Abstract

Europium-doped gallium oxide (Ga2O3:Eu) thin films have successfully been grown using direct current magnetron sputtering by means of Eu concentration variation. Energy-dispersive X-ray spectroscopy spectra indicate gallium, oxygen, and europium elements as the growing films' chemical compositions. Based on scanning electron microscopy images, the morphology of Ga2O3:Eu thin film is seemingly like a granulated nano-size configuration. In this study, UV-visible spectrophotometer results show that the variation of Eu doping concentration inflicted no change toward the optical bandgap of the growing films. The optical bandgaps of undoped Ga2O3 film and Ga2O3:Eu film were seen to be relatively similar, i.e., approximately 3.4 eV. Yet, the presence of Eu doping in Ga2O3 configuration had led to blueshift phenomenon when the concentration was 2% and redshift phenomenon when it was 5%. Photoluminescence emissions of all samples were observed in the red area with the emission peak between 593 and 602 nm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Gallium oxide (Ga2O3) material has long been a concern by many researchers, engineers, and scientists due to its transparency in ultraviolet range. Its wavelength is recorded up to the areas of 280 nm. Hence, Ga2O3 material has a high potential to be the new generation of optoelectronic devices applied as transparent conductive oxide [1]. The melting point of Ga2O3 is around 1,740°C. Thus, Ga2O3 is considered to be one of the materials that will remain stable at high temperature. The conductivity of Ga2O3 material depends on the atmospheric environment so that it is suitable for gas sensor application [2]. Ga2O3 material can be applied as passivation material on the gate of field effect transistor because it has a high dielectric constant [3]. Besides, Ga2O3 is one of the fascinating oxide-based phosphor materials that are physically and chemically more stable than sulfide-based phosphor materials for flat-panel display application [4]. Moreover, Ga2O3 material has amazing luminescence properties that make it appropriate to be used as thin-film electroluminescence (TFEL)-based devices [5].

Ga2O3 has extensively been used for luminescent phosphorus application due to its fascinating luminescence properties especially when it is doped with rare earth elements. Ga2O3 is an oxide-crystal structure with a high anisotropy degree, which has a tetrahedral or octahedral interconnection. It forms a wide tunnel in the crystal. This tunnel is believed to be playing an important role in the process of hot electron transport that is required for electroluminescence emission [6]. Luminescence characteristics of undoped Ga2O3 were observed in the color spectrum of UV (3.40 eV), blue (2.59 eV), and green (2.48 eV) areas. In order to increase the luminescence intensity of oxide-based phosphor material, Mn and Eu elements were used as dopants to activate luminescence, which produces green and red emissions [5]. Mn is one of the transition elements that have potential for phosphorus luminescence application and TFEL-based devices for its excellent luminescent center. Meanwhile, Eu element is used because it leads to high quantum efficiency and high-speed radiation luminescence of organic materials whenever it is used as a dopant [7].

Ga2O3 thin film has been grown through various methods, such as metalorganic chemical vapor deposition (MOCVD) [8], MBE [9], floating zone [10], rf magnetron sputtering [11], photoelectrochemical [12], and pulse laser ablation [8]. The film's properties strongly depend on the growth condition, such as chamber partial pressure, substrate temperature, and annealing process pasca-deposition. In this study, Ga2O3 is doped by Eu (Ga2O3:Eu thin films) and grown by homemade direct current (DC) magnetron sputtering. DC magnetron sputtering is one of the simple deposition techniques with low operation cost but have stable growth process and high deposition rates. The doping element is given in order to enhance the optical properties of Ga2O3 film. Eu is chosen as the doping element because of its capability in producing luminescence emission that lies on the red area [5]. This study focused on the investigation of the structural and optical properties of Ga2O3:Eu thin films. Then, the optical properties of Ga2O3:Eu thin films will be compared with the optical properties of undoped Ga2O3 thin film.

Results and discussion

In order to find out if only Eu element can be doped and deposited together with Ga2O3 on the substrate surface, the experiment was carried out using Ga2O3:Eu(5%) pellet as target. The film was grown on Si(100) substrate. The deposition temperature, plasma power, argon pressure, oxygen pressure, and deposition time were set at 600°C, 40 W, 600 mTorr, 100 mTorr, and 3 h, respectively. The grown sample was characterized using energy-dispersive X-ray spectroscopy (EDX), and its spectra are shown in Figure 1. The occurrence of oxygen (O), gallium (Ga), and europium (Eu) on the growing film, based on EDX analysis, indicated that Eu-doped Ga2O3 thin film has been successfully grown on Si(100) substrate using DC magnetron sputtering. This result is in line with the findings found in some previous studies regarding XRD analysis [13, 14].

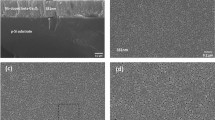

The morphology of Ga2O3:Eu thin films was investigated using scanning electron microscopy (SEM). The films were grown in two target variations. Those were Ga2O3:Eu(2%) and Ga2O3:Eu(5%). Figure 2 shows SEM images of Ga2O3:Eu thin films grown with Eu-doped variation. SEM images show that the morphology of Ga2O3:Eu thin film was seemingly like a granulated nano-size configuration [15]. Ga2O3:Eu(2%) thin film grew up in a high density of identic granulated nano-size, which made it have a relatively smooth surface morphology as shown in Figure 2a. In contrast, the bigger granulated configuration with rough surface morphology was observed on Ga2O3:Eu(5%) thin film as shown in Figure 2b. The roughness of the surface morphology and the grain size of the growing films are likely related to the concentration of Eu element that was deposited. As the surface's roughness and the uniformity of grain size have been believed to be the parameters that determine the growing film's crystal quality, thus, Ga2O3:Eu(2%) thin film was then considered to have a higher crystalline quality than Ga2O3:Eu(5%) thin film.

Generally, the surface morphology of the thin film has a great relationship with the crystal quality of the film itself. By introducing Eu element on Ga2O3 host material, it was expected that it will be able to stimulate the transformation structure from a single crystal to poly-crystal structures. The Ga2O3:Eu thin film that was grown was noted to have a granulated configuration with a single orientation. Therefore, Ga2O3:Eu thin film has a low degree of magnetic anisotropy but a high magnetic permeability degree. Based on this characteristics, Ga2O3:Eu film is then viewed to be suitable for TFEL device application. In comparison to the undoped Ga2O3 thin film that has been grown by Sugianto et al.,[13], the surface morphology of Ga2O3:Eu thin films is smoother. It has a smaller grain size, and the distribution of the grains on the surface of the substrate seems to be more uniform [13]. As a consequence, it can be concluded that the existence of Eu(2%) atoms on Ga2O3 thin film will lead to smoothing effect on the surface morphology of the thin film. However, it can be noted as well that the rising concentration of Eu did not significantly change the surface morphology of Ga2O3 thin films.

The optical properties of Ga2O3:Eu(2%) and Ga2O3:Eu(5%) thin films have been analyzed using room-temperature UV-nir spectrophotometer in the wavelength range of 200 to 2,400 nm. The reflectance spectra of Eu-doped Ga2O3 thin films were then been compared with the reflectance spectra of undoped Ga2O3 film [14] as shown in Figure 3. The reflectance pattern of all films was basically similar. It meant that the presence of Eu doped on Ga2O3 host material did not change the reflectance pattern but contributed in changing the intensity of the reflectance spectra. It can be seen afterward that Ga2O3:Eu(2%) thin film has the highest spectra intensity, followed by undoped Ga2O3 film. Surprisingly, the rising of Eu doping concentration from 2% to 5% decreases the reflectance intensity of Ga2O3:Eu(5%) film instead. This phenomenon is believed to occur due to the surface morphology effect of the thin film, which was discussed previously based on SEM observation results.

The reflectance spectra in Figure 3 show the existence of oscillations in each films in the reflectance spectra below 3.4 eV, which is associated with the interference of light in the Ga2O3 layer [16]. Furthermore, based on Figure 3, it can be estimated that the value of optical bandgap (Eg) of Ga2O3 film was around 3.4 eV, related to the band-to-band absorption. This value is similar with the photoluminescence (PL) characterization result of undoped Ga2O3 thin film that was reported by Villora et al.[17]. They reported that the luminescence peak of undoped Ga2O3 film was observed in the UV area of 3.40 eV [17].

Based on the theoretical approach, the bandgap of Ga2O3 materials should be 2.71 eV [18], whereas from the experiment results, it varies depending on the growth conditions (parameters) and the substrate. The bandgap of Ga2O3 films that were grown on fused silica disks under oxygen flow with electron beam evaporation method is recorded as 4.4 eV [19]. Besides, Villora et al. reported that the bandgap of Ga2O3 thin film grown by floating zone method is around 4.8 eV [20].

Ga2O3:Eu thin films grown on corning glass (transparent substrate) at a plasma power of 40 W were analyzed using UV-visible (vis) spectrometer in the wavelength range of 200 to 850 nm as shown in Figure 4. Based on Figures 3 and 4, it can be seen that Ga2O3:Eu(2%) thin films had both the highest transmittance intensity and reflectance intensity as compared to all samples. Ga2O3:Eu(5%) thin films that were grown with the same growth condition have lower transmittance intensity, but when the plasma power was increased to 50 W, its transmittance intensity was increasing although it was still lower than the intensity of Ga2O3:Eu(2%) film.

The optical absorption spectra of Ga2O3: Eu thin film which functions as photon energy is shown in Figure 5. It can be seen that when Ga2O3: Eu (2%) film was grown with a plasma power of 40 W, it has absorption edge on the absorption spectra of approximately 3.8 eV, which is related to the band-to-band transition, whereas when Ga2O3:Eu (5%) thin film was grown with a plasma power of 40 W, its absorption edge was observed at approximately 2.1 and approximately 3.5 eV. Then, when the plasma power was increased to 50 W, the absorption edge of Ga2O3:Eu(5%) film was clearly observed at approximately 2.4 eV (green region) and approximately 3.5 eV (UV area) with the absorption peak of approximately 3 eV. The band edge (2.1 and 2.4 eV) of Ga2O3:Eu(5%) film that was grown with a plasma power of 40 and 50 W, respectively, indicate the occurrence of band tails on the Ga2O3:Eu(5%) bandgap. The localized band tails of Ga2O3:Eu(5%) thin film are similar with the experimental result of the previous study by Robertson [21]. It is believed that the band tail occurs due to the existence of defects, which is raising up from the abundance of Eu doping on the Ga2O3:Eu configuration. It is also believed that the abundance of Eu doping leads to crystallographic transformation from crystal structure to amorphous structure. Kim and Kim reported that Ga2O3 thin films grown by MOCVD method have an amorphous structure [16]. Hence, it can be said that the introduction of Eu doping with a concentration of 5% on the Ga2O3 material leads to the formation of amorphous structure. Consequently, Ga2O3:Eu(5%) thin film grew with low crystallinity quality. It can be seen that Ga2O3:Eu(5%) thin film that was deposited at a plasma power of 50 W has defects spectra starting from the energy area of approximately 2.4 eV and concentrated in the energy area of approximately 3 eV with higher defects intensity compared with the Ga2O3:Eu(5%) film grown with a plasma power of 40 W. Thus, it can be concluded that the increasing plasma power leads to the increasing degree of crystal defect in the thin film. The absorption edge at the energy range of approximately 3.5 to approximately 4 eV agrees with the energy gap which has been obtained from the reflectance spectrum as shown in Figure 3.

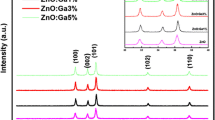

Figure 6 shows PL spectra of Ga2O3:Eu(2%) and Ga2O3:Eu(5%) thin films with excitation wavelength of 203 nm, which was compared with PL spectra of undoped Ga2O3 film as reference. It can be seen that all of the thin films emit the photoluminescence spectra on the red color region. Based on the luminescence spectra, it can be noted that the luminescence peaks of Ga2O3:Eu(2%), Ga2O3:Eu(5%), and undoped Ga2O3 films were at wavelengths of 599 nm (approximately 2.1 eV), 602 nm (approximately 2.06 eV), and 593 nm (approximately 2.1 eV), respectively. Ga2O3:Eu(5%) thin film has the highest intensity at a wavelength of 602 nm, which is related to the electron transition of Eu3+[22], followed by Ga2O3:Eu(5%) film, then by undoped Ga2O3 thin film. The luminescence peak of Ga2O3:Eu thin film is associated with the electron transition of 5Do → 7 F2 for Eu3+[4]. It can be seen that the luminescence intensity of Ga2O3:Eu film is proportional to the Eu doping concentration. The luminescence intensity can be increased by increasing the concentration of Eu doping (mole fraction of the Eu element). This phenomenon is similar to the luminescence spectra of Ga2O3:Mn thin film that was reported by Kim and Kim [4], in which the luminescence intensity is increased by increasing Mn doping. It is then recorded that Mn2+ (3d5) ions, which are introduced into Ga2O3:Mn (host material), behave as the luminescence activator in the Ga2O3:Mn material [22]. Therefore, it can be said that the emission intensity depends on the concentration of Eu doping.

Although it does not give a significant effect, the presence of Eu(2%) doping in the Ga2O3 material leads to the luminescence peak of the film, which tends to shift to a shorter wavelength. Hence, it is considered to be a blueshift phenomenon. In contrast, the luminescence peak shift to the longer wavelength when the Eu doping was increased to 5%was called as redshift phenomenon. The shifting of photoluminescence peak is generally caused by lattice distortion and relaxation of the charge carrier into deep-gap-states condition before recombination process happens. Nevertheless, this phenomenon is slightly different from the luminescence shifting of Ga2O3:Mn thin film. In the case of Ga2O3:Mn thin film, higher concentration of Mn doping in the Ga2O3 material will increase the lattice strain. Variation of lattice strain in the Ga2O3:Mn material causes crystal field variations around Mn2+ elements region [22]. Mn2+ crystal field with weak intensity would lead emission shifting band to the shorter wavelength region, which will result in a wider bandgap (energy gap Eg is inversely proportional to the wavelenght λ). Thus, it can be said that the emission band of Mn2+ was slightly shifting due to the effect of variation of crystal field. Besides, in correlation with charge carrier relaxation in the luminescence shifting, it is believed that the presence of Mn atom in the Ga-O configuration leads to the relaxation of Ga-O bonding and stressing of the bandgap. As a result, the energy bandgap of luminescence spectra becomes wider. Meanwhile, in the case of Ga2O3:Eu thin film, the emission characteristic of Eu(III) is produced by means of electric dipole transition [4].

It can be seen that the emission intensity of Ga2O3 thin film luminescence spectra (at approximately 2.1 eV) was lower than the peak intensity of optical bandgap of the reflectance spectra (at 3.4 eV). It confirmed that the optical transitions did not occur due to band-to-band transition but because of the defect-to-defect hopping mechanism, which was dominant at the energy distance of approximately 2.1 eV. These defects act as trap in the band tail of the bandgap. Besides the effect of Eu doping, defects can also occur due to the breaking of Ga-O bonding during deposition process. Based on Figure 6, it can be noted that the photoluminescence peak of all films was around of 2.1 eV. This value agrees with the absorption band edge of Ga2O3:Eu thin films as shown in Figure 4. Previous researchers also reported similar results. Hao et al. reported that Ga2O3:Eu thin film grown by spray pyrolysis method also produced luminescence emission in the range of red color with an emission peak of approximately 2.1 eV [4]. Kim and Kim have also reported that the luminescence peak of Ga2O3 thin film grown by MOCVD was at a wavelength of 457 nm (2.71 eV) [15]. In general, three possible pathways of photoluminescence mechanism are shown in Figure 7.

Conclusions

Ga2O3:Eu thin films have successfully been grown using DC magnetron sputtering. EDX result shows that the grown film contains Ga, O, and Eu elements. It means that Eu-doped Ga2O3 thin film has been successfully grown. SEM images show that the morphology of Ga2O3:Eu thin film is seemingly like a granulated nano-size configuration. Ga2O3:Eu(2%) thin film grew in a high density of similar granulated nano-size, which made it have a relatively smooth surface morphology. Conversely, Ga2O3:Eu(5%) thin film grew with bigger grain size and has rough surface morphology. Both reflectance and transmittance intensity spectra of Ga2O3:Eu(2%) thin film were higher than those of Ga2O3:Eu(5%) thin film. Variation of Eu doping concentration did not change the optical bandgap of the growing films. The optical bandgaps of undoped Ga2O3 film and Ga2O3:Eu film are relatively similar, i.e., 3.4 eV. The existence of Eu(2%) doping in the Ga2O3 configuration leads the luminescence peak shift to the shorter wavelength region (blueshift). In contrast, the presence of Eu(5%) doping leads the luminescence peak shift to the longer wavelength region (redshift). Photoluminescence emissions of all samples were observed in the red region with the emission peak at the range of 593 to 602 nm.

Methods

Ga2O3:Eu thin films were grown using DC magnetron sputtering (homemade). The scheme of DC magnetron sputtering system is shown in Figure 8. Ga2O3 (99.999%) and Eu(III) oxide (99.999%) powders were used as pellet-made materials. Eu(2%) and Eu(5%) were used as doping elements in the production of Ga2O3:Eu(2%) and Ga2O3:Eu(5%) pellets. Si(100) wafer and corning glass were used as substrate. High-purity argon (Ar) and oxygen (O2) were used as sputter gas and dilute gas during deposition process. The growth process of Ga2O3:Eu thin films were done in three main steps. The first step was the fabrication of Ga2O3:Eu target. In this process, Ga2O3 and Eu(III) oxide powders were milled and mixed, and were then pressed to form the rigid Ga2O3:Eu target (pellet). Ga2O3:Eu pellet was then sintered at 900°C for 3 h. Ga2O3:Eu(2%) target and Ga2O3:Eu(5%) target were produced by varying the concentration of Eu doping in the mixing process with Ga2O3 powders. The second stage was substrate preparation. Si(100) and corning glass substrates were cut into 1 × 1 cm2 and washed using acetone and methanol in ultrasonic bath for 10 min and 5 min, respectively. The substrates were then cleaned using deionized water (DI water) and, after that, were immersed in 10% HF solution. Next, they were re-cleaned using DI water and subsequently blow-dried with nitrogen (N2). The final stage was the growth process of Ga2O3:Eu thin films. In this process, the substrate was placed on the anode, while the target was put on the cathode. Ga2O3:Eu thin films were grown on Si(100) and corning glass substrates under oxygen flow with plasma power variation. During the growing time, the growth temperature and argon gas pressure were set at 3 h, 600°C, and 600 mTorr, respectively. The morphology and chemical composition of the growing films were analyzed using SEM and EDX. The optical properties of the film were then analyzed using UV–vis spectrophotometer and PL spectrometer.

References

Hosono H, Ohta H, Orita M, Ueda K, Hirani M: Frontier of transparent conductive oxide thin films. Vacuum 2002, 66: 419. 10.1016/S0042-207X(02)00165-3

Hoefer U, Frank J, Fleisher M: High temperature Ga2O3-gas sensors and SnO2-gas sensors: a comparison. Sens. Actuators 2001, 78: 6. 10.1016/S0925-4005(01)00784-5

Lee CT, Chen HW, Lee HY: Metal–oxide–semiconductor devices using Ga2O3 dielectrics on n-type GaN. Appl Phys Lett 2003, 82: 4304. 10.1063/1.1584520

Hao J, Zhidong L, Renaud I, Cocivera M: Electroluminescence of europium-doped gallium oxide thin films. Thin Solid Films 2004, 467: 182. 10.1016/j.tsf.2004.03.037

Minami T: Oxide thin film electroluminescent device and materials. Solid State Electronics 2003, 47: 2237. 10.1016/S0038-1101(03)00204-1

Ting WY, Kitai AH, Mascher P: Crystallization phenomena in b-Ga2O3 investigated by positron annihilation spectroscopy and X-ray diffraction analysis. Mater Sci Eng 2002, 91: 541.

Fang JF, Ma DG: Efficient red organic light-emitting devices based on a europium complex. Appl Phys Lett 2003, 83: 4041. 10.1063/1.1626022

Kim HW, Kim NH: Microstructure of Mn-doped γ-Ga2O3 epitaxial film on sapphire (0001) with room temperature ferromagnetism. Mater Sci Eng 2004, 110: 34. 10.1016/j.mseb.2004.01.012

Yu Z, Overgaard CD, Drooped R: Growth and physical properties of Ga2O3 thin films on Gas(001) substrate by molecular-beam epitaxial. Appl Phys Lett 2003, 82: 2978. 10.1063/1.1572478

Villora EG, Morioka Y, Atou T, Sugawara T, Kikuchi M, Fukuda T: Infrared reflectance and electrical conductivity of β-Ga2O3. Phy. Stat. Sol 2002, 193: 187. 10.1002/1521-396X(200209)193:1<187::AID-PSSA187>3.0.CO;2-1

Ogita M, Higo K, Nakanishi Y, Hatanaka Y: Ga2O3 thin film for oxygen sensor at high temperature. Appl Surf Sci 2001, 175: 721.

Lee CT, Lee HY, Chen HW: Metal–oxide–semiconductor devices using Ga2O3 dielectrics on n-type GaN. IEEE Electron Device Lett. 2003, 24: 54.

Sugianto S, Wiyanto W, Sumpono I, Ngurah Made DP: Penumbuhan film tipis Ga2O3 dengan metode dc magnetron sputtering. Jurnal Ilmu Dasar (Journal of Fundamental Science), Fak. MIPA Univ. Jember (Jember University) 2004, 5: 109.

Marwoto P, Sugianto S, Wiyanto W: Growth of gallium oxide thin films on silicon deposited by DC magnetron sputtering. The Proceeding of Regional Annual Fundamental Science, Seminar 2007, Joho; 2007. Universiti Teknologi Malaysia Universiti Teknologi Malaysia

Kim HW, Kim NH: Annealing effects on the properties of Ga2O3 thin films grown on sapphire by MOCV. Appl Surf Sci 2004, 230: 301. 10.1016/j.apsusc.2004.02.063

Kudrawiec R, Syperek M, Misiewicz J, Paszkiewicz R, Paszkiewicz W, Tlaczala M: Heterostructures with a two dimensional electron gas. Superlatices and Microstructures 2004, 36: 633. 10.1016/j.spmi.2004.09.021

Villora EG, Hatanak K, Odaka H, Sugawara T, Miura T, Fukumura H, Fukuda T: Luminescence of undoped β-Ga2O3 single crystals exited by picosecond X-ray and sub-picosecond UV pulses. Solid Stated Community 2003, 127: 385. 10.1016/S0038-1098(03)00439-3

Gowtham S, Deshpande M, Costales A, Pandey R: Structural, energetic, electronic, bonding, and vibrational properties of Ga3O, Ga3O2, Ga3O3, Ga2O3, and GaO3 clusters. J. Phys. Chem. B 2005, 109: 14836. 10.1021/jp050801u

Passlack M, Schubert EF, Hong M, Moriya M, Chu SNG, Konstadinidis K, Mannaerts JP, Schnoes ML, Zydzik GJ: Ga2O3 films for electronic and optoelectronic applications. J Appl Phys 1995, 77: 686. 10.1063/1.359055

Villora EG, Atou T, Sekiguchi T, Sugawara T, Kikuchi M, Fukuda T: Cathodoluminescence of undoped b-Ga2O3 single crystals. Solid State Commun 2001, 120: 455. 10.1016/S0038-1098(01)00409-4

Robertson J: Diamond-like amporphous carbon. Mater Sci Eng 2002, 37: 129. 10.1016/S0927-796X(02)00005-0

Gollakota P, Lunardi LM, Muth JF, Oztruk MC: Investigation of europium doped widebandgap oxides and an annealing study of the amorphous oxide semiconductor indium gallium oxide (thesis). North Carolina State University 2006, 15: 23.

Acknowledgements

We would like to thank the Directorate General of Higher Education Republic of Indonesia for the financial support via Fundamental Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

PM participated in the coordination of the study, preparation and growth of the samples as well as drafting the manuscript. SS participated in the growth and characterization of the samples. EW participated in the characterization, analysis of the data, and editing the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Marwoto, P., Sugianto, S. & Wibowo, E. Growth of europium-doped gallium oxide (Ga2O3:Eu) thin films deposited by homemade DC magnetron sputtering. J Theor Appl Phys 6, 17 (2012). https://doi.org/10.1186/2251-7235-6-17

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7235-6-17