Abstract

In 2006, some authors determined that the triboluminescence (TL) of manganese-doped zinc sulfide (ZnS:Mn) increases with increasing impact velocity. In 2011, the authors discovered a method of synthesizing europium dibenzoylmethide triethylammonium (EuD4TEA) that produced TL 106% greater than ZnS:Mn. In fact, this material is bright enough to be seen in daylight. This paper investigates the effects of increasing impact energy on the TL of EuD4TEA and various grain sizes of ZnS:Mn using a drop tower. The low energy results indicate that increasing impact energy can increase the triboluminescent light yield for impact energies up to 1.4 J, the upper limit of the drop tower. The minimum activation energies required for each material are also explored. In addition, the effects of the increasing impact energy on the triboluminescent decay time are also investigated. The details of the experimental setup, synthesis of EuD4TEA, and results are discussed in this paper.

Similar content being viewed by others

Background

One of the most unique crystal properties is the ability to emit light when it undergoes fracture. This property is present in about 50% of known crystals and is called triboluminescence (TL) [1]. Scientists have yet to come up with a complete theory that can predict this unique phenomenon; however, this has not stopped scientists from around the world devising useful applications for such materials [1].

Damage detection is one use for TL [2–7]. There are a number of techniques currently being used for damage detection and monitoring of civil, aerospace/military structures, and aircraft [6]. However, the major drawbacks of the current techniques are the lack of in situ and distributed sensing [6, 8–10]. In addition, the associated cost resulting from the downtime required for periodic nondestructive inspections can be very high for aerospace structures like aircrafts and civil structures like bridges [6].

TL-based sensor systems may be able to overcome these challenges as they have the potential for wireless, in situ, and distributed sensing that can enable real-time continuous monitoring [6]. In addition, TL-based sensor systems comprising of triboluminescent materials could allow for real-time monitoring of both the magnitude and location of damage with reference to the host structure [2, 3]. They can also be used as stress, fracture, and damage sensors [4, 5].

If these sensors are to become a reality, however, the TL emitted must be bright. Of the hundreds of known triboluminescent materials, only a few are bright enough to be seen in daylight. One organic material that is bright enough is europium tetrakis dibenzoylmethide triethylammonium (EuD4TEA) [11–18]. This material has 206% of the TL yield compared to ZnS:Mn subjected to low-energy impacts [11]. However, due to its organic nature, EuD4TEA appears to be more easily damaged than ZnS:Mn [11].

Theory and measured properties

The luminescence induced by any mechanical action on solids is known as mechanoluminescence (ML) [1, 19]. ML can generally be divided into two more categories: (1) light emitted during elastic and plastic strain known as deformation luminescence (DL) and (2) light emitted during fracture known as TL. The ML intensity depends on a large number of factors, including stress, strain, strain rate, pressing rate, temperature, atmospheric pressure, dielectric constant, mobility, particle/crystal, sample mass, trap depth, piezoelectric constant, trap concentration, radiation fluence, dopant type and concentration, sample firing temperature, sample sintering temperature, sample annealing temperature, firing time, sintering time, charge carrier capture cross section, number of successive pressings, efficiency for the conversion of mechanical energy into light energy, crystal structure, crystallographic direction, piezoelectric constant, dislocation density, area of newly created surfaces, dislocation charge, sample hardness, and sample age [19]. As a result, the exact cause of ML is unknown [1, 19]. Despite this limitation, great progress has been made to increase our understanding of ML [1, 19].

In 1888, Walton coined the term ‘triboluminescence’ to denote the light emission resulting from fracturing materials as cited in [1]. While there has been much study on the topic of TL, there is no single theory that can predict TL. However, since 1888, several facts have been learned [1]:

-

1.

TL occurs more frequently in crystals whose structure lacks a center of symmetry.

-

2.

If a compound is optically active and one of the isomers is TL, the other one may or may not be TL.

-

3.

With certain compounds, the TL activity may fade over a period of weeks or months after the crystals have been grown. Thus far, only arsenic trioxide has been shown to possess this property.

-

4.

The TL intensity produced depends on the physical conditions of the crystallization.

-

5.

For every material, there is a crystal size below which the substance is not TL.

-

6.

Elements by themselves are not TL.

-

7.

Few amorphous substances are TL, which indicates that a crystalline structure is required.

-

8.

TL emission can arise from the dielectric breakdown of the surrounding gas during fracture.

Since the 1930s, it has been known that alkali halide crystals irradiated by x- or γ-rays experience DL [1]. The emission yield varies between materials; however, as an estimate, approximately 10% of the light occurs in the elastic region, 75% from the plastic region, and 15% from TL [1]. In addition, it has been discovered that generally no DL is produced from alkali halide crystals which are either not irradiated or merely additively colored [1]. However, TL is observed in both cases [1].

It is believed that DL comes from the recombination of free electrons (e) with luminescence centers (L). The free electrons are produced when a mobile dislocation (D) interacts with an F-center (color center). This can be expressed as [1]

In 1970, Senchukov and Shmurak discovered that the DL hysteresis existing under both elastic and plastic deformation is consistent with electrons being released from F-centers as cited in [1]. At low stresses, dislocation lines bend elastically about their pinning points (point defects). As they bend, electrons are released from the F-centers [1]. The electrons will then combine with luminescent centers to produce DL. In 1969, Shmurak showed that the total number of photons emitted from irradiated KCl is proportional to the area swept out by the dislocation lines as cited in [1]. It was also discovered that after removing the samples from low stress, the dislocation lines return to their original positions by the tensions acting along these lines. As they do, they move through the regions of the crystal cleared of F-centers. To produce new luminescence, a stress must be applied which will bend the dislocation lines further than in the previous cycle. At even higher stresses, a dislocation line will unpin itself. This freely moving dislocation processes a glide in the crystal. This is consistent with the observation that the DL peaks which occur during plastic deformation do so in the glide region of the stress–strain curve [1].

Bohun, in 1956, and Pirog and Sujak, in 1968, observed that electrons are emitted from the surface of x-ray-irradiated alkali halides when they are stressed as cited in [1]. This emission was attributed to the presence of F-centers in the surface regions of the crystal [1]. It should be noted that no emission of electrons was detected when the crystal had been bleached prior to stressing. In addition, Gyulai and Hartly discovered that plastic deformation produced a large transient increase in the conductivity of natural rock salt crystals as cited in [1]. The stress required to produce the first substantial rise in conductivity agreed roughly with the yield stress [1]. If the load was returned to its original value, removal and reapplication of the same load had no further effect [1]. A new transient effect was produced only if the previous total load was exceeded [1]. This result was attributed to the electrons being released by the motion of the dislocation [1].

In 1966, Butler studied the luminescence produced when straining γ-irradiated alkali halides as cited in [1]. When deformed plastically, the crystals glowed [1]. The maximum wavelength at which the main peak occurred in each salt's DL spectrum was found to fall on a single line in a Mollwo-Ivey plot [1]. In this particular type of plot, the maximum wavelength is graphed against the square of the lattice constant of the salt under consideration [1]. The results from this indicated that the luminescence that was produced from each salt was similar [1]. In another experiment, Butler measured the fraction of F- and M-centers remaining after various bleaching times when the KCl crystal was flooded with light absorbed by the F-band [1]. Their data indicated that the DL curve goes through a maximum at the same bleaching time as does the M-center concentration [1]. Therefore both the F and M-centers are involved in the luminescence process [1]. Because additively colored crystals containing both F and M-centers do not exhibit DL, a second type of center known as the recombination center must also be involved in the luminescence process [1].

Current DL materials include ZnS:Mn, x- or γ-irradiated alkali halide crystals, SrAl2O4:Eu, SrAl2O4:Ce, SrAl2O4:Ce,Ho, SrMgAl6O11:Eu, SrCaMgSi2O7:Eu, SrBaMgSi2O7:Eu, Sr2MgSi2O7:Eu, Ca2MgSi2O7:Eu,Dy, CaYAl3O7:Eu, (Ba,Ca)TiO3:Pr3+, ZnGa2O4:Mn, MgGa2O4:Mn, Ca2Al2SiO7:Ce, ZrO2:Ti, and ZnS:Mn,Te [19–39]. DL has also been observed in the nanoparticles of ZnS:Mn [30], SrAl2O4:Eu [40, 41], and ZnMnTe [41].

In this paper, we investigate the triboluminescent properties of ZnS:Mn and EuD4TEA. It should be noted that the luminescence of EuD4TEA is purely TL. The triboluminescent light emitted by ZnS:Mn, on the other hand, is only 15% of the emission. The remaining is caused by DL. To be more exacting, 80% comes from the plastic region and 5% comes from the elastic region [1].

Experiment

Previous research

One of the brightest inorganic TL materials is ZnS:Mn. In 2006, Bergeron et al. quantified the relationship between the triboluminescent intensity and impact velocity for ZnS:Mn [7, 42–44]. Using a drop tower as described in [44], the triboluminescent response from ZnS:Mn powder was measured. It was found that the intensity of the triboluminescent response appears to be a function of impact velocity with two regions of interest as shown in [7, 44]. The first region is in the velocity range below 2 m/s. Here, the production of triboluminescent light appears to have a threshold of approximately 0.5 m/s [44]. Above this threshold, the projectile has sufficient velocity (or energy) to break ZnS:Mn crystals and to produce triboluminescent light as shown in (Figure 1) [44] .

Plot of the photomultiplier detector potential as a function of impact velocity for ZnS:Mn[45].

In addition, Bergeron et al. found that the triboluminescent intensity increases rapidly until about 2 m/s [44]. The second region begins at 2 m/s and appears to be a saturation state, where the slope is not as steep. This was likely due to the ball breaking as many crystals as possible in the impact area. Increasing the energy above this threshold cannot generate more light due to the lack of crystals in the impact area, thus indicating less sensitivity to impact velocity [44].

In 2011, the authors found that europium dibenzoylmethide triethylammonium (EuD4TEA) is 106% brighter than ZnS:Mn [45]. Due to its unique properties, a low-velocity impact study similar to that of Bergeron et al. was performed to determine if EuD4TEA and three ZnS:Mn samples from Phosphor Technology of Great Britain with different grain sizes would behave in a similar manner. Additionally, instead of using the peak potential as was done in Bergeron et al., [7, 44] the total light yield would be determined.

Synthesis of EuD4TEA

The first EuD4TEA material was synthesized by Hurt et al. [12]. Using this method, it was discovered that TL was dependent on the concentration of the chloride ions present, with TL increasing as the concentration of chloride decreases by washing [15]. Due to the high cost of anhydrous europium(III) chloride and the time required filtering, the authors in 2011 replaced the chloride salt with europium(III) nitrate hexahydrate [16]. This replacement caused the triboluminescent light yield to increase by 82%, and the product yield also increased due to the lack of washing required [16].

In 2012, the authors investigated the effect of various solvents on the TL of EuD4TEA [17]. Here, the data showed that using different solvents can make a difference in the amount of TL produced upon impact [17]. The large crystal-sized samples made with acetone produced the most TL [17]. Surprisingly, however, the use of the expensive pure anhydrous ethyl alcohol failed to produce the largest light yield [17]. Instead, the use of an inexpensive laboratory-grade acetone as a solvent to synthesize EuD4TEA crystals produces the most TL of all the solvents tested [17].

Furthermore, in 2011, it was discovered that doping EuD4TEA can increase the TL yield even more [11, 14, 18]. However, if a functional impact sensor is to be designed and fabricated, a TL light yield as a function of the impact energy must be known. This paper investigates the TL light yield versus impact energy of some the brightest known TL materials.

EuD4TEA was synthesized using the method described in [16]. The synthesis began by dissolving 4 mmol of europium nitrate hydrate in 25 mL of heated pure anhydrous ethanol. To this hot solution, 13 mmol of 1,3-diphenyl-1,3-propanedione also known as dibenzoylmethane (DBM) was added, followed by the addition of 14 mmol of triethylamine (TEA). The solution was heated until the mixture was clear, and then kept aside to cool slowly overnight at ambient temperature. The EuD4TEA crystals that formed were collected under suction [16].

Low-velocity triboluminescent light yield

Once the crystals were completely dried, they were placed in a small, clear, round, wide-mouth jar for storage. Using a custom-built drop tower described in [45], the crystalline products shown in Table 1 were tested for their triboluminescent properties. The measurement began by placing 0.1 g of sample powder on a Plexiglas plate. The powder is arranged so that it is positioned around the center of the tube with a minimum height. A 130-g steel ball is positioned on a pull pin at a set distance between 2 and 42 in. above the material. The pin is pulled and the ball falls and impacts with the sample material producing TL. After each test, the drop tube is removed, the ball is cleaned, and the sample powder is redistributed near the center of the target area [45].

To determine the triboluminescent yield for a given sample, a United Detector photodiode (San Diego, CA, USA) is positioned under the Plexiglas plate 2.25 cm below the sample. A Melles Griot large-dynamic-range linear amplifier (Albuquerque, NM, USA) set to a gain of 200 μA increases the signal amplitude. A Tektronix 2024B oscilloscope (Beaverton, OR, USA) records the signal in single sequence mode with a 500-μs measurement time. Once the signal is acquired, it is analyzed using custom LabVIEW program (National Instruments, Austin, TX, USA) that integrates the area under the curve and calculates the decay time for the particular emission [45].

Photoluminescence spectra

In order to determine the luminescent center for each material, the photoluminescence spectra were measured. This was accomplished by exciting the samples with a UV transilluminator manufactured by UVP, Inc. (Upland, CA, USA) The photoluminescence was recorded using an Avantes AvaSpec 2048 USB2 spectrometer (Apeldoorn, The Netherlands), which has a wavelength range of 445 to 680 nm and a resolution of 0.13 nm. The integration time was controlled using the AvaSoft software program (Avantes). The integration time was increased by the software until the photoluminescent emission spectrum reached its maximum that was just below the saturation limit of the spectrometer or until the background could no longer be subtracted due to a large integration time. Once this was determined, 100 spectra were recorded and averaged.

Results and discussion

Triboluminescent light yield

Using the drop tower and LabVIEW VI tools as described above, the TL produced by the various drop heights were analyzed. The first observation noticed is that the EuD4TEA organic material does not survive drops as well as the inorganic ZnS:Mn. As Figure 2 shows, the TL decreases exponentially very quickly. In fact, most of the EuD4TEA crystals had most of their TL extinguished after approximately ten drops. ZnS:Mn, on the other hand, can withstand over 50 drops, though still decreasing exponentially [46].

As Figure 2 shows, taking the average of the first five drops will not provide reliable data for this experiment. The reason is due to the fact that a majority of the TL is extinguished after five drops. As a result, the TL yield becomes not a result of the drop height, but instead a function of the material itself. Interestingly, it appears as though the total TL light produced over all drops and heights remains relatively constant.

In order to determine how the TL light yield changes with impact energy, only the first two values of each drop height was averaged for the EuD4TEA and the first five drops were averaged for the ZnS:Mn samples. The error in this case was estimated to be 5% for the energy. In addition, the TL change between the two EuD4TEA drops is smaller and more comparable to the change exhibited by ZnS:Mn over five drops.

The results from this test are shown in Figure 3. The data presented in Figure 3 were normalized to the 8.5-μm Zns:Mn TL yield collected from a drop height of 6 in. (152 mm). A 6-in. drop corresponds to an impact energy of 0.1944 J. The experimental uncertainty was estimated to be 7% of the normalized light yield as discussed in [47]. The ZnS:Mn TL results measured here are completely consistent with data collected by Bergeron et al. [42]. The TL data for ZnS:Mn exhibit a region where the emission yield experiences a rapid increase from 0.06 to 0.19 J, which corresponds to drop heights of 2 to 6 in. (51 to 152 mm). Due to experimental uncertainty, the TL yield does not appear to be a function of ZnS:Mn grain size for energies less than or equal to 0.19 J. Above 0.19 J, the TL emission yield continues to increase; however, it is at a much slower rate. The reason for this could be that for the lower energy impacts, there is not enough energy to break all the grains of powder. However, above 0.19 J, there is sufficient energy to break all the grains in the area of impact. For impacts with energies above 0.8 J, the TL yield for the 8.5-μm ZnS:Mn powder is statistically larger than the equivalent data for the 24.1- and 30-μm samples. It is possible that the methods used to manufacture these samples could play a significant role in TL yield. Additional research should be completed to better understand this phenomenon.

Results from Figure 3 also indicate that the TL yield from impacts with the EuD4TEA samples are significantly brighter than those observed from the ZnS:Mn powders over any of the tested kinetic energies. In addition, the increase in TL does not appear to be linear. Below an impact kinetic energy of 0.2 J, the TL emission yield rises rapidly. Conversely, the TL yield rises more slowly above 0.2 J.

In order to determine the minimum amount of energy needed to produce TL, the 0.13-kg steel drop ball was replaced with a 10-g wooden ball (made for a drawer handle) and 1-g Styrofoam ball (used with a fishing stopper). Both of these new balls had the same diameter as the original 0.13-kg steel bearing. Using balls of smaller mass allowed the impact energy to decrease proportionally. The Styrofoam ball dropped from a height of 2 in. had an available kinetic energy of 5 × 10−4 J (500 μJ) at impact. By contrast, the wooden ball had an available kinetic energy of 5 × 10−3 J (5 mJ) at impact.

When tested with the wooden ball dropped from a height of 2 in., all three ZnS:Mn and the one EuD4TEA samples produced a strong TL signal. By using the Styrofoam ball also dropped from a height of 2 in., both the 8.5- and 30-μm ZnS:Mn samples produced small amounts of detectable light. As a result, it can be safely assumed that the realistic limit for the 8.5- and 30-μm grain-sized ZnS:Mn is 500 μJ. It is possible that the detection kinetic energy might be lower if more expensive photomultiplier tubes were used to measure the emitted light in complete darkness.

Interestingly, the 24.1-μm ZnS:Mn sample did not produce light when the Styrofoam ball was dropped below a distance of 12 in. (305 mm), which corresponds to a kinetic energy of about 3.0 mJ. Light was also observed when the ball was dropped from a height of 18 in. (kinetic energy of 4.5 mJ). No other measurements were attempted between 12 and 18 in. Therefore, light is produced when a minimum of 3.0 to 4.5 mJ of energy is applied to the 24.1-μm ZnS:Mn powder. This result is likely caused by oxygen defects being added to the 24.1μm powder during synthesis. Additional research is needed to understand this phenomenon.

The most intriguing result is the fact that EuD4TEA appears to have an activation energy that is significantly less than that for 8.5-μm ZnS:Mn (500 μJ). A strong light emission was observed when a 1-g Styrofoam ball was dropped over a distance of 2 in. on the EuD4TEA powder. In fact, when the amplifier gain was reduced by a factor of 10, the resulting measured light yield from EuD4TEA was found to be similar to what was measured for ZnS:Mn. From this observation it can be concluded that the activation energy for EuD4TEA is approximately ten times less, or 50 μJ, than what was measured for ZnS:Mn.

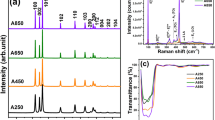

Photoluminescent and triboluminescent spectra

The measured photoluminescent and triboluminescent emission spectra for EuD4TEA are shown in Figure 4. Notice that both emission peaks have the same peak wavelengths but differ in intensity yield. The spectra indicate that the luminescence from EuD4TEA comes from the typical Eu4+-centered transitions from the 5D0 levels to the lower 7 F0-4 levels as shown in Figure 5[48]. Due to the high resolution of the spectrometer, multiple peaks were observed for each transition as shown in Table 2. The main emission occurred from the 5D0 → 7 F2 transition. In addition, the 5D0 → 7 F4 transition was not observed due to the transition occurring around 705 nm, which is outside the limit of the Avantes spectrometer. This peak has been observed using an Ocean Optics S2000 spectrometer (Dunedin, FL, USA) with a larger wavelength range and is shown in [14].

The measured photoluminescent emission spectra for all three grain sizes are shown in Figure 6. The spectra indicate that the luminescence from ZnS:Mn comes from the Mn+-centered transitions from the 6D9/2 level to the lower 6 S5/2 level as shown in Figure 5[48]. The average emission peak wavelength for all three grain sizes of ZnS:Mn is about 585 nm. However, the peak wavelength for the 30-μm ZnS:Mn powder is slightly smaller than the equivalent value for the 8.5-μm sample. This small difference is likely caused by the presence of oxygen traps in the 30-μm ZnS:Mn that were put there during the high-temperature manufacturing process. Due to the limitations of the experiment, it was not possible to measure the triboluminescent emission spectra for each ZnS:Mn material using the Avantes spectrometer.

Triboluminescent decay times

For many luminescent materials, the reduction in light intensity from the cessation of excitation can be written as

where I is the fluorescence light intensity (arbitrary units), I0 is the initial fluorescence light intensity (arbitrary units), t is the time since cessation of excitation source (seconds), and τ is the fluorescence decay time (seconds).

The time needed to reduce the light intensity to e−1 (36.8%) of its original value is defined as the fluorescence decay time (τ). Luminescence can be divided into two groups: fluorescence and phosphorescence. Phosphorescence, also known as delayed emission, has a much longer decay lifetime than fluorescence. Typical phosphorescence lifetimes can vary from 100 ms up to many seconds in duration, while the lifetimes of fluorescent materials usually range from 1 ns to 10 ms. More specifically, phosphorescence is the emission of light from a triplet excited state, where the electron in the ground state and excited state has the same spin orientation. The triplet state is due to the fact that the spin flips take more time to complete. Fluorescence occurs in singlet states, with the excited electron having the opposite spin of the paired ground state, resulting in a short emission time for photons. The fluorescence decay time is unique to each material. It might be possible to use the fluorescence decay time as an indicator to gauge the production of TL from impacts. Some materials such as ZnS:Mn,Cu have multiple decay times. Equation 1 would be valid over a limited range of times.

Using decay time software as described in [45], the decay times were determined for each drop. From the data shown in Table 3, it appears though that the impact energy does not change the TL decay time for ZnS:Mn or EuD4TEA. The average EuD4TEA TL decay time over all drops was 583.116 ± 33.788 μs. The average 8.5-μm ZnS:Mn decay time was 299.901 ± 36.304 μs. The average 24.1-μm ZnS:Mn decay time was 278.071 ± 51.659 μs, and the average 30-μm ZnS:Mn decay time was 314.195 ± 50.722 μs. The error for each was estimated using the standard deviation of all the drops.

Conclusions

This research shows that the TL light yield of EuD4TEA and ZnS:Mn is a function of impact energy and can be used as the active element of an impact sensor. While both materials are affected by impact energy, they do not behave in the same manner. The ZnS:Mn TL light yield increases steeply in the lower region, while the EuD4TEA shows a nonlinear increase. ZnS:Mn, on the other hand, has two regions with the second region experiencing an increase that appears to flatten out. The data also indicate that ZnS:Mn could be a better candidate for impact sensors if the impact energy needs to be determined very accurately. The ZnS:Mn can discern an energy difference of about 0.4 J while EuD4TEA can only discern about 0.6 J. The data also indicate that EuD4TEA is much better at detecting lower energy impacts. The activation energy for EuD4TEA powder was found to be about 50 μJ, which is ten times less than the 500 μJ that was measured for 8.5-μm ZnS:Mn. As a result, it can be used to detect lower energy impacts with inexpensive light detectors.

While the triboluminescent emission spectrum may be influenced by the impact energy, the decay time for each material is not affected. As a result, using two different materials such as EuD4TEA and ZnS:Mn at different locations can discern not only the impact energy, but also the location using their unique decay times. More research is needed to determine if the triboluminescent emission energy keeps increasing for higher intensity impacts caused by ballistic and hypervelocity speeds.

Authors’ information

R.S.F. is a graduate student pursuing his higher studies leading to Ph.D. degree in physics at Alabama A&M University.

W.A.H. holds the position of Dr. and Mrs. Sammie W. Cosper/BORSF Endowed Associate Professor of Physics at the University of Louisiana at Lafayette.

K.N.B. holds the position of Assistant Professor of Chemistry at Alabama A&M University.

M.D.A. holds the position of professor of physics and Chairman of the Department of Physics, Chemistry, and Mathematics at Alabama A&M University.

References

Walton AJ: Triboluminescence. Adv. Phys. 1977, 26: 887. 10.1080/00018737700101483

Sage I, Badcock R, Humberstone L, Geddes N, Kemp M, Bourhill G: Triboluminescent Damage Sensors. Smart Mater. Struct. 1999, 8: 504. 10.1088/0964-1726/8/4/308

Sage I, Bourhill G: Triboluminescent materials for structural damage monitoring. J. Mater. Chem. 2001, 11: 231. 10.1039/b007029g

Chandra BP, Zink JI: Triboluminescence and the dynamics of crystal fracture. Phys. Rev. B 1980, 21: 816. 10.1103/PhysRevB.21.816

Chandra BP, Baghel RN, Chandra VK: Mechano-luminescence glow curve of ZnS:Mn. ChalcogenideLett 2010, 7: 1.

Olawale DO, Dickens T, Sullivan WG, Okoli OI, Sobanjo JO, Wanga B: Progress in triboluminescence-based smart optical sensor system. J. Lumin. 2011, 131: 1407. 10.1016/j.jlumin.2011.03.015

Bergeron NP, Hollerman WA, Goedeke SM, Hovater M, Hubbs W, Finchum A, Moore RJ, Allison SW, Edwards DL: Experimental evidence of triboluminescence induced by hypervelocity impact. Int. J. Impact Eng. 2006, 33: 91. 10.1016/j.ijimpeng.2006.09.079

Chong KP, Carino NJ, Washer G: Health monitoring of civil infrastructures. Smart Mater. Struct. 2003, 12: 483. 10.1088/0964-1726/12/3/320

Merzbacher CI, Kersey AD, Friebele EJ: Fiber optic sensors in concrete structures: a review. Smart. Mater. Struct. 1996, 5: 196. 10.1088/0964-1726/5/2/008

Childs P, Wong ACL, Terry W, Peng GD: Measurement of crack formation in concrete using embedded optical fibre sensors and differential strain analysis. Meas. Sci. Technol. 2008, 19: 065301. 10.1088/0957-0233/19/6/065301

Hollerman WA, Fontenot RS, Bhat KN, Aggarwal MD, Guidry CJ, Nguyen KM: Comparison of triboluminescent emission yields for 27 luminescent materials. Opt. Mater. 2011, 34: 1517–1521.

Hurt C, McAvoy N, Bjorklund S, Fillipescu N: High Intensity Triboluminescence in Europium Tetrakis (Dibenzoylmethide)-triethylammonium. Nature 1966, 212: 179–180.

Aggarwal MD, Penn BG, Miller J: Triboluminescent materials for smart optical damage sensors for space applications. Technical report, NASA/TM—2008–215410. (2008). http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20080025731_2008024193.pdf

Fontenot RS, Bhat KN, Hollerman WA, Aggarwal MD: Synthesis and characterization of highly triboluminescent doped europium tetrakis compounds. J. Lumin. 2012, 132: 1812. 10.1016/j.jlumin.2012.02.027

Sweeting LM, Rheingold AL: Crystal disorder and triboluminescence: triethylammonium tetrakis(dibenzoylmethanato)europate. J. Am. Chem. Soc. 1987, 109: 2652. 10.1021/ja00243a017

Fontenot RS, Bhat KN, Hollerman WA, Aggarwal MD: Triboluminescent materials for smart sensors. Mater. Today 2011, 14: 292. 10.1016/S1369-7021(11)70147-X

Fontenot RS, Bhat KN, Hollerman WA, Aggarwal MD, Nguyen KM: Comparison of the triboluminescent yield and decay time for europium dibenzoylmethide triethylammonium synthesized using different solvents. CrystEngComm 2012, 14: 1382. 10.1039/c2ce06277a

Zeng XR, Xiong RG, You XZ, Cheung KK: Triboluminescent spectrum and crystal structure of a europate complex with the most intensely triboluminescent emission at ambient temperatures. Inorg. Chem. Commun. 2000, 3: 341. 10.1016/S1387-7003(00)00084-8

Chandra VK, Chandra BP: Dynamics of the Mechanoluminescence induced by elastic deformation of persistent luminescent crystals. J. Lumin. 2012, 132: 858. 10.1016/j.jlumin.2011.09.054

Chandra BP, Bisen DP: Electronic excitation during elastic deformation of γ-irradiated LiF single crystals. Phys. Status Solidi (A) 1992, 13: K101.

Chandra BP, Mahobia SK, Jha P, Kuraria SR, Baghel RN, Thaker S: Transient behaviour of the mechanoluminescence induced by impulsive deformation of fluorescent and phosphorescent crystals. J. Lumin. 2008, 128: 2038. 10.1016/j.jlumin.2008.07.003

Akiyama M, Nishikubo K, Nonaka K: Intense visible light emission from stress-activated SrMgAl6O11:Eu. Appl. Phys. Lett. 2003, 83: 650. 10.1063/1.1594828

Xu CN, Yamada H, Wang X, Zheng XG: Volume Incorrect. Should be volume 84. Strong eslasticoluminescence from monoclinic-structure SrAl2O4. Appl. Phys. Lett. 2004, 74: 3040.

Chandra BP, Xu CN, Yamada H, Zheng XG: Luminescence induced by elastic deformation of ZnS:Mn nanoparticles. J. Lumin. 2010, 130: 442. 10.1016/j.jlumin.2009.10.010

Kim JS, Kibble K, Kwon YN, Sohn SK: Rate-equation model for the loading-rate-dependent mechanoluminescence of SrAl2O4:Eu2+,Dy3+. Opt. Lett. 2009, 34: 1915. 10.1364/OL.34.001915

Chandra BP, Baghel RN, Luka AK, Sanodiya TR, Kuraria RK, Kuraria SR: Strong mechanoluminescence induced by elastic deformation of rare-earth-doped strontium aluminate phosphors. J. Lumin. 2009, 129: 760. 10.1016/j.jlumin.2009.02.015

Jia Y, Yei M, Jia W: Making red emitting phosphors with Pr3+. Opt. Mater. 2006, 28: 974. 10.1016/j.optmat.2005.05.014

Xu CN: Coatings. In Encyclopedia of Smart Materials. Edited by: Schwartz M. John Wiley and Sons, Inc., Hoboken; 2002:190–201.

Reynold GT, Ausin RH: Mechanoluminescence of plastic scintillation counters. J. Lumin. 2001, 92: 9.

Xu CN, Watanabe T, Akiyama M, Zheng XG: Artificial skin to sense mechanical stress by visible light emission. Appl. Phys. Lett. 1999, 74: 1236. 10.1063/1.123510

Chandra BP: Development of mechanoluminescence technique for impact studies. J. Lumin. 2011, 131: 1203. 10.1016/j.jlumin.2011.02.027

Sohn KS, Seo SY, Kwon YN, Dong H: Direct observation of crack tip stress field using the mechanoluminescence of SrAl2O4:(Eu,Dy,Nd). J. Am. Ceram. Soc. 2002, 85: 712.

Kim JS, Kwon YN, Shin N, Sohn KS: Mechanoluminescent SrAl2O4:Eu, Dy phosphor for use in visualization of quasidynamic crack propagation. Appl. Phys. Lett. 2007, 90: 241916. 10.1063/1.2748100

Akiyama M, Xu CN, Li Y, Nonaka K, Watanabe T: Influence of Eu, Dy co-doped strontium aluminate composition on mechanoluminescence intensity. J. Lumin. 2002, 97: 13. 10.1016/S0022-2313(01)00419-7

Akiyama M, Xu CN, Matsui H, Nonaka K: Recovery phenomenon of mechanoluminescence from Ca2SiO7:Ce by irradiation with ultraviolet light. Appl. Phys. Lett. 1999, 75: 2548. 10.1063/1.125073

Akiyama M, Xu CN, Nonaka K: Intense visible light emission from stress-activated ZrO2:Ti. Appl. Phys. Lett. 2002, 81: 457. 10.1063/1.1494463

Chandra BP, Sonwane VD, Haldar BK, Pandey S: Mechanoluminescence glow curves of rare-earth doped strontium aluminate phosphors. Opt. Mater. 2011, 33: 444. 10.1016/j.optmat.2010.10.014

Zhang H, Terasaki N, Yamada H, Xu CN: Mechanoluminescence of Euopium-Doped SrAMgSi2O7 (A=Ca,Sr,Ba). Jpn. J. Appl. Phys 2009, 48: 04C109–1.

Xu CN, Li C, Imai Y, Yamada H, Adachi Y, Nishikubo K: Development of Elastico-Luminescent Nanoparticles and their Applications. Adv. Sci. Technol. 2006, 45: 939.

Li C, Adachi Y, Imai Y, Nishikubo K, Xu CN: Processing and Properties of SrAl2O4:Eu Nanoparticles Preopared via Polymer-Coated Precursor. J. Electrochem. Soc. 2007, 154: J362. 10.1149/1.2772197

Raja Reddy D, Reddy BK: Laser-like mechanoluminescence in ZnMnTe-diluted magnetic semiconductor. Appl. Phys. Lett. 2002, 81: 460. 10.1063/1.1494116

Bergeron NP, Hollerman WA, Goedeke SM, Moore RJ: Triboluminescent properties of zinc sulfide phosphors due to hypervelocity impact. Int. J. Impact Eng. 2008, 35: 1587. 10.1016/j.ijimpeng.2008.07.007

Bergeron NP: Detection of triboluminescence from ZnS:Mn and ZnS:Cu. Master’s thesis. University of Louisiana, Lafayette; 2006.

Goedeke SM, Allison SW, Womack FN, Bergeron NP, Hollerman WA: Tribolumininescence and its application to space-based damage sensors. Technical report. Engineering Science and Technology Division at Oak Ridge National Laboratory; 2003.

Fontenot RS, Hollerman WA, Aggarwal MD, Bhat KN, Goedeke SM: A versatile low-cost laboratory apparatus for testing triboluminescent materials. Measurement 2012, 45: 431. 10.1016/j.measurement.2011.10.031

Womack F: Development of a drop tower to study the triboluminescence of ZnS:Mn with attention to possible applications to spacecraft. Master’s thesis. University of Louisiana, Lafayette; 2004.

Hollerman WA, Fontenot RS, Bhat KN, Aggarwal MD: Measuring the process variability in triboluminescence emission yield for EuD4TEA. Metallurgical and Materials Transactions A 2012. 10.1007/s11661-012-1202-9

Ralchenko Y, Kramida AE, Reader J National Institute of Standards and Technology (NIST) ASD Team: NIST Atomic Spectra Database (ver. 4.1.0), Gaithersburg (Online).http://physics.nist.gov/asd3 (2011). Accessed 3 April 2012

Acknowledgements

This research was funded in part by NASA Alabama Space Grant Consortium fellowship under Training Grant NNX10AJ80H, NSF-RISE Project HRD 0927644, and other grants from the State of Louisiana and federal agencies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

All authors contributed equally to this work. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Fontenot, R.S., Hollerman, W.A., Bhat, K.N. et al. Comparison of the triboluminescent properties for europium tetrakis and ZnS:Mn powders. J Theor Appl Phys 6, 15 (2012). https://doi.org/10.1186/2251-7235-6-15

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7235-6-15