Abstract

The spacecraft for deep space exploration missions will face extreme environments, including cryogenic temperature, intense radiation, wide-range temperature variations and even the combination of conditions mentioned above. Harsh environments will lead to solder joints degradation or even failure, resulting in damage to onboard electronics. The research activities on high reliability solder joints using in extreme environments can not only reduce the use of onboard protection devices, but effectively improve the overall reliability of spacecraft, which is of great significance to the aviation industry. In this paper, we review the reliability research on SnPb solder alloys, Sn-based lead-free solder alloys and In-based solder alloys in extreme environments, and try to provide some suggestions for the follow-up studies, which focus on solder joint reliability under extreme environments.

Similar content being viewed by others

1 Introduction

Deep space exploration such as Lunar Exploration Project, Manned Lunar Landing Project, space station and Mars Exploration are of great strategic significance in politics, science and national economy. Globally, the United States, Europe, Russia, China, Japan, India, South Korea, Brazil and other countries have formulated and launched deep space exploration plans. China began its Lunar Exploration Project which named as “Chang’E Project” in 2004. Following the successful launch of Chang’E-1 in 2007, Chang’E-4 probe landed autonomously in the Von Karman Impact crater in the Aitken Basin at the South Pole on the moon on January 3, 2019, achieving the first soft landing of a human probe on the far side of the moon. Chang’E-5 spacecraft dug the lunar soil from the Moon’s surface and then sent it back to the Earth on Dec. 2, 2020. Later, the Mars probe project “Tianwen-1” blasted off on July 23, 2020, and entered orbit around Mars on February 10, 2021.

When a spacecraft escapes from the earth’s atmosphere to space, it will be affected by radiation such as high-energy electrons and protons from the solar wind, space plasma, extreme temperature, wide range temperature variation environment, etc., which will damage onboard electronics and affect the reliability of the spacecraft electronic systems. In order to reduce the damage from the space environments, the electronic devices are usually placed in an enclosure or equipped with an active thermal control device. The enclosure plays a role in heat insulation, cooling, and radiation or corrosion prevention. While the thermal control device plays as the heating or cooling device [1]. Meantime, this approach reduces the spacecraft payload ratio, increases launch costs, and fails to protect the electronics which inevitably exposes outside, such as the solar arrays.

With the progress of technology, miniaturized high-power electronic devices have become the mainstream, and the decreasing packaging size has strongly affected the reliability of solder joints, especially under the drive of an increasingly severe service environment of the electronic device. It is well known that solder joints play an important role in electronic packaging, which serves as both mechanical bridges and electrical interconnections between the component and the substrate. Once a solder joint fails, the IC even the whole device might be destroyed. Package failure accounts for 70% of the total number of onboard electronic failures while solder joint failure is the main reason [2, 3].

Now the third-generation semiconductor devices such as SiC, GaN which have strong radiation resistance, can normally operate at a temperature from − 223 ℃ to 600 ℃. In contrast, the operation temperature range of Sn-based solder joints cannot exceed − 196 ℃ to 250 ℃. The solder joint reliability has limited the application of electronic devices under extreme environments. For a long-term exploration mission, the amount of fuel in the spacecraft is limited. If the reliability of solder joints can be ensured in extreme environments, the dependence of spacecraft on active thermal control devices and enclosures can be greatly reduced, thus reducing energy consumption, launching costs and system complexity, which is of great significance to deep space exploration activities. This paper reviews the research progress of solder joint reliability in three typical extreme environments: thermal cycle, cryogenic environment and radiation environment. With an increase in the range and duration of deep space exploration missions, existing solder joint reliability cannot meet the requirements of harsh environments. The reliability of solder joints in onboard electronics under cryogenic and large temperature variation environments needs to be further improved. More attention should be paid to the radiation resistance of solder joints. The reliability of solder joints under multi-extreme environments coupling conditions is an urgent problem to be solved in future deep space exploration missions.

2 Space Environments

2.1 Cryogenic Environments

The military specification temperature range of CMOS integrated circuits is from – 55 ℃ to 125 ℃, and the environment below − 55℃ is usually called a cryogenic environment in the aerospace industry [4]. The surface temperatures of many planets are less than − 55 °C, such as Mars, where the winter temperature at the poles is below − 143 °C. The space exploration vehicles, such as the James Webb Space Telescope, will operate at − 246 °C. Obviously, the service temperature environment in space exploration activities has a significant difference from the service temperature environment on the earth.

2.2 Large Temperature Variations

Moon, which is the nearest planet to earth, has a surface temperature in straight sunlight surpassing 120 °C while the surface temperature would be below − 230 °C during the night. The maximum instantaneous temperature change rate of the moon is as high as 2 ℃/min.

Actually, the most harmful effects on the solder joints’ reliability in aircraft electronics are the large temperature variation range and the temperature change rate instead of the extreme upper or lower environmental temperatures.

2.3 Radiation-rich Environments

Three significant radiation effects are 1) displacement effects that high-energy particles displace atoms or nuclei; 2) ionization effects that the materials are ionized when they are traversed by high-energy charged particles; and 3) total dose effect that charges dielectric causing cumulative parametric shifts that render a device nonfunctional.

3 Solder Joint Reliability in Space Environments

Traditional SnPb solder alloys were widely applied in the electrical industry in the last century. For sake of its toxicity, Pb is forbidden to be used in commercial electronics currently. However, the electronics in the aerospace industry are free from the restriction of hazardous substances (RoHS) and waste electrical and electronic equipment (WEEE) directive and thus SnPb solder alloys with excellent wettability and cryogenic performance, still have wide application in the electronics used in aircraft [5].

3.1 SnPb Solder Alloys

3.1.1 Effect of Thermal Cycling

Statistically, 70% of electronic device failure is caused by the failure of packaging. Thermal fatigue and creep are the main mechanisms of solder joint failure, which are mainly caused by large temperature variations [4, 6]. A large number of studies have shown that the formation and growth of hard and brittle intermetallic compounds (IMCs) is the main cause of solder joint fracture under thermal cycling conditions [5, 7].

Tian et al. [8] explored the reliability and failure mechanism of Sn37Pb BGA solder joints under thermal cycling conditions of -196 °C to 150 °C for 400 times. As shown in Figure 1(a), IMC Au0.5Ni0.5Sn4 was formed between the Ni3Sn4 IMC layer and the Sn37Pb solder during thermal shock. As shown in Figure 1(b), (c), brittle fracture occurred along the Ni3Sn4/Au0.5Ni0.5Sn4 interface during thermal shock. The characteristic lifetime of Sn37Pb BGA solder joints was 304 cycles.

Schematic diagram of IMC cracks and its mechanism at the interface [8]: (a)–(c) Cross-sectional SEM micrographs of Sn37Pb solder joints after 300 cycles

Hang et al. [9] investigated the evolution and growth behavior of IMCs and their effects on the pull strength and fracture behavior of quad flat package (QFP) with Sn37Pb solder joints under extreme temperature thermal shock test from − 196 °C to 150 °C, as shown in Figure 2(a), (b). As shown in Figure 2(c)–(f), a continuous (Cu, Ni)6Sn5 IMC layer was formed at the interface between the Cu lead and the Sn37Pb solder alloy after reflowing, and the IMC formed between the solder and Ni-P layer was (Ni, Cu)3Sn4 IMC. A thin layer of Cu3Sn IMCs was formed between the Cu lead and (Cu, Ni)6Sn5 IMC layer after 150 cycles. The morphology of interfacial (Cu, Ni)6Sn5 IMC changed from scallop-type to plane-type, and the morphology of interfacial (Ni, Cu)3Sn4 IMC evolved from needle-type to scallop-type, and finally to plane-type during extreme temperature thermal shock.

Microstructure and microstructure of Sn37Pb solder joints before and after 300 times thermal cycling [9]

3.1.2 Effect of Low Temperature Storage

The transition of β-Sn to α-Sn under cryogenic conditions which is also called "tin disease", is a serious problem for electronic devices. Compared with the lead-free solder alloys, the SnPb solder alloys have good "tin disease" resistance and low-temperature performance because Pb could impede the "tin disease" [10, 11]. Thus SnPb solder alloy is widely used in spacecraft onboard electronics. The ductile-to-brittle transition temperature (DBTT) of SnPb eutectic solder alloy is about − 80 ºC [12]. With the increase of Pb content, the toughness and DBTT of SnPb solder alloy become fuzzy. When the Pb content is more than 90 wt.%, the ductile-to-brittle transition phenomenon in the solder alloy disappeared [12]. Under low-temperature impact conditions, solder joint failure mainly occurs at the IMC interfaces. During long-term usage under low temperatures, the types of interfacial IMCs are usually stable. The increased interfacial IMCs thickness and interfacial stress are the main causes of solder joint failure [13].

Tian [14] conducted long-term storage experiments at − 196 ºC and − 100 ºC for Sn37Pb solder joints to explore the growth mechanism of interfacial IMCs. As shown in Figure 3, after storage at − 196 ºC for 960 h, the thickness of interfacial Cu6Sn5 IMC increased and its shape changed from scallop-type to columnar-type. The IMC growth rate decreased with the storage time, and the growth rate at − 196 ºC was higher than that at − 100 ºC.

Interfacial microstructure of Sn-37Pb/Cu solder joints stored at − 196 ºC for different periods [14]: (a) 240 h, (b) 480 h, (c) 720 h, (d) 960 h

Ji et al. [15] investigated the uniaxial tensile deformation and fracture mechanisms of Sn37Pb solder alloy over a full temperature range from 20 ºC to − 196 ºC. As the ambient temperature declined to − 150 ºC, the tensile strength and quasi-static toughness were significantly improved while the fracture elongation was maintained at 25 % to 30 %. The optimal combinations of strength, ductility and toughness were achieved at − 150 ºC. The deformation harmony between the two phases coupled with deformation twins occurring in the Sn matrix leads to the simultaneous enhancement of strength, ductility, and toughness.

An et al. [16] explored the failure mode and the fracture mechanism of six kinds of Sn-based bulk solders (Sn, 99.3Sn0.7Cu, 96.5Sn3Ag0.5Cu, 62Sn36Pb2Ag, 63Sn37Pb, 10Sn90Pb) with the temperature range of − 150 ºC to 20 ºC. The ductile-to-brittle transition became more significant in all the Pb-free solders at lower temperatures. For pure Sn solder, the ductile-to-brittle transition occurred between − 40 ºC and − 60 ºC. For 62Sn36Pb2Ag solder, the fracture mode is a quasi-cleavage fracture which is between cleavage fracture and dimple fracture. With higher Pb content, the solder toughness would be higher, and the ductile-to-brittle transition phenomenon in the solder tends to be insignificant.

3.1.3 Effect of Radiation Environment

An in-orbit spacecraft not only has to endure extremely high and low temperatures and large temperature variations, but also faces the space strong radiation environments. With the sustained improvement of the micro-electronic circuit integration, the solder joint volume decreases and the solder joint number increases, which makes solder joints more sensitive to intense cosmic radiation. At present, researches about solder joint reliability in extreme environments mainly focus on large temperature variations, extreme high and low temperature conditions, but few researchers pay attention to the radiation resistance of SnPb solder joints.

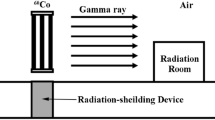

Wang et al. [17] irradiated Sb37Pb solder alloy/Cu and Sn50Pb49Sb1 solder alloy/Cu solder joints [18] by 60Co γ-rays with a dose rate of 0.25 Gy/s for 0 to 960 h to investigate the effect of γ-ray irradiation on the microstructure and mechanical property of SnPb solder joints. γ-ray irradiation has an insignificant effect on the thickness and morphology of IMCs layer for both joints. However, the formation and growth of micro-voids and micro-cracks were observed in Pb-based solid solutions for both joints. Due to the Compton effect, the γ-ray photon could knock the electron out of its orbit, which created energetic electrons. Solder joint atoms were knocked by the energetic electrons and hence displacement. As shown in Figures 4 and 5, after γ-ray irradiation, the microhardness of both solder joints significantly decreased. After 960 h irradiation, the shear forces of Sn37Pb/Cu and Sn50Pb49Sb1/Cu solder joints were decreased by 11.47% (Figure 4) and 22% (Figure 5), respectively.

The maximum force of Sn37Pb solder joints at various irradiation time in the impact test [17]

The pull force of the Sn50Pb49Sb1/Cu solder joints at various irradiation times [18]

3.2 Sn-based Lead-free Solder Alloys

As the inevitable trend of deep space exploration spacecraft onboard electronics solder joints, the reliability of lead-free solder joints in extreme environments has been widely concerned by researchers. At present, the main Sn-based lead-free solder alloys are SnAgCu, SnAg and, SnBi. Wherein SnAgCu solder alloys have good wettability, high welding reliability, excellent thermal fatigue resistance and creep resistance [19, 20]. Therefore, SnAgCu solder alloys are considered as the most potential candidate for SnPb solder alloys and are widely used in spacecraft onboard electronics [21–25].

3.2.1 Effect of Thermal Cycling

Now a series of researches have been conducted to test the reliability of lead-free solder joints under thermal cycling conditions, the majority of which focus on the temperature range from − 40 ℃ to 155 ℃ [26–31]. The thermal cycling performance increases with Ag content in SnAgCu lead-free solder alloys. SAC305 (96.5Sn3Ag0.5Cu) and SAC405 (95.5Sn4Ag0.5Cu) solder alloys have good thermal cycling reliability which is desirable for high temperature electronic devices used in aerospace, military, and automotive industry [32, 33]. The failure mechanism of SnAgCu solder alloys under thermal cycling conditions has attracted a lot of researchers’ attention due to the increasingly harsh service environments of solder joints [34, 35]. During the high temperature stage of thermal cycling, the growing IMCs layer at SnAgCu solder alloy/Cu substrate interface is observed with the formation of Cu6Sn5/Cu3Sn bilayer microstructure, which is similar to that in thermal aging process [36]. Exposing to the low-temperature stage, the stress at the interface would greatly increase due to the different coefficient of thermal expansion (CTE) of brittle Cu3Sn and Cu6Sn5 and hence generated some microcracks.

Chen et al. [37] compared the influences of two different thermal cycling temperature ranges (25 ℃ to 125 ℃ and 25 ℃ to 185 ℃) on the interfacial microstructure in SAC305 solder alloy/Cu substrate. The Cu6Sn5 and Cu3Sn IMC layers could be evidently observed after rapid thermal cycling, and the IMC layers thickness was increased with the elevated heating temperature and time. The thickness and compositions of interfacial IMCs evidently changed compared to that in the original specimen.

Tian et al. [38] investigated the tensile behaviors of SAC305 solder alloy and SAC305/Cu solder joints with the strain rates of 10−3 s−1 and 10−2 s−1 within the temperature range from − 196 ℃ to 25 ℃. The tensile strength of SAC305 solder alloy and SAC305/Cu solder joints increased firstly and then decreased with descending temperature. The tensile strength of joints under the strain rate of 10−2 s−1 was always higher than that under the strain rates of 10−3 s−1 with the same temperature. The fracture mode of SAC305/Cu solder joints transferred from ductile fracture to brittle fracture as the test temperature decreased from 25 ℃ to − 196 ℃, as shown in Figure 6.

Fracture surfaces of SAC305 solders at 10−3 s−1 under different temperatures [38]: (a) 25 ℃, (b) − 50 ℃, (c) − 100 ℃, (d), (e) − 150 ℃ and (f) − 196 ℃

Pang et al. [39] investigated the effect of thermal cycling aging on the lead-free 95.5Sn3.8Ag0.7Cu solder joint. Two temperature cycling modes: thermal cycling (− 40 ℃ to 125 ℃, 12.7 ℃/min) and thermal shock (− 55 ℃ to 125 ℃, 51.4 ℃/min) with 1000 and 2000 cycles, were investigated. The average shear strength of the solder joints decreased with increasing thermal cycling times resulting from the growth and coarsening of intermetallic compounds. The average shear strength of samples subjected to thermal cycling is higher than that of thermal shock samples. And the growth rate of thermal shock samples is higher than that of thermal cycling samples.

3.2.2 Effect of Low Temperature Storage

Compared with Sn/Pb solder alloys, the lead-free solder alloys do not contain Pb elements, which cannot prevent "tin disease" at low temperatures. Lead-free solder joints under low temperature conditions are in danger of fracture due to the different CTE and brittleness between β-Sn and α-Sn. Current researches suggest that long-term low temperature storage would not generate new IMCs, but lead to the growth of an interfacial IMC layer [14]. The lower storage temperature brings a faster IMCs growth rate. The thermal mismatch between materials in solder joints leads to a high-stress gradient and promotes the diffusion of atoms [14, 40], which accelerated the IMCs growth. Therefore, long-term low temperature usage will increase the interfacial IMCs thickness in the lead-free solder joints and thus reduce their shear strength.

Li et al. [41] investigated the influence of deep cryogenic treatment (DCT) (− 196 ℃ for 0 h, 24 h, 72 h, 168 h, 600 h) on the mechanical properties and microstructure of SAC305 solder joints. The solder alloy and IMC strength show different change trends with the increase of DCT time. After 24 h of DCT, the strength of solder increased rapidly. After 72 h of DCT, the strength of solder increased while the strength of IMC decreased, which is mainly due to the mismatch of thermal expansion coefficient and the stress concentration that happened at the solder alloy/IMC interface. With the increase of DCT time, the fracture mode changed from ductile fracture inside solder to brittle fracture along the solder alloy/IMC interface or inside the IMC layer.

Li et al. [42] investigated the failure mechanism of SAC305 BGA solder joints under − 100 ℃. At − 100 ℃, the fracture characteristic of SAC305 solder joints was brittleness, which was different from ductile fracture under room temperature (RT). The transition temperature range was confirmed as − 70 ℃ to − 80 °C by verification experiments. Because of the low-temperature characteristics of SAC305, there may be a higher failure risk of actual operation, more attention should be paid to the reliability of Pb-free material applications for deep space exploration.

Liu et al. [43] investigated the effects of low temperature (− 40 °C to RT) on the mechanical strength and fracture modes of SnAgCu solder joints with a high shear rate of 1.0 m/s. As shown in Figure 7(a), (b), the peak load of SnAgCu solder joints was slightly decreased with decreased temperature, and the value of energy to peak load was dramatically dropped by about 40% from RT to − 40 °C. Low temperature results in a mechanical strength reduction at the solder joint/Cu interface.

Low temperature micro-impact test of SnAgCu BGA solder joints [43]

3.2.3 Effect of Radiation Environment

It is well known that lead-free solder alloys do not contain Pb elements that can effectively block cosmic radiation, thus their radiation resistance is relatively weak. Energetic radiation particles in cosmic radiation can cause supersaturated micro-defects in the lead-free solder matrix along with the degradation of solder joints properties. In recent years, researchers have carried out a large number of studies about the irradiation resistance of third-generation semiconductor devices, including SiGe [44–46], GaN [47–49] and SiC [50–52].

Paulus et al. [53] investigated the effects of the 60Co γ-ray irradiation with a dose rate of 0.53 Gy/s on the microhardness of SAC/ENIG/Cu solder joints. As shown in Figure 8, the microhardness value of the joints reached the maximum when the γ-ray irradiation dose was 5 Gy. When the γ-ray irradiation dose was increased to 50 Gy and 500 Gy, the SAC/ENIG/Cu solder joints are softened.

Graph of averaged hardness calculated from indentation test for control (0 Gy) and irradiated samples (5, 50, 500 Gy) [53]

Yusoff et al. [54] investigated the effect of low dose 60Co γ-ray irradiation (from 5 Gy to 25 Gy) with a 0.26 Gy/s dose rate on microhardness and microstructural properties of SAC305 solder joints. As shown in Figure 9(a), the microhardness value of solder joints reached the maximum when the irradiation dose was 5 Gy, and it decreased with the increase of irradiation dose, which was similar to the result in Ref. [53]. As shown in Figure 9(b), the IMC layer thickness increased with the increment of radiation dose, which is attributed to heat from gamma ray enhancing the formation of IMC.

Microhardness and microstructure of SAC305 solder joints before and after irradiation [54]

Wen et al. [55] investigated the effect of 60Co γ-ray irradiation with a dose rate of 0.2 Gy/s on the microstructure and mechanical properties of the AuSn20 solder joints. The irradiation treatment was performed at the atmospheric condition for different durations of 300 h, 600 h, and 1000 h at RT. As shown in Figure 10(a)–(d), the number and size of voids in joints gradually increased during the irradiation process due to the migration and agglomeration of irradiation-induced vacancies. As shown in Figure 10(e)–(h), the (Au,Ni)Sn and (Ni,Au)3Sn2 IMC layers were formed by the activation of interfacial reaction between Au/Sn solder and plating metal. The failure mode of solder joints was altered from ductile fracture to brittle fracture, and the shear strength was decreased by 37.23% after 1000 h γ-ray irradiation.

Microstructure of the joints after irradiation [55]: X-ray images of joints with irradiation durations (a) 0 h, (b) 300 h, (c) 600 h, (d) 1000 h; SEM micrograph of MoCu20/Cu solder joints (e) 0 h, (f) 300 h, (g) 600 h, (h) 1000 h

3.3 In-based Solder Alloys

Indium (In) is one of the softest materials with a low melting point (156.7 °C) and has been used in various solder alloys, such as In-Sn, In-Sn-Ag-Zn, In-Bi, In-Ag and In-Bi-Sn. In-based solder alloys are potential materials in cryogenic applications due to their excellent electrical conductivity and ductility at a cryogenic temperature [56, 57]. They have been used for die/substrate bonding in SiGe BiCMOS modules for Martian and Lunar exploration.

3.3.1 Effect of Thermal Cycling

In-based solder alloys can effectively relieve the interface thermal stress during the thermal cycle and thus improve packaging reliability [58]. In particular, the In-based solder alloys can operate at temperatures near their melting points and have good ductility at a lower temperature. The fracture of hard and brittle Cu-In and Ni-In IMCs during thermal cycling is the main failure mechanism of the In-based solder joints.

Chang et al. [59] assessed thermal fatigue and isothermal mechanical fatigue of In solder joints. The packaged structure is shown in Figure 11. At extremely low temperatures (below − 55 ℃), the dominant failure mode of In solder joints was an interfacial fracture at Au-In IMC layer under mechanical cyclic loading. However, the thin IMC layers strengthen the joint (less than 15 μm) and do not have a detrimental effect on solder joint fatigue life.

Drawing of packaged structure [59]

Deshpande et al. [60] investigated the shear property of four different In-based solder alloys (In-3Ag, In-34Bi, In-51Bi and In-32Bi-20Sn) to explore their suitability for cryogenic applications. The shear strength of In-based solder joints was measured at RT, deep cryogenic temperature (− 196 ℃) and after 10 thermal cycles (RT to − 196 ℃). The maximum shear strengths of 47.2 MPa and 32.5 MPa were obtained in Cu/In32Bi20Sn/Cu joints at RT and after thermal cycling, respectively. At − 196 ℃, the maximum shear strength of Cu/In3Ag/Cu joint was found to be 67.5 MPa. It was believed that the In32Bi20Sn solder alloy was the most appropriate for thermal cycling under cryogenic temperature [60].

3.3.2 Effect of Low Temperature Storage

Sn-based solder alloys have the nature of low temperature phase transformation. Few pieces of research focus on their mechanical properties and microstructure under low temperatures. As In is a kind of face centered cubic (FCC) metal and multiple close pack systems present in FCC, which brings In-based solder alloys with good ductility at low temperatures [60, 61].

Cheng et al. [62] investigated the interfacial reactions of thin and thick In/Cu (Figure 12(a)) and In/Ni/Cu (Figure 12(b)) solder joints under low-temperature cycling conditions (− 196 ℃ to 27 ℃), respectively. Low-temperature cycling had an insignificant effect on the growth of Cu-In IMCs for thick In joints. However, the effect of low-temperature cycling on the evolution of Cu-In and Ni-In IMCs is significant, which was different from that in the thick In joints. The properties of thick indium joints were close to those of pure indium, while the thin In joints were suggested to be regarded as a composite due to a drastic increase in the volume ratio of IMCs. It was believed that when the joint thickness was reduced to less than 230 µm, the negative effect of IMCs on the In joints reliability would be significant in the cryogenic application.

Specimen configurations and thermal cycle temperature profile [62]: (a) Single chip indium joint, (b) Sandwich type joint

4 Conclusions and Prospects

At present, there are many pieces of research focusing on solder joint reliability under thermal cycling and low temperature conditions, and the failure mechanism is mainly related to the fracture of hard and brittle IMCs. The evolution of solder joint interface IMCs under these conditions has been widely studied. However, there still have some issues of solder joint reliability under extreme environments which need more attention:

-

(1)

The wide bandgap semiconductors, such as SiC and GaN, are presented as suitable candidates for extreme temperature applications which exceed the boundaries of 500 °C and 900 °C. Their limit operating temperatures are far higher than the solder alloy melting points, which means that the solder joints have become weak sections in spacecraft onboard electronics. There are some approaches, such as element addition and nanoparticles addition in solder alloy, which are believed to be promising ways to enhance the reliability of solder alloys under extreme temperature conditions.

-

(2)

The SAC305 and SAC405 solder alloys have good thermal cycling reliability, but their high Ag content makes their drop shock performance poor. In-based solder alloys have good low temperature and thermal cycling performances and excellent plasticity. SnPb solder alloys have good thermal cycling reliability, low temperature performance and radiation resistance, which can better adapt to the harsh space environments and is irreplaceable in most of the aerospace industry for now. Developing lead-free solder alloys that can adapt multiple extreme environments simultaneously is the trend of onboard electronics solder joint development in future deep space explorations.

-

(3)

With the increase of the micro-electronic circuit integration and the increase of range and duration of deep space exploration spacecraft, deep space exploration spacecraft will face more severe radiation environments. The solder joint radiation resistance of onboard electronics will become an inevitable problem. However, at present, there is still a lack of systematic research on the reliability of solder joints under space radiation environments.

-

(4)

Sn-based solder alloys generally occur a β-Sn to α-Sn phase transition under low temperature conditions, which makes them not suitable for low temperature environments in deep space exploration. However, In-based solder alloys have good conductivity and toughness at low temperature, and there is no low temperature phase transition in such alloys. Therefore In-based solder alloys have a better application prospect when operating in cryogenic environments in deep space exploration. However, at present, there are very few reports on low temperature In-based solder alloys, especially on the solders containing nanomaterials and rare earth elements.

References

A Hammoud, R L Patterson, S Gerber, et al. Electronic components and circuits for extreme temperature environments. 10th IEEE International Conference on Electronics, Sharjah, United Arab Emirates, December 14-17, 2003(1): 44-47.

J Zhang, X F Sun, B B Zhang, et al. Effects of extreme temperature on the performance of electronic materials and components in deep space. Spacecraft Environment Engineering, 2018, 35(6): 547-554. (in Chinese)

N Jiang, L Zhang, Z Q Liu, et al. Reliability issues of lead-free solder joints in electronic devices. Science and Technology of Advanced Materials, 2019, 20(1): 876-901.

Y D Han, H Y Jing, L Y Xu, et al. Study on the Reliability of Sn-Ag-Cu Lead-free Solders. Electronics & Packaging, 2007, 7(3): 4-6. (in Chinese)

R Ramesham. Reliability of Sn/Pb and lead-free (SnAgCu) solders of surface mounted miniaturized passive components for extreme temperature (-185℃ to +125℃) space missions. Reliability, Packaging, Testing, and Characterization of MEMS/MOEMS and Nanodevices X, San Francisco, California, USA, February 18, 2011: 79280F.

N Chen. Dynamic mechanical properties of lead free solders. Beijing: Beijing University of Technology, 2008. (in Chinese)

R Rameshamf. Reliability assessment of ceramic column grid array (CCGA717) interconnect packages under extreme temperatures for space applications (-185 ºC to +125 ºC). Reliability, Packaging, Testing, and Characterization of MEMS/MOEMS and Nanodevices IX, San Francisco, California, USA, February 4, 2010: 75920F.

R Y Tian, C J Hang, Y H Tian, et al. Brittle fracture of Sn-37Pb solder joints induced by enhanced intermetallic compound growth under extreme temperature changes. Journal of Materials Processing Technology, 2019, 268: 1-9.

C J Hang, R Y Tian, L Y Zhao, et al. Influence of interfacial intermetallic growth on the mechanical properties of Sn-37Pb solder joints under extreme temperature thermal shock. Applied Sciences, 2018, 8(11): 2056.

K C R Abell, Y L Shen. Deformation induced phase rearrangement in near eutectic tin-lead alloy. Acta Materialia, 2002, 50(12): 3193-3204.

K N Tu, K Zeng. Tin-lead (SnPb) solder reaction in flip chip technology. Materials Science and Engineering: R: Reports, 2001, 34(1): 1-58.

A Lupinacci, A A Shapiro, J O Suh, et al. A study of solder alloy ductility for cryogenic applications. 2013 IEEE International Symposium on Advanced Packaging Materials, Irvine, CA, USA, February 27-March 1, 2013: 82-88.

P Limaye, W Maurissen, K Lambrinou, et al. Low-temperature embrittlement of lead-free solders in joint level impact testing. 2007 9th Electronics Packaging Technology Conference, Singapore, December 10-12, 2007: 140-151.

R Y Tian. Microstructure evolution and failure mechanism of Sn-based solder joints in extreme temperature environment. Harbin: Harbin Institute of Technology, 2019. (in Chinese)

X L Ji, Q An, Y P Xia, et al. Maximum shear stress-controlled uniaxial tensile deformation and fracture mechanisms and constitutive relations of Sn-Pb eutectic alloy at cryogenic temperatures. Materials Science and Engineering: A, 2021, 819: 141523.

Q An, C Q Wang, X X Zhao, et al. The mechanism study of low-temperature brittle fracture of bulk Sn-based solder. 2017 18th International Conference on Electronic Packaging Technology (ICEPT), Harbin, China, August 16-19, 2017: 1233-1237.

J H Wang, S B Xue, Z P Lv, et al. Effect of gamma-ray irradiation on microstructure and mechanical property of Sn63Pb37 solder joints. Journal of Materials Science: Materials in Electronics, 2018, 29: 20726-20733.

J H Wang, S B Xue, Z P Lv, et al. Study on the reliability of Sn50Pb49Sb1/Cu solder joints subjected to γ-ray irradiation. Applied Sciences, 2018, 8(10): 1706.

A Wattanakornphaiboon, R Canyook, K Fakpan. Effect of SnO2 reinforcement on creep property of Sn-Ag-Cu solders. Materials Today: Proceedings, 2018, 5(3): 9213-9219.

V M F Marques, B Wunderle, C Johnston, et al. Nanomechanical characterization of Sn-Ag-Cu/Cu joints-Part 2: Nanoindentation creep and its relationship with uniaxial creep as a function of temperature. Acta Materialia, 2013, 61(7): 2471-2480.

A M Erer, S Oguz, Y Türen. Influence of bismuth (Bi) addition on wetting characteristics of Sn-3Ag-0.5Cu solder alloy on Cu substrate. Engineering Science and Technology, an International Journal, 2018, 21(6): 1159-1163.

B Ali, M F M Sabri, S M Said, et al. Microstructural and tensile properties of Fe and Bi added Sn-1Ag-0.5Cu solder alloy under high temperature environment. Microelectronics Reliability, 2018, 82: 171-178.

A E Hammad, A A Ibrahiem. Enhancing the microstructure and tensile creep resistance of Sn-3.0Ag-0.5Cu solder alloy by reinforcing nano-sized ZnO particles. Microelectronics Reliability, 2017, 75: 187-194.

A Sharma, B G Baek, J P Jung. Influence of La2O3 nanoparticle additions on microstructure, wetting, and tensile characteristics of Sn-Ag-Cu alloy. Materials & Design, 2015, 87: 370-379.

K M Kumar, V Kripesh, A A O Tay. Single-wall carbon nanotube (SWCNT) functionalized Sn-Ag-Cu lead-free composite solders. Journal of Alloys and Compounds, 2008, 450(1-2): 229-237.

E Bradley, K Banerji. Effect of PCB finish on the reliability and wettability of ball grid array packages. 1995 Proceedings. 45th Electronic Components and Technology Conference, Las Vegas, NV, USA, May 21-24, 1995: 1028-1038.

T Hirano, K Fukuda, K Ito, et al. Reliability of lead free solder joint by using chip size package. Proceedings of the 2001 IEEE International Symposium on Electronics and the Environment, Denver, CO, USA, May 9, 2001: 285-289.

A Syed. Reliability and Au embrittlement of lead free solders for BGA applications. Proceedings International Symposium on Advanced Packaging Materials Processes, Properties and Interfaces, Braselton, GA, USA, March 11-14, 2001: 143-147.

S W R Lee, B H W Lui, Y H Kong, et al. Assessment of board level solder joint reliability for PBGA assemblies with lead-free solders. Soldering and Surface Mount Technology, 2002, 14(3): 46-50.

T T Mattila, V Vuorinen, J K Kivilahti, et al. Impact of printed wiring board coatings on the reliability of leadfree chip-scale package interconnections. Journal of Materials Research, 2004, 19(11): 3214-3223.

X Y Li, F H Li, F Guo, et al. Effect of isothermal aging and thermal cycling on interfacial IMC growth and fracture behavior of SnAgCu/Cu joints. Journal of Electronic Materials, 2011, 40: 51-61.

D A A Shnawah, M F B M Sabri, I A Badruddin, et al. A review on effect of minor alloying elements on thermal cycling and drop impact reliability of low-Ag Sn-Ag-Cu solder joints. Microelectronics International, 2012, 29(1): 47-57.

X Y Niu, Z B Zhang, G X Wang, et al. Low silver lead-free solder joint reliability of VFBGA packages under board level drop test at -45°C. 2014 15th International Conference on Electronic Packaging Technology, Chengdu, China, August 12-15, 2014: 762–765.

L Y Gao, Z Q Liu, C F Li. Failure mechanisms of SAC/Fe-Ni solder joints during thermal cycling. Journal of Electronic Materials. 2017, 46: 5338-5348.

T T Mattila, V Vuorinen, J K Kivilahti. Impact of printed wiring board coatings on the reliability of lead-free chip-scale package interconnections. Journal of Materials Research, 2004, 19(11): 3214-3223.

H T Chen, J Han, J Li, et al. Inhomogeneous deformation and microstructure evolution of Sn-Ag-based solder interconnects during thermal cycling and shear testing. Microelectronics Reliability, 2012, 52(6): 1112-1120.

J B Chen, Y P Wu, B An. Effect of rapid thermal cycles on the microstructure of single solder joint. 2011 12th International Conference on Electronic Packaging Technology and High Density Packaging, Shanghai, China, August 8-11, 2011: 1-4.

R Y Tian, Y H Tian, C X Wang, et al. Mechanical properties and fracture mechanisms of Sn-3.0Ag-0.5Cu solder alloys and joints at cryogenic temperatures. Materials Science and Engineering: A, 2017, 684: 697-705.

J H L Pang, T H Low, B S Xiong, et al. Thermal cycling aging effects on Sn-Ag-Cu solder joint microstructure, IMC and strength. Thin Solid Films, 2004, 462-463: 370-375.

B Xiao. Investigation on mechanics behavior and microstructure evolution of tin-lead-silver solders and joints at extremely low temperature. Harbin: Harbin Institute of Technology, 2018. (in Chinese)

X Li, Y Yao. Effect of Cryogenic treatment on mechanical properties and microstructure of solder joint. 2017 18th International Conference on Electronic Packaging Technology, Harbin, China, August 16-19, 2017: 1327-1330.

Y R Y Li, G C Fu, B Wan, et al. Failure analysis of SAC305 ball grid array solder joint at extremely cryogenic temperature. Applied Sciences, 2020, 10(6): 1951.

D S Liu, C L Hsu, C Y Kuo, et al. Effect of low temperature on the micro-impact fracture behavior of Sn-Ag-Cu solder joint. 2010 5th International Microsystems Packaging Assembly and Circuits Technology Conference, Taipei, China, October 20-22, 2010: 1-3.

J A Babcock, J D Cressler, L S Vempati, et al. Ionizing radiation tolerance of high-performance SiGe HBTs grown by UHV/CVD. IEEE Transactions on Nuclear Science, 1995, 42(6): 1558-1566.

J M Roldan, G F Niu, W E Ansley, et al. An investigation of the spatial location of proton-induced traps in SiGe HBTs. IEEE Transactions on Nuclear Science, 1998, 45(6): 2424-2429.

S M Zhang, G F Niu, J D Cressler, et al. The effects of proton irradiation on the RF performance of SiGe HBTs. IEEE Transactions on Nuclear Science, 1999, 46(6): 1716-1721.

A Y Polyakov, I H Lee. Deep traps in GaN-based structures as affecting the performance of GaN devices. Materials Science and Engineering: R: Reports, 2015, 94: 1-56.

K A Son, A N Liao, G Lung, et al. GaN-based high temperature and radiation-hard electronics for harsh environments. Nanoscience and Nanotechnology Letters, 2010, 2(2): 89-95.

A C V Boas, M A A de Melo, R B B Santos, et al. Ionizing radiation hardness tests of GaN HEMTs for harsh environments. Microelectronics Reliability, 2021, 116: 114000.

M Bhatnagar, B J Baliga. Analysis of silicon carbide power device performance. Proceedings of the 3rd International Symposium on Power, Baltimore, MD, USA, April 22-24, 1991: 176-180.

Y Tanaka, S Onoda, A Takatsuka, et al. Radiation hardness evaluation of SiC-BGSIT. Materials Science Forum, 2010, 645-648: 941-944.

A A Lebedev, V V Kozlovski, K S Davydovskaya, et al. Radiation hardness of silicon carbide upon high-temperature electron and proton irradiation. Materials, 2021, 14(17): 4976.

W Paulus, I A Rahman, A Jalar, et al. Effect of gamma radiation on micromechanical hardness of lead-free solder joint. AIP Conference Proceedings, 2015, 1678(1): 040018.

W Y W Yusoff, N F N M Lehan, N S Sobri, et al. Influences of low dose gamma radiation on hardness and microstructure properties of green solder joint. Journal of Physics: Conference Series, 2021, 1816: 012118.

L Wen, S B Xue, J H Wang, et al. Effects of γ‑ray irradiation on microstructure and mechanical property of AuSn20 solder joint. Journal of Materials Science: Materials in Electronics, 2019, 30: 9489-9497.

Y W Wang, C R Kao. Interfacial reactions of Cu and In for low-temperature processes. 2019 IEEE 21st Electronics Packaging Technology Conference, Singapore, December 4-6, 2019: 435-439.

K K Xu, L Zhang, L L Gao, et al. Review of microstructure and properties of low temperature lead-free solder in electronic packaging. Science and Technology of Advanced Materials, 2020, 21(1): 689-711.

X Cheng, C Liu, V V Silberschmidt. Numerical analysis of thermo-mechanical behavior of indium micro-joint at cryogenic temperatures. Computational Materials Science, 2012, 52(1): 274-281.

R W Chang, F P McCluskey. Reliability assessment of indium solder for low temperature electronic packaging. Cryogenics, 2009, 49(11): 630-634.

M Deshpande, R Chaudhari, P R Narayanan, et al. Evaluation of shear properties of indium solder alloys for cryogenic applications. Journal of Materials Engineering and Performance, 2021, 30(11): 7958-7966.

H D Gui, R R Chen, J H Niu, et al. Review of Power Electronics Components at Cryogenic Temperatures. IEEE Transactions on Power Electronics, 2020, 35(5): 5144-5156.

X Cheng, C Liu, V V Silberschmidt. Intermetallics formation and evolution in pure indium joint for cryogenic application. 2009 11th Electronics Packaging Technology Conference, Singapore, December 9-11, 2009: 562-566.

Acknowledgements

Not applicable.

Funding

Supported by National Natural Science Foundation of China (Grant No. 51775141) and Heilongjiang Touyan Innovation Team Program.

Author information

Authors and Affiliations

Contributions

CH was in charge of the whole trial; QG wrote the manuscript; SL, DY, YD, XW and YT assisted with sampling and laboratory analyses. All authors read and approved the final manuscript.

Authors’ Information

Qilong Guan, born in 2000, is currently a PhD candidate at State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, China. His research interests include solder joint reliability under extreme conditions.

Chunjin Hang, born in 1978, is currently an associate professor and a PhD supervisor of the State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, China.

Shengli Li, born in 1992, is currently a PhD candidate at State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, China.

Dan Yu, born in 1979, is currently an engineer at Beijing Institute of Spacecraft Environment Engineering, China.

Ying Ding, born in 1978, is currently an engineer at Beijing Institute of Control Engineering, China.

Xiuli Wang, born in 1982, is currently an engineer at Beijing Institute of Control Engineering, China.

Yanhong Tian, born in 1975, is currently a professor and a PhD supervisor at State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, China.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing financial interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Guan, Q., Hang, C., Li, S. et al. Research Progress on the Solder Joint Reliability of Electronics Using in Deep Space Exploration. Chin. J. Mech. Eng. 36, 22 (2023). https://doi.org/10.1186/s10033-023-00834-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10033-023-00834-4