Abstract

Nanostructured TiO2 has been synthesized using one-step sol–gel method and characterized by different characterization techniques (SEM, EDS, XRD, and UV–vis spectroscopy). The photocatalytic degradation of methylene blue (MB) and Congo red (CR) is studied with the synthesized TiO2. The photocatalytic degradation data has been validated using several kinetic models. The TiO2 showed efficient photocatalytic degradation performance on MB and CR. In addition to this, the effect of pH on the photocatalytic degradation has been investigated. The TiO2 showed enhanced photocatalytic performance in basic media than that in neutral or acidic ones.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Titanium dioxide is a promising material and is widely used in many applications such as disinfection, medical treatment, environmental purification, and photovoltaic cell[1, 2] due to its high photocatalytic activity[3, 4], excellent gas-sensitivity[5], and dielectric properties[6]. TiO2 particles, which are smaller than tens of nanometers, are of particular interest for the synthesis of new materials due to their special optical properties, high catalytic activity, and unusual mechanical properties in comparison to their bulk material counterpart[7]. TiO2 can be synthesized into various shapes - nanoporous materials, nanoparticles, nanowires, nanorods, nanotubes, and nanofibers using different preparation methods[5]. Many methods have been developed to control the size of nanoparticles, which include Langmuir-Blodgett films[8], vesicles[9], and reverse micro-emulsion method[10]. The chemical and physical properties exhibited by these materials depend on both the composition and the degree of homogeneity. Therefore, different synthesis strategies have been developed. These studies include co-precipitation, flame hydrolysis, impregnation, and chemical vapor deposition[11, 12]. So far, sol–gel route has demonstrated a high potential for controlling the bulk and surface properties of the oxides[13–15]. Additionally, non-hydrolytic sol–gel routes have been reported in the literature[16]. The physical and chemical properties of TiO2 in the nanometer size range depend on phase composition, grain size, and dispersity[17]. Nanosized TiO2 crystals, of less than 10 nm, show significant differences with the bulk TiO2 in many aspects due to the quantum size effect[18, 19].

The photocatalytic oxidation technology is frequently used for the complete degradation of organic micro-pollutants (dyes) in water, utilizing sunlight and UV radiation as energy sources[13, 20]. However, TiO2 is active only under near-ultraviolet irradiation region, because of its wide-bandgap energy of 3.0 to 3.2 eV. As a result, significant efforts have been made over the last two decades to develop modified TiO2 particles that are functioning under visible-light irradiation (λ > 400 nm). TiO2 has been used in a wide range of application including thin films or as submicron powders[21].

In the present paper, 20 g of nanostructured TiO2 powder is synthesized from Ti (O-iC3H7)4 (referred to hereafter as TIP) without the addition of catalyst or stabilizer at room temperature and atmospheric pressure. Under such conditions, nanosized particles (20 to 60 nm) are partly crystallized in the anatase phase. The objective of this paper is threefold: (1) to investigate the photocatalytic activity of the synthesized TiO2 on methylene blue (MB) and Congo red (CR), reactive dyes which are mostly used in textile processing industries, (2) to investigate and reveal the photocatalytic degradation kinetics using several mathematical models, and (3) to determine the pH level at which the photocatalytic reaction proceeds with acceptable reaction rate and completion of photocatalytic degradation.

Methods

Materials

Titanium (IV) isopropoxide (Alfa Aesar, USA), 2-propanol (Alfa Aesar), MB (Merck, Germany), and CR (Merck) have been used as received. Water used in experiments was triple distilled and produced in laboratory. P25 (Degussa, Germany) was used as a reference photocatalyst (TiO2) throughout this study.

Synthesis

Nanostructured TiO2 was prepared by following sol–gel chemistry methods. The sol–gel method is a promising method, because the morphology of the nanomaterial is varied simply by changing the solution composition and deposition condition. The synthesis reactor consists of a three-necked round bottom reactor equipped with a vertical condenser fitted to the middle neck. A separatory funnel was connected to one of the two side necks. Deionized water (24.13 mL) was added to 102.34 mL of 2-propanol under vigorous stirring to the remaining neck on the reactor. Following the addition of water, this neck was closed using a rubber stopper. Alkoxide precursor (50 mL) was added dropwise to the solution over a 4-h period using the separatory funnel fitted to the flask. This mixture was stirred continuously over a period of 24 h at room temperature. At this stage, a stable colloidal suspension of approximately 175 mL was formed. The excess water and alcohol were removed at room temperature and 10 kPa pressures using a rotary evaporator (Buchi R2015, BÜCHI Labortechnik AG, Switzerland) over a 7-day period. Approximately, 20 g of titania was obtained using this procedure.

Photocatalytic experiment

TiO2 samples, each amounting 0.5 g, was taken into different ceramic crucibles and calcined in a muffle furnace (JSMF-30 T, JS Research Inc., Korea) at 450°C, 550°C, and 650°C. The photocatalytic activity of titanium dioxides was studied by exposing the TiO2 samples, which contained MB and CR, to solar-like light. For photocatalytic reactions, the irradiation was carried out in solution at 308 K using a SOL 21500 lamp (SOL, Inc., USA). The SOL bulb yielded a spectrum very similar to natural sunlight ranging from ultraviolet to infrared radiation (approximately 295 to 3,000 nm). For this purpose, an aqueous solution (0.05% w/v) of reagent grade MB and CR was prepared for the impregnation of the reference and the synthesized TiO2 in the different volumetric flask. The same amount of each TiO2 sample was inserted under very mild stirring in the same amount of solution and remained there for 2 to 3 min to complete the mixing. The solution was then placed under the solar-like light (50 to 60 mW/cm2). UV–vis spectrum was recorded from the UV spectrophotometer (UV-1650, Shimadzu Corporation, Kyoto, Japan) in the wavelength range of 200 to 800 nm. The highest absorbance at 664 nm and 498 nm was recorded for MB and CR, respectively. The decrement of UV–vis band upon photocatalytic degradation was determined in an equal time interval. The pH (range 2 to 8) effect on photocatalytic degradation of MB and CR was investigated. The same experimental procedure was adopted for commercial P25 to compare with the synthesized one. The adsorption and photocatalytic degradation cycles were repeated twice on each sample to remove any experimental errors.

Photocatalytic kinetic models

Four kinetic models were used to investigate the photocatalytic degradation profiles[22–24].

-

(1)

Zero-order model can be generally expressed as

(1) -

(2)

The first-order model expresses the photocatalytic degradation systems and can be generally written as

(2) -

(3)

The parabolic diffusion model elucidates the diffusion-controlled photocatalytic degradation and the equation is as follows:

(3) -

(4)

The modified Freundlich model explains the experimental data on molecular ion exchange and diffusion-controlled process with the following equation:

(4)

In these equations, C 0 and C are the concentration of dyes at irradiation time 0 and t, respectively, k is the corresponding rate constant.

Characterization techniques

Scanning electron micrographs (SEM) were obtained using a Hitachi-4800 field emission scanning microscope (Hitachi Ltd., Tokyo, Japan) operated at 3 kV to investigate the morphology. Transmission electron micrographs (TEM) were obtained using a JEOL 2010 (JEOL Ltd., Akishima, Tokyo, Japan) operated at 200 kV and equipped with an energy dispersive spectroscopic (EDS) microanalysis system (OXFORD Instruments, Oxfordshire, UK). The images were obtained using a CCD Mega Vision (III) camera (MegaVision, Inc., CA, USA).

The X-ray diffraction (XRD) patterns were obtained using a Bruker D5000 diffractometer (Bruker Daltonik GmbH, Bremen, Germany) equipped with a Cu-Kα radiation of wavelength of 1.5418 Å. The accelerating voltage and the applied current were 45 kV and 40 mA, respectively.

Results and discussion

Morphology and structure analysis

The SEM image of the prepared TiO2 nanoparticles by sol–gel method at room temperature (25°C) is shown in Figure 1. The TiO2 aggregates consist of individual nanoparticles that are approximately in the range of 50 to 100 nm. The image shows that the supported aggregates are lumped together with the large numbers of pores of very small dimensions. This feature suggests that the pores have a high surface area and can preferentially adsorb organic molecules or pollutants adhered to the surface. This feature suggests the uniformity of the aggregates. These particles consist of individual particles that are in the nanoscale range. A small portion of the samples sonicated for 5 min and analyzed by TEM is shown in Figure 2. The structures of TiO2 clusters consist of individual nanosized structures, which are approximately in the 50- to 60-nm range. The small size of TiO2 nanoparticles suggests that the exposed surface area of the supported aggregates is very large, which is in agreement with the BET surface area analysis. The surface area and the average pore size (dBJH) of the synthesized nanostructure are found to be 545 m2g−1 and 2.4 nm, respectively (BET plot and the pore size distributions are not shown for the sake of brevity). The nanostructured matrix is the origin of preferential adsorption of the organic molecule on the exposed surface which should undergo photocatalytic degradation by UV light illumination. EDS analysis, which is carried out during TEM analysis, shows only the titanium and oxygen peaks (Figure 3). This implies that, following synthesis at low temperatures, the nanostructured support material is free of contaminants.

The XRD patterns of the synthesized TiO2 calcined at different temperatures are reported in Figure 4 (curves 1 to 3). Curves 1 and 2 show three broad peaks and one intense peak at 38.0°, 47.5°, 54.20°, and 25.1°, respectively, which constitute the XRD pattern of TiO2 of anatase phase. No additional peaks belonging to other phases are observed. The remarkable width of the peaks associated with the TiO2 phase suggests that the size of the particle is quite small. From full width at half maximum (FWHM) of the peaks at 25.1° and 38.01°, as well as the use of Scherrer's equation, Lc = Kλ/(β cosθ)[25] (where K is the shape factor, which has been assumed to be 0.9; λ is the x-ray wavelength; β is the FWHM of the diffraction line, and θ is the Bragg's angle), an average particle diameter (3 to approximately 20 nm) can be calculated. This result is strongly consistent with the SEM and TEM results described above. In conclusion, by comparing the results from different techniques, the most efficient sample shows average particle diameter of 4 nm (Figure 4, curve 2). In fact, curve 3 shows a certain amount (12.2%) of rutile phase with comparatively larger particle size (17 to approximately 20 nm) due to calcination of the sample at the highest temperature (650°C).

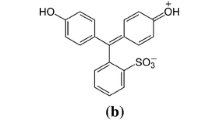

Photocatalytic activity

The photocatalytic activity of TiO2 has been investigated at high temperatures by exposing the reactor with MB and CR to UV light. In the absence of UV light irradiation, a reportable adsorption of dye molecules on the external TiO2 surface causes the successive photocatalytic degradation. The UV–vis reflectance spectra before (curve i) and after illumination with increasing time on synthesized TiO2 on MB and CR, and reference P25 on MB system are compared in Figures 5,6, and7. From this comparison, it is inferred that the complex adsorption bands in the 500- to 750-nm (20,000 to 12,000 cm−1) interval, due to adsorption of MB, change rapidly because TiO2 promotes the catalytic photodegradation (Figure 5, curve b). The photocatalytic degradation of CR has also been investigated (Figure 6). The simple absorption due to CR appears within the range of 400 to 600 nm (approximately 12,000 cm−1). The photocatalytic activity of P25, an excellent TiO2 photocatalyst, is reported in Figure 7. The disappearance rate within the absorption band of MB on the P25 surface is much faster than that observed in the case of the synthesized TiO2 calcined at lower temperatures due to lower conversion of hydrogen titanate to TiO2. Conversion of TiO2 is obtained by the subsequent heat treatment of hydrogen titanate at around 300°C to 500°C. A small band was observed at the wavelength of around 600 nm for both cases of TiO2 (P25) and synthesized TiO2 samples due to decomposition of the dimers of MB molecules to MB monomers[26]. The results obtained in this work are in agreement with those of Uddin et al.[13] who found that UV–vis bands of MB at 600 and 660 nm are assigned to the monomeric and aggregated MB (mostly dimeric and trimeric species) adsorbed on the surface. Under exposure to light, the aggregate species disappear first, followed by the monomeric ones. This indicates that the photodegradation destroys not only the conjugate system (including -N = N-) but also the intermediate products partially or totally[27, 28]. Between the two dyes, the chemical structure of MB is more susceptible to oxidation by hydroxyl radicals than that of CR. Moreover, it is also possible that MB absorbs less UV light than CR. This would make more photons available to impinge on the catalyst and promote the formation of hydroxyl radicals. However, it must be stated that the degradation between the dyes has been compared on mass basis. On a molar basis, the analysis is much different. The molecular weight of MB and CR are 356 and 697, respectively. This means that the number of moles per parts per million is two times higher for MB, and consequently, the molecular degradation rate of MB is higher than that of CR. As mentioned above, the bands at 660 and 600 nm are assigned to monomeric and aggregated MB, respectively, adsorbed on the TiO2 surface, while the CR shows only one absorption band, which explains monomeric layer of CR on the surface. The photocatalytic degradation rate of CR is lower than that of MB due to its weaker adsorption constant (Kads, CR = 2.0 × 10−3 L/μmol and Kads, MB 6.65 × 10−3 L/μmol). This fact can be explained by the large steric hindrance arising from the large aromatic ensembles, including one central biphenyl group and two symmetric naphthenic groups[29]. The photocatalytic degradation kinetics of MB and CR on synthesized TiO2 samples and reference P25 is shown in Figures 8,9, and10. It is evident from the Figures that the samples calcined at higher temperatures require comparatively more time to complete the photodegradation (Figures 8 and9) of dyes. At high temperature, TiO2 of anatase phase substantially converts to rutile phase, which shows more stability and less photoactivity toward organic strains or dye molecules. It should be noted that the sample calcined at or above 650°C contains a certain amount of rutile TiO2, which lowers the overall photoactivity. The sample calcined at the temperature of 550°C (which results an average particle diameter of 4.0 nm) is efficiently capable of photocatalytic degradation of MB and CR (Figures 8 and9). It can be concluded that the photocatalytic activity is directly affected by the size of nanoparticles and dye characteristics. The photocatalytic performance of this particular sample is relatively competitive with P25, which is the most effective commercial TiO2 photocatalyst.

Photocatalytic degradation kinetic models

To explore more into the mechanisms, including successive adsorption and photocatalytic degradation processes at room temperature, four types of kinetic models are applied (zero-order, first-order, parabolic-diffusion, and modified Freundlich model; Figures 11,12 and13). A calculation was also made for the corresponding linear correlation coefficients (R2) and photocatalytic degradation rate constant (k) (shown in Tables 1,2, and3).

The experimental data are analyzed with the selected four types of kinetic models. The experimental data do not fit well to the zero and parabolic diffusion models. Based on the fitting of kinetic data for the MB and CR adsorption, simultaneous photodegradation on TiO2 and P25 to the first order and modified Freundlich model, the R2 values (Tables 1,2, and3) are close to unity (0.94 to approximately 0.99) for all cases. From Figures 11,12, and13, it can be speculated that the kinetics of adsorption of MB and CR on the as-synthesized titanate nanostructures can be described more accurately by the modified Freundlich kinetic model. This is an indication for the heterogeneous surface binding caused by the monolayer adsorption, and that the molecules follow successive photocatalytic degradation under the UV light illumination. The modified Freundlich model fit the photocatalytic degradation data on synthesized TiO2 with the linear correlation coefficients of R2 = approximately 0.98 (Table 1) for MB and R2 = approximately 0.99 (Table 2) for CR, and the fitted value of k is found to be 0.0086 to 0.0200 units for MB and 0.0030 to 0.0100 units for CR. The modified Freundlich model, in fact, describes heterogeneous diffusion from the flat surfaces via molecular ion exchange. Additionally, the kinetic model prediction suggests similarities in the photocatalytic activity of synthesized TiO2 and P25. As smaller TiO2 particles provide more side edges/surfaces and a shorter diffusion path, the bulk dyes can be more readily adsorbed toward the edge/surface in a relatively continuous way even at the beginning of photocatalytic degradation. This result suggests that (1) the system is adsorption-photocatalytic degradation controlled, and (2) the photocatalytic degradation is occurring on the TiO2 surface.

Influence of pH on degradation kinetics

The photocatalytic degradation is studied in the pH range of 2 to 8. From Figure 14, it is evident that the photocatalytic degradation rate increased with the increasing pH, an effect attributed to the variation of the nature and the density of surface charge on the catalyst surface with the change in the pH of the solution.

Adsorption of H2O molecules at the surface sites is followed by the dissociation of the -OH groups, leading to coverage with chemically equivalent metal hydroxyl groups (Ti-OH). For metal hydroxides, the following equilibrium can be considered in aqueous solution:

From the above equations, it is clear that the catalyst surface will be pH sensitive and will assume positive or negative charge depending on the pH of the solution. The zero-point charge (pHzpc) of the metal oxide is defined as the pH at which the concentrations of the protonated and deprotonated surface groups are equal. The isoelectric points of TiO2 may vary over a range of pH depending upon the processing history. This makes the effects of pH on the dissolution of TiO2 powders in aqueous solutions still unclear. Wang and Ying[30] find the pHzpc of TiO2 to be 6.8. Other authors report that the pHzpc of TiO2 lies between 4 and 6[31].

At high pH, the catalyst surface is predominantly negatively charged, and a strong interaction occurs between the catalysts surface and the dye cations, resulting in strong adsorption. At low pH, however, both the TiO2 surface and the dye molecules are positively charged, resulting in weak adsorption. Thus, it is reasonable that with an increase in pH, the adsorption of the dye on the catalyst surface increases, resulting in higher degradation rate.

Conclusion

The results reveal that the synthesized TiO2 nanoparticles can effectively remove MB (98%) and CR (98%) under UV light. Moreover, the photocatalyst can be successfully recovered following exposition under UV light irradiation due to the capacity of the photocatalytic process to mineralize organic compounds by transforming them into carbon dioxide, water, and harmless ions. From this experiment, it is obvious that the higher the calcination temperature of the synthesized TiO2 nanoparticles, the less the photocatalytic degradation efficiency is, due to appearance of the rutile phase in the TiO2 nanoparticles, which is unfavorable. It is also found that the modified Freundlich model describes the degradation process very well at higher pH.

Authors' information

MJU is a Ph.D. degree holder and an associate professor in the Chemical Engineering and Polymer Science Department. MAI is a Ph.D. holder, a professor, and the chair of the said department. MMR is a Ph.D. degree holder and an associate professor in the same department. MSAA is a BS ChE degree holder and an assistant professor in the same department as well. SAH and SH are graduate students of the Chemical Engineering and Polymer Science Department.

References

Herrmann JM, Duchamp C, Karkmaz M, Hoai BT, Lachheb H, Puzenat E, Guillard C: Environmental green chemistry as defined by photocatalysis. J. Hazard. Mater. 2007, 145: 624–629.

Diebold U: The surface science of titanium dioxide. Surf. Sci. Rep. 2003, 48: 55–229.

Porkodi K, Arokiamary SD: Synthesis and spectroscopic characterization of nanostructured anatase titania: a photocatalyst. Mater. Charact. 2007, 58: 495–503.

Allen NS, Edge M, Verran J, Stratton J, Maltby J, Bygott C: Photocatalytic titania based surfaces: environmental benefits. Polym. Degrad. and Stab. 2008, 93: 1632–1646.

Chen X, Mao SS: Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem. Rev. 2007, 107: 2891–2959.

Cao F, Oskam G, Searson PC, Stipkala JM, Heimer TA, Farzad F, Meyer GJ: Electrical and optical properties of porous nanocrystalline TiO2 films. J. Phys. Chem. 2007, 99: 11974–11980.

Siegel RW: Cluster-assembled nanophase materials. Ann. Rev. Mater. Sci. 1991, 21: 559–578.

Yi KC, Fendler JH: Between the head groups of Langmuir-Blodgett films. Langmuir 1990, 6: 1519–1526.

Youn HC, Baral S, Fendler JH: Preparations of nanosized TiO2 in reverse micro emulsion. J. Phys. Chem. 1988, 92: 6320–6327.

Fendler JH: Atomic and molecular clusters in membrane mimetic chemistry. Chem. Rev. 1987, 87: 877–899.

Toba M, Mizukami F, Niwa S, Sano T, Maeda K, Annila A, Komppa V: Effect of the type of preparation the 2 properties of titania/silicas. J. Molec. Catal 1994, 1: 277–288.

Gao X, Wachs E: Titania-silica as catalysts: molecular structural characteristics and physico-chemical properties. Catal. Today 1999, 51: 233–254.

Uddin MJ, Cesano F, Bonino F, Bordiga S, Spoto G, Scarano D, Zecchina A: Photoactive TiO2 films on cellulose fibres: synthesis and characterization. J. Photochem. Photobiol. A-Chem. 2007, 189: 286–294.

Uddin MJ, Cesano F, Scarano D, Bonino F, Agostini G, Spoto G, Bordiga S, Zecchina A: Cotton textile fibres coated by Au/TiO2 films: synthesis, characterization and self cleaning properties. J. Photochem. Photobiol. A-Chem 2008, 199: 64–72.

Liu Z, Davis RJ: Investigation of the structure of microporous Ti-Si mixed oxides by X-ray, UV reflectance, FT-Raman, and FT-IR spectroscopies. J. Phys. Chem. 1994, 98: 1253–1261.

Uddin MJ, Cesano F, Bertarione S, Bonino F, Bordiga S, Scarano D, Zecchina A: Tailoring the activity of Ti-based photocatalysts by playing with surface morphology and silver doping. J. Photochem. Photobiol. A-Chem. 2008, 196: 165–173.

Wang LY, Sun YP, Xu BS: Comparison study on the size and phase control of nanocrystalline TiO2 in three Ti-Si oxide structures. J. Mater. Sci. 2008, 43: 1979–1986.

Jia YX, Han W, Xiong GX, Yang WS: Diatomite as high performance and environmental friendly catalysts for phenol hydroxylation with H2O. J. Colloid Interface Sci. 2008, 323: 326–331.

Zhao Y, Li C, Liu X, Gu F, Du HL, Shi L: Zn-doped TiO2 nanoparticles with high photocatalytic activity synthesized by hydrogen–oxygen diffusion flame. Appl. Catal. B Environ. 2008, 79: 208–215.

Fox MA, Dulay MT: Heterogeneous photocatalysis. Chem. Rev.. 1993, 93: 341–357.

Ollis DF, Pelizzetti E, Serpone N: Photocatalyzed destruction of water contaminants. Environ. Sci. Technol. 1991, 25: 1522–1529.

Gu Z, Thomas AC, Xu ZP, Campbell JH, Lu GQ: In vitro sustained release of LMWH from MgAl-layered double hydroxide nanohybrids. Chem. Mater. 2008, 20: 3715–3722.

Kodama T, Harada Y, Ueda M, Shimizu K, Shuto K, Komarneni S: Selective exchange and fixation of strontium ions with ultrafine Na-4-mica. Langmuir 2001, 17: 4881–4886.

Li ZH: Sorption kinetics of hexa decyltri methyl ammonium on natural clinop-tilolite. Langmuir 1999, 15: 6438–6445.

Birks LS, Friedman H: Particle size determination from X-ray line broadening. J. Appl. Phys. 1946, 17: 687–692.

Lee C, Sung YW, Park JW: Multiple equilibria of phenothiazine dyes in aqueous cyclodextrin solutions. J. Phys. Chem. B 1999, 103: 893–898.

Al-Oaradawi S, Salman SR: Photocatalytic degradation of methyl orange as a model compound. J. Photochem. Photobiol. A 2002, 148: 161–168.

Guettai N, Amar HA: Photocatalytic oxidation of methyl orange in presence of titanium dioxide in aqueous suspension. Desalination 2005, 185: 427–437.

Lachheb H, Puzenat E, Houas A, Ksibi M, Elaloui E, Guillard C, Herrmann JM: Photocatalytic degradation of various types of dyes (Alizarin S, Crocein orange G, methyl red, Congo red, methylene blue) in water by UV-irradiated titania. App. Catal. B Environ. 2002, 39: 75–90.

Wang CC, Ying JY: Sol–gel synthesis and hydrothermal processing of anatase and rutile titania nanocrystals. Chem. Mater. 1999, 11: 3113–3120.

Chen ZC, Ring TA, Lemaitre J: Stabilization of aqueous BaTiO3 suspension with polyacrylic acid. J. Am. Ceram. Soc. 1992, 75: 3201–3208.

Acknowledgments

This work was funded by a research development fund from Shahjalal University of Science and Technology, Sylhet. The authors express their deep gratitude to Prof. Ulrike Diebold (Tulane University) for providing equipment support for this work and to Prof. M. R. Khan for fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

The authors' contributions in this article are the same. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Uddin, M.J., Islam, M.A., Haque, S.A. et al. Preparation of nanostructured TiO2-based photocatalyst by controlling the calcining temperature and pH. Int Nano Lett 2, 19 (2012). https://doi.org/10.1186/2228-5326-2-19

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-2-19