Abstract

Nanopowders of Centella asiatica was produced using planetary ball mill by varying milling parameters such as milling time, mass concentration, and bead amount. Particle size analysis employing photon correlation spectroscopy was carried out to record the effect of milling parameters on the particle size produced. The morphology of milled powders was also analyzed using a field emission scanning electron microscope. The bioactive component, asiatic acid, was extracted from various sizes of C. asiatica powders, and its extraction yield at different powder size was calculated by high-performance liquid chromatography. Optimization of milling parameters was found to be a crucial step in determining the content of asiatic acid extracted. In this study, the highest amount of asiatic acid extracted was 25.4 mg/g, obtained at moderate conditions of the following milling parameters: 4 h of milling time, 1.2% (w/v) concentration of powder, and 25 g of bead load.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Centella asiatica is a perennial plant that mostly grows in the tropical and subtropical climate. It is known as mandukarpani (Indian), gotu kala (Chinese), or pennywort (English). It is commonly used as a wound-healing agent and for treatment of mental disorders and skin cancer. Studies also show that the herb extract could increase collagen production and strengthen tensile strength [1]. Thus, this herb is widely used in formulations of cosmetic and pharmaceutical products and possesses high commercial value. All these therapeutic effects are mainly contributed by the triterpene glycosides, mainly asiatic acid and asiaticoside (Figure 1). Asiatic acid, a pentacyclic triterpene, is the aglycone form of asiaticoside which consists of a sugar moiety: a trisaccharide containing α-L-rhamnopyranoside linked to the disaccharide gentiobiose [2]. Although the pharmacological effect of asiaticoside has been well known, some data suggest that asiatic acid is the actual component responsible for the plant's therapeutic effects since asiaticoside is being hydrolyzed to asiatic acid in vivo[3–5]. Thus, asiatic acid can be considered as the bioactive compound of C. asiatica. [4]. Recent studies showed that asiatic acid could treat liver fibrosis [6], protect primary neurons against C2-ceramide-induced apoptosis [7], inhibit acetylcholinesterase [8], and induce neurotoxicity. Furthermore, modification of asiatic acid functional groups have been carried out with the aim of improving the compound's potential as a hepatoprotective agent [9, 10].

Natural products have been important sources of drugs and will continue to play an important role as a major source of new drugs in the years to come [11–13]. Normally, bioactive components exist in a low concentration; thus, an effective method is urgently needed to retrieve the analyte from their cell matrix. Many methods have been introduced such as ultrasonic extraction (UE), microwave-assisted extraction, accelerated solvent extraction, pressurized hot water extraction [14–16], and supercritical/subcritical extraction [17, 18]. However, the extraction efficiency of each method is greatly dependent on the particle size of plant material itself [19, 20]. Among the methods, UE has been known for their extraction efficiency with reduced processing time and solvent consumption [14].

Ball milling is a common method in the size reduction of material. The milling process produces nanopowders through the impact forces generated by action of centrifugal forces. Milling parameters such as milling time, mass concentration, and bead amount are important parameters that need to be considered in producing superfine powders. In this research, our aim is to investigate the effect of particle size on the amount of asiatic acid extracted employing high-performance liquid chromatography (HPLC).

Results and discussion

Optimization of milling parameters

To obtain a uniform distribution of particle size in the nanometer range, milling parameters such as milling time, mass concentration, and bead amount were varied. The results as shown in Figure 2 indicate that each set of milling condition produced different particle sizes of powder. Varying milling time, mass concentration, and bead amount from 2 to 8 h, 0.4% to 2.8% (w/v), and 5 to 100 g varied the particle size from 408.8 to 191.1, 237.1 to 581.1, and 442.6 to 212.8 nm, respectively. Statistically, increasing milling time from 2 to 4 h significantly reduced the particle size since sufficient energy was provided for size reduction. However, no significant reduction in particle size was observed after an extended milling time of 4 to 8 h. This is due to the fibrous structure of plant material itself which limited further size reduction [21]. An increase of particle size from 237.1 to 581.13 nm was observed as mass concentration is increased from 0.4% to 2.8% (w/v). Increase of mass concentration led to inefficient energy distribution in the milling process caused by the weak interaction between bead media and particles [22]. At a higher mass concentration, the viscosities of slurries increase and the distance between individual particles is reduced leading to ineffective particle capture by the grinding beads. The higher viscosities will then weaken the motion of grinding media; thus, velocity of grinding media and kinetic energy of bead decreased tremendously leading to ineffective milling operation [23]. The study on the effect of bead amount on particle size showed an inverse correlation. The smallest particle size (212.8 nm) was achieved with the highest amount (100 g) of bead load, and the largest particles size (442.6 nm) was found with the lowest bead amount (5 g). This can be understood by the limited amount of beads present in the reaction. With a low amount of bead load, the limiting reactant is the bead itself since the low numbers of bead present in the physical reaction will cause a reduction in the collision frequency due to limited amounts of bead per mass powder and reduced energy efficiency. Similarly, with higher bead amount, the energy efficiency would be higher, as reported by He et al. [22].

Microstructures of ground powder

As shown in Figure 3, the microstructures of coarse and milled powders showed a huge reduction of the size of nanopowders from the micropowder. It proves that the impact of collision in the milling process has tremendously broken down the micropowder to nanosize powder. The nanopowders exist in random structure in an agglomerated form. This is common since a higher surface energy possessed by the nanoparticles caused them to aggregate once it goes into a solid-state condition [24].

Effect of milling parameters on extraction yield of asiatic acid

To evaluate the amount of asiatic acid extracted, each powder from each set of milling condition was extracted and analyzed using HPLC. From the HPLC chromatogram, asiaticoside was eluted for 8 min (tR = 8 min), while asiatic acid had a tR of 23 min. This method shows a good separation of the two compounds for both micro- and nanosamples (Figure 4). As shown in Figure 4, all milled samples showed no presence of asiaticoside, and we believe that asiaticoside have been hydrolyzed to asiatic acid during the milling process. As shown in Figure 5, increasing the milling time, mass concentration, and bead amount from 2 to 8 h, 0.4% to 2.8% (w/v), and 5 to 100 g during grinding significantly varied the amount of asiatic acid extracted from 4.5 to 25.4 mg/g, from 2.3 to 25.4 mg/g, and from 4.1 to 25.4 mg/g, respectively. The difference in the amount of asiatic acid extracted could be caused by the degree of efficiency of extraction due to the difference in particle size of the powder and the ability of asiatic acid to retain their structure during the milling process. Each set of milling time (2, 4, 6, and 8 h) showed a reduction of particles to nanosize range. We further observed that a shorter milling time of 2 h produced a lower yield of asiatic acid content compared to 4 h of milling which could be explained by the difference in particle size of the powder as shown in Figure 2. Interestingly, after 6 h of milling, the content of asiatic acid reduced tremendously as compared to after 4 h of milling, and the amount is further reduced after 8 h of milling. At this time, further nanosize reduction has occurred, and the energy the milling process may have degraded the asiatic acid and consequently reduce the amount of asiatic acid extracted. Kormin also reported that the asiatic acid content in C. asiatica juice extract reduced significantly at higher temperatures [25]. Other findings have also showed that heat is an important factor that should be considered in extracting bioactive compound from plants. Effect of heat in the extraction of saponins from ginseng was clearly significant as the level of ginsenosides Rg1, Re, Rb1, Rc, R2, Rb3, and Rd decreased after the steaming process [26]. The same trend was also observed in experiments that investigate the effect of bead amounts on asiatic acid content. Effect of the nanopowders in improving extraction of asiatic acid can be clearly observed by varying mass concentrations. The parameter values range from 0.4% to 2.8% (w/v) because our preliminary study showed that at this range, nanopowders range from 100 to 1,000 nm could be produced. Above these values, the milled product produced a greater size of particle (microrange). In this experiment, samples that were ground at 0.4% and 1.2% (w/v) showed a high amount of asiatic acid (24.5 and 25.4 mg/g) extracted due to increased extraction efficiency caused by smaller particle size that resulted from efficient energy distribution in the milling process. When milled at a higher concentration (2.0% (w/v)), the asiatic acid content was reduced to 13 mg/g, and further milling at 2.8% (w/v) caused a further drop in the extracted asiatic acid content (2.3 mg/g). The sudden drop in the amount of extracted asiatic acid amount was probably due a lower extraction efficiency caused by a larger particle size (500.7 and 581.7 nm). In this study, optimized milling parameters for the extraction of asiatic acid from C. asiatica is 4 h of milling time, 1.2% (w/v) mass concentration, and 25 g of bead load. To our knowledge, this method yields the highest amount of extracted asiatic acid from the plant compared to other methods previously reported which ranges from 7 to 14 mg/g [15, 17].

Extraction mechanism in nanopowders

Generally, extraction of plant material involved two physical phenomena: diffusion through the cell wall and washing out the analyte into extraction solvent. Using nanopowders in the extraction of bioactive compound uses the same principles as using micron powders, but the only difference lies in the particle size used in the extraction. In this section, we discuss how the unique properties of nanopowders results in higher extraction yields.

Size reduction prior to extraction has been reported to be a crucial step to obtain from the plant matrix [15, 19, 27, 28]. The reduction in size is reported to enhance the contact ratio between plant cell and the surrounding solvent [28]. In our study, the higher amount of asiatic acid extracted from milled samples can be explained by the amazing properties of nanoparticles contributed by an increase in surface area and the reduction of diffusional distance of the particles (Figure 6) [29]. Decreasing the particle size to the nanometer range caused an increase of surface area, leading to a higher number of cells directly exposed to the extraction by the solvent [28]. Based on Noyes-Whitney equation [30], the dissolution velocity of particles increases due to surface area enlargement as described in Equation 1:

where dc/dt is the rate of dissolution velocity, D is the diffusion coefficient, A is the surface area of the solid, C s is the concentration of the solid in the diffusion layer surrounding the solid, and C x is the concentration of the solid in the bulk dissolution medium. The dissolution velocity dc/dt described in the above equation also depends on the concentration gradient (C s - C x )/h where h, the diffusional distance is reduced for smaller particles [31]. Due to the reduced h, the concentration gradient of nanoparticles is large (Figure 5) [29, 32] which causes the dissolution velocity to increase. This will enhance the diffusion of solvent into the cell wall, which in turn will allow the rapid release of active ingredients from the cell matrix of the plant. This is also supported by the phenomena where the disrupted cell wall structure of the plant material itself cause the active compound in the inner cytoplasm to be exposed directly while not being released from cell walls making effective ingredients dissolve out rapidly [33]. Past studies have shown that nanonization will allow the rapid release of active component from their cytoplasm matrix [34–36] and help improve the extraction of bioactive components of plants.

Conclusions

In general, we have provided further proof that nanonization of plant material played an important role in contributing to the extraction yield of bioactive compounds from plant materials. In this research, we have successfully produced nanopowders of C. asiatica by planetary ball milling. Our findings showed that a smaller particle size gave a higher extraction yield of asiatic acid compared to a bigger particle size. However, if the particle size is too small, the extraction yield of the compound will be reduced due to the effect of heat and pressure in the milling jar. As a conclusion, optimized milling parameters for high extraction yield of asiatic acid from C. asiatica was found to be 4 h of milling time, 1.2% (w/v) concentration of powder, and 25 g of bead load.

Methods

Chemicals and materials

Asiaticoside and asiatic acid standards (Biopurify Chegdu, Sichuan, China) were purchased from Sigma-Aldrich Corporation (St. Louis, MO, USA), acetonitrile (LC grade) was purchased from Fisher Chemicals, and methanol (HPLC grade) was purchased from Friedemann Schmidt (Berlin, Germany). Distilled water was purified using a Milli-Q water purification system (Millipore, Bedford, MA, USA).

Sample preparation

The plant material was washed with running tap water and rinsed with distilled water to remove dirt and contaminants. The clean plant material was stored in an oven at 50°C and was left to dry for 3 days. The dried plant material was ground using a conventional rotor mixer. The ground powder was then sieved through a 250-μm sieve and stored at 4°C prior to the ball milling process.

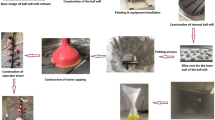

Optimization of ball milling parameters

Ball milling is a common mechanical process to produce superfine powders. In this research, a planetary ball mill was chosen as a grinding tool due to its simplicity. The sieved powder was first mixed with Pluronic F127 and milled at different mass concentrations (0.4%, 1.2%, 2.0%, and 2.8% (w/v)) at a constant milling time (4 h) and fixed bead amount (25 g). The resulting milling product was freeze-dried and analyzed for their physical characteristics. The best condition of milling (% (w/v)) was determined by the size of powder yielding the highest amount of asiatic acid extracted. This condition was then applied at different milling times (2, 4, 6, and 8 h) and different bead amounts (5, 25, 50, and 100 g), and the sample was analyzed for their physical characteristic and amount of asiatic acid extracted.

Particles size analysis

Prior to the measurement, nanosuspensions of each sample were taken and adjusted to 0.01% (w/v) and introduced into a disposable cuvette to be measured in triplicates. z-Average and polydispersity were recorded. Field emission scanning electron microscopy (FESEM; SMT SUPRA 40VP, Carl Zeiss AG, Oberkochen, Germany) imaging was carried out by placing 10 μL of the nanosuspension onto a glass slide and stored in an electronic desiccator (temperature 20°C, humidity 18% RH) for drying purposes. The dried samples were then coated with gold (approximately 10-nm thick) and were placed onto an adhesive tape on the FESEM stub.

HPLC analysis

Extraction

Coarse powder (0.5 g) was weighed and sonicated for 1 h using an ultrasonic processor (UP400S Ultrasonic Processor, Hielscher Ultrasonics GmbH, Teltow, Germany) at 60% amplitude and 1 cycle. The solids were removed by gravitational filtration, and the filtrate was collected. The nanopowders were also extracted in the same manner as above. The extract was dissolved in methanol (1 mg/mL) before being subjected to HPLC analysis.

HPLC conditions

The chromatographic separation was based on a modified method of Inamdar et al. [37] using a Zorbax Eclipse XDB-C18 4.6 × 150 mm (Agilent Technologies, Inc., Santa Clara, CA, USA), 5 μm at 25°C. The mobile phase, solvent A (ultrapure water) and solvent B (acetonitrile), was delivered at a flow rate of 1.0 mL min-1. Gradient elution was employed with the ratio of A/B and varied as follows: 0 min, 80:20 and 35 min, 45:55. Standards or samples were introduced into the HPLC using an Agilent 1200 G1367B auto sampler, injection volume was 40 μL, and the detection wavelength was 206 nm. The amount of asiatic acid was determined using a standard calibration curves.

Conflict of interest

Hereby I, Muhammad Zuhairi Bin Borhan declare that as the author of the manuscript, have or do not have a direct financial relation with the commercial identities mentioned in my paper that might lead to a conflict of interest for any of the authors.

References

Shukla A, Rasik AM, Jain GK, Shankar R, Kulshrestha DK, Dhawan BN: In vitro and in vivo wound healing activity of asiaticoside isolated from Centella asiatica . J. Ethnopharmacol. 1999, 65: 1–11. 10.1016/S0378-8741(98)00141-X

Monti D, Candido A, Cruz Silva MM, Křen V, Riva S, Danieli B: Biocatalyzed generation of molecular diversity: selective modification of the saponin asiaticoside. Adv. Synth. Catal. 2005, 347: 1168–1174. 10.1002/adsc.200505047

Shim PJ, Park JH, Chang MS, Lim MJ, Kim DH, Jung YH, Jew SS, Park EH, Kim HD: Asiaticoside mimetics as wound healing agent. Bioorg. Med. Chem. Let. 1996, 6: 2937–2940. 10.1016/S0960-894X(96)00540-9

Rush WR, Murray GR, Graham DJM: The comparative steady-state bioavailability of the active ingredients of Madecassol. Eur. J. Drug Metab. Pharmacokinet. 1993, 18: 323–326. 10.1007/BF03190180

Zheng XC, Wang SH: Determination of asiatic acid in beagle dog plasma after oral administration of Centella asiatica extract by precolumn derivatization RP-HPLC. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 2009, 877: 477–481. 10.1016/j.jchromb.2008.11.045

Tang L, He R, Yang G, Tan J, Zhou L, Meng X, Huang XR, Lan HY: Asiatic acid inhibits liver fibrosis by blocking TGF-beta/smad signaling in vivo and in vitro . PLoS ONE 2012,7(2):e31350. 10.1371/journal.pone.0031350

Park BC, Bosire KO, Lee ES, Lee YS, Kim JA: Asiatic acid induces apoptosis in SK-MEL-2 human melanoma cells. Cancer Lett. 2005, 218: 81–90. 10.1016/j.canlet.2004.06.039

Nasir MN, Abdullah J, Habsah M, Ghani RI, Rammes G: Inhibitory effect of asiatic acid on acetylcholinesterase, excitatory post synaptic potential and locomotor activity. Phytomedicine 2012, 19: 311–316. 10.1016/j.phymed.2011.10.004

Jeong BS, Mi KL, Young CK, Lee ES: Modification of C2 functional group on asiatic acid and the evaluation of hepatoprotective effects. Arch. Pharm. Res. 2007, 30: 282–289. 10.1007/BF02977607

Jeong BS, Young CK, Lee ES: Modification of C2,3,23,28 functional groups on asiatic acid and evaluation of hepatoprotective effects. Bull. Korean Chem. Soc. 2007, 28: 977–982.

Sticher O: Natural product isolation. Nat. Prod. Rep. 2008, 25: 517. 10.1039/b700306b

Choi JY, Yoo JY, Kwak HS, Nam BU, Lee J: Role of polymeric stabilizers for drug nanocrystal dispersions. Curr. Appl. Phys. 2005, 5: 472–474. 10.1016/j.cap.2005.01.012

Newman DJ, Cragg GM: Natural products as sources of new drugs over the 30 years from 1981 to 2010. J. Nat. Prod. 2012, 75: 311–335. 10.1021/np200906s

Shirsath SR, Sonawane SH, Gogate PR: Intensification of extraction of natural products using ultrasonic irradiations—a review of current status. Chem. Eng. Process. Process Intensif. 2012, 53: 10–23.

Shen Y, Liu A, Ye M, Wang L, Chen J, Wang XR, Han C: Analysis of biologically active constituents in Centella asiatica by microwave-assisted extraction combined with LC-MS. Chromatographia 2009, 70: 431–438. 10.1365/s10337-009-1152-6

Teo CC, Tan SN, Yong JWH, Hew CS, Ong ES: Pressurized hot water extraction (PHWE). J. Chromatogr. A 2010, 1217: 2484–2494. 10.1016/j.chroma.2009.12.050

Kim WJ, Kim J, Veriansyah B, Kim JD, Lee YW, Oh SG, Tjandrawinata RR: Extraction of bioactive components from Centella asiatica using subcritical water. J. Supercrit. Fluids 2009, 48: 211–216. 10.1016/j.supflu.2008.11.007

Kim W-J, Veriansyah B, Lee Y-W, Kim J, Kim J-D: Extraction of mangiferin from Mahkota Dewa ( Phaleria macrocarpa ) using subcritical water. J. Ind. Eng. Chem. 2010, 16: 425–430. 10.1016/j.jiec.2009.08.008

Wu J, Lin L, Chau FT: Ultrasound-assisted extraction of ginseng saponins from ginseng roots and cultured ginseng cells. Ultrason. Sonochem. 2001, 8: 347–352. 10.1016/S1350-4177(01)00066-9

Mustafa A, Turner C: Pressurized liquid extraction as a green approach in food and herbal plants extraction: a review. Anal. Chim. Acta. 2011, 703: 8–18. 10.1016/j.aca.2011.07.018

Rajkhowa R, Wang L, Kanwar J, Wang X: Fabrication of ultrafine powder from eri silk through attritor and jet milling. Powder Technol. 2009, 191: 155–163. 10.1016/j.powtec.2008.10.004

He M, Wang Y, Forssberg E: Parameter effects on wet ultrafine grinding of limestone through slurry rheology in a stirred media mill. Powder Technol. 2006, 161: 10–21. 10.1016/j.powtec.2005.08.026

He M, Forssberg E: Influence of slurry rheology on stirred media milling of quartzite. Int. J. Miner. Process. 2007, 84: 240–251. 10.1016/j.minpro.2006.08.001

Lee J: Drug nano- and microparticles processed into solid dosage forms: physical properties. J. Pharm. Sci. 2003, 92: 2057–2068. 10.1002/jps.10471

Kormin S Master’s thesis. In The effect of heat processing on triterpenes glycosides and antioxidant activity of herbal Pegaga (Centella asiatica L. Urban) drink. Universiti Teknologi Malaysia; 2005.

Sun S, Wang CZ, Tong R, Li XL, Fishbein A, Wang Q, He TC, Du W, Yuan CS: Effects of steaming the root of Panax notoginseng on chemical composition and anticancer activities. Food Chem. 2010, 118: 307–314. 10.1016/j.foodchem.2009.04.122

Sun Y, Bi J, Zhang L, Ye B: Ultrasound-assisted extraction of three bufadienolides from Chinese medicine ChanSu. Ultrason. Sonochem. 2012, 19: 1150–1154. 10.1016/j.ultsonch.2012.03.003

Vinatoru M: An overview of the ultrasonically assisted extraction of bioactive principles from herbs. Ultrason. Sonochem. 2001, 8: 303–313. 10.1016/S1350-4177(01)00071-2

Mauludin R, Müller RH, Keck CM: Development of an oral rutin nanocrystal formulation. Int. J. Pharm. 2009, 370: 202–209. 10.1016/j.ijpharm.2008.11.029

Noyes AA, Whitney WR: The rate of solution of solid substances in their own solutions. J. Am. Chem. Soc. 1897, 19: 930–934. 10.1021/ja02086a003

Müller RH, Peters K: Nanosuspensions for the formulation of poorly soluble drugs: I: preparation by a size-reduction technique. Int. J. Pharm. 1998, 160: 229–237. 10.1016/S0378-5173(97)00311-6

Müller RH, Böhm BHL, Grau MJ: Formulations for poorly soluble drugs with poor bioavailability/2nd communication: stability, biopharmaceutical aspects, possible drug forms and registration aspects. Nanosuspensionen–Formulierungen fur schwerlosliche arzneistoffe mit geringer bioverfugbarkeit: 2 Mitteilung: Stabilitat, biopharmazeutische aspekte, mogliche arzneiformen und zulassungsfragen 1999, 61: 175–178.

Su YL, Fu ZY, Wang WM, Wang H, Wang YC, Zhang JY, Ma PY: Ultrafine grinding of Radix salvia miltiorrhiza particles and the physicochemical properties by high speed centrifugal sheering. Book Ultrafine grinding of Radix salvia miltiorrhiza particles and the physicochemical properties by high speed centrifugal sheering (Editor ed.^eds.), vol. 330–332 I. pp. 215–218. City; 2007:215–218 (Editor ed.^eds.), vol. 330-332 I. pp. 215-218. City; 2007:215-218

Su YL, Fu ZY, Quan CJ, Wang WM: Fabrication of nano Rhizama Chuanxiong particles and determination of tetramethylpyrazine. Trans. Nonferrous Metals Soc. China 2006, 16: S393-S397.

Ma PY, Fu ZY, Su YL, Ma JJ: The nano pulverization of traditional Chinese medicine Liuwei Dihuang. J. Wuhan University of Tech-Mat. Sci. Ed. 2006, 21: 105–108.

Ma PY, Fu ZY, Su YL, Zhang JY, Wang WM, Wang H, Wang YC, Zhang QJ: Modification of physicochemical and medicinal characterization of Liuwei Dihuang particles by ultrafine grinding. Powder Technol. 2009, 191: 194–199. 10.1016/j.powtec.2008.10.008

Inamdar PK, Yeole RD, Ghogare AB, De Souza NJ: Determination of biologically active constituents in Centella asiatica . J. Chromatogr. A 1996, 742: 127–130. 10.1016/0021-9673(96)00237-3

Acknowledgements

We would like to thank Universiti Teknologi MARA (UiTM) for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Authors’ contributions

MZBB: Mainly involve in all laboratory works; Experimental Design, Sample preparation, Analysis sample; Mainly involve in preparation of manuscript. RA: Assisting in all laboratory works; Extraction of compound, HPLC Analysis; Assisting in preparation of manuscript. MR: Assisting in all laboratory works; FESEM Analysis, Particle Size Analysis; Assisting in preparation of manuscript. SA: Assisting in all laboratory works; FESEM Analysis, Particle Size Analysis, HPLC Analysis; Assisting in preparation of manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Borhan, M.Z., Ahmad, R., Rusop, M. et al. Optimization of ball milling parameters to produce Centella asiatica herbal nanopowders. J Nanostruct Chem 3, 79 (2013). https://doi.org/10.1186/2193-8865-3-79

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-79