and decorative performance [23,24,25,26,27,28,29]. However, decaying fungi decreased the mechanical properties of wood [30]. Compared with decaying fungi, stain fungi do not cause an obvious reduction of mechanical properties [31]. Therefore, stain fungi may have more potential for wood dyeing.

Blue-stained wood is the most prevalent phenomenon in wood stain, and it often takes place on all kinds of wood, and rubberwood (Hevea brasiliensis) is prone to be infested by blue staining fungus. Rubberwood is a tropical hardwood species mainly distributed in countries such as China, Indonesia, Malaysia, Thailand, and India [32]. Rubberwood can be used to make wood-based panels, furniture, and joinery products, but rubberwood is also prone to attack by stain fungi in green and dry conditions. The stain reduces the decorative value of wood, and causes financial losses not only in Southeast Asia, but also in the wood industry worldwide [33, 34]. Much research has classified the blue stain fungi, and some methods have been proposed to prevent wood stain. The results have indicated that the most popular stain fungus is Lasiodiplodia theobromae, which can seriously attack rubberwood in less than 3 days [35,36,37,38,39]. Additional results have shown that the mechanical properties of stained wood not only did not obviously diminish, but also were slightly enhanced [39,40,41,42]. In recent years, several papers paid attention on the decoration of wood dyed with blue stains [11, 26, 41]. This paper mainly studied the relationship between L. theobromae and rubberwood, sought the path that how the fungi enter the rubberwood, analyzed the degradation of fungi on wood component, and physical and mechanical properties. The purpose was to learn about the mechanism of fungi and rubberwood, control the movement of fungi in rubberwood, and increase the decoration of rubberwood. The final purpose was to control decorative pattern on wood surface in further research.

Materials and methods

Materials

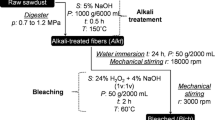

Wood and fungi species selection

Lasiodiplodia theobromae is the most popular stain fungi, and rubberwood is easily infested by it; so this paper chose them as experimental material. The rubberwood was provided by Hainan State Farms Forest Industrial Group Co., Ltd. The diameter of the rubberwood was about 20 cm in radial direction, and the wood was cut to the size of 20 × 20 × 20 mm for further use. L. theobromae (Pat.) Griffon & Maubl (cfcc 87131) was provided by the China Forestry Culture Collection Center, and which was extracted from the popular wood in the Siyang, Jiangsu province. According to the Regulations on Biosafety Management of Pathogenic Microorganism Laboratories in China [43], L. theobromae (Pat.) Griffon & Maubl belongs to the fourth type of pathogenic microorganisms, which have been proven to be safe to human. L. theobromae (Pat.) Griffon & Maubl was generally cultivated into a potato dextrose agar culture medium (PDA) that was obtained from Beijing Aoboxing Biology Technology Co., Ltd.

Expand incubation and inoculation procedure

Lasiodiplodia theobromae (Pat.) placed in PDA slant culture medium were largely cultivated in plain culture medium. The culture dishes were conditioned at (28 ± 1) °C and (80 ± 5)% relative humidity (RH) for 3 days, and hyphae filled with culture dishes.

The steps above were repeated, and the hole puncher was used to make the medium grow for 3 days into the fungi cake, the diameter of which was 5 mm, and then the fungi cake was brought to the middle surface of the medium. The culture dishes were conditioned at (28 ± 1) °C and (80 ± 5)% RH for 7 days. The fungi grew in the culture dish in 3 days, and secreted the pigment over the culture dish in 7 days.

The rubberwood was sterilized in autoclave under 0.1 MPa and 121 °C for 30 min, and then put into a constant temperature humidity chamber for 7 days, which made the moisture content of wood about 12%, and the specific gravity about 0.6–0.65. Next, the wood was placed on the culture in the grain direction. In addition, the wood was cultivated at (28 ± 1) °C and (80 ± 5)% RH for 0, 5, 10, 20, 30, and 40 days, respectively, for the fungi can make the properties of rubberwood change with time increasing. What is more, the number of woods was sufficient, because the number of specimens for most tests in 2.2 was at least 5 times.

Characterization

Scanning electron microscopy (SEM)

A Gemini SEM 300 made in Germany was used to analyze the distribution of hyphae in wood cells, and the samples were studied under energy-dispersive spectrometer (EDS) analysis to determine the element content of wood. EDS can analysis the element content of sample surface. Before the above steps were taken, the samples were cut into cubes less than 10 mm on each side, and then the top surfaces were coated with gold. The magnification was set from 150 to 500 times enlargement.

X-ray diffraction (XRD) analysis

The relative crystallinity was investigated by an XRD analyzer (Burker D8 ADVANCE, Germany) at 40 kV and 40 mA at a rate of 4°/min. The scanning range was from 5 to 45°. All of the samples were ground into powder using a 200-mesh griddle. The crystallinity index (CI) for rubberwood was determined by the following equation [44]. Each sample was repeated for 3 times.

where I002 represents the maximum value of bands at 22.5°, and Iam represents the minimum value of bands at 18.5°.

Fourier transform infrared spectroscopy (FTIR) characterization

FTIR spectra at 0 and 40 days of rubberwood (200 mesh powder) were analyzed with a Nicolet 6700 made in the USA, and with a resolution of 4 cm−1 from 400 to 4000 cm−1. The purpose of this analysis was to observe the differences between the chemical bonds by examining the band values.

Measurement of dyed wood color

The effect of fungi on rubberwood color was analyzed with a NH310 portable colorimeter from Shenzhen 3nh Technology Co., Ltd. L* (lightness and darkness), a* (redness and greenness), and b* (yellowness and blueness) were the color parameters. At first, the colorimeter needs to read the primary L0*, a0*, and b0* values of the untreated wood, and then measure the ΔL*, Δa*, Δb*, and ΔE* values of rubberwood from 5 to 40 days. ΔE* represents the total color difference, and each parameter is the average value of five times.

Color change of rubberwood dyed with fungi was analyzed with a one-way analysis of variance (ANOVA) followed by a Tukey’s honestly significant difference (Turkey HSD) test run on statistical product and service solutions (SPSS) version 18.0, which mainly analyzed the relationship between time and color change.

ΔL*, Δa*, Δb*, and ΔE* were calculated according to the following equation, and the subscript n in Eqs. (2)–(4) represents the different days from 0 to 40 days.

Measurement of contact angle

The contact angle was measured by a Contact Angle System Optical Contact Angle (DataPhysics, Germany), with time set between 0 and 16 s, and the amount of a drop of water was 3 μL which contacted on cross section. The measurement of each sample was repeated at least 5 times.

Wood pH value characterization

The pH value of rubberwood was tested according to the Chinese standard [45]. The rubberwood was made into powder using 40–60 mesh. A combination of 3 g of wood powder and 30 mL of distilled water was mixed into a 50-mL beaker and blended for 5 min, then remained still for 15 min. It was then blended again for 5 min, and remained still for another 20 min. Finally, the pH value was measured by a pH meter (Sartorius PB-10, Germany) twice.

Method of 24-h water absorption, mass loss ratio, and 24-h swelling of wood

The 24-h water absorption was measured according to the Chinese standard [46], and the results of different days were calculated by the following equation

where m0 and m represent the absolutely dry weight and the absorptive water weight after 24 h, respectively. The mass loss ratio was measured according to the Chinese standard [47]. The equation of mass loss ratio is similar to that of the 24-h water absorption, but m represents the weight when the rubberwood was dyed with fungi, and dried in an air dry oven at 70 °C for 12 h.

The 24-h swelling of wood primarily consisted of radial and tangential swelling, which was calculated according to [48]. The equation for this measurement is

where l0 and l represent the absolutely dry length and the absorptive water length after 24 h, respectively.

Method of compressive strength parallel to the grain

The compressive strength parallel to the grain was measured according to [49] at the speed of 5 mm/s. The universal mechanical testing machine was provided by Jinan Nai’er Testing Machine Co., Ltd, and the equation is

where Pmax represents the failure load (N), and b and t represent the length and width, respectively, of the surface in millimeters.

Results and discussion

SEM analysis

Figure 1 shows SEM of vessels in undyed and dyed rubberwood. Figure 1a, b shows that there were no hyphae vessels on the cross section or radial section of the rubberwood. Figure 1c, d showed many “lines” on the cross section and radial section in the vessels of rubberwood dyed with fungi at 40 days. Figure 1e, f were the enlarged views of Fig. 1c, d. As it is illustrated in Fig. 1e, the “lines” can be identified as hyphae. Figure 1e shows that the inside of hyphae was vacant, and that the structure inside the hyphae was vacant. Figure 1f illustrates that the hyphae consisted of sections, and the curve shape can be attributed to the high-pressure steam in the process of sterilization [50]. Furthermore, hyphae and fibers twisted together in the cell wall, and hyphae tried to enter the pit with difficulty. Therefore, fungi can enter the vessels easily because of their large pore diameter, though it is difficult for hyphae, fungi can enter the pit or into other small pores.

Table 1 shows the EDS analysis of undyed wood, dyed wood, and fungi. The results show that the undyed wood and dyed wood primarily contained C, O, K, and Ca. Fungi mainly contained C, O, K, and Na. However, although the content of the C element in the dyed wood decreased compared with that of the undyed wood, the content of O, K, and Ca increased after dyeing wood with fungi. The reason for this phenomenon could be that some structures that contained the C element (such as cellulose, hemicellulose, and extractives) degraded, and new structures formed when the fungi dyed the rubberwood. The XRD analysis determined the new structure to be CaC2O4.

XRD analysis

Figure 2 shows the XRD curves and relative crystallinity of rubberwood dyed with fungi between 0 and 40 days. The characteristic bands were measured at 15.0, 22.0, and 34.6°, and these values corresponded to the crystal plane diffraction bands of (101), (002), and (040) in cellulose, respectively. However, after the rubberwood was dyed with fungi, bands at 15.0° noticeably increased. Furthermore, several new bands appeared at 24.4, 30.0, 35.6, and 38.2° between 5 and 40 days. According to the XRD standard comparison card, the bands belonged to the structure of calcium oxalate (CaC2O4), which corresponded to the results in previous studies [51]. Additionally, the results from some researchers also showed that there was a close relationship between the fungi and calcium oxalates [52,53,54]. EDS analysis in Table 1 also indicates that the Ca content in dyed wood was greater than that in undyed wood.

According to the bar chart above, relative crystallinity at 0 days was 33.03%, and after fungi cultivated on the rubberwood, the relative crystallinity had a sharp increase to 37.15% at 5 days. The relative crystallinity then decreased gradually between 10 and 40 days, and was measured to be 36.17 and 35.20%, respectively. However, the values of the relative crystallinity of rubberwood dyed with fungi are greater than those of the undyed wood. Although the CaC2O4 crystals produced on wood surface, according to the formula (1), the peaks in the formula were not the peaks in CaC2O4; therefore, it is difficult to explain that the production of CaC2O4 increased the crystallinity in different days. There may be one more possible reason that the reduction of non-crystalline or amorphous regions increased the crystallinity, and the further research is needed.

FTIR analysis

Figure 3 shows the FTIR spectra of rubberwood dyed with fungi at 0 and 40 days. In general, the rubberwood dyed with fungi at 40 days was not obviously distinct from rubberwood dyed at 0 days. However, there were some differences between the band values at 0 and 40 days. The band at 3405 cm−1 showed –OH in cellulose and hemicellulose, and the band value decreased between 0 and 40 days [55]. The band value at 2928 decreased, which illustrated the vibration of –CH in cellulose [56]. The bands located at 1742 cm−1 corresponded to the acetyl (CH3–CO–) and C=O stretching of the acetyl group in the hemicellulose, and the reduction tendency showed that the hemicellulose was broken [13, 57]. The bands at 1506, 1463, and 1423 cm−1 illustrated the aromatic skeleton and C–H in the lignin was integrated, but the decrease of bands at 1238 cm−1 indicated the decrease of –OH in lignin [58]. The decrease of the band at 1373 cm−1 illustrated the vibration of –C–H in cellulose and hemicellulose. Furthermore, bands at 1623 and 794 cm−1 became broadened, which illustrated the increase of COO– and CaC2O4. Therefore, FTIR determined that the –OH in cellulose, hemicellulose, and lignin was slightly broken, and it is possible that the decrease of –OH was due to its relationship with water, which could have reacted with –OH when water entered the rubberwood. The C–H in cellulose also slightly decreased.

Effects of fungi pigment on wood color

Table 2 shows the color effects of rubberwood dyed with fungi in increments between 0 and 40 days. L*, a*, and b* refer to brightness, red and green value, and yellow and blue value, respectively. The L0*, a0*, and b0* values of the untreated wood are 70.01, 7.71, and 17.24, respectively. The NH310 portable colorimeter showed the ΔL*, Δa*, and Δb* values. With time increasing, ΔL* had a positive value and gradually became smaller, which indicated that the color turned darker. The values of Δa* and Δb* were negative and became smaller, which indicated that the color turned green and blue. The difference value of ΔE* gradually became smaller, which indicated that the color changed more slowly with time increasing. These values above were measured by NH310 portable colorimeter, and the visual effect may be a little different from measured values. Figure 4 shows that the color of the rubberwood visually. Additionally, it is evident that the color became darker and more uniform. The color at 5 days obviously showed an asymmetrical distribution on the surface of rubberwood visually, especially around the vessels, which demonstrates that fungi enter the rubberwood through the vessels. This phenomenon corresponded to the SEM analysis. The surface at 40 days was covered with pigment produced by hyphae, which distributed uniformly. Therefore, the fungi have the potential to dye the surface of wood. The ANOVA and Tukey analysis showed that significant color change was achieved (p < 0.05) from 0 to 30 days, but no significant color change (p > 0.05) showed between 30 and 40 days, which corresponded to the color visually.

Effects of fungi on wetting angle

Figure 5 shows the influence of fungi on the wetting angle, which illustrates the properties of surface wettability. The chart shows that the wetting angle of undyed rubberwood was 116.9°; however, the wetting angle of dyed rubberwood was higher than that of the undyed wood. The contact angle of dyed wood increased from about 133° at 5 days to 145° at 40 days. If the fungi’s hyphae were more intensive on the surface, the wetting angle would be larger until about 150°, at which an almost highly hydrophobic state is reached. Within 16 s, the contact angle gradually decreases, but the contact angle decreased more dramatically between 0 and 5 days than it did between 10 and 40 days. Additionally, as time increased, the decrease rate became slower, and when the fungi fully covered the wood surface, the contact angle was nearly stable over time at 150°. It is possible that the fungi had a highly waterproof characteristic. Therefore, the wettability of rubberwood dyed with fungi is poorer than the wettability of undyed wood. The surface dyed with fungi is too smooth to glue with adhesives; so the dyed face is more suitable for surface decoration, coatings, adhesives and so on.

Effects of fungi pigment on pH value of rubberwood

Table 3 shows the pH value of dyed rubberwood on different days. The pH value of undyed rubberwood was 5.12, and the pH value of dyed rubberwood increased gradually from 5 to 40 days until it reached 6.80. Wood acidity primarily comes from wood extractives, uronic acid (R–) and acetyl (CH3–CO–) in hemicellulose, and –OH in cellulose. –OH in uronic acid connects with CH3–CO– to form acetic ester (R–OCOCH3), and acetic ester can react with water to form acetic acid (CH3COOH), which makes wood acidic [59]. However, FTIR analysis found a degradation of CH3–CO– in hemicellulose, which reduced the production of CH3COOH. The extractives of rubberwood contain abundant carbohydrates and protein, which decrease significantly when fungi entered the wood; therefore, pH went up with time increase.

Effects of fungi on mass loss ratio, 24-h water absorption and compressive strength

Figure 6 shows the influence of fungi on mass loss ratio, 24-h water absorption, and compressive strength. Mass loss ratio increased slowly from 0 (0%) to 10 days (1.19%), and then increased more rapidly from 10 to 20 days (3.41%). It also increased at a stable speed. 24-h water absorption decreased sharply from 0 to 5 days, and then increased gradually from 5 to 40 days. The ANOVA analysis of the mass loss ratio and 24 h water absorption both showed a significantly change (p < 0.05) from 0 to 20 days, and changed insignificantly (p > 0.05) from 20 to 40 days. This is possibly because the fungi abundantly gathered in vessels and the wood surface, and received plenty of its nutrients (such as carbohydrates and water from extractives) from the rubberwood, and the vessels were blocked by hyphae, so that the oxygen and water enter the rubberwood difficultly, so 24-h water absorption decreased. In the latter few days, fungi grew slowly due to a lack of oxygen, water, and other nutrition, and therefore the mass loss ratio increased slowly, and due to the slight degradation of cellulose and hemicellulose, the pore became larger than before, which made water absorption slightly increased.

The ANOVA analysis showed there was no obvious relationship between time and compressive strength (p > 0.05). However, Fig. 6 showed a slight increase at 5 days, and Humar [31] and Lum et al. [39] also drew a similar conclusion that the mechanical properties of wood improved after the wood was dyed with fungi, which illustrated mechanical properties would not reduce significantly. The FTIR analysis also showed the relationship between fungi and wood component, which illustrated there were no obviously effects on mechanical properties. What is more, the surface color analysis showed that fungi had the potential to be dyed on the rubberwood.

Conclusions

Lasiodiplodia theobromae can enter the rubberwood through vessels, and control the surface color with time increased. A highly hydrophobic surface formed on the rubberwood dyed with fungi. There was a slight degradation of cellulose and hemicellulose of wood, and the properties of rubberwood were not been affected obviously.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- SEM:

-

scanning electron microscope

- EDS:

-

energy-dispersive spectrometer

- XRD:

-

X-ray diffraction

- FTIR:

-

fourier transform infrared spectrometer

- L. theobromae :

-

Lasiodiplodia theobromae

- CIE:

-

commission internationale eclairage

- RH:

-

relative humidity

- Turkey HSD:

-

Tukey’s honestly significant difference

- SPSS:

-

statistical product and service solutions

References

Zhao Y, Tan XY, Wang XQ, Liu W (2011) Dyeing properties of acetylated wood with red disperse dyes. Adv Mater Res 335–336:1061–1066

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Matsuo M, Umemura K, Kawai S (2014) Kinetic analysis of color changes in keyaki (Zelkova serrata) and sugi (Cryptomeria japonica) wood during heat treatment. J Wood Sci 60:12–20

Tuong VM, Jian L (2010) Effect of heat treatment on the change in color and dimensional stability of acacia hybrid wood. BioResources 5:1257–1267

Ananias RA, Ulloa J, Elustondo DM, Salinas C, Rebolledo P, Fuentes C (2012) Energy consumption in industrial drying of radiata pine. Dry Technol 30:774–779

Kielmann BC, Adamopoulos S, Militz H, Koch G, Mai C (2014) Modification of three hardwoods with an N-methylol melamine compound and a metal-complex dye. Wood Sci Technol 48:123–136

Wang XQ, Tang RL, Zhang Y, Yu ZM, Qi CS (2016) Preparation of a novel chitosan based biopolymer dye and application in wood dyeing. Polymers 8:338–351

Canevari C, Delorenzi M, Invernizzi C, Licchelli M, Malagodi M, Rovetta T, Rovetta M (2016) Chemical characterization of wood samples colored with iron inks: insights into the ancient techniques of wood coloring. Wood Sci Technol 50:1057–1070

Christie R (2007) Environmental aspects of textile dyeing. Waste Manag 1:717–725

Goktas O, Duru ME, Yeniocak M (2008) Determination of the color stability of an environmentally friendly wood stain derived from laurel (Laurus nobilis L.) leaf extracts under UV exposure. For Prod J 58:77–80

Hernandez VA, Galleguillos F, Robinson S (2016) Fungal pigments from spalting fungi attenuating blue stain in Pinus spp. Int Biodeterior Biodegrad 107:154–157

de Souza-Cruz PB, Freer J, Siika-Aho M, Ferraz A (2004) Extraction and determination of enzymes produced by Ceriporiopsis subvermispora during biopulping of Pinus taeda wood chips. Enzyme Microb Technol 34:228–234

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegrad 52:151–160

Jacobs K, Plaschkies K, Scheiding W, Weiß B, Melcher E, Conti E, Fojutowski A, Le Bayon I (2019) Natural durability of important European wood species against wood decay fungi. Part 2: field tests and fungal community. Int Biodeterior Biodegrad 137:118–126

Plaschkies K, Jacobs K, Scheiding W, Melcher E (2014) Investigations on natural durability of important European wood species against wood decay fungi. Part 1: laboratory tests. Int Biodeterior Biodegrad 90:52–56

Gao S, Yue X, Wang L (2019) Effect of the degree of decay on the electrical resistance of wood degraded by brown-rot fungi. Can J For Res 49:145–153

da Silveira MF, Gouveia FN, Moreira ACO, Oliveira JRV, Silva ASVS, Almeida GF, Costa AF (2019) Natural resistance of eight Brazilian wood species from the region Caatinga determined by an accelerated laboratory decay test against four fungi. Holzforschung 73:151–154

Schubert M, Volkmer T, Lehringer C, Schwarze FWMR (2011) Resistance of bioincised wood treated with wood preservatives to blue-stain and wood-decay fungi. Int Biodeterior Biodegrad 65:108–115

Clausen CA, Coleman RD, Yang VW (2010) Fatty acid-based formulations for wood protection against mold and sapstain. For Prod J 60:301–304

Yu S, Zheng S, Li K, Feng G (2015) Assessment of human health in northeast china apartments with mould growth. Procedia Eng 121:122–128

Robinson SC, Michaelsen H, Robinson JC (2016) Spalted wood, history, science and art of an unique material. Schiffer Publishing, Pennsylvania

Robinson SC, Laks PE, Richter DL, Pickens JB (2007) Evaluating loss of machinability of spalted sugar maple. For Prod J 57:33–37

Mallett KI, Hiratsuka Y (1986) Nature of the “black line” produced between different biological species of the Armillaria mellea complex. Can J Bot 64:2588–2590

Robinson SC (2011) Destroying uniformity: using fungi to add a tactile and visual experience to functional wood. Leonardo 44:144–151

Hinsch EM, Robinson SC (2018) Comparing colorfastness to light of wood-staining fungal pigments and commercial dyes: an alternative light test method for color fastness. Coatings 8:189–201

Qin L, Guo MH, Qiu J, Liu C (2011) Study on the formation of wood zone line pattern induced by the fungi. Adv Mater Res 197–198:190–193

Robinson SC, Tudor D, Cooper PA (2011) Feasibility of using red pigment producing fungi to stain wood for decorative applications. Can J For Res 41:1722–1728

Tudor D, Robinson SC, Cooper PA (2013) The influence of pH on pigment formation by lignicolous fungi. Int Biodeterior Biodegrad 80:22–28

Tudor D, Robinson SC, Cooper PA (2012) The influence of moisture content variation on fungal pigment formation in spalted wood. AMB Express 2:69

Bouslimi B, Koubaa A, Bergeron Y (2014) Effects of biodegradation by brown-rot decay on selected wood properties in eastern white cedar (Thuja occidentalis L.). Int Biodeterior Biodegrad 87:87–98

Humar M, Vek V, Bucar B (2008) Properties of blue-stained wood. Drvna Ind 59:75–79

Uzunovic A, Yang DQ, Gagne P, Breuil C, Byrne A, Gignac M, Kim SH (1999) Fungi that cause sapstain in Canadian softwoods. Can J Microbiol 45:914–922

Teoh YP, Don MM, Ujang S (2011) Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): a case study in Malaysia. J Wood Sci 57:255–266

Bruce A, Stewart D, Verrall S, Wheatley RE (2003) Effect of volatiles from bacteria and yeast on the growth and pigmentation of sapstain fungi. Int Biodeterior Biodegrad 51:101–108

Bulcke JVD, Acker JV, Stevens M (2006) Assessment of blue-stain resistance according to the EN 152 and a reverse test method using visual and computer-aided techniques. Int Biodeterior Biodegrad 57:229–238

Guillén Y, Machuca A (2008) The effect of copper on the growth of wood-rotting fungi and a blue-stain fungus. World J Microbiol Biotechnol 24:31–37

Schubert M, Mourad S, Schwarze FWMR (2011) Automated image processing for quantification of blue-stain discolouration of Norway spruce wood. Wood Sci Technol 45:331–337

Mohali SR, Castro-Medina F, Úrbez-Torres JR, Gubler WD (2017) First report of Lasiodiplodia theobromae and L. venezuelensis associated with blue stain on Ficus insipida wood from the natural forest of Venezuela. For Pathol 47:1–5

George J (1985) Preservative treatment of bamboo, rubber wood and coconut palm. Simple methods for treating building timbers. In: Findlay WPK (ed) Preservation of timber in the tropics. Forestry Sciences, vol 17. Springer, Dordrecht

Lum C, Byrne T, Casilla R (2006) Mechanical properties of lodgepole pine containing beetle-transmitted blue stain. For Prod J 56:45–50

Krzisnik D, Lesar B, Thaler N, Humar M (2018) Performance of bark beetle damaged norway spruce wood against water and fungal decay. BioResources 13:2473–3486

Chow S, Obermajer A (2007) Moisture and blue stain distribution in mountain pine beetle infested lodgepole pine trees and industrial implications. Wood Sci Technol 41:3–16

WS 233-2017 (2007) General biosafety standard for causative bacteria laboratories. PRC National health and family planning commission, Beijing

Inagaki T, Siesler HW, Mitsui K, Tsuchikawa S (2010) Difference of the crystal structure of cellulose in wood after hydrothermal and aging degradation: a NIR spectroscopy and XRD study. Biomacromolecules 11:2300–2305

GB/T 6043-2009 (2009) Method for determination of pH value of wood. PRC National Standard, Beijing

GB/T 1934 1-2009 (2009) Method for determination of the water absorption of wood. PRC National Standard, Beijing

GB/T 13942.1-2009 (2009) Durability of wood-Part 1: method for laboratory test of natural decay resistance. PRC National Standard, Beijing

ISO 4859-1982 (1982) Determination of radial and tangential swelling. International Standard Organization, London

ISO 13061-17 (2017) Determination of ultimate stress in compression parallel to grain. International Standard Organization, London

Salem MZM (2016) EDX measurements and SEM examination of surface of some imported woods inoculated by three mold fungi. Measurement 86:301–309

Kirboga S, Oner M (2015) Inhibition of calcium oxalate crystallization by graft copolymers. Cryst Growth Des 9:2159–2167

Guggiari M, Bloque R, Aragno M, Verrecchia E, Job D, Junier P (2011) Experimental calcium-oxalate crystal production and dissolution by selected wood-rot fungi. Int Biodeterior Biodegrad 65:803–809

Gadd GM, Bahri-Esfahani J, Li Q, Rhee YJ, Wei Z, Fomina M, Liang X (2014) Oxalate production by fungi: significance in geomycology, biodeterioration and bioremediation. Fungal Biol Rev 28:36–55

Ray MRSRC (2009) Oxalic acid Production by Fusarium oxysporum Schlecht and Botryodiplodia theobromae Pat. Post-harvest fungal pathogens of yams (Dioscorea rotundata L.) and detoxification by Bacillus subtilis CM1 isolated from culturable cowdung microflora. Arch Phytopathol Plant Protect 42:666–675

Wei XY, Tao DH, Sheng XL, Zhang MH (2018) Modification of poplar wood using polyhexahydrotriazine and its effect on hygroscopicity. J Wood Chem Technol 38:214–223

Khalila HPSA, Ismail H, Rozman HD, Ahmad MN (2001) The effect of acetylation on interfacial shear strength between plant fibres and various matrice. Eur Polym J 37:1037–1045

Stefke B, Windeisen E, Schwanninger M, Hinterstoisser B (2008) Determination of the weight percentage gain and of the acetyl group content of acetylated wood by means of different infrared spectroscopic methods. Anal Chem 80:1272–1279

Genestar C, Palou J (2006) SEM–FTIR spectroscopic evaluation of deterioration in an historic coffered ceiling. Anal Bioanal Chem 384:987–993

Liu YX, Zhao GJ (2014) The chemical properties of wood. In: Wood science, 2nd edn. China Forestry Publishing House, Beijing

Acknowledgements

The authors wish to thank the Hainan State Farms Forest Industrial Group Co., Ltd and the China Forestry Culture Collection Center for supporting the experimental materials.

Funding

This work was sponsored by the Beijing Outstanding Talent Training Foundation (CN) (2017000020124G092).

Author information

Authors and Affiliations

Contributions

BZ wrote the manuscript, performed the experiment of the study and was responsible for data collection; ZY designed the experiments and analyzed the data. YZ and CQ helped performed the experiment and revised the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Zhao, B., Yu, Z., Zhang, Y. et al. Physical and mechanical properties of rubberwood (Hevea brasiliensis) dyed with Lasiodiplodia theobromae. J Wood Sci 65, 63 (2019). https://doi.org/10.1186/s10086-019-1843-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10086-019-1843-z