Abstract

Background

Pomegranate peel carbon was tested for its ability to adsorb iron(II) ions from solutions with alterations in the parameters such as pH, contact time, sorbent weight, metal concentration, and temperature.

Results

The adsorption process was analyzed on the basis of pseudo-first-order, pseudo-second-order kinetic models and also by Freundlich and Langmuir isotherm models. The maximum adsorption capacity for pomegranate peel activated carbon as calculated by Langmuir model was found to be 18.52 mg g−1 at pH 6.0 and 1 g L−1 of biosorbent concentration at 29°C.

Conclusions

The ability of new sorbent is compared with other biomass waste materials. Thermodynamic parameters such as the changes of free energy, enthalpy, and entropy were also evaluated. The results indicated that the sorption of iron(II) ions onto the pomegranate peel carbon was an exothermic process that could be well fitted with the Langmuir adsorption model and pseudo-first-order kinetic model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Punica granatum L. (Punicaceae), commonly called pomegranate, is one of the most popular fruits in the word due to its pleasant taste, high nutritional value, and many medical features. In Iran, pomegranate production is over 700,000 tons/year that is mainly cultivated in central part of the country. It consists of edible part, seeds, and peel. The pomegranate peel constitutes 5% to 15% of its total weight[1]. The extracted dye from the pomegranate peel had been used as natural colorant for textiles from ancient times. But nowadays, with the growth of synthetic dyes, pomegranate peel is discarded as a pollutant residue that can be used as a low cost and renewable source of biomass. Recently, some studies have been done using pomegranate peel to remove Cr(VI)[2], Ni(II)[3], Pb(II)[4], Cu(II)[5], and Congo red[6] from water samples.

Fe(II) is needed in plant metabolism, but when it presents in excess, it can become extremely toxic. Since several decades along with the growth of industrial activities, contamination of the environment with wastewaters including heavy metals has become a major problem[7]. Iron ion as an important corrosive product is one of the substances that is commonly found in fluids of many industries. Conventional techniques aimed at removing heavy metals usually include chemical precipitation, ion exchange, membrane process, crystallization, and electrochemical treatment[8]. Although many investigations have been conducted so far about the ability of some biomass or waste materials to remove Fe(III)[9–18], only a few investigators have studied Fe(II) biosorption using crab shell[19], bark of a tree[20], waste coir fiber[21], wooden charcoal[22], and pine bark[23].

In this study, the ability of pomegranate peel carbon to remove Fe(II) from aqueous solutions has been assessed in a batch process. The effects of different parameters such as contact time of biosorbent and aqueous solution, pH of the aqueous solution, initial metal ion concentration, and different biomass amounts have been investigated. The biosorption isotherm and thermodynamic parameters were deduced from biosorption measurements.

Methods

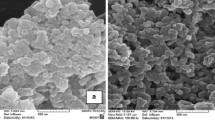

Preparation of adsorbent using pomegranate peel waste

According to[5], the waste peels of pomegranate fruit were first washed with double-distilled water and dried in an oven at 70°C overnight. The dried pomegranate peels were grounded, and this material was then thermally activated at 500°C in a furnace for 1 h in the absence of air. After activation, the ash was removed by washing it with HCl solution (0.1 M) and distilled water and then dried again in an oven at 90°C overnight. The particle size of BSS 150 to 200 (0.075 to 0.104 mm) was obtained by sieving, and this product was kept in a desiccator for further use. Porosity (%), density (kg m−3), moisture content (wt.%), and ash content (wt.%) were 60, 584.6, 6.79, and 9.98, respectively.

Adsorption studies

The adsorption of iron on pomegranate peel carbon adsorbent was studied by batch method. A known volume of Fe(II) solutions with different initial concentrations was taken in a 50-mL conical flask and agitated in a mechanical shaker at 120 rpm with a known dose of adsorbent for a specified contact time. After equilibration, samples were filtered using Whatman 42 filter paper (Maidstone, Kent, UK), and the concentration of iron was determined according to spectrophotometric standard method[24]. The data obtained in the batch mode was used to calculate the equilibrium metal adsorptive quantity using the following expression:

where qe is the amount of heavy metal ion adsorption per unit weight of the biomass (mg g−1); V, the volume of solution treated (L); C0, the initial concentration of metal ion (mg L−1); Ce, the equilibrium metal ion concentration (mg L−1); and m, the biomass (g).

Results and discussion

Effect of pH

pH has a direct influence on the biosorption mechanism and uptake of metal by the adsorbent. To understand the effect of pH, the adsorption of Fe(II) as a function of pH in the range of 2.5 to 7.5 was measured, and the result was shown in Figure 1. There was an increase in the biosorption capacity of the biomass with the increase in pH from 2.5 to 5.0 and was maximum in the pH range of 5.0 to 6.0. Then, it decreased when pH reached 7.5. This fact can be explained by the competition between the surface charge and solution chemistry as two important factors. In highly acidic pH, adsorbent surface is protonated and act as a positive charge. Deprotonation occurs when pH increases and causes negative charges on the surface to appear, and these negative charges attract Fe(II) ions. The pH can also affect the solution chemistry. In acidic pHs, Fe(II) remains with the positive charge, but in alkali pHs, the hydroxide ions(OH−) causes precipitation of Fe(II) in the form of Fe(OH)2.

Effect of contact time

To know the kinetics of the adsorption process and equilibration time on pomegranate peel carbon, the effect of contact time on Fe(II) biosorption was studied, and the results were shown in Figure 2. According to Figure 2, the adsorption quantity of Fe(II) ion increases as the contact time increases. The equilibration was nearly reached after 40 min. Therefore, equilibration period of 40 min was selected for all further experiments. The time profiles are single, smooth, and continuous curves leading to saturation, suggesting the possible monolayer coverage of Fe(II) on the surface of the adsorbent.

Effect of initial metal ion concentration

The metal uptake mechanism was particularly dependent on the initial Fe(II) concentration. Biosorption experiments with pomegranate peel carbon in equilibrium time were conducted for solutions containing 1 to 100 mg L−1 Fe(II) ion. Figure 3 shows the effect of Fe(II) initial concentration on the removal amount of Fe(II) in percentage. It is clear that with increasing initial concentration, the amount of metal removal decreases. At low concentrations, Fe(II) is adsorbed to specific sites, while with the increase of Fe(II) concentration, the specific sites are saturated and the exchange sites are occupied.

Effect of biosorbent concentration

The effect of biosorbent concentration as one of the parameters that strongly affects the adsorption capacity is shown in Figure 4. It can be observed that with the fixed Fe(II) concentration, the amount of removed Fe(II) ions increases with the increase of the adsorbent weight. The increase in Fe(II) removal percentage by increasing the adsorbent dose is due to greater availability of the exchange sites or surface area.

Kinetic modeling

One of the most important characteristics in evaluating adsorption efficiency is kinetics. In order to clarify the biosorption kinetics of Fe(II) ions onto pomegranate peel carbon, the kinetic models, Lagergren's pseudo-first-order[25] and pseudo-second-order models[26], were used. For kinetic studies, different concentrations of Fe(II) ranging from 1 to 40 mg and biosorbent concentration of 0.3 g L−1 were used at optimum condition of pH (6.0) and agitation time (40 min).

The Lagergren model as a pseudo-first-order rate equation is obtained under the ideal assumption of a totally homogenous adsorption surface and is given as follows:

where qe and qt are the amounts of adsorbed metal ion (mg g−1) at equilibrium and at time t, respectively. K1 is the Lagergren rate constant relating to adsorption energy (L min−1). The values of K1 and qe that are presented in Table 1 are calculated from the slope and intercept of log (qe − qt) versus t.

The pseudo-second-order kinetic model of McKay and Ho can be expressed as follows:

where qe and qt are the amounts of iron adsorbed (mg g−1) at equilibrium and at time t (min), respectively, and ks (g mg−1 min−1) is the rate constant of pseudo-second-order kinetics. The values of qe and Ks that are presented in Table 1 are calculated from the slope and intercept of t / qt versus t.

As can be seen from Table 1, the theoretical qe (cal) values in the case of the pseudo-first-order model agree well with the experimental uptake values, qe (exp), whereas the pseudo-second-order model does not give reasonable values. Further, the correlation coefficient (R2) for the pseudo-first-order kinetic model was better than the pseudo-second-order model. Thus, the pseudo-first-order kinetic model was suggested to describe the kinetic behavior of Fe(II) adsorption onto pomegranate peel carbon.

Adsorption isotherms

The isotherm model is a mathematical model to describe the distribution of metal ions between the solid and liquid phases that are in contact. The adsorption of Fe(II) at optimum pH (6.0) and agitation time (40 min) was carried out at different concentrations ranging from 1 to 100 mg L−1 and 0.1 to 1 g L−1 for ions and biosorbent, respectively. Adsorption isotherm can be used to describe how the solute interacts with the adsorbent and so is critical in optimizing the use of adsorbent. In addition, it can be used for column design purposes. In this research, adsorption isotherm study was carried out on two well-known isotherm models for the single-solute systems, i.e., Langmuir and Freundlich.

Langmuir isotherm

The Langmuir model[27] is one of the first theoretical models. It assumes that biosorption occurs at specific homogenous active sites of the sorbent. In addition, the energy of adsorption is constant, and there is no migration of adsorbate molecules in the surface plane. This model, which is used successfully in many monolayer biosorption processes, is given by the equation:

where qm (mg g−1) is the monolayer adsorption saturation capacity; KL (L mg−1), Langmuir constant relating to adsorption energy; qe (mg g−1), the amount of metal ion bound to per gram of the biomass at equilibrium; and Ce, the residual (equilibrium) metal ion concentration left in the solution after binding. The qm and KL can be determined from Ce / qe versus the Ce plot which gives a straight line of slope 1 / qm and intercept 1 / KL∙ qm. As shown in Figure 5, R2 values are greater than 0.9983 which indicate that the biosorption of Fe(II) onto pomegranate peel carbon follows the Langmuir model. The maximum adsorption capacity for pomegranate peel activated carbon as calculated by Langmuir model was found to be 18.52 mg g−1 at pH 6.0 and 1 g L−1 of biosorbent concentration at 29°C.

The Freundlich isotherm

The Freundlich isotherm[28] model is based on sorption heterogeneous energetic distribution of active sites accompanied by interactions between adsorbed molecules. This model is expressed by the following:

where KF (mg1 − 1 / n g−1 L1 / n) is the adsorption capacity and n is the adsorption intensity of metal ions on the sorbent that can be determined from the linear plot of log (qe) versus log (Ce). The linear Freundlich isotherm plots are presented in Figure 6. Values of the correlation coefficients show that the Freundlich isotherm is poorly appropriate to characterize for the adsorption of the Fe(II) ions onto pomegranate peel carbon.

Table 2 gives the maximum capacity and required equilibration time of different waste adsorbents for the removal of Fe(II) from aqueous solutions. It can be seen that the values are different for different materials. This depends on the physical nature and chemical composition of the waste substances. The pomegranate carbon peel has relatively short equilibration time and also has the best capacity compared to all of the other waste materials used for removing the Fe(II).

Thermodynamic parameters

In order to confirm the nature of adsorption process, the important thermodynamic parameters such as the standard Gibbs free energy, ∆ G°, enthalpy, ∆ H°, and entropy, ∆ S°, changes were calculated according to the following equations[5]:

where R is the universal gas constant; T, the absolute temperature in Kelvin; and K, the equilibrium constant that can be calculated by multiplying the molar concentration of the solvent (55.5 mol L−1) to the Langmuir constant ‘b’[3]. For the determination of the thermodynamic parameters, experiments in two different temperatures of 29°C and 50°C were done. As shown in Figure 7, adsorption decreases with increasing temperature, suggesting that the process is exothermic in nature.

Thermodynamic parameters obtained for the adsorption of Fe(II) ions onto pomegranate peel carbon are given in Table 3. As shown in the table, the negative value of ∆ G° confirms the feasibility of the process and the spontaneous nature of the sorption. The values of ∆ H° were negative, indicating that the sorption reaction is exothermic. The negative value of ∆ S° shows the decreasing randomness at the solid/liquid interface during the adsorption.

Experimental

Reagents and instruments

All reagents used were of analytical reagent grades and were purchased from the Merck company (Darmstadt, Germany). All the solutions were prepared with double-distilled water with zero levels of dissolved oxygen. Iron stock solution was prepared by (NH4)2Fe(SO4)2·6H2O. The stock solution was diluted further to obtain the standard solutions. Ortho-phenanthroline solution was prepared by dissolving 1 g of 1,10-phenanthroline monohydrate in water and diluting to 1,000 mL. Buffer solution (pH = 6) was prepared by dissolving appropriate amounts of ammonium acetate in acetic acid. Iron concentration was obtained from absorbance measurement by a Jenway spectrophotometer model 6505 (Jenway, England, UK). Measurements of pH were made with a Jenway 3510 pH meter using a combined glass electrode.

Conclusion

In this study, pomegranate peel carbon biosorbent was applied successfully for the biosorption of Fe(II) from aqueous solution. The kinetic studies proved that the first-order kinetic was the best applicable model. The isotherm equilibrium studies confirmed that the Langmuir form and generalized models were the highest fitted models for the adsorption process. The maximum adsorption potential of pomegranate peel adsorbent for Fe(II) removal was ca. 18.5 mg g−1. Thermodynamic parameters showed that the adsorption process was exothermic and spontaneous. The comparison of this study with the previous studies shows that the new biosorbent has more ability than the other waste biomasses for removing Fe(II).

References

Eikani MH, Golmohammad F, Homami SS: Extraction of pomegranate ( Punica granatum L.) seed oil using superheated hexane. Food Biprod Process 2012, 91: 32–36.

El Nemr A: Potential of pomegranate peel carbon for Cr(VI) removal from wastewater: kinetic and isotherm studies. J Hazard Mater 2009, 161: 132–141. 10.1016/j.jhazmat.2008.03.093

Bhatnagar A, Minocha AK: Biosorption optimization of nickel removal from water using Punica granatum peel waste. Colloid Surface B 2010, 76: 544–548. 10.1016/j.colsurfb.2009.12.016

Alam M, Nadeem R, Jilani MI: Pb(II) removal from wastewater using Pomegranate waste biomass. Int J Chem Biochem Sci 2012, 1: 24–29.

El-Ashtoukhy ESZ, Amin NK, Abdelwahab O: Removal of lead (II) and copper (II) from aqueous solution using pomegranate peel as a new adsorbent. Desalination 2008, 223: 162–173. 10.1016/j.desal.2007.01.206

Ghaedi M, Tavallali H, Sharifi M, Nasiri Kokhdan S, Asghari A: Preparation of low cost activated carbon from Myrtus communis and pomegranate and their efficient application for removal of Congo red from aqueous solution. Spectrochim Acta Part A 2012, 86: 107–114.

Chandra Sekhar K, Kamala CT, Chary NSN, Anjaneyulu Y: Removal of heavy metals using a plant biomass with reference to environmental control. Int J Miner Process 2003, 68: 37–45. 10.1016/S0301-7516(02)00047-9

Babel S, Kurniawan TA: Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 2003, 97: 219–243. 10.1016/S0304-3894(02)00263-7

Razmovski R, Šciban M: Iron(III) biosorption by Polyporus squamosus . Afr J Biotec 2008, 7: 1693–1699.

García-Mendieta A, Olguín MT, Solache-Ríos M: Biosorption properties of green tomato peel (Physalis philadelphica Lam) for iron, manganese and iron–manganese from aqueous systems. Desalination 2012, 284: 167–174.

Abdel-Ghani NT, Hegazy AK, El-Chaghaby GA, Lima EC: Factorial experimental design for biosorption of iron and zinc using Typha domingensis phytomass. Desalination 2009, 249: 343–347. 10.1016/j.desal.2009.02.065

Tuzen M, Uluozlu OD, Usta C, Soylak M: Biosorption of copper(II), lead(II), iron(III) and cobalt(II) on Bacillus sphaericus -loaded Diaion SP-850 resin. Anal Chim Acta 2007, 581: 241–246. 10.1016/j.aca.2006.08.040

Selatnia A, Boukazoula A, Kechid N, Bakhti MZ, Chergui A: Biosorption of Fe3+ from aqueous solution by a bacterial dead Streptomyces rimosus biomass. Proc Biochem 2004, 39: 1643–1651. 10.1016/S0032-9592(03)00305-4

Aryal M, Ziagova M, Liakopoulou-Kyriakides M: Study on arsenic biosorption using Fe(III)-treated biomass of Staphylococcus xylosus . Chem Eng J 2010, 162: 178–185. 10.1016/j.cej.2010.05.026

Sag Y, Kutsal T: The simultaneous biosorption of Cr(VI), Fe(III) and Cu(II) on Rhizopus arrhizus . Proc Biochem 1998, 33: 571–579. 10.1016/S0032-9592(98)00020-X

Lugo-Lugo V, Barrera-Díaz C, Ureña-Núñez F, Bilyeu B, Linares-Hernández I: Biosorption of Cr(III) and Fe(III) in single and binary systems onto pretreated orange peel. J Environ Manage 2012, 112: 120–127.

Aksu Z, Açikel U: Modelling of a single-staged bioseparation process for simultaneous removal of iron(III) and chromium(VI) by using Chlorella vulgaris . Biochem Eng J 2000, 4: 229–238. 10.1016/S1369-703X(99)00053-4

Saravanan A, Brindha V, Manivannan E, Krishnan S: Kinetics and isotherm studies of mercury and iron biosorption using Sargassum sp . Int J Chem Sci Appl 2010, 1: 50–60.

Porpino KKP, Silva Barreto MC, Cambuim KB, Salata Toscano A: Fe (II) adsorption on Ucides Cordatus crab shells. Quim Nova 2011, 34: 928–932. 10.1590/S0100-40422011000600003

Rose EP, Rajam S: Equilibrium study of the adsorption of iron (II) ions from aqueous solution on carbons from wild jack and jambul. Adv Appl Sci Res 2012, 3: 1889–1894.

Shukla SR, Pai RS, Shendarkar AD: Adsorption of Ni(II), Zn(II) and Fe(II) on modified coir fibres. Sep Purif Technol 2006, 47: 141–147. 10.1016/j.seppur.2005.06.014

Ahamad K, Jawed M: Kinetics, equilibrium and breakthrough studies for Fe(II) removal by wooden charcoal: a low-cost adsorbent. Desalination 2010, 251: 137–145. 10.1016/j.desal.2009.08.007

Acemioglu B: Removal of Fe(II) ions from aqueous solutionby Calabrian pine bark wastes. Bioresource Technol 2004, 93: 99–102. 10.1016/j.biortech.2003.10.010

Eaton AD, Clescri LS, Greenberg AE, Franson MAH: Standard methods for the examination of water and wastewater. Washington, DC: American Public Health Association; 1995:122.

Lagergren S: Zur theorie der sogenannten adsorption geloster stoffe. K Sven Vetenskapsakad Handl 1898, 24: 1–39.

Ho YS, McKay G, Wase DAJ, Foster CF: Study of the sorption of divalent metal ions on to peat. Adsorpt Sci Technol 2000, 18: 639–650. 10.1260/0263617001493693

Langmuir I: The sorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 1918, 40: 1361–1403. 10.1021/ja02242a004

Freundlich HMF: Über die adsorption in lösungen. Zeitschrift für Physikalische Chemie (Leipzig) 1906, 57: 385–470.

Acknowledgment

The authors are thankful to Dr. Amir Mohammad Goodarzian for his contribution.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MRM, ZD, and NN carried out the experiments, and EB participated in the calculations. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Moghadam, M.R., Nasirizadeh, N., Dashti, Z. et al. Removal of Fe(II) from aqueous solution using pomegranate peel carbon: equilibrium and kinetic studies. Int J Ind Chem 4, 19 (2013). https://doi.org/10.1186/2228-5547-4-19

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-4-19