Abstract

A kind of water–oil separation material was fabricated by depositing mesoporous silica microspheres (MS) on filter paper. MS had been prepared via surfactant-template method and modified by octyltriethoxysilane (OTS). The diameter of the microspheres was in the range of 200 to 800 nm. There were uniform mesopores in the microspheres, and the surface area of the microspheres was more than 1,000 m2 g-1. The thin film, showing both hydrophobicity and lipophilicity, had a high contact angle for water (greater than 130°) and a low one for n-hexane (about 0°). Meanwhile, the film presented excellent separating efficiency between water and oil, which could reach 98.8%. Good selectivity and simple preparation procedure might lead the material to be highly valuable on water–oil separation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Recently, due to the urgent environmental requirement, there has been an intense increase on the demand for materials able to separate oil spills from water [1–3]. Several separating membranes were reported, such as nano-filtration polymer membranes [4, 5] and metal mesh [6–8]. In principle, the wettability of solid surfaces is controlled by their chemical composition and geometrical structure [9, 10]. Under this condition, a quantity of films with a rough and low-energy surface have been built and explored well the separation property for water–oil. Feng et al. [6] reported that a stainless steel mesh coating with Teflon (polytetrafluoroethylene, a low-surface-energy material) did well in water–oil separation. Similarly, Xua et al. [7] also prepared a copper mesh with a super-hydrophobic layer.

Herein, we fabricated a novel hydrophobic hierarchically porous silica film. Via stacking of mesoporous microspheres which are modified by octyltriethoxysilane (OTS), the film has been fabricated, showing great performance on inconsistent liquid mixture separation. With surfactant-template method, mesoporous silica microspheres have been prepared, followed by modification of the microspheres with OTS. The modified microspheres can be easily deposited on filter paper. Then, a hierarchically porous film has been formed after filtering and drying. The contact angle for water on this film is greater than 130°, and for n-hexane, it is 0°. Such novel properties contributed to the hierarchically porous morphology and the long-carbon-chain modifier (OTS). The fabrication procedure of our hybrid film is very simple and the materials are of low cost. The film can be used effectively for the separation between water and oil and may prevail over current membranes as a practical separating material.

Methods

Ethyl orthosilicate (TEOS), cetyltrimethylammonium bromide (CTAB), ethanol (95%), ammonia solution (28 wt%), petroleum ether, toluene and red dyes were purchased from Beijing Chemical Reagents Company (Beijing, China) and used without further purification. N-Octyltriethoxysilane was obtained from Aldrich Chemical Co. Inc. (St. Louis, MO, USA). The qualitative filter paper (the pore size was about 30 to 50 μm) was bought from Dongyang Industrial and Trading Co., LTD (Fushun, China).

CTAB (1.2 g) was dissolved in deionized water (25 g) and ethanol (25 mL), and aqueous ammonia (6 mL) was added. TEOS (1.68 g) was added into the solution after 10 min of stirring. After another 2 h of stirring at room temperature, the mesoporous silica microspheres (MS) were recovered by filtration and calcinated at 823 K for 6 h to remove the template. The samples were modified by reaction with OTS. An appropriate amount of MS was allowed to react with modified agents in toluene (50 mL) at reflux for 12 h. Subsequently, the products were washed with petroleum ether several times and dried at 373 K for 12 h. The mesoporous silica modified by OTS (MS-OTS; 0.5 g) was dispersed in toluene (50 mL), and the mixture was deposited on a filter paper by vacuum filtration. Then, a hydrophobic film was obtained after being heated at 353 K for 3 h in air.

The separating efficiency of the hydrophobic film was tested using an oil–water mixture. The sample was prepared by mixing 5 mL of n-hexane into 15 mL of distilled water. A few drops of red dyes were added for clarity. A certain amount of mixture was filtrated using the as-prepared film. The water (did not pass the film) was gathered together and the volume was tested. The separating efficiency of water from the mixture could be calculated by

Scanning electron microscopy (SEM) images were taken with a JEOL JSM-6700 F field emission scanning electron microscope (FESEM; 20 kV, Akishima-shi, Japan). Transmission electron microscopy (TEM) images were taken on a JEOL-2010 instrument operated at 120 kV. Nitrogen adsorption and desorption isotherms were measured at 77 K using an ASAP 2010 analyzer (Micromeritics Co. Ltd., Norcross, GA, USA). Before measurement, the samples were degassed under vacuum at 373 K for 4 h. An SL200B (Solon Tech. Inc., Ltd., Shanghai, China) contact angle goniometer was used for static contact angle measurements. The software offered by the instrument manufacturer calculates the contact angles based on the method of the tangent. Fourier transform infrared (FT-IR) spectra (4,000 to 500 cm-1) in KBr were collected on a Nicolet Avatar 360 FT-IR spectrometer by the KBr disc technique.

Results and discussion

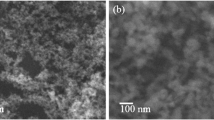

As shown clearly by Figure 1a,b, the spherical material had ordered mesopores about 2 nm in diameter. After modifying the MS, there was no visible change on the microstructure (Figure 1b). After depositing the MS-OTS on the filter paper, a coating film was formed. Such film was distinguished by two characteristics: a rough surface and a porous structure. The rough surface had a ball-like morphology, and the diameters of the balls were in a random distribution from 200 to 800 nm; the porous structure ensured free passage of air or fluid through the film (shown by Figure 1c,d).

The specific surface areas and pore size distribution of the prepared samples were determined by nitrogen adsorption-desorption isotherms. As shown by Figure 2, the isotherms of MS and MS-OTS were both type IV isotherms under the IUPAC classification. It illuminated that the porous structure would not be destroyed in the modification process. However, the specific areas of MS-OTS decreased from 1,314 to 1,202 m2 g-1, and the pore diameter shrank from 2.5 to 1.9 nm. These changes seemed to be caused by the introduction of a long carbon chain which covered the surface of mesopores.

FT-IR was also used to prove that the OTS was modified on the surface of MS. As shown by Figure 3, the characteristic absorption bands of carbon chains were at 2,850 and 2,920 cm-1. Obviously, these bands disappeared after extraction, indicating that CTAB has been removed. In contrast, besides the absorption bands at 1,066, 952, and 3,000 to 3,500 cm-1 assigned to Si-O-Si and Si-O-H stretching vibrations, the characteristic adsorption bands of the modified OTS were clearly visible at 2,860 and 2,930 cm-1, which were similar to those of CTAB but had a small shifting.

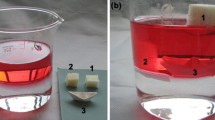

There were a series of comparisons between the coated and the uncoated filter paper, which are shown by Figure 4. Firstly, the filter paper coated by MS-OTS worked differently on the area of wettability: hydrophobic (Figure 4a) yet oleophilic (Figure 4b). However, as to the uncoated paper, there was no difference on wettability (Figure 4c,d). The water contact angle (CA) on this film was 130.8, while the CA of n-hexane was nearly 0. It meant that hexane could pass through the hydrophobic porous film freely but water could not. A mixture of hexane and water was used to test the real separation property of the hydrophobic film. After filtration, hexane successfully passed the film without water (Figure 4e). The separating efficiency of water from the mixture was 98.8%. Recycle experiments were done in order to measure the stability of the hydrophobic film. The film was simply washed with some petroleum ether and dried at 373 K for 1 h. Then, it could be totally recyclable. The separating efficiency did not show an obvious decrease after 16 cycles (Figure 5).

Wettability of the filter paper, the contact angle of water, and the separation process. Wettability of the filter paper (a, b) coated and (c, d) uncoated with MS-OTS to (a, c) water and (b, d) n-hexane. (e) The contact angle of water in image (a). (f) The separation process of the water and oil mixture.

Compared with the hydrophobic porous film, the modified glass (a sheet glass modified by OTS) has a smaller water contact angle, which is less than 95°. It implies that the surface roughness has played an important role for the high hydrophobicity. The following equation, first derived by Cassie and Baxter, can explain the apparent contact angle on the rough surfaces of the hydrophobic porous film [11]:

where θr is the apparent contact angle on the rough surface, θ is the equilibrium contact angle of the same material, f1 is the ratio of the surface area of the liquid contacted with the solid to the apparent area, and f2 is the ratio of the surface area of the liquid contacted with air on the rough surface to the apparent area (f1 + f2 = 1). The f2 value of the rough surface is estimated to be 0.64 (θ is substituted by the water contact angle of glass). According to the calculated result, it is the fraction of air in the interspaces that is an important factor to get high hydrophobicity. Obviously, high roughness of the porous structure has undoubtedly led to the richness of the fraction of air.

Conclusions

In summary, a novel hydrophobic separation film has been fabricated. Via adjusting the modifier, the porous silica film exhibits not only hydrophobicity but also a satisfying property on water–oil separation. In addition, there are also several advantages on preparation such as a simple fabrication procedure and inexpensive raw materials. Furthermore, the discovery is beneficial to design other water–oil separating materials.

References

Adebajo M, Frost R, Kloprogge JT, Carmody O, Kokot S: Porous materials for oil spill cleanup: a review of synthesis and absorbing properties. J. Porous. Mater. 2003, 10: 159. 10.1023/A:1027484117065

Yuan JK, Liu XG, Akbulut O, Hu JQ, Suibm SL, Kong J, Stellacci F: Superwetting nanowire membranes for selective absorption. Nat. Nanotechnol. 2008, 136: 332.

Zhu Q, Tao F, Pan Q: Fast and selective removal of oils from water surface via highly hydrophobic core-shell Fe 2 O 3 @C nanoparticles under magnetic field. ACS Appl. Mater. Interfaces 2010, 2: 3141. 10.1021/am1006194

Merkel TC, Freeman BD, Spontak RJ, He Z, Pinnau I, Meakin P, Hill AJ: Ultrapermeable reverse-selective nanocomposite membranes. Science 2002, 296: 519. 10.1126/science.1069580

Wang L, Yang S, Wang J, Wang C, Chen L: Fabrication of superhydrophobic TPU film for oil–water separation based on electrospinning route. Mater. Letters 2011, 65: 869. 10.1016/j.matlet.2010.12.024

Feng L, Zhang ZY, Mai ZH, Ma YM, Liu BQ, Jiang L, Zhu DB: A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew. Chem. Int. Ed. 2004, 43: 2012. 10.1002/anie.200353381

Xua X, Zhang Z, Yang J, Zhu X: Study of the corrosion resistance and loading capacity of superhydrophobic meshes fabricated by spraying method. Colloids Surf., A 2011, 377: 70. 10.1016/j.colsurfa.2010.12.024

Yang H, Pi PH, Cai ZQ, Wen XF, Wang XB, Cheng J, Yang ZR: Facile preparation of super-hydrophobic and super-oleophilic silica film on stainless steel mesh via sol–gel process. Appl. Surf. Sci. 2010, 256: 4095. 10.1016/j.apsusc.2010.01.090

Shirtcliffe NJ, McHale G, Newton MI, Perry CC, Roach P: Porous materials show superhydrophobic to superhydrophilic switching. Chem. Commun. 2005, 25: 3135.

Wang XF, Shen YH, Xie AJ, Qiu LG, Li SK, Wang Y: Novel structure CuI/PANI nanocomposites with bifunctions: superhydrophobicity and photocatalytic activity. J. Mater. Chem. 2011, 21: 9641. 10.1039/c0jm04558f

Cassie ABD, Baxter S: Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40: 546.

Acknowledgements

We are genuinely grateful to the National Natural Science Foundation of China (51273030).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

YW participated in the best of materials. ST conceived of the study and synthesized the materials, and drafted the manuscript. Both authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Tao, S., Wang, Y. Synthesis of hierarchically porous silica film with controllable surface wettability. Int Nano Lett 4, 1 (2014). https://doi.org/10.1186/2228-5326-4-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-4-1