Abstract

The broadband optical absorption properties of silicon nanowire films fabricated by electroless metal deposition technique followed by HF/Fe(NO3)3 solution-based chemical etching at room temperature on p-type silicon substrates have been measured and we have found higher absorption than that of the solid thin films of equivalent thickness. The observed behavior is effectively explained by light scattering and light trapping, though some of the observed absorption is due to a high density of surface states in the nanowire films. The synthesized structures absorbed more than 82% of incident radiation in case of Cu-deposited silicon nanowires, whereas for Ag it was a maximum of 83%, which is much greater than that of the bulk silicon as they absorbed a maximum of 43% of the radiation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

To date, the catastrophic environmental pollution arising from burning fossil fuels is a discriminating public concern and thus alternatively increases the dependence on renewable clean energy. Amongst the alternative energy sources, solar energy represents one of the most sustainable, environmentally acceptable, and technologically promising renewable clean energy sources [1, 2]. Since the invention of solar cells in the 1950s [3], the solid-state junction photovoltaic solar cell devices have dominated photovoltaic solar energy converters. The most common material used in solar cells is silicon. Silicon accounts for more than 98% of the solar cell market [4]. This is primarily because of silicon is earth abundant, highly efficient, and air stable. Crystalline silicon solar cells have achieved efficiencies approaching 25% in the laboratory and 20% commercially [5]. Much attention has been drawn on the investigation of solar cells for decades.

A potential candidate for the next generation of solar cells is silicon nanowires (SiNWs) and have already found application as antireflective layers [6] and as active elements in organic [7], dye-sensitized [8], quantum-dot-sensitized [9], liquid-junction [10, 11], and inorganic solid-state devices [6]. Silicon nanowires are 1D material, and there has been interest to incorporate them into photovoltaic cell design due to the wide availability of the material and existing processing infrastructure and direct path for charge transport afforded by the geometry. In addition to that, SiNWs have higher absorption capability, nearly 70%, which is much greater than that of bulk silicon [12, 13]. Silicon nanowires show higher absorption since when the silicon nanowire arrays are placed in orthogonal direction to light absorption and charge separation by fabricating radial p-n junctions, it enables efficient carrier collection and light trapping in optically thick nanowire arrays, even when minority carrier diffusion lengths are shorter than the optical absorption length [14–16]. Silicon nanowire arrays also show comparatively low reflection losses than planner semiconductor [14] which definitely leads to higher absorption also. The advantage of using nanowires is that like quantum dots, we can tune the bandgap to a specific part of the solar spectrum by simply controlling the chemical composition and the coverage density of the wire surface. Significant shrinking of bandgap occurs if halogens such as Cl, Br, and I are used instead of H as surface passivation elements without changing the characteristics of semiconductor nanowires [17, 18]. In this paper we have measured the optical absorption of silicon nanowires of different dimensions synthesized by electroless metal deposition (EMD) over the range from 200 to 1,000 nm. Our finding shows that the absorption of silicon nanowires has greatly modified than that of the bulk silicon.

Methods

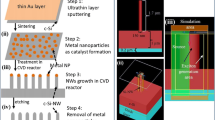

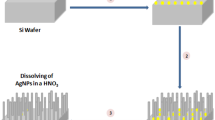

Silicon nanowires array was grown by an aqueous electroless etching method by depositing noble metal nanoparticles like silver and copper. The fabrication process of silicon nanowires composed of three steps: (1) cleaning of the silicon wafers with ultrasonic bath, (2) electroplating the films of metal nanoparticles onto the cleaned silicon surface, and (3) immersion of the nanoparticle-deposited silicon wafers into HF-based aqueous chemical etching solutions. All the processes were conducted in Teflon-lined autoclave.

For silver nanoparticle deposition, the concentration of AgNO3 was 0.02 M with deposition time varied from 60 to 75 s. In case of copper nanoparticle deposition, the concentration of Cu(NO3)2 was 0.02 and 0.05 M with deposition time which varied from 60 to 120 s. In both the cases, the concentration of HF was 5.0 M. After the electroless deposition of the silver and copper nanoparticle, the silver/copper metal-covered Si substrate which was confirmed by scanning electron microscopy (SEM). Then, those metal (Ag/Cu)-deposited Si samples were immersed in an aqueous HF/Fe(NO3)3 solution for etching. The concentration of HF and Fe(NO3)3 was 5 and 0.02 M, respectively. Etching was performed at room temperature for 30 to 75 min in case of Ag-treated Si samples and 60 to 120 min for Cu-deposited Si samples. Then after the preparation process, the obtained samples were rinsed copiously in deionized water and dried at room temperature.

Figure 1 shows a schematic picture of the top view of SEM image of silicon nanowires, and Figure 2 shows a schematic picture of side view of SEM image of silicon nanowire array which is fabricated on p-type Si substrate. From the SEM micrograph, it has been seen that silicon nanowires have formed with excellent vertical alignment, uniformity, and packing density, with about 50% area density. The typical wire diameter from the SEM ranges from 45 to 300 nm having length from 2 to 4 μm.

The optical absorption spectra were obtained on a UV-1700 spectrophotometer employing halogen lamps and equipped to measure the wavelength range from 200 to 1,000 nm.

The effective absorption (A) in the films was defined as A = 1 - (T + R) without any correction for thin film effects or other possible losses, since comparisons of samples on the same types of transparent substrate were made.

Results and discussion

The absorption measurement was carried out over a range of wavelengths of 200 to 1,000 nm, which covers most of the spectrum that is useful for SiNWs-based solar cells. Figure 3 shows typical total optical absorption spectra of Cu treated samples: type A sample (sample b, sample c, and sample d) along with absorption of bulk silicon (sample a). The absorbance of the solid silicon film shows typical behavior as expected for silicon shown by Rung et al. 2012 [19]. Here we have noted that Si film's absorption begin to increase at 400 nm and remain almost steady up to 1,000 nm and might be decrease somewhere around 1,100 nm because of back reflected loss for long wavelength from top surface [20]. Si absorbs maximum of 47% of incident radiation whereas absorption of SiNWs for Cu-treated samples (sample b, sample c, and sample d of Figure 3) was maximum of 78%. For sample b, etching time was 1 h and concentration of Cu(NO3)2 was 0.05 M. Whereas for sample c and sample d, the treating time was 2 h with 0.02 M and 0.05 M Cu(NO3)2.

Absorption of SiNWs for Cu-treated samples. (a) Optical absorption spectrum of p-type Si (111) wafer. (b) Absorption spectrum of nanowires arrays prepared in 5.0 M HF containing 0.02 M Fe(NO3)3 and 0.05 M Cu(NO3)2 with etching time of 1 h. (c) Absorption image of Cu-treated nanowires film using 0.02 M Cu(NO3)2 with etching time of 2 h. (d) Absorbance of nanowire film with etching time of 2 h with 0.05 M Cu(NO3)2.

From the above discussion, we have observed that the absorption of bulk Si film is much smaller than that of SiNWs array over the same wavelength range. This is because by precisely controlling the orientation (vertical vs. slanted), the size (nano- vs. microscale), density, and length of SiNWs' reflectivity can be reduced. It is also well known that porous SiNWs can reduce the back reflection up to 5.8% in the wavelength range of 400 to 1,000 nm [6], which leads to higher absorption and therefore can replace other surface-textured microstructure and anti-reflection coatings. At the same time, the high aspect ratio of nanowires and micropillars enhances absorption through superior light trapping mechanism, allowing significantly thinner structures and thus reduced material cost. This is especially important for Si because of the low absorption cross section inherent to its indirect bandgap, which requires tens to hundreds of times thicker materials for complete absorption compared to direct bandgap material solar cells. The thicker structure also adversely affects carrier extraction due to bulk recombination, especially for less-pure, low-cost materials. Additionally, high aspect ratio structures allow core-shell radial p-n junctions, which effectively lessen the minority carrier collection path to be on the same order of the wire or pillar diameter.

From Figure 3 it has also been observed that the absorbance of the Cu-deposited silicon nanowire films increases continually with increasing etching time. The length of the silicon nanowire films with 2-h etching was greater than that of the silicon nanowires synthesized by 1-h etching time and the diameter decreases with etching time elapse. It has also been looked into that with increasing treating time and concentration, a higher absorption can be accomplished, may be due to better light trapping capability. Therefore, greater quantum confinement of photon occurs and for this reason high absorption is achieved. Consequently, we can say that at optimum condition of etching time and density of the catalytic metal, better findings might be possible.

Absorption measurement was also carried out for Ag-synthesized samples: type B sample (sample b, sample c, and sample d) with different etching times for same wavelength range of 200 to 1,000 nm as shown in Figure 4. It has been found that the absorption of sample b was slightly low for wavelength range of 350 to 1,000 nm, but the absorbance increased to 80% in the range of 200 to 350 nm. For sample c and sample d, the absorption of light energy was greater than the silicon wafer in 350 to 1,000 nm, but it was increased tremendously up to 83% in 200 to 350 nm.

Absorption measurements with different etching times for same wavelength range of 200 to 1,000 nm. (a) Optical absorption spectrum of solid Si film. (b) Absorption of Ag-deposited nanowire film on Si substrate with etching time of 45 min. (c) Absorption data for Ag-deposited nanowire film on Si substrate with etching time of 45 min with 0.02 M AgNO3. (d) Absorption measurement for Ag-treated Si substrate with etching time of 75 min by means of 0.02 M AgNO3.

Conclusions

We have demonstrated that Si nanowire films possess unique macroscopic optical properties. The nanowires yield significantly increased optical absorption over the full spectrum above the bandgap, as well as reduced transmission and reflectance for wavelengths in case of Cu-deposited SiNWs, whereas for Ag-deposited SiNWs, absorbance was maximum of 83% which is much greater than that of the bulk silicon as they absorbed a maximum of 43% of the radiation. This inspection facilitates that the synthesized nanostructure could be a potential contender for efficient PV solar cell.

Abbreviations

- EMD:

-

Electroless metal deposition

- HF:

-

Hydrogen fluoride

- PV:

-

Photovoltaic

- SEM:

-

Scanning electron micrograph

- SiNW:

-

Silicon nanowire

- UV:

-

Ultraviolet.

References

Shah A, Torres P, Tscharner R, Wyrsch N, Keppner H: Photovoltaic technology: the case for thin-film solar cells. Science 1999,285(5428):692–698. 10.1126/science.285.5428.692

Green MA: Recent developments and future prospects for third generation and other advanced cells. Conference Record of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion 1st edition. 2006, 15–19.

Chapin DM, Fuller CS, Pearson GS: A new silicon p-n junction photocell for converting solar radiation into electrical power. J. Appl. Phys. 1954, 25: 676. 10.1063/1.1721711

Ginley D, Green MA, Collins R: Solar energy conversion towards 1 terawatt. MRS Bull. 2008,33(2):355–364.

Green MA, Emery K, Hishikawa Y, Warta W: Solar cell efficiency tables (version 35). Prog. Photovolt. 2010, 18: 144–150. 10.1002/pip.974

Peng K, Xu Y, Wu Y, Yan Y, Lee ST, Zhu J: Aligned single-crystalline Si nanowire arrays for photovoltaic applications. Small. 2005, 1: 1062–1067. 10.1002/smll.200500137

Hu L, Chen G: Analysis of optical absorption in silicon nanowire arrays for photovoltaic applications. Nano Lett. 2007, 7: 3249–3252. 10.1021/nl071018b

Law M, Greene LE, Johnson JC, Saykally R, Yang PD: Nanowire dye-sensitized solar cells. Nat. Mater. 2005, 4: 455–459. 10.1038/nmat1387

Leschkies KS, Divakar R, Basu J, Enache-Pommer E, Boercker JE, Carter CB, Kortshagen UR, Norris DJ, Aydil ES: Photosensitization of ZnO nanowires with CdSe quantum dots for photovoltaic devices. Nano Lett. 2007, 7: 1793–1798. 10.1021/nl070430o

Maiolo JR, Kayes BM, Filler MA, Putnam MC, Kelzenberg MD, Atwater HA, Lewis NS: High aspect ratio silicon wire array photo electrochemical cells. J. Am. Chem. Soc. 2007,129(41):12346–12347. 10.1021/ja074897c

Goodey AP, Eichfeld SM, Lew KK, Redwing JM, Mallouk TE: Silicon nanowire array photoelectrochemical cells. J. Am. Chem. Soc 2007,129(41):12344–12345. 10.1021/ja073125d

Jia Z, Zongfu Y, Burkhard GF, Ching-Mei H, Stephen TC: Optical absorption enhancement in amorphous silicon nanowire and nanocone arrays. Nano Lett. 2009,9(1):279–282. 10.1021/nl802886y

Kelzenberg MD, Boettcher SW, Petykiewicz JA, Turner-Evans DB: Enhanced absorption in silicon nanocone arrays for photovoltaics. Nat. Mater. 2010,9(3):239.

Garnett E, Yang P: Light trapping in silicon nanowire solar cells. Nano Lett. 2010,10(3):1082–1087. 10.1021/nl100161z

Xie WQ, Oh JI, Shen WZ: Realization of effective light trapping and omnidirectional antireflection in smooth surface silicon nanowire arrays. Nanotechnology 2011, 22: 065704. 10.1088/0957-4484/22/6/065704

Liu WF, Oh JI, Shen WZ: Light trapping in single coaxial nanowires for photovoltaic applications. IEEE 2011,32(1):5–47.

Conibeer G, Green M, Cho EC, Knig D, Cho YH, Fangsuwannarak T, Scardera G, Pink E, Huang Y, Puzzer T, Huang S, Song D, Flynn C, Park S, Hao X, Mansfield D: Silicon quantum dot nanostructures for tandem photovoltaic cells. Thin Solid Films 2008,516(20):6748–6756. 10.1016/j.tsf.2007.12.096

Leu PW, Shan B, Cho K: Surface chemical control of the electronic structure of silicon nanowires: Density functional calculations. Phys. Rev. B 2006,73(19):195320–195324.

Long R, English JN: Band gap engineering of (N, Si)-codoped TiO 2 from hybrid density functional theory calculations. New J. Phys. 2012, 14: 053007. 10.1088/1367-2630/14/5/053007

Tsakalakos L, Balch J, Fronheiser J, Shih MY, LeBoeuf SF: Strong broadband optical absorption in silicon nanowire films. J Nanophotonics 2007, 1: 013552. 10.1117/1.2768999

Acknowledgements

Author’s would like to thank Mr. Mahbubul Haq, Director of the Institute of Electronics, Atomic Energy Research Establishment (AERE), Savar, for providing with the Silicon wafer from the project on “Center of Excellence for the Development of Very Large Scale Integration (VLSI) Technology in Bangladesh” supported by Government of the Peoples Republic of Bangladesh, and to Mrs. Rumana Islam, project fellow in Centre for Advance Research in Science (CARS), University of Dhaka, for her help to work with UV spectrophotometer.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Asgar, M.A., Hasan, M., Huq, M.F. et al. Broadband optical absorption measurement of silicon nanowires for photovoltaic solar cell applications. Int Nano Lett 4, 3 (2014). https://doi.org/10.1186/2228-5326-4-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-4-3