Abstract

It is thought that the world coal reserve is close to 150 years, which only includes recoverable reserves using conventional techniques. Mining is the typical method of extracting coal, but it has been estimated that only 15% to 20% of the total coal resources can be recovered in this manner. If unrecoverable coal is considered in the reserves, the lifetime of this resource would be greatly extended, by perhaps a couple hundred years. Mining involves a large amount of time, resources, and personnel and contains many challenges such as drastic changes in landscapes, high machinery costs, elevated risk to personnel, and post-extraction transport. A new type of coal extraction method, known as underground coal gasification (UCG), that addresses most of the problems of coal mining is being investigated and implemented globally. UCG is a gasification process applied to in situ coal seams. UCG is very similar to aboveground gasification where syngas is produced through the same chemical reactions that occur in surface gasifiers. UCG has a large potential for providing a clean energy source through carbon capture and storage techniques and offers a unique option for CO2 storage. This paper reviews key concepts and technologies of underground coal gasification, providing insights into this developing coal conversion method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Review

Introduction

The global energy supply is comprised of many different sources, including fossil fuels, uranium, and various alternative and renewable sources. Currently, over 85% of the global energy supply is derived from fossil fuels, and a high fossil fuel dependency appears likely to remain in the immediate future [1]. The amount of energy required globally is projected to increase due to growing population and industrialization [2, 3]. Some feel that the total primary energy demand will double or even triple by the year 2050 relative to levels today, and as the energy demand continues to increase, future fossil fuel shortages are predicted [4, 5].

Hammond [6] argues that fossil fuel depletion is a significant factor when considering sustainable energy systems for the future. Fossil fuel resources are finite and being consumed rapidly, beginning with the most economically attractive resources [7]. In the future, fossil fuel resource extraction and production rates are expected to peak and begin to decline [7]. Oil production is predicted to peak in 5 to 15 years and gas production within 40 years, with significant exhaustion of oil and gas reserves by the years 2050 and 2070, respectively [4, 8]. As fossil fuel demand approaches supply levels, the cost of energy is anticipated to increase drastically, prompting research and technological developments for improved ways to convert more fossil fuel resources into useable reserves [9].

Currently, coal generates 41.5% of the world’s electricity and provides 26.5% of global primary energy needs [1]. Coal has the largest reserves in the world of the fossil fuels and is abundant in many countries. It is thought that the world’s recoverable coal reserve is close to 150 years at current production rates, but this only represents 15% to 20% of the entire resource [8]. Remaining global coal resources have recently been estimated to be 18 trillion tonnes [10]. This contrasts significantly with the typical figure of tens of billions of tonnes for recoverable reserves [4]. If unrecoverable coal is considered in the recoverable reserves, the lifetime of the resource could be extended by a couple hundred years. For this to be realized, new, economic extraction techniques need to be implemented.

Coal is conventionally extracted by mining, both underground and open pit. Mining operations require much time, personnel, and natural resources; typically, coal reserves lie too deep underground, or are otherwise too costly, to exploit using conventional mining methods. Conventional mining also has other issues including land subsidence, high machinery costs, hazardous work environments, coal transport requirements, localized flooding, and methane buildup in cellars of nearby homes [11].

Underground coal gasification (UCG) is a newer type of coal extraction that is being investigated and implemented around the world and that avoids most of the problems of mining coal. UCG involves the conversion of unmined coal, where coal seams are gasified, without mining, and synthetic gas (syngas) is produced for use in power generation or as chemical feedstock [12]. UCG limits the amount of underground work required by personnel, lowering risks of harm relative to conventional mining. Power generation and chemical processing plants can be built directly above a coal resource and use syngas produced through UCG, avoiding coal transport. UCG has the ability to significantly widen the resource base, where the energy contained within inaccessible coal reserves, considered uneconomical for recovery, could be recovered using UCG [11]. It has been estimated by the Underground Coal Gasification Partnership that around 4 trillion tonnes of otherwise unusable coal could be suitable for UCG [9].

UCG is appealing for expanding recoverable coal reserves, but as with the combustion of all fossil fuels, there are associated greenhouse gas emissions. Coal is the most carbon-intensive of all fossil fuels and has high associated CO2 emissions [4]. The calorific value of fossil fuel sources varies, with typical values of 50 GJ/tonne for natural gas, 45 GJ/tonne for crude oil, and 30 GJ/tonne for coal [4]. Hence, coal has the highest CO2 emissions per unit of thermal energy produced [13]. If coal is to become a major contributor in the future global energy supply, CO2 capture and storage techniques would need to be incorporated in the process. UCG has good potential for CO2 reduction. During gasification, CO2 is produced, which can be captured from the syngas and stored for long terms. If UCG is successfully linked to such carbon capture and storage (CCS), a method will be available for exploiting the energy in previously unrecoverable coal reserves while satisfying standards for reducing CO2 emissions.

The aim of this paper is to review key areas and technologies for underground coal gasification so as to provide insights into this developing coal conversion method.

Underground coal gasification

Brief UCG history

The concept of coal gasification has been recognized for more than 200 years and was first used during the late 1800 s to produce town gas fuel for heating and lighting applications [14]. Today, coal gasification is primarily used to provide fuel for advanced power plants and chemical feedstocks for use in the chemical industry [9]. Conventionally, coal is extracted from the ground through mining, processed, transported, and then gasified in a surface gasifier unit to produce syngas. Underground coal gasification is a combined extraction and conversion process.

Experimentation on UCG was first performed in 1912 by Sir William Ramsay in England [4]. The experiments demonstrated the potential of UCG, but Ramsay’s work was interrupted by the First World War. After the war, further UCG research did not continue, since coal was relatively inexpensive and available through conventional mining techniques in Western Europe [4]. The former Soviet Union was the first to begin considerable research and development programs with respect to large-scale UCG systems in the 1930s [15, 16]. UCG technology was first utilized within commercial operations by the former Soviet Union for heating and power generation applications, which has continued to implement these systems for over 50 years [17]. Even though UCG has the appearance of being commercially mature, the technology from the former Soviet Union has been gaining interest only recently, with a rapid increase in the number of pilot plants throughout the rest of the world over the last decade. There are many commercial projects entering pilot plant phase and undergoing study, in Australia, New Zealand, the USA, India, Pakistan, Canada, and Italy. National research programs are being reconsidered in the USA and the UK, after preliminary systems failed to reach commercial maturity. As of 2008, the number of UCG trials includes 200 in the former Soviet Union, 33 in the USA, and approximately 40 distributed between South Africa, China, Australia, Canada, New Zealand, India, Pakistan, and Europe [17, 18].

UCG concepts and technology

UCG is similar to surface gasification [19], with syngas produced through the same chemical reactions [12]. The main difference is that surface gasification occurs in a manufactured reactor whereas the reactor for a UCG system is a natural geological formation containing unmined coal [19, 20]. UCG also has similarities to in situ combustion processes applied in heavy-oil recovery and oil shale retorting, with such common operational parameters as roof/floor stability, seam continuity and permeability, and ground water influx [19, 21].

The basic UCG concept is illustrated in Figure 1. UCG involves an arrangement of injection and production wells drilled into coal seams. The coal is ignited and compressed gasification agents are fed into the coal seam through injection wells which triggers and controls an in situ sub-stoichiometric combustion process, producing syngas [22]. Syngas is extracted using production wells and is processed for use [17]. Suitable gasifying agents include air, oxygen, steam/air, and steam/oxygen [23]. The main difference between using oxygen and atmospheric air is that utilization of oxygen increases the heating value of the syngas [24], but producing pure oxygen requires additional energy and resources.

Schematic of in situ underground coal gasification process (modified from[21]).

Coal ignition is initiated through the use of an electric coil or gas firing near the face of the coal seam. Continuous oxidant flow through the injection well allows for gasification to be sustained [1]. The temperature of the gasification process is maintained through varying the oxidant flow to the reactor [23]. In UCG systems, the temperature of the coal face can reach temperatures in excess of 1,500 K [24, 25].

Various chemical reactions, temperatures, pressures, and gas compositions exist at different locations within a UCG gasifier. The gasification channel is normally divided into three zones: oxidization, reduction, and dry distillation and pyrolysis [26, 27]. In the oxidization zone, multiphase chemical reactions occur involving the oxygen in the gasification agents and the carbon in the coal. The highest temperatures in the gasifier occur in the oxidation zone, due to the large release of energy during the initial reactions [28]. The following reactions occur in the oxidation zone:

In the reduction zone, the main reactions involve the reduction of H2O(g) and CO2 into H2 and CO at high temperatures within the oxidation zone [26]. The following endothermic reactions occur in the reduction zone [21, 28]:

Under the catalytic action of coal ash and metallic oxides, a methanation reaction occurs:

The energy terms, within the above equations, represent the amount of energy released or consumed during each reaction with the stoichiometric coefficients in equations representing moles. Equations 1 to 6 are taken from [21] and [28]. The endothermic reactions in the reduction zone decrease the temperature in the gasification channel to below that required for the reduction reactions.

Within the distillation (pyrolysis) zone, the coal seam is decomposed into multiple volatiles including H2O, CO2, CO, C2H6, CH4, H2, tar, and char [21, 28]. At the exit of the gasification channel, the volatile composition of the syngas consists mostly of CO, H2, and CH4. The UCG process can also have other products, including H2S, As, Hg, Pb, and ash [27, 29, 30]. The composition of syngas is highly dependent on the gasification agent, air injection method, and coal composition [31, 32]. During operation, the three gasification zones move along the direction of the air flow, ensuring continuous gasification reactions [21]. A distinguishing feature of UCG, compared to surface gasification, is that drying, pyrolysis, and char gasification occur simultaneously within the coal [26].

By-products of the UCG process pose an environmental hazard to the local surroundings through leaching of organic and inorganic materials into groundwater. Environmental data were first made available after later trials in the USA, including Hanna and Hoe Creek UCG trials, for which groundwater contamination monitoring was conducted before, during, and after gasification. The results illustrated that at shallow depths, UCG can pose a significant risk to groundwater in adjacent strata [30].

Groundwater pollution around UCG zones is mainly caused by one of the following mechanisms: dispersion and penetration of the pyrolysis products of the coal seam to the surrounding rock layers, the emission and dispersion of high contaminants with gas products after gasification, and migration of residue by leaching and penetration of groundwater [30]. In addition, the escaped gases such as carbon dioxide, ammonia, and sulfide may change the pH value of the local strata if dissolved.

The entire process is confined to the space of the coal seam and is sealed from the surface by natural geological formations or man-made barriers; the coal seam and strata serve, to some extent, as a natural groundwater cleaning system. In general, systems have active pressure control, in which the cavity pressure is held in equilibrium or below that of the surrounding strata [17, 30]. The pressure difference induces flow into the reactor space, which inhibits gasification products from leaking away from the cavity [33, 34].

The quality of the product gas is influenced by several parameters - such as the pressure inside the coal seam, coal properties, feed conditions, kinetics, and heat and mass transport within the coal seam - and the product of the UCG process is a multi-compound, high-temperature, and high-pressure syngas [1]. When the syngas reaches the surface, it is cleaned and undesired by-products are removed from the product stream [24]. Removal techniques are similar to those used with surface gasifiers. Once the by-products are removed, they can be disposed of safely, or used for other chemical processes [16]. The degree of cleaning required is dependent on the use of the syngas; syngas is cleaned either to meet the specification for input into a gas turbine (for electricity generation) or to be of sufficient purity for use as a chemical feedstock for conversion to synthetic fuels [20].

Methods for UCG. Two standard methods of preparing a coal seam for gasification have been utilized successfully: shaft and shaftless. The method implemented is dependent on parameters such as the natural permeability of the coal seam, geochemistry of the coal, seam thickness, depth, width and inclination, proximity of urban developments, and the amount of mining desired [34].

-

1.

Shaft UCG methods. Shaft methods use coal mine galleries and shafts to transport gasification reagents and products, which sometimes entail the creation of shafts and the drilling of large-diameter openings through underground labor [34]. The shaft method was the first technique utilized within UCG systems. Currently, the shaft method is only employed in closed coal mines due to economic and safety reasons [34]. The following are examples of common UCG shaft methods:

Schematic of the structure of a LLT underground gasifier (modified from[28]).

-

Chamber or warehouse method. This method utilizes constructed underground galleries with brick walls separating coal panels. Gasification agents are supplied to a previously ignited coal face on one side of the wall, and the syngas is removed from a gallery on the other side. The chamber method strongly relies on the natural permeability of the coal seam to allow for sufficient oxidant flow through the system. The syngas composition may vary during operation, and the gas production rates are often low. To improve system output, coal seams are often outfitted with explosives for rubblization prior to the reaction zone [21].

-

Borehole producer method. For this method, parallel underground galleries are created within a coal seam with sufficient distance between them. The galleries are connected by drilling boreholes from one gallery to the other [34]. Remote electric ignition of the coal in each borehole is used to initiate the gasification process. This method is designed to gasify considerably flat-lying seams. Some variations exist where linking of the galleries is accomplished through hydraulic and electric linking [21, 34].

-

Stream method. This method is designed for sharply inclined coal beds. Parallel pitched galleries following the contour of the coal seam are constructed and are connected at the bottom of the seam by a horizontal gallery also known as a fire-drift. To initiate gasification, fire is introduced within the horizontal gallery. The hot coal face moves up the seam slope with oxidant fed through one inclined gallery and syngas leaving through the other. The main advantage of this method is that the ash and roof material drop down to fill the void space created during the process, which prevents suffocating the gasification process at the coal front [21].

-

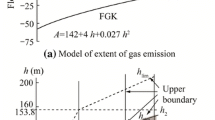

LLT gasification method. This method utilizes mined tunnels or constructed roadways to connect the injection well to the production well [4]. Typical long and large tunnel (LLT) systems consist of a gasification channel, two auxiliary holes, and two auxiliary tunnels (Figure 2). The auxiliary holes are arranged between the injection and production wells and are used as malfunction holes for the injection of air and water vapor, or to discharge gas for added gasifier control. LLT also includes an auxiliary tunnel constructed of bricks, which is an auxiliary installation for air injection that prevents blockage in the gasification channel. The mined tunnels are isolated by sealing walls to prevent leakage of combustible gases from the gasifier [35]. The location and height of the oxidant injection points and gas outlet points can be adjusted, allowing for two-dimensional control of oxidant injection and gas production [28].

-

2.

Shaftless UCG methods. Recently, most of the focus of research has been on the shaftless methods, which employ directional drilling techniques [6]. The preparation of a reactor for the directional drilling technique consists of the creation of dedicated in-seam boreholes for oxidant injection and product collection using drilling and completion technology that has been adapted from oil and gas production.

With shaftless methods, all preparation and operational processes are carried out through a series of boreholes drilled from the surface into a coal seam and do not require underground labor. Preparation of a shaftless reactor consists of the creation of dedicated in-seam boreholes for oxidant injection and product collection using drilling and completion technology that has been adapted from oil and gas production [34]; the approach generally includes drilling inlet and outlet boreholes into a coal seam, increasing the coal permeability between the inlet and outlet boreholes, igniting the coal seam, introducing an oxidant for gasification, and extraction of the product gas from the outlet well [21]. Currently, there are two main classifications of shaftless UCG methods: linked vertical well (LVW) and controlled retractable injection point (CRIP).

-

LVW method. The LVW method is one of the oldest methods for UCG and is derived from technology developed in the former Soviet Union [16]. Vertical wells are drilled into a coal seam, and internal pathways in the coal are utilized to direct the oxidant and product gas flow from the inlet to the outlet borehole. Internal pathways can be naturally occurring or constructed [35]. In its simplest form, the LVW method has inlet and outlet borehole locations that are static for the life of the system. During operation, the coal face migrates and it is found that system control, performance, and syngas quality are affected negatively as the distance from the coal face to the oxidant injection point increases [4]; this factor greatly reduces the feasibility of simple LVW systems.

A more advanced LVW approach involves a series of dedicated injection boreholes located along the length of a coal seam [21]. Over the life of a UCG reactor, the coal face, being gasified, travels as localized coal is exhausted [4]. Having multiple boreholes for injection allows for improved static operating conditions. A more complex variation of the LVW method also exists where multiple inlet and outlet boreholes are drilled into a coal seam, forming inlet and outlet borehole pairs. Parallel inlet and outlet manifolds are connected to the boreholes to provide a path for oxidant and syngas flows, respectively. Coal between each pair of inlet and outlet boreholes forms a zone. When the coal in a zone has been exhausted, new boreholes are drilled in a location of fresh coal, forming new zones [21].

Low-rank coals, such as lignites, have considerable natural permeability and can be exploited for UCG without the need for linking technologies. However, high-rank coals, such as anthracites, are far less permeable, making the gas production rate more limited if UCG is employed [35]. For the use of high-rank coals in UCG, a method of linking must be employed to increase the permeability and fracture the coal seam [36]. The boreholes in traditional LVW gasifiers are linked by special methods including forward combustion, reverse combustion, fire linkage, electric linkage, hydrofracturing, and directional drilling to create sizable gasification channels [35, 37].

Controlled retractable injection point. Over the span of a coal seam, the geometry may change, resulting in variable UCG operation and system performance [38]. In the past, this problem was solved by having multiple injection and/or production wells so that static operating conditions could be accomplished through moving the gasifier zones to fresh coal [16]. CRIP offers an alternative approach where the vertical injection well is not moved, but the injection point is moved within the coal seam to fresh coal when necessary [39].

The CRIP method relies on a combination of conventional drilling and directional drilling to access the coal seam and physically form a link between the injection and production wells, without the use of linking technologies utilized in LVW methods [38]. A vertical section of injection well is drilled to a predetermined depth, after which directional drilling is used to expand the hole and drill along the bottom of the coal seam creating a horizontal injection well [40]. At the end of the injection well, a gasification cavity is initiated in a horizontal section of the coal seam, creating a localized reactor. The CRIP system utilizes a burner attached to retractable coiled tubing which is used to ignite the coal [39]. The burner burns through the borehole casing to ignite the coal. The ignition point can be moved to any desired location along the horizontal injection well for the creation of a new gasification cavity after a deteriorating reactor has been deserted [38]. Typically, the injection point is retracted using a gas burner, which burns a section of the liner at a desired location [39]. In this manner, accurate control of the gasification process can be obtained. This UCG method has gained popularity in Europe and the USA, but the use of the CRIP method for UCG is fairly new and currently has not become commonly employed [4].

UCG with CO2 capture and storage

All fossil fuels emit CO2 when combusted. Currently, coal has the highest CO2 emissions, per unit energy produced, of the fossil fuels used in combustion [13, 41]. To maintain and expand the use of coal, implementation of CCS technologies is becoming imperative.

CO2 capture can be performed in three main fashions: pre-combustion, post-combustion, and oxy-firing [42]. A broad range of technology options are available for capturing CO2 including physical absorption, chemical absorption, membrane separation, and cryogenic separation [42, 43]. Within UCG, the syngas compositions, temperatures, and pressures of production streams at the exit of a production well are comparable to those of surface gasifiers, which allow similar methods of CO2 capture. Due to similarities, it is believed that UCG syngas could take advantage of separation using physical sorbents, within a pre-combustion arrangement, which has costs comparable to capture technologies commonly utilized in integrated gasification combined cycles [4, 12]. Post-combustion methods are also applicable and would be directly comparable in terms of cost and performance to typical post-combustion systems utilized in power plants. Oxy-firing options are possible for UCG as well, and within a power generating scenario, an air separation unit can generate O2 streams for injection into the UCG and for use in an oxy-fired plant utilizing the syngas [12].

The spatial coincidence of geological carbon storage (GCS) options with UCG opportunities suggests that designers could colocate and combine UCG and GCS systems with high potential for effective CO2 storage [18]. In general, these storage options would be the same for conventional carbon sequestration operations, including saline formations and mature oil and gas fields [44]. For UCG-CCS utilizing conventional sequestration options, there could exist common interests in site characterization and monitoring between UCG and CCS projects, where work performed during the design and implementation of one project could be used within the other. Coordinating UCG and CCS designs would improve economics for both projects.

If UCG and CCS are coupled, there is an attractive carbon management scheme associated, where most of the expected CO2 emissions are sequestered back into a coal seam void that has been recently created by spent subsurface reactors through existing injection and production wells [13, 21]. When voids are created, they typically collapse, similar to voids produced during longwall coal mining, leaving zones of artificial breccias with high permeability. Suitable containment zones prevent vertical flow of CO2 to the surface, where storage locations are isolated from the surface by low-permeability strata (known as seals or caprocks, often shales or evaporites) [4, 45]. For a spent UCG system to accommodate CO2 storage, the void must be at depths below approximately 800 to 1,000 m [44–46]. These depths are required so that supercritical pressures and temperatures exist that allow the CO2 density to be high enough (approximately 500 to 700 kg/m3) to limit the storage volume required [45].

The UCG-CCS approach, if successful, could offer an integrated energy recovery and CO2 storage system, which exploits a new sequestration resource created during operation. A significant challenge with CCS is its large energy requirement [47], of which a considerable portion is consumed during CO2 capture and compression [48]. The pressure after compression is generally high enough to allow for a reduction in pressure during transport while allowing the fluid to be in a liquid state [9]. If CO2 storage is accommodated in spent UCG reactors, CO2 transport and compression requirements decline. CO2 transport accounts for 5% to 15% of a conventional CCS financial budget, which can be lowered with a self-contained UCG-CCS project, through reduced piping and shipping requirements associated with long-distance transport [18]. A large portion of the budget for a CCS project is allotted for CO2 storage, typically 10% to 30%, most of which is used for geological and geophysical studies and drilling injection wells [18, 48]. These tasks are commonly completed during UCG construction and would not need to be repeated for the implementation of CCS, thus reducing system cost relative to conventional storage methods [18].

As of 2009, it remains unclear if CCS using UCG-produced voids is viable [44]. Until recently, this alternative has received little attention, and there remains substantial scientific uncertainty associated with the technological challenges and environmental risks of storing CO2 in this manner [13, 44]. For full-scale commercialization, extensive research and development is needed to alleviate the uncertainties. Currently, CO2 sequestration is under development internationally by such organizations as the Intergovernmental Panel on Climate Change and Carbon Sequestration Leadership Forum [13].

Conclusions

Although the earth is an abundant source of coal, a significant amount is currently unrecoverable. With the introduction of UCG, recoverable coal reserves can be expanded by possibly a couple hundred years. Coal is likely to remain used in many countries, increasing the needs for new technologies that permit more environmentally benign extraction and utilization. Wide-scale use of UCG is such a technology option, with the syngas it produces usable as a fuel. Fossil fuels typically utilized in power production could then be used for other purposes, which would result in large reductions in their consumption rates.

UCG offers a coal extraction and conversion method in a single process that avoids many of the challenges associated with conventional mining practices. UCG has a high potential for integration with CCS using conventional methods utilized in power production due to similarities with surface gasifier units. UCG also has the potential to store CO2 within voids created during its operation, which reduces the need for transport and storage site identification. In essence, UCG could provide a cost-effective, near-zero-carbon, energy source through the use of a self-contained system with a closed carbon loop.

Authors’ information

SS is a PhD candidate at the University of Ontario Institute of Technology studying Mechanical Engineering. His fields of research include energy production and use, thermal energy storage, advanced energy systems, thermofluids, and exergy analysis. BR is a professor in the Faculty of Engineering and Applied Science at the University of Ontario Institute of Technology in Canada. His research interests are energy systems, including heat transfer in fluidized bed combustors, coal, biomass, natural gas, waste heat recovery energy systems analysis, hydrogen, and solar energy. BR has supervised graduate students and postdoctoral fellows, and is actively involved in the organization of conferences. He has delivered invited keynote presentations on energy systems and developments in international conferences, and has published over 120 papers in various technical journals and conferences and contributed book chapters in the energy area. He has received the Best Professor Award for Teaching Excellence three times. MR is a professor in the Faculty of Engineering and Applied Science at the University of Ontario Institute of Technology in Canada, where he was the founding dean of the faculty from 2002 to 2008. He has served as the President of the Engineering Institute of Canada and the Canadian Society for Mechanical Engineering. With over 70 research grants and contracts and 700 technical publications, MR is an active teacher and researcher in thermodynamics, energy technology, sustainable energy, and the environmental impact of energy systems. He has worked for such organizations as Imatra Power Company in Finland, Argonne National Laboratory near Chicago, and the Institute for Hydrogen Systems near Toronto. MR has received numerous awards and honors, including the Engineering Institute of Canada’s Smith Medal for achievement in the development of Canada.

Abbreviations

- CCS:

-

carbon capture and storage

- CRIP:

-

controlled retractable injection point

- GCS:

-

geological carbon storage

- LLT:

-

long and large tunnel

- LVW:

-

linked vertical well

- UCG:

-

underground coal gasification.

References

Daggupati S, Mandapati RN, Mahajani SM, Ganesh A, Pal AK, Sharma RK, Aghalayam P: Compartment modeling for flow characterization of underground coal gasification cavity. Ind. Eng. Chem. Res. 2011, 50: 277-290. 10.1021/ie101307k

Tanaka N(e): World Energy Outlook 2009. International Energy Agency, Paris; 2009.

Energy Information Administration: International Energy Outlook 2010. Department of Energy, U.S. Government, Washington; 2010.

Roddy DJ, Younger PL: Underground coal gasification with CCS: a pathway to decarbonising industry. Energy Environ. Sci. 2010, 3: 400-407. 10.1039/b921197g

Ediger VS, Hosgor E, Surmeli AN, Tatlidil H: Fossil fuel sustainability index: an application of resource management. Energy Policy 2007, 35: 2969-2977. 10.1016/j.enpol.2006.10.011

Hammond GP: Energy, environment and sustainable development: a UK perspective. Transactions of the Institution of Chemical Engineers, Part B 2000, 78: 304-323.

Aleklett K, Hook M, Jakobsson K, Lardelli M, Snowden S, Soderbergh B: The peak of the oil age–analyzing the world oil production reference scenario in World Energy Outlook 2008. Energy Policy 2010, 38: 1398-1414. 10.1016/j.enpol.2009.11.021

World Energy C: Survey of Energy Resources 2007. London, World Energy Council; 2007.

Ghose MK, Paul B: Underground coal gasification: a neglected option. Int. J. Environ. Stud. 2007,64(6):777-783. 10.1080/00207230701775375

Couch G: Underground Coal Gasification. IEA Clean Coal Centre, London; 2009.

Shackley S, Mander S, Reiche A: Public perceptions of underground coal gasification in the United Kingdom. Energy Policy 2006, 34: 3423-3433. 10.1016/j.enpol.2005.07.010

Burton E, Friedmann J, Upadhye R: Best Practices in Underground Coal Gasification. Lawrence Livermore National Laboratory, Livermore; 2006.

Khadse A, Qayyumi M, Mahajani S, Aghalayam P: Underground coal gasification: a new clean coal utilization technique for India. Energy 2007, 32: 2061-2071. 10.1016/j.energy.2007.04.012

Breault RW: Gasification processes old and new: a basic review of the major technologies. Energies 2010, 3: 216-240. 10.3390/en3020216

Gregg DW, Hill RW, Olness DU: An Overview of the Soviet Effort in Underground Gasification of Coal. Lawrence Livermore National Laboratory, Livermore; 1976.

Shafirovich E, Varma A: Underground coal gasification: a brief review of current status. Ind. Eng. Chem. Res. 2009, 48: 7865-7875. 10.1021/ie801569r

Van der Riet M: Underground coal gasification. In Proceedings of the SAIEE Generation Conference. Eskom College, Midrand; 19 Feb 2008.

Roddy D, Gonzalez G: Underground coal gasification (UCG) with carbon capture and storage (CCS). In Issues in Environmental Science and Technology. Edited by: Hester RE, Harrison RM. Royal Society of Chemistry, Cambridge; 2010:102-125.

Pana C: Review of Underground Coal Gasification with Reference to Alberta’s Potential. Energy Resources Conservation Board, Edmonton; 2009.

Walker L: Underground coal gasification: a clean coal technology ready for development. The Australian Coal Review 1999, 8: 19-21.

Lee S, Speight JG, Loyalka SK: Handbook of Alternative Fuel Technologies. CRC, Boca Raton; 2007.

Kempka T, Plötz ML, Schlüter R, Hamann J, Deowan SA, Azzam R: Carbon dioxide utilisation for carbamide production by application of the coupled UCG-urea process. Energy Procedia 2011, 4: 2200-2205.

Perkins G, Sahajwallaa V: Modelling of heat and mass transport phenomena and chemical reaction in underground coal gasification. Chem. Eng. Res. Des. 2007,85(3):329-343. 10.1205/cherd06022

Perkins G, Sahajwalla V: Steady-state model for estimating gas production from underground coal gasification. Energy Fuel 2008, 22: 3902-3914. 10.1021/ef8001444

Peng FF, Lee IC, Yang RYK: Reactivities of in situ and ex situ coal chars during gasification in steam at 1000-1400 °C. Fuel Process. Technol. 1995, 41: 233-251. 10.1016/0378-3820(94)00086-9

Perkins G, Sahajwallaa V: A mathematical model for the chemical reaction of a semi-infinite block of coal in underground coal gasification. Energy Fuel 2005, 19: 1679-1692. 10.1021/ef0496808

Yang LH, Pang XL, Liu SQ, Chen F: Temperature and gas pressure features in the temperature-control blasting underground coal gasification. Energy Sources: Part A 2010, 32: 1737-1746. 10.1080/15567030903078087

Yang L, Liang J, Yu L: Clean coal technology—study on the pilot project experiment of underground coal gasification. Energy 2003, 28: 1445-1460. 10.1016/S0360-5442(03)00125-7

Liu S, Wang Y, Yu L, Oakey J: Thermodynamic equilibrium study of trace element transformation during underground coal gasification. Fuel Process. Technol. 2006, 87: 209-215. 10.1016/j.fuproc.2005.07.006

Shu-qin L, Jing-gang L, Mei M, Dong-lin D: Groundwater pollution from underground coal gasification. J. China Univ. Mining & Technol. 2007,17(4):0467-0472. 10.1016/S1006-1266(07)60127-8

Stańczyk K, Howaniec N, Smoliński A, Świadrowski J, Kapusta K, Wiatowski M, Grabowski J, Rogut J: Gasification of lignite and hard coal with air and oxygen enriched air in a pilot scale ex situ reactor for underground gasification. Fuel 2011, 90: 1953-1962. 10.1016/j.fuel.2010.12.007

Prabu V, Jayanti S: Integration of underground coal gasification with a solid oxide fuel cell system for clean coal utilization. Int. Journal of Hydrogen Energy 2012, 37: 1677-1688. 10.1016/j.ijhydene.2011.09.132

Yang LH: A review of the factors influencing the physicochemical characteristics of underground coal gasification. Energy Sources, Part A 2008,30(11):1038-1049. 10.1080/15567030601082803

Wiatowski M, Stańczyk K, Świądrowski J, Kapusta K, Cybulski K, Krause E, Grabowski J, Rogut J, Howaniec N, Smoliński A: Semi-technical underground coal gasification (UCG) using the shaft method in Experimental Mine “Barbara”. Fuel 2012, 99: 170-179.

Liang J, Liu S, Yu L: Trial study on underground coal gasification of abandoned coal resource. In Proceedings of the '99 International Symposium on Mining Science and Technology, Beijing, August 1999. Mining Science and Technology 99. Edited by: Xie H, Golosinki TS. A.A. Balkema, Rotterdam; 1999:271-275.

Blinderman MS, Klimenko AY: Theory of reverse combustion linking. Combustion and Flame 2007, 150: 232-245. 10.1016/j.combustflame.2006.12.021

Blinderman MS, Saulov DN, Klimenko AY: Forward and reverse combustion linking in underground coal gasification. Energy 2008, 33: 446-454. 10.1016/j.energy.2007.10.004

Nourozieh H, Kariznovi M, Chen Z, Abedi J: Simulation study of underground coal gasification in Alberta reservoirs: geological structure and process modeling. Energy Fuel 2010, 24: 3540-3550. 10.1021/ef9013828

Klimenko AY: Early ideas in underground coal gasification and their evolution. Energies 2009, 2: 456-476. 10.3390/en20200456

Wang GX, Wang ZT, Feng B, Rudolph V, Jiao JL: Semi-industrial tests on enhanced underground coal gasification at Zhong-Liang-Shan coal mine. Asia-Pac. J. Chem. Eng. 2009, 4: 771-779. 10.1002/apj.337

Nag B, Parikh J: Indicators of carbon emission intensity from commercial energy use in India. Energy Economics 2000, 22: 441-461. 10.1016/S0140-9883(99)00032-8

Göttlicher G, Pruschek R: Comparison of CO2 removal systems for fossil-fuelled power plant processes. Energy Convers. Mgmt. 1997, 38: 173-178. 10.1016/0196-8904(96)00028-3

Ho MT, Allinson G, Wiley DE: Comparison of CO 2 separation options for geo-sequestration: are membranes competitive? Desalination 2006, 192: 288-295. 10.1016/j.desal.2005.04.135

Friedmann SJ, Upadhye R, Kong FM: Prospects for underground coal gasification in carbon-constrained world. Energy Procedia 2009,1(1):4551-4557. 10.1016/j.egypro.2009.02.274

Orr FM: Onshore geologic storage of CO 2 . Science 2009,325(5948):1656-1658. 10.1126/science.1175677

Budzianowski WM: Value-added carbon management technologies for low CO2 intensive carbon-based energy vectors. Energy 2012, 41: 280-297. 10.1016/j.energy.2012.03.008

Steinberg M: Fossil fuel decarbonization technology for mitigating global warming. International Journal of Hydrogen Energy 1999, 24: 771-777. 10.1016/S0360-3199(98)00128-1

Gibbins J, Chalmers H: Carbon capture and storage. Energy Policy 2008, 36: 4317-4322. 10.1016/j.enpol.2008.09.058

Acknowledgments

The authors acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

SS carried out the review and drafted the manuscript. BR and MR co-supervised the investigation, conceived of the study, reviewed the manuscript, and helped draft parts. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Self, S.J., Reddy, B.V. & Rosen, M.A. Review of underground coal gasification technologies and carbon capture. Int J Energy Environ Eng 3, 16 (2012). https://doi.org/10.1186/2251-6832-3-16

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-6832-3-16