Abstract

Background

The effect of the ratio of catalyst to carbon source on the growth of vertically aligned carbon nanotubes (VACNTs) has been studied.

Results

Dense VACNTs were successfully synthesised on optimised nanostructured porous silicon templates using modified floated carbon source-catalyst in a two-stage hot filament thermal chemical vapour deposition system with different amounts of ferrocene as the catalyst at 800°C. The surface morphologies of the VACNTs were analysed using field emission scanning electron microscopy, and the crystallinity of the nanotubes was observed using micro-Raman spectroscopy.

Conclusions

These data revealed that the amount of catalyst used significantly affected the diameter, crystallinity and growth rate of the synthesised nanotubes. The average diameter of the nanotubes ranged from ≈ 9 to 30 nm with lengths of ≈ 110 μm when 0.5 g ferrocene was used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Carbon nanotubes (CNTs) are tube-shaped structures made of carbon atoms and can have diameters on the nanometre and micrometre scales [1]. CNTs have attracted much attention since their discovery 20 years ago [2] due to their properties. They can be used as components in light-emitting diodes [3], electron field emitters for optical displays and electrode materials for fuel cells and lithium ion batteries due to their extraordinary properties [4]. CNTs have superior mechanical, chemical, electronic and optoelectronic properties [3].

Camphor (C10H16O) is a valued material in biotechnology and nanotechnology research, and it was first reported that CNTs could be synthesised using camphor in 2001. This environmentally friendly carbon source for the synthesis of CNTs can be used to produce multiwall carbon nanotubes, single-wall carbon nanotubes (SWCNT) and vertically aligned nanotubes. In this context, the striking feature of camphor as a precursor is that a small amount of catalyst is needed compared to what is needed in other similar kinds of CNT syntheses that employ hydrocarbons [5].

Carbon nanotubes are commonly synthesised using one of three techniques: arc discharge, laser ablation and chemical vapour deposition (CVD) [6]. CVD is the most popular and extensively used method because it is easy to scale-up, can be performed at a lower temperature [6], has a lower set-up cost and higher production yield than other approaches [1]. Most of the CNT literature claims that the additional template synthesis used in the CVD technique is a promising way to synthesise well-aligned CNT structures with control over diameter, size uniformity and density [6–9]. The pore diameter of the template can be controlled which consequently enables tube diameter and orientation to the dictated [10]. For example, anodic aluminium oxide (AAO) has been used as a template to grow aligned carbon nanotubes (ACNTs). ACNTs are defined as quasione-dimensional carbon cylinders oriented in a parallel fashion perpendicular to a substrate [11]. Thess et al. [12] first reported the synthesis of ACNTs in bundle form, where 70% of the volume produced consisted of nanotubes. Ali et al. [13] reported that the pore sizes of the substrates used played a role in controlling the growth directions and diameters of the carbon nanotubes. The literature also reports the use of porous silicon templates with pore sizes ranging from 10 to 100 nm [14].

By using an AAO template, ACNTs were successfully grown, as reported by Sui [15]; however, fabrication of AAO is a time-intensive and expensive process that takes approximately 10 h to complete [10]. In a different approach to synthesising well-aligned CNTs, Cao et al. [16] reported the use of a gold-patterned quartz substrate. According to Li et al. [6], porous silicon templates have been loaded with catalytic particles by sputtering iron (Fe) as a route to the synthesis of ACNTs. In addition, Kordás et al. [17] reported that carbon nanotubes have been synthesis on oxidised porous silicon. Catalysts play an important role in the synthesis of CNTs; common catalysts that are widely used for the preparation of CNTs include nickel (Ni), iron (Fe), cobalt (Co) and combinations thereof [18].

This paper will report the use of a porous silicon template and an Fe catalyst to produce vertically aligned carbon nanotubes (VACNTs) using a novel method that involves modifying the catalyst-nanotemplate interaction in the CVD technique. In this study, we focused on understanding how the ratio of the catalyst to carbon source affected the nanotube growth rate and size, and the carbon and ferrocene distributions.

Methods

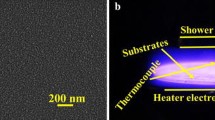

NPSiT were prepared as outlined by Asli et al. [19]. Briefly, boron-doped, p-type (100) Si wafers that were 525 ± 25-μm thick were subjected to a photo-electrochemical anodisation process with 30-min etching time and 20 mA/cm2 of current density. These Si wafers were placed in Teflon cells with an electrolyte consisting of a 1:1 ratio of ethanol and HF (48%) and illuminated with a halogen lamp. Then, the resulting templates were annealed in ambient air at 300°C overnight. A quartz tube with a length of 80 cm and an inner diameter of 3 cm served as a thermal CVD reactor and was kept horizontal in a two-stage zone furnace. The samples were prepared by varying the weight of ferrocene (obtained from Sigma-Aldrich, MO, USA) from 0.3 to 0.8 g, while holding the weight of camphor oil used at 5 g. The catalyst and carbon source were then placed in separate alumina boats and positioned side-by-side in furnace zone 1. NPSiT was placed in the centre of furnace zone 2. Zone 2 was heated to 800°C and was left to stabilise for 10 min after it was purged with nitrogen gas (0.05 to 1.00 L min−1). Then, zone 1 was heated to 180°C for the precursor vaporisation process. Once it reached the required temperature, the synthesis process continued for 60 min. The nitrogen gas was continuously flowed before, during and after synthesis to prepare the ambient nitrogen environment. Zone 1 was turned off after the synthesis process was complete, and zone 2 was left for 30 min after the annealing process. The samples were taken out for characterisation after the furnaces cooled down to room temperature.

Results and discussion

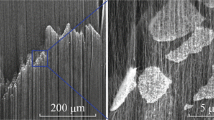

Figure 1 is a typical field emission scanning electron microscope (FESEM) top-view image of a nanostructured porous silicon template (NPSiT) fabricated by the photo-electrochemical anodisation technique that was described in a previous study [19]. In the top-view image, the dark areas are pores that have an average diameter of approximately 20 nm. Figure 2a,b,c,d,e,f shows the morphology of CNTs grown on the optimised NPSiT using different amounts of catalyst. FESEM images at low (×100) and high magnifications (×100,000, insets) are shown for CNTs prepared with varying amounts of ferrocene (from 0.3 to 0.8 g) and a constant amount of camphor oil (5 g). The low magnification image in Figure 2a shows that a low yield of randomly entangled CNTs was obtained when 0.3-g ferrocene was used. The high magnification FESEM image in the inset of Figure 2a shows randomly entangled nanotubes with an abundance of amorphous carbon (a-C) content. When a low amount of ferrocene was used, the nanotubes form in low yield, bend and grow in random directions. The nanotubes grow without support from neighbouring nanotubes, resulting in the growth of randomly oriented carbon nanotubes. When the amount of ferrocene used is less than 0.4 g, aligned CNTs are not produced. By increasing the ferrocene amount, the CNT yield increases substantially, as seen in Figure 2b,c,d,e,f. Nevertheless, carbonaceous crusts were present and covered the top part of the vertically aligned nanotubes, as seen in Figure 2d,e,f. The formation of this crust might be due to the higher amount of ferrocene present relative to the amount of carbon source and related to the non-uniformity in the evaporation processes of ferrocene and camphor oil during synthesis [8]. The CNTs produced using 0.5 g ferrocene and 5 g camphor oil are shown in Figure 2c. In this image, the nanotubes are densely packed uniform vertical columns; CNTs, as long as 110 to 113 μm are evident. In this case, the growing carbon nanotubes are densely packed on the NPSiT in vertical columns and support each other to grow in the same direction (perpendicular to the template surface). Therefore, a low amount of catalyst resulted in less dense CNTs with a-C content and poor alignment, as seen in Figure 2a,b. Disproportionate catalyst addition results in the agglomeration of the catalyst, leaving unwanted catalyst impurities in the final product (Figure 2d,e,f).

The diameters of the CNTs were also significantly affected by the amount of ferrocene used. In addition, the size of catalyst particles determined the diameter of the tubes. The carbon atoms diffused into the iron nanoparticles during the CVD process and formed FeC. Fe catalyst particles with various dimensions were found encapsulated within the tubes. Therefore, when catalyst particles become supersaturated with carbon atoms, the diameters of the tubes become bigger, and precipitate carbon atoms were found attached to the nanotube bundles [20].

Nanotube sizes in the range of 14.0 to 25.0 nm were observed when a low amount of ferrocene (0.3 g) was used. By increasing the ferrocene amount to 0.4 g, the tube size increased greatly to between 30.1 to 39.9 nm. Interestingly, the smallest diameter (9.9 nm) was observed when 0.5 g ferrocene was used. However, when this amount of ferrocene was used, the tube diameters ranged from 9.9 to 30.5 nm. The inconsistency in the size of the tubes is due to their growth from inside the pores and on the top surface of the NPSiTs. It was clearly observed that CNTs grew from both sites, as verified by examining the cross-sectional FESEM images and energy dispersive X-ray spectrometer (EDX) analysis showing carbon signals both inside and outside the pores (Figure 3). In contrast, the nanotube diameters continue to increase when the amount of ferrocene used was greater than 0.5 g. In summary, ferrocene amounts greater or less than 0.5 g are not capable of producing nanotubes with small diameters when 5 g camphor oil is used.

Using the data collected from the FESEM images, the growth rate of the nanotubes can be calculated. The relationship between the growth rate of the VACNTs and the amount of ferrocene used (ranging from 0.3 to 0.8 g for 5 g camphor oil) is shown in Figure 4. The growth rate can be calculated as α = β (μm) / γ (min) [15], where β is the distribution length of the tubes, and γ is the deposition time. The lengths, diameters and growth rates of CNTs synthesised using at 0.3 to 0.8 g of ferrocene and 5 g of camphor oil are shown in Table 1. As the amount of ferrocene used increased from 0.3 to 0.5 g, the growth rate of the VACNTs increased rapidly from 0 to 1.9 μm/min. The growth rates continued to increase gradually, and a maximum rate of 2.1 μm/min was found for a sample catalysed with 0.7 g ferrocene. Then, the growth rate decreased to 1.9 μm/min when 0.8 g of ferrocene was used. Figure 2a shows entangled tubes with short length and poor alignment which resulted from an insufficient number of Fe particles to catalyse the growth of VACNTs. However, the reduced growth rates for samples synthesised with 0.8 g ferrocene were due to low catalytic activity that resulted from an increment of Fe particle size. Figure 2e,f shows that the CNTs produced contain impurities that stick to the nanotubes and result in nanotube with larger diameters. This phenomenon happens at high ferrocene concentrations when ferrocene decomposes to an abundance of Fe particles, which tend to agglomerate into a larger cluster. The catalytic effect is reduced when the catalyst size increases, resulting in larger nanotube diameters as discussed before. According to Bai et al. [21], the catalyst acts as a nucleation site and dictates the tube diameter.

Figure 5 shows the FESEM images and corresponding EDX maps for CNTs synthesised using 0.5 g ferrocene and 5 g camphor oil. EDX mapping was utilised to pinpoint catalyst location and distribution, and relate it to carbon production. The optimised parameters were found to be 0.5 g ferrocene and 5 g carbon precursor because this synthesis showed tolerable ferrocene catalyst in the final product. This conclusion is supported by the top-view image shown in Figure 2c and the Raman spectra that will be discussed later.

Figure 6 shows the Raman spectra of VACNTs synthesised using different amounts of ferrocene. The Raman peak positions and ID/IG ratios are summarised in Table 2. Significant radial breathing mode (RBM) peaks were detected in the samples synthesised using 0.5 g ferrocene and 5 g camphor oil, as shown in Figure 7. Peaks were observed at 205.8, 272.9 and 382.9 cm−1, which correspond to SWCNT with diameters of 1.21, 0.91 and 0.64 nm, respectively. RBM peaks were not observed for the samples synthesised at catalyst concentrations lesser or greater than 0.5 g ferrocene. A low ID/IG ratio of 0.72 was detected for samples synthesised using 0.5 g ferrocene; the ratio increases to a maximum value of 0.98 for samples synthesised using 0.8 g catalyst. The poor graphite crystallinity observed for the sample prepared using 0.8 g ferrocene resulted from the low catalytic properties owing to the bigger catalyst size. A low ferrocene concentration results in an imbalance of carbon atoms compared to Fe catalyst; the huge amount of carbon is not completely decomposed by the low amount of Fe catalyst. In this situation, the catalyst is rendered inactive and low quality nanotubes are produced, as detected for samples prepared with 0.3 g ferrocene.

Experimental

As-obtained VACNTs deposited on NPSiT were visualised using a FESEM (SUPRA 40 VP, Carl Zeiss SMT, Oberkochen, Germany), and an EDX was used to identify the elements constituting the specimen (qualitative analysis) and the weight concentration of the contained elements (quantitative analysis). Structural properties were observed by micro-Raman spectroscopy using argon ion laser excitation at 514.532 nm (DU420A-OE-325, Horiba Jobin Yvon, Kyoto, Japan).

Conclusion

In summary, CNT growth was detected when as little as 0.3 g ferrocene was used. However, at least 0.4 g ferrocene must be used to produce VACNTs. As the catalyst concentration increases, the density and growth rate of VACNTs were found to increase (up to 2.1 μm min−1) until 0.7 g ferrocene was reached. The VACNTs produced when 0.5 g ferrocene was used have small diameters and were found to have low defect levels, as indicated by the calculated ID/IG ratio of 0.72. Only at this concentration, RBM peaks were clearly observed for the as-synthesised SWCNTs. The growth of vertically aligned carbon nanotubes has been successfully reported using a porous template and the appropriate amount of catalyst such that the pores can physically hold the nanotubes in the vertical direction and the bundles of nanotubes can support each other during growth. Further studies should be carried out to assess the prospective applications of these structures; for example, VACNT exhibits excellent properties for use as field electron emission cathodes.

Authors’ information

NAA is currently a Ph.D. student in the Faculty of Applied Sciences and doing research at NANO-SciTech Centre, Institute of Science, University Teknologi MARA. Her studies focus on the growth of carbon nanotubes on nanoporous materials .She received a BS degree in Materials Technology from Universiti Teknologi MARA, Malaysia in 2009. She has authored and co-authored over 15 peer-reviewed papers in journals and conference proceedings in the field of nanostructured carbon materials and serves as a reviewer for several national and international journals. MSS is currently a graduate research assistant in the Faculty of Engineering and the Environment at University of Southampton Malaysia Campus, where his studies focus on the growth of graphene. He is also one of the members in Centre of Nanoscience and Nanotechnology, UiTM, where his research interest involves the synthesis and characterization of carbon nanotubes. He received a BS degree in Physics from Universiti Teknologi MARA, Malaysia in 2010. He has authored and co-authored over 15 peer-reviewed papers in journals and conference proceedings in the field of nanostructured carbon materials and serves as a reviewer for several national and international journals. SAB is currently a senior lecturer in the Department of Physics, Faculty of Science and Mathematics, Universiti Pendidikan Sultan Idris. She is also head of the Centre of Nanoscience and Nanotechnology, UiTM, where her research interest involves the synthesis and characterization of carbon nanotubes based on palm oil. She received a Ph.D. degree in nanomaterials from the Universiti Teknologi MARA, Malaysia in 2010. She has authored and co-authored over 25 peer-reviewed papers in journals and conference proceedings in the field of nanostructured carbon materials and serves as a reviewer for several national and international journals. MRM is currently a professor and founder in NANO-Electronic Centre, Faculty of Electrical Engineering, Universiti Teknologi MARA. He is also head of the Centre of Nanoscience and Nanotechnology, UiTM, where his research interest involves the synthesis and characterization of nanomaterials and their application in electronic devices. He received a Ph.D. degree in Optoelectronics Engineering from Nagoya Institute of Technology, Japan in 2004. He has authored and co-authored over 100 peer-reviewed papers in journals and conference proceedings in the field of nanostructured carbon materials and serves as a reviewer for several national and international journals. SA is currently a professor and lecturer in the Faculty of Applied Sciences, Universiti Teknologi MARA. He is also one of the members of the Centre of Nanoscience and Nanotechnology, UiTM, where his research interest involves the synthesis and characterization of carbon nanotubes and nanoporous materials. He received his Ph.D. degree in Physics from the University of Malaya, Malaysia in 2002. He has authored and co-authored over 100 peer-reviewed papers in journals and conference proceedings in the field of nanostructured carbon materials and serves as a reviewer for several national and international journals.

References

Kumar M, Ando Y: Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production. J Nanosci Nanotechnol 2010, 10: 3739–3758. 10.1166/jnn.2010.2939

Iijima S: Helical microtubules of graphitic carbon. Nature 1991, 354: 56–58. 10.1038/354056a0

Lee WY, Weng CH, Juang ZY, Tsai CH: Lateral growth of single-walled carbon nanotubes across electrodes and the electrical property characterization. Diamond Relat Mater 2005, 14: 1852–1856. 10.1016/j.diamond.2005.08.043

Somani SP, Somani PR, Tanemura M, Lau SP, Umeno M: Carbon nanofibers and multiwalled carbon nanotubes from camphor and their field electron emission. Curr Appl Phys 2009, 9: 144–150. 10.1016/j.cap.2008.01.002

Mukul K, Tsugio O, Mineo H, Ando Y: The use of camphor-grown carbon nanotube array as an efficient field emitter. Carbon 2007, 45: 1899–1904. 10.1016/j.carbon.2007.04.023

Li J, Lei W, Zhang X, Wang B, Ba L: Field emission of vertically-aligned carbon nanotube arrays grown on porous silicon substrate. Solid State Electron 2004, 48: 2147–2151. 10.1016/j.sse.2004.06.011

Lee WY, Liao TX, Juang ZY, Tsai CH: Patterned aligned growth of carbon nanotubes on porous structure templates using chemical vapor deposition methods. Diamond Relat Mater 2004, 13: 1232–1236. 10.1016/j.diamond.2004.01.030

Musso S, Porro S, Rovere M, Giorcelli M, Tagliaferro A: Fluid dynamic analysis of gas flow in a thermal-CVD system designed for growth of carbon nanotubes. J Cryst Growth 2008, 310: 477–483. 10.1016/j.jcrysgro.2007.10.064

Lee TJ, Seo J, Lee H, Lee JW, Yi W: Fabrication of single-walled carbon nanotube three-dimensional networks inside the pores of a porous silicon structure. Carbon 2010, 48: 1473–1479. 10.1016/j.carbon.2009.12.042

Merchan-Merchan W, Saveliev AV, Kennedy L, Jimenez WC: Combustion synthesis of carbon nanotubes and related nanostructures. Prog Energy Combust Sci 2010, 36: 696–727. 10.1016/j.pecs.2010.02.005

Afre RA, Soga T, Jimbo T, Kumar M, Ando Y, Sharon M: Growth of vertically aligned carbon nanotubes on silicon and quartz substrate by spray pyrolysis of a natural precursor: turpentine oil. Chem Phys Lett 2005, 414: 6–10. 10.1016/j.cplett.2005.08.040

Thess A, Lee R, Nikolaev P, Dai H, Petit P, Robert J: Crystalline ropes of metallic carbon nanotubes. Science 1996, 273: 483–487. 10.1126/science.273.5274.483

Ali NK, Hashim MR, Aziz AA, Hamammu I: Method of controlling spontaneous emission from porous silicon fabricated using pulsed current etching. Solid State Electron 2008, 52: 249–254. 10.1016/j.sse.2007.08.022

Guo T, Nikolaev P, Thess A, Colbert DT, Smalley RE: Catalytic growth of single-walled nanotubes by laser vaporization. Chem Phys Lett 1995, 243: 49–54. 10.1016/0009-2614(95)00825-O

Sui YC, González-León JA, Bermúdez A, Saniger JM: Synthesis of multi branched carbon nanotubes in porous anodic aluminum oxide template. Carbon 2001, 39: 1709–1715. 10.1016/S0008-6223(00)00297-9

Cao A, Zhang X, Xu C, Liang J, Wu D, Wei B: Synthesis of well-aligned carbon nanotube network on a gold-patterned quartz substrate. Appl Surf Sci 2001, 181: 234–238. 10.1016/S0169-4332(01)00396-8

Kordás K, Pap AE, Vähäkangas J, Uusimäki A, Leppävuori S: Carbon nanotube synthesis on oxidized porous silicon. Appl Surf Sci 2005, 252: 1471–1475. 10.1016/j.apsusc.2005.02.120

Azira AA, Zainal NFA, Nik SF: Properties of carbon nanotubes synthesised using fluidized floating catalyst method from camphor oil. Malayas J Sci 2009, 28: 123–128.

Asli NA, Yusop SFM, Rusop M, Abdullah S: Surface and bulk structural properties of nanostructured porous silicon prepared by electrochemical etching at different etching time. Ionics 2011, 17: 653–657. 10.1007/s11581-011-0543-5

Sharma SN, Sharma RK, Bhagavannarayana G, Samanta SB, Sood KN, Lakshmikumar ST: Demonstration of the formation of porous silicon films with superior mechanical properties, morphology and stability. Mater Lett 2006, 60: 1166–1169. 10.1016/j.matlet.2005.10.101

Bai X, Li D, Wang Y, Liang J: Effects of temperature and catalyst concentration on the growth of aligned carbon nanotubes. Tsinghua Science & Technology 2005, 10: 729–735. 10.1016/S1007-0214(05)70142-5

Acknowledgements

The authors would like to thank the staff of the NANO-SciTech Centre, Universiti Teknologi MARA for their technical support. This work was financially supported by the Excellent Fund (600-RMI/ST/DANA 5/3/Dst (20/2011) and the Fundamental Research Grant Scheme (600-RMI/ST/FRGS 5/3/Fst (204/2010), Malaysian Ministry of Higher Education.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

NAA and MSS carried out the experiments and drafted the manuscript. SAB built the experimental setup. MRM and SA reviewed the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Asli, N.A., Shamsudin, M.S., Bakar, S.A. et al. Effect of the ratio of catalyst to carbon source on the growth of vertically aligned carbon nanotubes on nanostructured porous silicon templates. Int J Ind Chem 4, 23 (2013). https://doi.org/10.1186/2228-5547-4-23

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-4-23