Abstract

Water-soluble cadmium telluride (CdTe) quantum dots (QDs) were synthesized using thioglycolic acid as capping agent; this reaction was carried out at pH = 10.2 and refluxed at 100°C for 18 h. The CdTe QDs prepared at various reflux times from 1 to 18 h were coated on the glass substrates to obtain thin films of the CdTe QDs with the same thickness. The CdTe thin films were characterized by X-ray diffraction, ultraviolet-vis spectroscopy, and photoluminescence spectroscopy. The absorption thresholds of the CdTe thin films are blueshifted by about 0.65 eV with respect to the bulk value (1.5 eV), due to the quantum size effect as expected from the nanocrystalline nature of the CdTe QDs. X-ray diffraction showed that the films consisted of small CdTe nanocrystallites, 2.91 to 3.57 nm in size, showing quantum size effects. The effects of temperature on the electrical properties of the films were studied in detail. Electrical resistivity measurements were carried out for different films in the temperature range from 343 to 463 K. It is shown that activation energy increases by increasing the reflux time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Colloidal semiconductor quantum dots (QDs) are promising candidate materials for realizing photovoltaics and optoelectronic devices. They can be fabricated near room temperature and scalable to large-area substrates [1–3]. Various artificially nanostructured materials have also become available which possess large transition dipole moments and consequently strong optical absorption [4]. Being coated on any surface and capability of the band gap to be tuned by changing the size and the shape of the particle are the potential advantages of colloidal QDs [5, 6]. Among these artificial nanostructures, of the most interest are colloidal synthesized QD semiconductors which can be processed from solution due to the broad optical response that can be tuned from visible to infrared by the selection of the type and physical size of the nanocrystals [7–9]. The CdTe QD semiconductors have a direct band gap that can be tuned from 1.5 to 2.1 eV, covering most of the range of the peak emission power of the solar spectrum, and hence, they are suitable materials for photovoltaic applications [10–13]. They are also beneficial for thermoelectric applications, as they have the lowest possible thermal conductivity [14].

Carrier transport in the QD thin films can manifest both hopping transport and conduction band transport features. The hopping transport regime is characterized by its dependence on different temperatures and much lower mobility values than the band conduction transport. What causes the transport regime prevail depends on the structural and morphological properties of the QD thin films. Despite its importance for practical applications, there has been relatively little work done on charge transport in the QD thin films [1]. Experimental investigation of thermal transport in such structures has also just begun [14]. For thermoelectric applications, it is important to measure both electrical and thermal conductivities in the same set of QD thin film samples.

In this paper, a monodisperse size series of thioglycolic acid-stabilized CdTe QDs with extremely small sizes was synthesized by a wet chemical route in aqueous solutions at various reflux times and coated on glass substrate for the formation of CdTe QD thin films. The synthesis allows obtaining a size series of highly luminescent CdTe QDs with emission colors covering the visible spectral range from green to red. Furthermore, the deposited thin films are also characterized in terms of optical, electrical, and nanocrystalline structural properties in details. Although several groups have performed the deposition of nanocrystalline CdTe thin films by different methods, there are only few reports discussing the electrical properties of CdTe QD thin films at different temperature ranges [15–18].

Methods

Materials and apparatus

Cadmium sulfate octahydrate (CdSO4 · 8H2O), tellurium (Te) powder, sodium borohydride (NaBH4), sodium hydroxide (NaOH), and thioglycolic acid (HSCH2CO2H) were of analytical grade and were not further purified before use. An Agilent 7200 UV-vis spectrophotometer was used to record the absorption spectra in the wavelength range of 300 to 800 nm at room temperature. X-ray diffraction (XRD) patterns were recorded in the thin film grazing angle mode with an automated Philips X’Pert X-ray diffractometer (Koninklijke Philips N.V., Amsterdam) with CuKα radiation (40 kV and 30 mA) for 2θ values over 10° to 80°. Photoluminescence (PL) measurements were performed at room temperature using a Cary Eclipse spectrofluorometer (Agilent Technologies Inc., Santa Clara, CA, USA) equipped with a 20-kW xenon discharge lamp as a light source. The excitation wavelength of photoluminescence was fixed at 390 nm. The thin film thickness was measured using an AlphaStep 500 profiler (KLA-Tencor Corp., Milpitas, CA, USA). The two-point probe method was employed to measure the electrical resistivity as a function of temperature in the range of working temperature between 343 K and 463 K. Using appropriate mask and evaporation of gold, ohmic contact was made on the thin films. The copper constantan thermocouple was employed to measure the temperature, and the voltage of the samples was controlled by a Keithley electrometer (Model 6517A, Keithley Instruments Inc., Cleveland, OH, USA).

Preparation of CdTe quantum dots

In a 50-mL two-neck flask, 278.8 mg NaBH4 and 7 mL double distilled water were deaerated with argon and stirred for 30 min. Then, 90 mg tellurium powder was added, and the resulting suspension was stirred under argon until tellurium powder was completely dissolved. After that, the resulting suspension was cooled down to 0°C under vigorous stirring and argon bubbling. During 15 min, the characteristic color of the suspension changed from faint pink to colorless state. The disappearance of the solution color is due to the formation of aqueous sodium hydrogen telluride (NaHTe) solution. After removal by filtration, the obtained solution transferred into the two-neck flask and 42 mL of double distilled water was added, deaerated with argon, and stirred for 120 min. Finally, the prepared NaHTe solution was kept at 5°C and was used freshly in the next experiments.

The CdTe QDs were prepared using the reaction between the Cd2+ and NaHTe solutions following the modified method described elsewhere [12]. In a three-neck flask (250 mL) equipped with flux condenser, 294.6 mg of CdSO4 · 8H2O was dissolved in 176 mL double distilled water. After the addition of 200 μL thioglycolic acid (TGA), the solution was adjusted to pH 10.2 with aqueous NaOH solution (1.0 M) and stirred under argon atmosphere at room temperature for 30 min. Then, freshly prepared NaHTe solution was injected under argon atmosphere, and the mixture was refluxed. The color of the precursor’s mixture turned from colorless to orange, clearly supporting the nucleation and growth of the TGA-stabilized CdTe nanocrystals. The resulting solution was refluxed under nitrogen atmosphere at different times and at constant temperature of 100°C to produce the TGA-stabilized CdTe QDs.

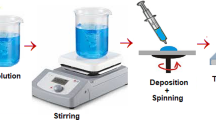

Preparation of thin films

Commercial microscope slide glass substrates (16 × 25 × 1 mm) were used as the substrate. The glass substrates were first ultrasonically cleaned in sulfochromic acid solution, washed with deionized water, isopropyl alcohol, and doubly distilled water, respectively, and dried in an oven at 90°C for about 1 h. The thin films of CdTe QDs were spin coated on glass substrates at 4,000 rpm for 60 s. Then, the glass substrates coated with CdTe QDs are placed in a vacuum environment (approximately 10-3 Torr) for approximately 1 h to evaporate the solvent.

Results and discussion

Characterization of CdTe thin films

Figure 1 shows the UV-vis absorption spectra of the CdTe QDs coated onto the glass substrates as a function of reflux time. The film thickness of the CdTe QDs coated on the glass substrates was about 130 nm. The measurement of the absorption spectra was carried out at various reflux times and extended to longer reflux times than 18 h to reveal the effect of reflux time on the optical, structural, and electrical characterization of the CdTe thin films. As shown in Figure 1, the presence of typical excitonic peak and redshifts from 520 to 575 nm with the CdTe precursor undergoing a continuous refluxing process which attributed to 1 s to 1 s electronic transition of the nanoparticles indicates that the size of CdTe QDs gradually increased [19]. The redshift of the absorption peaks in Figure 1 clearly demonstrates the growth of the nanocrystals and formation of the CdTe QDs with various sizes at different reflux times. It also confirms by the change of the CdTe thin films’ color from transparent light yellow at initial reflux time to orange after 18 h. This is an effect of the Ostwald ripening mechanism as smaller particles dissolve in the process of producing larger particles [20, 21]. The relative sharpness of the absorption edges is attributed to the formation of the CdTe QDs with a narrow size distribution. So, there is a blueshift of at least 230 nm, 0.65 eV in energy, in comparison with that of the bulk CdTe at 810 nm (1.5 eV). This blueshift in the absorption edges is most probably due to the quantum size effect as expected from the nanosized nature of the CdTe QDs [22, 23].

According to the literature survey, the particle size of CdTe QDs is estimated using the following empirical fitting expression [24]:

In the above function, D (nm) is the size of a given CdTe QD, and λ (nm) is the wavelength of the first excitonic absorption peak of the corresponding CdTe QDs. Our results show that the particle sizes of the prepared CdTe QDs are 2.81, 3.01, 3.24, and 3.47 nm, corresponding to the first excitonic absorption peaks of 520, 530, 550, and 575 nm for the CdTe QDs obtained at different reflux times.

The PL emission spectra of the CdTe thin films were performed to investigate the optical variation of the CdTe QDs during their growth at different reflux times from 1 to 18 h. As shown in Figure 2, the PL spectra are dominated by single large peaks centered in 532, 545, 557, and 578 nm, corresponding to the reflux times of 1, 3, 7, and 18 h, respectively. The PL bands (Figure 2) are located close to the absorption thresholds (so called band edge) and are sufficiently narrow (full width at half maximum, as low as 45 nm being increased up to 65 to 70 nm for size fractions of large CdTe QDs).

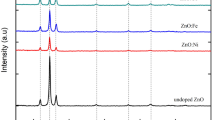

Figure 3 shows the XRD patterns obtained from thin films of the CdTe QDs synthesized at different reflux times. The standard XRD pattern for CdTe (Joint Committee for Powder Diffraction Standards, JCPDS card No. 10–0207) is given at the bottom of Figure 3. The thin films are all polycrystalline with random crystal orientation and show no signs of texturing. The three broad peaks observed in the diffractogram at around 23.8°, 44.3°, and 52.2° reveal a cubic lattice structure of CdTe (zinc blende). These peaks could be readily assigned to the planes (111), (200), and (311), respectively, of the cubic phase [25]. From the full width at half maximum of the (111) diffraction peaks, the average sizes of the CdTe QDs have been calculated using the Debye-Scherrer equation [26], and the results are shown in Table 1.

Electrical properties

Electrical conductivity is a prominent factor revealing information about the transport phenomenon. Recent works on electrical properties of nanocrystalline semiconductors have paid considerable attention toward the conduction mechanism [27]. In nanocrystalline materials due to the small size of grain and large grain boundaries, the electronic states close to Fermi levels are localized. When the states are localized, the conduction occurs by hopping of carriers between occupied and unoccupied localization which depends on the density of the state and the position of the Fermi level. Ichimura et al. established a dependence of conductivity with temperature for such systems [28]. The electrical conductivity of the CdTe QD thin films was carried out in the temperature range of 343 to 463 K at different reflux times of 1, 3, 7, and 18 h. The conductivity measurement shows that the thin films have an electrical resistivity order of 106 Ω · cm at room temperature. The high resistivity of the thin films may be due to the high grain boundary density, discontinuities, and small grain size of the CdTe QDs [29].

The glass substrate was heated by a specially designed heater, and the temperature was measured by a cupper-constantan thermocouple placed on the surface of the substrate. The conductivity was obtained by applying a DC voltage bias across the film with a gold electrode, and the current and voltage were simultaneously recorded using a standard two-point probe method. The activation energy (Ea) was determined using the following equation [30]:

where σ is the resistivity at temperature T, σ0 is a constant, k is the Boltzman constant, and T is the absolute temperature. The activation energies were calculated from the local gradients of the lnσ versus the inverse temperature plots.

The plot of lnσ versus 1,000/T for the different films was shown in Figure 4. It is interesting to note that conductivity appears to vary continuously with inverse temperature, and the variation of their slopes suggests a thermally activated conduction mechanism. The conductivity of these samples cannot be represented by a single exponential but can be fitted by a smoothed curve with gradually increasing slope, providing a spectrum of activation energies. Therefore, the whole temperature region was divided into three temperature ranges: (1) high temperature range (413 to 463 K), (2) intermediate temperature range (373 to 412 K), and (3) low temperature range (343 to 372 K). It must be considered that at temperature less than 343 K, all the samples show similar behaviors (Figure 4). The activation energies for the four different CdTe thin films including QDs with grain sizes of 2.91, 3.05, 3.32, and 3.57 nm were obtained (Table 1). It was observed that the increase in the reflux time leads to an increase in the amount of thin film activation energy. Moreover, it is clear from Table 1 that as temperature increases, the activation energy increases for all the investigated films. Therefore, it can be assumed that at higher temperatures, the carriers are activated to the localized states, and the conductivity moves away from the states near the Fermi level. The gradual increase in the activation energy may suggest the probability of several impurity levels in the band gap.

The grain size dependence of the activation energy is due to the grain boundary barrier effect and large dislocation density [31]. Our results show that increasing the reflux time, which in itself leads to the increasing size of the CdTe QDs, increases the activation energy in a way that the largest one is observed within the time span of 18 h. The point to notice with this regard is the fact that although the size of the CdTe QDs will increase in commensurate with the increase in the reflux time, the considerable impact regarding the increase in the activation energy is widening the distance between the CdTe QD grains which have out formed as thin films.

According to Table 1, it is clear that the activation energy at the three different branches is a function of the reflux time. This behavior could be attributed to the grain size dependence of the activation energy [31].

It is interesting that the CdTe QD thin film synthesized at reflux time of 18 h shows the semiconducting features earlier than the other thin films (Figure 5). Although the CdTe QD thin film synthesized at the reflux time of 18 h has a greater Ea, it shows a better thermally conduction mechanism at lower temperature than the other thin films. Therefore, the sample synthesized at the reflux time of 18 h is a good semiconductor to use in semiconducting devices. The main reason for this can be attributed to the increase in the distance between grain boundaries and the size of quantum dots simultaneously.

Conclusion

In this study, tunable CdTe QD thin films were prepared using a simple aqueous method with TGA as the capping agent at 100°C and at different reflux times. A photoluminescence peak with full width at half maximum of around 45 to 70 nm indicating a homogeneous and narrow size distribution of the CdTe QD thin films and structural measurements through XRD analysis demonstrated that the CdTe thin films have a cubic structure. The electrical properties of the CdTe thin films were presented, and it was found that the temperature increase will increase the activation energy but will decrease the thin film’s electronic thermal conductivity. It was also shown that the electrical conductivity in the higher temperature is due to the hopping of the carriers between localized states at the Fermi levels. Moreover, the results obtained in this study showed that the increase in the thin film activation energy depends not only on the reflux time but also on the distance between the grain boundaries of quantum dots in the thin films.

Authors’ information

Rostam Moradian: full Prof. of condensed matter physics - Department of Physics, Razi University, Kermanshah, Iran.

Mohhamad Elahi: Assosiated Prof. of condensed matter physics - Department of Physics, Razi University, Kermanshah, Iran.

Ahmad Hadizadeh: Phd student of condensed matter physics - Department of Physics, Razi University, Kermanshah, Iran.

Mahmoud Roushani: Assistant Prof. of chemistry Department of Chemistry, Ilam University, Ilam, Iran.

Atefeh Taghizadeh: Master of degree of condensed matter physics.

Reza Sahraeid: Assistant Prof. of chemistry Department of Chemistry, Ilam University, Ilam, Iran.

References

Geyer S, Porter VJ, Halpert JE, Mentzel TS, Kastner MA, Bawendi MG: Charge transport in mixed CdSe and CdTe colloidal nanocrystal films. Phys. Rev. B 2010, 82: 155201.

Mane RK, Ajalkar BD, Bhosale PN: Opto-structural and electrical properties of chemically grown Ga doped MoBi2Se5 thin films. Mater. Chem. Phys. 2004, 84: 247–250. 10.1016/S0254-0584(03)00333-X

Levy-Clement C, Tena-Zaera R, Ryan MA, Katty A, Hodes G: CdSe-Sensitized p-CuSCN/Nanowire n-ZnO Heterojunctions. Adv. Mater. 2005, 17: 1512–1515. 10.1002/adma.200401848

Osedach TP, Geyer SM, Ho JC, Arango AC, Bawendi MG, Bulović V: Lateral heterojunction photodetector consisting of molecular organic and colloidal quantum dot thin films. Appl. Phys. Lett. 2009, 94: 043307. 10.1063/1.3075577

Peng ZA, Peng X: Formation of High-Quality CdTe, CdSe, and CdS Nanocrystals Using CdO as Precursor. J. Am. Chem. Soc. 2001, 123: 183–184. 10.1021/ja003633m

Yin YD, Alivisatos AP: Colloidal nanocrystal synthesis and the organic–inorganic interface. Nature 2005, 437: 664–670. 10.1038/nature04165

Steckel JS, Coe-Sullivan S, Bulović V, Bawendi MG: 1.3 μm to 1.55 μm Tunable Electroluminescence from PbSe Quantum Dots Embedded within an Organic Device. Adv. Mater. 2003, 15: 1862–1866. 10.1002/adma.200305449

Burda C, Chen XB, Narayanan R, El-Sayed MA: Chemistry and properties of Nanocrystals of Different Shapes. Chem. Rev. 2005, 105: 1025–1102. 10.1021/cr030063a

Norris DJ, Bawendi MG: Measurement and assignment of the size-dependent optical spectrum in CdSe quantum dots. Phys. Rev. B 1996, 53: 16338. 10.1103/PhysRevB.53.16338

Gur I, Fromer NA, Geier ML, Alivisatos AP: Air-stable all-inorganic nanocrystal solar cells processed from solution. Science 2005, 310: 462–465. 10.1126/science.1117908

Morales-Acevedo A: Analytical model for the photocurrent of solar cells based on graded band-gap CdZnTe thin films. Sol. Energy Mater. Sol. Cells 2006, 90: 2213–2220. 10.1016/j.solmat.2006.02.019

Gaponik N, Talapin DV, Rogach AL, Hoppe K, Shevchenko EV, Kornowski A, Eychmuller A, Weller H: Thiol-Capping of CdTe Nanocrystals: An Alternative to Organometallic Synthetic Routes. J. Phys. Chem. B 2002, 106: 7177–7185.

Kapitonov AM, Stupak AP, Gaponenko SV, Petrov EP, Rogach AL, Eychmuller A: Luminescence Properties of Thiol-Stabilized CdTe Nanocrystals. J. Phys. Chem. B 1999, 103: 10109–10113. 10.1021/jp9921809

Bao Y, Liu WL, Shamsa M, Alim K, Balandin AA, Liu JL: Electrical and Thermal Conductivity of Ge ∕ Si Quantum Dot Superlattices Semiconductor Devices, Materials, and Processing. J. Electrochem. Soc. 2005, 152: 432–435. 10.1149/1.1897365

Sharma K, Al-Kabbi AS, Saini GSS, Tripathi SK: Electrical conduction mechanism in nanocrystalline CdTe (nc-CdTe) thin films. Appl. Phys. A 2012, 108: 911–920. 10.1007/s00339-012-6993-4

Gao M, Lesser C, Kirstein S, Mohwald H: Electroluminescence of different colors from polycation/CdTe nanocrystal self-assembled films. J. Appl. Phys. 2000, 87: 2297–2302. 10.1063/1.372177

Mandal SK, Chaudhuri S, Pal AK: Nanocrystalline CdTe films deposited by high-pressure sputtering: carrier transport at low temperature. Thin Solid Films 1999, 357: 102–110. 10.1016/S0040-6090(99)00566-0

Al-Ghamdia AA, Abd El-sadek MS, Nagata AT, El-Tantawy F: synthesis, electrical properties and transport mechanisms of thermally vacuum evaporated CdTe nanocrystalline thin films. Solid State Commun. 2012, 152: 1644–1649. 10.1016/j.ssc.2012.05.029

Eychmüller A, Rogach AL: Chemistry and photophysics of thiol-stabilized II-VI semiconductor nanocrystals. Pure Appl. Chem. 2000, 72: 179–188. 10.1351/pac200072010179

Jun YW, Choi JS, Cheon J: Shape control of semiconductor and metal oxide nanocrystal through nonhydrolyc colloidal routes. Angew. Chem. Int. Ed. 2006, 45: 3414–3439. 10.1002/anie.200503821

Sahraei R, Mihandoost A, Nabiyouni G, Daneshfar A, Roushani M, Majles Ara MH: Room temperature synthesis and characterization of ultralong Cd(OH)2 nanowires: a simple and template-free chemical route. Appl. Phys. A 2012, 109: 471–475. 10.1007/s00339-012-7056-6

Zhang H, Wang L, Xiong H, Hu L, Yang B, Li W: Hydrothermal ynthesis for High-Quality CdTe Nanocrystals. Adv. Mater. 2003, 15: 1712–1715. 10.1002/adma.200305653

Scholes GD: Controlling the optical properties of inorganic nanoparticles. Adv. Funct. Mater. 2008, 18: 1157–1172. 10.1002/adfm.200800151

Yu W, Qu L, Guo W, Peng X: Experimental determination of the extinction coefficient of CdTe, CdSe, and CdS nanocrystals. Chem. Mater. 2003, 15: 2854–2860. 10.1021/cm034081k

Ghaedi M, Hekmati Jah A, Khodadoust S, Sahraei R, Daneshfar A, Mihandoost A, Purkait MK: Cadmium telluride nanoparticles loaded on activated carbon as adsorbent for removal of sunset yellow. Spectrochim. Acta, Part A 2012, 90: 22–27.

Goudarzi A, Motedayen Aval G, Sahraei R, Ahmadpoor H: Ammonia-free chemical bath deposition of nanocrystalline ZnS thin film buffer layer for solar cells. Thin Solid Films 2008, 516: 4953–4957. 10.1016/j.tsf.2007.09.051

Rakhesh K, Joshi H, Sehgal K: Density of states near Fermi level in PbS nanoparticle films. Physica E 2004, 23: 168–170. 10.1016/j.physe.2004.03.005

Ichimura M, Gota F, Arai E: Structural and optical characterization of CdS films grown by photochemical deposition. J. Appl. Phys. 1999, 85: 7411–7417. 10.1063/1.369371

Kale RB, Lokhande CD: Influence of air annealing on the structural, optical and electrical properties of chemically deposited CdSe nano-crystallites. Appl. Surf. Sci. 2004, 223: 343–351. 10.1016/j.apsusc.2003.09.022

Khemiri N, Chaffar Akkari F, Kanzari M, Rezig B: Studies of structural and optical properties of Cu–In–O thin films. Phys. Stat. Sol. A 2008, 205: 1952–1956. 10.1002/pssa.200778897

Das VD, Ganesan PG: Electrical conduction studies on (Bi 0.6 Sb 0.4 ) 2 Te 3 thin films. Semicond. Sci. Technol. 1997, 12: 195–202. 10.1088/0268-1242/12/2/008

Acknowledgements

The authors would like to acknowledge the Mrs. Atefeh Ghaderi for her guidance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

H, AT, MR carried out the experiments, analyzed the data and participated in the manuscript preparation. RM as the corresponding author participated throughout the investigations and manuscript writing. Other read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Moradian, R., Elahi, M., Hadizadeh, A. et al. Structural, optical, and electrical properties of thioglycolic acid-capped CdTe quantum dots thin films. Int Nano Lett 3, 56 (2013). https://doi.org/10.1186/2228-5326-3-56

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-3-56