Abstract

Influence of mismatch on quantum dot formation during heteroepitaxial growth of thin films with zinc blende structure on GaAs substrate is investigated. A kinetic Monte Carlo model is used for simulation of thin films with different values of lattice mismatch in the range of 4% to 14%. Simulation is performed at a substrate temperature of 700 K and deposition rate of 0.3 ML/s. Also, ‘reflection high-energy electron diffraction’ (RHEED) intensity of simulated thin films is evaluated during growth. Results of simulation show that at constant temperature and deposition rate, quantum dot size decreases with increasing lattice mismatch, and their distribution function becomes sharp. Simulated RHEED oscillations have a good agreement with morphology of simulated thin films, and results show that growth mode changed from Stranski-Krastanov to Volmer Webber by increasing lattice mismatch.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

During heteroepitaxial growth of semiconductors, releasing the stress which created due to lattice mismatch of layer and substrate leads to growth of self-assembled nanostructures and nano-patterns with special properties[1–3]. Among these nanostructures, quantum dots can be pointed out[4, 5]. Recently, the quantum dots have been investigated widely because of the development of IR lasers, photodiodes, solar cells, and thermophotovoltaic convertors[6–8]. The efficiency of these devices is strongly influenced by different properties of quantum dots (QDs) such as crystal and electronic structure, size and distribution, and also residual stress and defects. Therefore, control of such nanostructural parameters strongly affects the efficiency of devices.

Among semiconductors, GaAs has special properties such as direct bandgap and high electron mobility which have made it a key element in integrated circuits, high-frequency transistors, and light-emitting diodes. Moreover, wide bandgap and high resistivity accompanied with high dielectric constant make it a very good choice for substrate, which causes isolation between the substrate and circuits. Because of this property, GaAs is widely used as a substrate for thin film growth or QD formation[9, 10]. An atomistic understanding of the processes which control the quality of interface during growth is very important, and simulation is a suitable tool for understanding strain and stress effects during growth and description of defect formation mechanisms.

Various simulation methods are used for simulation of thin film growth and islands or QD formation. Generally, these methods can be divided into two major groups: continuous and atomistic simulations. The continuous models such as ‘phase field model’ are based on partial differential equations and have a low computational cost, but they are not appropriate for atomic scale simulation[11]. Molecular dynamic (MD) and Monte Carlo (MC) are the most important models for atomistic scale simulation, while MC involves with a lower computational cost compared to MD method and is suitable for simulation of thin film growth and QD formation[12].

In this study, a kinetic Monte Carlo simulation with valence force field approximation is used for strain energy calculation to describe QD formation during heteroepitaxial growth of a model material with GaAs structure. Also, ‘reflection high-energy electron diffraction’ (RHEED) patterns are simulated by a model.

Simulation model

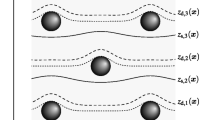

An ‘on-lattice’ kinetic Monte Carlo (KMC) method with valence force field approximation is used for simulation of heteroepitaxial growth of thin films and formation of quantum dots. The simulation is performed on an array of 60 × 60 unit cells of GaAs which approximately equals to 30 × 30 nm area of substrate. To consider the effect of mismatch, it is assumed that all physical properties of deposited material such as binding energy and structure are the same as the substrate material except lattice constant. In on-lattice simulation, all suitable points for accommodation or relaxation of deposited atoms are identified at the beginning of simulation, and during simulation, the final points for relaxation are selects based on KMC algorithm[13, 14]. Therefore, zinc blende structure is used for identification of both substrate atoms and suitable points for relaxation of deposited atoms, but lattice constant of the region that identifies the layer is different from the substrate in the range of 4% to 14%. After the definition of substrate, the simulation continues as follows:

-

1.

Atoms of Ga and As with equal rates accommodated on the substrate randomly.

-

2.

An adatom on the substrate is selected randomly, and all transition states and related probabilities w i → j are evaluated:

(1)

In this stage, surface diffusion and also interlayer migration are considered. For interlayer migration, the model introduced by Fazouan et al.[15] is used. In this model, each adatom in the N layer is allowed to migrate to a proper position two atomic layers above or below the N layer. The energy of adatoms in each position is evaluated using the following:

where m is the number of nearest neighbors; φ ij , the binding energy; and E s , the energy of strain resulting from the mismatch. In GaAs structure, the normal bond angle of Ga-As-Ga is 109.47°, but at the interface of layer and substrate because of mismatch, bond angles vary from this value and result to an additional term in energy. In valence force field approximation[16],

where θ is the bond angle and k θ is a constant.

-

3.

The values of Q n are evaluated as follows:

(4) -

4.

A random number (0 < R < 1) has to be generated, and in case of Q n < R < Q n + 1, the state of n + 1 accepts and the system transits to state of n + 1.

-

5.

Another random number 0 < U < 1 have to be generated in relation to simulation time, and the simulation time increases by .

-

6.

If the mean value of Δt is greater than the average time interval between arrival of two atoms, then the algorithm returns to stage 1, otherwise it goes to stage 2. During simulation of thin film growth and formation of QD RHEED intensity of thin films was also simulated using the following [17]:

(5)

where θ n is the coverage of nth layer.

Results and discussion

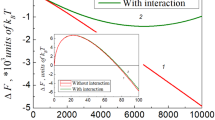

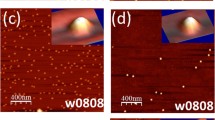

For GaAs system, the interaction energies are φGa-As = 0.75 eV, φGa-Ga = 0.17 eV, and φAs-As = 0.2 eV and k θ = 1.1 eV[15]. Results of simulation for growth of four layers of model GaAs thin films for different values of mismatch in the range of 4% to 14% at a substrate temperature of 700 K and deposition rate of 0.3 ML/s are shown in Figure 1. Results show that simulated thin films consist of pyramid and dome-shaped islands (QDs). The pyramid and dome-shaped islands are experimentally observed during heteroepitaxial growth of thin films such as Ge/Si system[1]. Considering that the melting point of GaAs is 1,535 K, the reduced temperature for our simulated film is about 0.5 which is at the lower part of zone III in structural zone model (SZM)[18–20]. In the case of homoepitaxial growth, formation of a smooth surface is expected in zone III of SZM, but in heteroepitaxial growth due to relaxation of misfit energy, the structure of thin film is changed to dome-shaped islands. Mean value of islands sizes (QDs) for different values of mismatch is shown in Figure 2. Results in Figures 1 and2 show reduction in the size of QDs by increasing the value of mismatch. RHEED intensities of simulated thin films are also evaluated using Equation 5, and results are shown in Figure 3. Results in this figure show that increasing of the mismatch results in a faster damping of RHEED oscillations. Results also show that by increasing the mismatch, the growth mode slowly switches from Stranski-Krastanov to Volmer Webber[15].

Size distribution of QDs is shown in Figure 4. This figure shows an approximately normal (or Gaussian) distribution which its width decreases by increasing the mismatch while its maximum shifts towards smaller values. Results are in agreement with Ratstc et al.’s simulation work[21].

Conclusion

In this paper, influence of lattice mismatch on island growth and QD formation of a model GaAs thin film is investigated. Results show that the size of QDs is decreased by increasing the mismatch while the size distribution becomes sharper. Results also show that by increasing the mismatch value, the growth mode is changed from Stranski-Krastanov to Volmer Webber.

References

Teichert C: Self-organization of nanostructures in semiconductor heteroepitaxy. Phys. Rep. 2002, 365: 335. 10.1016/S0370-1573(02)00009-1

Dilliway GDM, Bagnall DM: Self-assembled germanium islands grown on (0 0 1) silicon substrates by low-pressure chemical vapor deposition. J. Mater. Sci. 2003, 14: 323.

Moriarty P: Nanostructured materials. Rep. Prog. Phys. 2001, 64: 297. 10.1088/0034-4885/64/3/201

Joyce BA, Vvedensky DD: Self-organized growth on GaAs surfaces. J. Mater. Sci. Eng. R. 2004, 46: 127. 10.1016/j.mser.2004.10.001

Franchi S, Trevisi G, Seravalli L, Frigeri P: Quantum dot nanostructures and molecular beam epitaxy. Progr. Cryst. Growth Char. Mater. 2003, 47: 166. 10.1016/j.pcrysgrow.2005.01.002

Monakhov AM, Sherstnev VV, Astakova AP, Yakhovlev YP, Boissier G, Teissier R, Baranov AN: Experimental observation of whispering gallery modes in sector disk lasers. Appl Phys. Lett. 2009, 94: 051102. 10.1063/1.3075852

Reddy MHM, Olesberg JT, Cao C, Prineas JP: MBE-grown high-efficiency GaInAsSb mid-infrared detectors operating under back illumination. Semicond. Sci. Technol. 2006, 21: 267. 10.1088/0268-1242/21/3/009

Mauk MG, Andreev VM: GaSb-related materials for TPV cells. Semicond. Sci. Technol. 2003, 18: 191. 10.1088/0268-1242/18/5/308

Kudo M, Mishima T, Iwamoto S, Nakaoka T, Arakawa Y: Long-wavelength luminescence from GaSb quantum dots grown on GaAs substrates. Physica E 2004, 21: 275. 10.1016/j.physe.2003.11.030

Ratto F, Rosei F: Order and disorder in the heteroepitaxy of semiconductor nanostructures. J. Mater. Sci. Eng. R 2010, 70: 243. 10.1016/j.mser.2010.06.011

Wise SM, Lowengrub JS, Kim JS, Johnson WC: Efficient phase-field simulation of quantum dot formation in a strained heteroepitaxial film. Superlattice Microst 2004, 36: 293. 10.1016/j.spmi.2004.08.029

Dalla Torre J, Djafari Rouhani M, Malek R, Esteve D, Landa G: Beyond the solid on solid model: an atomic dislocation formation mechanism. J. Appl. Phys 1998, 84: 5487. 10.1063/1.368312

Schulze TP: Efficient kinetic Monte Carlo simulation. J. Comp. Phys. 2008, 227: 2455. 10.1016/j.jcp.2007.10.021

Voter AF: Introduction to the kinetic Monte Carlo method. Radiation effects in solid. Math Phys. Chem. 2007, 235: 1.

Fazouan N, Atmani E, Djafari Rouhani M, Esteve A: A Monte Carlo investigation of growth and characterization of heteroepitaxial thin films. Thin Solid Films 2009, 517: 6260. 10.1016/j.tsf.2009.02.097

Djafari M, Malek R, Gue AM, Bouyssou G, Esteve D: Monte Carlo simulation of the effect of interstitial atoms interaction on the heteroepitaxial growth of compound semiconductors. J. Mater. Sci. Eng. B. 1997, 44: 82. 10.1016/S0921-5107(96)01750-3

Daniluk A: Kinematical calculations of RHEED intensity oscillations during the growth of thin epitaxial films. Comput. Phys. Comm. 2005, 170: 265. 10.1016/j.cpc.2005.04.005

Messier R, Giri AP, Roy RA: Revised structure zone model for thin film physical structure. J. Vac. Sci. Technol. A 1984, 2: 500. 10.1116/1.572604

Barna PB, Adamik M: Fundamental structure forming phenomena of polycrystalline films and the structure zone models. Thin Solid films 1998, 317: 27. 10.1016/S0040-6090(97)00503-8

Savaloni H, Gholipour Shahraki M: A computer model for the growth of thin films in a structure zone model. Nanotechnology 2004, 15: 3.

Ratstc C, Devita J, Smereka P: Level-set simulation for the strain-driven sharpening of the island-size distribution during submonolayer heteroepitaxial growth. Phys. Rev. B 2009, 80: 155309.

Acknowledgments

This work has been financially supported by Arak University and Iranian Nanotechnology Initiative Council.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MGS and EE both carried out the simulations. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Shahraki, M.G., Esmaili, E. Computer simulation of quantum dot formation during heteroepitaxial growth of thin films. J Theor Appl Phys 6, 46 (2012). https://doi.org/10.1186/2251-7235-6-46

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7235-6-46